Abstract

The use of biodigesters and the circular economy (CE) has been gaining attention in recent years. Both biodigesters and CE have the potential to minimize negative impacts—not only environmental, but also economic and social. However, little attention has been paid to the relationship between biodigesters and CE. Therefore, the objective of this paper is to identify and analyze the implications of the use of biodigesters in the light of a CE concept. To do this, a SWOT matrix was developed based on the opinion of experts and two case studies were conducted in companies operating in different sectors in Brazil. The results showed that the use of biodigesters can drive CE through biogas, which is a renewable energy source, closing the cycle of organic materials, increasing the economic power of companies and small producers, improving basic sanitation in remote areas, and stimulating industrial symbiosis. However, this study identified barriers in the use of biodigesters in the context of CE, such as lack of government incentives and composting being shown to be more cost-effective than the use of biodigesters for the treatment of solid waste.

1. Introduction

The circular economy (CE) has been one of the main recent approaches to environmental sustainability since it proposes the adoption of a regenerative system in which the input of resources and waste are minimized by slowing, narrowing, and closing loops of materials and energies [1,2]. It is understandable that to meet the needs of the population growth that has occurred in recent decades, there has been a need for an expansion of urban areas and agricultural food production, the detouring of water courses, and increased use of fertilizers. These facts have caused a significant loss of biodiversity, decreasing the natural support capacity of ecosystems [3]. The exacerbated consumption of natural resources has been part of a so-called linear socioeconomic system, which has already been pointed out by many studies as unsustainable [4,5,6].

CE emerges as a proposal that aims to transpose the linear extract–produce–dispose economy, which does not consider all the negative impacts it may trigger [7,8]. Although it is in an early stage of adoption in many companies, CE constitutes an important concept towards sustainable development [9,10]. The concept of CE is also aligned with the use of renewable energy sources, since its use consists of a form of closing cycles [2,11,12]. A system will only be circular if the energy used in the production processes is in fact renewable.

A renewable energy source that is being strongly adopted in both rural and urban areas consists of biogas produced by biodigesters. Biodigesters are constructions composed of a gasometer and a closed chamber that stores fresh organic matter or biomass for the purpose of producing biogas and biofertilizer. In this way, biodigesters have a relevant role in driving the CE [13]. Biogas and biofertilizer are products obtained through the anaerobic digestion (AD) of organic material occurring inside a biodigester, also called an anaerobic digester [14]. The main use of biogas is to generate electricity and heat, such as for heating, operating machinery, or cooking [15].

Because of its functionality, the use of biodigesters is aligned with CE principles, especially with regard to its biological cycle. Holm-Nielsen et al. [16] suggested that animal waste should be considered an important resource for renewable energy and a source of nutrients for agriculture, considering that at least 25% of all future bioenergy could come from biogas. In addition, the use of small-scale biodigesters is growing around the world, and are widely used in Asia but also with reports of use in Latin America and some regions of West Africa [17]. In Brazil, since 2010, Law No. 12305, regulated by Decree No. 7404, referring to the National Policy on Solid Waste, has been implemented. This stimulates the deployment of digesters and brings incentives for the creation of biodigestion projects of solid urban organic waste [18]. Thus, the use of biodigestion in Brazil is already significant for the treatment of urban sewage, and its use has been growing in the treatment of solid waste from livestock farms, especially pigs and cattle [19].

Although Brazil is one of the largest producers of agricultural commodities in the world, as are other developing countries, it still does not have effective policies for managing agro-industrial waste [20]. As well as positive environmental impacts, the use of digesters can be a source of income for farming communities in Brazil, although there is still a lack of knowledge and greater clarification is needed about the benefits of recycling organic waste using digesters [21]. For example, Brazil is one of the largest producers of acai berry in the world, but only 10–20% of the pulp is used for consumption and there is no proper disposal for the remaining agro-industrial waste, which makes the acai seed an urban waste, generating great inconvenience for the population [22]. Despite the potential of digesters for the adoption of CE, there are still few studies that describe and integrate these themes in South American countries, especially in Brazil, which is one of the main food producers.

Aiming to contribute to this theme, this paper identifies the main drivers and limiting factors of the use of biodigesters in the context of CE. This research contributes to the literature by identifying and analyzing the barriers and facilitators in the use of biodigesters in the context of CE. To this end, initially, a Strengths, Weaknesses, Opportunities, and Threats (SWOT) analysis was performed, carried out with 24 experts from Brazilian companies, academia, and agricultural cooperatives. Subsequently, two case studies were conducted in companies that are adopting the principles of CE and have biodigesters in their operations.

The remainder of this article is structured in four more sections. Section 2 presents the principles of CE and the importance of biodigesters for its application in relation to organic waste. Section 3 provides, in detail, the method adopted to carry out this work, namely, the elaboration of the SWOT matrix and the case studies. Section 4 presents the results, followed by Section 5, which discusses the results, comparing them with those in the literature. Finally, Section 6 brings the conclusion of this paper and suggestions for future research.

2. Circular Economy and the Role of Biodigesters

Kirchherr et al. [23] defined CE as an economic system that replaces the concept of “end of life” with reduction, reuse, recycling, and recovery. The principles of CE are aligned with the environmental, economic, and innovative goals of companies, as they aim to transform manufactured products and by-products into resources for other industries [24]. CE presents itself as a regenerative system in which resource input and waste are minimized by slowing, closing, and narrowing material and energy loops [1].

Biodigesters have been shown to be an appropriate technology for the challenges of proper waste treatment, energy generation, sustainable food production, and nutrient recycling as proposed by CE [25]. One contributing factor is the fact that biogas is a source of renewable and clean energy, whose sale can further increase the economic power of those involved [26].

The concept of CE suggests transforming waste into inputs to close resource cycles and, in the production of biogas, the digesters can be supplied with various inputs, widening the possibilities of the use of biodigesters. Some examples of waste that can become biodigester inputs are leftovers from wine production [27], the seed of acai [28], sugarcane bagasse [29], wastewater from urban sewage [30], and waste from pig farming [31]. Xue et al. [32] presented relationships in the livestock cycle between the use of biodigesters and CE concepts, which occur through reduced carbon emissions as organic waste from animals returns to the system through the generation and use of biogas in replacing fossil fuels and biofertilizer replacing traditional fertilizers.

