A Sustainability Assessment Framework for On-Site and Off-Site Construction Logistics

Abstract

:1. Introduction

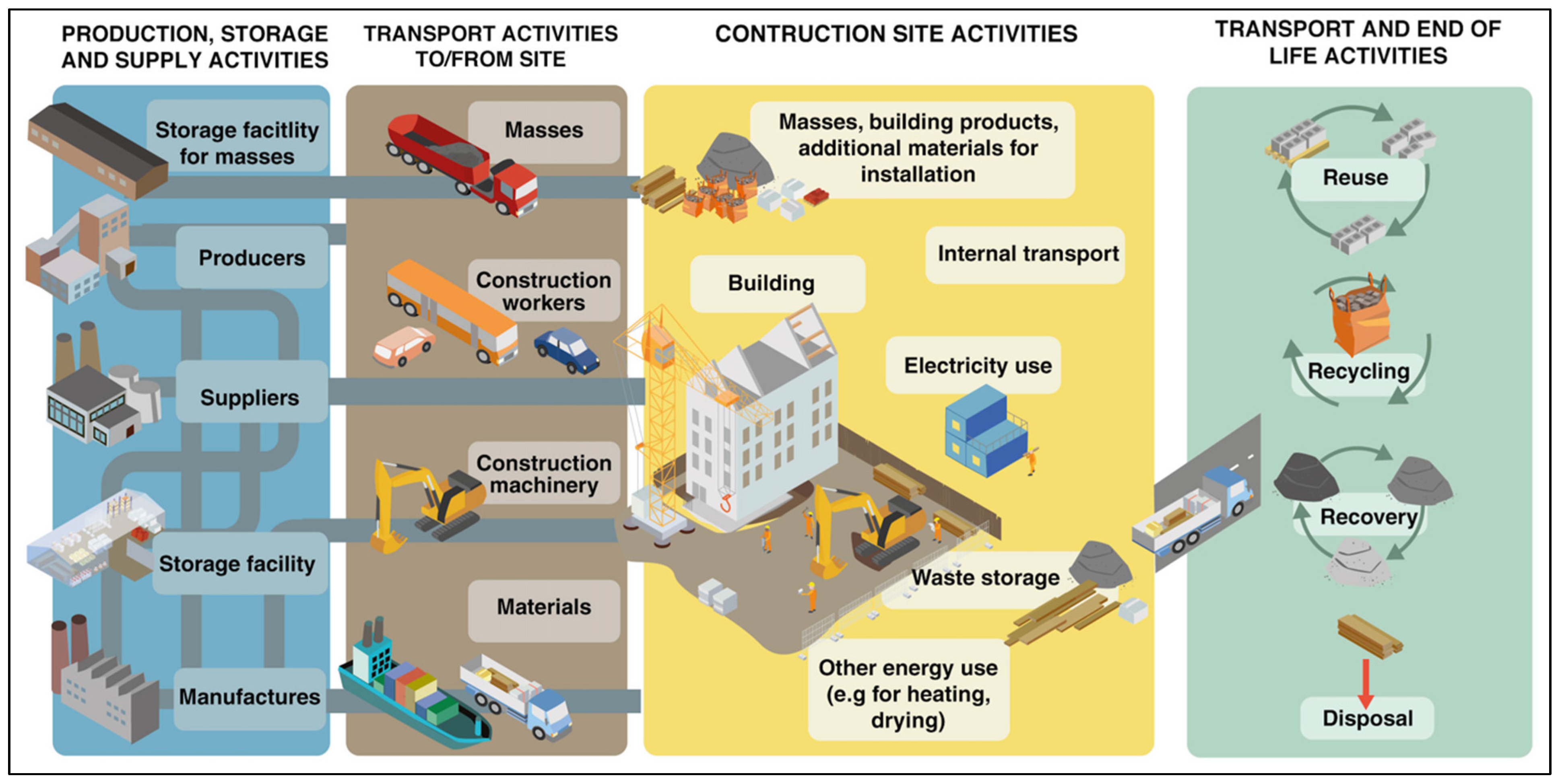

2. Theoretical Impact Assessment Framework

3. Materials and Methods

3.1. Case Study Description and System Boundaries

