Study on the Characteristics of Water Jet Breaking Coal Rock in a Drilling Hole

Abstract

:1. Introduction

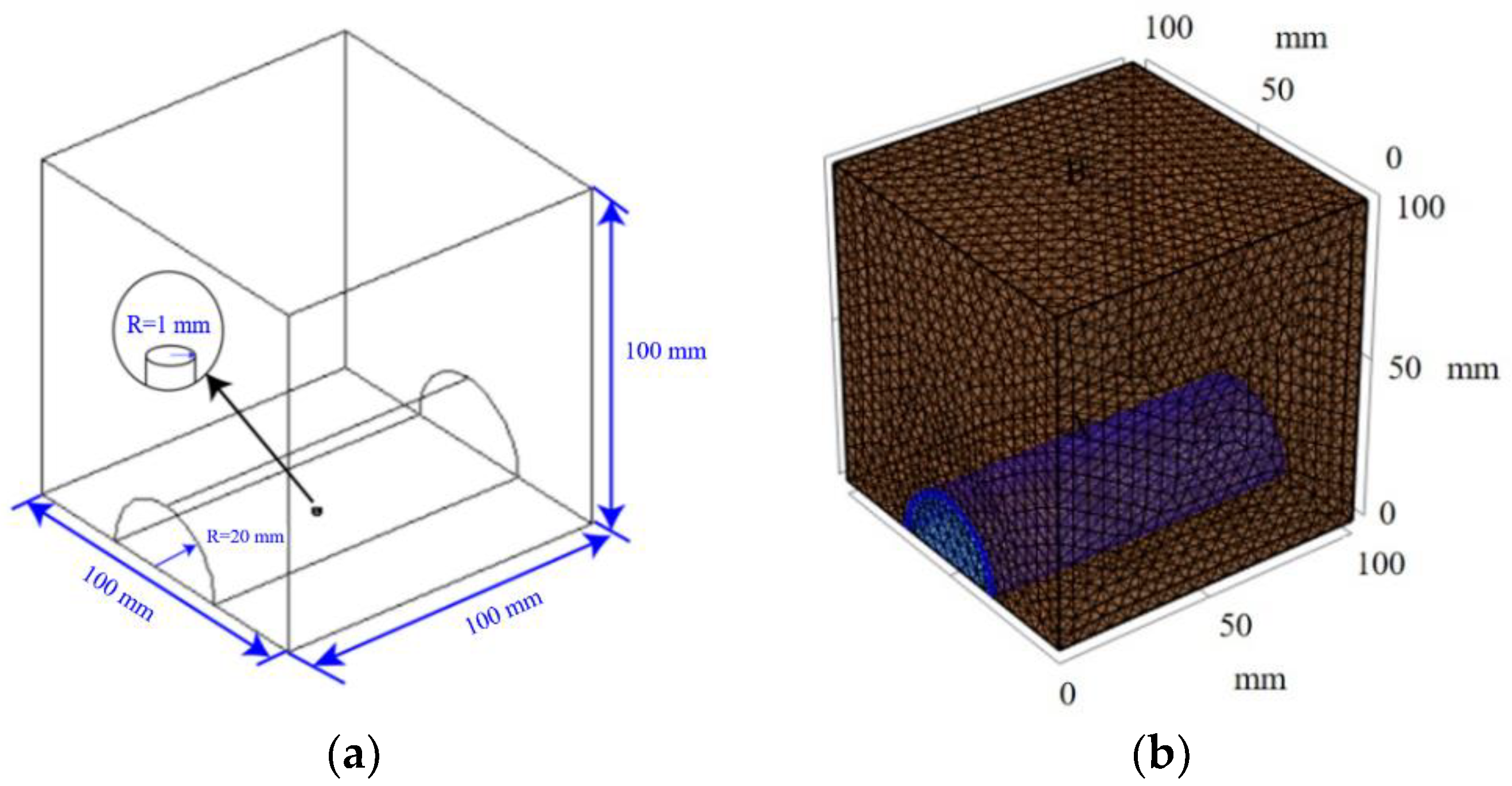

2. Materials and Methods

2.1. Description of Water Jet Impact Test Block

2.2. Characteristics of Water Jet Impact Test Block

- (1)

- The continuity equation is the specific expression form of the law of conservation of mass in fluid mechanics. The fluid adopts the continuum model, and the velocity and density are both continuous and differentiable functions of space coordinates and time, the formula for which is as follows:

- (2)

- The energy equation refers to an equation that reflects the law of conservation of energy including internal energy when considering changes in density, temperature, and internal energy, the formula for which is as follows:

- (3)

- The velocity of the high-pressure water jet is very high, its Reynolds number being far beyond the range of laminar flow. Therefore, the turbulence model should first be selected. In order to make the simulation results closer to reality and more reliable, we select the standard equation, the formula for which is as follows:where is the density of the fluid, ; is the component of the velocity, ; is pressure, ; is the dynamic viscosity,; k is the turbulent kinetic energy,; is the dissipation rate of the turbulent kinetic energy, , and , , and are the empirical constants, the respective values of which are = 1.44, = 1.92, = 1.0 and = 1.3.

