Literature Review by Scientometric Methods on the Impact of the Circular Economy on Sustainable Industrial Products

Abstract

:1. Introduction

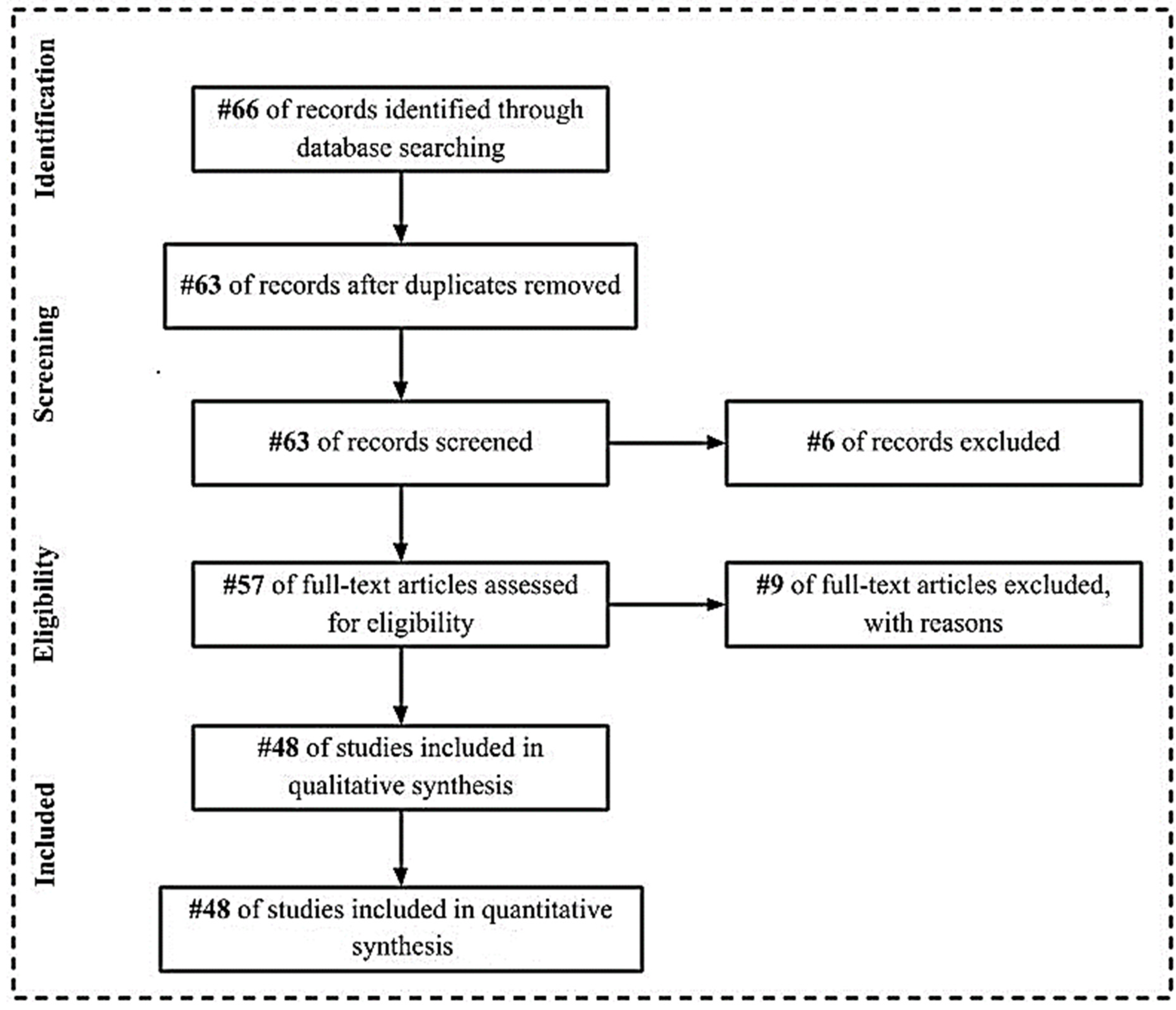

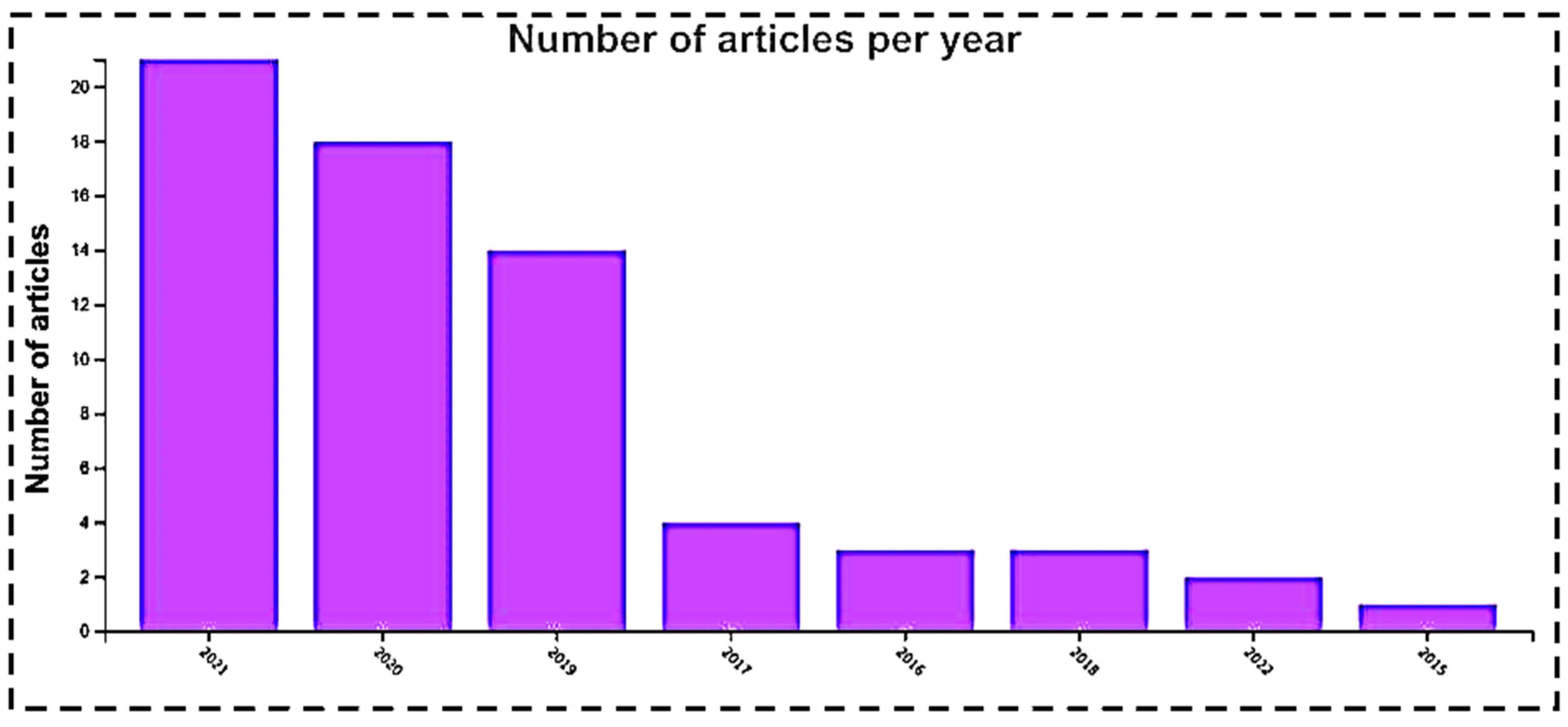

2. Research Method

2.1. Literature Review by Scientometric Methods

- identification of all articles;

- examination of relevant articles;

- eligibility assessment;

- inclusion/exclusion decision.