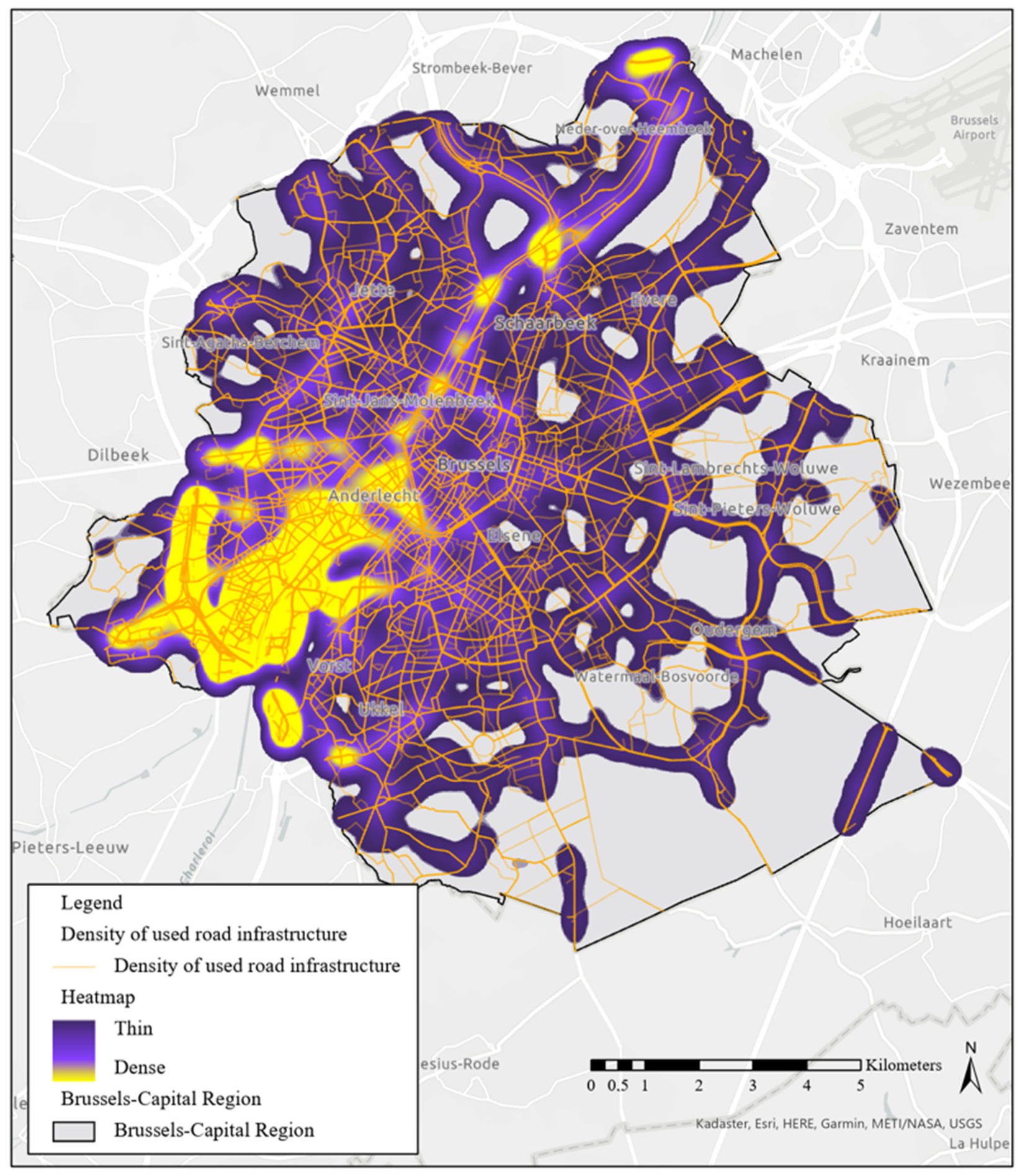

3.2. Transport Data

3.3. Scenarios

3.4. ECC and LCA Methodologies: Environmental Performance

4. Use Case Analysis and Results

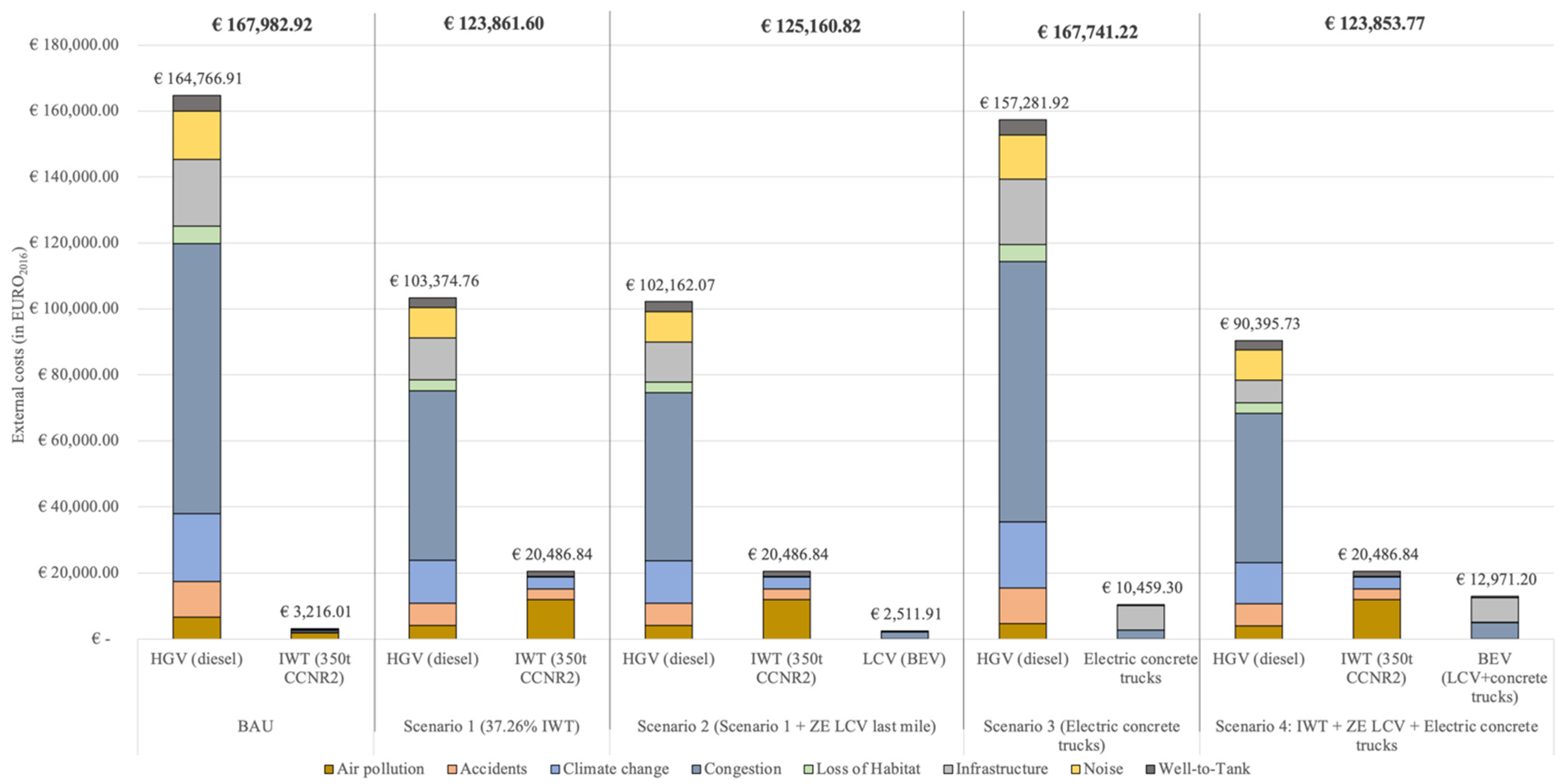

4.1. Impact Assessment Results

4.2. Scenario Evaluation

5. Conclusions and Limitations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- FIEC. Key Figures 2019: Construction Activity in Europe. Sustainability Report. 2020. Available online: https://www.aldi-nord.de/en/sustainability-report/2019/key-figures-2019.html (accessed on 30 March 2022).