Table 1 presents elements identified in the literature that show how CE is driven by the adoption of biodigesters.

Table 1.

Circular economy facilitators and biodigesters.

As shown in Table 1, one of the advantages most addressed by studies when looking at the use of biodigesters and CE is the reuse of waste. This occurs due to the possibility of closing the cycles, in which the transformation of a waste into raw material occurs, with the treatment of organic waste, generating clean energy (biogas), recycling the nutrients of the waste streams, and reducing the emission of greenhouse gases (GHG) [40].

On the other hand, the use of biodigesters can also have negative consequences for CE. Dahlin et al. [57] compared the concentration of cadmium (Cd) in wheat grains from land fertilized with biofertilizer and land fertilized in a traditional manner and found that the inappropriate use of chlorine in soils with digested material significantly increased the concentration of Cd in the crop products. For Rada et al. [58], food waste management at the local level has the risk of bad smell as a negative factor, but this can be minimized with AD and, if the organic volume is high, additional treatment plants will be needed, raising the cost of the infrastructure needed to build the digesters.

Islam et al. [59] found that the main barriers to the adoption of renewable energy from bovine waste are (i) financial investment, which makes a cost–benefit assessment necessary; (ii) high infrastructure cost for large-scale biogas utilization; (iii) lack of technology diffusion of biogas use; and (iv) lack of knowledge on methane capture and utilization. Although the use of biofertilizers resulting from the AD of livestock waste is an increasingly growing practice and consistent with CE, their use can lead to problems in the soil because, added to the ecosystem already existing in the soil, they can become a potential source of antibiotics, genes, and other resistant microorganisms in agroecosystems [60].

In addition, the use of biogas has the disadvantage of generating CO2 when burned [61]. However, although the production of biogas requires the construction of biodigesters and the combustion of methane gas, which is one of the main components of biogas, both processes also generate carbon emissions. However, the overall carbon footprint of the circular model is still usually smaller than that of the traditional model [32]. Table 2 presents the elements identified in the literature that can be considered barriers to the adoption of biodigesters from the CE perspective.

Table 2.

Barriers to circular economy and biodigesters.

3. Materials and Methods

Initially, to identify, in an exploratory way, barriers and facilitators in the adoption of biodigesters in the context of CE, a consultation was made with experts to develop the SWOT matrix. Subsequently, there were two case studies that looked at the finding of the initial analysis in practice: a company in the agro-industrial sector and another in the energy generation and distribution sector and in the extraction, conversion, and transport of oil and gas, both of which have adopted biodigesters. SWOT analysis has been used in several management studies (e.g., [65,66]) including analyzing the production of biogas in China [67] and even in the relationship between organic solid waste with CE [68]. Other research methods are recommended along with the SWOT analysis, such as primary data analysis and interviews with experts [69]. This research opted for SWOT analysis added to case studies to understand the barriers and facilitators in the adoption of biodigesters in the CE context.

With the goal of developing a SWOT matrix, an online questionnaire was prepared with the use of Google Forms based on the theoretical review carried out and mainly presented in Table 1 and Table 2. The questions were designed considering the main barriers and facilitators of the use of biodigesters considering the CE concept. The questionnaire was designed with four sections, and each section had four statements to be answered according to the Likert scale, ranging from 1 (strongly disagree) to 5 (strongly agree). There was also a discursive question at the end of each section.

The snowball sampling method was used to disseminate the questionnaire. According to Vinuto [70], “snowball” sampling is a non-probability sampling that uses chains of references. Thus, in this paper the initial sampling, called “seeds”, was identified through social networks and websites of companies, academics, and agricultural cooperatives using the keywords in the area of biodigesters, such as “biodigester”, “biogas”, and “biofertilizer”. The sample selection criteria included agricultural companies and cooperatives that use biodigesters in their facilities and academics who develop research on biodigesters and CE, located in Brazil. After the first contact with the seeds, it was requested that, besides answering the questionnaire, they also indicate new contacts that use biodigesters from their personal networks, thus increasing the number of answers. The questionnaire was sent to 81 “seeds”, and from this total 24 responses were obtained from diverse people who work for companies that use biodigesters in their processes or who conduct research on the subject. These were 6 universities, 4 agribusinesses companies, 3 specialized biodigester companies, 3 industries, 2 agricultural cooperatives, 2 institutes for agricultural research, 1 specialized law practice in environmental law, 1 agricultural school, 1 private hospital, and 1 anonymous.

After the elaboration of the SWOT matrix with the main barriers and facilitators of the adoption of biodigesters in the context of CE, two case studies were conducted in companies that operate in different sectors: Company A, which operates in the industry, and Company B, from agribusiness, more specifically in the meatpacking sector.

For this stage of the research, an interview script was prepared with 31 questions divided into five sections: Section A—characterization of the company (5 questions), Section B—characterization of the biodigesters used by the company (3 questions), Section C—definition of the waste used (3 questions), Section D—operational description of the biodigester process (9 questions), and Section E—use of biodigesters in the context of CE (11 questions). To meet the social distancing protocols imposed by the COVID-19 pandemic, the interviews were conducted online.

4. Results

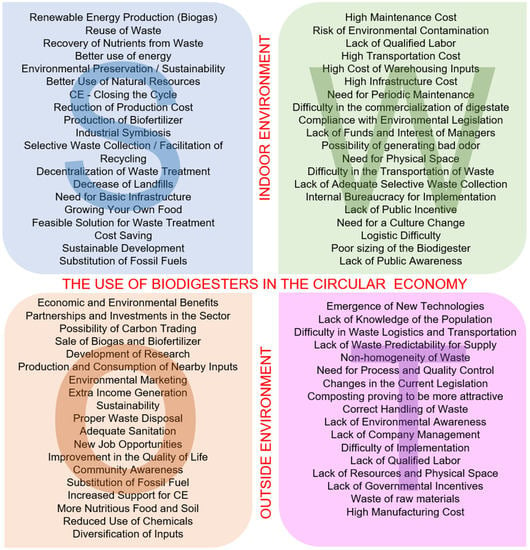

This section is divided into two subsections. Section 4.1 presents the results obtained through the questionnaire applied with the companies and academics who use or study the use of biodigesters. The results of the descriptive statistics of the variables and the calculation of Cronbach’s alpha are presented in Table 3 and the results of the discursive questions of the questionnaire are presented in Figure 1 by means of the SWOT matrix. Section 4.2 presents the results obtained through the case studies carried out in companies A and B.

