1. Introduction

With ever-increasing demand for energy, the energy sources such as oil, natural gas, coal have contributed to meeting the demands since the beginning of the last century. The growth in population and technologic and economic developments suggest that this growth will escalate in the near future [

1,

2]. Currently, the production of energy has a prominent impact on the environment, natural ecosystems, human communities, and many other areas [

3]. Keeping in mind these impacts, many efforts are underway to minimize the consumption of oil, coal, and other non-renewable energy resources. On the other hand, renewable energy systems are becoming the major candidates to meet the energy demand [

4,

5]. The renewable energy systems are cost effective, reliable, and environment friendly as compared to the traditional fossil fuels. For the sustainable energy supply, the renewable energy sources are proven to be proficient and effective solutions. Among all the types of renewable energy systems, wind energy installation has been experiencing a tremendous demand in the past few decades [

6,

7]. It has certain benefits over the other resources for reducing the hydrocarbons for producing electricity.

More than 80% of humanity’s energy need is fulfilled with fossil fuels. However, the world’s reliance on fossil fuels is decreasing and shifting towards clean and green renewable energy. Wind turbines are the best option for clean energy. Placing turbines with expert estimates produces less energy than an optimized layout of turbines. Large difference in energy production can be created by wisely selecting the positions of turbines. This can be done using an optimization algorithm in a computer program.

