Abstract

The paper considers the integration and joint operation of a methane steam reforming unit (MSRU) and a heat pump unit (HPU) at a thermal power plant (TPP) as one of the possible ways to follow the global decarbonization policy. Research methods are simulation modeling of a thermal power plant in the program “United Cycle” and analysis of thermodynamic cycles of heat pumps. The Petrozavodskaya combined heat and power plant (CHPP) was selected as the object of the research. During the research, technological schemes for hydrogen production at the Petrozavodskaya CHPP were developed: with steam extraction to MSRU from a live steam collector and with the use of production steam. A scheme for HPU integration is proposed to reduce the cost of hydrogen and to reduce waste heat. A heat pump is used to preheat natural gas before going to MSRU. A method for determining fuel costs for hydrogen production in the trigeneration cycle of a thermal power plant was developed. The minimum specific fuel consumption for hydrogen production—7.854 t ref.f./t H2—is achieved in the mode with steam extraction to MSRU from the turbine PT-60-130/13 (industrial extraction with a flow rate of 30 t/h). At this mode, the coefficient of fuel heat utilization is the highest among all modes with hydrogen production—66.18%.

1. Introduction

Over the past two decades, there has been an active development and implementation of the global decarbonization policy. The direction of this policy was set by the United Nations (UN), which in 1992 held a conference on environment and development in Rio de Janeiro [1]. In order to implement the concept of decarbonization and control the progress of countries on the path of such a policy, conferences on environmental protection and decarbonization began to be held periodically [2,3,4].

The countries of the European Union (EU) are the most active participants in the campaign to reduce the carbon footprint. In 2020, the EU countries announced the program “A European Green Deal” to achieve decarbonization [5].

As part of the EU strategy on energy system integration [6], in which, in addition to forming links between the EU sectors in various energy carriers (electricity, heat, fuel, cold), it is planned to include hydrogen in the list of the above energy carriers. In 2020, simultaneously with the EU hydrogen strategy, the European Clean Hydrogen Alliance [7] was created as part of a new industrial strategy for Europe.

In Australia, in 2019, the government presented its Australia’s National Hydrogen Strategy, together with the authorities of individual states. Its goal is to position its industry as a major global player in the hydrogen industry by 2030 [8].

In the Russian Federation, in order to reduce the harmful impact of the production and energy sectors on the environment, the Federal Law “About Limiting Greenhouse Gas Emissions” was issued [9]. Such a policy of Russia stimulates research in the field of using secondary energy resources [10,11,12,13,14], in particular, heat pump units (HPU) [12,13,14].

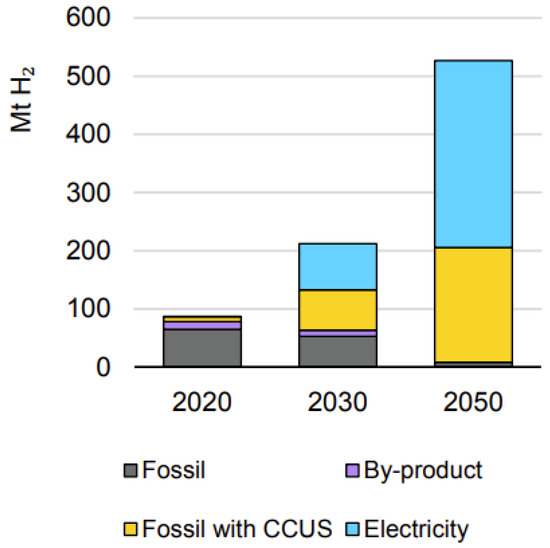

By 2020, fossil resources accounted for 96% of the main sources of hydrogen, of which steam reforming of natural gas is about 48% [15]. With the implementation of Net Zero Emissions Scenario—the pathway for the global energy sector to achieve net zero CO2 emissions by 2050 [16]—by the International Energy Agency, as hydrogen production increases, the share of hydrogen produced by electrolysis will increase significantly (Figure 1). However, with the widespread introduction of carbon capture, utilization, and storage (CCUS) technologies into production, the share of hydrogen obtained from fossil fuels with CCUS will also increase.

Figure 1.

Sources of hydrogen production in Net Zero Emissions Scenario, 2020–2050 from IEA Global Hydrogen Review 2021 [16].

One of the possible directions for the implementation of the above is “n-generation”. This idea of simultaneous production of several different types of products at the facilities of the energy sector has been actively developed over the past two decades by both foreign [17,18,19] and Russian theoretical studies [20,21].

In addition to electricity and heat, hydrogen is most often offered as an additional product [20,21], and low-grade heat is considered as an energy carrier [12,13,14]. It is assumed that during off-peak times, electricity and heat consumption can be used to produce additional technological products.

In connection with the above, under the influence of global trends in the transition to a low-carbon economy, hydrogen production should become one of the most dynamically developing areas of energy resource processing [22]. The Russian hydrogen policy is supported by federal strategic documents: the economic security strategy [23], the energy strategy [24], the environmental security strategy [25], and the concept for the development of hydrogen energy in the Russian Federation [22].

More than half of the hydrogen produced industrially in the world is produced by the conversion of natural gas. An analysis of the scientific literature indicates the possibility of a transition to low-carbon energy by obtaining hydrogen from synthesis gas [26,27] generated in methane steam reforming units [28,29].

Methane steam reforming (MSR) is widely used to produce hydrogen in oil refineries and petrochemical complexes. Some studies began to appear aimed at integrating MSRU into technological schemes of thermal power plants [28,29].

The authors of [28] considered the possibility and expediency of integrating a methane steam reforming unit into the technological scheme of a combined cycle power plant. The authors proposed to mix the synthesis gas generated by the unit with the natural gas supplied to the gas turbine, or to install an additional gas turbine that runs entirely on the resulting synthesis gas. The second option turned out to be technically the most efficient due to the increase in the total power generation of a plant.