- Lundesjö, G. Supply Chain Management and Logistics in Construction: Delivering Tomorrow’s Built Environment; Kogan Page Publishers: London, UK, 2015. [Google Scholar]

- Scholman, H.S.A. Uitbesteding Door Hoofdaannemers. In Subcontracting by Main Contractors; Economissch Instituut voor de Bouwnijverheid: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Lindén, S.; Josephson, P.-E. In-housing or out-sourcing on-site materials handling in housing? J. Eng. Des. Technol. 2013, 11, 90–106. [Google Scholar] [CrossRef]

- Van Lier, T.; Macharis, C. Assessment Framework: Demonstrations and Assessment of Progress and Results; CIVIC: Gothenburg, Sweden, 2016. [Google Scholar]

- VIL. Bouwlogistiek. 2020. Available online: https://vil.be/project/bouwlogistiek/ (accessed on 30 March 2022).

- Fredriksson, A.; Janné, M.; Rudberg, M. Characterizing third-party logistics setups in the context of construction. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 325–349. [Google Scholar] [CrossRef]

- Dubois, A.; Hulthén, K.; Sundquist, V. Organising logistics and transport activities in construction. Int. J. Logist. Manag. 2019, 30, 620–640. [Google Scholar] [CrossRef]

- Wegelius-Lehtonen, T. Performance measurement in construction logistics. Int. J. Prod. Econ. 2001, 69, 107–116. [Google Scholar] [CrossRef]

- RazaviAlavi, S.; AbouRizk, S. Construction Site Layout Planning Using a Simulation-Based Decision Support Tool. Logistics 2021, 5, 65. [Google Scholar] [CrossRef]

- Wibowo, M.A.; Handayani, N.U.; Mustikasari, A.; Wardani, S.A.; Tjahjono, B. Reverse Logistics Performance Indicators for the Construction Sector: A Building Project Case. Sustainability 2022, 14, 963. [Google Scholar] [CrossRef]

- Wijewickrama MK, C.S.; Rameezdeen, R.; Ochoa, J.J.; Chileshe, N. Minimizing macro-level uncertainties for quality assurance in reverse logistics supply chains of demolition waste. Sustainability 2021, 13, 13069. [Google Scholar] [CrossRef]

- Studer, W.P.; De Brito Mello, L.C.B. Core Elements Underlying Supply Chain Management in the Construction Industry: A Systematic Literature Review. Buildings 2021, 11, 569. [Google Scholar] [CrossRef]

- Brusselaers, N.; Mommens, K.; Janné, M.; Fredriksson, A.; Venås, C.; Flyen, C.; Mommens, K.; Macharis, C. Economic, social and environmental impact assessment for off-site construction logistics: The data availability issue. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 32030. [Google Scholar] [CrossRef]

- van Essen, H.; van Wijngaarden, L.; Schroten, A.; Sutter, D.; Bieler, C.; Maffii, S.; Brambilla, M.; Fiorello, D.; Fermi, F.; Parolin, R.; et al. Handbook on the External Costs of Transport, Version 2019; CE Delft: Delft, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Fredriksson, A.; Nolz, P.C.; Seragiotto, C. A mixed method evaluation of economic and environmental considerations in construction transport planning: The case of Ostlänken. Sustain. Cities Soc. 2021, 69, 102840. [Google Scholar] [CrossRef]

- Ghanem, M.; Hamzeh, F.; Seppänen, O.; Zankoul, E. A new perspective of construction logistics and production control: An exploratory study. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction (IGLC 26), Chennai, India, 16–22 July 2018; Gonzalez, V.A., Ed.; International Group for Lean Construction (IGLC): Edmonton, AB, Canada, 2018; pp. 992–1001. [Google Scholar]

- Bellona Europa. Norwegian Cities Lead the Way in Reaching Zero-Emissions in Construction Sites. 2021. Bellona.org. Available online: https://bellona.org/news/climate-change/2021-03-norwegian-cities-lead-the-way-in-reaching-zero-emissions-in-construction-sites (accessed on 13 May 2021).

