Non-Destructive Testing of Pipe Conveyor Belts Using Glass-Coated Magnetic Microwires

Abstract

:1. Introduction

2. Materials and Methods

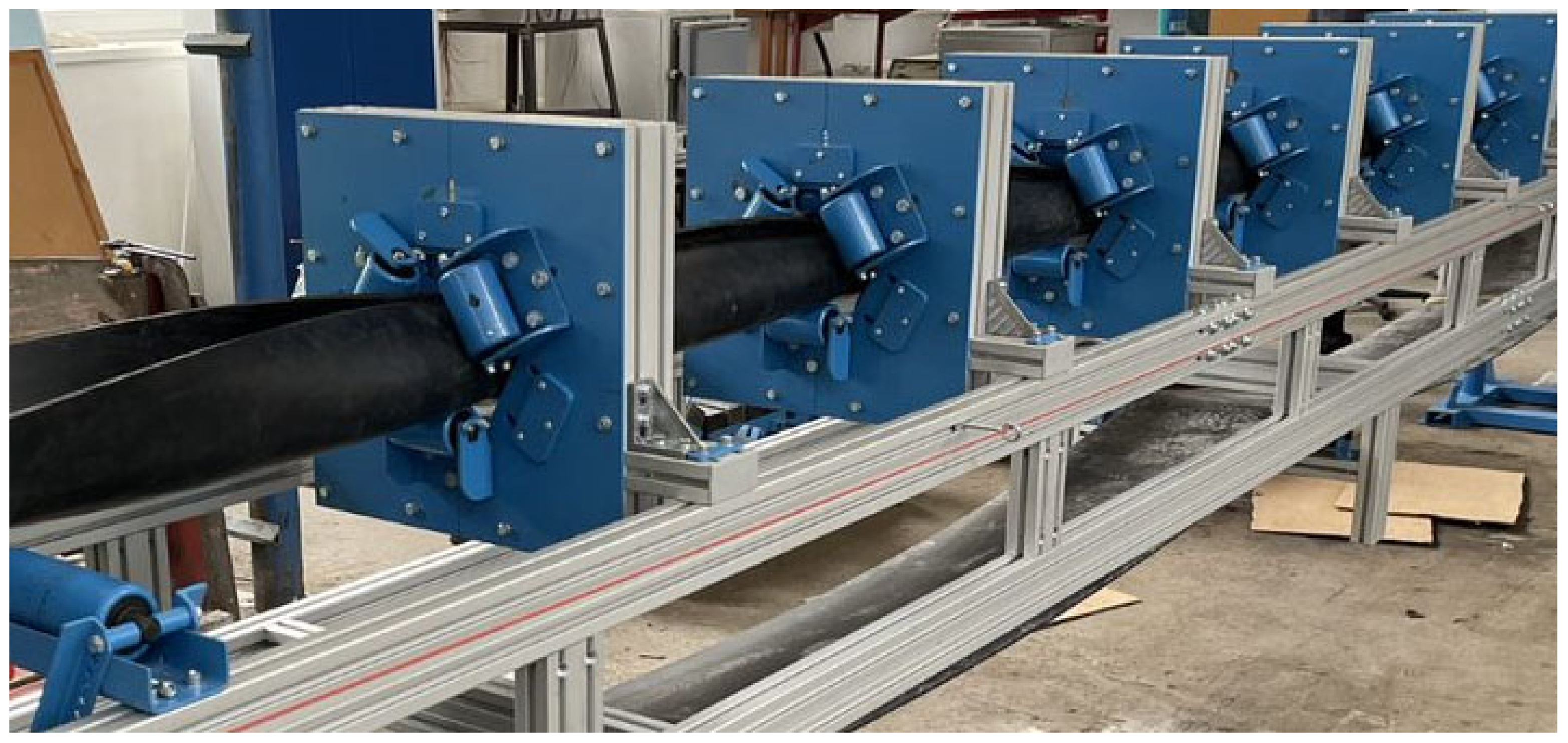

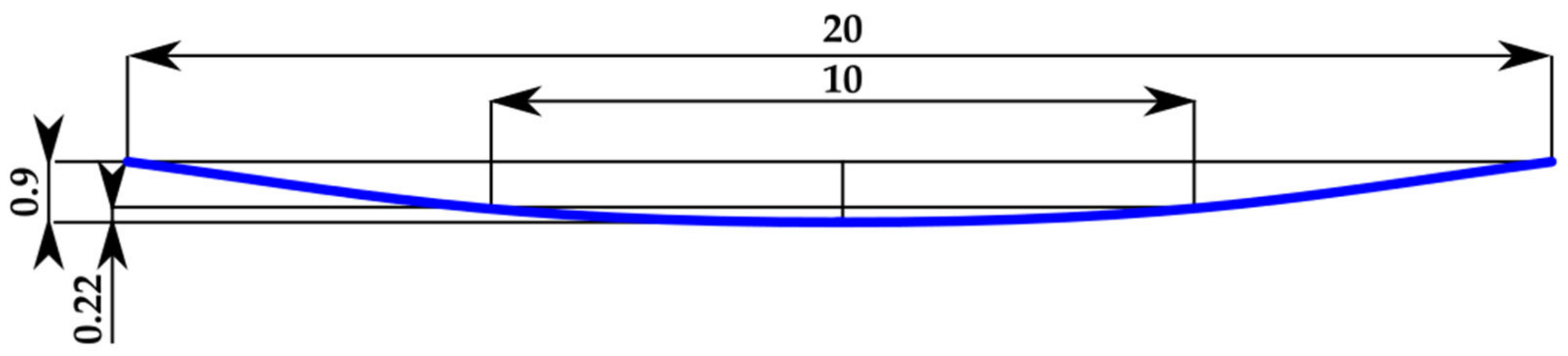

2.1. Pipe Belt Conveyor