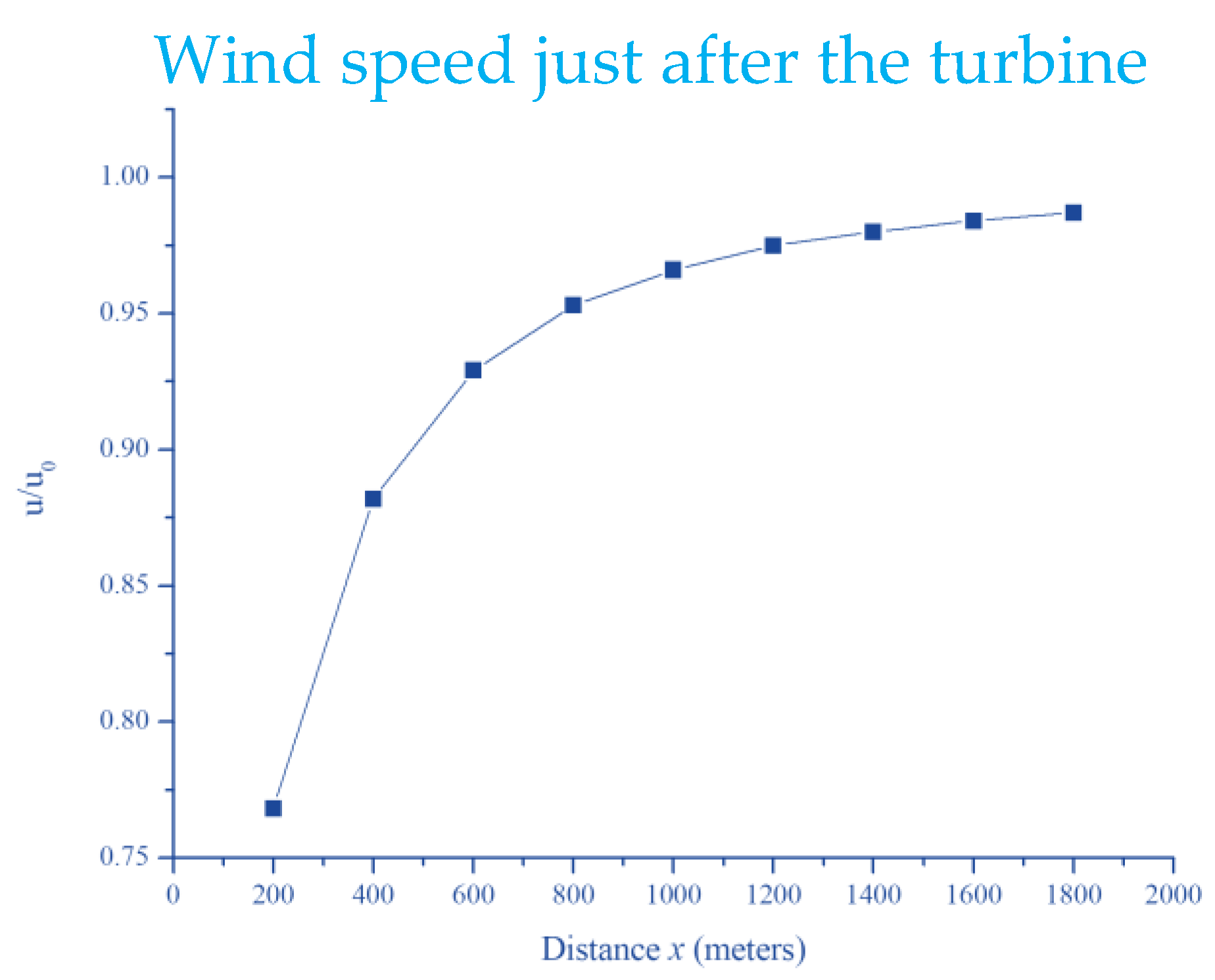

There are certain challenges faced by wind technology, such as the reduction in the wind speed caused by the significant interference of other neighboring turbines, resulting in reduced speed of the turbines and high wake effect, which possibly cause mechanical failure resulting in the increase in requirement of maintenance and decrease in the electricity production. Therefore, there is a need to find the optimal distance between the turbines to reduce the effect of wake generated by the wind turbines. Many studies in the past have proposed a rule that has gained support among the scientific community. The rule states that the turbines should not be placed at a distance less than 5 m rotor diameters to generate a minimum interference among the other turbines to produce the maximum power output [

8,

9,

10]. With continuous development in computer technology, computational intelligence techniques are expanding their application area to the renewable energy resources. These techniques have been very effective in solving complex optimization problems and generating efficient solutions. During the last decade, these techniques have been widely used for the positioning optimization of wind turbines. To place a large number of wind turbines in the wind farm, it is necessary to find the optimal placement of these turbines to obtain the maximum expected power production at a minimized cost. Several studies have been performed to optimize the placement of wind turbines. Mosetti et al. employed the genetic algorithm to find the optimal wind turbine placement in a wind farm [

1]. They used Jensen’s analytical wake model [

11] for modelling the wake effect and their main objective was to minimize the value of cost per unit power. Mosetti et al. produced results for three different scenarios for fixed wind direction at constant speed, but with change in direction, variable wind speed, and variable direction with some preferred directions, respectively. Grady et al. [

2] challenged the results of Mosetti et al. and claimed that the results produced by Mosetti et al. were sub-optimal. They suggested that the sufficient number of generations did not reach the optimum point. Rabia et al. [

9] proposed a method for wind farm layout optimization by using definite point selection and genetic algorithm, which can improve the output power of a wind farm by changing the dimensions of a wind farm with an area size of

. They rotated the square shaped wind farm by 45 degrees towards the uniform direction of the wind and a definite point selection criterion was set in order to face upstream wind [

9]. Several other evolutionary techniques such as viral based algorithm [

12], greedy algorithm [

8], particle swarm optimization algorithm [

13], mixed integer linear programming technique [

14], multi-population genetic algorithm [

15], ant colony algorithm [

16], random and local search algorithm [

17,

18,

19], and many more have been used to find the optimal placement of the wind turbines to maximize the power output while minimizing the cost [

20,

21,

22,

23,

24].

Wind energy presents one of the significant promising renewable energy sources and ranks as the best source of clean energy technology worldwide [

25]. In order to reduce the cost/kW, the L-SHADE algorithm has been used to enhance the performance of the Differential Evolution (DE) process. SHADE is a DE parameter adaptation technique that is based on success history. LSHADE enhances SHADE’s performance by progressively and linearly reducing the population size. Historically, continuous variable optimization has been the principal use of DE [

26,

27]. Wind farm area shape optimization has been performed using newly developed multi-objective evolutionary algorithms [

28,

29]. The placement task of turbines can be seen as a combinatorial optimization problem that requires finding the optimum set of positioning among the available finite set (multi-positioning by discretizing the continuous wind farm) [

30,

31]. If it is necessary to allocate

turbines to

n available placements, then there are

combinations. In this context, the computational complexity increases with increasing

n. Thus, many exhaustive search methodologies and local search techniques such as Monte Carlo simulation and integer programming may fail. Therefore, the meta-heuristics methodologies pose higher searching capabilities in solving complex optimization tasks [

32,

33]. Many researchers have employed them to address the wind farm layout discrete optimization (WFL-DO) problems. Gao et al. [

34,

35] developed the Genetic Algorithm (GA) with many individuals within the population size to improve searching inside the search space and then obtain better output. Additionally, a hybrid GA by Rethore et al. [

36], and Huang [

37,

38] was presented to address these problems. Pookpunt and Ongsakul [

39] proposed a particle swarm optimizer (PSO) with binary formulation to achieve optimal wind turbines for the WFL-DO problem. Chen et al. [