Table 3.

Descriptive statistics of the variables and Cronbach’s alpha of the dimensions (n = 24).

Figure 1.

SWOT matrix of the use of biodigesters in the circular economy identified in the survey.

4.1. Questionnaire Results and SWOT Matrix

Table 3 presents the descriptive statistics of the questionnaire variables and the Cronbach’s alpha of the four dimensions analyzed (strengths, weaknesses, opportunities, and threats).

As shown in Table 3, the highest means and lowest standard errors were in the variables of the strengths and opportunities dimensions. The lowest negative skewness values on an absolute scale for the variables of the strengths dimension show that the level of agreement for this dimension was higher among the respondents than for the variables of the other dimensions.

In the strengths dimension, the highest mean was obtained in the variable of performance of the company within sustainable development, a productive process that respects the limitations of the environment and does not pollute. The lowest means were obtained for the variable of high cost with transportation and storage of the inputs used to supply the biodigester, as well as the final products—biofertilizer and biogas—and the possibility of soil, water, and air contamination.

All variables in the weakness dimension had a median of 3 and the means were very close to 3. The skewness values of these variables were close to zero. In the threat dimension, the medians of more attractive renewable energy sources and the possibility of decline in input production were 3.5 and 3.0, respectively. The medians of the variables in the strengths and opportunities dimensions were above 4.0.

The strengths, weaknesses, and opportunities dimensions showed satisfactory values for the Cronbach’s alpha, indicating consistency in the internal reliability of the variables selected to measure the mentioned dimensions [71]. The Cronbach’s alpha of the threats dimension was not satisfactory, indicating that the chosen variables did not appropriately measure the analyzed dimension. One justification for this problem may be the small sample size. Lack of government incentive and lack of knowledge among the population were the main threats in the view of the respondents.

Using the answers to the open-ended questions in the questionnaire, the SWOT matrix presented in Figure 1, which is divided into its four quadrants, was drawn up. The two upper quadrants (S and W) refer to the internal environment of the companies, whereas the lower quadrants (O and T) refer to the external environment. The left quadrants (S and O) are points raised by the respondents that facilitate the use of biodigesters in the CE context. The quadrants on the right (W and T) are the points raised by the respondents that hinder (cause barriers) the use of biodigesters in the context of CE.

Some of the factors presented by the respondents were addressed in more than one quadrant of the matrix, depending on the focus of each company. Some companies identified the “sustainability” factor as a strength, whereas others classified it as an opportunity that can be transformed into a strength. The same occurred with the factor “difficulty with waste transportation”, which was presented as a weakness and also as a threat.

Detailing some factors presented in Figure 1, the CE with the closing of cycles is considered a strength because the use of biodigesters allows for the reuse of organic waste, causing a closing of the cycle and contributing to the CE. Industrial symbiosis is also considered a strength since the waste from one industry can be used as raw material in another. In addition, the decentralization of waste treatment is a strength by not sending it to a single place and overloading that place. Another strength is the cultivation of food because, with the production of biogas and biofertilizer, small farmers can obtain good-quality soil for family farming at low cost, as well as the use of energy from biogas in the equipment used in cultivation.

The high cost of the infrastructure necessary for the construction of the biodigester and the use of biogas was considered a weakness. Another weakness is the difficulty in marketing the final product from the biodigestion process due to the lack of knowledge of the consumer market in relation to the reliability and the quality of the product. The possibility of generating bad smell can also be a weakness if the residues are not stored correctly, before being destined to the biodigester. Another weakness pointed out is the internal bureaucracy for the execution of a biodigester project since the lack of technical knowledge and specific laws can generate an increase in bureaucracy in companies. The need for a change in culture, both organizational and in the population as a whole, was also indicated as a weakness because, being a new concept, it still generates doubts and uncertainties.

The factor of partnerships and investments in the sector was considered an opportunity, due to the possibility of renting a biodigester or a cooperative to centralize the waste in a single biodigester. An outstanding opportunity is the possibility of carbon trading, a growing practice in which a company with lower CO2 production rates can sell its quotas to companies that have not yet adapted to the laws in force. Another opportunity is the production and consumption of nearby inputs, which would be the use of biofertilizer and biogas in areas adjacent to the biodigester. Environmental marketing was also pointed out as an opportunity because it is a possibility for companies to benefit from a more environmentally conscious public. The opportunity of adequate sanitation was also presented because the use of biodigesters enables the realization of quality basic sanitation in remote areas. Food and more nourished soil with the use of biofertilizer and fewer chemical products, as well as the diversification of inputs, considering that the biodigester can be filled with any organic material, were also considered opportunities.

The emergence of new technologies and the lack of predictability of waste for supply were pointed out as a threat because, in the future, more attractive technologies than the biodigester may arise. Along this same line of reasoning, composting proving to be more attractive was also pointed out as a threat. The non-homogeneity of the residues is also considered a threat because inadequate selective collection can mix residues with different characteristics. Another threat identified is the lack of management in companies because a badly managed company may not make the most of all the benefits that the use of biodigesters and CE can provide.

4.2. Case Study Results

Company A is a German multinational with a presence in 90 countries and over 90,000 employees worldwide. It is a global leader in power generation and distribution and in the extraction, conversion, and transportation of oil and gas. Company B is a family-owned company located in the interior of the state of São Paulo, with 500 employees. It has a vertical structure in the production of animal feed; care of the breeding, rearing, and fattening processes; animal slaughter; distribution; and direct sales.

Since the companies are not from the same segment and use the biodigester for different purposes, they have different visions of the barriers and facilitators of the use of biodigesters in the context of CE. However, both companies identified more facilitators than barriers, which suggests a favorable view of the use of biodigesters for CE.

Company A opted for the implementation of the biodigester to mitigate the waste from a local restaurant because, with a daily preparation of approximately 900 meals, this is one of the main sources of waste generated by the company.

The biodigester used by the company is rented. The rental contract also includes the necessary maintenance of the equipment. The biodigester is of continuous supply and can be opened and refilled according to the needs of the cafeteria. Its technology also allows it to be connected to the company management system, and employees can access information in real time through application software. Information such as daily supply quantity, idle capacity, history by period, etc., is available.