2.2. Microwire

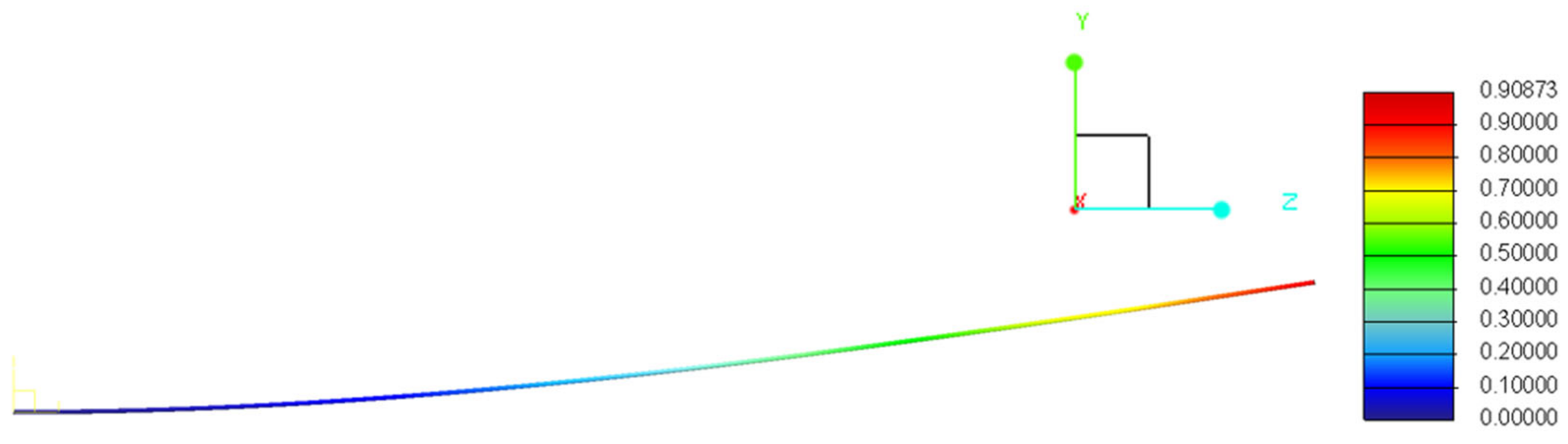

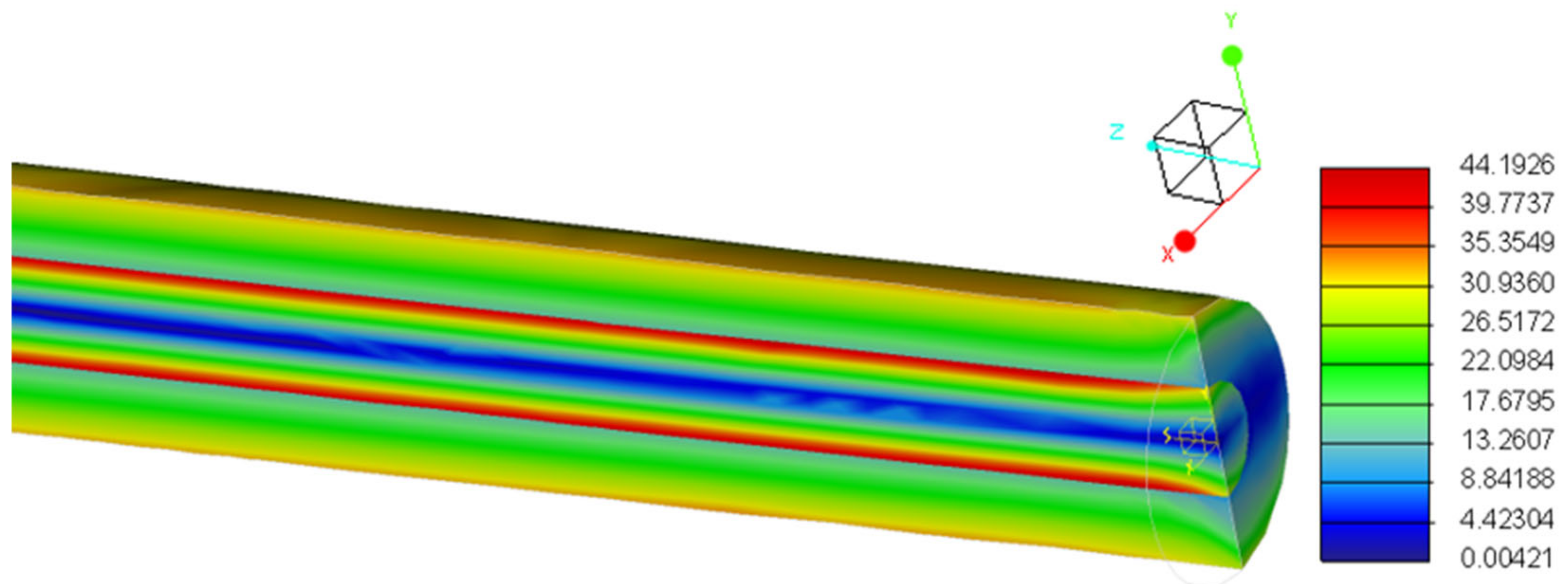

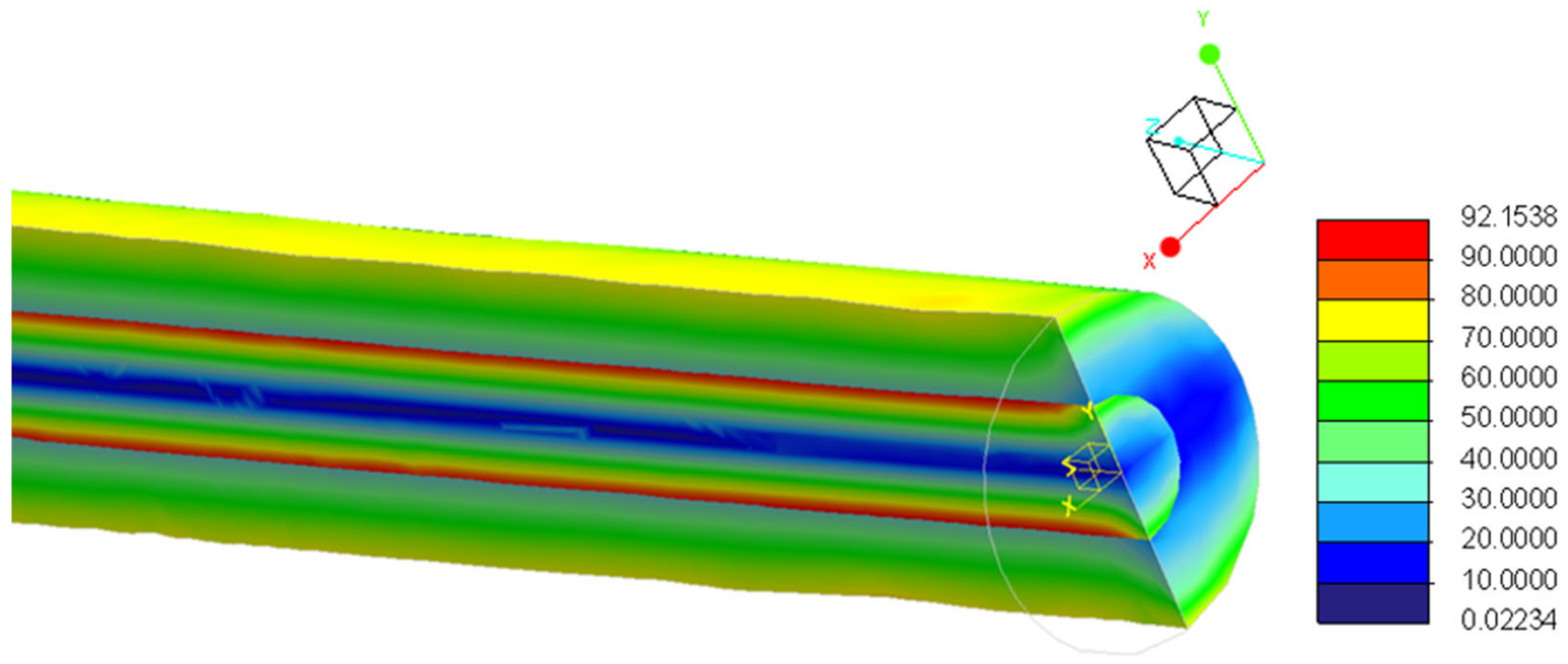

2.3. FEM (Finite Element Method) Analysis of the Magnetic Microwire

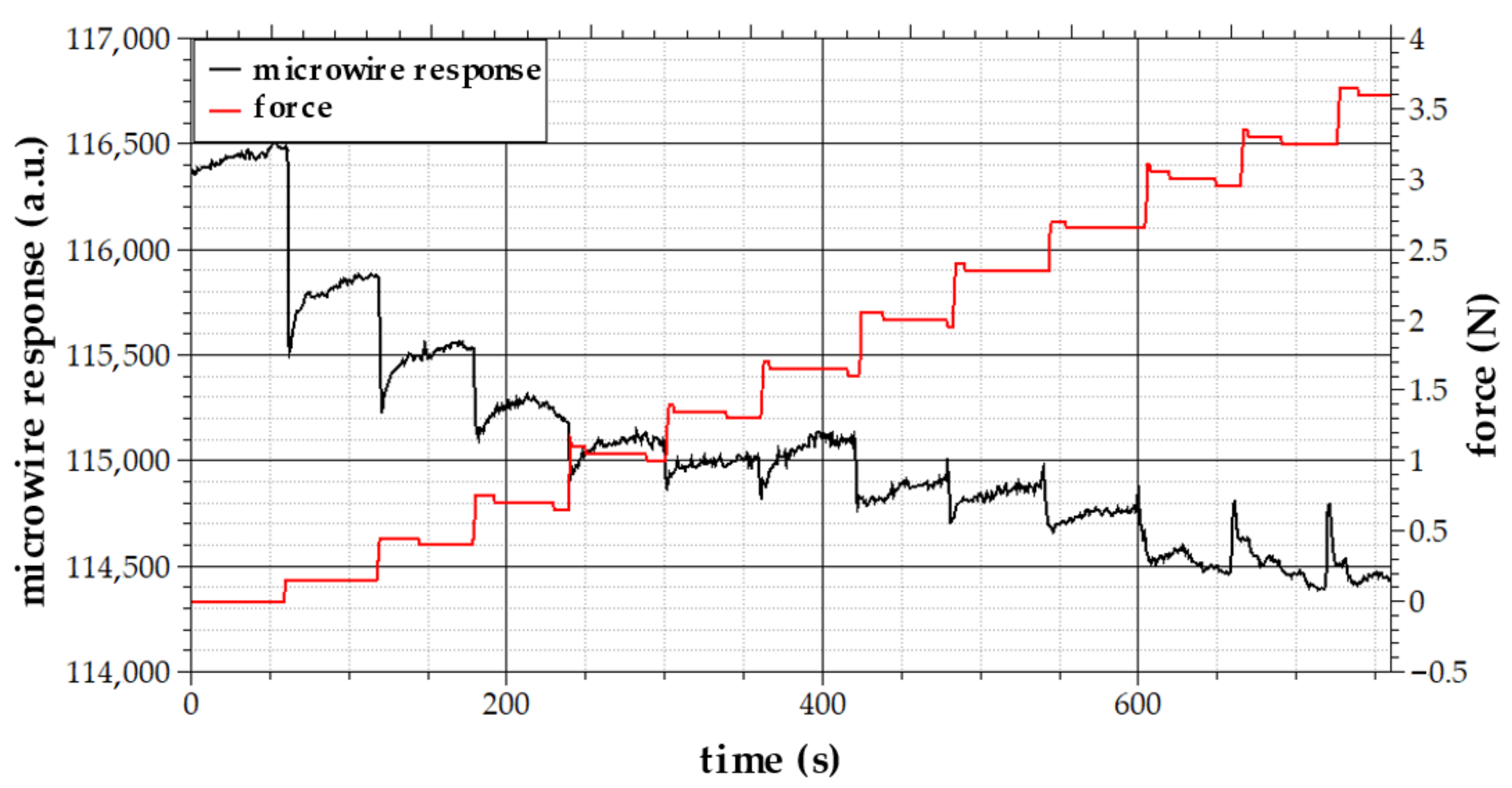

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhattacharya, J.; Gavel, S.; Kumar, S.; Choudhary, A.S. Pipe belt conveyor: Cost estimation under various design constraints. J. Mines Met. Fuels 2019, 67, 345–359. [Google Scholar]