- Venås, C.; Flyen, C.; Fufa, S.M.; Janné, M.; Fredriksson, A.; Brusselaers, N.; Mommens, K.; Macharis, C. No or low emissions from construction logistics Just a dream or future reality? IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 42003. [Google Scholar] [CrossRef]

- Fufa, S.M.; Wiik, M.K.; Mellegard, S.; Andresen, I. Lessons learnt from the design and construction strategies of two Norwegian low emission construction sites. IOP Conf. Ser. Earth Environ. Sci. 2019, 352, 012021. [Google Scholar] [CrossRef]

- Brusselaers, N.; Mommens, K.; Macharis, C. Building Bridges: A Participatory Stakeholder Framework for Sustainable Urban Construction Logistics. Sustainability 2021, 13, 2678. [Google Scholar] [CrossRef]

- Janné, M.; Fredriksson, A. Construction logistics governing guidelines in urban development projects. Constr. Innov. 2019, 19, 89–109. [Google Scholar] [CrossRef] [Green Version]

- Brussels Mobility. Good Move—Gewestelijk Mobiliteitsplan 2020–2030: Strategisch En Operationeel Plan. 2020. Available online: https://goodmove.brussels/nl/gewestelijk-mobiliteitsplan/ (accessed on 30 March 2022).

- MIMIC. About MIMIC, MIMIC. 2018. Available online: https://www.mimic-project.eu/en/about-mimic (accessed on 26 December 2021).

- Janné, M.; Fredriksson, A.; Billger, M.; Brusselaers, N.; Fufa, S.; Al Fahel, R.; Mommens, K. Smart Construction Logistics Governance—A systems view of construction logistics in urban development. In Proceedings of the 57th ISOCARP World Planning Congress, Doha, Qatar, 8–11 November 2021. [Google Scholar]

- Brusselaers, N.; Fufa, S.M. MIMIC Deliverable 2.2: Evaluation of the Construction Logistics Impact Assessment Framework. 2021. Available online: https://www.mimic-project.eu/sites/default/files/content/resource/files/20211213_d2.2_evaluation_of_the_application_of_impact_assessment_framework_of_construction_logistics_final.pdf (accessed on 30 March 2022).

- Fredriksson, A.; Flyen, C.; Fufa, S.M.; Venås, C.; Hulthén, K.; Brusselears, N.; Mommens, K.; Macharis, C. MIMIC Deliverable 1.1: Scenarios of Construction Logistics. 2020. Available online: https://www.mimic-project.eu/sites/default/files/content/resource/files/delivarable_1.1_final_1.pdf (accessed on 30 March 2022).

- van Lier, T. The Development of An External Cost Calculator Framework for Evaluating the Sustainability of Transport Solutions; Vrije Universiteit Brussel: Brussels, Belgium, 2014. [Google Scholar]

- Macharis, C. The importance of stakeholder analysis in freight transport. Q. J. Transp. Law Econ. Eng. 2005, 8, 114–126. [Google Scholar]

- ViaPass. ViaPass kilometer charge for HGVs of +3,5t tons since April 1st 2016. 2021. Available online: https://www.viapass.be/en/ (accessed on 30 March 2022).

- Vlaams Verkeerscentrum. Verkeersindicatoren. 2021. Available online: http://indicatoren.verkeerscentrum.be/vc.indicators.web.gui/indicator/index# (accessed on 30 March 2022).

- TomTom. Traffic Index Belgium. 2021. Available online: https://www.tomtom.com/en_gb/traffic-index/belgium-country-traffic (accessed on 30 March 2022).