2.2. Results Analysis

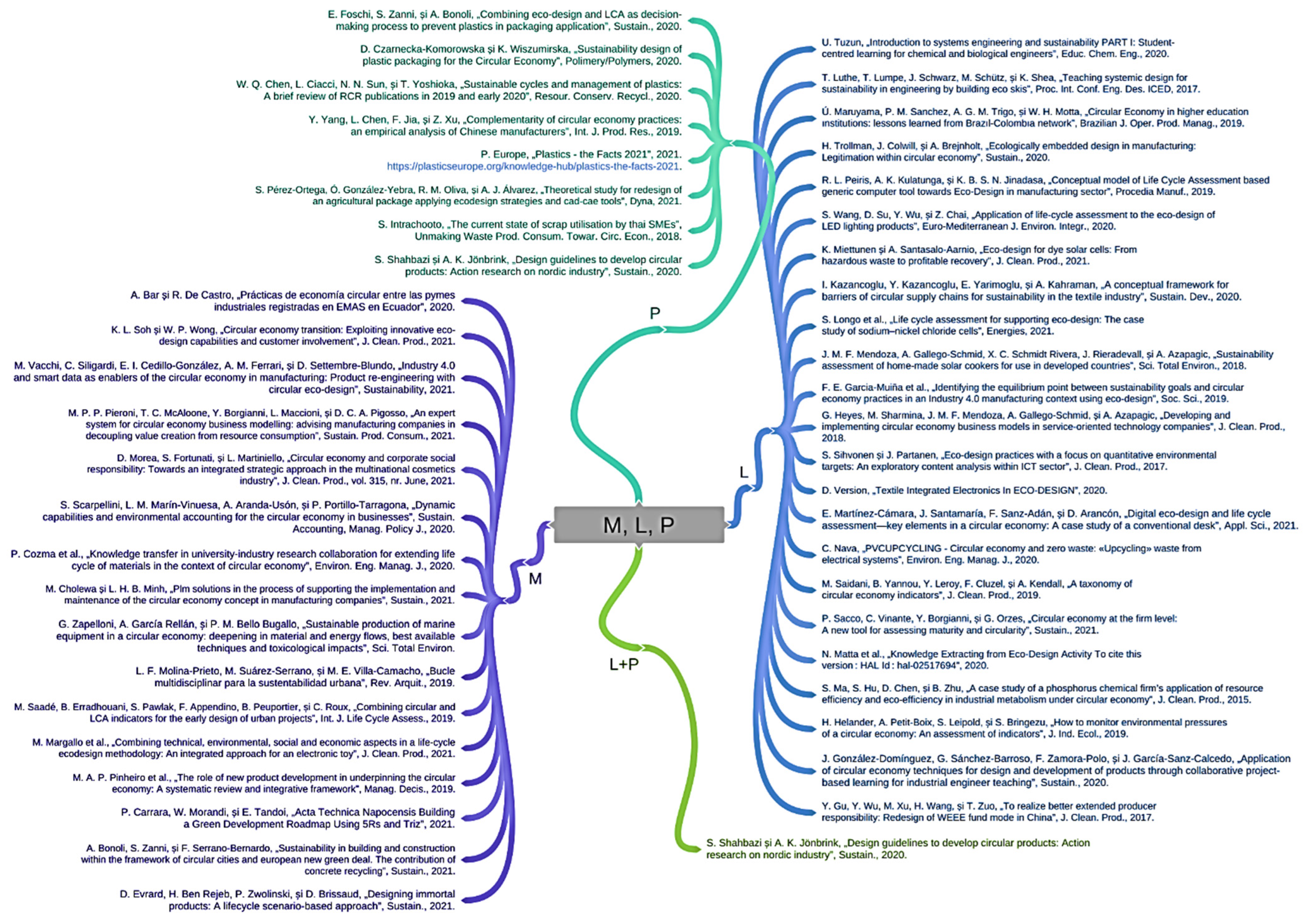

2.2.1. Management—M

- (a)

- material and energy flow analysis to identify the process’s improvable flows;

- (b)

- best available techniques analysis to suggest the most appropriate techniques to enhance those improvable flows;

- (c)

- impact analysis to analyze and compare the impacts on persons and ecosystems.

2.2.2. Packing—P

2.2.3. Learning—L

- (a)

- The “reinvent” method is connected to paradigm shifts in which physical objects become obsolete by performing the same purpose, which is typically activated by fundamentally different products and/or technology.

- (b)

- The “rethink and reconfigure” method is concerned with business model innovation, function, and value delivery to the market, and how customers may use, engage with, and experience the goods.

- (c)

- The “restore, reduce, and avoid” technique is related to traditional supply chains (take, make, use, and logistics) and strives to decrease excess consumption, enhance efficiency, and extend product life.

- (d)

- The “recirculate parts and products” method refers to the end-of-life and closing-the-loop phases when the analyzed components and products can still be fixed, remanufactured, and reused.

- (e)

- The “recirculate material” strategy focuses on recirculating materials that can be recycled and reused.

3. Discussion

3.1. Management—M

- (a)

- material and energy flow analysis to identify the process’s improvable flows;

- (b)

- best available techniques analysis to suggest the most appropriate techniques to enhance those improvable flows;

- (c)

- impact analysis to analyze and compare the impacts on persons and ecosystems.

3.2. Packing—P

3.3. Learning—L

- Reinvent strategy;

- Rethink and reconfigure strategy;

- Restore, reduce, and avoid strategy;

- Recirculate parts and products strategy;

- Recirculate material strategy.

4. Conclusions

- Reinvention;

- Rethinking and reconfiguring;

- Restoration, reduction, and avoidance;

- Recirculation of parts and products;

- Recirculation of materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| No. | Authors | Title | Ref. | Criteria for Exclusion |

|---|---|---|---|---|

| 1. | S. Sehnem, A. de Queiroz, S. Pereira et al. | Circular economy and innovation: A look from the perspective of organizational capabilities | [56] | Research focuses on tools and mechanisms that allow the creation of business models based on the premises of the CE. |

| 2. | M. Aguiar, J. Mesa, D. Jugend et al. | Circular product design: strategies, challenges and relationships with new product development | [57] | It addresses aspects of circular design for new products, but it is not clear what kind of products they refer to. |

| 3. | N. Bocken, L. Strupeit, K. Whalen et al. | A Review and Evaluation of Circular Business Model Innovation Tools | [58] | Although it complies with the established criteria, the procedures by which the operationalization stage can be replicated are missing. |