- Zareiforoush, H.; Bakhshipour, A.; Bagheri, I. Performance Evaluation and Optimization of a Solar-Assisted Multi-Belt Conveyor Dryer Based on Response Surface Methodology. J. Renew. Energy Environ. 2022, 9, 78–92. [Google Scholar] [CrossRef]

- Dos Santos, J.A. Sandwich belt high angle conveyors: In harmony with the environment 2020. In Proceedings of the PEERS/IBBC, Virtual Conference, online, 2–4 November 2020; pp. 39–63. [Google Scholar]

- Bortnowski, P.; Król, R.; Nowak-Szpak, A.; Ozdoba, M.A. Preliminary Studies of the Impact of a Conveyor Belt on the Noise Emission. Sustainability 2022, 14, 2785. [Google Scholar] [CrossRef]

- Vaka, G.A.; Robins, K. Development and Advantages. Available online: http://www.pipeconveyor.com/Case%20Studies/Advantages/Advantages.htm (accessed on 5 May 2022).

- Galkin, V.I. Expanding range of application of pipe conveyor belts through innovative design concepts. Gorn. Zhurnal 2020, 2020, 52–56. [Google Scholar] [CrossRef]

- Guo, Y.-C.; Wang, S.; Hu, K.; Li, D.-Y. Optimizing the Pipe Diameter of the Pipe Belt Conveyor Based on Discrete Element Method. 3D Res. 2016, 7, 5. [Google Scholar] [CrossRef]

- Zamiralova, M.E.; Lodewijks, G. Shape stability of pipe belt conveyors: From throughability to pipe-ability. FME Trans. 2016, 44, 263–271. [Google Scholar] [CrossRef]

- Xiao, D.; Li, X.; He, K. Power Balance of Starting Process for Pipe Belt Conveyor Based on Master-Slave Control. IEEE Access 2018, 6, 16924–16931. [Google Scholar] [CrossRef]

- He, D.; Liu, X.; Zhong, B. Sustainable belt conveyor operation by active speed control. Measurement 2020, 154, 107458. [Google Scholar] [CrossRef]

- dos Santos e Santos, L.; Ribeiro Filho, P.R.C.F.; Macêdo, E.N. Indentation rolling resistance in pipe conveyor belts: A review. J. Braz. Soc. Mech. Sci. 2021, 43, 230. [Google Scholar] [CrossRef]

- Zamiralova, M.E.; Lodewijks, G. Energy consumption of pipe belt conveyors: Indentation rolling resistance. FME Trans. 2012, 40, 171–176. [Google Scholar]

- dos Santos e Santos, L.; Ribeiro Filho, P.R.C.F.; Macêdo, E.N. Development of idler for measuring indentation rolling resistance in pipe conveyor belts. Measurement 2020, 153, 107413. [Google Scholar] [CrossRef]

- Wang, S.; Li, D.-Y.; Guo, Y.-C. Research on Magnetic Model of Low Resistance Permanent Magnet Pipe Belt Conveyor. 3D Res. 2016, 7, 23. [Google Scholar] [CrossRef]

- Molnár, V.; Sabovčík, M. Static testing evaluation of pipe conveyor belt for different tensioning forces. Open Eng. 2019, 9, 580–585. [Google Scholar] [CrossRef]

- Stehlikova, B.; Molnar, V.; Fedorko, G.; Michalik, P.; Paulikova, A. Research about influence of the tension forces, asymmetrical tensioning and filling rate of pipe conveyor belt filled with the material on the contact forces of idler rolls in hexagonal idler housing. Measurement 2020, 156, 107598. [Google Scholar] [CrossRef]

- Zheng, Q.J.; Xu, M.H.; Chu, K.W.; Pan, R.H.; Yu, A.B. A coupled FEM/DEM model for pipe conveyor systems: Analysis of the contact forces on belt. Powder Technol. 2017, 314, 480–489. [Google Scholar] [CrossRef]

- Zamiralova, M.E.; Lodewijks, G. Measurement of a pipe belt conveyor contact forces and cross section deformation by means of the six-point pipe belt stiffness testing device. Measurement 2015, 70, 232–246. [Google Scholar] [CrossRef]

- Wang, S.; Guo, Y.-C.; Li, D.-Y.; Hu, K. Research of lateral force of pipe conveyor belt’s vertical transport section. Arch. Transp. 2016, 37, 67–75. [Google Scholar] [CrossRef] [Green Version]

- Guo, Y.-C.; Wang, S.; Hu, K.; Li, D.-Y. Optimization and experimental study of transport section lateral pressure of pipe belt conveyor. Adv. Powder Technol. 2016, 27, 1318–1324. [Google Scholar] [CrossRef]

- Wang, S.; Li, D.; Hu, K. Analysis and Experimental Study on Pressure Characteristics of Supporting Roller Group of Pipe Belt Conveyor. Shock. Vib. 2019, 2019, 7061847. [Google Scholar] [CrossRef] [Green Version]

- Bin, G.; Zhang, W.; Li, X.; Ye, G. Dynamic contact force analysis considering pipe conveyor belt elasticity. Meitan Xuebao/J. China Coal Soc. 2017, 42, 2483–2490. [Google Scholar] [CrossRef]

- Xiaoxia, S.; Wenjun, M.; Hui, Z.; Yuan, Y.; Zhengmao, Y. Analysis on the bending stiffness and the form force of the pipe conveyor belt. Sens. Transducers 2013, 161, 655–660. [Google Scholar]

- Minkin, A.; Jungk, A.; Hontscha, T. Belt replacement at a long distance pipe conveyor: Belt design, installation and power measurements. Bulk Solids Handl. 2012, 32, 16–21. [Google Scholar]

- Yasutomi, A.Y.; Enoki, H. Localization of Inspection Device Along Belt Conveyors With Multiple Branches Using Deep Neural Networks. IEEE Robot. Autom. Lett. 2020, 5, 2921–2928. [Google Scholar] [CrossRef]

- Yasutomi, A.Y.; Enoki, H.; Yamaguchi, S.; Tamura, K. Inspection System for Automatic Measurement of Level Differences in Belt Conveyors Using Inertial Measurement Unit. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Madrid, Spain, 1–5 October 2018; pp. 6155–6161. [Google Scholar]

