A Comprehensive Review on the Ground Granulated Blast Furnace Slag (GGBS) in Concrete Production

Abstract

:1. Introduction

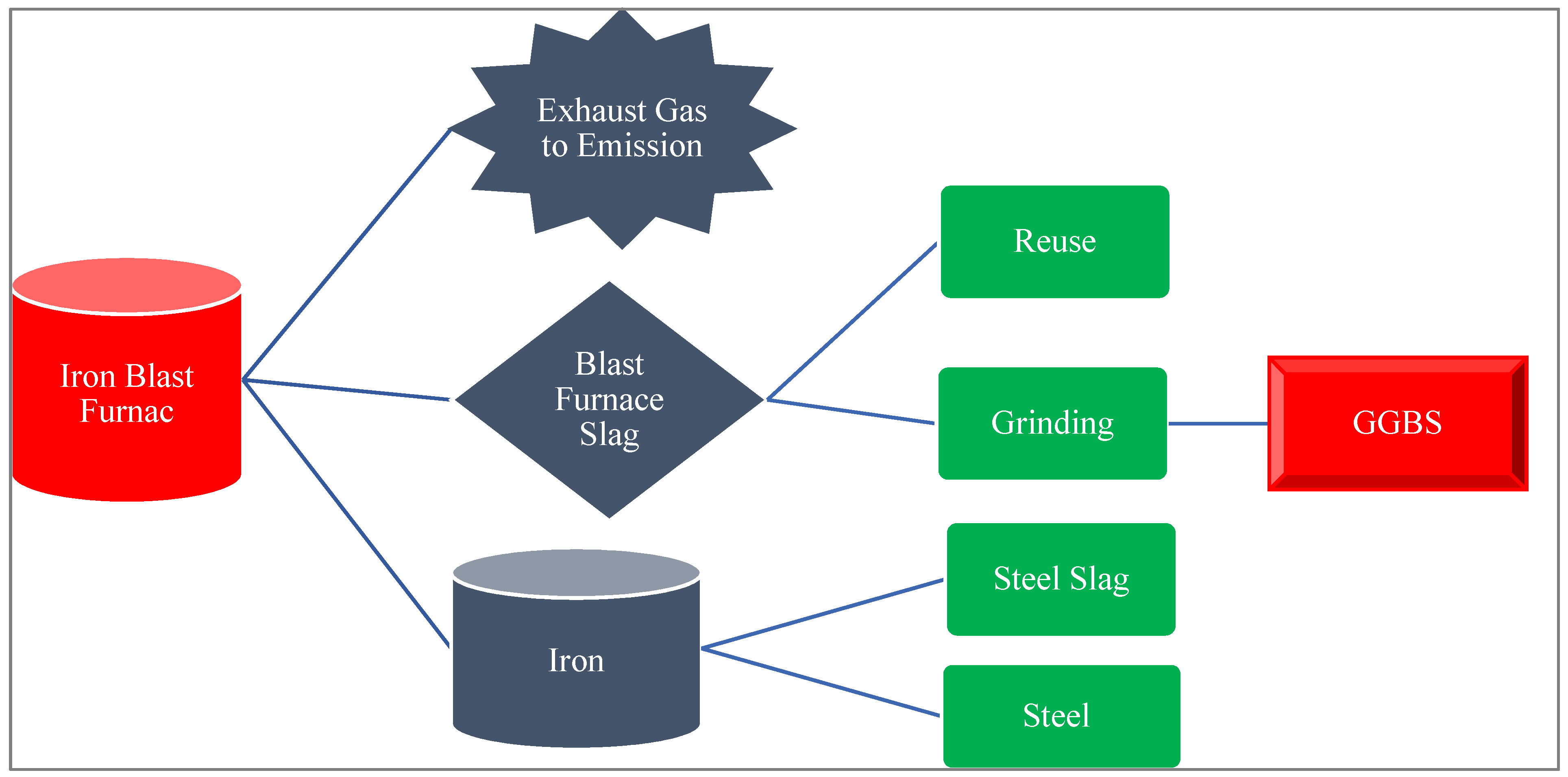

2. Environmental Assessment

3. Ground-Granulated Blast-Furnace Slag (GGBS)

4. Physical Properties of GGBS

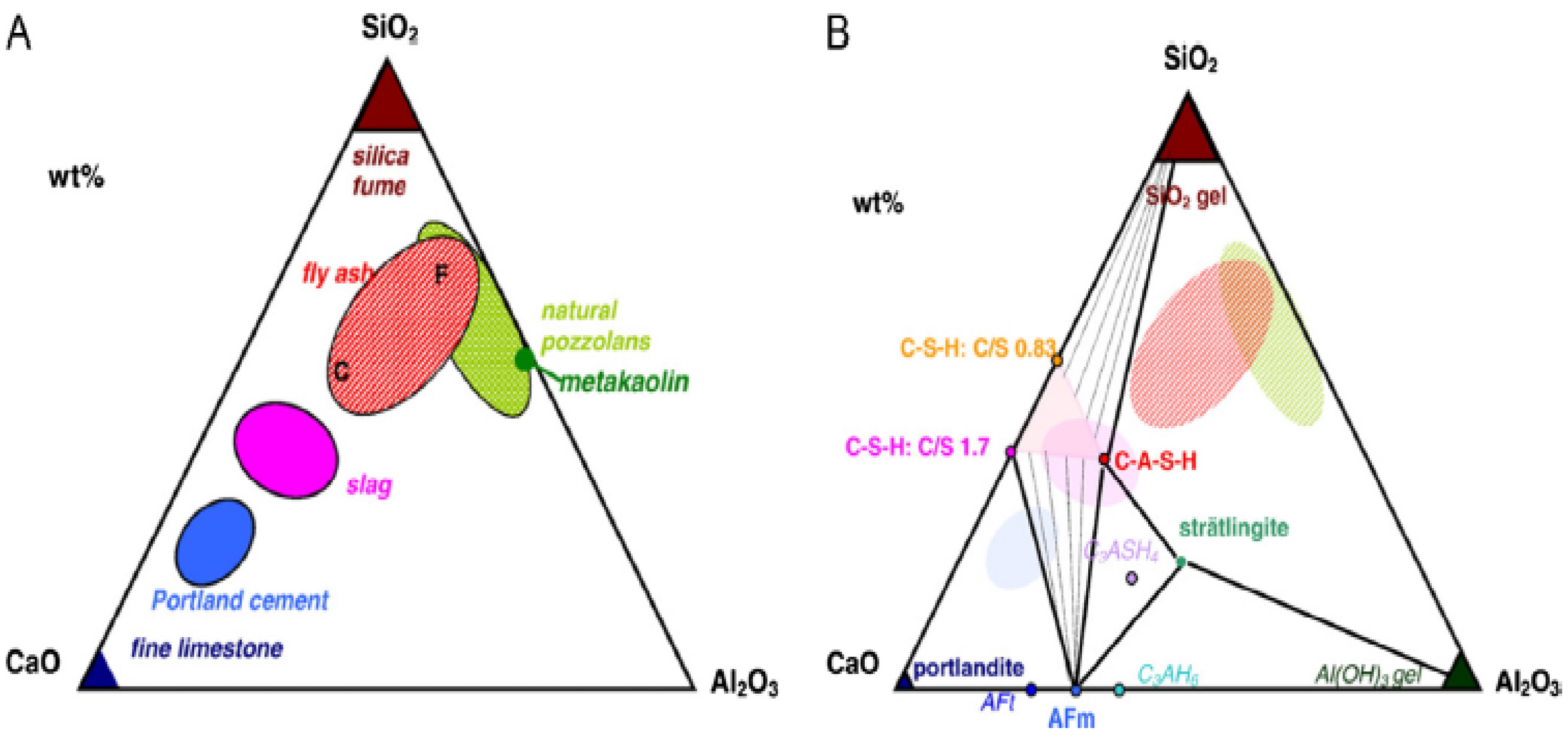

5. Chemical Composition

6. Hydraulic Activity of Slag

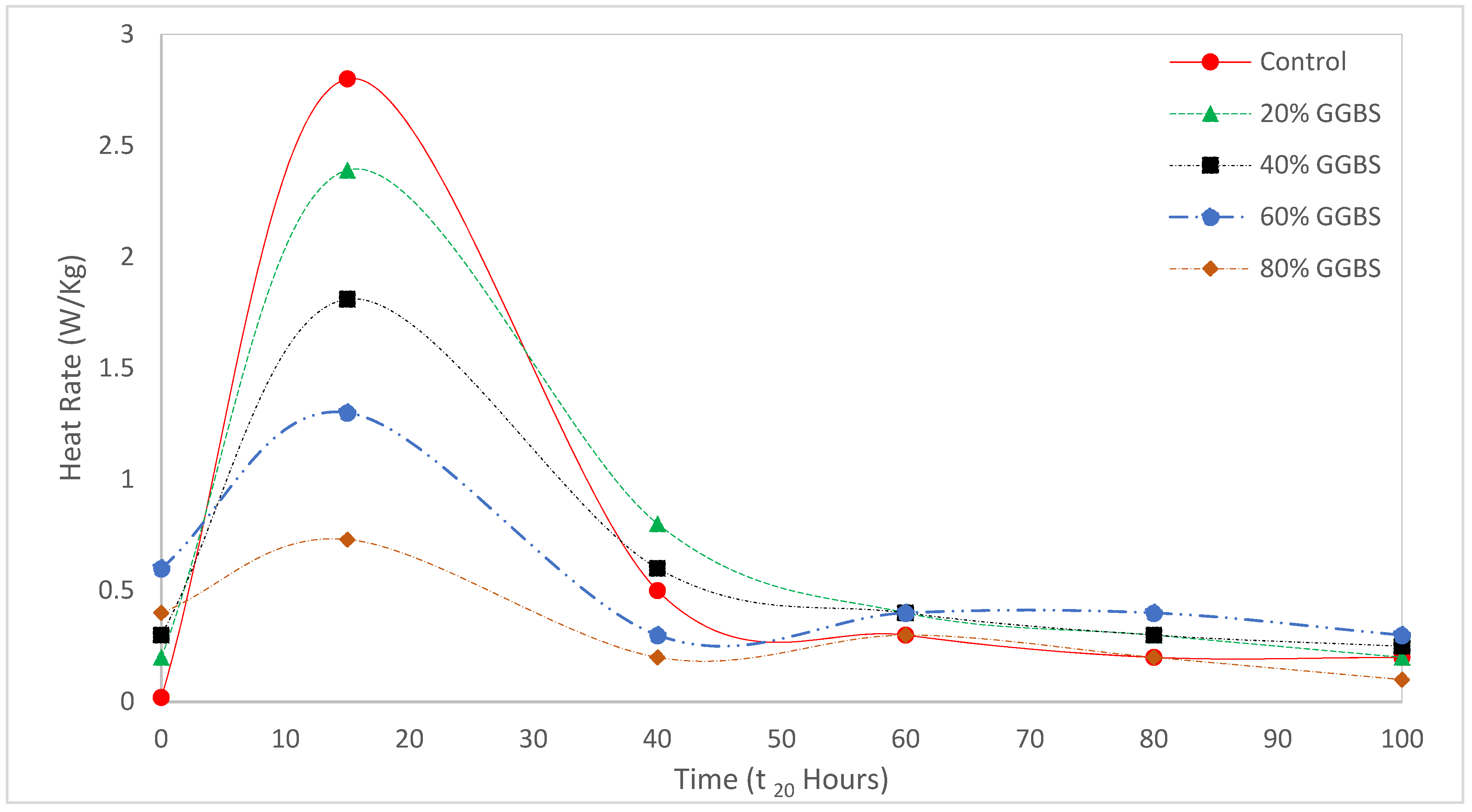

