Behavior Investigation of Necking Pile with Caps Assisted with Transparent Soil Technology

Abstract

:1. Introduction

2. Experimental Work

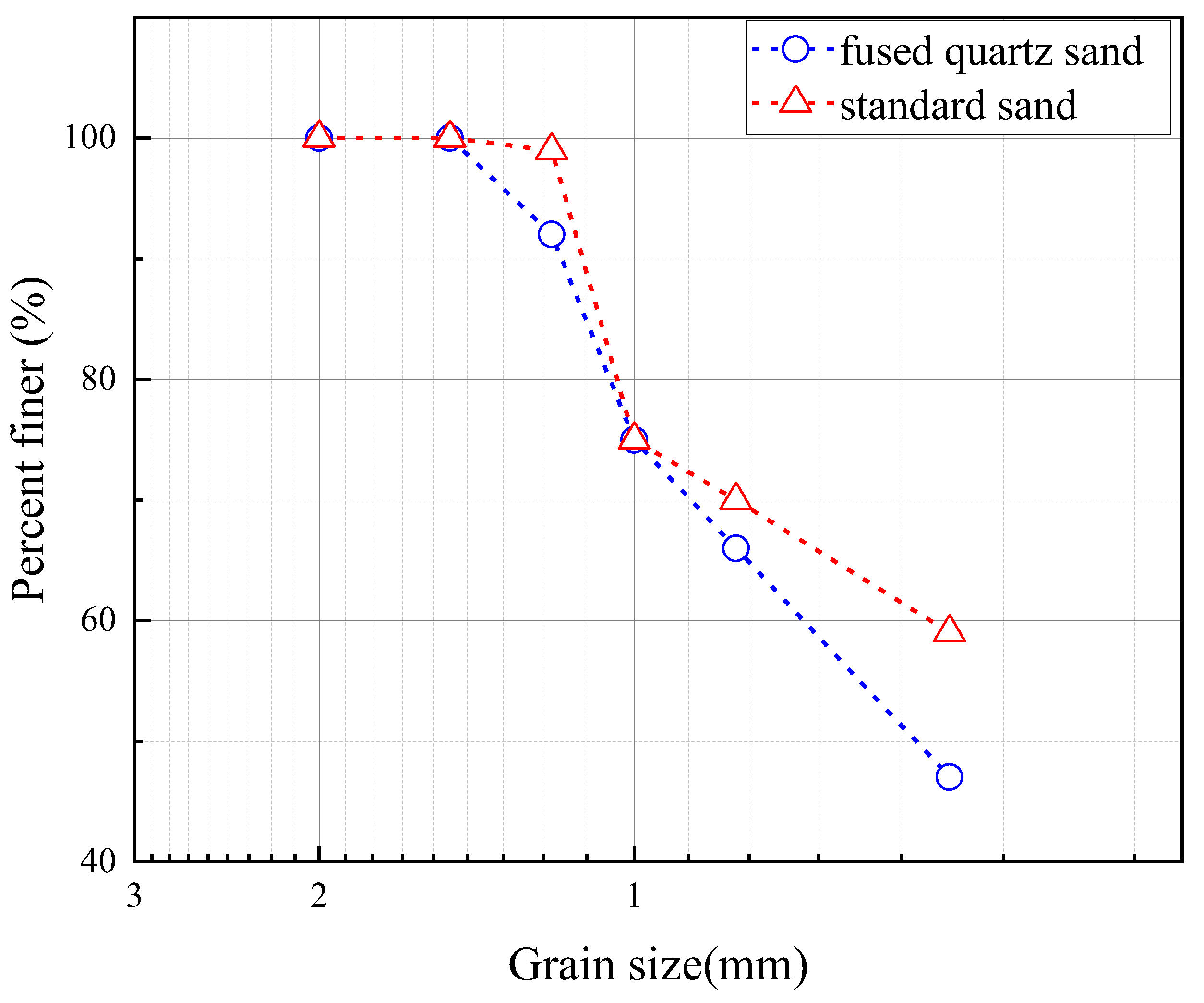

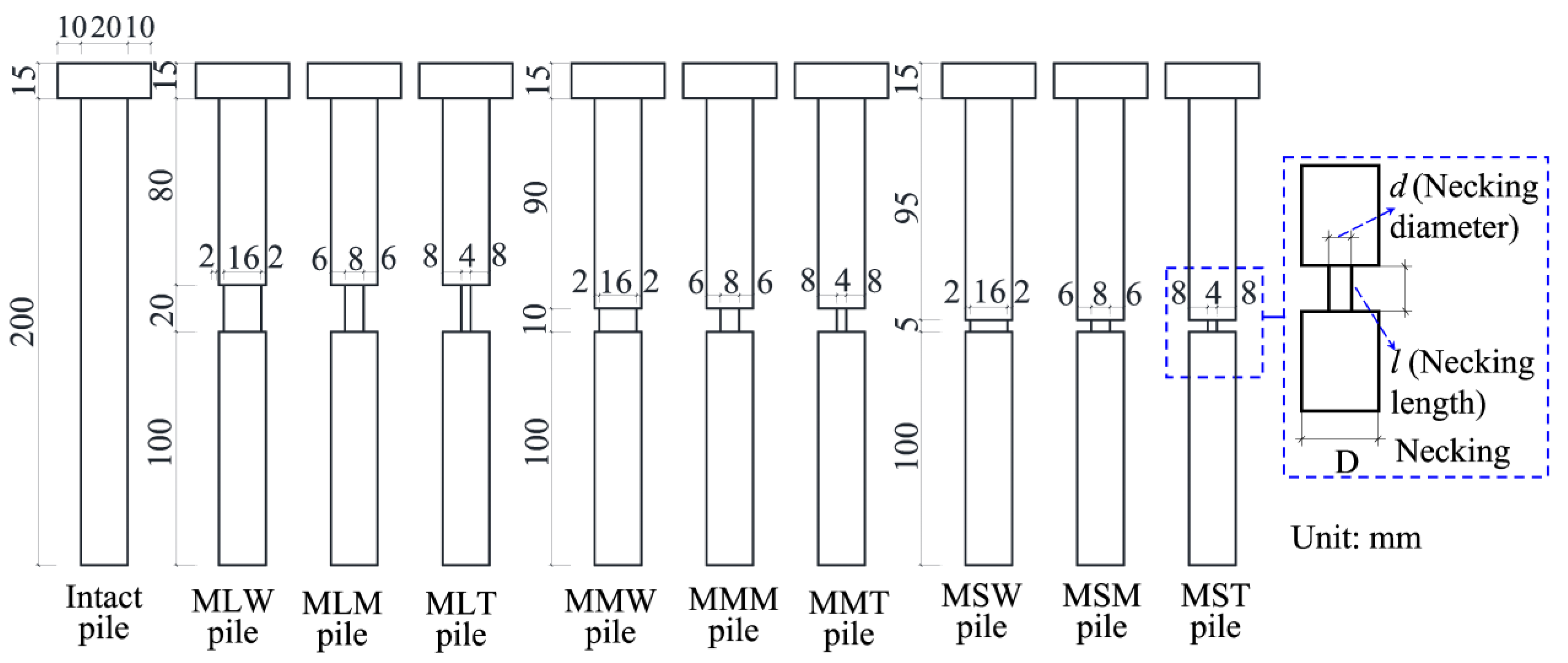

2.1. Materials and Model Pile

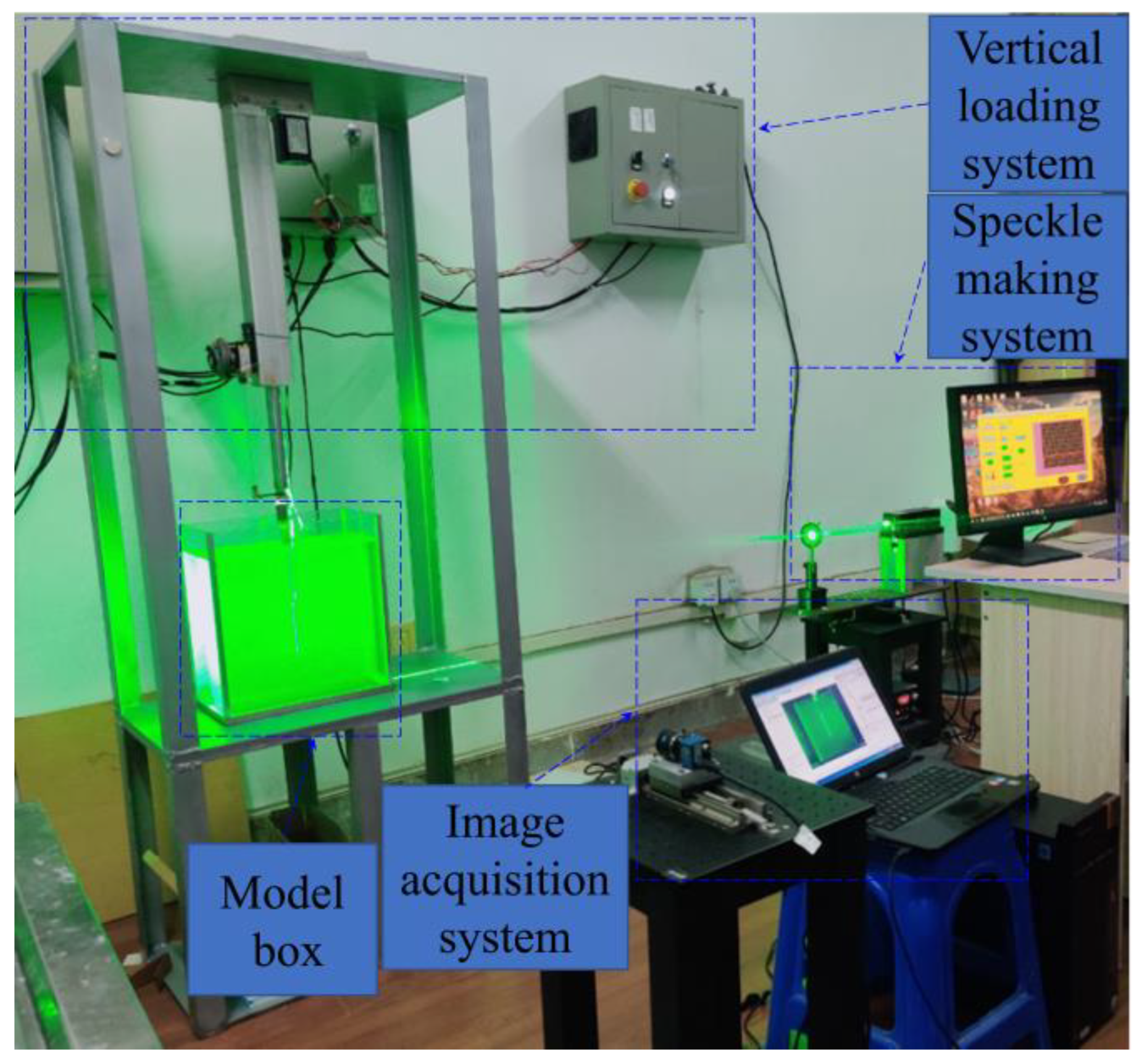

2.2. Experimental Set-Up

2.3. Experimental Process

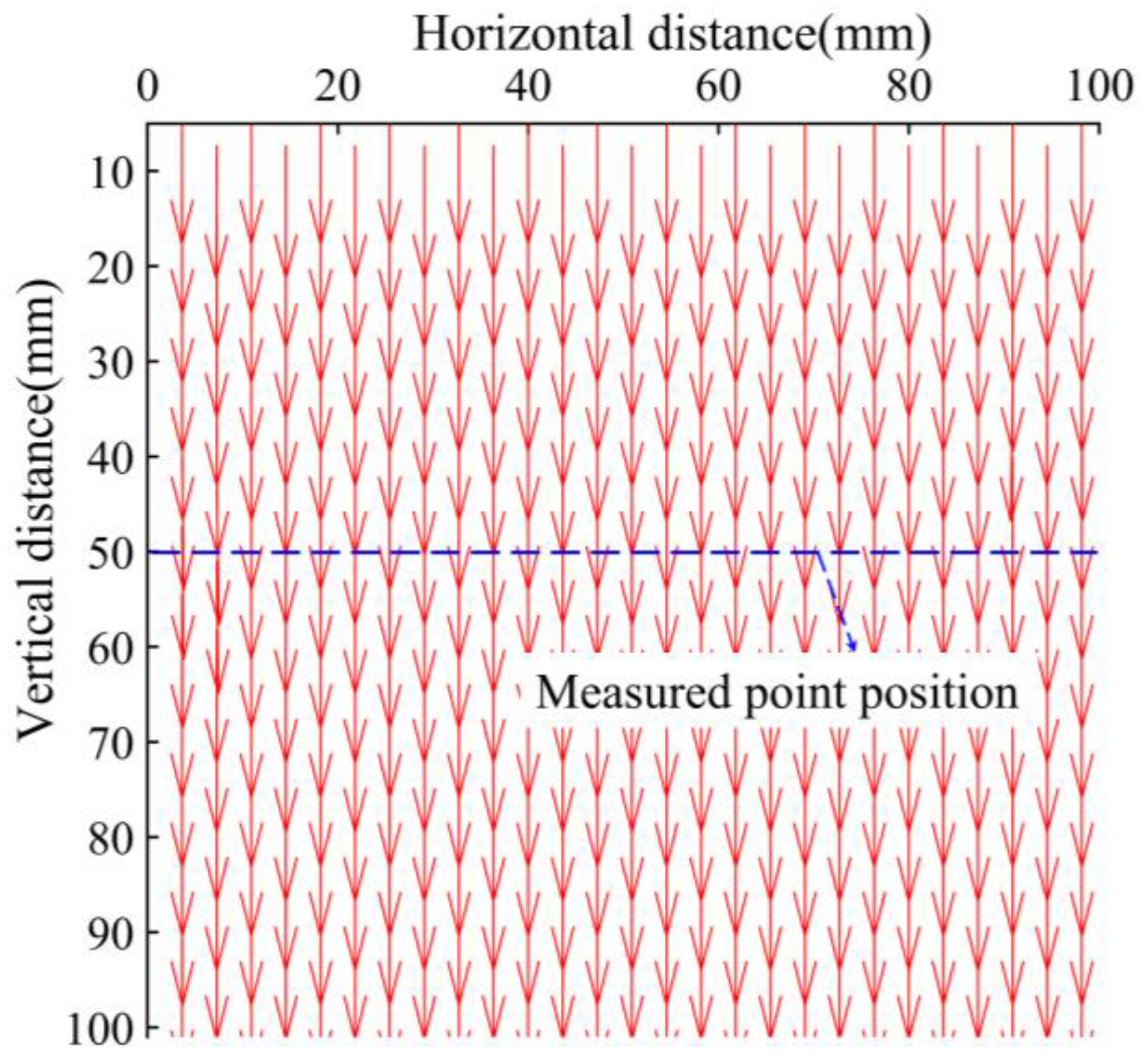

2.4. Accuracy Analysis of PIV

3. Results and Discussion

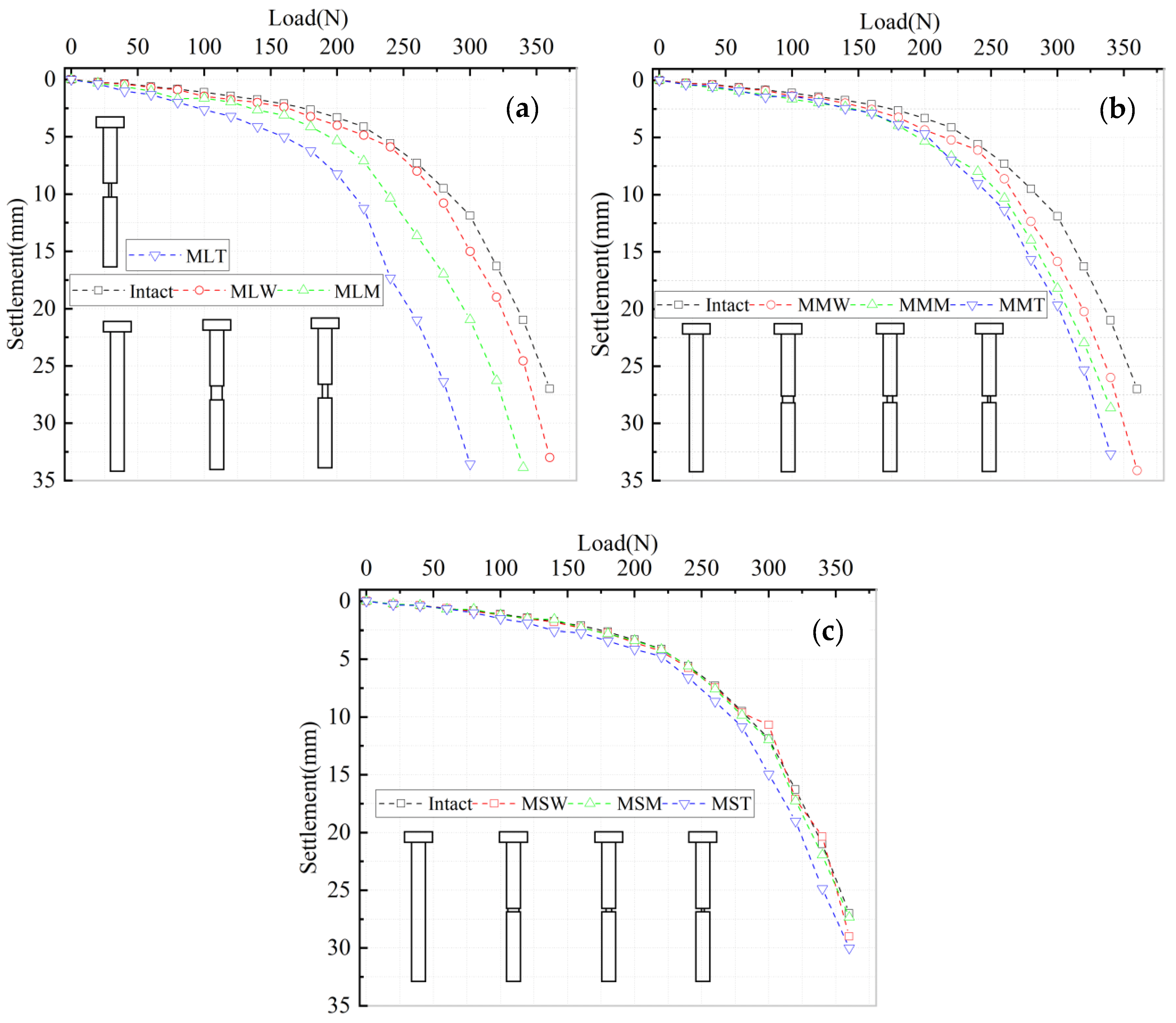

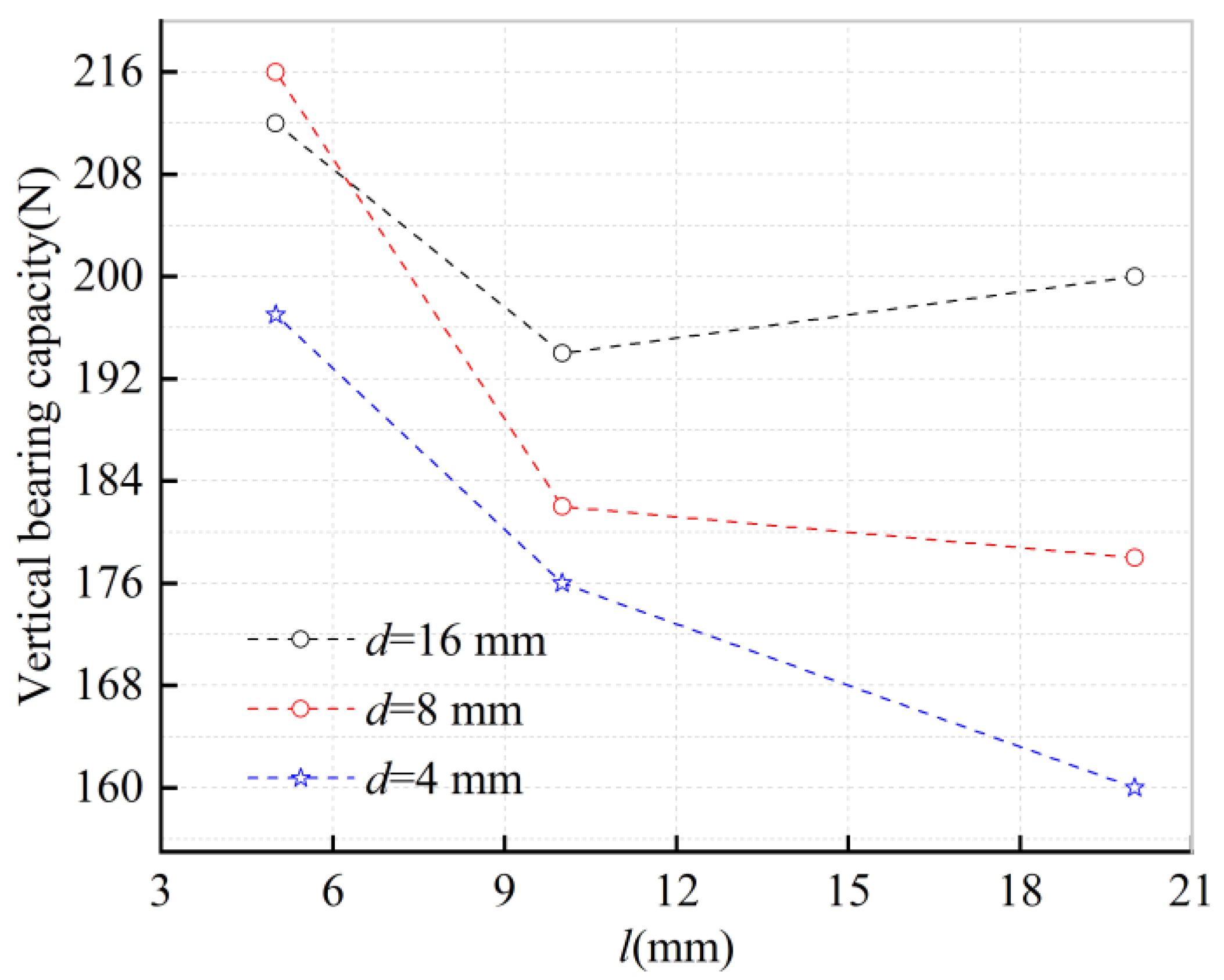

3.1. Vertical Bearing Capacity Analysis

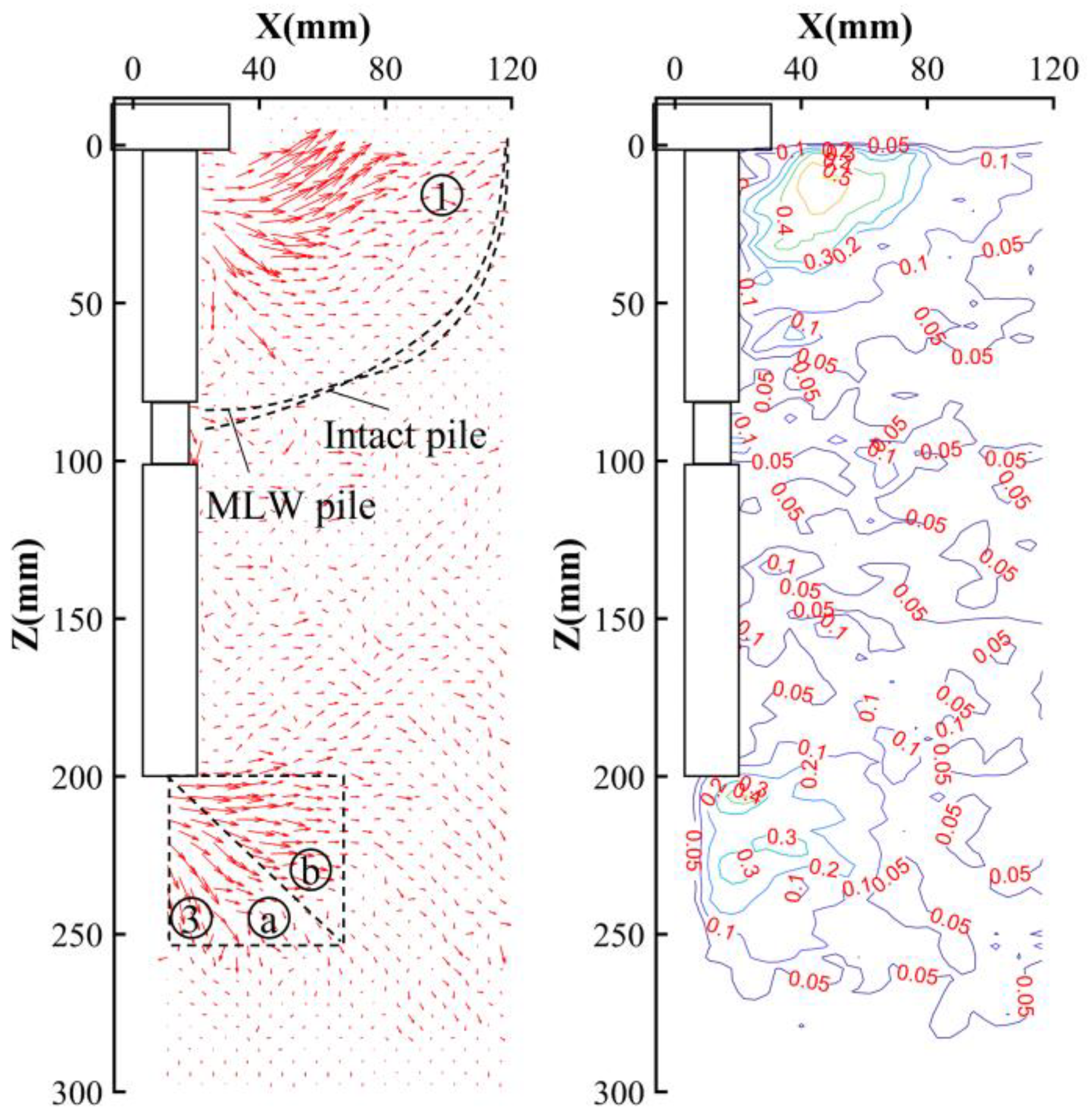

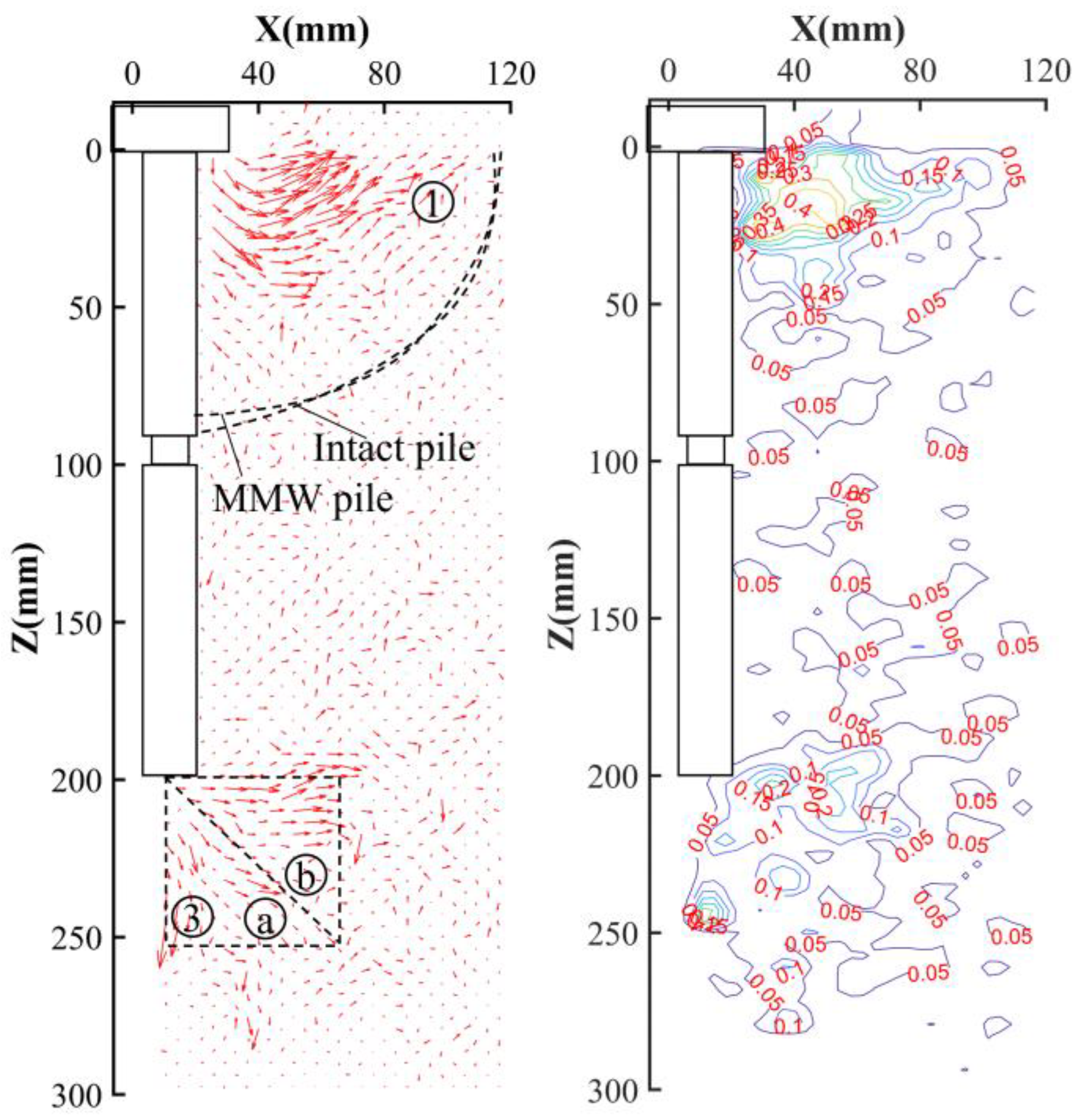

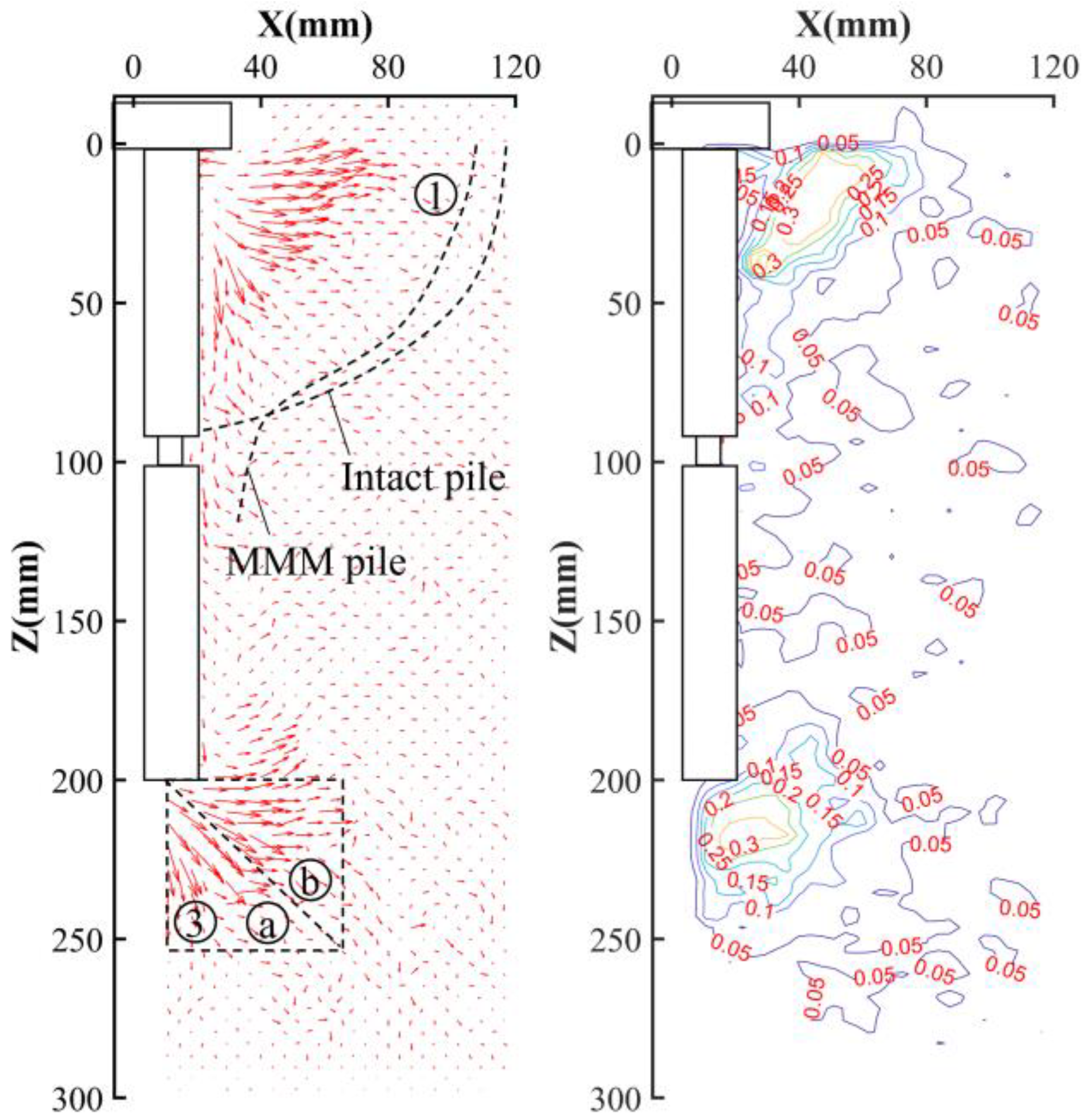

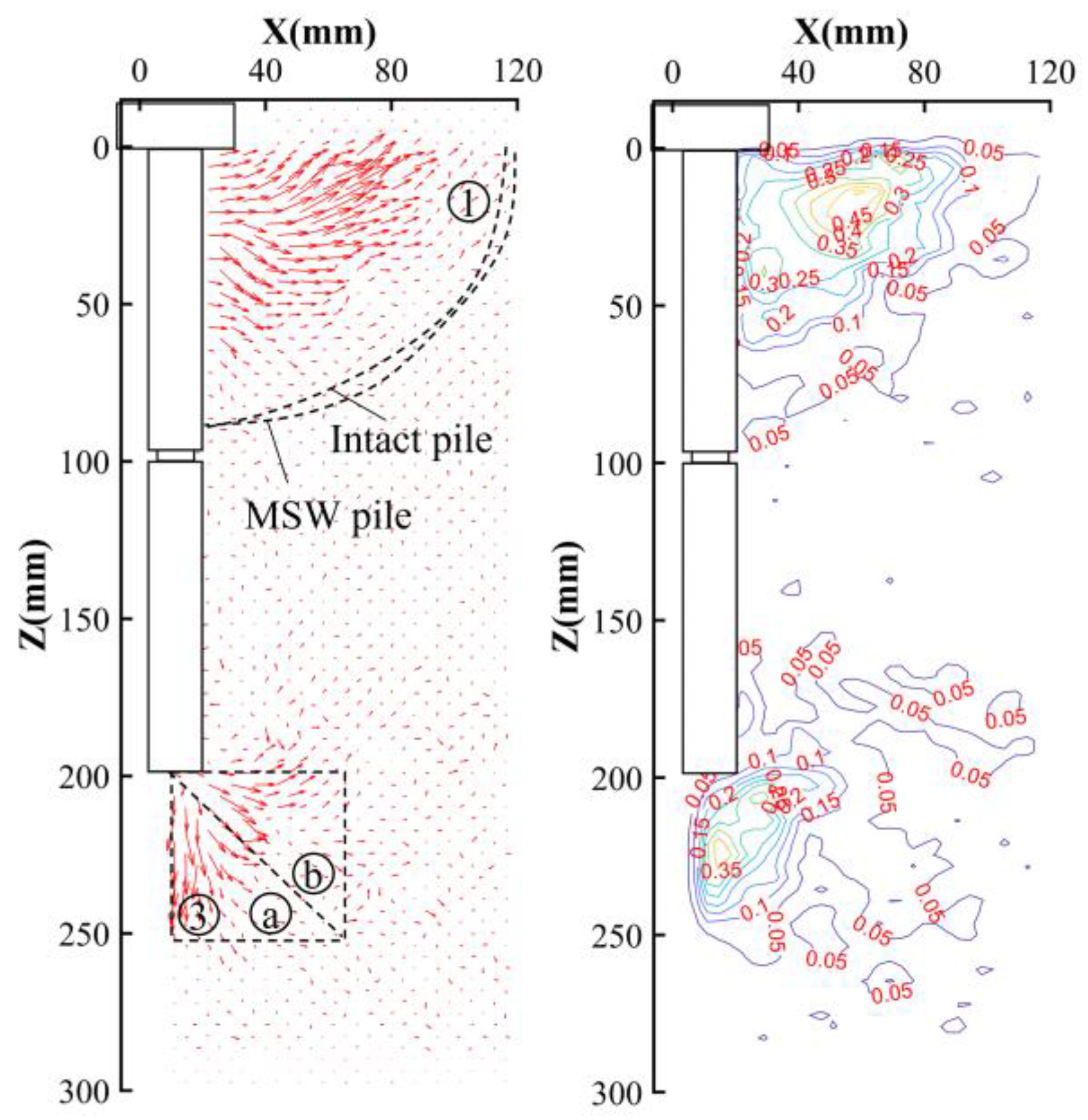

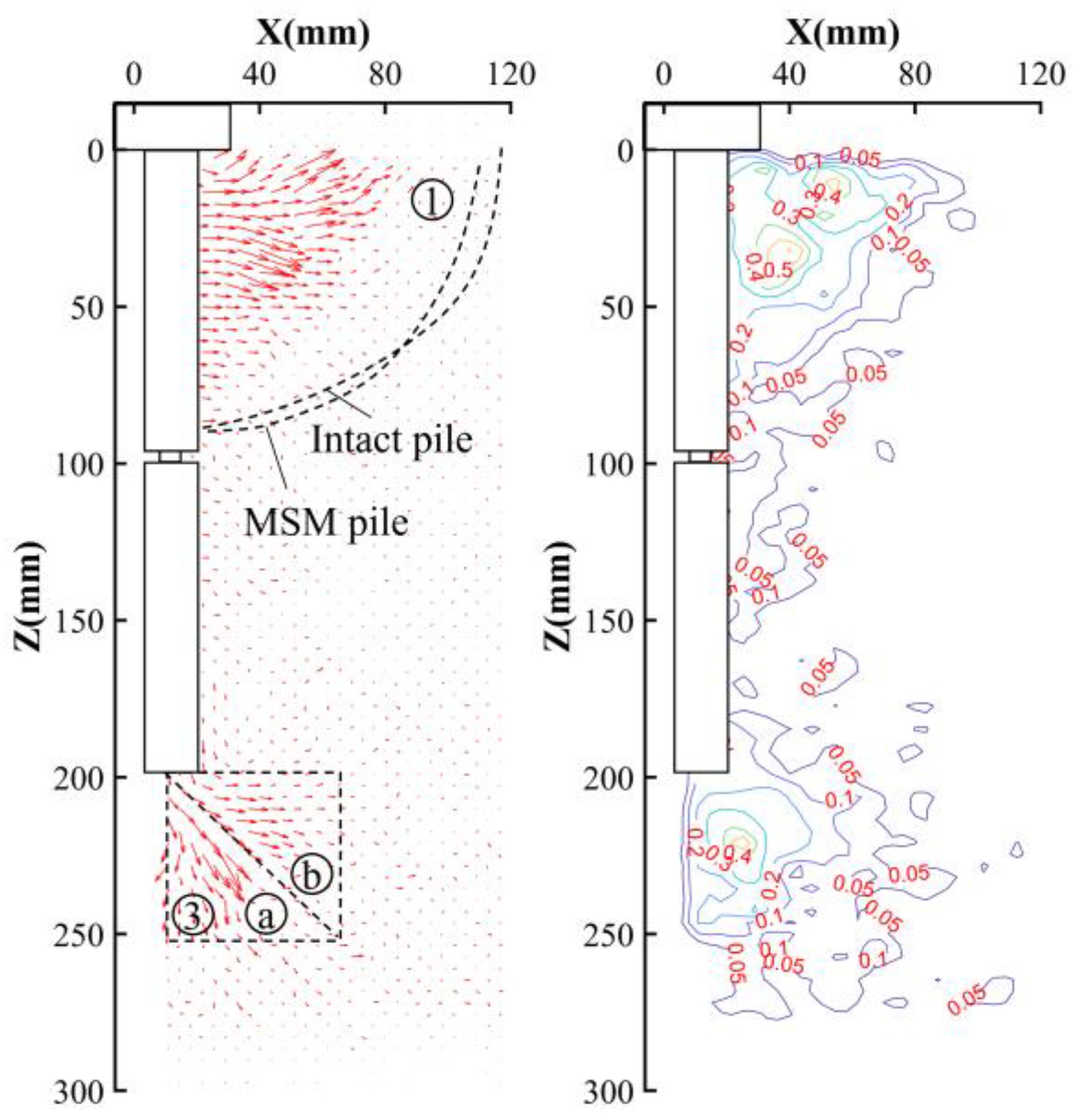

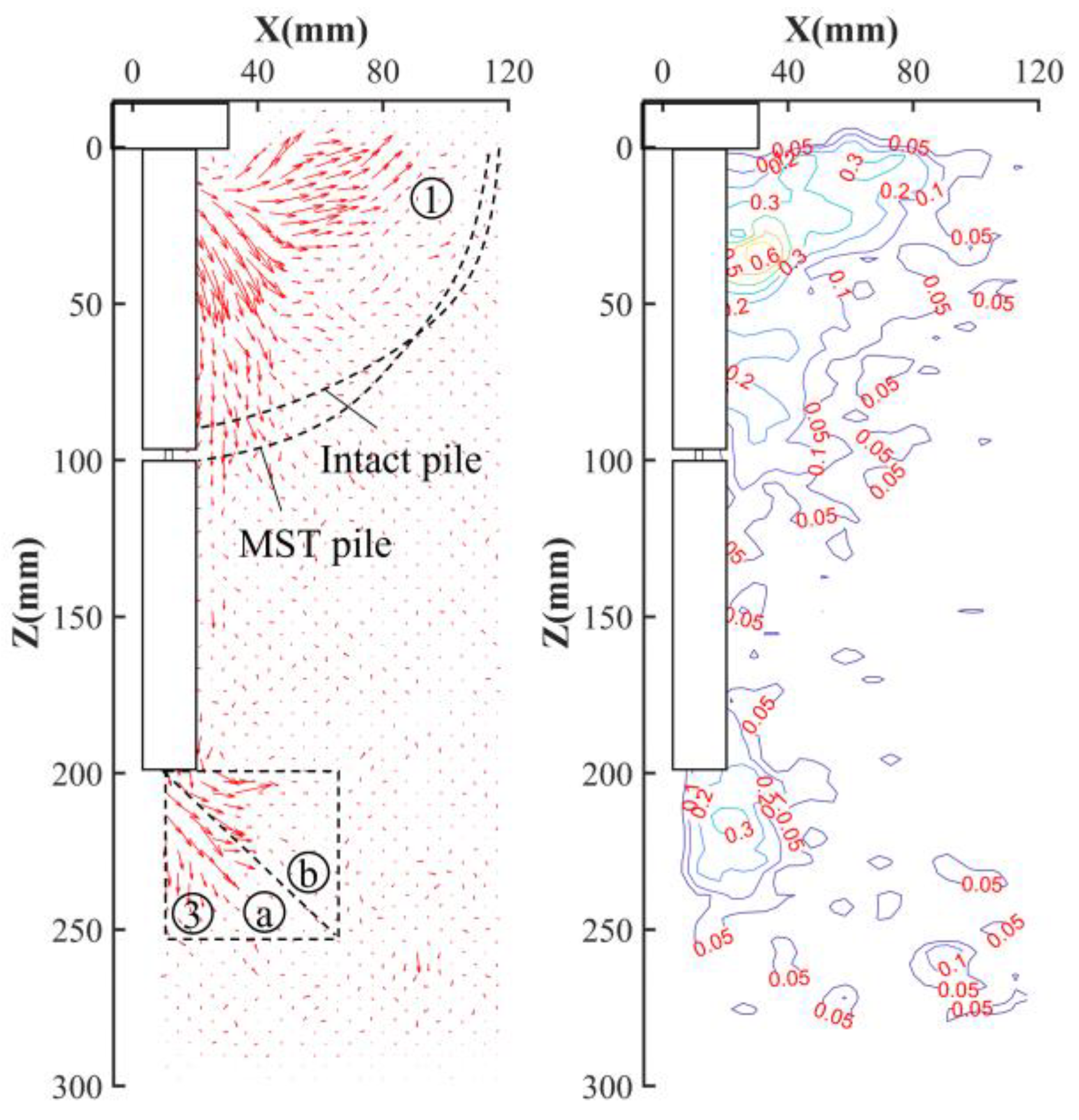