- Szrek, J.; Jakubiak, J.; Zimroz, R.A. Mobile Robot-Based System for Automatic Inspection of Belt Conveyors in Mining Industry. Energies 2022, 15, 327. [Google Scholar] [CrossRef]

- Rocha, F.; Garcia, G.; Pereira, R.F.S.; Henrique, D.F.; Thales, H.S.; Ricardo, H.R.A.; Evelyn, S.B.; André, A.; Emanuel, C.; Wagner, A.; et al. ROSI: A Robotic System for Harsh Outdoor Industrial Inspection—System Design and Applications. J. Intell. Robot. Syst. Theory Appl. 2021, 103, 30. [Google Scholar] [CrossRef]

- Chamorro, J.; Vallejo, L.; Maynard, C.; Guevara, S.; Solorio, J.A.; Soto, N.; Singh, K.V.; Bhate, U.; Ravi, K.G.V.V.; Garcia, J.; et al. Health monitoring of a conveyor belt system using machine vision and real-time sensor data. CIRP J. Manuf. Sci. Technol. 2022, 38, 38–50. [Google Scholar] [CrossRef]

- Liu, Y.; Miao, C.; Li, X.; Ji, J.; Meng, D. Research on the fault analysis method of belt conveyor idlers based on sound and thermal infrared image features. Measurement 2021, 186, 110177. [Google Scholar] [CrossRef]

- Zeng, F.; Zhang, S.; Wang, T.; Wu, Q. Mini-crack detection of conveyor belt based on laser excited thermography. Appl. Sci. 2021, 11, 10766. [Google Scholar] [CrossRef]

- Dabek, P.; Szrek, J.; Zimroz, R.; Wodecki, J. An Automatic Procedure for Overheated Idler Detection in Belt Conveyors Using Fusion of Infrared and RGB Images Acquired during UGV Robot Inspection. Energies 2022, 15, 601. [Google Scholar] [CrossRef]

- Wang, Y.; Li, S.; Meng, W. Thermo-mechanical strong coupling analysis on braking device of pipe belt conveyor. J. Mech. Sci. Technol. 2018, 32, 1277–1285. [Google Scholar] [CrossRef]

- Yang, Y.; Hou, C.C.; Qiao, T.Z.; Zhang, H.T.; Ma, L. Longitudinal tear early-warning method for conveyor belt based on infrared vision. Measurement 2019, 147, 106817. [Google Scholar] [CrossRef]

- Shiri, H.; Wodecki, J.; Ziętek, B.; Zimroz, R. Inspection robotic UGV platform and the procedure for an acoustic signal-based fault detection in belt conveyor idler. Energies 2021, 14, 7646. [Google Scholar] [CrossRef]

- Popescu, F.D. Ways of controlling transport capacity variation of belt conveyors. In Proceedings of the 9th WSEAS International Conference Automation and Information (ICAI’08), Bucharest, Romania, 24–26 June 2008; pp. 120–123. [Google Scholar]

- Wang, Y.; Miao, C.; Liu, Y.; Meng, D. Research on a sound-based method for belt conveyor longitudinal tear detection. Measurement 2022, 190, 110787. [Google Scholar] [CrossRef]

- Yang, M.; Peng, C.; Li, Z. An Audio-based Intelligent Fault Classification System for Belt Conveyor Rollers. In Proceedings of the Chinese Control Conference, CCC, Shanghai, China, 26–28 July 2021; pp. 4647–4652. [Google Scholar] [CrossRef]

- Martínez Quintero, J.C.; Estupiñán Cuesta, E.P.; García Ramírez, J.S. Reconfigurable software-defined radar testbed with built-in validation. Bull. Electr. Eng. Inform. 2022, 11, 825–837. [Google Scholar] [CrossRef]

- Ma, G.; Lu, J.; Gao, M. Design of metal detecting system based on HMC1001 magnetic sensor. In Proceedings of the 13th IEEE Conference on Industrial Electronics and Applications, ICIEA 2018, Wuhan, China, 31 May–2 June 2018; pp. 1703–1708. [Google Scholar] [CrossRef]

- Błażej, R.; Jurdziak, L.; Kozłowski, T.; Kirjanów, A. The use of magnetic sensors in monitoring the condition of the core in steel cord conveyor belts —Tests of the measuring probe and the design of the DiagBelt system. Measurement 2018, 123, 48–53. [Google Scholar] [CrossRef]

- Dey, S.; Salim, O.; Masoumi, H.; Karmakar, N.C. A Novel UHF RFID Sensor Based Crack Detection Technique for Coal Mining Conveyor Belt. IEEE J. Radio Freq. Identif. 2022, 6, 19–30. [Google Scholar] [CrossRef]

- Buffi, A.; Nepa, P.; Lombardini, F. A phase-based technique for localization of uhf-rfid tags moving on a conveyor belt: Performance analysis and test-case measurements. IEEE Sens. J. 2015, 15, 387–396. [Google Scholar] [CrossRef]

- Megalou, S.; Chatzistefanou, A.R.; Tzitzis, A.; Yioultsis, T.V.; Dimitriou, A.G. Passive UHF-RFID Hyperbolic Positioning of Moving Tags by Exploiting Neural Networks. IEEE J. Radio Freq. Identif. 2022, in press. [Google Scholar] [CrossRef]

- Guo, X.; Liu, X.; Zhou, H.; Stanislawski, R.; Królczyk, G.; Li, Z. Belt Tear Detection for Coal Mining Conveyors. Micromachines 2022, 13, 449. [Google Scholar] [CrossRef]

- Andrejiova, M.; Grincova, A.; Marasova, D. Monitoring dynamic loading of conveyer belts by measuring local peak impact forces. Measurement 2020, 158, 107690. [Google Scholar] [CrossRef]

- Ravikumar, S.; Kanagasabapathy, H.; Muralidharan, V. Multi-component fault diagnosis of self aligning troughing roller (SATR) in belt conveyor system using decision tree-A statistical approach. FME Trans. 2020, 48, 364–371. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Y.; Zhou, M.; Jiang, K.; Shi, H.; Yu, Y.; Hao, N. Application of lightweight convolutional neural network for damage detection of conveyor belt. Appl. Sci. 2021, 11, 7282. [Google Scholar] [CrossRef]