7. Heat of Hydration

| Mix Composition | Time to qmax (t20 h) | qmax (W/kg) | to 100% CEM I (W/kg) |

|---|---|---|---|

| 100-OPC | 17.6 | 2.80 | 2.80 |

| 20-GGBS | 15.3 | 2.39 | 2.99 |

| 40-GGBS | 15.7 | 1.81 | 3.02 |

| 60-GGBS | 14.2 | 1.30 | 3.25 |

| 80-GGBS | 10.7 | 0.73 | 3.65 |

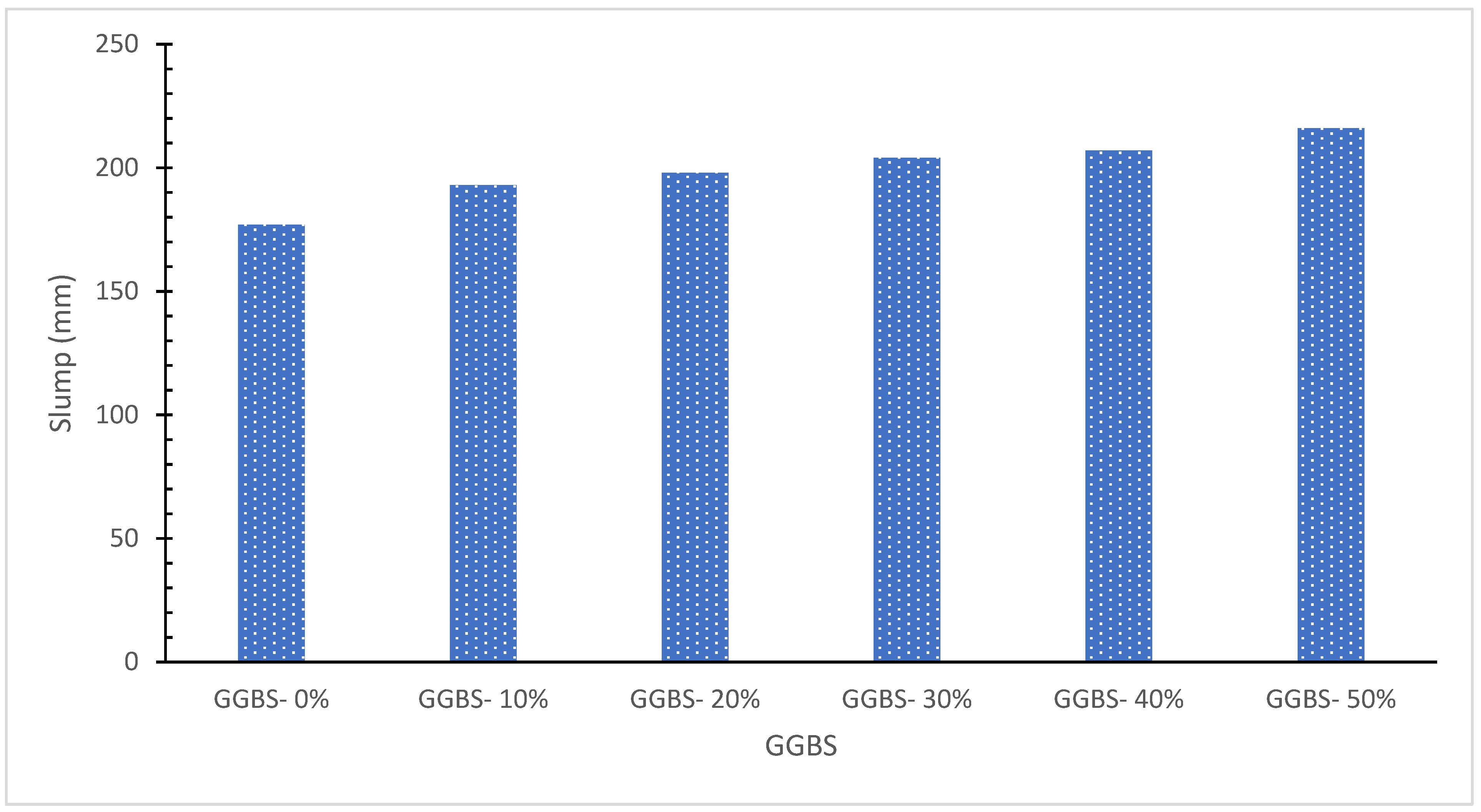

8. Workability

9. Mechanical Properties

