The Circular Economy Paradigm: Modification of Bagasse-Derived Lignin as a Precursor to Sustainable Hydrogel Production

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sugar Cane Bagasse Preparation

2.3. Lignin Extraction

2.4. Chemical Modification of Lignin

2.4.1. Lignin Acetylation

2.4.2. Lignin Silanization

2.5. Preparation of Lignin Based Hydrogels

2.5.1. Heating Method for Hydrogel Preparation

2.5.2. Freeze-Thawing Method for Hydrogel Preparation

2.6. Characterization Experiments

2.6.1. Fourier Transform Infrared Spectroscopy (FTIR)

2.6.2. Thermal Properties and Elemental Assessment

2.6.3. Solubility Measurements

2.6.4. Swelling Ratios of the Hydrogels

2.6.5. Scanning Electron Microscopy of Hydrogels

2.6.6. Rheological Properties of Hydrogels

3. Results

3.1. Yield and Thermochemical Characterization of Lignin Samples

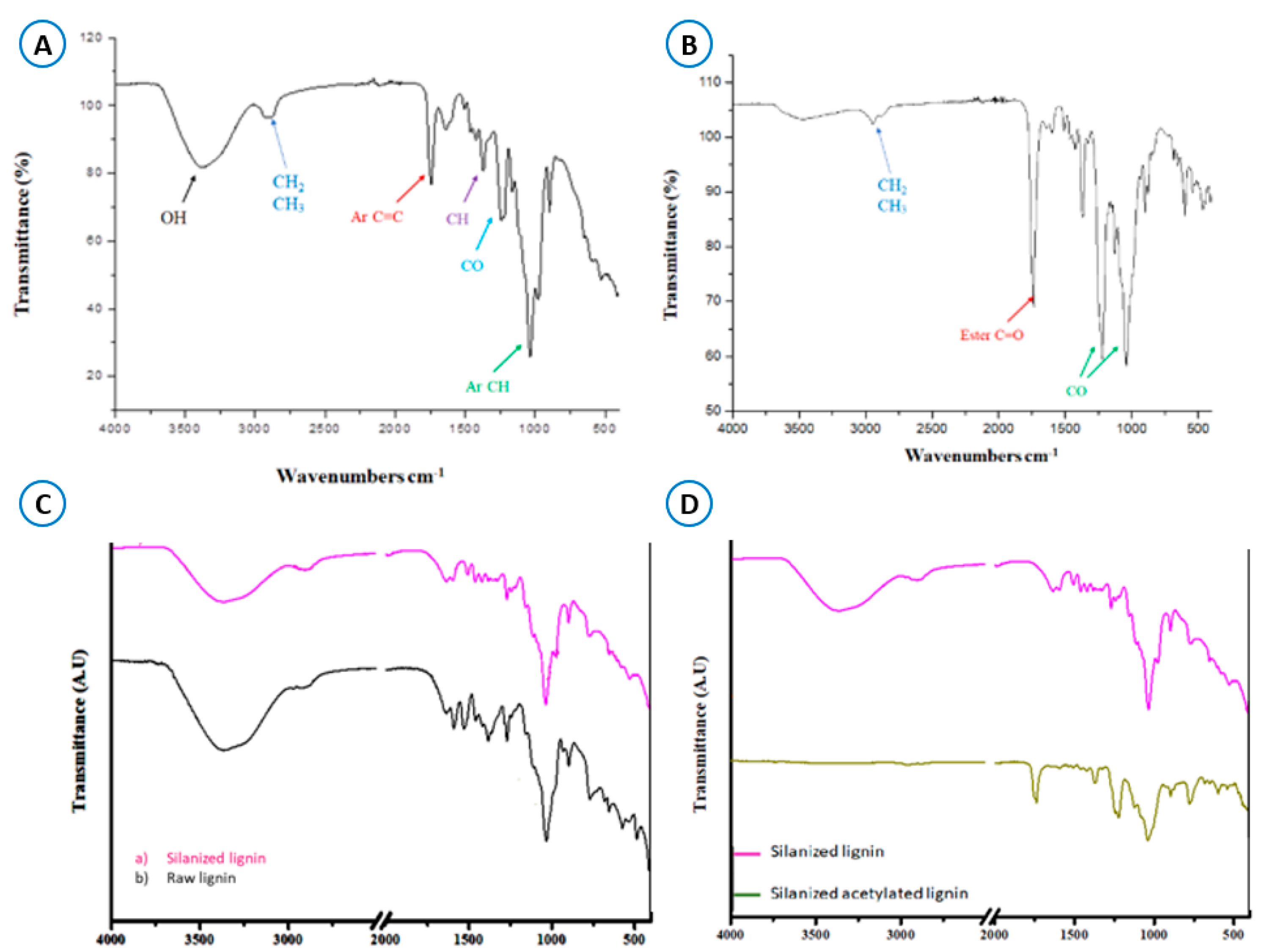

3.1.1. Fourier Transform Infrared Spectroscopy Analysis of Lignin Samples

3.1.2. Thermal Properties of the Lignin

3.1.3. Elemental Analyses of the Lignin Samples

3.2. Solubility Assessments

3.3. Yield, Swelling Ratio and Rheology of the Prepared Hydrogels

3.4. Fourier Transform Infrared Spectroscopy and Scanning Electron Microscopy Analysis of Produced Hydrogels

4. Discussion

4.1. Fourier Transform Infrared of Lignin Samples

4.2. Thermal Assessments of the Lignin Samples

4.3. Elemental Analyses of the Lignin Samples

4.4. Solubility Characteristics of the Lignin Samples

4.5. Hydrogel Yields and Swelling Ratios

4.6. Rheological Properties of the Prepared Hydrogels

4.7. Fourier Transform Infrared Scanning Electron Microscopy Analysis of Prepared Hydrogels

4.8. Notable Considerations