The paper [29] also considers the possibility of integrating MSRU with an additional CO2 trap into the circuit of a thermal power plant, which includes a combined cycle plant. The results showed a greater efficiency of their circuit design in comparison with a conventional autothermal reformer due to the greater simplicity and low cost of the proposed circuit.

The use of heat pump units for the utilization of a secondary energy resource—waste heat—can provide an increase in the energy efficiency of production, especially in conditions of energy-intensive products. The involvement of consumers of low-grade heat, not suitable for direct use, in the technological process of energy facilities, opens up great prospects in terms of energy saving and rationalization of environmental management both at the level of a particular enterprise and at the general economic level [12].

Due to the presence of a sufficiently large number of low-grade heat sources at plants with combined heat and power generation, many researchers are considering the possibility of increasing the efficiency of work and improving the output characteristics of thermal power plants of various types and with a different composition of equipment.

The article [30] presented a new heat supply strategy for the CO2 capture process for a 600 MW coal-fired power plant based on the heat recovery from turbine exhaust steam using a two-stage heat pump. Due to more latent heat recovery from the exhaust steam, the fuel utilization coefficient was significantly enhanced.

In [31], researchers propose a new cogeneration system based on organic Rankine cycle and an absorption heat pump to achieve the dual effects of improving power output and heating capacity in a 135 MW coal-fired power plant. The increases in the power output and heating capacity were respectively increased by 1.47 MW and 32.1 MW.

Authors of [32] analyzed the use of absorption heat pump units integrated in coal-fired combined heat and power plants. In the paper, the authors created the mathematical models of a combined heat and power system with an absorption heat pump recovering waste heat of exhausted steam from a steam turbine of a coal-fired direct air-cooling unit. Authors suggested a partial replacing of a heat exchanger of a heating network. Use of heat pumps can lead to the total increase of the plant’s thermal efficiency up to 2% and, thus, reduction in the coal consumption. Thus, a possible and interesting way is the use of HPUs for heating the return network water.

Researchers studied the possibility of integrating heat pumps in order to recover low-grade heat emissions at enterprises in [33]. Integration of heat pump units in thermal schemes of manufactures leads to boosting heat generating capacities while not increasing consumption of primary fuel. Moreover, the same authors suggested some designs of the inclusion of absorption heat pumps to such an enterprise [34].

The above research on optimizing the schemes of traditional thermal power plants with combined generation of thermal energy and electricity was carried out to reduce the rather large heat losses of the cycle itself. The limited amount of fuel sources and the constantly increasing needs in electricity stimulated the development of production of electrical and heat energy by means of combined-cycle gas turbine combined heat and power plants [12]. In parallel with the active commissioning of combined cycle plants, research is underway to integrate heat pumps into the thermal circuits of such plants in order to improve the output characteristics of the combined cycle.

In [35], researchers created the model of integrating a heat pump into the circuit of a gas–steam combined cycle power plant for heating the return network water. The exhaust steam played the role of a low-potential heat source for a heat pump. The increase of the energy efficiency amounted to 2%.

The [36] research work shows that the integration of heat pumps into a combined cycle gas turbine for heating network water can enhance its performances. The authors used the flue gas as a source of a low-potential heat. The integration of heat pumps totally increases seasonal global efficiency up to 5%.

Heat pump units perform well in the conditions of their use for heating low-temperature fluids, in particular for heating gas turbines intake air at thermal power plants operating in zones of low temperatures and high humidity [12]. In [37,38], possibility of regulating the intake air temperature in summertime using absorption heat pumps and, as a result, the increase of a combined cycle gas turbine electricity generation was highlighted.

Since, at the moment, the direction associated with the integration of hydrogen-generating units into schemes of thermal power plants has not been sufficiently studied, and there are no works to optimize such a cycle with the use of heat pumps, this field of knowledge seems to be promising.

When integrating the solutions proposed in the course of this research work into existing thermal power plants, it is possible to achieve a comprehensive solution to the existing scientific problem. Along with increasing the energy efficiency of the main production at TPPs, the issue of reducing the specific energy intensity of hydrogen production through the use of low-potential heat sources (LPHS) is being addressed. Applying this approach, power plants can become system producers of science-intensive products with a lower cost due to the use of secondary energy resources.

The novelty of this work lies in:

- Development and research of schemes for transferring real thermal power plants to a trigeneration cycle with the production of a new product—hydrogen—by the method of methane steam reforming;

- Increasing the efficiency of trigeneration plants by integrating a heat pump that uses waste heat from the power plant;

- Development of a methodology for determining the cost of fuel for the production of hydrogen in the trigeneration cycle of a thermal power plant.

The purpose of the work is to study the possibility of using heat pumps in the hydrogen production cycle at thermal power plants.

Tasks:

- To develop a technological scheme for the production of hydrogen at TPPs;

- To propose a scheme for including HPUs in TPPs schemes to reduce the cost of hydrogen and reduce waste heat;

- To develop a methodology for determining fuel costs for hydrogen production in the cogeneration cycle of a thermal power plant.

2. Materials and Methods

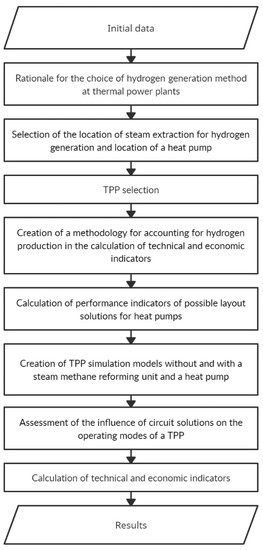

The algorithm for conducting this study is shown in Figure 2 in the form of a flowchart.

Figure 2.

Methodology for conducting a study on the integration of a hydrogen generation plant into the technological scheme of a CHPP.

2.1. Substantiation of the Choice of Hydrogen Generation Method

In connection with what was said in the introduction and the fact that in large cities of the Russian Federation the main fuel at TPPs is natural gas, a unit for the production of hydrogen by steam reforming is of interest for integration into the TPP scheme. Methane acts as the natural gas used in the unit, so the process of methane steam reforming is considered in this research.