- Federaal Planbureau. Aantal Voertuigkilometer Afgelegd Per Gewest, Wegtype En Voertuigcategorie Op Het Belgisch Grondgebied—Miljoen Voertuigkilometer (Ttbe_Tf_Rd_Km). 2017. Available online: https://www.plan.be/databases/PVarModal.php?lang=nl&VC=TTBE_TF_RD_KM&DB=TRANSP (accessed on 30 March 2022).

- Esri. ArcGIS, Pro 2.8; Esri HQ: Redlands, CA, USA, 2022. [Google Scholar]

- WTCB. Vrachtwagen Met Betonmixer Op Gas of Elektriciteit in Plaats Van Op Diesel. 2021. Available online: https://www.wtcb.be/nieuws/vrachtwagen-met-betonmixer-op-gas-of-elektriciteit-in-plaats-van-op-diesel/ (accessed on 30 March 2022).

- Volvo Trucks. Groundbreaking Collaboration to Accelerate Green Transport of Concrete. 2022. Available online: https://www.volvotrucks.com/en-en/news-stories/press-releases/2022/feb/volvo-trucks-groundbreaking-collaboration.html (accessed on 30 March 2022).

- Fredriksson, A.; Janné, M.; Fufa, S.M.; Venås, C.; Brusselaers, N. MIMIC Deliverable 1.2: Application of scenarios of construction logistics. 2021, pp. 1–23. Available online: https://www.mimic-project.eu/sites/default/files/content/resource/files/d1.2_application_of_scenarios_of_construction_logistics.pdf (accessed on 30 March 2022).

- ICCT. CO2 Emissions and Fuel Consumption Standards for Heavy-Duty Vehicles in the European Union. 2018. The ICCT Briefing Paper. Available online: https://www.theicct.org/publications/co2-emissions-and-fuel-consumption-standards-heavy-duty-vehicles-european-union (accessed on 30 March 2022).

- SPP Regions. Life Cycle Costing State of the Art Report. 2018. Available online: https://sppregions.eu/fileadmin/user_upload/Life_Cycle_Costing_SoA_Report.pdf (accessed on 30 March 2022).

- Rebitzer, G.; Hunkeler, D. Life Cycle Costing in LCM: Ambitions, opportunities, and limitations. Int. J. LCA 2003, 8, 253–256. [Google Scholar] [CrossRef]

- Bouwunie. 88% Van Bouwbedrijven Heeft Collectieve Vakantiesluiting En Dat Heeft Zo Zijn Voordelen. 2018. Available online: https://www.bouwunie.be/nl/news/bouwverlof-zomer2018 (accessed on 30 March 2022).

- Bouwverlof België. Bouwverlof per Regio. 2021. Available online: www.bouwverlof.com (accessed on 30 March 2022).

| External Cost Calculations (ECC) | Life Cycle Assessment (LCA) | |

|---|---|---|

| Damage costs or impact categories | All major transport-related externalities:

| Impact categories for LCA:

|

| Logistics activities (scope/physical system boundaries) | Transport activities (all transport modes off-site: cargo bike, road, IWT, rail, maritime, air):

| On-site and off-site logistics activities (road):

|

| Life cycle stages for logistics activities and geographical representativeness | Off-site CL across all transport modes (cargo bike, road, IWT, rail, maritime, air):

| Entire life cycle of on-site and off-site logistics activities, including:

|

| Granularity and differentiation of calculation variables (life cycle inventory) | Calculation variables:

| Type of data for life cycle inventory:

|

| Scenario | Definition |

|---|---|

| 0. Business-As-Usual (BAU) | Baseline scenario which considers construction operations as they have been operated during the period of analysis. |

| 1. Increased material deliveries by barge (IWT) | Scenario simulating the effect of delivering 37.26% of the total material volume compared to BAU by means of inland waterway transport in the same nearby construction hub used in the BAU scenario. Last mile delivery from the hub is organised using HGVs. |