| 4. | M. Garcia, A. Alonso, M. Tello et al. | Identifying agri-food research priorities for Spain—2017 results | [59] | It is not the object of study of this work, the subject being from the food area. |

| 5. | P. Jiang, E. Dieckmann, J. Han et al. | A Bibliometric Review of Sustainable Product Design | [60] | The authors offer four eco-design directions, but there are no specified procedures by which they can be adapted to various applications. |

| 6. | F. Eleonore, P. Tamburrini, M. Franca | Designing Major Appliances: A Decision Support Model | [61] | The redesign criteria restrict the range of products to which it could be applied. |

| 7. | S. Sihvonen, J. Partanen | Implementing environmental considerations within product development practices: a survey on employees’ perspectives | [62] | It is not clear how they investigated product development practices based on employee perceptions. |

| 8. | J. Payet | Assessment of Carbon Footprint for the Textile Sector in France | [63] | It is not the subject of study of this work, the authors address the carbon footprint of household clothes and underwear. |

| 9. | M. Watkins, J. Casamayor, M. Ramirez et al. | Sustainable Product Design Education: Current Practice | [64] | The research fits very well on the criterion of “Management,” but the geographical area studied is limited to confirm the application of learning methods. |

| 10. | J. Albaek, S. Shahbazi, T. McAloone et al. | Circularity Evaluation of Alternative Concepts During Early Product Design and Development | [65] | It does not refer to what kind of products the tool for evaluating the circularity of a product has been applied. |

| 11. | M. Roffeis, J. Almeida, M. Wakefield et al. | Life Cycle Inventory Analysis of Prospective Insect Based Feed Production in West Africa | [66] | It is not the object of study of this work, the subject being from the food area. |

| 12. | M. Bukhari, R. Carrasco Gallego, E. Ponce-Cueto | Developing a national programme for textiles and clothing recovery | [67] | It is not the subject of study of this work, the authors approaching the management of clothing and textiles in the CE sphere. |

| 13. | F. Aran-Ais, C. Ruzafa-silvestre, M. Carbonell-Blasco et al. | Sustainable adhesives and adhesion processes for the footwear industry | [68] | It is not the subject of study of this paper, the authors addressing aspects of the CE for the manufacture of shoes. |

| 14. | D. Jugend, P. Fiorini, M. Pinheiro et al. | Building circular products in an emerging economy: An Initial Exploration Regarding Practices, Drivers and Barriers Case studies of new product development from medium and large Brazilian companies | [69] | The case study for the three companies is too small to validate the application of CE practices in NPD. |

| 15. | C. Chaudron, M. Faucher, L. Bazinet et al. | The cost is not enough—An alternative eco-efficiency approach applied to cranberry de-acidification | [70] | It is not the object of study of this work, the subject being from the food area. |

| 16. | R. Agrawal, D. Vonodh | Prioritisation of drivers of sustainable additive manufacturing using best worst method | [71] | It is not clear how the data were collected from 40 drivers, for whom the additive manufacturing method was applied. |

| 17. | F. Brones, E. Zancul, M. Carvalho | Insider action research towards companywide sustainable product innovation: eco-design transition framework | [72] | It is not the subject of study of this work. The research was carried out on a company producing cosmetics. |

| 18. | N. Prioux, R. Ouaret, G. Hetreux et al. | Environmental assessment coupled with machine learning for circular economy | [73] | It is not the subject of study of this work. The case study was applied to the field of pretreatment processes for corn and rice straw. |

References

- Lakatos, E.S.; Crișan, O.A.; Lakatos, D.G.; Bejan, M. Paradigma economiei circulare. o provocare pentru oraşul inteligent. Bul. AGIR 2017, 1, 191–201. [Google Scholar]

- Pacurariu, R.L.; Vatca, S.D.; Lakatos, E.S.; Bacali, L.; Vlad, M. A Critical Review of EU Key Indicators for the Transition to the Circular Economy. Int. J. Environ. Res. Public Health 2021, 18, 8840. [Google Scholar] [CrossRef] [PubMed]

- Walker, A.M.; Opferkuch, K.; Lindgreen, E.R.; Raggi, A.; Simboli, A.; Vermeulen, W.J.; Caeiro, S.; Salomone, R. What Is the Relation between Circular Economy and Sustainability? Answers from Frontrunner Companies Engaged with Circular Economy Practices. Circ. Econ. Sustain. 2021, 1, 1–28. [Google Scholar] [CrossRef]

- Grobe, K. Improved sustainability in WDM transport-network elements. In Proceedings of the 2016 Electronics Goes Green 2016+, Berlin, Germany, 6–9 September 2016. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Willskytt, S. Design of Consumables in a Resource-Efficient Economy—A Literature Review. Sustainability 2021, 13, 1036. [Google Scholar] [CrossRef]