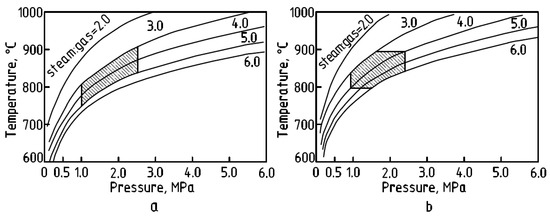

Methane steam reforming is an endothermic catalytic reaction in which methane and steam react at high temperature in a coiled furnace. The study considers the introduction of MSRU with a capacity of 75 thousand m3/h (6.74 t/h). For the needs of such a unit, (30 ÷ 90) t/h of steam is required [39]. It makes sense to carry out the reaction at a pressure not lower than 1.0 MPa (Figure 3) and a temperature not lower than 750 °C [40]. A furnace is used to heat the mixture of steam with natural gas to the required reaction temperature. In order to compensate for pressure losses along the coil of MSRU furnace, it was decided to supply steam with a pressure of 12.5 kgf/cm2 to MSRU. The steam from the live steam collector or industrial steam can be used for hydrogen production.

Figure 3.

Modes of the methane steam reforming process, providing it is under conditions of thermodynamic equilibrium, for obtaining (a) 95% H2 and (b) 98% H2 [40].

In this paper, we consider four options for supplying steam to the MSR unit:

- -

- Use of industrial extraction steam with a flow rate of 30 t/h;

- -

- Use of industrial extraction steam with a flow rate of 90 t/h;

- -

- Use of steam from the live steam collector with a flow rate of 30 t/h;

- -

- Use of steam from the live steam collector with a flow rate of 90 t/h.

At a stage of selecting steam extraction sites for the steam reforming of methane, it is possible to predict the results in advance, using the power underproduction factor of steam. The extraction of part of the steam from the turbine leads to underproduction of electric power in the turbine by this flow. The power underproduction factor of the steam extraction shows what proportion of the enthalpy drop was not completed by the extracted steam in the turbine in relation to the total enthalpy drop of the steam flow.

The product of the underproduction factor and the steam consumption in the extraction is nothing more than some additional amount of fresh steam that must be sent to the turbine head to compensate for the part of the steam extracted from the steam turbine.

The underproduction coefficient is calculated by the equation:

where —enthalpy of the extracted steam, kJ/kg; —enthalpy of steam going to the turbine condenser, kJ/kg; —steam enthalpy in the turbine head, kJ/kg.

Based on the above equation, it can be seen that in order to compensate for steam extracted from the boiler header (yext = 1), it will be necessary to increase the steam production by boilers by the same amount that is planned to be extracted to the MSRU.

2.2. Schematic Solution for Integration of a Heat Pump

The temperature of the gas entering MSRU coincides with the outside air temperature, so the steam–gas mixture should be heated using a gas-fired MSRU furnace. It is proposed to use a vapor compression heat pump (VCHP) of a simple scheme for the purpose of gas heating before mixing with steam. Such a solution will allow not only to utilize the waste heat, but also to reduce the fuel consumption for heating the mixture to the required temperature of the steam reforming reaction (minimum 750 °C [40]).

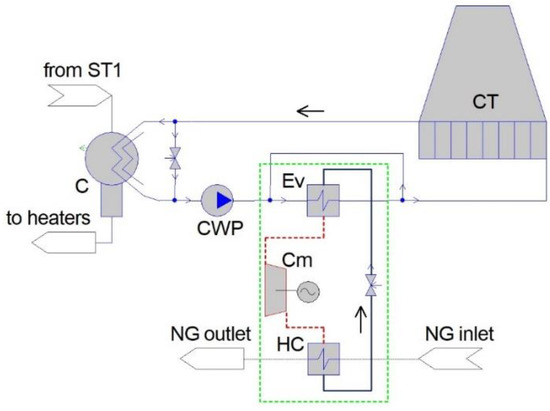

Figure 4 shows a variant of a heat pump integration for heating natural gas before MSRU.

Figure 4.

Scheme for integrating HPU into the scheme of a thermal power plant. CT—cooling tower of the circulating water supply system; Ev—HPU evaporator; C—steam turbine condenser; Cm—HPU compressor; HC—HPU condenser; CWP—cooling water pump; NG—natural gas.

The water of the circulating cooling system can act as a LPHS. This source has a constant temperature throughout the whole year and is also closer than the others to the possible location of MSRU—directly near a turbine. Such a place for MSRU is needed to reduce losses in steam pipelines.

In addition to calculating the indicators of a heat pump, the “CoolPack” (Denmark) software product is used to analyze thermodynamic cycles of HPUs and their working fluids properties. Ozone-friendly R134a is considered as the working fluid for the integrated HPU [14].

2.3. TPP Selection and Model Creation

When choosing an energy facility for MSRU integration, it is important to fulfill the following conditions: availability of steam extraction with necessary parameters; availability of free space for MSRU construction; high coefficient of utilization of installed capacity; low degree of development of the park resource.

The combined heat and power plant of TGC-1—the Petrozavodskaya CHPP (PCHPP)—was chosen as the object of study. This object meets the above criteria:

- -

- CHPP has a live steam collector and production steam extraction;

- -

- The CHPP is located on the outskirts of Petrozavodsk, and, as a result, has the opportunity to expand the territory for new constructions;

- -

- The coefficient of utilization of installed capacity of the Petrozavodskaya CHPP in 2020 was 44.2%, in 2019—51.0%.

Installed electric power—280 MW; installed thermal power—801.3 MW (689 Gcal/h). The CHPP consists of 3 boilers BKZ-420-140NGM, 1 turbine unit PT-60-130/13 st. No 1 (ST1), 2 turbines T-110/120-130 st. No 2, st. No 3.