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Okoro, O.V.; Nie, L.; Alimoradi, H.; Shavandi, A. Waste Apple Pomace Conversion to Acrylic Acid: Economic and Potential Environmental Impact Assessments. Fermentation 2022, 8, 21. [Google Scholar] [CrossRef]

- Uppal, S.; Kaur, R.; Yuvraj; Chandni; Kaur, P.; Dhir, C. Evaluation of potential of sweet sorghum bagasse for production of value-added chemicals: 5-Hydroxymethyl furfural and its derivatives. Indian J. Chem. Technol. 2016, 23, 412–418. [Google Scholar]

- Anastas, P.T.W.J.C. Green chemistry: Theory and Practice; Oxford University Press: Oxford, UK; New York, NY, USA, 1998. [Google Scholar]

- Shavandi, A.; Hosseini, S.; Okoro, O.V.; Nie, L.; Eghbali Babadi, F.; Melchels, F. 3D Bioprinting of Lignocellulosic Biomaterials. Adv. Healthc. Mater. 2020, 9, 2001472. [Google Scholar] [CrossRef]

- Safarzadeh Kozani, P.; Safarzadeh Kozani, P.; Hamidi, M.; Valentine Okoro, O.; Eskandani, M.; Jaymand, M. Polysaccharide-based hydrogels: Properties, advantages, challenges, and optimization methods for applications in regenerative medicine. Int. J. Polym. Mater. Polym. Biomater. 2021, 1–15. [Google Scholar] [CrossRef]

- Krol, P.; Krol, B.; Dziwiński, E. Influence of the synthesis conditions on the properties of low-molecular weight epoxy resin. Polimery 2003, 48, 549–556. [Google Scholar] [CrossRef] [Green Version]

- Bhatnagar, M.S. Epoxy Resins (Overview). In Polymeric Materials Encyclopedia; Salamone, J.C., Ed.; CRC Press: New York, NY, USA, 1996. [Google Scholar]

- Okoro, O.V.; Amenaghawon, A.; Podstawczyk, D.; Alimoradi, H.; Khalili, M.R.; Anwar, M.; Milan, P.B.; Nie, L.; Shavandi, A. Fruit pomace-lignin as a sustainable biopolymer for biomedical applications. J. Clean. Prod. 2021, 328, 129498. [Google Scholar] [CrossRef]