40] implemented the multi-objective GA for optimal wind turbines placement, but they utilized a micro-siting to replace the grid-based placement aspect. Mora et al. [

41] presented an evaluative algorithm to the WFL-DO problem by maximizing the profits of the wind farm. Gonzalez et al. proposed an improved version of the evaluative algorithm, where the optimization process considered the wind farm cost with Mora’s model [

42]. Decomposition based multi-objective evolutionary algorithm for windfarm layout optimization has been implemented by Biswas et al. [

43]. Using an optimally designed parameters including rotor radius, hub height, and rated power, a strategy to reduce the cost of energy (COE) of wind turbines on high-altitude sites has been implemented by Song et al. [

44]. Yang and Hu implemented modified GA based on Boolean code for wind farm layout optimization [

45]. The water cycle algorithm [

46], a novel equilibrium optimizer [

47] for optimal placement of wind turbines, has also been implemented. A teaching–learning based optimization technique [

48] has been implemented for core reload pattern optimization of a research reactor [

49], solving complex constrained optimization problems [

50], unconstrained optimization problems [

51], and constrained mechanical design optimization problems [

52]. Other novel approaches, such as the bat algorithm for numerical optimization [

53] and particle swam optimization with new initialization technique, can also be applied for wind farm optimization [

54,

55]. Based on the previous studies, the teaching–learning based optimization technique has not been implemented to solve problems considered in this study. The effectiveness of the algorithm is checked by comparing the results with other studies and approaches.

The main objectives of this study are:

To check the effectiveness of the multi-objective teaching–learning based optimization technique.

To determine the optimal locations of the wind turbines in a given land area of to achieve the maximum energy production while minimizing the total cost.

To find the optimal layouts along with the optimal number of turbines in a given land area of with minimum fitness evaluation.