Another point highlighted by the company is the reduction of carbon emissions in the transportation of waste to landfills, previously done by trucks. It also eliminates the risk of incidents on the way and reduces labor. The company does not reveal figures but claims that the savings using the biodigester are significant. However, the biodigester does not generate biogas and biofertilizers. The model used is an electric one, used only for waste reduction and performing the final disposal of the by-product directly into the domestic sewage system, assisting in the cleaning of grease traps.

Although Company A does not make use of the products generated by the biodigester, the company still considers the biodigester to be crucial to the circular economy in relation to organic waste because it allows for the recovery of the energy existing in the waste. The environmental coordinator interviewed emphasized that, “in my opinion the biodigester is crucial for this type of waste that we are using, which is organic […] and we understand that the biodigester also recovers, in a way, the energy from the waste, which is what we want.”

Company B works practically with a complete production cycle because it has farms to raise animals, a slaughterhouse to slaughter pigs and cattle, and stores to sell the product. Additionally, there is an agricultural part, producing corn and pasture to feed the animals. This company has two digesters: the main biodigester, which is larger and is supplied with waste from the slaughterhouse, and a smaller one, which is supplied with waste from the pig-breeding stalls (mainly urine, feces, and some feed).

The company opted for the construction of the digesters to use the biogas to supply the boiler and to use the bio-fertilizer for irrigation of the agriculture and pasture areas. With the use of the biogas coming from the biodigester, the company started saving approximately US$ 3,000.00 per month.

As there is no pre-treatment of the residues to supply the biodigester, no chemicals are used to produce the biogas and the biofertilizer. There is also no need to add water to the biodigester since most of the waste is already in liquid form. The supply of the biodigester is continuous, with a retention period of 15 days and an average daily production of 1000 m³ of biogas.

The company believes that biogas is a renewable energy and that the main advantage of using the biodigester is the better use of the residues. As a disadvantage, the difficulty in performing maintenance was highlighted due to the need for heavy machinery for periodic cleaning. It was mentioned throughout the case study, by the technical manager of the meat packing plant, that the biodigester is part of the CE concept: “…because it is through the biodigester that we can progress through the stages of utilization of organic matter. So, without the biodigester I can’t obtain the gas […] I can’t obtain the liquid that I use for fertigation […]”.

The non-use of biogas and biofertilizer was only presented as a barrier by Company A. The barriers presented only by Company B were manure destined for composting, reducing the waste to supply the biodigester; difficult maintenance of the biodigester (periodic cleaning); the need for specialized labor to perform maintenance; technological lag in the use of biogas; lack of dissemination of the benefits for the employees themselves; lack of interest in exploring more possibilities arising from the use of biodigesters; and lack of predictability for the future.

Both companies mentioned the following barriers: lack of government incentive, non-use of all the residue to supply the biodigester, and lack of knowledge of all the technology.

With regard to the facilitators, Company A presented the following: help in cleaning the grease traps; reduction in landfill disposal; improvement in the environment, health, and safety (EHS) performance indicators; automation of the biodigester; interconnection of the biodigester with the company management system; real-time information on the biodigester data, such as the quantity supplied or the storage capacity; the possibility of renting the biodigester; lower investment cost with the rental of the biodigesters; reduction of carbon emissions by trucks; elimination of the environmental risk of accidents with waste transportation; reduction of labor; reduction of costs; low maintenance; low cost for waste disposal; ergonomics for the employees, who no longer need to walk long distances with boxes of waste; and aesthetics of the equipment (“…its design is cool, I think it is very beautiful, futuristic, it looks very nice in the kitchen, where it is discarded. It is futuristic, it has a little display […] I can access it through the application…”).

In contrast, Company B presented the following facilitators: decreased consumption of firewood; fertigation of the agricultural part producing corn and pasture; no use of chemicals for wastewater treatment; renewable energy; no pollution of river waters; improved quality of fertigation areas; decreased use of herbicides and use of biofertilizer; being an example for other companies; and closing of the product cycle.

Both companies presented these as facilitators: adequate waste disposal; energy recovery from waste; financial savings; and contribution to a circular economy “[…] I can’t close this process if I don’t have the biodigester”.

5. Discussion

5.1. Facilitators of Using Biodigesters to Promote the Circular Economy

The integration of the results of the literature review, SWOT matrix, and case studies shows that the main facilitators of the use of biodigesters in the context of CE are (i) reduction of disposal in landfills; (ii) proper disposal of waste; (iii) production of renewable energy; (iv) use of biofertilizer; (v) sustainability, highlighting the better use of natural resources, sustainable development, and environmental preservation; and (vi) contribution to CE by closing resource cycles.

The research shows that the adoption of CE practices, through means such as the use of biodigesters, reduces waste disposal in landfills, ensures the proper treatment of organic waste, and enables basic sanitation in remote areas and wastewater treatment in urban areas. In addition to the environmental benefits, Company A cited reduced waste transportation costs to landfills and reduced labor and incidentals along the way. The inadequate disposal of waste and the lack of basic sanitation bring harmful consequences to health and loss of residual energy of the materials. Adherence to these practices is critical to meeting sustainable development goals [46].

One of the main facilitators for the use of biodigesters, considering their alignment with the CE concept, is the generation of renewable energy. This enabler, mentioned as a strength in the SWOT matrix, besides being highlighted by Company B is also recognized in the literature [34,40,43,47,55].

Like biogas, biofertilizer also plays an important role within CE. Since it is the final input in the production cycle, it finalizes the process of the proper disposal of waste, avoiding the release of GHG by waste that is not properly treated. Its use reduces the consumption of industrialized chemicals, as well as being cheaper and natural. As emphasized by Company B, the use of biofertilizer for fertigation can significantly improve the quality of pasture areas.

The characteristics of biofertilizer make it another facilitating element, presented as a strength in the SWOT matrix: growing one’s own food. Although it was not mentioned in any other step, this facilitator should be taken into consideration, because it refers to the understanding that, through the production of biofertilizer by small producers, it can favor their fertilization of land with a quality product at low cost. In addition, the use of biodigesters to produce biogas can generate energy for the equipment needed in the cultivation and subsistence of the property of these farmers. The increase in economic power with the use of the biodigester by farmers is recognized in several studies (e.g., [27,37,38,62]).