- Fatimi, A.; Tassin, J.-F.; Turczyn, R.; Axelos, M.A.V.; Weiss, P. Gelation studies of a cellulose-based biohydrogel: The influence of pH, temperature and sterilization. Acta Biomater. 2009, 5, 3423–3432. [Google Scholar] [CrossRef] [Green Version]

- Fatimi, A.; François Tassin, J.; Quillard, S.; Axelos, M.A.V.; Weiss, P. The rheological properties of silated hydroxypropylmethylcellulose tissue engineering matrices. Biomaterials 2008, 29, 533–543. [Google Scholar] [CrossRef] [Green Version]

- Thakur, V.K.; Thakur, M.K.; Raghavan, P.; Kessler, M.R. Progress in Green Polymer Composites from Lignin for Multifunctional Applications: A Review. ACS Sustain. Chem. Eng. 2014, 2, 1072–1092. [Google Scholar] [CrossRef]

- Qian, Y.; Deng, Y.; Li, H.; Qiu, X. Reaction-Free Lignin Whitening via a Self-Assembly of Acetylated Lignin. Ind. Eng. Chem. Res. 2014, 53, 10024–10028. [Google Scholar] [CrossRef]

- Rico-García, D.; Ruiz-Rubio, L.; Pérez-Alvarez, L.; Hernández-Olmos, S.L.; Guerrero-Ramírez, G.L.; Vilas-Vilela, J.L. Lignin-Based Hydrogels: Synthesis and Applications. Polymers 2020, 12, 81. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fatimi, A.; Okoro, O.V.; Podstawczyk, D.; Siminska-Stanny, J.; Shavandi, A. Natural Hydrogel-Based Bio-Inks for 3D Bioprinting in Tissue Engineering: A Review. Gels 2022, 8, 179. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Zhao, Y.; Wei, H.; Nie, L.; Ding, P.; Sun, H.; Guo, Y.; Chen, T.; Okoro, O.V.; Shavandi, A.; et al. Injectable hydrogels based on silk fibroin peptide grafted hydroxypropyl chitosan and oxidized microcrystalline cellulose for scarless wound healing. Colloids Surf. A Physicochem. Eng. Asp. 2022, 647, 129062. [Google Scholar] [CrossRef]

- Figueroa-Pizano, M.D.; Vélaz, I.; Peñas, F.J.; Zavala-Rivera, P.; Rosas-Durazo, A.J.; Maldonado-Arce, A.D.; Martínez-Barbosa, M.E. Effect of freeze-thawing conditions for preparation of chitosan-poly (vinyl alcohol) hydrogels and drug release studies. Carbohydr. Polym. 2018, 195, 476–485. [Google Scholar] [CrossRef] [PubMed]

- Yue, Y.; Han, J.; Han, G.; French, A.D.; Qi, Y.; Wu, Q. Cellulose nanofibers reinforced sodium alginate-polyvinyl alcohol hydrogels: Core-shell structure formation and property characterization. Carbohydr. Polym. 2016, 147, 155–164. [Google Scholar] [CrossRef] [Green Version]

- Nadji, H.; Diouf, P.N.; Benaboura, A.; Bedard, Y.; Riedl, B.; Stevanovic, T. Comparative study of lignins isolated from Alfa grass (Stipa tenacissima L.). Bioresour. Technol. 2009, 100, 3585–3592. [Google Scholar] [CrossRef]

- Moubarik, A.; Grimi, N.; Boussetta, N.; Pizzi, A. Isolation and characterization of lignin from Moroccan sugar cane bagasse: Production of lignin–phenol-formaldehyde wood adhesive. Ind. Crops Prod. 2013, 45, 296–302. [Google Scholar] [CrossRef]

- Ezhumalai, S.; Thangavelu, V. Kinetic and optimization studies on the bioconversion of lignocellulosic material into ethanol. Bioresources 2010, 5, 1879–1894. [Google Scholar]