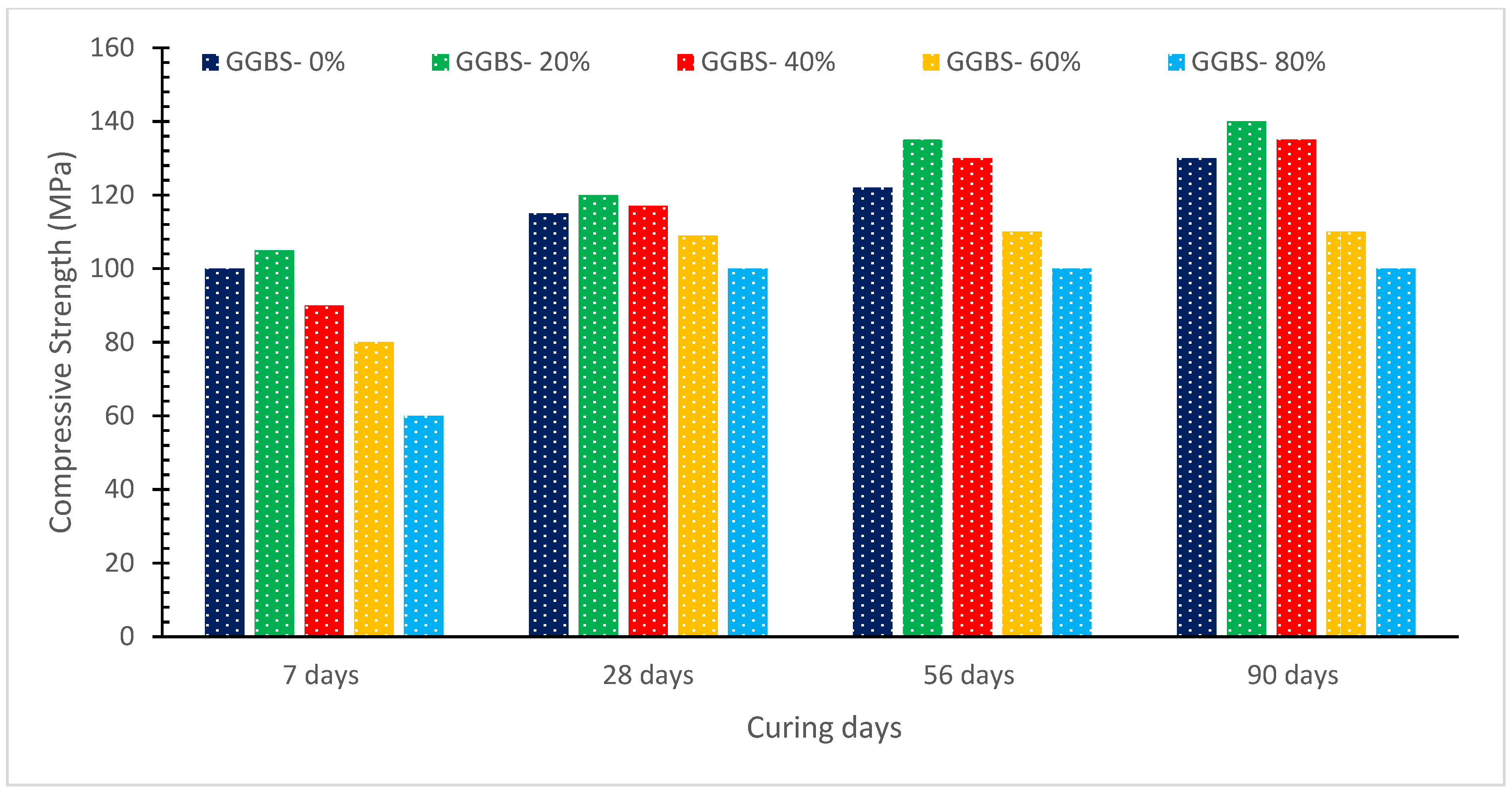

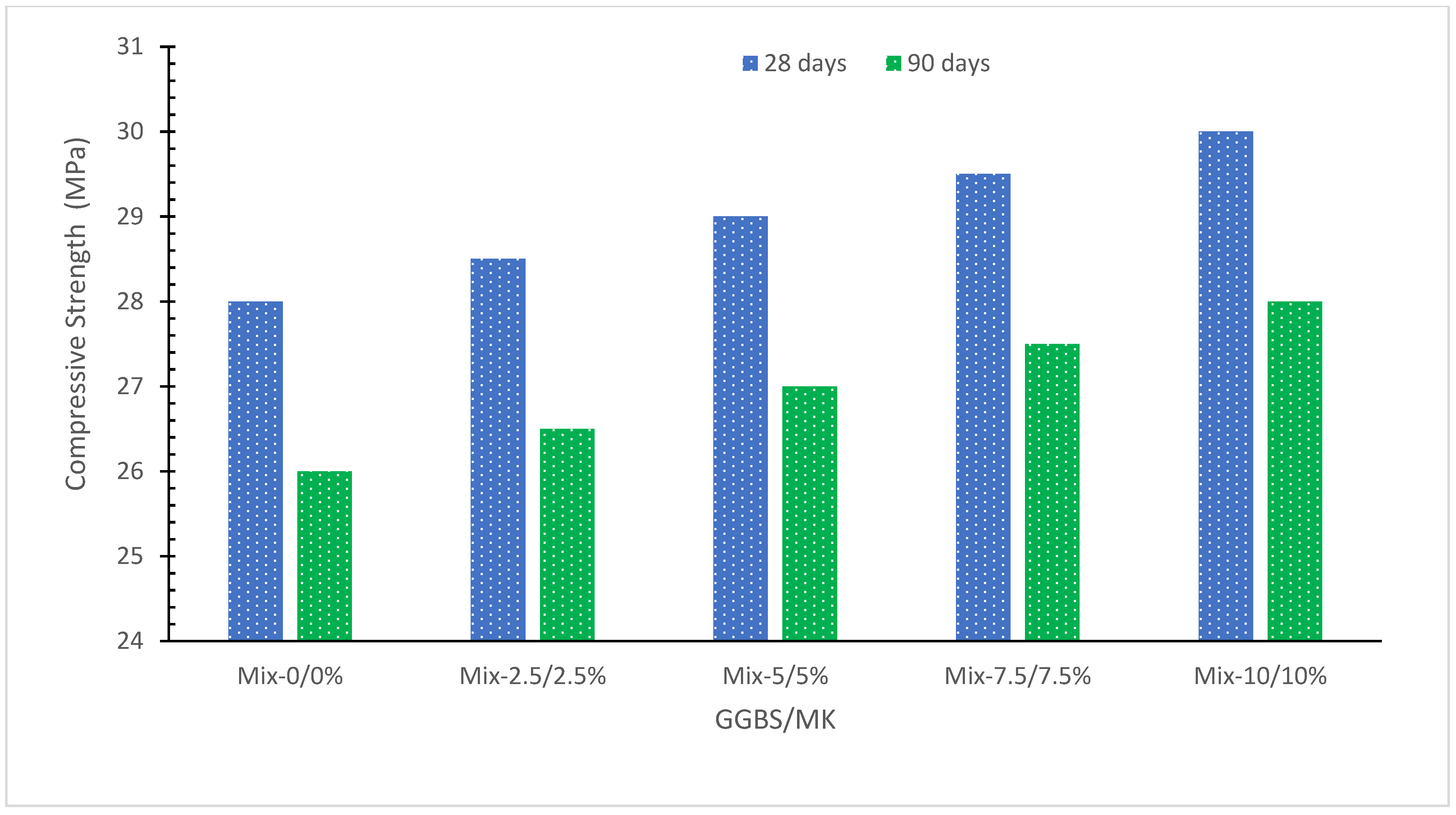

9.1. Compressive Strength (CPS)

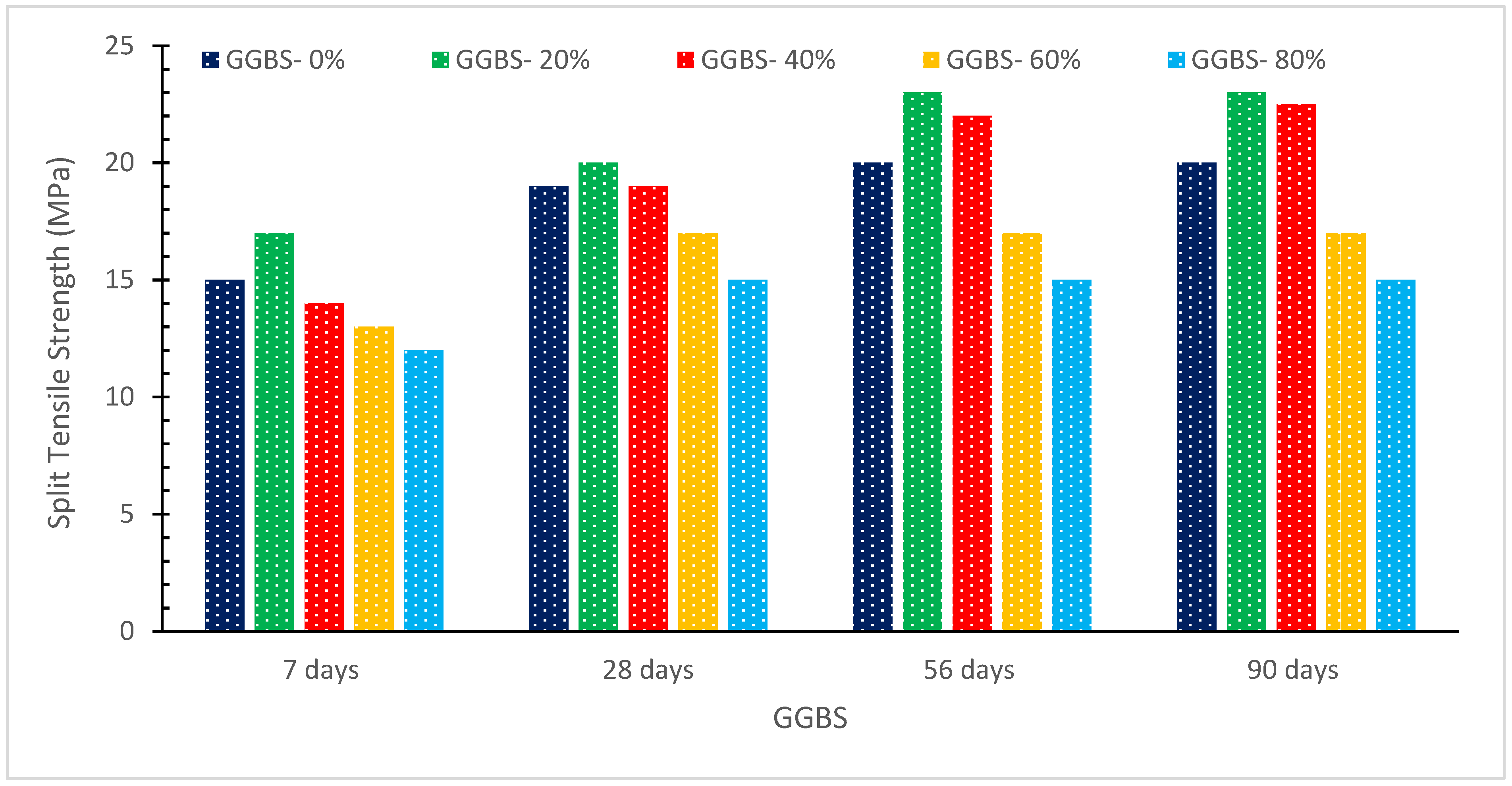

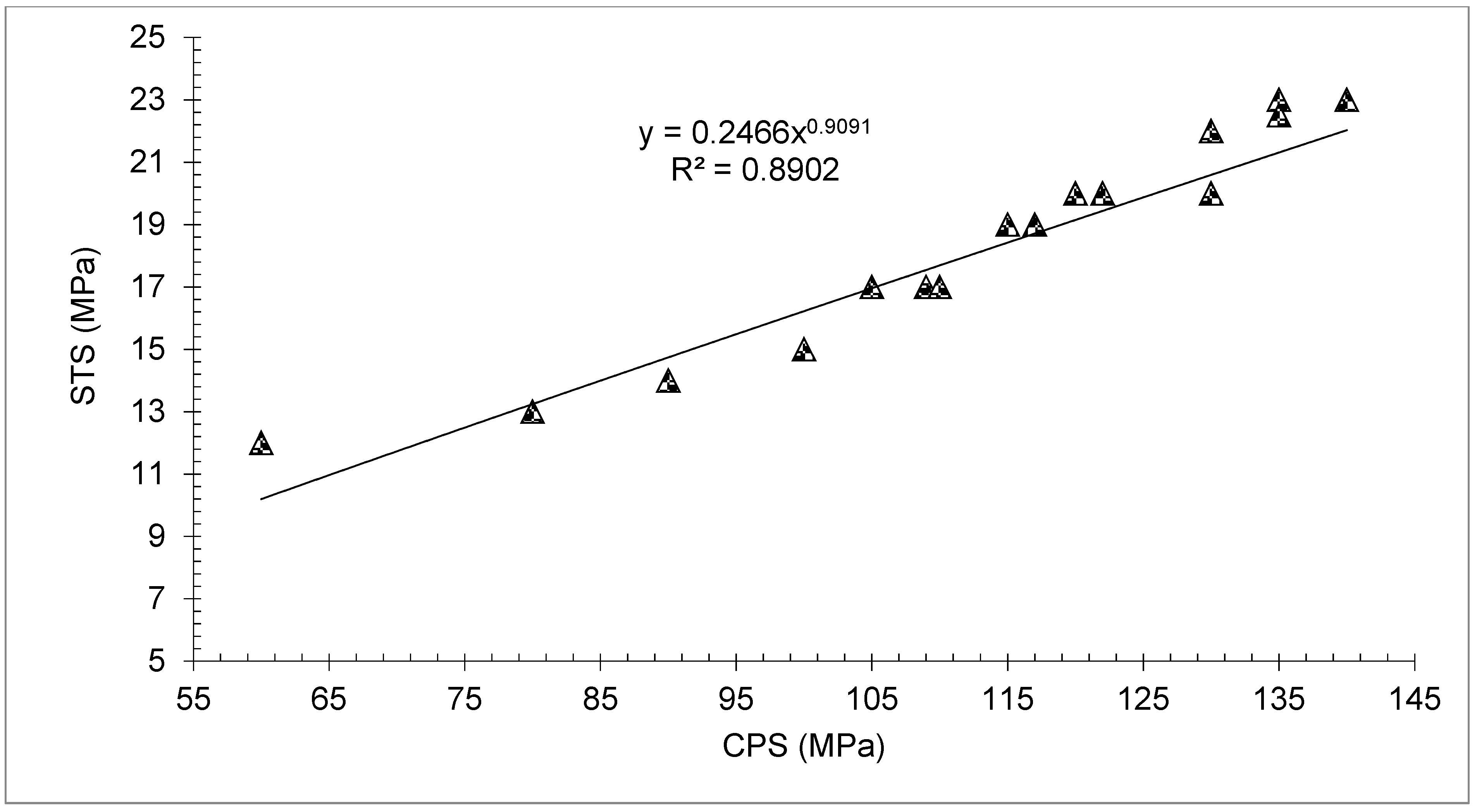

9.2. Split Tensile Strength (STS)

9.3. Flexure Strength (FS)

10. Durability

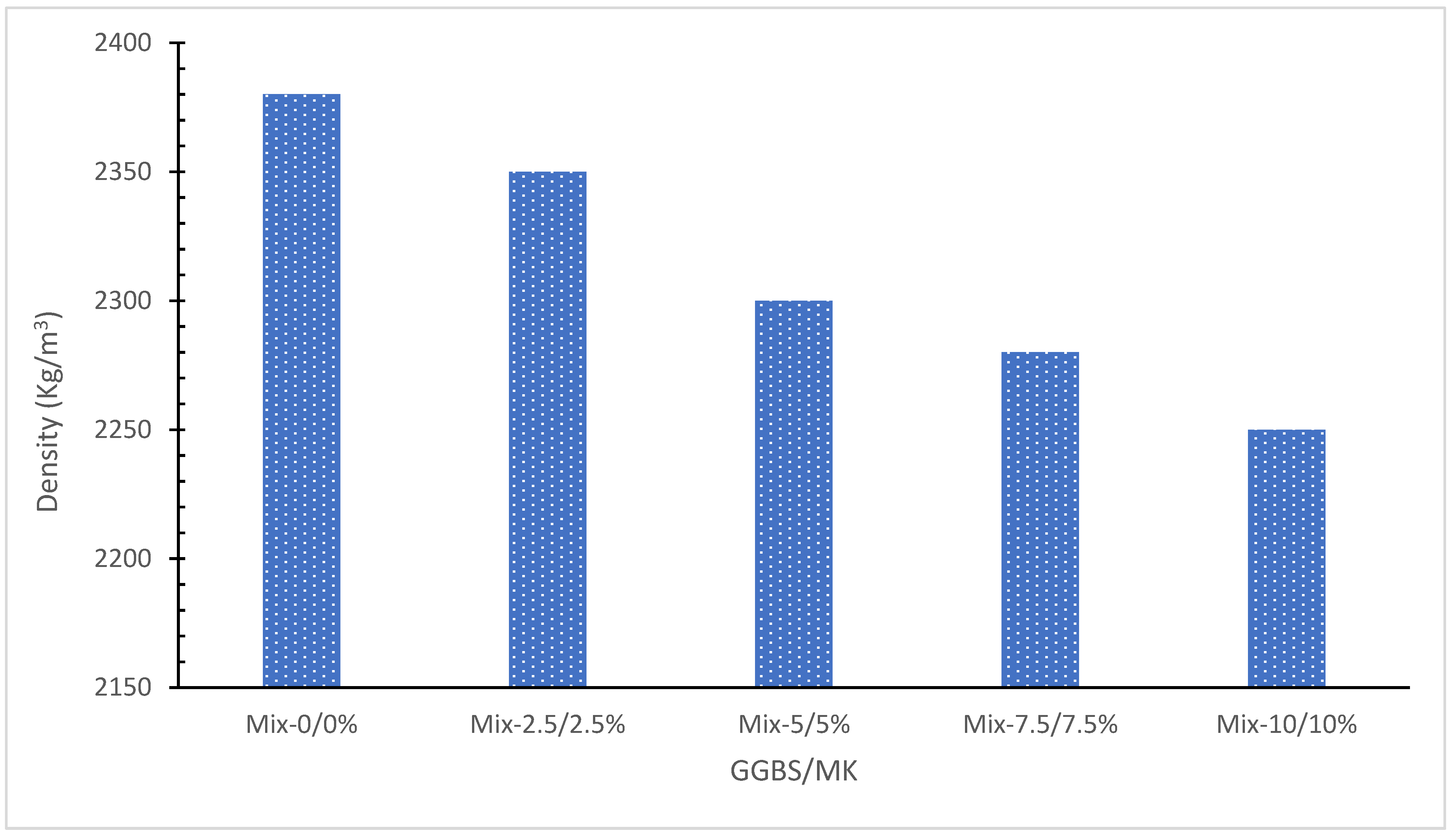

10.1. Density

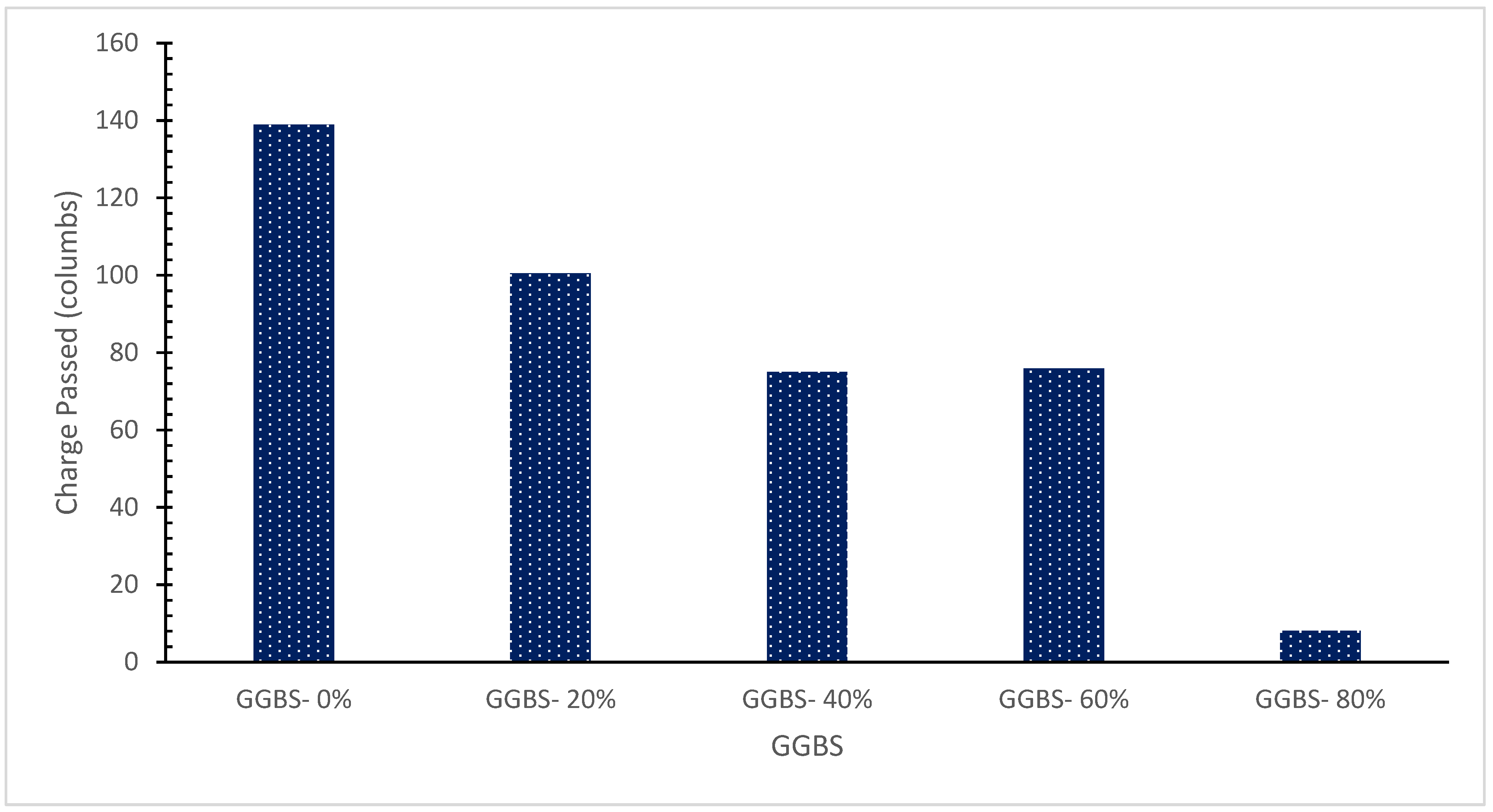

10.2. Rapid Chloride Ion Penetration (RCPT)