- Pati, D.; Lorusso, L.N. How to write a systematic review of the literature. Health Environ. Res. Des. J. 2018, 11, 15–30. [Google Scholar] [CrossRef] [PubMed]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA Statement for Reporting Systematic Reviews and Meta-Analyses of Studies That Evaluate Health Care Interventions: Explanation and Elaboration. PLoS Med. 2009, 6, e1000100. [Google Scholar] [CrossRef]

- Barón, A.; De Castro, R.; Giménez, G. Circular Economy Practices among Industrial EMAS-Registered SMEs in Spain. Sustainability 2020, 12, 9011. [Google Scholar] [CrossRef]

- Soh, K.L.; Wong, W.P. Circular economy transition: Exploiting innovative eco-design capabilities and customer involvement. J. Clean. Prod. 2021, 320, 128858. [Google Scholar] [CrossRef]

- Vacchi, M.; Siligardi, C.; Cedillo-González, E.I.; Ferrari, A.M.; Settembre-Blundo, D. Industry 4.0 and Smart Data as Enablers of the Circular Economy in Manufacturing: Product Re-Engineering with Circular Eco-Design. Sustainability 2021, 13, 366. [Google Scholar] [CrossRef]

- Pieroni, M.P.; McAloone, T.C.; Borgianni, Y.; Maccioni, L.; Pigosso, D.C. An expert system for circular economy business modelling: Advising manufacturing companies in decoupling value creation from resource consumption. Sustain. Prod. Consum. 2021, 27, 534–550. [Google Scholar] [CrossRef]

- Morea, D.; Fortunati, S.; Martiniello, L. Circular economy and corporate social responsibility: Towards an integrated strategic approach in the multinational cosmetics industry. J. Clean. Prod. 2021, 315, 128232. [Google Scholar] [CrossRef]

- Scarpellini, S.; Marín-Vinuesa, L.M.; Aranda-Usón, A.; Portillo-Tarragona, P. Dynamic capabilities and environmental accounting for the circular economy in businesses. Sustain. Account. Manag. Policy J. 2020, 11, 1129–1158. [Google Scholar] [CrossRef] [Green Version]

- Gavrilescu, M.; Cozma, P.; Smaranda, C.; Comanita, E.-D.; Rosca, M.; Ghinea, C.; Campean, T. Knowledge transfer in university-industry research collaboration for extending life cycle of materials in the context of circular economy. Environ. Eng. Manag. J. 2020, 19, 2097–2112. [Google Scholar] [CrossRef]

- Cholewa, M.; Minh, L.H.B. PLM Solutions in the Process of Supporting the Implementation and Maintenance of the Circular Economy Concept in Manufacturing Companies. Sustainability 2021, 13, 10589. [Google Scholar] [CrossRef]

- Zapelloni, G.; García Rellán, A.; Bugallo, P.M.B. Sustainable production of marine equipment in a circular economy: Deepening in material and energy flows, best available techniques and toxicological impacts. Sci. Total Environ. 2019, 687, 991–1010. [Google Scholar] [CrossRef]

- Molina-Prieto, L.F.; Suárez-Serrano, M.Y.; Villa-Camacho, M.E. Bucle multidisciplinar para la sustentabilidad urbana. Rev. Arquit. 2019, 21, 76–88. [Google Scholar] [CrossRef]

- Saadé, M.; Erradhouani, B.; Pawlak, S.; Appendino, F.; Peuportier, B.; Roux, C. Combining circular and LCA indicators for the early design of urban projects. Int. J. Life Cycle Assess. 2022, 27, 1–19. [Google Scholar] [CrossRef]

- Margallo, M.; Ruiz-Salmón, I.; Laso, J.; Bala, A.; Colomé, R.; Gazulla, C.; Fullana-I-Palmer, P.; Aldaco, R. Combining technical, environmental, social and economic aspects in a life-cycle ecodesign methodology: An integrated approach for an electronic toy. J. Clean. Prod. 2020, 278, 123452. [Google Scholar] [CrossRef]

- Pinheiro, M.A.P.; Seles, B.M.R.P.; De Camargo Fiorini, P.D.; Jugend, D.; Jabbour, A.B.L.D.S.; Da Silva, H.M.R.; Latan, H. The role of new product development in underpinning the circular economy: A systematic review and integrative framework. Manag. Decis. 2019, 57, 840–862. [Google Scholar] [CrossRef]

- Carrara, P.; Morandi, W.; Tandoi, E. Acta Technica Napocensis Building a Green Development Roadmap Using 5Rs and Triz. Acta Tech. Napoc. Ser. Appl. Math. Mech. Eng. 2021, 64, 465–474. [Google Scholar]

- Bonoli, A.; Zanni, S.; Serrano-Bernardo, F. Sustainability in Building and Construction within the Framework of Circular Cities and European New Green Deal. The Contribution of Concrete Recycling. Sustainability 2021, 13, 2139. [Google Scholar] [CrossRef]