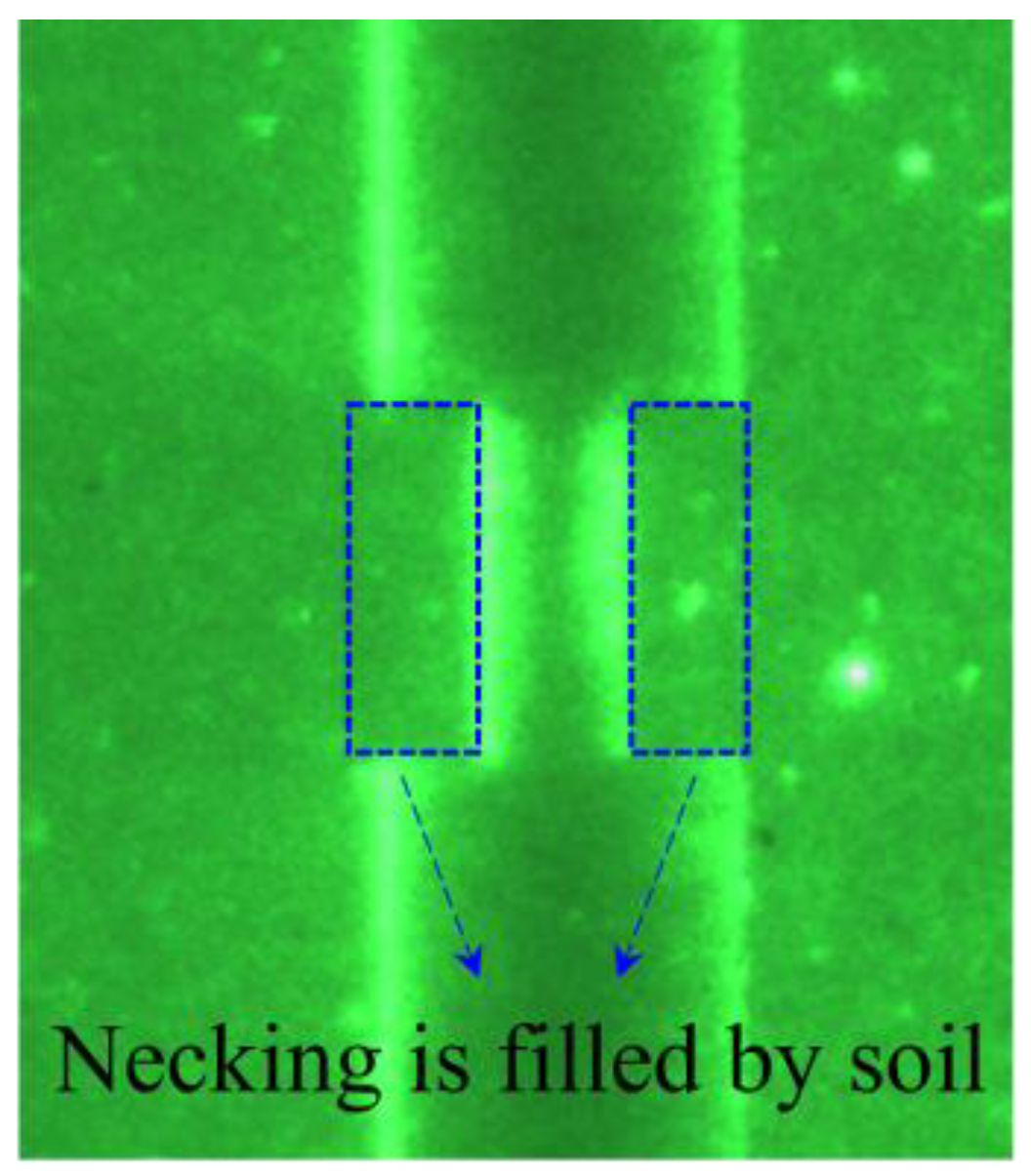

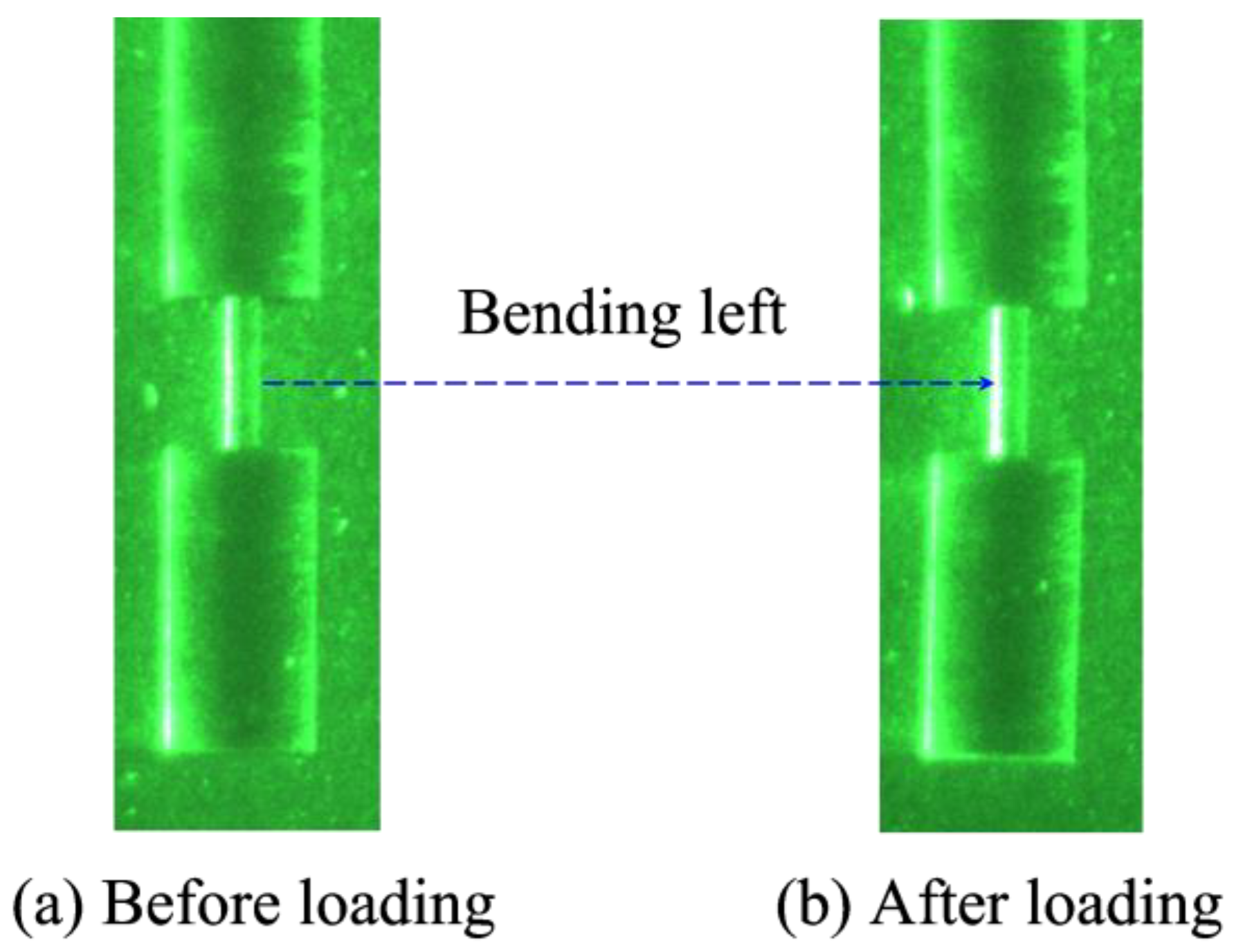

3.2. Analysis of Soil Displacement around Piles

4. Discussion of Bearing Capacity Loss

5. Conclusions

- (1)

- The bearing capacity of capped pile is greatly damaged by the existence of necking. When the necking diameter is 4 mm and the necking length is 20 mm, the loss of VUBC is as high as 26.6%. For the pile with the same necking diameter, the vertical bearing capacity will decrease with the increase in necking length. However, when the necking diameter is 16 mm, the VUBC of MLW pile only is increased by 3% compared with that of MMW pile. For the pile with the same necking length, the vertical bearing capacity will increase with the increase in necking diameter.

- (2)