| 2. Zero-emission last mile delivery | Scenario based on Scenario 1, with the exception that only zero-emission propulsion technologies are allowed or the last mile road delivery from the water-bound hub. |

| 3. Electric concrete trucks | Scenario based on BAU, envisioning the concrete delivery to the City Campus construction site to be operated by electric concrete trucks using the same concrete supplier as in BAU. |

| 4. Combination of measures (Sc.2 + 3) | Scenario in which 37.26% of the material volume was shipped over water, zero-emission vans stood in for the last mile delivery and all concrete was transported with electric concrete trucks. |

| BAU | Scenario 1 (37.26% IWT) | Scenario 2 (Scenario 1 + ZE LCV Last Mile) | Scenario 3 (Electric Concrete Trucks) | Scenario 4: IWT + ZE LCV + Electric Concrete Trucks | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HGV (diesel) | IWT (350 t CCNR2) | HGV (diesel) | IWT (350 t CCNR2) | HGV (diesel) | IWT (350 t CCNR2) | LCV (BEV) | HGV (diesel) | Electric concrete trucks | HGV (diesel) | IWT (350 t CCNR2) | BEV (LCV + concrete trucks) | |

| Air pollution | 6646.92 | 1960.30 | 4170.27 | 11,993.13 | 4162.57 | 22,993.13 | 3.17 | 4756.94 | 4.53 | 4087.86 | 22,993.13 | 7.71 |

| Accidents | 10,780.59 | 100.12 | 6763.74 | 3206.67 | 6755.75 | 3206.67 | 73.80 | 10,703.09 | 108.45 | 6678.26 | 3206.67 | 182.25 |

| Climate change | 20,539.91 | 592.96 | 12,886.74 | 3627.70 | 12,842.09 | 3627.70 | 0.00 | 19,949.68 | 0.00 | 12,408.80 | 3627.70 | 0.00 |

| Congestion | 81,870.65 | 0.00 | 51,365.64 | 0.00 | 50,783.65 | 0.00 | 2158.71 | 78,933.76 | 2603.45 | 45,136.74 | 0.00 | 4762.16 |

| Loss of habitat | 5192.99 | 171.57 | 3258.08 | 54.95 | 3249.36 | 54.95 | 33.19 | 5108.33 | 118.49 | 3164.69 | 54.95 | 151.68 |

| Infrastructure | 20,241.37 | 131.42 | 12,699.43 | 15.87 | 12,154.71 | 15.87 | 83.68 | 19,911.36 | 7396.80 | 6869.44 | 15.87 | 7480.48 |

| Noise | 14,710.88 | 0.00 | 9229.61 | 0.00 | 9224.99 | 0.00 | 0.00 | 13,272.61 | 0.00 | 9180.16 | 0.00 | 0.00 |

| Well-to-tank | 4783.60 | 259.64 | 3001.23 | 1588.51 | 2988.95 | 1588.51 | 159.36 | 4646.14 | 227.56 | 2869.77 | 1588.51 | 386.92 |

| SUM | 167,982.92 | 123,861.60 | 125,160.82 | 167,741.22 | 123,853.77 | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brusselaers, N.; Fufa, S.M.; Mommens, K. A Sustainability Assessment Framework for On-Site and Off-Site Construction Logistics. Sustainability 2022, 14, 8573. https://doi.org/10.3390/su14148573

Brusselaers N, Fufa SM, Mommens K. A Sustainability Assessment Framework for On-Site and Off-Site Construction Logistics. Sustainability. 2022; 14(14):8573. https://doi.org/10.3390/su14148573

Chicago/Turabian StyleBrusselaers, Nicolas, Selamawit Mamo Fufa, and Koen Mommens. 2022. "A Sustainability Assessment Framework for On-Site and Off-Site Construction Logistics" Sustainability 14, no. 14: 8573. https://doi.org/10.3390/su14148573

APA StyleBrusselaers, N., Fufa, S. M., & Mommens, K. (2022). A Sustainability Assessment Framework for On-Site and Off-Site Construction Logistics. Sustainability, 14(14), 8573. https://doi.org/10.3390/su14148573