3. Results

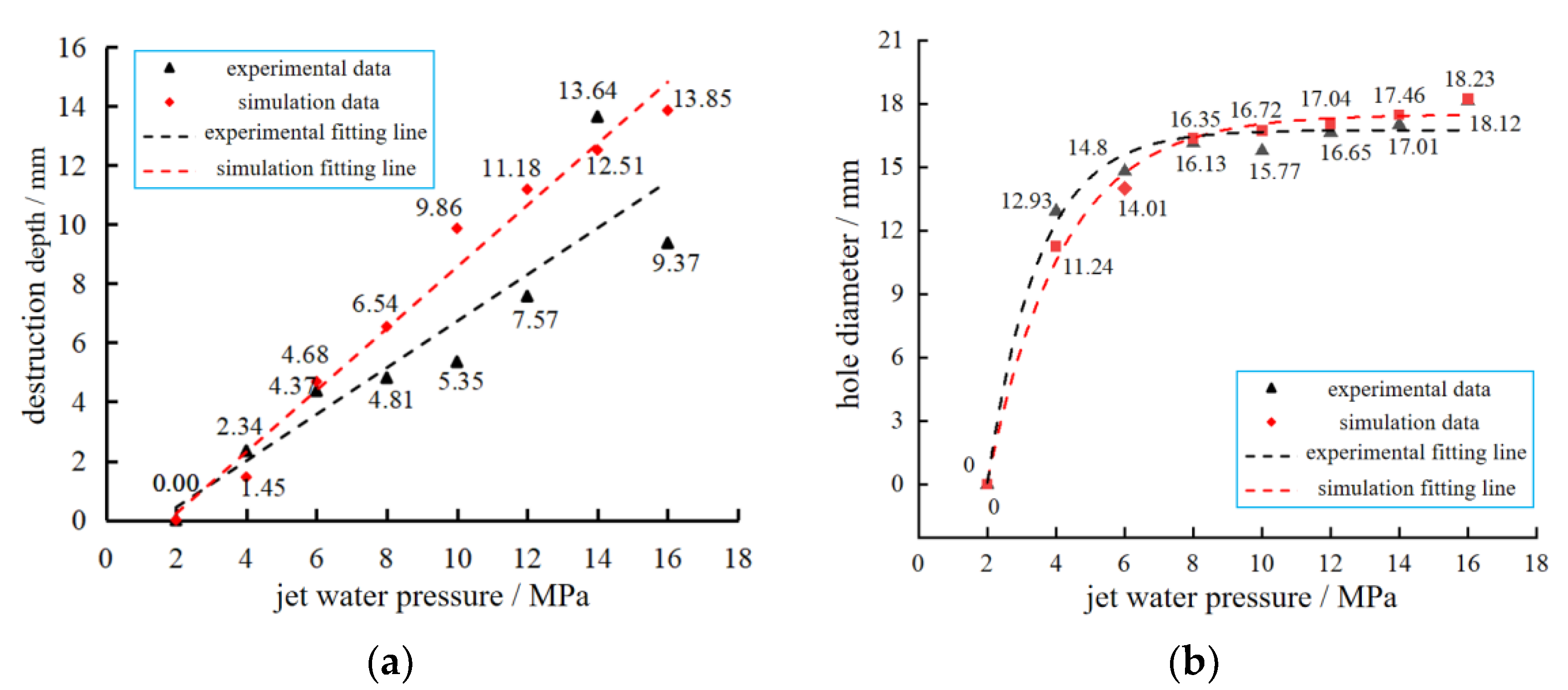

3.1. Model Verification

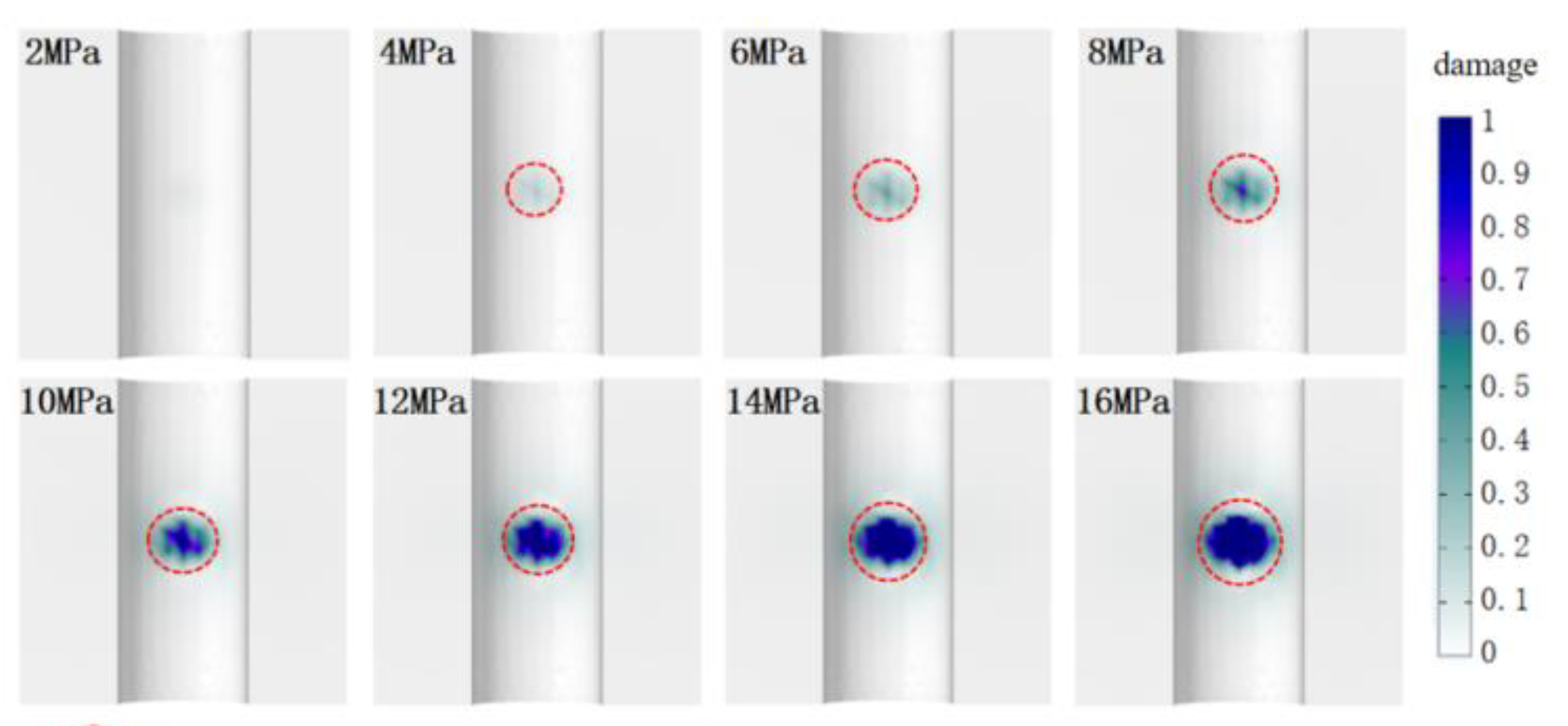

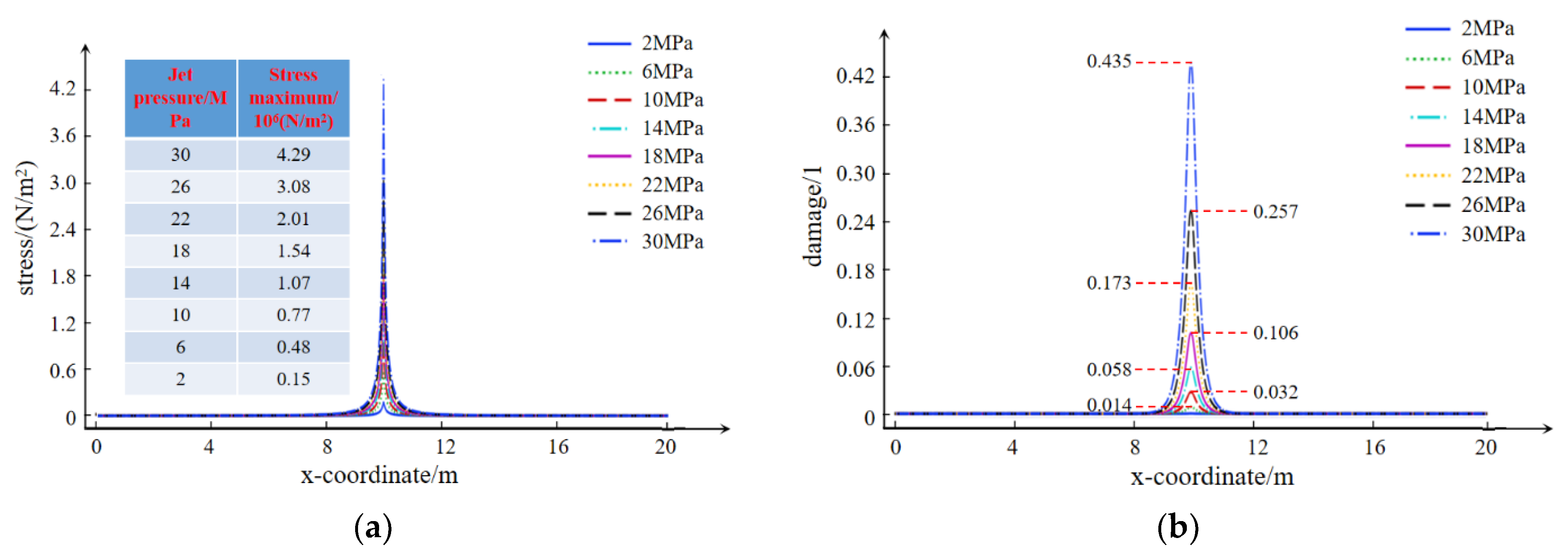

3.1.1. Damage Results of Different Jet Pressure Impacts

3.1.2. Feasibility of the Model

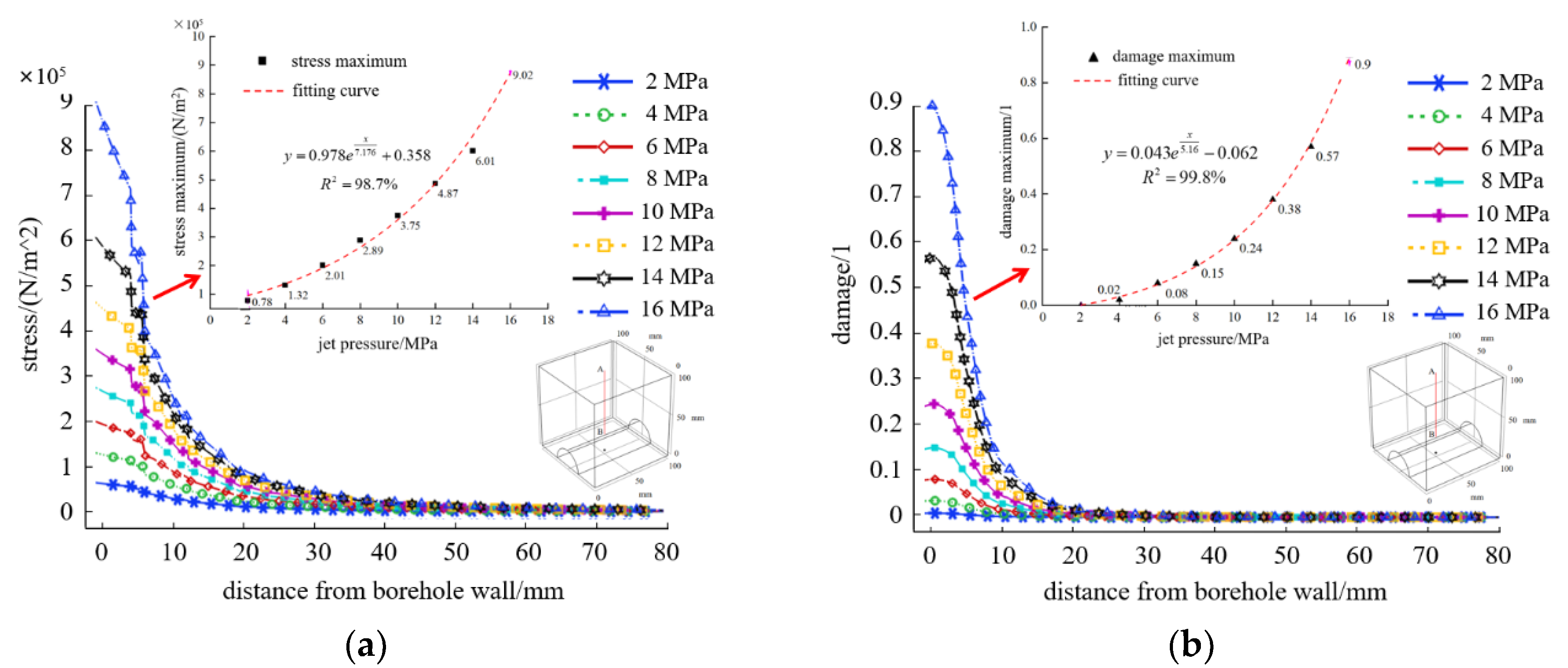