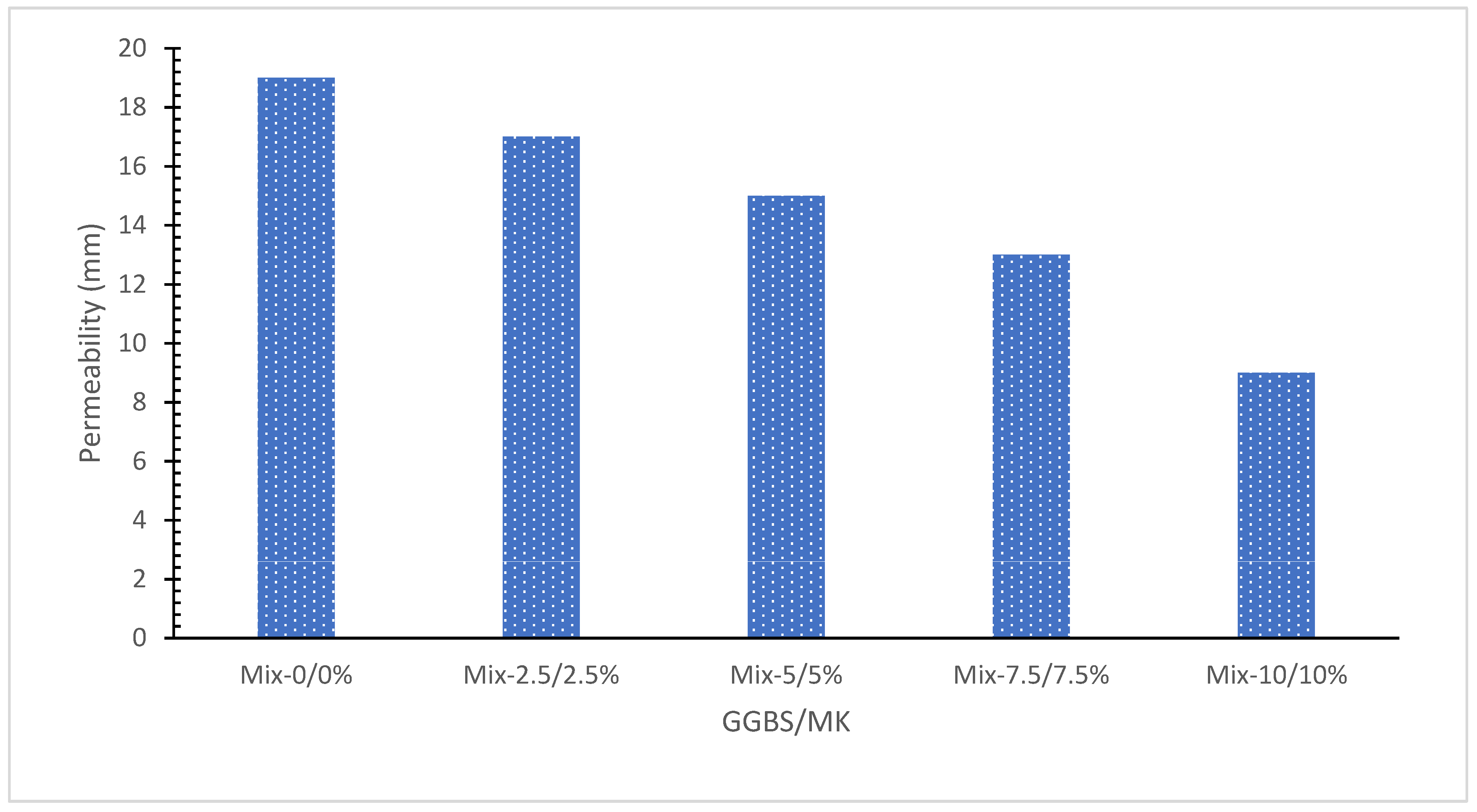

10.3. Permeability

10.4. Chloride Attack

10.5. Dry Shrinkage

11. Conclusions

- Physical assets of GGBS, such as specific gravity and bulk density of concrete, are approximately equal to the cement. However, the surface area of GGBS is larger than cement. Furthermore, the SEM of GGBS shows the angular and rough surface texture of GGBS particles.