- Evrard, D.; Ben Rejeb, H.; Zwolinski, P.; Brissaud, D. Designing Immortal Products: A Lifecycle Scenario-Based Approach. Sustainability 2021, 13, 3574. [Google Scholar] [CrossRef]

- Foschi, E.; Zanni, S.; Bonoli, A. Combining Eco-Design and LCA as Decision-Making Process to Prevent Plastics in Packaging Application. Sustainability 2020, 12, 9738. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Wiszumirska, K. Sustainability design of plastic packaging for the Circular Economy. Polimery 2020, 65, 8–17. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.-Q.; Ciacci, L.; Sun, N.-N.; Yoshioka, T. Sustainable cycles and management of plastics: A brief review of RCR publications in 2019 and early 2020. Resour. Conserv. Recycl. 2020, 159, 104822. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, L.; Jia, F.; Xu, Z. Complementarity of circular economy practices: An empirical analysis of Chinese manufacturers. Int. J. Prod. Res. 2019, 57, 6369–6384. [Google Scholar] [CrossRef]

- Plastics—the Facts 2021, by Europe Plastics. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021/ (accessed on 14 February 2022).

- Pérez-Ortega, S.; González-Yebra, O.; Oliva, R.; Martínez, A.J. Theoretical study for redesign of an agricultural package applying ecodesign strategies and cad/cae tools. DYNA 2021, 96, 435–440. [Google Scholar] [CrossRef]

- Intrachooto, S. Chapter 12 The Current State of Scrap Utilisation by Thai SMEs. In Unmaking Waste in Production and Consumption: Towards the Circular Economy; Emerald Publishing Limited: Bingley, UK, 2018; pp. 213–223. [Google Scholar] [CrossRef]

- Shahbazi, S.; Jönbrink, A.K. Design Guidelines to Develop Circular Products: Action Research on Nordic Industry. Sustainability 2020, 12, 3679. [Google Scholar] [CrossRef]

- Tuzun, U. Introduction to systems engineering and sustainability PART I: Student-centred learning for chemical and biological engineers. Educ. Chem. Eng. 2020, 31, 85–93. [Google Scholar] [CrossRef]

- Luthe, T.; Lumpe, T.; Schwarz, J.; Schütz, M.; Shea, K. Teaching systemic design for sustainability in engineering by building eco skis. In Proceedings of the 21st International Conference on Engineering Design (ICED 17) Vol 1: Resource Sensitive Design, Design Research Applications and Case Studies, Vancouver, BC, Canada, 21–25 August 2017; Volume 1, pp. 189–198. [Google Scholar]

- Maruyama, Ú.; Sanchez, P.M.; Trigo, A.G.M.; Motta, W.H. Circular Economy in higher education ınstitutions: Lessons learned from Brazıl-Colombıa network. Braz. J. Oper. Prod. Manag. 2019, 16, 88–95. [Google Scholar] [CrossRef]

- Trollman, H.; Colwill, J.; Brejnholt, A. Ecologically Embedded Design in Manufacturing: Legitimation within Circular Economy. Sustainability 2020, 12, 4261. [Google Scholar] [CrossRef]

- Peiris, R.; Kulatunga, A.; Jinadasa, K. Conceptual model of Life Cycle Assessment based generic computer tool towards Eco-Design in manufacturing sector. Procedia Manuf. 2019, 33, 83–90. [Google Scholar] [CrossRef]

- Wang, S.; Su, D.; Wu, Y.; Chai, Z. Application of life-cycle assessment to the eco-design of LED lighting products. Euro-Mediterr. J. Environ. Integr. 2020, 5, 1–10. [Google Scholar] [CrossRef]

- Miettunen, K.; Santasalo-Aarnio, A. Eco-design for dye solar cells: From hazardous waste to profitable recovery. J. Clean. Prod. 2021, 320, 128743. [Google Scholar] [CrossRef]

- Kazancoglu, I.; Kazancoglu, Y.; Yarimoglu, E.; Kahraman, A. A conceptual framework for barriers of circular supply chains for sustainability in the textile industry. Sustain. Dev. 2020, 28, 1477–1492. [Google Scholar] [CrossRef]

- Longo, S.; Cellura, M.; Cusenza, M.; Guarino, F.; Mistretta, M.; Panno, D.; D’Urso, C.; Leonardi, S.; Briguglio, N.; Tumminia, G.; et al. Life Cycle Assessment for Supporting Eco-Design: The Case Study of Sodium–Nickel Chloride Cells. Energies 2021, 14, 1897. [Google Scholar] [CrossRef]

- Mendoza, J.M.F.; Gallego-Schmid, A.G.; Schmidt Rivera, X.C.; Rieradevall, J.; Azapagic, A. Sustainability assessment of home-made solar cookers for use in developed countries. Sci. Total Environ. 2018, 648, 184–196. [Google Scholar] [CrossRef]