Simulation modeling methods are used to assess the mutual influence of the operating modes of CHPP equipment on the efficiency of the HPU and MSRU and their influence on the characteristics of the Petrozavodskaya CHPP. Analysis of the impact of the MSRU integration into the technological scheme of the CHPP on the operating modes is carried out using simulation methods in “United Cycle” (UC).

The “United Cycle” program was created by the company “M Systems” (Russia). The program allows to simulate almost all types of thermal power plants and systems—steam power cycle, combined cycle, boilers, industrial power systems. UC is used to develop technical documentation at various design stages: feasibility study; development of project documentation; development of working documentation.

Assessment of the thermal efficiency of new plants or ways to modernize existing power units, obtaining real operating characteristics of thermal mechanical equipment, processing thermal test data, can be and are solved within the framework of a unified approach based on balance equations. The latter are nothing but the equations of the laws of conservation of mass, energy (in thermodynamic form), and momentum [41].

“United Cycle” is designed to solve the problems of determining the best structure and composition of the equipment of a heat and power plant and calculating stationary operating modes. This package is based on an algorithm in which the solution of a system of nonlinear equations is sought in a single iterative process without splitting the original graph into subgraphs. The algorithm allows for determining the characteristics of power plants with technological schemes of any complexity for various stationary operating modes, using the parameters of the base case [41].

The package “United Cycle” is notable for the following features [42]:

- Level of detailing for a heat-flow diagram of a simulated object is high;

- Models of equipment elements have been debugged and adjusted during many years of operation;

- Calculation accuracy of material and heat balance is high (10−6);

- There are several stages of testing at each step of model construction, calculation, and the analysis of calculation results;

- Graphical environment of the software is well developed; the results are visual.

The disadvantage of creating a model in the program “United Cycle” is the complexity of determining the necessary “completeness of modeling” when creating a thermal circuit. The created simulation model, on the one hand, should be easy to work with, on the other hand, it should provide the ability to simulate any stationary operating conditions at plants (taking into account possible shutdowns of the main and auxiliary equipment/groups of equipment, etc.; taking into account partial or complete bypass of equipment).

The process of creating a mathematical model can be represented as follows:

- Creation of a mathematical model of an object, or design of a scheme;

- Parameterization of the mathematical model of the object, i.e., setting the parameters of the environment and the characteristics of the equipment for calculating the base case;

- Setting the operating mode of the object by entering the mode parameters.

For operating plants, the parameterization stage consists of two parts: parameterization according to the factory characteristics of the equipment and adjustment of these characteristics, taking into account the actual state of the equipment of a plant.

An important condition for creating a mathematical model is to provide the possibility of simulating the same variety of operational regime states that a real plant has.

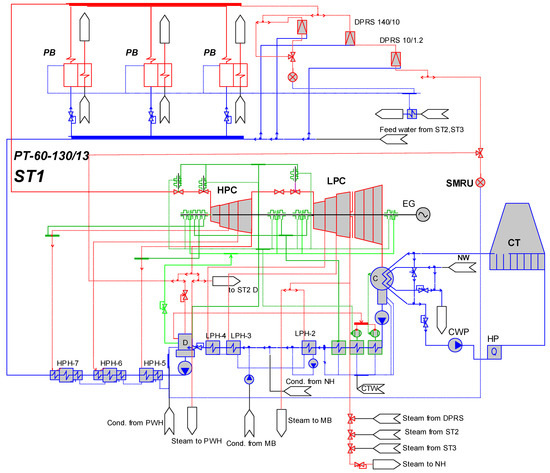

Figure 5 shows a part of the simulation model of the Petrozavodskaya CHPP—a diagram of the integration of a hydrogen generation unit when the boilers take live steam from a collector next to the PT-60-130/13 turbine.

Figure 5.

Simulation model of PT-60/130/13 st. No 1. D—deaerator; PB—power boiler; HPH—high-pressure heater; LPH—low-pressure heater; PWH—peaking water heater; MB—main boiler; RNW—return network water; NH—network heater; DPRS—desuperheating and pressure reducing system; ST—steam turbine unit; HPC—high-pressure turbine cylinder; LPC—low-pressure turbine cylinder; EG—electric generator.

During the simulation, a constant level of heat supply (359.4 MW) to consumers and electricity generation at the generator terminals of steam turbines (252.0 MW) are maintained.

2.4. Model Adequacy

The adequacy of a mathematical model is the correspondence of the results of a computational experiment to the behavior of a real object. This relevance should be assessed in terms of the objectives of the study. Therefore, various approaches to assessing the adequacy of different models are possible.

The verification of the adequacy of a created mathematical model in relation to the real CHPP was carried out by the method of step-by-step analysis of the calculated modes parameters using the «United Cycle» CAD system and control parameters of the power equipment operation.

As control parameters, we used the actual parameters of the characteristic operating mode of the turbine units for 14 January 2021, obtained using hourly archives of the readings of standard instruments of the automated process control system (APCS). Table 1 shows the APCS data for PT-60-130/13 st. No 1 for its operating mode and their comparison with the results of simulation using UC. The average deviation is 1.52%, which indicates the adequacy and applicability of the created model.

Table 1.

Model data and control parameters of the Petrozavodskaya CHPP ST1.

2.5. Accounting for Hydrogen Production When Calculating Technical and Economic Indicators

The technical and economic indicators include specific fuel consumption for the production of energy products and coefficient of fuel heat utilization (CFHU).

In the course of this work, a “physical” method, also called balance, was used to distribute fuel consumption for the generation and release of trigeneration products at the thermal power plant. This method has been official for the Russian Federation since 2013 [43].

The method is based on the distribution of fuel costs in proportion to the amount of fuel consumed for each type of energy based on the heat balance. At the same time, it is assumed that the same amount of fuel is spent on obtaining thermal energy from turbine extractions as when heat is supplied directly from boiler units.

Total heat output of steam boilers, MW:

where —steam energy for electricity generation, MW; —steam energy for industrial steam extraction, MW; —steam energy for heat generation, MW.