- The chemical composition of GGBS shows that it can be used as a cement replacement up to a certain extent.

- The heat of hydration decreased with the substitution of GGBS as the pozzolanic reaction proceeds slowly as compared to the hydration of cement.

- The workability of concrete is reduced by replacing OPC with GGBS due to the larger surface area and rough surface texture of GGBS particles. Therefore, plasticizer was recommended particularly for the higher dose of GGBS.

- Mechanical performance of concrete, such as compressive strength, split tensile strength and flexure, improved with GGBS due to the pozzolanic reaction and micro filling voids. However, a higher dose caused a decrease in the mechanical and durability of concrete due to lack of workability.

- Increased durability performance, such as dry shrinkage, permeability, chloride penetration and acid attack, was observed with GGBS. The combined micro filling and the pozzolanic reaction of GGBS results in more durable concrete.

- The optimum dose is important for better mechanical and durability aspects of concrete. Different researchers reported different values of optimum quantity of GGBS due to varying sources of GGBS. However, most researchers reported a 20% optimum dose of GGBS.

- Environmental assessments show the reduction of carbon dioxide emissions and the conservation of natural resources have a significant impact on environmental protection.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ganesh, P.; Murthy, A.R. Tensile Behaviour and Durability Aspects of Sustainable Ultra-High Performance Concrete Incorporated with GGBS as Cementitious Material. Constr. Build. Mater. 2019, 197, 667–680. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards Sustainable Concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Oh, D.-Y.; Noguchi, T.; Kitagaki, R.; Park, W.-J. CO2 Emission Reduction by Reuse of Building Material Waste in the Japanese Cement Industry. Renew. Sustain. Energy Rev. 2014, 38, 796–810. [Google Scholar] [CrossRef]

- Mehta, P.K. Greening of the Concrete Industry for Sustainable Development. Concr. Int. 2002, 24, 23–28. [Google Scholar]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of Incorporation of High Volume of Recycled Concrete Aggregates and Fly Ash on the Strength and Global Warming Potential of Concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Mohseni, E.; Ranjbar, M.M.; Yazdi, M.A.; Hosseiny, S.S.; Roshandel, E. The Effects of Silicon Dioxide, Iron(III) Oxide and Copper Oxide Nanomaterials on the Properties of Self-Compacting Mortar Containing Fly Ash. Mag. Concr. Res. 2015, 67, 1112–1124. [Google Scholar] [CrossRef]

- Smirnova, O. Compatibility of Shungisite Microfillers with Polycarboxylate Admixtures in Cement Compositions. ARPN J. Eng. Appl. Sci. 2019, 14, 600–610. [Google Scholar]

- Vigneshpandian, G.V.; Shruthi, E.A.; Venkatasubramanian, C.; Muthu, D. Utilisation of Waste Marble Dust as Fine Aggregate in Concrete. IOP Conf. Ser. Earth Environ. Sci. 2017, 80, 012007. [Google Scholar] [CrossRef] [Green Version]

- Yang, K.-H.; Jung, Y.-B.; Cho, M.-S.; Tae, S.-H. Effect of Supplementary Cementitious Materials on Reduction of CO2 Emissions from Concrete. J. Clean. Prod. 2015, 103, 774–783. [Google Scholar] [CrossRef]

- Oyak Cement. World Cement Association. Available online: https://www.worldcementassociation.org/images/info-graphics/001-World-Wide-Cement-Production.pdf (accessed on 16 June 2022).

- Ahmad, J.; Zaid, O.; Shahzaib, M.; Abdullah, M.U.; Ullah, A.; Ullah, R. Mechanical Properties of Sustainable Concrete Modified by Adding Marble Slurry as Cement Substitution. AIMS Mater. Sci. 2021, 8, 343–358. [Google Scholar] [CrossRef]

- Mirza, J.; Riaz, M.; Naseer, A.; Rehman, F.; Khan, A.N.; Ali, Q. Pakistani Bentonite in Mortars and Concrete as Low Cost Construction Material. Appl. Clay Sci. 2009, 45, 220–226. [Google Scholar] [CrossRef]

- ASTM D6868; Standard Specification for Biodegradable Plastics Used as Coatings on Paper and Other Compostable Substrates. ASTM International: West Conshohocken, PA, USA, 2017.

- Karimipour, A.; de Brito, J. Influence of Polypropylene Fibres and Silica Fume on the Mechanical and Fracture Properties of Ultra-High-Performance Geopolymer Concrete. Constr. Build. Mater. 2021, 283, 122753. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, K.; Wang, J.; Guo, J.; Ling, Y. Macroscopic and Microscopic Analyses on Mechanical Performance of Metakaolin/Fly Ash Based Geopolymer Mortar. J. Clean. Prod. 2021, 294, 126193. [Google Scholar] [CrossRef]

- Nazarpour, H.; Jamali, M. Mechanical and Freezing Cycles Properties of Geopolymer Concrete with Recycled Aggregate. Struct. Concr. 2020, 21, 1004–1012. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, C.; Zhang, Z.; Li, N.; Shi, D. Mechanical and Fracture Properties of Ultra-High Performance Geopolymer Concrete: Effects of Steel Fiber and Silica Fume. Cem. Concr. Compos. 2020, 112, 103665. [Google Scholar] [CrossRef]

- Bakharev, T. Thermal Behaviour of Geopolymers Prepared Using Class F Fly Ash and Elevated Temperature Curing. Cem. Concr. Res. 2006, 36, 1134–1147. [Google Scholar] [CrossRef]

- Mwiti, M.J.; Karanja, T.J.; Muthengia, W.J. Thermal Resistivity of Chemically Activated Calcined Clays-Based Cements. In RILEM Bookseries; Springer: Dordrecht, The Netherlands, 2018; Volume 16, pp. 327–333. ISBN 9789402412062. [Google Scholar]

- Imbabi, M.S.; Carrigan, C.; McKenna, S. Trends and Developments in Green Cement and Concrete Technology. Int. J. Sustain. Built Environ. 2012, 1, 194–216. [Google Scholar] [CrossRef] [Green Version]

- Smirnova, O.M.; Potyomkin, D.A. Influence of Ground Granulated Blast Furnace Slag Properties on the Superplasticizers Effect. Int. J. Civ. Eng. Technol. 2018, 9, 874–880. [Google Scholar]

- Smirnova, O.M.; Menéndez Pidal de Navascués, I.; Mikhailevskii, V.R.; Kolosov, O.I.; Skolota, N.S. Sound-Absorbing Composites with Rubber Crumb from Used Tires. Appl. Sci. 2021, 11, 7347. [Google Scholar] [CrossRef]

- Rondi, L.; Bregoli, G.; Sorlini, S.; Cominoli, L.; Collivignarelli, C.; Plizzari, G. Concrete with EAF Steel Slag as Aggregate: A Comprehensive Technical and Environmental Characterisation. Compos. Part B Eng. 2016, 90, 195–202. [Google Scholar] [CrossRef]

- De Domenico, D.; Faleschini, F.; Pellegrino, C.; Ricciardi, G. Structural Behavior of RC Beams Containing EAF Slag as Recycled Aggregate: Numerical versus Experimental Results. Constr. Build. Mater. 2018, 171, 321–337. [Google Scholar] [CrossRef]

- Olivier, J.G.J.; Schure, K.M.; Peters, J. Trends in Global CO2 and Total Greenhouse Gas Emissions. PBL Neth. Environ. Assess. Agency 2017, 5, 1–11. [Google Scholar]

- Hogan, F.J. Ground Granulated Blast Furnace Slag As A Cementitious Material. In Acimanual of Concrete Practice, Part 1; American Concrete Institute: Farmington Hills, MI, USA, 1982; pp. 299–316. [Google Scholar]

- Thomas, M.D.A.; Hooton, R.D.; Scott, A.; Zibara, H. The Effect of Supplementary Cementitious Materials on Chloride Binding in Hardened Cement Paste. Cem. Concr. Res. 2012, 42, 1–7. [Google Scholar] [CrossRef]

- Şanal, İ. Fresh-state Performance Design of Green Concrete Mixes with Reduced Carbon Dioxide Emissions. Greenh. Gases Sci. Technol. 2018, 8, 1134–1145. [Google Scholar] [CrossRef]

- Flower, D.J.M.; Sanjayan, J.G. Green House Gas Emissions Due to Concrete Manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Piatak, N.M.; Parsons, M.B.; Seal, R.R., II. Characteristics and Environmental Aspects of Slag: A Review. Appl. Geochem. 2015, 57, 236–266. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sivapullaiah, P. V Ground Granulated Blast Furnace Slag Amended Fly Ash as an Expansive Soil Stabilizer. Soils Found. 2016, 56, 205–212. [Google Scholar] [CrossRef]

- Aydın, S.; Baradan, B. Effect of Activator Type and Content on Properties of Alkali-Activated Slag Mortars. Compos. Part B Eng. 2014, 57, 166–172. [Google Scholar] [CrossRef]

- Flynn, R.T.; Grisinger, T.J.; Mather, B.; Hooton, R.D.; Dewey, G.R.; Luther, M.D.; Thomas, M.A.D. Slag Cement in Concrete and Mortar; American Concrete Institute: Farmington Hills, MI, USA, 2003. [Google Scholar]

- Wang, X.-Y.; Lee, H.-S. Modeling the Hydration of Concrete Incorporating Fly Ash or Slag. Cem. Concr. Res. 2010, 40, 984–996. [Google Scholar] [CrossRef]

- Dinakar, P.; Sethy, K.P.; Sahoo, U.C. Design of Self-Compacting Concrete with Ground Granulated Blast Furnace Slag. Mater. Des. 2013, 43, 161–169. [Google Scholar] [CrossRef]