The increased economic power provided by using biodigesters was an opportunity cited by experts and in the case studies. This occurs through the possibility of carbon trading, sale of biogas and biofertilizer, generation of economic benefits, and generation of extra income and new job opportunities.

The practice of carbon trading is growing and was pointed out as an opportunity. The adequate management of residues tends to reduce carbon emissions, and companies that generate lower carbon emission rates can sell their quotas to companies that have not yet adapted to the current regulations. This possibility of the circular model allows the conversion of environmental benefits into economic benefits, in addition to the reduction in carbon emissions and the numerous other benefits attributed to biogas [32].

5.2. Barriers to the Use of Biodigesters

The integration of the findings from the literature review, the SWOT matrix, and the case studies shows that the main barrier to the use of biodigesters in the CE context is the lack of government incentive. This result is in line with the findings of Winquist et al. [40], Cucchiella et al. [47], and Xue et al. [32], since companies A and B agreed that if there was more government incentive, this technology would be more widespread and better utilized. According to Company B, the government could also make profits from these partnerships, either financially or as green marketing. It should be emphasized that this barrier was indicated in the SWOT analysis both as a weakness and as a threat.

Other barriers that appeared with less intensity were bureaucracy, cultural change, and composting. The excessive internal bureaucracy for the execution of the project and the difficulty in implementing the biodigesters were marked as a weakness and a threat, respectively. Several factors contribute to the existence and even the aggravation of these barriers, the main ones being the lack of knowledge of the technology and the lack of clearer and more specific laws.

In the same context, the need for a cultural change at the organizational and population level was also cited in the SWOT matrix as a weakness and highlighted as a barrier in this study. Although the use of biodigesters for the production of biogas and biofertilizer is not a new technology, many are still unaware of its importance and the underlying benefits. According to experts, this is the main threat to the use of biodigesters in the adoption of CE.

This change in thinking is also associated with the barriers of emergence of new technologies and the lack of predictability of waste to supply the biodigester, which were mentioned as threats in both the SWOT matrix and the case studies. Some experts pointed to composting as a threat because it is more attractive than the use of biodigesters for the treatment of solid waste. Since it is considered more cost-effective, most of the solid waste from the production process of Company B, which is not segregated for the rendering plant, is destined for composting.

On the other hand, the biodigester used by Company A is fed exclusively with food waste from its restaurant. This result is in line with the findings of Cecchi and Cavinato [45], who noted that organic waste from food is the most promising as a renewable resource, due to its high availability and its high degree of GHG generation if disposed of incorrectly.

6. Conclusions

This study contributes to increased knowledge about the possibilities of adopting biodigesters as part of CE. The results of the analyses presented in this paper show that the use of biodigesters drive CE by reusing waste, optimizing natural resources and their energy, and closing the cycle of organic waste, thus producing biogas and biofertilizer. Biogas is a renewable energy source, considered one of the pillars of CE. Biofertilizer contributes to the recovery of natural resources through the biological cycle of CE. It is environmentally friendly and more economical than chemical fertilizers and is rich in phosphorus and nitrogen, elements that are scarce and finite in the environment.

Biodigesters also drive CE towards sustainability by increasing the economic power of companies and small producers, favoring basic sanitation in remote areas and environmental preservation through proper waste disposal. On the other hand, some barriers still need to be overcome, such as the lack of governmental incentive in its adoption, the excess of bureaucracy, the lack of technical knowledge in its implantation, the lack of understanding of its benefits by the population, and the apprehension to invest in biodigesters.

The results of this study may be useful in identifying and generating discussion on how the opportunities and strengths identified in the SWOT matrix can guide actions to mitigate the threats and weaknesses in the adoption of biodigesters for CE. For example, the possibility of economic gains from reduced electricity costs and carbon trading can broaden the understanding of the economic benefits of adopting biodigesters and encourage financial investment in this technology. The increase in income of small producers can guide government actions through fiscal policies to encourage the acquisition of biodigesters.

This paper contributes to the theory since, to the best of our knowledge, it is the first that investigates barriers and facilitators for the adoption of biodigesters in the context of CE. To this end, besides the theoretical review (Table 1 and Table 2), a SWOT matrix based on the judgment of experts in this field was used along with results from two case studies. By systematically identifying and analyzing the barriers and facilitators of biodigesters from the perspective of CE, the results of this paper can guide managers interested in deploying this technology and especially with the goal of achieving better results and also addressing CE. The results can also be useful to support decision-makers in the area of environmental public policy since it shows the difficulties and challenges faced by various professionals involved in the adoption of biodigesters and the operationalization of CE. The disclosure of these difficulties and challenges, added to the opportunities and strengths, as evidenced in the SWOT matrix, can guide public policies that promote CE through biodigesters.

Although this work focuses on a case study in Brazil, the barriers and facilitators of the use of biodigesters for CE identified in this research can also be applied in other countries. Furthermore, the findings of this study can guide governments, companies, and communities in developing countries to better understand the barriers and facilitators related to the use of biodigesters in conjunction with CE principles, such as renewable energy generation, proper waste treatment, the commercialization of carbon, and decreasing the use of chemical fertilizers.

This study has methodological limitations that must be acknowledged. Even though it is an exploratory study, the number of experts that participated in the SWOT matrix survey is small. Furthermore, only two case studies were conducted. Therefore, the results presented in this study cannot be generalized. So, a proposal for future study is to expand the empirical understanding of how biodigesters can contribute to the CE. In this context, case studies of companies operating in different economic sectors and even in various countries could be useful. Quantitative studies that relate the adoption of biodigesters with the performance of CE may also reveal new insights and broaden knowledge in this area.