The first step in the balance method is to allocate the total fuel consumption to the products of a thermal power plant.

Reference fuel consumption for electricity generation, t ref.f./h:

where —fuel consumption at a CCHP, t ref.f./h.

Reference fuel consumption for industrial steam generation, t ref.f./h:

Reference fuel consumption for heat generation, t ref.f./h:

The second step in the balance method is the calculation of the specific fuel consumption.

Specific reference fuel consumption for electricity supply, t ref.f./(MW∙h):

where —electricity generation, MW; —the electricity for own needs, MW.

Specific reference fuel consumption for industrial steam supply, t ref.f./(MW∙h):

where —own needs for industrial steam, MW.

Specific reference fuel consumption for heat supply, t ref.f./(MW∙h):

where —own heating needs, MW.

Since the disadvantage of this method is the equalization of high-potential and low-potential heat, this method cannot be called “fair”. Therefore, the next stage of the study will use other methods for distributing fuel costs when integrating MSRU into the CHPP scheme. Of particular interest is the consideration of the exergy method, since in addition to quantitative indicators, it also takes into account the qualitative indicators of the products produced.

Since hydrogen is a completely new product produced at thermal power plants, it is necessary to revise the existing methodology for distributing fuel consumption in the combined production of several products at thermal power plants. The specific consumption of reference fuel for hydrogen production will be determined, first of all, by the consumption of fuel supplied to the MSR unit (for the implementation of the MSR reaction and for the furnace of MSRU), as well as the fuel consumption spent to generate steam, which goes to the methane steam reforming unit.

In the mode when industrial extraction steam is used for the needs of MSRU, the consumption of reference fuel for hydrogen production, t ref.f./h:

where —fraction of industrial steam extraction used for hydrogen production (); —heat load of industrial steam extraction of ST1, MW; —reference fuel consumption for industrial steam extraction, t ref.f./h; —thermal power of the ST1 turbine unit, MW; —reference fuel consumption for the reaction implementation, t ref.f./h; —reference fuel consumption for the MSRU furnace, t ref.f./h.

Reference fuel consumption for hydrogen production in the mode with steam extraction from the collector behind the boilers for the MSRU needs, t ref.f./h:

where —thermal power of steam extracted for the MSRU needs, MW.

Specific reference fuel consumption for steam supply at MSRU, t ref.f./t:

where —amount of produced hydrogen, t/h.

CFHU is the ratio of useful energy from a CHPP to the available heat of the burned fuel:

where —thermal load of network heaters, MW; —thermal load of built-in condenser bundle, MW; —net calorific value of hydrogen; 1.163—the coefficient for converting Gcal/h to MW: 1.163 MW = 1 Gcal/h; —net calorific value of reference fuel.

3. Results and Discussions

The extracted steam parameters and characteristics of HPU are presented in Table 2.

Table 2.

The extracted steam parameters and characteristics of HPU.

To ensure the performance of MSRU—75 thousand m3/h (6.74 t/h)—the supply of 28.79 t/h of methane is required. A heat pump is used for methane preheating in order to reduce fuel consumption in the furnace of the unit. The steam taken for the MSRU is superheated steam, i.e., has a temperature above the saturation temperature (at a pressure of 12.5 kgf/cm2, the temperature of saturated steam is 188.9 °C). Therefore, fuel costs for heating the mixture of steam with methane are further reduced.

As follows from Table 3, under given conditions—maintaining constant levels of electricity generation and heat supply—integration of the methane steam reforming unit and the heat pump leads to a significant increase in fuel consumption of about 50%. The increase in fuel consumption is associated with the use of natural gas as a feedstock for the steam reforming process. Gas is also needed to heat the furnace of the methane steam reformer.

Table 3.

Research results.

The use of a heat pump unit for the purpose of preheating natural gas before the methane steam reformer can save some of the fuel used to heat the feedstock for methane steam reforming in the MSRU furnace. Such a circuit solution can be relevant for generating enterprises of any type, including thermal power plants, condensation electric power plants, stations with a combined cycle, as well as boiler houses. This is due to the presence of a large number of low-grade heat sources of both natural and artificial origin at energy facilities. The use of this resource allows not only to reduce the cost of production of technological products, but also to reduce the environmental burden.

As follows from the results, the use of a vapor compression heat pump unit of low power (1.47 MW) saves only 0.16 thousand m3/h of natural gas. Since this paper considers the use of HPU of a simple scheme, and refrigerant R134a is used as the working fluid of the heat pump, it is proposed to heat methane to a temperature of 95 °C. This is due to the fact that the temperature of the critical point for R134a is 101.5 °C. In order to improve the performance of a heat pump, further studies should consider a VCHP with a regenerative heat exchanger and a subcooler, provided that refrigerants with a higher critical temperature are used. In a further study, it also makes sense to consider the use of two-stage heat pumps in order to increase the heating temperature of methane before MSRU. It is also worth considering the scaling of the methane steam reformer and the use of HPUs of higher capacity for MSRU.

The minimum specific fuel consumption for hydrogen generation is achieved in the mode with industrial steam extraction with a capacity of 30 t/h to MSRU. This is due to the fact that the steam going to MSRU has the lowest power underproduction factor in comparison with other options under consideration. On the other hand, live steam taken from the boiler collector has a higher temperature, which allows saving some fuel for heating the mixture of natural gas and steam in the furnace of the methane steam reformer. However, this steam is sharp, and, therefore, has the highest power underproduction factor (yext = 1). To compensate for steam extraction from the boiler header, it is necessary to increase the steam production by the boilers by the same amount that is extracted to MSRU. The use of such a circuit solution leads to a significant decrease of CFHU (up to 5%) and, as a result, is the least profitable among the considered options. When MSRU and HPU are included in the PCHPP, a decrease in electricity supply from the plant is observed, which is due to an increase in own needs: the consumption of electricity by MSRU and HPU amounted to 7.39 MW. The decrease of CFHU in all considered modes is associated with maintaining a constant level of electricity generation at a generator terminal. When using Equation (12), where the numerator includes exactly the useful energy supplied from a plant, for a more adequate assessment of the proposed circuit solutions during the study, it was necessary to maintain a constant level of electricity supply to consumers. In further studies, it is required to consider modes with an increase in electricity generation at a generator terminal in order to compensate for the growing own needs.