- Dhir, R.K.; Dyer, T.D.; Tang, M.C. Alkali-Silica Reaction in Concrete Containing Glass. Mater. Struct. 2009, 42, 1451–1462. [Google Scholar] [CrossRef]

- Abbass, M.; Singh, D.; Singh, G. Properties of Hybrid Geopolymer Concrete Prepared Using Rice Husk Ash, Fly Ash and GGBS with Coconut Fiber. Mater. Today Proc. 2021, 45, 4964–4970. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Use of Waste Glass as Sand in Mortar: Part II—Alkali–Silica Reaction and Mitigation Methods. Cem. Concr. Compos. 2013, 35, 118–126. [Google Scholar] [CrossRef]

- Sumitha, Y.; Abraham, R. Experimental Study on Bentonite Clay Powder with Silica Fume and GGBS as Partial Replacement of Cement in M40 Grade Concrete. Int. J. Eng. Res. Technol. 2016, 5, 339–343. [Google Scholar] [CrossRef]

- Naik, T.R. Sustainability of Concrete Construction. Pract. Period. Struct. Des. Constr. 2008, 13, 98–103. [Google Scholar] [CrossRef] [Green Version]

- Sumajouw, D.M.J.; Hardjito, D.; Wallah, S.E.; Rangan, B.V. Fly Ash-Based Geopolymer Concrete: Study of Slender Reinforced Columns. J. Mater. Sci. 2007, 42, 3124–3130. [Google Scholar] [CrossRef]

- Zhang, T.-S.; Yu, Q.-J.; Wei, J.-X.; Zhang, P.-P.; Li, S. Effect of Size Fraction of Ground Granulated Blast Furnace Slag on Its Strength Contribution and Hydraulic Activity. Adv. Sci. Lett. 2011, 4, 1286–1291. [Google Scholar] [CrossRef]

- Sharmila, P.; Dhinakaran, G. Compressive Strength, Porosity and Sorptivity of Ultra Fine Slag Based High Strength Concrete. Constr. Build. Mater. 2016, 120, 48–53. [Google Scholar] [CrossRef]

- Teng, S.; Lim, T.Y.D.; Divsholi, B.S. Durability and Mechanical Properties of High Strength Concrete Incorporating Ultra Fine Ground Granulated Blast-Furnace Slag. Constr. Build. Mater. 2013, 40, 875–881. [Google Scholar] [CrossRef]

- Vignesh, P.; Vivek, K. An Experimental Investigation on Strength Parameters of Flyash Based Geopolymer Concrete with GGBS. Int. Res. J. Eng. Technol. 2015, 2, 135–142. [Google Scholar]

- Majhi, R.K.; Nayak, A.N.; Mukharjee, B.B. Development of Sustainable Concrete Using Recycled Coarse Aggregate and Ground Granulated Blast Furnace Slag. Constr. Build. Mater. 2018, 159, 417–430. [Google Scholar] [CrossRef]

- Patra, R.K.; Mukharjee, B.B. Influence of Incorporation of Granulated Blast Furnace Slag as Replacement of Fine Aggregate on Properties of Concrete. J. Clean. Prod. 2017, 165, 468–476. [Google Scholar] [CrossRef]

- Siddique, R.; Bennacer, R. Use of Iron and Steel Industry By-Product (GGBS) in Cement Paste and Mortar. Resour. Conserv. Recycl. 2012, 69, 29–34. [Google Scholar] [CrossRef]

- Ramakrishnan, K.; Pugazhmani, G.; Sripragadeesh, R.; Muthu, D.; Venkatasubramanian, C. Experimental Study on the Mechanical and Durability Properties of Concrete with Waste Glass Powder and Ground Granulated Blast Furnace Slag as Supplementary Cementitious Materials. Constr. Build. Mater. 2017, 156, 739–749. [Google Scholar] [CrossRef]

- Rathod, S.; Hombal, G. A Comparative Study on Strength and Durability Aspects of Fly Ash-GGBS Based Geopolymer Concrete over Conventional Concrete. Int. J. Eng. Res. Technol. 2017, 6, 1062–1067. [Google Scholar]

- MohanKumar, R.; Raju, R.S.; Ramesh, V. Strength and Durability Studies on Concrete with Partial Replacement of Cement by GGBS. J. Impact Factor 2017, 2, 23. [Google Scholar]

- Bilir, T. Effects of Non-Ground Slag and Bottom Ash as Fine Aggregate on Concrete Permeability Properties. Constr. Build. Mater. 2012, 26, 730–734. [Google Scholar] [CrossRef]

- Pal, S.C.; Mukherjee, A.; Pathak, S.R. Investigation of Hydraulic Activity of Ground Granulated Blast Furnace Slag in Concrete. Cem. Concr. Res. 2003, 33, 1481–1486. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Boğa, A.R. Effect of Ground Granulate Blast-Furnace Slag on Corrosion Performance of Steel Embedded in Concrete. Mater. Des. 2010, 31, 3358–3365. [Google Scholar] [CrossRef]

- Yazıcı, H.; Yiğiter, H.; Karabulut, A.Ş.; Baradan, B. Utilization of Fly Ash and Ground Granulated Blast Furnace Slag as an Alternative Silica Source in Reactive Powder Concrete. Fuel 2008, 87, 2401–2407. [Google Scholar] [CrossRef]

- Nkinamubanzi, P.C.; Baalbaki, M.; Bickley, J.; Aitcin, P.C. The Use of Slag for Making High Performance Concrete. In Proceedings of the 6th NCB International Seminar on Cement and Bulding Materials, New Delhi, India, 24–27 November 1998. [Google Scholar]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary Cementitious Materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Regourd, M. Characterization and Thermal Activation of Slag Cements. In Proceedings of the 7th International Congress on the Chemistry of Cement; Cement Research Institute: Paris, France, 1980; Volume 3, pp. 105–111. [Google Scholar]

- Sajedi, F.; Razak, H.A. Effects of Thermal and Mechanical Activation Methods on Compressive Strength of Ordinary Portland Cement–Slag Mortar. Mater. Des. 2011, 32, 984–995. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.-H.; Islam, J.; Peethamparan, S. Use of Nano-Silica to Increase Early Strength and Reduce Setting Time of Concretes with High Volumes of Slag. Cem. Concr. Compos. 2012, 34, 650–662. [Google Scholar] [CrossRef]

- Mostafa, N.Y.; El-Hemaly, S.A.S.; Al-Wakeel, E.I.; El-Korashy, S.A.; Brown, P.W. Hydraulic Activity of Water-Cooled Slag and Air-Cooled Slag at Different Temperatures. Cem. Concr. Res. 2001, 31, 475–484. [Google Scholar] [CrossRef]

- Sajedi, F.; Razak, H.A. The Effect of Chemical Activators on Early Strength of Ordinary Portland Cement-Slag Mortars. Constr. Build. Mater. 2010, 24, 1944–1951. [Google Scholar] [CrossRef] [Green Version]

- Shabab, M.E.; Shahzada, K.; Gencturk, B.; Ashraf, M.; Fahad, M. Synergistic Effect of Fly Ash and Bentonite as Partial Replacement of Cement in Mass Concrete. KSCE J. Civ. Eng. 2016, 20, 1987–1995. [Google Scholar] [CrossRef]

- Batog, M.; Giergiczny, Z. Influence of Mass Concrete Constituents on Its Properties. Constr. Build. Mater. 2017, 146, 221–230. [Google Scholar] [CrossRef]

- Mengxiao, S.; Qiang, W.; Zhikai, Z. Comparison of the Properties between High-Volume Fly Ash Concrete and High-Volume Steel Slag Concrete under Temperature Matching Curing Condition. Constr. Build. Mater. 2015, 98, 649–655. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P. Hydration Properties of Basic Oxygen Furnace Steel Slag. Constr. Build. Mater. 2010, 24, 1134–1140. [Google Scholar] [CrossRef]

- Zhang, T.; Yu, Q.; Wei, J.; Li, J. Investigation on Mechanical Properties, Durability and Micro-Structural Development of Steel Slag Blended Cements. J. Therm. Anal. Calorim. 2012, 110, 633–639. [Google Scholar] [CrossRef]

- Hu, J. Comparison between the Effects of Superfine Steel Slag and Superfine Phosphorus Slag on the Long-Term Performances and Durability of Concrete. J. Therm. Anal. Calorim. 2017, 128, 1251–1263. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, D.; Yan, P. Design and Experimental Study of a Ternary Blended Cement Containing High Volume Steel Slag and Blast-Furnace Slag Based on Fuller Distribution Model. Constr. Build. Mater. 2017, 140, 248–256. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P.; Mi, G. Effect of Blended Steel Slag–GBFS Mineral Admixture on Hydration and Strength of Cement. Constr. Build. Mater. 2012, 35, 8–14. [Google Scholar] [CrossRef]

- Ballim, Y.; Graham, P.C. The Effects of Supplementary Cementing Materials in Modifying the Heat of Hydration of Concrete. Mater. Struct. 2009, 42, 803–811. [Google Scholar] [CrossRef]

- Wu, X.; Roy, D.M.; Langton, C.A. Early Stage Hydration of Slag-Cement. Cem. Concr. Res. 1983, 13, 277–286. [Google Scholar] [CrossRef]

- Ahmad, J.; Martínez-García, R.; Szelag, M.; de-Prado-Gil, J.; Marzouki, R.; Alqurashi, M.; Hussein, E.E. Effects of Steel Fibers (SF) and Ground Granulated Blast Furnace Slag (GGBS) on Recycled Aggregate Concrete. Materials 2021, 14, 7497. [Google Scholar] [CrossRef]

- Lenka, B.P.; Majhi, R.K.; Singh, S.; Nayak, A.N. Eco-Friendly and Cost-Effective Concrete Utilizing High-Volume Blast Furnace Slag and Demolition Waste with Lime. Eur. J. Environ. Civ. Eng. 2021, 1–23. [Google Scholar] [CrossRef]

- Meusel, J.W.; Rose, J.H. Production of Granulated Blast Furnace Slag at Sparrows Point, and the Workability and Strength Potential of Concrete Incorporating the Slag. Spec. Publ. 1983, 79, 867–890. [Google Scholar]

- Wan, H.; Shui, Z.; Lin, Z. Analysis of Geometric Characteristics of GGBS Particles and Their Influences on Cement Properties. Cem. Concr. Res. 2004, 34, 133–137. [Google Scholar] [CrossRef]

- Prakash, S.; Kumar, S.; Biswas, R.; Rai, B. Influence of Silica Fume and Ground Granulated Blast Furnace Slag on the Engineering Properties of Ultra-High-Performance Concrete. Innov. Infrastruct. Solut. 2022, 7, 117. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.İ. Utilization and Efficiency of Ground Granulated Blast Furnace Slag on Concrete Properties—A Review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Majhi, R.K.; Nayak, A.N.; Mukharjee, B.B. Characterization of Lime Activated Recycled Aggregate Concrete with High-Volume Ground Granulated Blast Furnace Slag. Constr. Build. Mater. 2020, 259, 119882. [Google Scholar] [CrossRef]

- Suda, V.B.R.; Rao, P.S. Experimental Investigation on Optimum Usage of Micro Silica and GGBS for the Strength Characteristics of Concrete. Mater. Today Proc. 2020, 27, 805–811. [Google Scholar] [CrossRef]

- Vediyappan, S.; Chinnaraj, P.K.; Hanumantraya, B.B.; Subramanian, S.K. An Experimental Investigation on Geopolymer Concrete Utilising Micronized Biomass Silica and GGBS. KSCE J. Civ. Eng. 2021, 25, 2134–2142. [Google Scholar] [CrossRef]

- Soni, Y.; Gupta, N. Experimental Investigation on Workability of Concrete with Partial Replacement of Cement by Ground Granulated Blast Furnace and Sand by Quarry Dust. Available online: https://www.academia.edu/29390523/Experimental_Investigation_on_Workability_of_Concrete_with_Partial_Replacement_of_Cement_by_Ground_Granulated_Blast_Furnace_and_Sand_by_Quarry_Dust (accessed on 16 June 2022).