- Garcia-Muiña, F.E.; González-Sánchez, R.; Ferrari, A.M.; Volpi, L.; Pini, M.; Siligardi, C.; Settembre-Blundo, D. Identifying the Equilibrium Point between Sustainability Goals and Circular Economy Practices in an Industry 4.0 Manufacturing Context Using Eco-Design. Soc. Sci. 2019, 8, 241. [Google Scholar] [CrossRef] [Green Version]

- Heyes, G.; Sharmina, M.; Mendoza, J.M.F.; Gallego-Schmid, A.; Azapagic, A. Developing and implementing circular economy business models in service-oriented technology companies. J. Clean. Prod. 2018, 177, 621–632. [Google Scholar] [CrossRef]

- Sihvonen, S.; Partanen, J. Eco-design practices with a focus on quantitative environmental targets: An exploratory content analysis within ICT sector. J. Clean. Prod. 2017, 143, 769–783. [Google Scholar] [CrossRef]

- Veske, P.; Ilén, E. Review of the end-of-life solutions in electronics-based smart textiles. J. Text. Inst. 2020, 112, 1500–1513. [Google Scholar] [CrossRef]

- Martínez-Cámara, E.; Santamaría, J.; Sanz-Adán, F.; Arancón, D. Digital Eco-Design and Life Cycle Assessment—Key Elements in a Circular Economy: A Case Study of a Conventional Desk. Appl. Sci. 2021, 11, 10439. [Google Scholar] [CrossRef]

- Nava, C. Pvcupcycling—Circular economy and zero waste: “Upcycling” waste from electrical systems. Environ. Eng. Manag. J. 2020, 19, 1823–1829. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kendall, A. A taxonomy of circular economy indicators. J. Clean. Prod. 2018, 207, 542–559. [Google Scholar] [CrossRef] [Green Version]

- Sacco, P.; Vinante, C.; Borgianni, Y.; Orzes, G. Circular Economy at the Firm Level: A New Tool for Assessing Maturity and Circularity. Sustainability 2021, 13, 5288. [Google Scholar] [CrossRef]

- Matta, N.; Reyes, T.; Bratec, F. Knowledge Extracting from Eco-Design Activity. In Artificial Intelligence for Knowledge Management; Springer: Cham, Switzerland, 2020; pp. 84–98. [Google Scholar]

- Ma, S.; Hu, S.; Chen, D.; Zhu, B. A case study of a phosphorus chemical firm’s application of resource efficiency and eco-efficiency in industrial metabolism under circular economy. J. Clean. Prod. 2015, 87, 839–849. [Google Scholar] [CrossRef]

- Helander, H.; Petit-Boix, A.; Leipold, S.; Bringezu, S. How to monitor environmental pressures of a circular economy: An assessment of indicators. J. Ind. Ecol. 2019, 23, 1278–1291. [Google Scholar] [CrossRef]

- González-Domínguez, J.; Sánchez-Barroso, G.; Zamora-Polo, F.; García-Sanz-Calcedo, J. Application of Circular Economy Techniques for Design and Development of Products through Collaborative Project-Based Learning for Industrial Engineer Teaching. Sustainability 2020, 12, 4368. [Google Scholar] [CrossRef]

- Gu, Y.; Wu, Y.; Xu, M.; Wang, H.; Zuo, T. To realize better extended producer responsibility: Redesign of WEEE fund mode in China. J. Clean. Prod. 2017, 164, 347–356. [Google Scholar] [CrossRef]

- Sehnem, S.; de Queiroz, A.A.F.S.L.; Pereira, S.C.F.; dos Santos Correia, G.; Kuzma, E. Circular economy and innovation: A look from the perspective of organizational capabilities. Bus. Strat. Environ. 2021, 31, 236–250. [Google Scholar] [CrossRef]

- Aguiar, M.F.; Mesa, J.A.; Jugend, D.; Pinheiro, M.A.P.; Fiorini, P.D.C. Circular product design: Strategies, challenges and relationships with new product development. Manag. Environ. Qual. Int. J. 2021, 33, 300–329. [Google Scholar] [CrossRef]

- Bocken, N.; Strupeit, L.; Whalen, K.; Nußholz, J. A Review and Evaluation of Circular Business Model Innovation Tools. Sustainability 2019, 11, 2210. [Google Scholar] [CrossRef] [Green Version]

- García, M.; Alonso, Á.; Tello, M.L.; De La Poza, M.; Villalobos, N.; Lansac, R.; Melgarejo, P.; Laínez, M. Editorial: Identifying agri-food research priorities for Spain-2017 results. Span. J. Agric. Res. 2018, 16, e0001. [Google Scholar] [CrossRef] [Green Version]