- The necking mainly affects the soil displacement around the pile cap and necking. The soil around the necking develops downward and concentrated displacement, and the pile-shaft resistance at the necking is lost. When the necking size is large, the soils at the necking and around the pile cap are connected. This increases the displacement range of the soil under the pile cap and has a significant impact on the soil displacement direction around the pile cap. In addition, the soil under the pile cap develops more vertically downward displacement, resulting in more loss of pile-shaft resistance.

- (3)

- In this study, the necked pile was placed in the middle of the pile for the first time. At present, there is no relevant study on middle necking pile. This study is compared with the existing studies on necking piles. For example, Xu et al. [31] shows that the necking seriously affects the bearing capacity of piles, the influence of the necking length and different necking diameters on the bearing capacity, which is consistent with the results of this study. The research results in the literature show that shallow shrinkage limits the performance of the pile cap. This study found that the intermediate shrinkage affects the performance of the pile side friction. The research results analyzed the causes of the bearing-capacity loss of necking piles and provided a certain theoretical and technical reference for the rational design and reinforcement of piles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- O’Neill, M.; Tabsh, S.W.; Sarhan, H. Response of drilled shafts with minor flaws to axial and lateral loads. Eng. Struct. 2003, 25, 47–56. [Google Scholar] [CrossRef]