- Kozłowski, E.; Borucka, A.; Liu, Y.; Mazurkiewicz, D. Conveyor Belts Joints Remaining Life Time Forecasting with the Use of Monitoring Data and Mathematical Modelling. In Proceedings of the 1st International Conference on Innovation in Engineering, ICIE 2021, Guimarães, Portugese, 28–30 June 2022; pp. 44–54. [Google Scholar] [CrossRef]

- Selvam, S.T.; Mukhopadhyay, A.K. Numerical Analysis of Belt Conveyors for Maintenance Decision Support System. Int. J. Eng. Trends Technol. 2022, 70, 151–161. [Google Scholar] [CrossRef]

- Liu, X.; He, D.; Lodewijks, G.; Pang, Y.; Mei, J. Integrated decision making for predictive maintenance of belt conveyor systems. Reliab. Eng. Syst. Saf. 2019, 188, 347–351. [Google Scholar] [CrossRef]

- Šmelko, M.; Draganová, K.; Lipovský, P.; Semrád, K.; Blišt’anová, M.; Kašper, P. Non-destructive testing of aircraft structures using microwire-based tensile stress sensor. Appl. Sci. 2020, 10, 8218. [Google Scholar] [CrossRef]

- Hudák, J.; Lipovský, P.; Bajús, J.; Čverha, A.; Klein, P.; Varga, R.; Onufer, Z.; Ziman, J. Fluxgate Sensors Based on Magnetic Microwires for Weak Magnetic Fields Measurement. J. Electr. Eng. 2015, 66, 153–156. [Google Scholar]

- Šmelko, M.; Kravčák, J.; Praslička, D.; Blažek, J.; Draganová, K. Impact of Modified Endings on Noise Characteristics of Fe-Based Glass-Coated Microwires. J. Electr. Eng. 2015, 66, 30–32. [Google Scholar]