- Jiang, P.; Dieckmann, E.; Han, J.; Childs, P.R.N. A Bibliometric Review of Sustainable Product Design. Energies 2021, 14, 6867. [Google Scholar] [CrossRef]

- Fiore, E.; Tamborrini, P.; Norese, M.F. Designing Major Appliances: A Decision Support Model. In Proceedings of the Conference on Electronics Goes Green 2016+, Berlin, Germany, 6–9 September 2016. [Google Scholar]

- Sihvonen, S.; Partanen, J. Implementing environmental considerations within product development practices: A survey on employees’ perspectives. J. Clean. Prod. 2016, 125, 189–203. [Google Scholar] [CrossRef]

- Payet, J. Assessment of Carbon Footprint for the Textile Sector in France. Sustainability 2021, 13, 2422. [Google Scholar] [CrossRef]

- Watkins, M.; Casamayor, J.L.; Ramirez, M.; Moreno, M.; Faludi, J.; Pigosso, D.C. Sustainable Product Design Education: Current Practice. She Ji J. Des. Econ. Innov. 2021, 7, 611–637. [Google Scholar] [CrossRef]

- Albæk, J.K.; Shahbazi, S.; McAloone, T.; Pigosso, D. Circularity Evaluation of Alternative Concepts During Early Product Design and Development. Sustainability 2020, 12, 9353. [Google Scholar] [CrossRef]

- Roffeis, M.; Almeida, J.; Wakefield, M.E.; Valada, T.R.A.; Devic, E.; Koné, N.; Kenis, M.; Nacambo, S.; Fitches, E.C.; Koko, G.K.D.; et al. Life Cycle Inventory Analysis of Prospective Insect Based Feed Production in West Africa. Sustainability 2017, 9, 1697. [Google Scholar] [CrossRef] [Green Version]

- Bukhari, M.A.; Carrasco-Gallego, R.; Ponce-Cueto, E. Developing a national programme for textiles and clothing recovery. Waste Manag. Res. J. Sustain. Circ. Econ. 2018, 36, 321–331. [Google Scholar] [CrossRef] [PubMed]

- Arán-Ais, F.; Ruzafa-Silvestre, C.; Carbonell-Blasco, M.P.; Pérez-Limiñana, M.A.; Orgilés-Calpena, E. Sustainable adhesives and adhesion processes for the footwear industry. J. Mech. Eng. Sci. 2020, 235, 585–596. [Google Scholar] [CrossRef]

- Jugend, D.; Fiorini, P.D.C.; Pinheiro, M.A.P.; Silva, H.; Seles, B.M.R.P. Building Circular Products in an Emerging Economy: An Initial Exploration Regarding Practices, Drivers and Barriers: Case studies of new product development from medium and large Brazilian companies. Johns. Matthey Technol. Rev. 2020, 64, 59–68. [Google Scholar] [CrossRef]

- Chaudron, C.; Faucher, M.; Bazinet, L.; Margni, M. The cost is not enough—An alternative eco-efficiency approach applied to cranberry de-acidification. J. Clean. Prod. 2019, 232, 391–399. [Google Scholar] [CrossRef]

- Agrawal, R.; Vinodh, S. Prioritisation of drivers of sustainable additive manufacturing using best worst method. Int. J. Sustain. Eng. 2021, 14, 1587–1603. [Google Scholar] [CrossRef]

- Brones, F.; Zancul, E.; Carvalho, M.M. Insider action research towards companywide sustainable product innovation: Ecodesign transition framework. Int. J. Manag. Proj. Bus. 2020, 14, 150–178. [Google Scholar] [CrossRef]

- Prioux, N.; Ouaret, R.; Hetreux, G.; Belaud, J.-P. Environmental assessment coupled with machine learning for circular economy. Clean Technol. Environ. Policy 2022, 24, 1–14. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torcătoru, C.; Săvescu, D.; Repanovici, A. Literature Review by Scientometric Methods on the Impact of the Circular Economy on Sustainable Industrial Products. Sustainability 2022, 14, 5084. https://doi.org/10.3390/su14095084

Torcătoru C, Săvescu D, Repanovici A. Literature Review by Scientometric Methods on the Impact of the Circular Economy on Sustainable Industrial Products. Sustainability. 2022; 14(9):5084. https://doi.org/10.3390/su14095084

Chicago/Turabian StyleTorcătoru, Constantin, Dan Săvescu, and Angela Repanovici. 2022. "Literature Review by Scientometric Methods on the Impact of the Circular Economy on Sustainable Industrial Products" Sustainability 14, no. 9: 5084. https://doi.org/10.3390/su14095084

APA StyleTorcătoru, C., Săvescu, D., & Repanovici, A. (2022). Literature Review by Scientometric Methods on the Impact of the Circular Economy on Sustainable Industrial Products. Sustainability, 14(9), 5084. https://doi.org/10.3390/su14095084