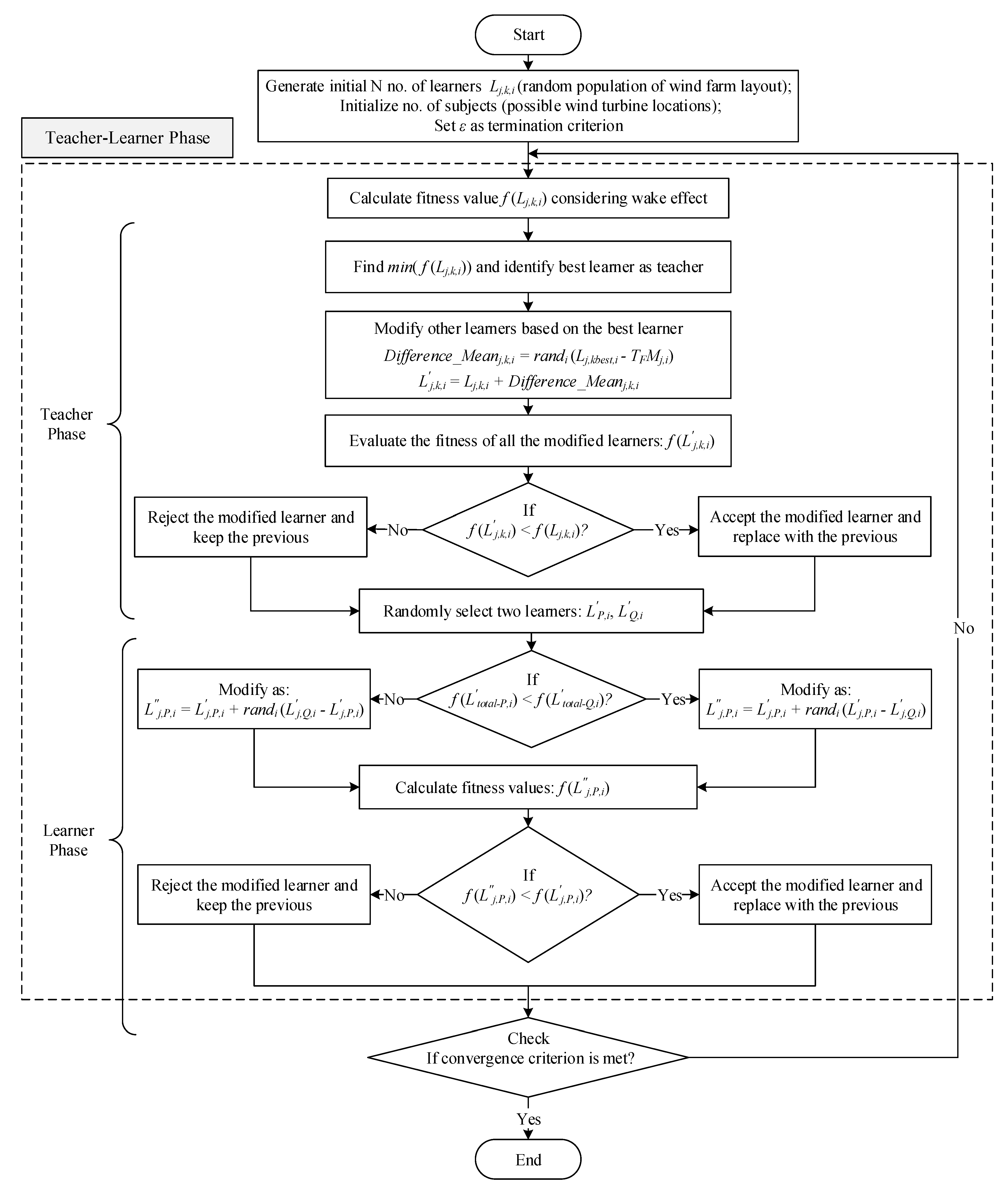

The selection of the algorithm was made due to its observed reliability, accuracy, robustness, less computational time, and consistency as compared to other optimization techniques. The most optimal placement of the turbines is performed for three different scenarios of wind (Scenario-I: fixed wind direction at constant speed, Scenario-II: variable wind direction at constant speed, and Scenario-III: variable wind direction at variable speed). The results obtained for these scenarios are compared with past studies available in the literature. In addition, the concept of elitism is implemented in TLBO. Results of TLBO and elitist-TLBO (ETLBO) are compared with those obtained by other studies for the same discrete optimization problems. The obtained results are observed to be more accurate and advantageous than the others and are discussed in detail in the subsequent sections.

4. Conclusions

This paper presents MO-ETLBO to find the optimal placement of wind turbines in a specified land area of of the wind farm. The wind farm layout optimization is formulated as a multi-objective optimization problem. In this context, a multi-objective version of MO-ETLBO is accomplished to deal with the multi-objective optimization problem. The algorithm is investigated with three different scenarios of wind (Scenario-I: fixed wind direction at constant speed, Scenario-II: variable wind direction and constant speed, and Scenario-II: variable wind direction and variable speed) to find the optimal number of turbines and turbine positioning that maximizes the power production while minimizing the total cost. For Scenario-I, it can be seen that the average power produced by the unit turbine is 499.88 KW/year, which is higher than all the other three studies along with the lowest fitness evaluation of 1.315. For Scenario-II, it can be observed that the average power produced by the unit turbine is 469.83 KW/year, which is higher than all the other studies except Mosetti et al’s. However, the fitness evaluation is 1.5271, which is the lowest as compared to all other studies. For Scenario-III, it can be confirmed that the average power produced by the unit turbine is 839.13 KW/year, which is higher than all the other studies except Mosetti et al’s. However, the fitness evaluation is 0.82517, which is lowest as compared to all other studies. Based on the results obtained for the multi-objective problem with MO-ETLBO, its superiority can be confirmed over the other state-of-the-art algorithms with acceptable levels of economic, profitable, and technical merits. The economic concern is shown through the obtained saving reached by the algorithm. The profitable aspect is achieved by maximizing energy’s total power output and the technical benefit provided by visualizing the farm efficiency. MO-ETLBO results show the superiority over the other algorithms. It can improve the convergence and coverage capabilities while solving the wind farm layout optimization problem for multi-objective aspects. The salient features regarding the implemented methodology can be mentioned as follows:

It has been efficiently implemented to solve the wind farm layout discrete optimization problem by considering the multiple objectives optimization.

The MO-ETLBO provides superior and promising results for a single scenario of the WFL-DO problem.

It can achieve a better convergence and well-distributed set of non-dominated solutions when dealing with multiple objectives of the wind farm layout discrete optimization problem. These characteristics are useful and can provide reasonable layouts for the decision-maker to extract the best compromise solution or operating solution from the available finite alternatives based on decision-making regulations or total cost obligations.

It can be concluded that the present study can provide a twofold contribution. The first one is incorporating the pattern search technique, and the second one is caused by simultaneously considering many objectives of the wind farm layout optimization problem.

For future work, the optimization results of different nonlinear wake models can be investigated. Additionally, the realistic shapes of wind farms using more recent and sophisticated wake models along with the new formulations of objective function by taking into account the available number of turbines and the available budget must be examined. The effects of the uncertain nature regarding the speed and wind scenarios on the produced power may be worth future research.