Author Contributions

Conceptualization, S.C.C., A.C.C. and D.J.; methodology, S.C.C. and D.J.; validation, S.C.C., A.C.C., D.J., G.M.K.J. and B.S.B.; formal analysis, S.C.C.; investigation, S.C.C.; resources, S.C.C., A.C.C. and D.J.; data curation, S.C.C. and G.M.K.J.; writing—original draft preparation, S.C.C.; writing—review and editing, S.C.C., A.C.C., D.J., G.M.K.J. and B.S.B.; supervision, D.J. and A.C.C.; project administration, S.C.C., A.C.C. and D.J.; funding acquisition, D.J. and A.C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Brazilian Federal Agency for Support and Evaluation of Graduate Education (CAPES), in the scope of the Program CAPES-PrInt, process number 88887.310463/2018-00, International Cooperation Project number 88887.310375/2018-00. Finance Code 001.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Geissdoerfer, M.; Morioka, S.N.; De Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Jesus, A.; Mendonça, S. Lost in transition? Drivers and barriers in the eco-innovation road to the circular economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef] [Green Version]

- Foley, J.A.; DeFries, R.; Asner, G.P.; Barford, C.; Bonan, G.; Carpenter, S.R.; Chapin, F.; Coe, M.; Daily, G.; Gibbs, H.; et al. Global consequences of land use. Science 2005, 309, 570–574. [Google Scholar] [CrossRef] [Green Version]

- Hysa, E.; Kruja, A.; Rehman, N.U.; Laurenti, R. Circular economy innovation and environmental sustainability impact on economic growth: An integrated model for sustainable development. Sustainability 2020, 12, 4831. [Google Scholar] [CrossRef]

- Michelini, G.; Moraes, R.N.; Cunha, R.N.; Costa, J.M.; Ometto, A.R. From linear to circular economy: PSS conducting the transition. Procedia CIRP 2017, 64, 2–6. [Google Scholar] [CrossRef]

- Åkerman, M.; Humalisto, N.; Pitzen, S. Material politics in the circular economy: The complicated journey from manure surplus to resource. Geoforum 2020, 116, 73–80. [Google Scholar] [CrossRef]

- Stanchev, P.; Vasilaki, V.; Egas, D.; Colon, J.; Ponsá, S.; Katsou, E. Multilevel environmental assessment of the anaerobic treatment of dairy processing effluents in the context of circular economy. J. Clean. Prod. 2020, 261, 121139. [Google Scholar] [CrossRef]

- Fischer, A.; Pascucci, S. Institutional incentives in circular economy transition: The case of material use in the Dutch textile industry. J. Clean. Prod. 2017, 155, 17–32. [Google Scholar] [CrossRef] [Green Version]

- Murray, A.; Skene, K.; Haynes, K. The circular economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Sauvé, S.; Bernard, S.; Sloan, P. Environmental sciences, sustainable development and circular economy: Alternative concepts for trans-disciplinary research. Environ. Dev. 2016, 17, 48–56. [Google Scholar] [CrossRef] [Green Version]

- Niero, M.; Olsen, S.I. Circular economy: To be or not to be in a closed product loop? A Life Cycle Assessment of aluminium cans with inclusion of alloying elements. Resour. Conserv. Recycl. 2016, 114, 18–31. [Google Scholar] [CrossRef] [Green Version]

- Brown, P.; Bocken, N.; Balkenende, R. How do companies collaborate for circular oriented innovation? Sustainability 2020, 12, 1648. [Google Scholar] [CrossRef] [Green Version]

- Zhang, R.; El-Mashad, H.M.; Hartman, K.; Wang, F.; Liu, G.; Choate, C.; Gamble, P. Characterization of food waste as feedstock for anaerobic digestion. Bioresour. Technol. 2007, 98, 929–935. [Google Scholar] [CrossRef] [PubMed]

- Feiz, R.; Ammenberg, J. Assessment of feedstocks for biogas production, part I—A multi-criteria approach. Resour. Conserv. Recycl. 2017, 122, 373–387. [Google Scholar] [CrossRef]

- Okonkwo, U.C.; Onokpite, E.; Onokwai, A.O. Comparative study of the optimal ratio of biogas production from various organic wastes and weeds for digester/restarted digester. J. King Saud Univ. Eng. Sci. 2018, 30, 123–129. [Google Scholar] [CrossRef] [Green Version]

- Holm-Nielsen, J.B.; Al Seadi, T.; Oleskowicz-Popiel, P. The future of anaerobic digestion and biogas utilization. Bioresour. Technol. 2009, 100, 5478–5484. [Google Scholar] [CrossRef]

- Mwakaje, A.G. Dairy farming and biogas use in Rungwe district, South-west Tanzania: A study of opportunities and constraints. Renew. Sust. Energy Rev. 2008, 12, 2240–2252. [Google Scholar] [CrossRef]

- Brazil. Law No. 12.305. Available online: http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2010/lei/l12305.htm (accessed on 22 April 2021).

- Biogas Portal. Legal Incentives for the Construction of Biodigesters in Brazil. Available online: https://www.portaldobiogas.com/incentivos-legais-para-construcao-de-biodigestores-brasil/#:~:text=A%20Pol%C3%ADtica%20Nacional%20de%20Res%C3%ADduos,de%20res%C3%ADduos%20s%C3%B3lidos%20org%C3%A2nicos%20urbanos (accessed on 1 July 2020).

- Ferreira, J.; Oliveira, D.; Maldonado, R.R.; Kamimura, E.S.; Furigo, A. Enzymatic pretreatment and anaerobic co-digestion as a new technology to high-methane production. Appl. Microbiol. Biotechnol. 2020, 104, 4235–4246. [Google Scholar] [CrossRef]

- Van der Velden, R.; Da Fonseca-Zang, W.; Zang, J.; Clyde-Smith, D.; Leandro, W.M.; Parikh, P.; Borrion, A.; Campos, L.C. Closed-loop organic waste management systems for family farmers in Brazil. Environ. Technol. 2021, 43, 2252–2269. [Google Scholar] [CrossRef]

- Martins, L.S.; Silva, N.G.; Claro, A.M.; Amaral, N.C.; Barud, H.S.; Mulinari, D.R. Insight on açaí seed biomass economy and waste cooking oil: Eco-sorbent castor oil-based. J. Environ. Manag. 2021, 293, 112803. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Lai, K.H. Circular economy practices among Chinese manufacturers varying in environmental-oriented supply chain cooperation and the performance implications. J. Environ. Manag. 2010, 91, 1324–1331. [Google Scholar] [CrossRef]

- Hidalgo, D.; Martín-Marroquín, J.M.; Corona, F. A multi-waste management concept as a basis towards a circular economy model. Renew. Sust. Energ. Rev. 2019, 111, 481–489. [Google Scholar] [CrossRef]