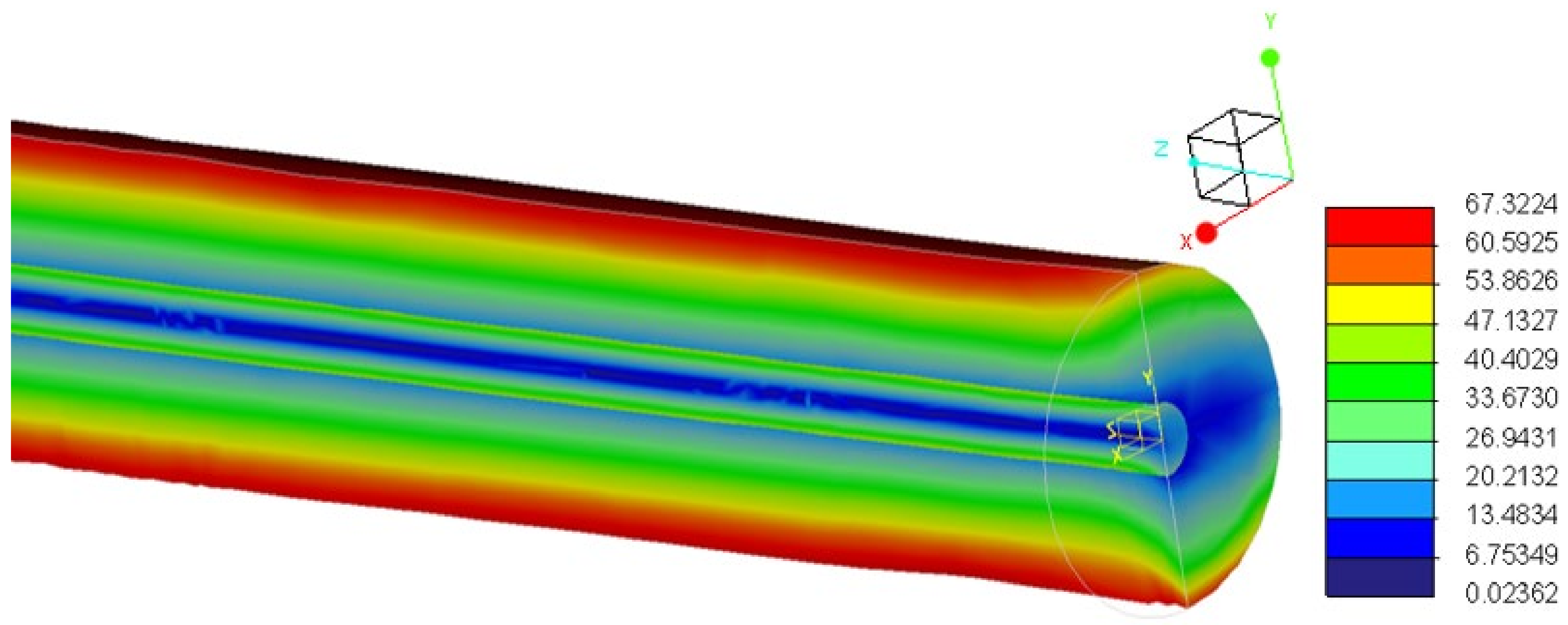

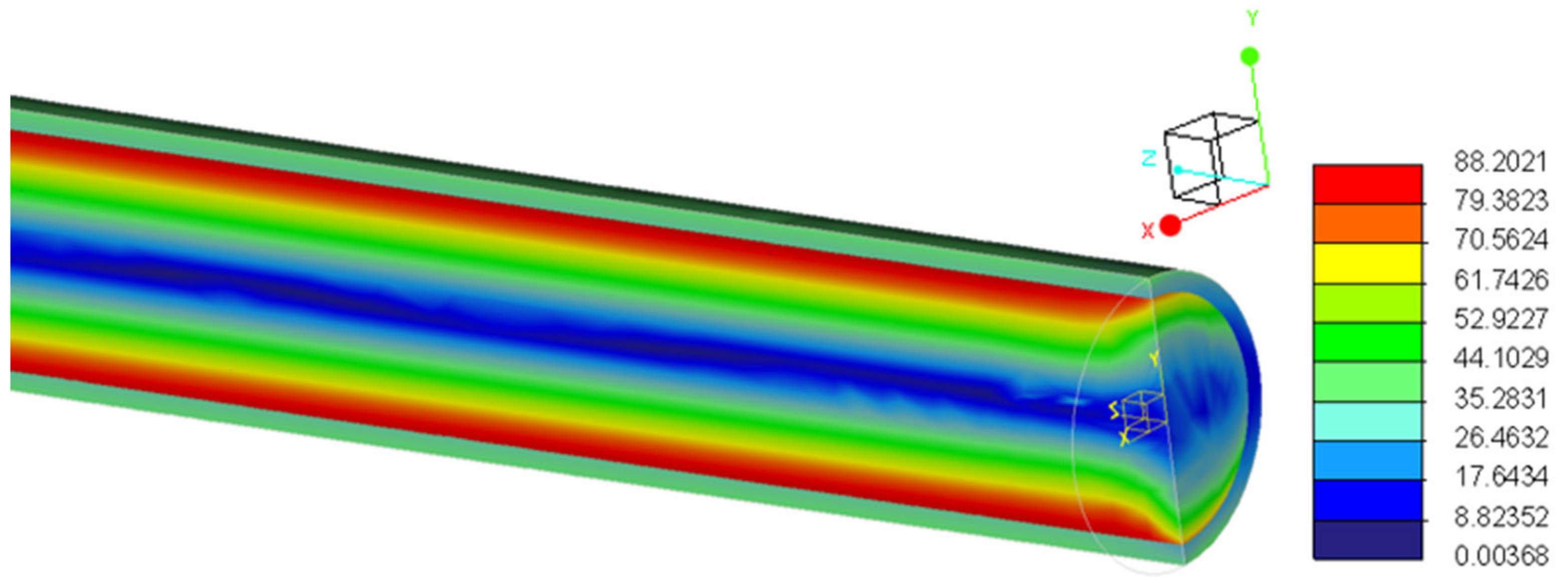

- Spodniak, M.; Semrád, K.; Šmelko, M.; Fozo, L.; Andoga, R.; Draganová, K.; Szabo, S. Estimation of Magnetic Microwire Mechanical Properties by FEM Modeling. Acta Physica Polonica A 2020, 137, 674–676. [Google Scholar] [CrossRef]