3.2. Simulation Result Analysis

4. Discussion on Influencing Factors

4.1. Water Jet Punching and Damage Evolution Model of Coal Rock

4.2. Simulation Results and Analysis

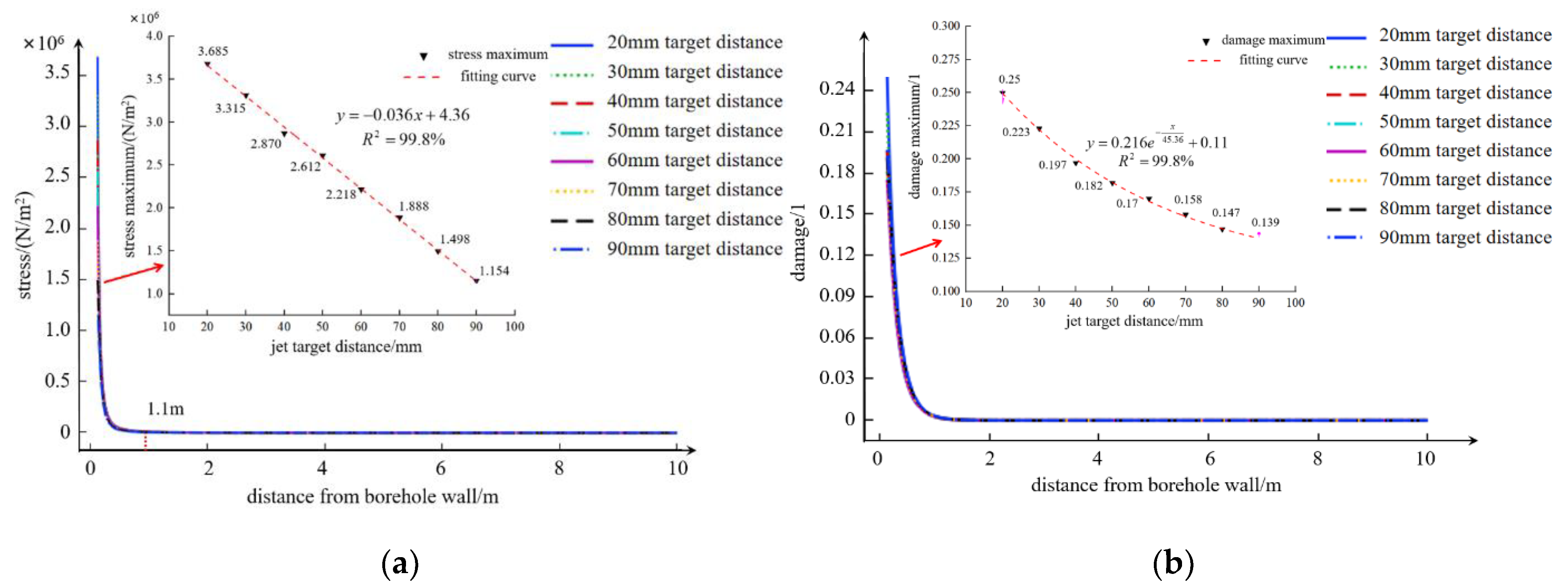

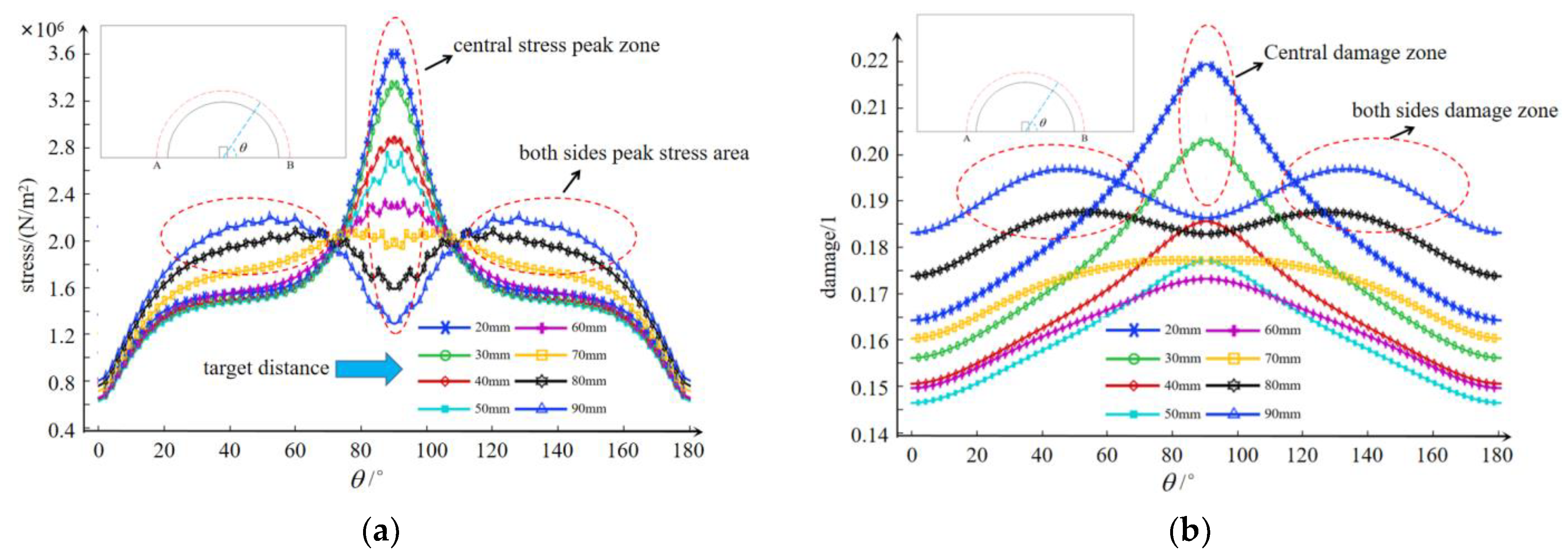