- Nath, P.; Sarker, P.K. Effect of GGBFS on Setting, Workability and Early Strength Properties of Fly Ash Geopolymer Concrete Cured in Ambient Condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef] [Green Version]

- Roy, D.M. Hydration, Structure, and Properties of Blast Furnace Slag Cements, Mortars, and Concrete. J. Proc. 1982, 79, 444–457. [Google Scholar]

- Valcuende, M.; Benito, F.; Parra, C.; Miñano, I. Shrinkage of Self-Compacting Concrete Made with Blast Furnace Slag as Fine Aggregate. Constr. Build. Mater. 2015, 76, 1–9. [Google Scholar] [CrossRef]

- Aghaeipour, A.; Madhkhan, M. Effect of Ground Granulated Blast Furnace Slag (GGBFS) on RCCP Durability. Constr. Build. Mater. 2017, 141, 533–541. [Google Scholar] [CrossRef]

- Raafidiani, R.; Sumargo, S.; Permana, R. The Influence of Ground Granulated Blast Furnace Slag (GGBFS) as Portland Composite Cement (PCC) Substitution in Improving Compressive Strength of Concrete. In Proceedings of the 5th Annual Applied Science and Engineering Conference (AASEC 2020), Bandung, Indonesia, 20–21 April 2020; Volume 1098, p. 22035. [Google Scholar]

- Ramani, P.V.; Chinnaraj, P.K. Geopolymer Concrete with Ground Granulated Blast Furnace Slag and Black Rice Husk Ash. Građevinar 2015, 67, 741–748. [Google Scholar]

- Makhdoom, O.; Makhdoom, I. Effect of Components Fineness of Ground Granulated Blast Furnace Slag (GGBFS) on Its Strength Efficiency in Roller Compact Concrete Mixes. Asian J. Nat. Appl. Sci. 2013, 2, 82–89. [Google Scholar]

- Nazari, A.; Riahi, S. Effects of Al2O3 Nanoparticles on Properties of Self Compacting Concrete with Ground Granulated Blast Furnace Slag (GGBFS) as Binder. Sci. China Technol. Sci. 2011, 9, 2327–2338. [Google Scholar] [CrossRef]

- Ahmad, J.; Martínez-García, R.; De-Prado-Gil, J.; Irshad, K.; El-Shorbagy, M.A.; Fediuk, R.; Vatin, N.I. Concrete with Partial Substitution of Waste Glass and Recycled Concrete Aggregate. Materials 2022, 15, 430. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; De-Prado-Gil, J.; Qaidi, S.M.A.; Brahmia, A. Effects of Waste Glass and Waste Marble on Mechanical and Durability Performance of Concrete. Sci. Rep. 2021, 11, 21525. [Google Scholar] [CrossRef]

- Ahmad, J.; Tufail, R.F.; Aslam, F.; Mosavi, A.; Alyousef, R.; Faisal Javed, M.; Zaid, O.; Khan Niazi, M.S. A Step towards Sustainable Self-Compacting Concrete by Using Partial Substitution of Wheat Straw Ash and Bentonite Clay Instead of Cement. Sustainability 2021, 13, 824. [Google Scholar] [CrossRef]

- Yuksel, I.; Genç, A. Properties of Concrete Containing Nonground Ash and Slag as Fine Aggregate. ACI Mater. J. 2007, 104, 397. [Google Scholar]

- Basar, H.M.; Aksoy, N.D. The Effect of Waste Foundry Sand (WFS) as Partial Replacement of Sand on the Mechanical, Leaching and Micro-Structural Characteristics of Ready-Mixed Concrete. Constr. Build. Mater. 2012, 35, 508–515. [Google Scholar] [CrossRef]

- ACI 318-11; Building Code Requirements for Structural Concrete. American Concrete Institute (ACI): Farmington Hills, MI, USA, 2011.

- EN 1992-1-1:2004; 1-1. Eurocode 2: Design of Concrete Structures–Part 1-1: General Rules and Rules for Buildings. European Committee for Standardisation: Brussels, Belgium, 2004.

- Sato, R.; Sogo, S.; Kanazu, T.; Kishi, T.; Noguchi, T.; Mizobuchi, T.; Miyazawa, S. JCI Guidelines for Control of Cracking of Mass Concrete 2008. In Proceedings of the Third International Conference on Sustainable Construction Materials and Technologies, Kyoto, Japan, 19–21 August 2013. [Google Scholar]

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; El Ouni, M.H.; Khedher, K.M. Performance of Sustainable Self-Compacting Fiber Reinforced Concrete with Substitution of Marble Waste (MW) and Coconut Fibers (CFs). Sci. Rep. 2021, 11, 23184. [Google Scholar] [CrossRef]

- Bheel, N.; Abbasi, S.A.; Awoyera, P.; Olalusi, O.B.; Sohu, S.; Rondon, C.; Echeverría, A.M. Fresh and Hardened Properties of Concrete Incorporating Binary Blend of Metakaolin and Ground Granulated Blast Furnace Slag as Supplementary Cementitious Material. Adv. Civ. Eng. 2020, 2020, 8851030. [Google Scholar] [CrossRef]

- Bassuoni, M.T.; Nehdi, M.L.; Greenough, T.R. Enhancing the Reliability of Evaluating Chloride Ingress in Concrete Using the ASTM C 1202 Rapid Chloride Penetrability Test; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- Thomas, M.D.A.; Bamforth, P.B. Modelling Chloride Diffusion in Concrete: Effect of Fly Ash and Slag. Cem. Concr. Res. 1999, 29, 487–495. [Google Scholar] [CrossRef]

- Xu, Y. The Influence of Sulphates on Chloride Binding and Pore Solution Chemistry. Cem. Concr. Res. 1997, 27, 1841–1850. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Pilvar, A.; Mahdikhani, M.; Moodi, F. Practical Evaluation of Relationship between Concrete Resistivity, Water Penetration, Rapid Chloride Penetration and Compressive Strength. Constr. Build. Mater. 2011, 25, 2472–2479. [Google Scholar] [CrossRef]

- Shi, X.; Xie, N.; Fortune, K.; Gong, J. Durability of Steel Reinforced Concrete in Chloride Environments: An Overview. Constr. Build. Mater. 2012, 30, 125–138. [Google Scholar] [CrossRef]

- Dharani, D.; iravida Selvan, V.A. Durability Studies on Concrete by Using Groundnut Shell Ash as Mineral Admixture. Int. J. Innov. Res. Sci. Technol. 2017, 3, 168–172. [Google Scholar]

- Ahmad, J.; Zaid, O.; Siddique, M.S.; Aslam, F.; Alabduljabbar, H.; Khedher, K.M. Mechanical and Durability Characteristics of Sustainable Coconut Fibers Reinforced Concrete with Incorporation of Marble Powder. Mater. Res. Express 2021, 8, 075505. [Google Scholar] [CrossRef]

| Chemical | Fly Ash | Silica Fume | Metakaolin | GGBS |

|---|---|---|---|---|

| SiO2 | 54.22 | 34.32 | 54 | 37.5 |

| Al2O3 | 31.18 | 15.57 | 43 | 6.4 |

| Fe2O3 | 2.63 | 0.58 | 1.2 | 0.51 |

| MgO | 0.47 | 6.89 | 0.4 | 8.6 |

| CaO | 1.24 | 37.52 | 0.4 | 34.6 |

| Na2O | 0.49 | 0.31 | 0.3 | 0.38 |

| K2O | 1.34 | 0.66 | 0.3 | - |

| Reference | [14] | [15] | [16] | [17] |

| Reference | [45] | [46] | [47] | [48] | [49] | [50] | [51] |

|---|---|---|---|---|---|---|---|

| Specific gravity | 2.54 | 2.82 | 2.56 | 2.9 | 2.85 | 2.75 | 2.85 |

| Absorption (%) | - | - | 1.2 | - | - | - | - |

| Fineness modulus (cm2/g) | 2.76 | 5000 | - | - | 4000 | - | - |

| Bulk density (kg/m3) | 1668 | - | 1394 | 1200 | - | 1165 | 1200 |

| Specific surface area, cm2/g | - | - | - | 4250–4700 | - | - | - |

| Unit weight (kg/m3) | - | - | - | 1555 | - | - | - |

| Authors | Topcu et al. [54] | Yazıcı et al. [55] | Majhi et al. [46] | Patra et al. [47] | Ramakrishnan et al. [49] |

|---|---|---|---|---|---|

| SiO2 | 39.41 | 39.66 | 34 | 35.6 | 91 |

| Al2O3 | 11.63 | 12.94 | 14 | 11.74 | - |

| Fe2O3 | 3.35 | 1.58 | 4 | 0.8 | - |

| MgO | 5.52 | 6.94 | 7 | 10.7 | 7.73 |

| CaO | 36.56 | 34.20 | 23 | 41.7 | - |

| Na2O | 0.32 | 0.20 | - | - | 0.12 |

| K2O | 1.21 | 1.44 | - | - | - |

| Author | (GGBS) Replacement Ratio | Slump (mm) |

|---|---|---|

| Erdogon et al. [78] | 0%, 15% and 30% | 260, 270 and 260 |

| Majhi et al. [46] | 0%, 25%, 50% and 100% | 70, 75, 85 and 95 |

| Majhi et al. [79] | GGBS (kg) 0 and 234 | 70 and 80 |

| Rakesh et al. [47] | 0%, 20%, 40% and 60% | 100, 80, 60 and 40 |

| Suda et al. [80] | 0 g, 97.2 g, 129.6 g and 162 g | 111, 119, 113 and 105 |

| Vediyappan et al. [81] | GGBS (kg/m3) 364.5, 324, 284, 243 and 0 | 147, 122, 146, 165 and 173 |