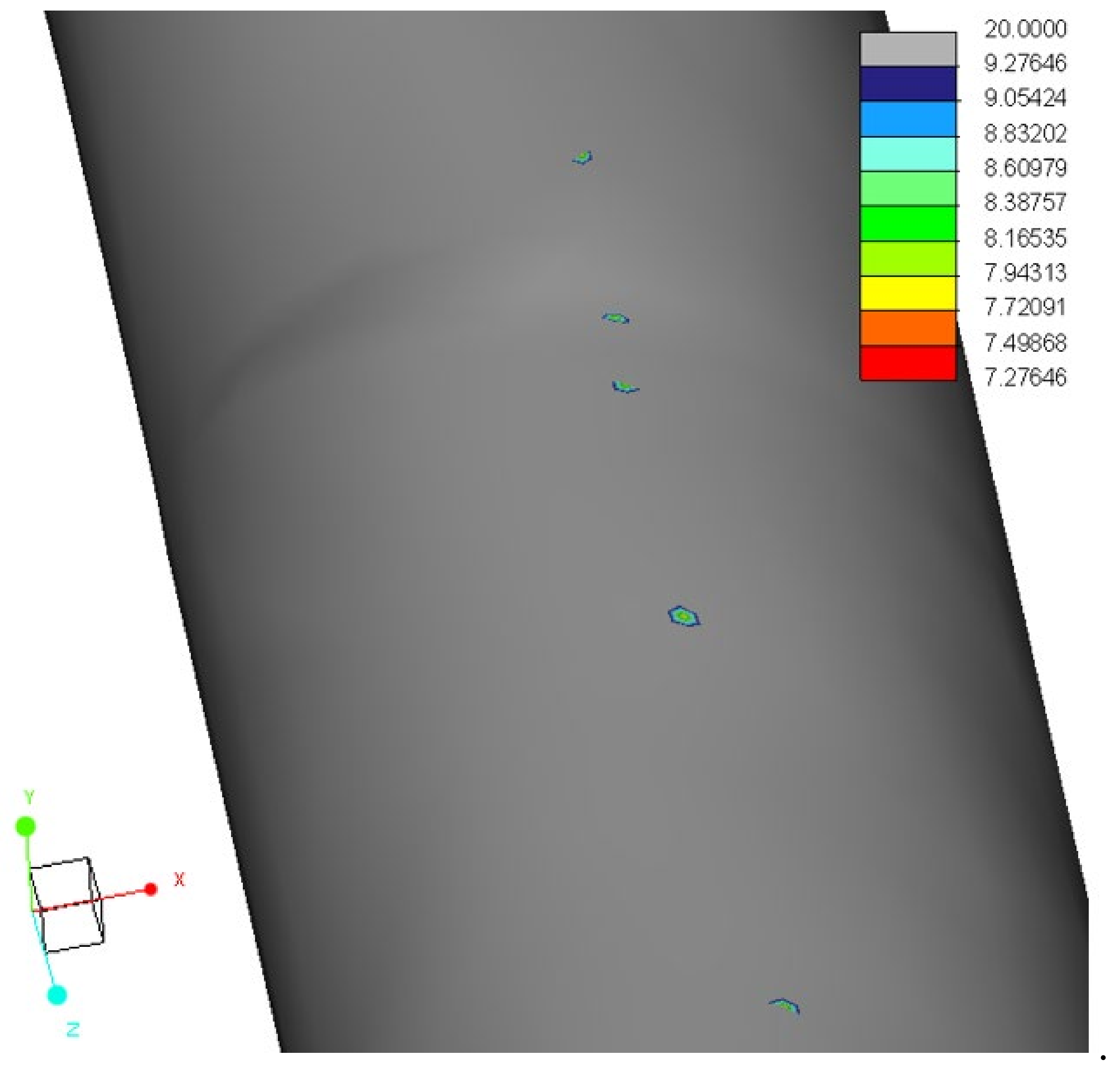

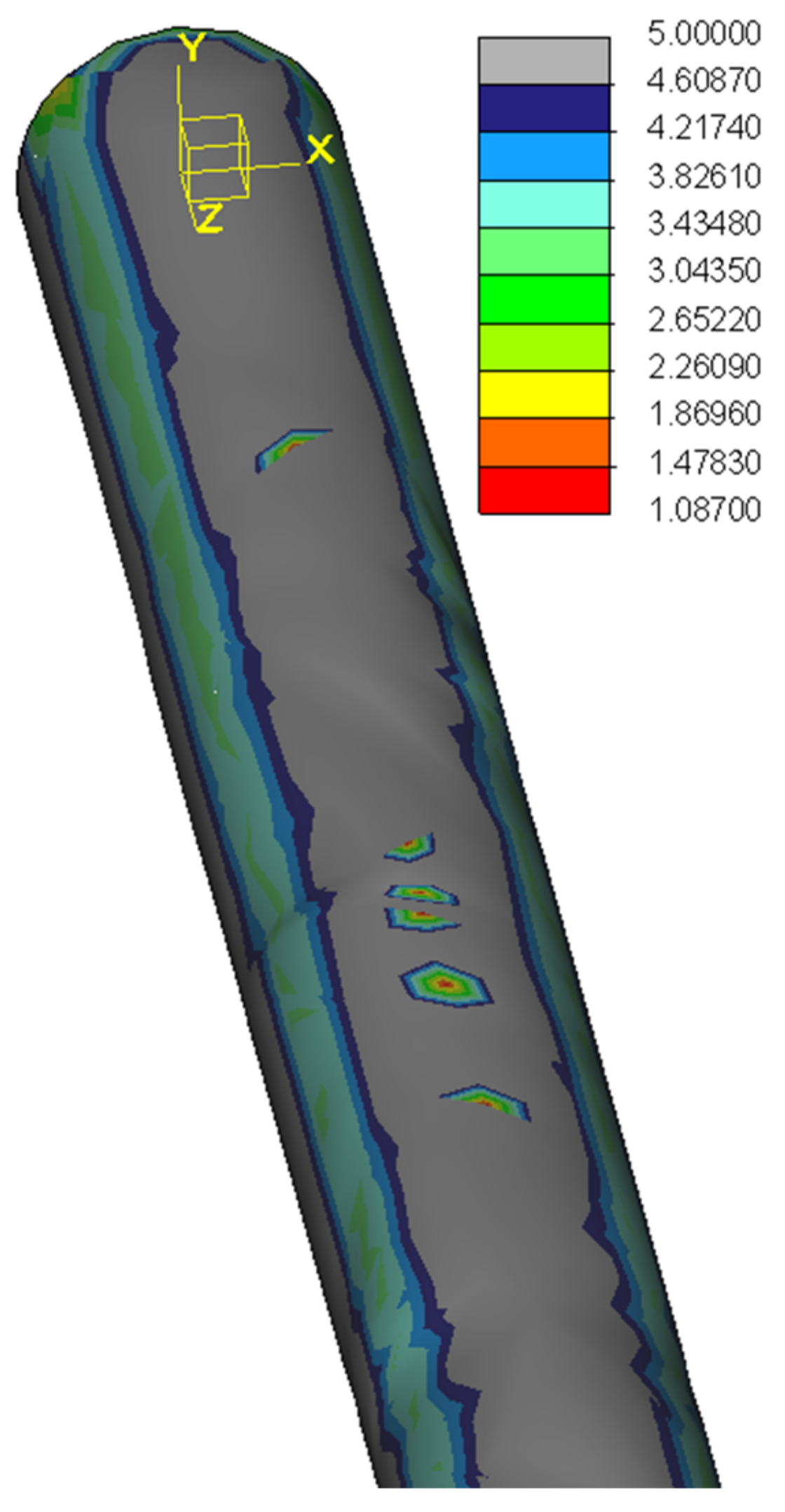

| Microwire Diameter (μm) | Microwire Core Diameter (μm) | Force (N) | Stress von Mises (MPa) | Fatigue Log Life (-) | Number of Zero-Peak Cycles (-) | Fatigue Factor of Safety (-) |

|---|---|---|---|---|---|---|

| 35 | 15 | 1.5 × 10−5 | 44 | 7.27646 | 18,899,921 | 1.08 |

| 70 | 15 | 2.2 × 10−4 | 67 | 5.30038 | 199,700 | 0.5 |

| 35 | 30 | 3 × 10−5 | 88 | 7.12418 | 13,310,059 | 1.04 |

| 70 | 30 | 2.5 × 10−4 | 92 | 5.19756 | 157,601 | 0.5 |

| Microwire Length (mm) | Microwire Diameter (μm) | Microwire Core Diameter (μm) | Force (N) | Stress von Mises (MPa) | Fatigue Log Life (-) | Number of Zero-Peak Cycles (-) | Fatigue Factor of Safety (-) |

|---|---|---|---|---|---|---|---|

| 20 | 35 | 15 | 1.5 × 10−5 | 44 | 7.27646 | 18,899,921 | 1.08 |

| 10 | 35 | 15 | 3 × 10−5 | 43 | 7.26174 | 18,270,061 | 1.083 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Semrád, K.; Draganová, K. Non-Destructive Testing of Pipe Conveyor Belts Using Glass-Coated Magnetic Microwires. Sustainability 2022, 14, 8536. https://doi.org/10.3390/su14148536

Semrád K, Draganová K. Non-Destructive Testing of Pipe Conveyor Belts Using Glass-Coated Magnetic Microwires. Sustainability. 2022; 14(14):8536. https://doi.org/10.3390/su14148536

Chicago/Turabian StyleSemrád, Karol, and Katarína Draganová. 2022. "Non-Destructive Testing of Pipe Conveyor Belts Using Glass-Coated Magnetic Microwires" Sustainability 14, no. 14: 8536. https://doi.org/10.3390/su14148536

APA StyleSemrád, K., & Draganová, K. (2022). Non-Destructive Testing of Pipe Conveyor Belts Using Glass-Coated Magnetic Microwires. Sustainability, 14(14), 8536. https://doi.org/10.3390/su14148536