The choice of circuit design depends on the parameters of the extracted steam. It is preferable to use partially exhausted steam, in particular industrial steam extraction. Due to the high prevalence at power plants with combined production of steam turbines with industrial steam extraction, the circuit solution considered in the course of the study for the MSRU integration can be used at a large number of enterprises. The proposed scheme can be adapted for use at condensation thermal power plants and boiler houses, provided that steam extraction lines are organized, as well as modeling and calculation of technical and economic indicators to assess the feasibility of upgrading thermal schemes are held.

The proposed methodology for determining the cost of fuel in the case of “n-generation” is based on the balance method of proportional distribution of fuel costs, which will be understandable and convenient for introduction into use both at existing thermal power plants under construction and modernized, regardless of the type of these plants. Further development of research is expected in the direction of developing new methods for determining the fuel consumption for hydrogen production, taking into account the second law of thermodynamics.

For the purpose of transition to low-carbon energy, it is advisable to consider transferring thermal power plants to the combustion of hydrogen and natural gas, with the creation of a gas transmission system of hydrogen and natural gas, in shares of 20% and 80%, respectively [44]. The proposed new methodology will require further elaboration during the modernization of thermal schemes for the use of the obtained hydrogen.

4. Conclusions

- Using the example of a real thermal power plant, schemes have been developed and studied that allow switching cogeneration plants to a trigeneration mode with hydrogen production by integrating a methane steam reformer.

- To optimize the hydrogen production cycle, it is proposed to use heat pumps for preheating natural gas before the methane steam reformer.

- The use of a heat pump for the purpose of heating natural gas before MSRU does not have a significant impact on the operating modes of the combined heat and power plant due to its low power (1.47 MW). HPU efficiency indicator—the energy conversion factor—is low due to the large temperature difference between the LPHS (up to 27 °C) and the gas temperature at HPU outlet (95 °C). The use of a heat pump of a simple scheme for heating natural gas from a temperature of 15 °C to 95 °C saves only 0.16 thousand m3/h of natural gas. There is a need for additional research on the optimization of cycles and the consideration of other circuit solutions for heat pumps for joint operation with MSRU.

- A new methodology was developed for the distribution of fuel consumption in the production of a new product—hydrogen—at thermal power plants. This method can be adapted for use at various types of power plants.

- The minimum specific fuel consumption for hydrogen production—7.854 t ref.f./t H2—is achieved in the mode with steam extraction to MSRU from the turbine PT-60-130/13 (industrial extraction with a flow rate of 30 t/h). At this mode, the coefficient of fuel heat utilization is the highest among all modes with hydrogen production—66.18%, which is 2.3% lower than in the scheme without the use of MSRU. This is explained by the increase in the cost of electricity for own needs to ensure the operation of MSRU and HPU (7.39 MW).

Author Contributions

Conceptualization, K.K. and I.A.; methodology, K.K. and I.A.; software, A.A.; validation, D.T., M.T. and I.A.; formal analysis, M.T.; investigation, K.K. and D.K.; resources, I.A.; data curation, A.K.; writing—original draft preparation, D.T.; writing—review and editing, A.A.; visualization, K.K.; supervision, D.K.; project administration, I.V. and A.A.; funding acquisition, I.V. and A.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was done at Peter the Great St. Petersburg Polytechnic University and supported under the strategic academic leadership program ‘Priority 2030’ of the Russian Federation (Agreement 075-15-2021-1333 dated 30 September 2021).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are not publicly available due to privacy considerations.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Abbreviations | |

| APCS | automated process control system |

| C | steam turbine condenser |

| CCUS | carbon capture, utilization, and storage |

| CFHU | coefficient of fuel heat utilization |

| CHPP | combined heat and power plant |

| Cm | HPU compressor |

| CT | cooling tower of the circulating water supply system |

| CWP | cooling water pump |

| D | deaerator |

| DRPS | desuperheating and pressure reducing system |

| EG | electric generator |

| Ev | evaporator |

| HC | HPU condenser |

| HPC | high-pressure turbine cylinder |

| HPH | high-pressure heater |

| HPU | heat pump unit |

| LPC | low-pressure turbine cylinder |

| LPH | low-pressure heater |

| LPHS | low-potential heat source |

| MB | main boiler |

| MSR | methane steam reforming |

| MSRU | methane steam reforming unit |

| NG | natural gas |

| NH | network heater |

| PB | power boiler |

| PCHPP | the Petrozavodskaya CHPP |

| PWH | peaking water heater |

| RNW | return network water |

| ST | steam turbine |

| ST1 | turbine unit PT-60-130/13 st. №1 |

| TPP | thermal power plant |

| UC | “United Cycle” |

| VCHP | vapor compression heat pump |

| Variables and Coefficients | |

| Q0Σ | total heat output of steam boilers, MW |

| QN | steam energy for electricity generation, MW |

| Qind | steam energy for industrial steam extraction, MW |

| Qh | steam energy for heat generation, MW |

| BN | reference fuel consumption for electricity generation t ref.f./h |

| Bref.f.Σ | reference fuel consumption at a CCHP, t ref.f./h |

| Bind | reference fuel consumption for industrial steam generation t ref.f./h |

| Bh | reference fuel consumption for heat generation t ref.f./h |

| ΣN | power generation, MW |

| ΣNON | electricity for own needs, MW |

| QindON | industrial steam extraction for own needs, MW |

| QhON | heat for own needs, MW |

| bN | specific fuel consumption for electricity release, t ref.f./h |

| bind | specific fuel consumption for industrial steam extraction release, t ref.f./h |