- Neves, L.C.M.; Converti, A.; Vessoni Penna, T.C. Biogas production: New trends for alternative energy sources in rural and urban zones. Chem. Eng. Technol. 2009, 32, 1147–1153. [Google Scholar] [CrossRef]

- Donia, E.; Mineo, A.M.; Sgroi, F. A methodological approach for assessing businness investments in renewable resources from a circular economy perspective. Land Use Policy 2018, 76, 823–827. [Google Scholar] [CrossRef]

- Maciel-Silva, F.W.; Buller, L.S.; MBB Gonçalves, M.L.; Rostagno, M.A.; Forster-Carneiro, T. Sustainable development in the Legal Amazon: Energy recovery from açaí seeds. Biofuels Bioprod. Biorefining 2021, 15, 1174–1189. [Google Scholar] [CrossRef]

- Brazil. Brazil Inaugurates One of the Largest Biogas Plants in the World, in SP. Plateau. 2020. Available online: https://www.gov.br/planalto/pt-br/acompanhe-o-planalto/noticias/2020/10/brasil-inaugura-uma-das-maiores-plantas-de-biogas-do-mundo-em-sp (accessed on 27 January 2021).

- Picardo, A.; Soltero, V.M.; Peralta, M.E.; Chacartegui, R. District heating based on biogas from wastewater treatment plant. Energy 2019, 180, 649–664. [Google Scholar] [CrossRef]

- Molina-Moreno, V.; Leyva-Díaz, J.C.; Llorens-Montes, F.J.; Cortés-García, F.J. Design of indicators of circular economy as instruments for the evaluation of sustainability and efficiency in wastewater from pig farming industry. Water 2017, 9, 653. [Google Scholar] [CrossRef]

- Xue, Y.N.; Luan, W.X.; Wang, H.; Yang, Y.J. Environmental and economic benefits of carbon emission reduction in animal husbandry via the circular economy: Case study of pig farming in Liaoning, China. J. Clean. Prod. 2019, 238, 117968. [Google Scholar] [CrossRef]

- Xu, X.; Ma, Z.; Chen, Y.; Gu, X.; Liu, Q.; Wang, Y.; SUN, M.; Chang, D. Circular economy pattern of livestock manure management in Longyou, China. J. Mater. Cycles Waste Manag. 2018, 20, 1050–1062. [Google Scholar] [CrossRef]

- Loizia, P.; Neofytou, N.; Zorpas, A.A. The concept of circular economy strategy in food waste management for the optimization of energy production through anaerobic digestion. Environ. Sci. Pollut. Res. 2019, 26, 14766–14773. [Google Scholar] [CrossRef] [PubMed]

- Slorach, P.C.; Jeswani, H.K.; Cuéllar-Franca, R.; Azapagic, A. Environmental sustainability of anaerobic digestion of household food waste. J. Environ. Manag. 2019, 236, 798–814. [Google Scholar] [CrossRef] [PubMed]

- Czekała, W.; Lewicki, A.; Pochwatka, P.; Czekała, A.; Wojcieszak, D.; Jóźwiakowski, K.; Waliszewska, H. Digestate management in polish farms as an element of the nutrient cycle. J. Clean. Prod. 2020, 242, 118454. [Google Scholar] [CrossRef]

- Paul, S.; Dutta, A.; Defersha, F.; Dubey, B. Municipal food waste to biomethane and biofertilizer: A circular economy concept. Waste Biomass Valorization 2018, 9, 601–611. [Google Scholar] [CrossRef]

- Grippo, V.; Romano, S.; Vastola, A. Multi-criteria evaluation of bran use to promote circularity in the cereal production chain. Nat. Resour. Res. 2019, 28, 125–137. [Google Scholar] [CrossRef]

- Lybæk, R.; Kjær, T. Enhancing identified circular economic benefits related to the deployment of the Solrød biogas plant. Eng. Appl. Sci. Res. 2017, 44, 97–105. [Google Scholar]

- Winquist, E.; Rikkonen, P.; Pyysiäinen, J.; Varho, V. Is biogas an energy or a sustainability product?-Business opportunities in the Finnish biogas branch. J. Clean. Prod. 2019, 233, 1344–1354. [Google Scholar] [CrossRef]

- Tampio, E.A.; Blasco, L.; Vainio, M.M.; Kahala, M.M.; Rasi, S.E. Volatile fatty acids (VFAs) and methane from food waste and cow slurry: Comparison of biogas and VFA fermentation processes. GCB Bioenergy 2019, 11, 72–84. [Google Scholar] [CrossRef]

- Stoknes, K.; Scholwin, F.; Krzesiński, W.; Wojciechowska, E.; Jasińska, A. Efficiency of a novel “Food to waste to food” system including anaerobic digestion of food waste and cultivation of vegetables on digestate in a bubble-insulated greenhouse. Waste Manag. 2016, 56, 466–476. [Google Scholar] [CrossRef]

- Kougias, P.G.; Angelidaki, I. Biogas and its opportunities—A review. Front. Environ. Sci. Eng. 2018, 12, 1–12. [Google Scholar] [CrossRef]

- Pérez-Camacho, M.N.; Curry, R.; Cromie, T. Life cycle environmental impacts of substituting food wastes for traditional anaerobic digestion feedstocks. Waste Manag. 2018, 73, 140–155. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cecchi, F.; Cavinato, C. Smart approaches to food waste final disposal. Int. J. Environ. Res. Public Health 2019, 16, 2860. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kiselev, A.V.; Magaril, E.R.; Rada, E.C. Energy and sustainability assessment of municipal wastewater treatment under circular economy paradigm. WIT Trans. Ecol. Environ. 2019, 237, 109–120. [Google Scholar]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M. An economic analysis of biogas-biomethane chain from animal residues in Italy. J. Clean. Prod. 2019, 230, 888–897. [Google Scholar] [CrossRef]

- Ferella, F.; Cucchiella, F.; D’Adamo, I.; Gallucci, K. A techno-economic assessment of biogas upgrading in a developed market. J. Clean. Prod. 2019, 210, 945–957. [Google Scholar] [CrossRef]