| Soni et al. [82] | 0%, 30%, 40% and 50% | 100, 85, 110 and 130 |

| Nath et al. [83] | GGBS (kg/m3) 0, 73, 146 and 219 | 250, 230, 235 and 205 |

| Author | (GGBS) Replacement Ratio | Compression Strength (MPa) |

|---|---|---|

| Erdogon et al. [78] | 0%, 15% and 30% | 35, 45 and 40 |

| Arash et al. [86] | 0%, 20%, 40% and 60% | 45, 45, 48 and 38 |

| Topçu et al. [54] | 0%, 25% and 50% | 28 days 35, 49 and 43 90 days 37, 53 and 44 |

| Ganesh et al. [1] | GGBS (kg/m3) 0, 192, 384, 576 and 768 | 115.67, 129.90, 117.98, 109.81 and 101.16 |

| Majhi et al. [46] | 0%, 25%, 50% and 100% | 40, 32, 35 and 15 |

| Majhi et al. [79] | GGBS (kg) 0 and 234 | 35 and 30 |

| Rakesh et al. [47] | 0%, 20%, 40% and 60% | 36.42, 39.1, 41.0 and 43.6 |

| Suda et al. [80] | 0 g, 97.2 g,129.6 g and 162 g | 36.50, 40.32, 42.95 and 39.30 |

| Siddique et al. [48] | 0% 20% 40% 60% 80% | 7 days 43.4, 35.6, 42.5, 35.2 and 35 28 days 54.3, 55.4, 63.6, 58.4 and 56 |

| Ramakrishnan et al. [49] | (C + GP + GGBS)% 50 + 40 + 10, 50 + 30 + 20, 50 + 20 + 30, 50 + 10 + 40 and 100 + 0 + 0 | 20.45, 18.16, 26.14, 31.26 and 29.05 |

| Raafidiani et al. [87] | 0%, 40%, 50% and 60% | 14 days 26.06, 22.99, 25.25 and 22.40 28 days 26.50, 23.03, 26.65 and 22.02 |

| Ramani et al. [88] | GGBS (kg/m3) 394, 355, 315 and 276 | 7 days 66.5, 67.6, 46.32 and 20.48 28 days 69.28, 70.72, 51.46 and 24.52 |

| Vignesh et al. [45] | FLYASH + GGBS 100 + 0, 90 + 10, 80 + 20, 70 + 30, 60 + 40 and 0 + 0 | 16.30, 21.11, 34.32, 42.48, 45.55 and 36.84 |

| Vediyappan et al. [81] | GGBS (kg/m3) 364.5, 324, 284, 243 and 0 | 45.51, 54.64, 62.39, 58.78 and 58.14 |

| Makhdoom et al. [89] | 0%, 25%, 50% and 75% | 10.73, 5.88, 3.96 and 3.4 |

| Nazari et al. [90] | 0%, 15%, 30%, 45% and 60% | 31.5, 35.4, 38.9, 43.7 and 40.6 |

| Nath et al. [83] | GGBS (kg/m3) 0, 73, 146 and 219 | 10, 25, 35 and 40 |

| Author | (GGBS) Replacement Ratio | Split Tensile Strength (MPa) |

|---|---|---|

| Topçu et al. [54] | 0%, 25% and 50% | 28 days 3.3, 3.5 and 3.3 90 days 3.7, 4.2 and 3.3 |

| Ganesh et al. [1] | GGBS (kg/m3) 0, 192, 384, 576 and 768 | 19.48, 20.37, 19.24, 17.71 and 14.96 |

| Majhi et al. [46] | 0%, 25%, 50% and 100% | 3.1, 3.2, 3 and 2.9 |

| Rakesh et al. [47] | 0%, 20%, 40% and 60% | 2.9, 3, 3.3 and 3.5 |

| Suda et al. [80] | 0 g, 97.2 g, 129.6 g and 162 g | 3.27, 3.52, 3.77 and 3.44 |

| Ramakrishnan et al. [49] | (C + GP + GGBS)% 50 + 40 + 10, 50 + 30 + 20, 50 + 20 + 30, 50 + 10 + 40 and 100 + 0 + 0 | 2.14, 1.58, 1.84, 2.31 and 2.03 |

| Ramaniet al. [88] | GGBS (kg/m3) 394, 355, 315 and 276 | 7 days 6.43, 6.69, 3.94 and 0.89 28 days 6.74, 6.92, 4.26 and 1.12 |

| Vignesh et al. [45] | FLYASH + GGBS 100 + 0, 90 + 10, 80 + 20, 70 + 30, 60 + 40 and 0 + 0 | 1.92, 3.15, 3.91, 4.37, 5.94 and 4.20 |

| Vediyappan et al. [81] | GGBS (kg/m3) 364.5, 324, 284, 243 and 0 | 3.055, 4.108, 4.621, 3.983 and 4.063 |

| Soni et al. [82] | 0%, 30%, 40% and 50% | 4.20, 4.33, 4.67 and 4.47 |

| Nazari et al. [90] | 0%, 15%, 30%, 45% and 60% | 1.6, 1.9, 1.9, 2.1 and 2.0 |

| Experimental CPS (MPa) | Experimental STS (MPa) | Equation (1) | ACI-318.11 [96] | Eurocode [97] | JSCE-07 [98] |

|---|---|---|---|---|---|

| 100 | 15 | 14.13 | 5.3 | 3 | 4.4 |

| 105 | 17 | 14.76 | 5.43 | 3.07 | 4.50 |

| 90 | 14 | 12.85 | 5.02 | 2.84 | 4.17 |

| 80 | 13 | 11.56 | 4.74 | 2.68 | 3.93 |

| 60 | 12 | 8.92 | 4.10 | 2.32 | 3.40 |

| 115 | 19 | 16.02 | 5.68 | 3.21 | 4.71 |

| 120 | 20 | 16.65 | 5.80 | 3.28 | 4.81 |

| 117 | 19 | 16.27 | 5.73 | 3.24 | 4.75 |

| 109 | 17 | 15.27 | 5.53 | 3.13 | 4.59 |

| 100 | 15 | 14.13 | 5.3 | 3 | 4.4 |

| 122 | 20 | 16.90 | 5.85 | 3.31 | 4.85 |

| 135 | 23 | 18.51 | 6.15 | 3.48 | 5.11 |

| 130 | 22 | 17.89 | 6.04 | 3.42 | 5.01 |

| 110 | 17 | 15.39 | 5.55 | 3.14 | 4.61 |

| 100 | 15 | 14.13 | 5.3 | 3 | 4.4 |

| 130 | 20 | 17.89 | 6.04 | 3.42 | 5.01 |

| 140 | 23 | 19.13 | 6.27 | 3.54 | 5.20 |

| 135 | 22.5 | 18.51 | 6.15 | 3.48 | 5.11 |

| 110 | 17 | 15.39 | 5.55 | 3.14 | 4.61 |

| 100 | 15 | 14.13 | 5.3 | 3 | 4.4 |

| Author | (GGBS) Replacement Ratio | Flexure Strength (MPa) |

|---|---|---|

| Erdogon et al. [78] | 0%, 15% and 30% | 4, 6 and 8 |

| Majhi et al. [46] | 0%, 25%, 50% and 100% | 5, 4.9, 4.8 and 4.8 |

| Rakesh et al. [47] | 0%, 20%, 40% and 60% | 4.2, 4.3, 4.5 and 4.6 |

| Suda et al. [80] | 0 g, 97.2 g, 129.6 g and 162 g | 4.74, 5.14, 5.56 and 5 |

| Ramakrishnan et al. [49] | (C + GP + GGBS)% 50 + 40 + 10, 50 + 30 + 20, 50 + 20 + 30, 50 + 10 + 40 and 100 + 0 + 0 | 21.07 - - 21.42 - |

| Ramani et al. [88] | GGBS (kg/m3) 394, 355, 315 and 276 | 7 days 5.75, 6.26, 3.57 and 1.05 28 days 6.06, 6.98, 4.12 and 1.27 |

| Vignesh et al. [45] | FLYASH + GGBS 100 + 0, 90 + 10, 80 + 20, 70 + 30, 60 + 40 and 0 + 0 | 2.40, 3.58, 4.16, 4.68, 5.97 and 4.45 |

| Vediyappan et al. [81] | GGBS (kg/m3) 364.5, 324, 284, 243 and 0 | 3.296, 3.913, 4.217, 4.103 and 4.109 |

| Nazari et al. [90] | 0%, 15%, 30%, 45% and 60% | 4.2, 4.6, 4.9, 5.4 and 5.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, J.; Kontoleon, K.J.; Majdi, A.; Naqash, M.T.; Deifalla, A.F.; Ben Kahla, N.; Isleem, H.F.; Qaidi, S.M.A. A Comprehensive Review on the Ground Granulated Blast Furnace Slag (GGBS) in Concrete Production. Sustainability 2022, 14, 8783. https://doi.org/10.3390/su14148783

Ahmad J, Kontoleon KJ, Majdi A, Naqash MT, Deifalla AF, Ben Kahla N, Isleem HF, Qaidi SMA. A Comprehensive Review on the Ground Granulated Blast Furnace Slag (GGBS) in Concrete Production. Sustainability. 2022; 14(14):8783. https://doi.org/10.3390/su14148783

Chicago/Turabian StyleAhmad, Jawad, Karolos J. Kontoleon, Ali Majdi, Muhammad Tayyab Naqash, Ahmed Farouk Deifalla, Nabil Ben Kahla, Haytham F. Isleem, and Shaker M. A. Qaidi. 2022. "A Comprehensive Review on the Ground Granulated Blast Furnace Slag (GGBS) in Concrete Production" Sustainability 14, no. 14: 8783. https://doi.org/10.3390/su14148783

APA StyleAhmad, J., Kontoleon, K. J., Majdi, A., Naqash, M. T., Deifalla, A. F., Ben Kahla, N., Isleem, H. F., & Qaidi, S. M. A. (2022). A Comprehensive Review on the Ground Granulated Blast Furnace Slag (GGBS) in Concrete Production. Sustainability, 14(14), 8783. https://doi.org/10.3390/su14148783