4.2.1. Damage Characteristics of the Coal Rock Impacted by the Target Distance

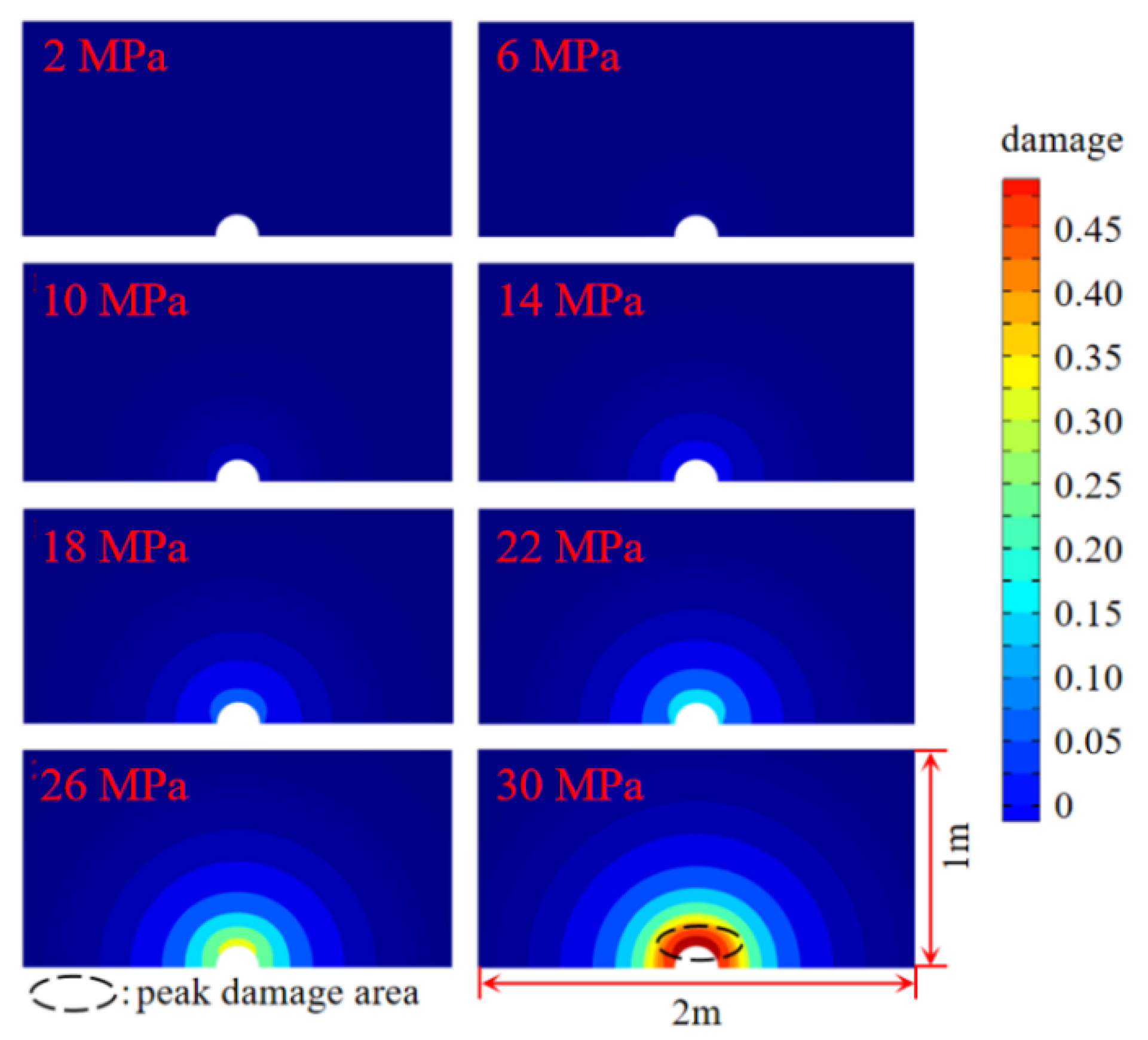

4.2.2. Damage Characteristics of Coal Rock Impacted by Different Water Jet Pressures

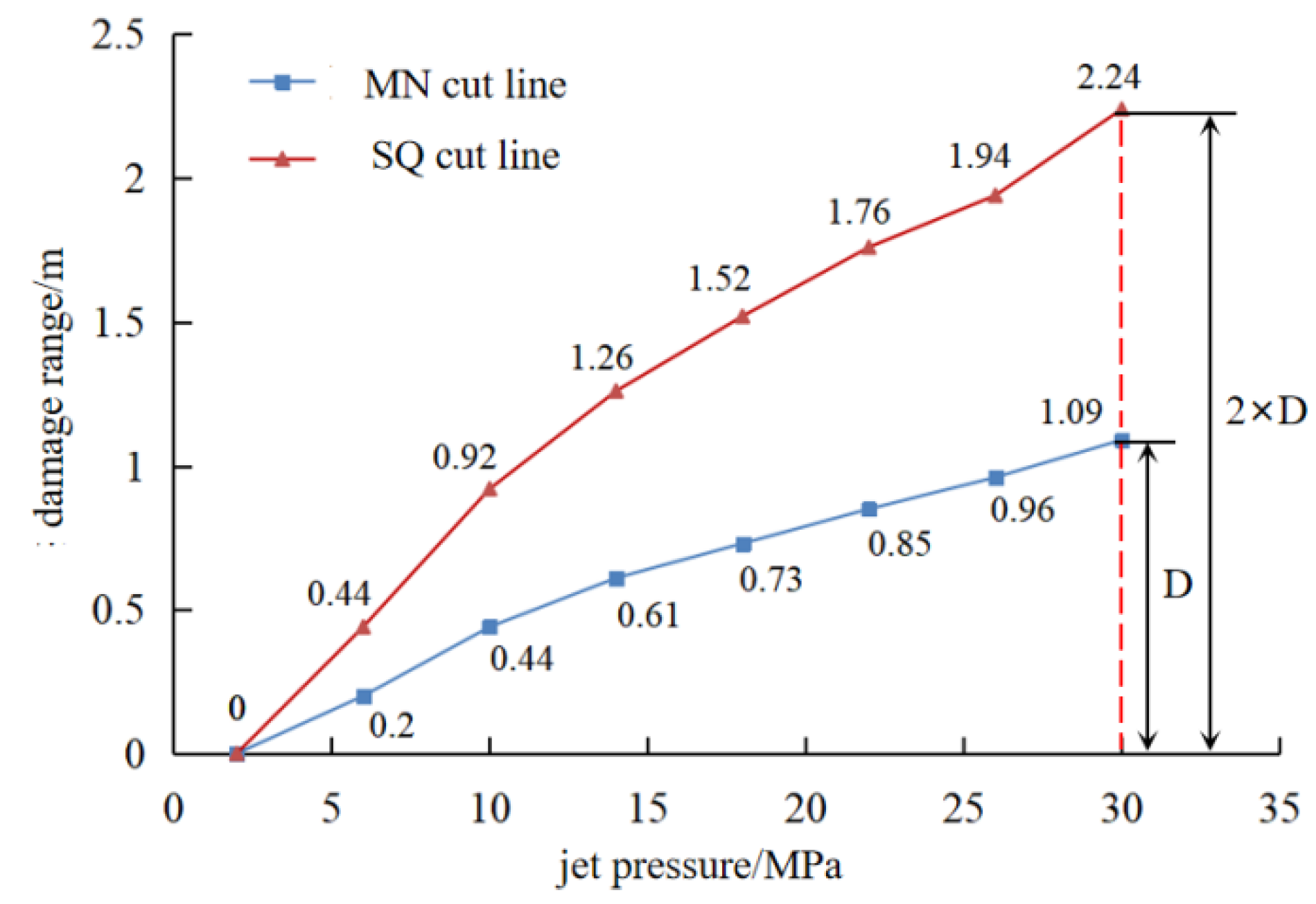

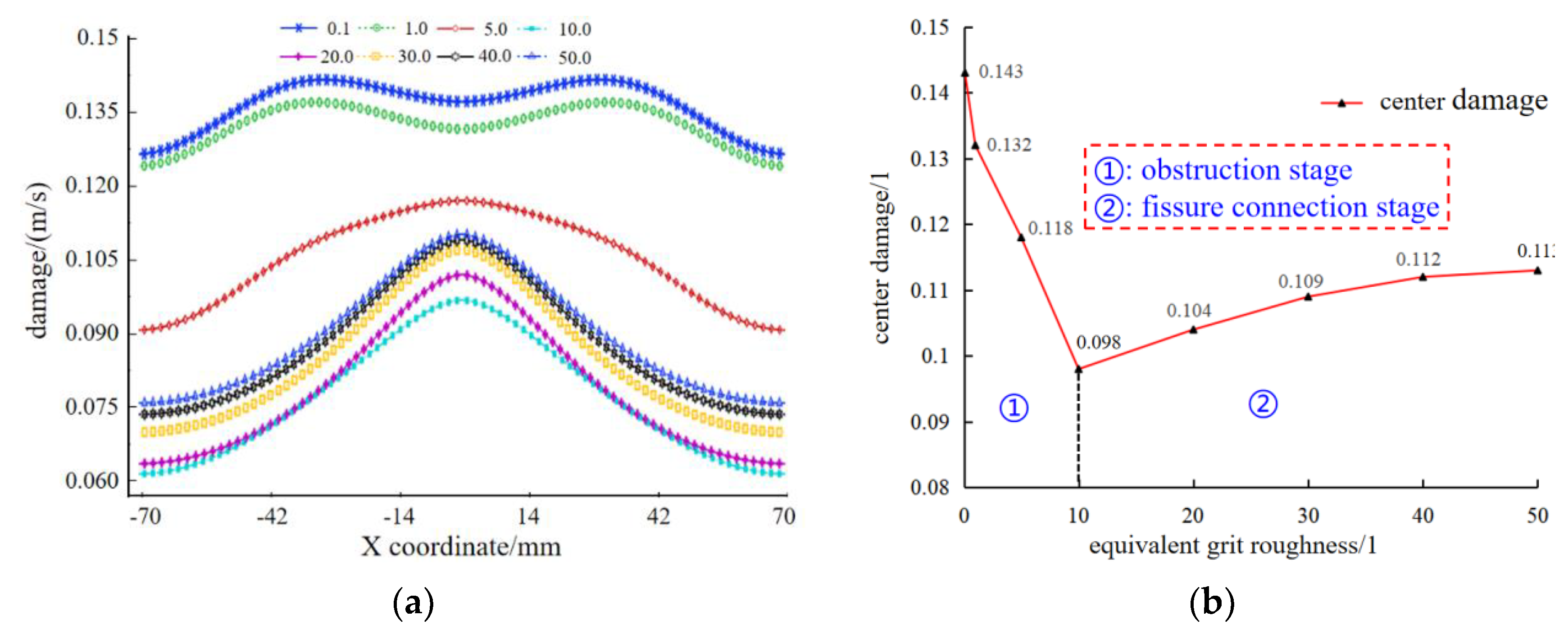

4.2.3. Damage Characteristics of Coal Rock Impacted by Different Wall Roughness

5. Conclusions

- (1)

- The phase-field model of the fracture variation method is used to calculate the phase-field variable through the strain energy density and critical energy release rate, which can effectively indicate the damage and destruction of the coal rock, and the method is shown to be feasible through simulation and experiments. As for water jet impact, the test block must continuously overcome the stress in the coal rock, and the damage degree is positively related to the jet pressure.