- Siuda, J.; Perdoch, W.; Mazela, B.; Zborowska, M. Catalyzed Reaction of Cellulose and Lignin with Methyltrimethoxysilane—FT-IR, 13C NMR and 29Si NMR Studies. Materials 2019, 12, 2006. [Google Scholar] [CrossRef] [Green Version]

- Morales, A.; Labidi, J.; Gullón, P. Impact of the lignin type and source on the characteristics of physical lignin hydrogels. Sustain. Mater. Technol. 2022, 31, e00369. [Google Scholar] [CrossRef]

- Sameni, J.; Krigstin, S.; Sain, M. Solubility of Lignin and Acetylated Lignin in Organic Solvents. Bioresources 2017, 12, 1548–1565. [Google Scholar] [CrossRef]

- Wu, L.; Huang, S.; Zheng, J.; Qiu, Z.; Lin, X.; Qin, Y. Synthesis and characterization of biomass lignin-based PVA super-absorbent hydrogel. Int. J. Biol. Macromol. 2019, 140, 538–545. [Google Scholar] [CrossRef] [PubMed]

- Ladeira, N.; Peixoto, V.; Penha, M.; Barros, E.; Leite, S. Optimization of 6-Pentyl-Alpha-Pyrone Production by Solid State Fermentation Using Sugarcane Bagasse as Residue. Bioresources 2010, 5, 2297–2306. [Google Scholar] [CrossRef]

- Xu, F.; Yu, J.; Tesso, T.; Dowell, F.; Wang, D. Qualitative and quantitative analysis of lignocellulosic biomass using infrared techniques: A mini-review. Applied Energy 2013, 104, 801–809. [Google Scholar] [CrossRef] [Green Version]

- Okoro, O.V.; Sun, Z. The characterisation of biochar and biocrude products of the hydrothermal liquefaction of raw digestate biomass. Biomass Convers. Biorefinery 2021, 11, 2947–2961. [Google Scholar] [CrossRef]

- Tobimatsu, Y.; Chen, F.; Nakashima, J.; Escamilla-Treviño, L.L.; Jackson, L.; Dixon, R.A.; Ralph, J. Coexistence but independent biosynthesis of catechyl and guaiacyl/syringyl lignin polymers in seed coats. Plant Cell 2013, 25, 2587–2600. [Google Scholar] [CrossRef] [Green Version]

- Lisperguer, J.; Perez, P.; Urizar, S. Structure and Thermal Properties of Lignins: Characterization by Infrared Spectroscopy and Differential Scanning Calorimetry. J. Chil. Chem. Soc. 2009, 54, 460–463. [Google Scholar] [CrossRef] [Green Version]

- Gwon, J.G.; Lee, S.Y.; Doh, G.H.; Kim, J.H. Characterization of chemically modified wood fibers using FTIR spectroscopy for biocomposites. J. Appl. Polym. Sci. 2010, 116, 3212–3219. [Google Scholar] [CrossRef]

- An, L.; Si, C.; Bae, J.H.; Jeong, H.; Kim, Y.S. One-step silanization and amination of lignin and its adsorption of Congo red and Cu(II) ions in aqueous solution. Int. J. Biol. Macromol. 2020, 159, 222–230. [Google Scholar] [CrossRef]

- Aoul-hrouz, S.; Essamellali, Y.; Zahouily, M. Extraction and characterization of lignin from moroccan sugarcane bagasse using response surface design. Int. J. Trend Res. Dev. 2017, 4, 185–191. [Google Scholar]

- Liu, Q.; Wang, S.; Zheng, Y.; Luo, Z.; Cen, K. Mechanism study of wood lignin pyrolysis by using TG–FTIR analysis. J. Anal. Appl. Pyrolysis 2008, 82, 170–177. [Google Scholar] [CrossRef]

- Orfão, J.J.M.; Antunes, F.J.A.; Figueiredo, J.L. Pyrolysis kinetics of lignocellulosic materials—Three independent reactions model. Fuel 1999, 78, 349–358. [Google Scholar] [CrossRef]

- Borchardt, R.; Kerns, E.; Lipinski, C.; Thakker, D.; Wang, B. Pharmaceutical Profiling in Drug Discovery for Lead Selection; American Association of Pharmaceutical Scientists: Arlington, TX, USA, 2005. [Google Scholar]