| bh | specific fuel consumption for heat release, t ref.f./h |

| BΣH2 | consumption of reference fuel for hydrogen production, t ref.f./h |

| α | fraction of industrial steam extraction used for hydrogen production |

| QindST1 | heat load of industrial steam extraction of ST1, MW |

| Bref.f.ST1 | reference fuel consumption for industrial extraction, t ref.f./h |

| QoST1 | thermal power of the ST1 turbine unit, MW |

| Bref.f.MSRU | reference fuel consumption for the reaction implementation, t ref.f./h |

| Bref.f.furn | reference fuel consumption for the MSRU furnace, t ref.f./h |

| QH2 | thermal power of steam extracted for the MSRU needs, MW |

| bH2 | specific reference fuel consumption for steam supply at MSRU, t ref.f./t |

| GH2 | amount of produced hydrogen, t/h |

| ΣQNH | thermal load of network heaters, MW |

| ΣQBB | thermal load of built-in condenser bundle, MW |

| Qcv.H2n = 33.8 Gcal/t | net calorific value of hydrogen |

| 1.163 | the coefficient for converting Gcal/h to MW: 1.163 MW = 1 Gcal/h |

| Qcv.ref.f.n = 7 Gcal/t ref.f. | net calorific value of reference fuel |

References

- The Rio Declaration on Environment and Development. Available online: https://www.un.org/ru/documents/decl_conv/declarations/riodecl.shtml (accessed on 12 September 2021).

- The United Nations Framework Convention on Climate Change (UNFCCC). Available online: https://www.un.org/ru/documents/decl_conv/conventions/climate_framework_conv.shtml (accessed on 12 September 2021).

- The Kyoto Protocol. Available online: https://www.un.org/ru/documents/decl_conv/conventions/kyoto.shtml (accessed on 12 September 2021).

- The Paris Agreement. Available online: https://unfccc.int/files/meetings/paris_nov_2015/application/pdf/paris_agreement_russian_.pdf (accessed on 12 September 2021).

- A European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 12 September 2021).

- EU Strategy on Energy System Integration. Available online: https://ec.europa.eu/energy/topics/energy-system-integration/eu-strategy-energy-system-integration_en (accessed on 19 September 2021).

- European Clean Hydrogen Alliance. Available online: https://ec.europa.eu/growth/industry/strategy/industrial-alliances/european-clean-hydrogen-alliance_en (accessed on 11 September 2021).

- Australia’s National Hydrogen Strategy. Available online: https://www.industry.gov.au/data-and-publications/australias-national-hydrogen-strategy (accessed on 15 September 2021).

- Russian Federal Law No. 296 on Limiting Greenhouse Gas Emissions. Available online: http://publication.pravo.gov.ru/Document/View/0001202107020031 (accessed on 12 September 2021).

- Vladimirov, I.A.; Mukhametova, L.; Yamashkin, M.V. Some Aspects of Use of Organic Containing Waste for Electrical and Thermal Energy Generation. In Proceedings of the High Speed Turbomachines And Electrical Drives Conference 2020 (HSTED-2020), Prague, Czech Republic, 14–15 May 2020; p. 1084. [Google Scholar] [CrossRef]

- Fomin, V.; Kalyutik, A. Combined-Cycle Gas Turbine Plant Based on Steam-Turbine Unit and a Parallel Superimposed Gas-turbine Plant with Waste Heat Recovery Boiler. In Proceedings of the International Scientific Electric Power Conference (ISEPC-2019), Saint Petersburg, Russia, 23–24 May 2019; p. 012139. [Google Scholar] [CrossRef] [Green Version]

- Sergeev, V.; Anikina, I.; Kalmykov, K. Using Heat Pumps to Improve the Efficiency of Combined-Cycle Gas Turbines. Energies 2021, 14, 2685. [Google Scholar] [CrossRef]

- Anikina, I.D.; Sergeyev, V.V.; Amosov, N.T.; Luchko, M.G. Use of heat pumps in turbogenerator hydrogen cooling systems at thermal power plant. Int. J. Hydrogen Energy 2017, 42, 636–642. [Google Scholar] [CrossRef]

- Sergeyev, V.V.; Anikina, I.D.; Kalmykov, K.S.; Naletov, I.D. Efficiency of Using Heat Pumps with Various Refrigerants in Real Steam Turbine Power Units with PT-80 and T-250 Turbines. In Proceedings of the International Scientific Conference on Energy, Environmental and Construction Engineering (EECE-2019), Saint Petersburg, Russia, 19–20 November 2019; Volume 140, p. 10001. [Google Scholar] [CrossRef] [Green Version]

- Cao, L.; Yu, I. Biorenewable hydrogen production through biomass gasification: A review and future prospects. Environ. Res. 2020, 186, 109547. [Google Scholar] [CrossRef] [PubMed]

- IEA. Global Hydrogen Review 2021; IEA: Paris, France, 2021; Available online: https://www.iea.org/reports/global-hydrogen-review-2021 (accessed on 20 September 2021).

- Chicco, G.; Mancarella, P. Distributed multigeneration: A comprehensive view. Renew. Sustain. Energy Rev. 2009, 13, 535–551. [Google Scholar] [CrossRef]

- Mancarella, P. MES (multi-energy systems): An overview of concepts and evaluation models. Energy 2014, 65, 1–17. [Google Scholar] [CrossRef]

- Jana, K.; Ray, A.; Majoumerd, M.M.; Assadi, M.; De, S. Polygeneration as a future sustainable energy solution—A comprehensive review. Appl. Energy 2017, 202, 88–111. [Google Scholar] [CrossRef]

- Tuvalbaev, B.G.; Moiseev, V.I. Operation of TPPs in a constant mode with the production of additional products on unclaimed energy. Energy Save Water Treat. 2013, 4, 24–27. [Google Scholar]

- Tuvalbaev, B.G.; Marchenko, M.E.; Marchenko, E.M.; Valitov, D.S. Conceptual directions of development of heat power engineering. Energy Save Water Prep. 2017, 3, 3–9. [Google Scholar]

- Decree of the Government of the Russian Federation No. 2162-r Dated August 5, 2021 on Approval of the Concept of Development of Hydrogen Energy in the Russian Federation. Available online: http://government.ru/docs/42971/ (accessed on 15 October 2021).