- (2)

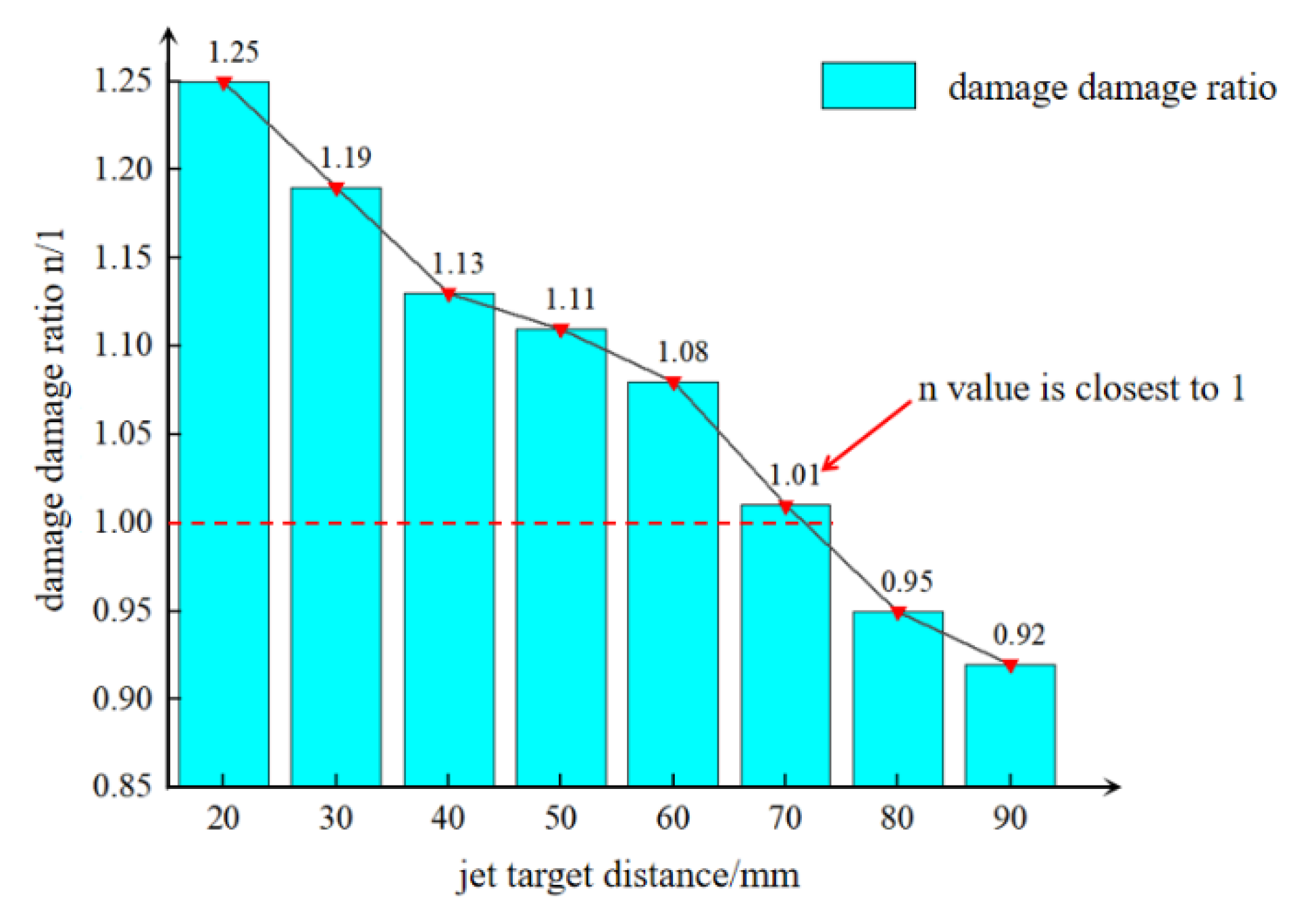

- The impact of the water jet in the borehole will form a central damage destruction zone and two-side damage failure zone. The damage failure ratio n is proposed to characterize the damage degree of coal rock. When n < 1, the two-side damage threshold is greater than the damage threshold at the center. In addition, when the jet target distance is 70 mm, then the damage failure ratio n is closest to 1, and the water jet has the best impact on breaking the coal rock.

- (3)

- The effect of the water jet impacting the coal rock is positively correlated with the jet pressure. When the jet target distance is 70 mm, then the jet pressure of 30 MPa affects the center and both sides of the coal rock. The damage range of the body reaches approximately 1.1 m. In order to achieve a better effect of drilling water jet impacting coal rock, the jet pressure must be increased under the condition of ensuring construction safety, and the jet pressure of 30 MPa has a good impact and coal rock breaking effect.

- (4)

- When a water jet impinges on the wall with roughness, there are two effects: the effect of hindering fluid movement and the effect of promoting fracture connectivity. When the wall roughness is less than 10 mm, the blocking effect is dominant, resulting in a negative correlation between the damage size and the roughness. When the wall roughness exceeds 10 mm, the development of cracks and the connecting effect exceeds the blocking effect, resulting in larger damage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, Y.Y.; Li, R.; Xian, X.F.; Ge, Z.L.; Xia, B.W. Discussion on efficient development of deep coalbed methane by surface directional well + hydraulic slotting pressure relief method. J. China Coal Soc. 2021, 46, 876–884. [Google Scholar]

- Eshraghi, H.; de Queiroz, A.R.; DeCarolis, J.F. US Energy-Related Greenhouse Gas Emissions in the Absence of Federal Climate Policy. Environ. Sci. Technol. 2018, 52, 9595–9604. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stephenson, T.; Valle, J.E.; Riera-Palou, X. Modeling the Relative GHG Emissions of Conventional and Shale Gas Production. Environ. Sci. Technol. 2011, 45, 10757–10764. [Google Scholar] [CrossRef] [PubMed]

- Niu, W.; Nie, W.; Yuan, M.; Bao, Q.; Zhou, W.; Yan, J.; Yu, F.; Liu, C.; Sun, N.; Xue, Q. Study of the microscopic mechanism of lauryl glucoside wetting coal dust: Environmental pollution prevention and control. J. Hazard. Mater. 2021, 412, 125223. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Sa, Z.; Cheng, W.; Zhang, R.; Yang, S. Effects of forced-air volume and suction region on the migration and dust suppression of air curtain during fully mechanized tunneling process. Process Saf. Environ. Prot. 2021, 145, 222–235. [Google Scholar] [CrossRef]