- Shukry, N.; Fadel, S.M.; Agblevor, F.A.; El-Kalyoubi, S.F. Some physical properties of acetosolv lignins from bagasse. J. Appl. Polym. Sci. 2008, 109, 434–444. [Google Scholar] [CrossRef]

- Van Den Bulcke, A.I.; Bogdanov, B.; De Rooze, N.; Schacht, E.H.; Cornelissen, M.; Berghmans, H. Structural and Rheological Properties of Methacrylamide Modified Gelatin Hydrogels. Biomacromolecules 2000, 1, 31–38. [Google Scholar] [CrossRef] [PubMed]

- Bian, H.; Jiao, L.; Wang, R.; Wang, X.; Zhu, W.; Dai, H. Lignin nanoparticles as nano-spacers for tuning the viscoelasticity of cellulose nanofibril reinforced polyvinyl alcohol-borax hydrogel. Eur. Polym. J. 2018, 107, 267–274. [Google Scholar] [CrossRef]

- Huang, S.; Shuyi, S.; Gan, H.; Linjun, W.; Lin, C.; Danyuan, X.; Zhou, H.; Lin, X.; Qin, Y. Facile fabrication and characterization of highly stretchable lignin-based hydroxyethyl cellulose self-healing hydrogel. Carbohydr. Polym. 2019, 223, 115080. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, S.; Wang, Q.; Fu, X.; Fatehi, P. Performance of polyvinyl alcohol hydrogel reinforced with lignin-containing cellulose nanocrystals. Cellulose 2020, 27, 8725–8743. [Google Scholar] [CrossRef]

- Schwanninger, M.; Rodrigues, J.C.; Pereira, H.; Hinterstoisser, B. Effects of short-time vibratory ball milling on the shape of FT-IR spectra of wood and cellulose. Vib. Spectrosc. 2004, 36, 23–40. [Google Scholar] [CrossRef]

- Kubo, S.; Kadla, J.F. Kraft lignin/poly(ethylene oxide) blends: Effect of lignin structure on miscibility and hydrogen bonding. J. Appl. Polym. Sci. 2005, 98, 1437–1444. [Google Scholar] [CrossRef]

- Panamgama, L.A.; Peramune, P.R.U.S.K. Extraction and modification of lignin biopolymer. In Proceedings of the 2017 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 29–31 May 2017; pp. 13–16. [Google Scholar]

- Kubo, S.; Kadla, J.F. The Formation of Strong Intermolecular Interactions in Immiscible Blends of Poly(vinyl alcohol) (PVA) and Lignin. Biomacromolecules 2003, 4, 561–567. [Google Scholar] [CrossRef]

- Wang, L.-Y.; Wang, M.-J. Removal of Heavy Metal Ions by Poly(vinyl alcohol) and Carboxymethyl Cellulose Composite Hydrogels Prepared by a Freeze–Thaw Method. ACS Sustain. Chem. Eng. 2016, 4, 2830–2837. [Google Scholar] [CrossRef]

| Sample | Si | S | Na | Mg | K | Ca | Pb | Al | Cr | Mn | Fe | Co | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mg/g | mg/g | mg/g | mg/g | mg/g | mg/g | µg/g | µg/g | µg/g | µg/g | µg/g | µg/g | µg/g | |

| S-lignin | 125.39 | 0.40 | 0.20 | 0.09 | 0.03 | 0.42 | 0.21 | 4095 | 0.71 | 0.28 | 18.10 | 0.13 | 1.38 |

| A-S-lignin | 32.01 | 2.60 | 1.46 | 0.64 | 0.05 | 3.22 | 0.31 | 2077 | 0.75 | 0.53 | 32.20 | 1.23 | 10.58 |

| R-lignin | 3.76 | 51.55 | 73.89 | 0.24 | 0.60 | 0.61 | 0.02 | 124 | 1.24 | 1.16 | 48.70 | 0.06 | 4.06 |