- Li, D.Q.; Tang, W.H.; Zhang, L.M. Updating occurrence probability and size of defect for bored piles. Struct. Saf. 2008, 30, 130–143. [Google Scholar] [CrossRef]

- Sarhan, H.A.; O’Neill, M.W.; Hassan, K.M. Flexural Performance of Drilled Shafts with Minor Flaws in Stiff Clay. J. Geotech. Geoenviron. Eng. 2002, 128, 974–985. [Google Scholar] [CrossRef]

- JGJ106-2014; Technical Code of Building Foundation Piles. China Academy of Building Research: Beijing, China, 2014.

- Samman, M.; O’Neill, M.W. The reliability of sonic testing of drilled shafts. Concr. Int. 1997, 19, 49–54. [Google Scholar]

- Magued, I.; Douglas, R.; Kelley, S.; Carl, E. Drilled shaft defects: Detection, and effects on capacity in varved clay. J. Geotech. Geoenviron. Eng. 2003, 129, 1128–1137. [Google Scholar]

- LI, D.Q.; Zhang, L.M.; Tang, W.H. Reliability evaluation of cross-hole sonic logging for bored pile integrity. J. Geotech. Geoenviron. Eng. 2005, 131, 1130–1138. [Google Scholar] [CrossRef] [Green Version]

- Chai, H.Y.; Phoon, K.K. Detection of shallow anomalies in pile integrity testing. Int. J. Geomech. 2013, 13, 672–677. [Google Scholar] [CrossRef]

- Lee, J.S.; Song, J.U.; Hong, W.T.; Wu, J.D. Application of time domain reflectometer for detecting necking defects in bored piles. NDT E Int. 2018, 100, 132–142. [Google Scholar] [CrossRef]

- Ni, S.H.; Yang, Y.Z.; Tsai, P.H.; Chou, W.H. Evaluation of pile defects using complex continuous wavelet transform analysis. NDT E Int. 2017, 87, 50–59. [Google Scholar] [CrossRef]

- Farenyuk, G.; Kaliukh, I.; Farenyuk, E.; Taras, K.; Yaroslav, B.; Viktoriia, B. Experimental and theoretical diagnostics of defects in ferroconcrete piles based on reflection of longitudinal and transverse waves. In High Tech Concrete: Where Technology and Engineering Meet; Spring: New York, NY, USA, 2018; pp. 1307–1317. [Google Scholar]

- Gao, L.; Wang, K.H.; Si, X.; Li, Z.Y.; Wu, J.T. An analytical solution for excited pile vibrations with variable section impedance in the time domain and its engineering application. Comput. Geotech. 2016, 73, 170–178. [Google Scholar] [CrossRef]

- Schilder, C.; Kohlhoff, H.; Hofmann, D.; Basedau, F.; Habel, W.R.; Baeßler, M.; Niederleithinger, E.; Georgi, S.; Herten, M. Static and dynamic pile testing of reinforced concrete piles with structure integrated fibre optic strain sensors. Proc. Spie 2013, 8794, 47–62. [Google Scholar]