- Barampouti, E.M.; Mai, S.; Malamis, D.; Moustakas, K.; Loizidou, M. Liquid biofuels from the organic fraction of municipal solid waste: A review. Renew. Sust. Energ. Rev. 2019, 110, 298–314. [Google Scholar] [CrossRef]

- Chang, C.C.; Chen, Y.H.; Lin, Y.S.; Hung, Z.S.; Yuan, M.H.; Chang, C.Y.; Li, Y.; Shie, J.; Chen, Y.; Wang, Y.; et al. A pilot plant study on the autoclaving of food wastes for resource recovery and reutilization. Sustainability 2018, 10, 3566. [Google Scholar] [CrossRef] [Green Version]

- Gontard, N.; Sonesson, U.; Birkved, M.; Majone, M.; Bolzonella, D.; Celli, A.; Angellier-Coussy, H.; Jang, G.; Verniquet, A.; Broze, J.; et al. A research challenge vision regarding management of agricultural waste in a circular bio-based economy. Crit. Rev. Environ. Sci. Technol. 2018, 48, 614–654. [Google Scholar] [CrossRef] [Green Version]

- Osman, M.M.; Shao, X.; Zhao, D.; Basheer, A.K.; Jin, H.; Zhang, Y. Methane Production from alginate-extracted and non-extracted waste of Laminaria japonica: Anaerobic mono-and synergetic co-digestion effects on yield. Sustainability 2019, 11, 1269. [Google Scholar] [CrossRef] [Green Version]

- Muradin, M.; Joachimiak-Lechman, K.; Foltynowicz, Z. Evaluation of eco-efficiency of two alternative agricultural biogas plants. Appl. Sci. 2018, 8, 2083. [Google Scholar] [CrossRef] [Green Version]

- Hadin, Å.; Hillman, K.; Eriksson, O. Prospects for increased energy recovery from horse manure—A case study of management practices, environmental impact and costs. Energies 2017, 10, 1935. [Google Scholar] [CrossRef] [Green Version]

- Vondra, M.; Touš, M.; Teng, S.Y. Digestate evaporation treatment in biogas plants: A techno-economic assessment by Monte Carlo, neural networks and decision trees. J. Clean. Prod. 2019, 238, 117870. [Google Scholar] [CrossRef] [Green Version]

- Magrí, A.; Giovannini, F.; Connan, R.; Bridoux, G.; Béline, F. Nutrient management from biogas digester effluents: A bibliometric-based analysis of publications and patents. Int. J. Environ. Sci. Technol. 2017, 14, 1739–1756. [Google Scholar] [CrossRef]

- Dahlin, A.S.; Eriksson, J.; Campbell, C.D.; Öborn, I. Soil amendment affects Cd uptake by wheat—Are we underestimating the risks from chloride inputs? Sci. Total Environ. 2016, 554, 349–357. [Google Scholar] [CrossRef] [PubMed]

- Rada, E.C.; Costa, L.; Pradella, C.; Adami, L. Unconventional small-scale biogas production with reduced local impact. Energy Resour. Policies Sustain. 2019, 4, 198–208. [Google Scholar] [CrossRef]

- Islam, K.N.; Sarker, T.; Taghizadeh-Hesary, F.; Atri, A.C.; Alam, M.S. Renewable energy generation from livestock waste for a sustainable circular economy in Bangladesh. Renew. Sust. Energ. Rev. 2021, 139, 110695. [Google Scholar] [CrossRef]

- Rauseo, J.; Caracciolo, A.B.; Ademollo, N.; Cardoni, M.; Di Lenola, M.; Gaze, W.; Stanton, I.; Grenni, P.; Pescatore, T.; Spataro, F.; et al. Dissipation of the antibiotic sulfamethoxazole in a soil amended with anaerobically digested cattle manure. J. Hazard. Mater. 2019, 378, 120769. [Google Scholar] [CrossRef]

- Arruda, M.H.; Amaral, L.D.P.; Pires, O.P.; Barufi, C.R. Sizing of biodigester for alternative energy generation. Sci. Electron. J. Agron. 2002, 1, 1–8. [Google Scholar]

- Abad, V.; Avila, R.; Vicent, T.; Font, X. Promoting circular economy in the surroundings of an organic fraction of municipal solid waste anaerobic digestion treatment plant: Biogas production impact and economic factors. Bioresour. Technol. 2019, 283, 10–17. [Google Scholar] [CrossRef]

- Svanström, M.; Heimersson, S.; Peters, G.; Harder, R.; I’Ons, D.; Finnson, A.; Olsson, J. Life cycle assessment of sludge management with phosphorus utilisation and improved hygienisation in Sweden. Water Sci. Technol. 2017, 75, 2013–2024. [Google Scholar] [CrossRef]

- Yazan, D.M.; Cafagna, D.; Fraccascia, L.; Mes, M.; Pontrandolfo, P.; Zijm, H. Economic sustainability of biogas production from animal manure: A regional circular economy model. Manag. Res. Rev. 2018, 41, 605–624. [Google Scholar] [CrossRef] [Green Version]

- Madsen, D.Ø. SWOT analysis: A management fashion perspective. Int. J. Bus. Res. 2016, 16, 39–56. [Google Scholar] [CrossRef]

- Vlados, C. On a correlative and evolutionary SWOT analysis. J. Strategy Manag. 2019, 12, 347–363. [Google Scholar] [CrossRef]

- Gottfried, O.; De Clercq, D.; Blair, E.; Weng, X.; Wang, C. SWOT-AHP-TOWS analysis of private investment behavior in the Chinese biogas sector. J. Clean. Prod. 2018, 184, 632–647. [Google Scholar] [CrossRef]

- Paes, L.A.B.; Bezerra, B.S.; Deus, R.M.; Jugend, D.; Battistelle, R.A.G. Organic solid waste management in a circular economy perspective–A systematic review and SWOT analysis. J. Clean. Prod. 2019, 239, 118086. [Google Scholar] [CrossRef]

- Helms, M.M.; Nixon, J. Exploring SWOT analysis–where are we now? A review of academic research from the last decade. J. Strategy Manag. 2010, 3, 215–251. [Google Scholar] [CrossRef]

- Vinuto, J. Snowball sampling in qualitative research: An open debate. Temáticas 2014, 22, 203–220. [Google Scholar]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).