- Lin, B.-Q.; Wu, H.-J.; Zhang, L.-J.; Lu, H.-L.; Zhang, H.-B.; Meng, F.-W. Integrative outburst prevention technique of high-pressure jet of abrasive drilling slotting. Procedia Earth Planet. Sci. 2009, 1, 27–34. [Google Scholar] [CrossRef] [Green Version]

- Song, D.; Wang, E.; Liu, Z.; Liu, X.; Shen, R. Numerical simulation of rock-burst relief and prevention by water-jet cutting. Int. J. Rock Mech. Min. Sci. 2014, 70, 318–331. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, F.; Liu, X.; Ao, X. On the failure pattern of sandstone impacted by high-velocity water jet. Int. J. Impact Eng. 2015, 76, 67–74. [Google Scholar] [CrossRef]

- Xue, Y.Z.; Si, H.; Yang, Z.L.; Xu, D.Y. Microscopic damage field in coal induced by water jets. J. Loss Prev. Process Ind. 2018, 56, 300–315. [Google Scholar] [CrossRef]

- Merzlyakov, V.G.; Baftalovsky, V.E.; Baydinov, V.N. On using hydraulic technology for mechanization of mining operations. Min. Equip. Electromech. 2010, 6, 2–6. [Google Scholar]

- Wang, K.; Li, B.; Wei, J.P.; Li, P. Change regulation of coal seam permeability around hydraulic flushing borehole. J. Min. Saf. Eng. 2013, 30, 778–784. [Google Scholar]

- Zhang, B.F.; Liu, Z.Y. Hydraulic punching technology optimization in “three-soft” severe outburst coal seam. Saf. Coal Mines 2013, 44, 141–143. [Google Scholar]

- Lin, B.Q.; Zhang, Q.Z.; Shen, C.M.; Yang, W. Permeability-increasing mechanism of network slotting boreholes and application in crossing borehole gas drainage. J. Coal. 2012, 37, 1425–1430. [Google Scholar]

- Chang, Z.; Zhao, Y.S.; Hu, Y.Q.; Yang, D. Theoretic and experimental studies on seepage law of single fracture under 3D stresses. Chin. J. Rock Mech. Eng. 2004, 23, 620–624. [Google Scholar]

- Liu, M.J.; Li, Z.F.; Liu, Y.; Hao, F.C. Research of the protrusion-dispelling mechanism of hydraulic cutting measures. Coal 2006, 15, 1–2. [Google Scholar]

- Bai, X.H.; Zhang, Z.M.; Zhang, Y.G. Analysis on order of importance of factors influencing hydraulic kerfing, coal breaking and winning efficiencies using AHP method. Hydraul. Coal Min. Pipeline Transp. 2008, 4, 1–4. [Google Scholar]

- Gao, Y.B. Research on the Mechanism of Permeability Enhancement Based on Breaking Coal-Rock by Dynamic Impact of Water Jet in Boreholes and Its Application on Gas Extraction. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2016. [Google Scholar]

- Lu, Y.; Liu, Y.; Li, X.; Kang, Y. A new method of drilling long boreholes in low permeability coal by improving its permeability. Int. J. Coal Geol. 2010, 84, 94–102. [Google Scholar] [CrossRef]

- Shen, T.F.; Gu, S.T.; Li, R.D.; Xiao, Z.M. Distribution law and influencing factors of elastic strain energy at coal thickness change. Coal Mine Saf. 2015, 46, 187–189. [Google Scholar]

- Zuo, B.C.; Chen, C.X.; Liu, C.C.; Shen, Q.; Xiao, G.F.; Liu, X.W. Experimental study on similar materials. Geotech. Mech. 2004, 25, 1805–1808. [Google Scholar]

- Hao, Z.Y. Study on Pressure Relief and Permeability Enhancement Mechanism and Application of High Pressure Water Jet in Soft and Hard Composite Coal Seam. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2020. [Google Scholar]

- Zhao, J.; Guo, D. Cracking mechanism of coal under high-pressure water jet and its applications for enhanced coalbed methane drainage. Arab. J. Geosci. 2018, 11, 427. [Google Scholar] [CrossRef]

| Density/(kg/m3) | Elastic Modulus/GPa | Compressive Strength/MPa | Tensile Strength/MPa | Angle of Internal Friction/° | Cohesion/MPa |

|---|---|---|---|---|---|

| 1183 | 1.663 | 2.697 | 0.637 | 29.3 | 0.582 |

| Density/(kg/m3) | Elastic Modulus/GPa | Compressive Strength/MPa | Tensile Strength/MPa | Angle of Internal Friction/° | Cohesion/MPa |

|---|---|---|---|---|---|

| 1467 | 1.455 | 2.208 | 0.580 | 26.3 | 0.625 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Han, P.; Wang, F.; Cao, J.; Zhang, S. Study on the Characteristics of Water Jet Breaking Coal Rock in a Drilling Hole. Sustainability 2022, 14, 8258. https://doi.org/10.3390/su14148258

Gao Y, Han P, Wang F, Cao J, Zhang S. Study on the Characteristics of Water Jet Breaking Coal Rock in a Drilling Hole. Sustainability. 2022; 14(14):8258. https://doi.org/10.3390/su14148258

Chicago/Turabian StyleGao, Yabin, Peizhuang Han, Fei Wang, Jing Cao, and Shaoqi Zhang. 2022. "Study on the Characteristics of Water Jet Breaking Coal Rock in a Drilling Hole" Sustainability 14, no. 14: 8258. https://doi.org/10.3390/su14148258

APA StyleGao, Y., Han, P., Wang, F., Cao, J., & Zhang, S. (2022). Study on the Characteristics of Water Jet Breaking Coal Rock in a Drilling Hole. Sustainability, 14(14), 8258. https://doi.org/10.3390/su14148258