| Preparation Methods | F/T | Heating | F/T | Heating | F/T | Heating | F/T | Heating |

|---|---|---|---|---|---|---|---|---|

| Type of lignin | R-lignin | R-lignin | A-lignin | A-lignin | S-lignin | S-lignin | A-S-lignin | A-S-lignin |

| Yield (wt. %) | 67 | 54 | 75 | 55 | 92 | 70 | 88 | 64 |

| Hydrogel Preparation Method | Type of Lignin + PVA | Maximum G’ with LVR at x = 10 rad/s, G’max (Pa) | G’’ with LVR at x = 10 rad/s, G’’ (Pa) | Flow Point (τf) (Pa) | Yield Point (τy) (Pa) |

|---|---|---|---|---|---|

| By F/T | A-S-lignin | 27,797.0 | 1196.8 | 4346.1 | 300.4 |

| S-lignin | 11,127.0 | 605.9 | 2635.1 | 60.9 | |

| A-lignin | 8441.3 | 698.0 | 378.4 | 35.7 | |

| R-lignin | 6062.6 | 557.1 | 47.5 | 11.2 | |

| With ECH and F/T | A-S-lignin | 47,959.0 | 3233.6 | 1843.7 | 262.2 |

| S-lignin | 31,115.0 | 1189.8 | 2598.4 | 166.0 | |

| A-lignin | 22,282.0 | 828.2 | 940.3 | 93.8 | |

| R-lignin | 23,116.0 | 859.5 | 3486.9 | 155.3 | |

| By Heating | A-S-lignin | 280.8 | 12.7 | 0.4 | 0.2 |

| S-lignin | 330.6 | 27.0 | 13.4 | 1.8 | |

| A-lignin | 6905.1 | 590.5 | 39.8 | 8.6 | |

| R-lignin | 67,092.0 | 5293.9 | 548.6 | 86.8 | |

| With ECH and heating | A-S-lignin | 6068.0 | 283.4 | 3372.5 | 336.5 |

| S-lignin | 28,233.0 | 1563.8 | 1179.2 | 119.2 | |

| A-lignin | 19,567.0 | 803.1 | 1149.3 | 52.6 | |

| R-lignin | 5435.1 | 367.9 | 671.6 | 671.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akhramez, S.; Fatimi, A.; Okoro, O.V.; Hajiabbas, M.; Boussetta, A.; Moubarik, A.; Hafid, A.; Khouili, M.; Simińska-Stanny, J.; Brigode, C.; et al. The Circular Economy Paradigm: Modification of Bagasse-Derived Lignin as a Precursor to Sustainable Hydrogel Production. Sustainability 2022, 14, 8791. https://doi.org/10.3390/su14148791

Akhramez S, Fatimi A, Okoro OV, Hajiabbas M, Boussetta A, Moubarik A, Hafid A, Khouili M, Simińska-Stanny J, Brigode C, et al. The Circular Economy Paradigm: Modification of Bagasse-Derived Lignin as a Precursor to Sustainable Hydrogel Production. Sustainability. 2022; 14(14):8791. https://doi.org/10.3390/su14148791

Chicago/Turabian StyleAkhramez, Soufiane, Ahmed Fatimi, Oseweuba Valentine Okoro, Maryam Hajiabbas, Abdelghani Boussetta, Amine Moubarik, Abderrafia Hafid, Mostafa Khouili, Julia Simińska-Stanny, Cecile Brigode, and et al. 2022. "The Circular Economy Paradigm: Modification of Bagasse-Derived Lignin as a Precursor to Sustainable Hydrogel Production" Sustainability 14, no. 14: 8791. https://doi.org/10.3390/su14148791

APA StyleAkhramez, S., Fatimi, A., Okoro, O. V., Hajiabbas, M., Boussetta, A., Moubarik, A., Hafid, A., Khouili, M., Simińska-Stanny, J., Brigode, C., & Shavandi, A. (2022). The Circular Economy Paradigm: Modification of Bagasse-Derived Lignin as a Precursor to Sustainable Hydrogel Production. Sustainability, 14(14), 8791. https://doi.org/10.3390/su14148791