- Xu, Z.J.; Liu, J.; Yuan, F. A Novel measurement method of toe debris thickness for bored piles based on one-dimensional wave theory. J. Vibroeng. 2019, 21, 1079–1091. [Google Scholar] [CrossRef]

- Wang, C.H.; Su, J.; Wang, G. Model Test Studies of the Vertical Bearing Behavior of Bored Piles with Breakage Defects. Appl. Mech. Mater. 2013, 256–259, 65–70. [Google Scholar] [CrossRef]

- Wang, C.H.; An, J.G. A Nonlinear Numerical Analysis of Vertical Bearing Behavior of Bored Pile Foundations Including Defective Piles with Stem Shrinkage. Adv. Mater. Res. 2011, 374–377, 2071–2077. [Google Scholar] [CrossRef]

- Neto, O.D.F.; Cunha, R.P.D.; Albuquerque, P.J.R.; Garcia, J.R.; Júnior, O.F.S. Experimental and numerical analyses of a deep foundation containing a single defective pile. Lat. Am. J. Solids Struct. 2020, 17, e270. [Google Scholar] [CrossRef]

- Poulos, H.G. Pile Behavior Consequences of Geological and Construction Imperfections. J. Geotech. Geoenviron. Eng. 2005, 131, 538–563. [Google Scholar] [CrossRef]

- Yan, Z.; Sun, X.P.; Yang, Z.X.; Fu, D.F. Lateral Bearing Performance of a Defective Pile-Supported Wharf with Batter Piles. J. Waterw. Port Coast. Ocean Eng. 2020, 146, 04020035.1–04020035.13. [Google Scholar] [CrossRef]

- Nadeem, M.; Chakraborty, T.; Matsagar, V. Nonlinear buckling analysis of slender piles with geometric imperfections. J. Geotech. Geoenviron. Eng. 2014, 141, 06014014. [Google Scholar] [CrossRef]

- Petek, K.; Felice, C.W.; Holtz, R. Capacity analysis of drilled shafts with defects. J. Deep Found. 2002, 256, 1120–1135. [Google Scholar]

- Albuquerque, P.J.R.; Garcia, J.R.; Neto, O.D.F.; Cunha, R.P.; Santos, O.F. Behavioral evaluation of small-diameter defective and intact bored piles subjected to axial compression. Soils Rocks 2017, 40, 109–121. [Google Scholar] [CrossRef]

- Sang, Y.; Zhao, J.; Duan, F.; Sun, W.; Zhao, H. A novel automatic device to measure deformation inside transparent soil based on DIC technology. Meas. Sci. Technol. 2018, 47, 451–460. [Google Scholar]

- Kong, G.; Lu, L. Performances of one new transparent glass soil. Mater. Res. Innov. 2014, 18, S2.537–S2.540. [Google Scholar] [CrossRef]

- Xiao, Y.; Yin, F.; Liu, H.; Chu, J.; Zheng, W. Model tests on Soil movement during the installation of piles in transparent granular soil. Int. J. Geomech. 2017, 17, 06016027. [Google Scholar] [CrossRef]

- Ding, X.H.; Zhou, W.; Lu, X.; Gao, Y. Physical simulation test of soil-rock mixture from synthetic transparent soil. J. Cent. South Univ. 2018, 25, 3085–3097. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, H.; Liu, H.; Ding, X.M.; Zhang, W.G. Geotechnical properties of 3D-printed transparent granular soil. Acta Geotech. 2021, 16, 1789–1800. [Google Scholar] [CrossRef]

- Kong, G.Q.; Cao, Z.H.; Zhou, H.; Sun, X.J. Analysis of Piles Under Oblique Pullout Load Using Transparent-Soil Models. Geotech. Test. J. 2015, 38, 725–738. [Google Scholar] [CrossRef]

- Xiang, Y.Z.; Liu, H.L.; Zhang, W.G.; Chu, J.; Zhou, D.; Xiao, Y. Application of transparent soil model test and DEM simulation in study of tunnel failure mechanism. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2018, 74, 178–184. [Google Scholar] [CrossRef]

- Yang, Q.N.; Shao, J.J.; Xu, Z.J.; Yu, M. Experimental investigation of the impact of necking position on pile capacity assisted with transparent Soil Technology. Adv. Civ. Eng. 2022, 2022, 9965974. [Google Scholar] [CrossRef]

- Xu, Z.J.; Guo, Z.X. Experimental Study on Bearing Characteristics and Soil Deformation of Necking Pile with Cap Using Transparent Soils Technology. Adv. Civ. Eng. 2021, 2021, 6625556. [Google Scholar] [CrossRef]

- GB178-77; Standard for Cement Strength Test. National Bureau of Standards and Metrology: Beijing, China, 1977.

- Ezzein, F.M.; Bathurst, R.J. A transparent sand for geotechnical laboratory modeling. Geotech. Test. J. 2011, 34, 590–601. [Google Scholar]

- Liu, J.; Iskander, M.G. Modelling capacity of transparent soil. Can. Geotech. J. 2010, 47, 451–460. [Google Scholar] [CrossRef]

- Iskander, M.; Liu, J. Spatial Deformation Measurement Using Transparent Soil. Geotech. Test. J. 2010, 33, 314–321. [Google Scholar]

- Iai, S. Similitude for shaking table tests on soil-structure-fluid model in 1g gravitational field. Soils Found. 1989, 29, 105–118. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.Y. Key Problems Investigation on Non-Destructive Integrity Detection of Piles with Elevated-Cap (Beam); Zhejiang University: Hangzhou, China, 2017; pp. 9–15. (In Chinese) [Google Scholar]

- GB50007-2011; Code for Design Building Foundation. China Academy of Building Research: Beijing, China, 2011.

- Liu, C.; Tang, X.W.; Wei, H.W.; Wang, P.P.; Zhao, H.H. Model tests of jacked-pile penetration into sand using transparent soil and incremental particle image velocimetry. KSCE J. Civ. Eng. 2020, 24, 1128–1145. [Google Scholar] [CrossRef]

- Massarsch, K.R.; Weraell, C. Cumulative lateral soil displacement due to pile driving in soft clay. In Geo-Congress, Sound Geotechnical Research to Practice; Geotechnical Special Publication (GSP230): San Diego, CA, USA, 2013; pp. 463–480. [Google Scholar]

- Tian, Y.Q.; Zhou, Z.J.; Dong, Y.Q.; Wang, K.C.; Feng, H.M. Study on the value of side friction of bored pile in loess area considering the influence of length diameter ratio. Arab. J. Geosci. 2021, 14, 2067. [Google Scholar] [CrossRef]

- Zhang, Q.Y.; Zhang, Y.; Lin, H.D.; Feng, L. Numerical investigation on bearing capacity of OWT foundation with large diameter monopile under Seismic load. Appl. Ocean Res. 2021, 108, 102518. [Google Scholar] [CrossRef]

| Cu | Cc | ρd/(g·cm−3) | ρdmax/(g·cm−3) | ρdmin/(g·cm−3) | γ/(kN·m−3) |

|---|---|---|---|---|---|

| 6 | 1.354 | 1.438 | 1.481 | 1.239 | 2.51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Le, X.; Cui, X.; Zhang, M.; Xu, Z.; Dou, L. Behavior Investigation of Necking Pile with Caps Assisted with Transparent Soil Technology. Sustainability 2022, 14, 8681. https://doi.org/10.3390/su14148681

Le X, Cui X, Zhang M, Xu Z, Dou L. Behavior Investigation of Necking Pile with Caps Assisted with Transparent Soil Technology. Sustainability. 2022; 14(14):8681. https://doi.org/10.3390/su14148681

Chicago/Turabian StyleLe, Xudong, Xiuqin Cui, Mengyang Zhang, Zhijun Xu, and Lin Dou. 2022. "Behavior Investigation of Necking Pile with Caps Assisted with Transparent Soil Technology" Sustainability 14, no. 14: 8681. https://doi.org/10.3390/su14148681

APA StyleLe, X., Cui, X., Zhang, M., Xu, Z., & Dou, L. (2022). Behavior Investigation of Necking Pile with Caps Assisted with Transparent Soil Technology. Sustainability, 14(14), 8681. https://doi.org/10.3390/su14148681