- Decree of the President of the Russian Federation No. 208 Dated May 13, 2017 on the Approval of the Economic Security Strategy of the Russian Federation for the Period up to 2030. Available online: http://www.kremlin.ru/acts/bank/41921 (accessed on 12 September 2021).

- Decree of the Government of the Russian Federation No. 1523-r Dated June 9, 2020 on the Approval of the Energy Strategy of the Russian Federation for the Period up to 2035. Available online: https://docs.cntd.ru/document/565068231 (accessed on 12 September 2021).

- Decree of the President of the Russian Federation No. 176 Dated April 19, 2017 on the Strategy of Environmental Safety of the Russian Federation for the Period up to 2025. Available online: http://government.ru/docs/all/111285/ (accessed on 15 October 2021).

- Balasubramanian, B.; Ortiz, A.L.; Kaytakoglu, S.; Harrison, D.P. Hydrogen from methane in a single-step process. Chem. Eng. Sci. 1999, 54, 3543–3552. [Google Scholar] [CrossRef]

- Abbas, H.F.; Daud, W.M.A.W. Hydrogen production by methane decomposition: A review. Int. J. Hydrogen Energy 2010, 35, 1160–1190. [Google Scholar] [CrossRef]

- Carapellucci, R.; Giordano, L. Upgrading existing gas-steam combined cycle power plants through steam injection and methane steam reforming. Energy 2019, 173, 229–243. [Google Scholar] [CrossRef]

- Romano, M.C.; Cassotti, E.N.; Chiesa, P.; Meyer, J.; Mastin, J. Application of the Sorption Enhanced-Steam Reforming process in combined cycle-based power plants. Energy Procedia 2011, 4, 1125–1132. [Google Scholar] [CrossRef] [Green Version]

- Guo, L.; Ding, Y.; Liao, Q.; Zhu, X.; Wang, H. A new heat supply strategy for CO2 capture process based on the heat recovery from turbine exhaust steam in a coal-fired power plant. Energy 2022, 239, 121817. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Liu, X.; Duan, C. Energy and exergy analysis of a new cogeneration system based on an organic Rankine cycle and absorption heat pump in the coal-fired power plant. Energy Convers. Manag. 2020, 223, 113293. [Google Scholar] [CrossRef]

- Zhang, H.S.; Zhao, H.B.; Li, Z.L. Performance analysis of the coal-fired power plant with combined heat and power (CHP) based on absorption heat pumps. J. Energy Inst. 2016, 89, 70–80. [Google Scholar] [CrossRef]

- Alimgazin, A.S.; Alimgazina, S.G.; Zhumagulov, M.G. Heat pump in a new modular configuration to recover low-grade heat emissions at enterprises. In Proceedings of the High Speed Turbomachines and Electrical Drives Conference 2020 (HSTED-2020), Prague, Czech Republic, 14–15 May 2020; Volume 178, p. 01003. [Google Scholar] [CrossRef]

- Alimgazin, A.S.; Prishchepova, S.A.; Sultanguzin, I.A. The use of heat transformers for the low-temperature secondary energy resources recovery in non-ferrous metallurgy enterprises. In Proceedings of the High Speed Turbomachines and Electrical Drives Conference 2020 (HSTED-2020), Prague, Czech Republic, 14–15 May 2020; Volume 178, p. 01017. [Google Scholar] [CrossRef]

- Zhang, H.S.; Zhao, H.B.; Li, Z.L.; Hu, E. Optimization Potentials for the Waste Heat Recovery of a Gas-steam Combined Cycle Power Plant Based on Absorption Heat Pump. J. Therm. Sci. 2019, 28, 283–293. [Google Scholar] [CrossRef]

- Vannoni, A.; Giugno, A.; Sorce, A. Integration of a flue gas condensing heat pump within a combined cycle: Thermodynamic, environmental and market assessment. Appl. Therm. Eng. 2021, 184, 116276. [Google Scholar] [CrossRef]

- Mendeleev, D.I.; Galitskii, Y.Y.; Marin, G.E.; Akhmetshin, A.R. Study of the work and efficiency improvement of combined-cycle gas turbine plants. In Proceedings of the International Scientific and Technical Conference Smart Energy Systems 2019 (SES-2019), Kazan, Russia, 18–20 September 2019; Volume 124, p. 05061. [Google Scholar] [CrossRef] [Green Version]

- Mendeleev, D.I.; Maryin, G.E.; Akhmetshin, A.R. Improving the efficiency of combined-cycle plant by cooling incoming air using absorption refrigerating machine. In Proceedings of the International Scientific Electric Power Conference, Saint Petersburg, Russia, 23–24 May 2019; Volume 643, p. 012099. [Google Scholar] [CrossRef]

- Steam Reforming of Methane—Hydrogen Production. Hydrogen Production in SMR. Available online: https://www.engineering-airliquide.com/ru/parovoj-riforming-metana-proizvodstvo-vodoroda (accessed on 20 September 2021).

- Pismen, M.K. Hydrogen Production in the Oil Refining Industry; Chemistry: Moscow, Russia, 1976. [Google Scholar]

- Romanov, S. “United Cycle” Software for Simulation of Flow Sheets of Power Plants. In Proceedings of the 16th International Conference on Efficiency, Cost, Optimization, Simulation, and Environmental Impact of Energy Systems (ECOS-2003), Copenhagen, Denmark, 30 June–2 July 2003; pp. 1691–1696. [Google Scholar]

- Romanov, S.N. Software “United Cycle” for Simulation of Static Operation Modes of Power Plants. In Proceedings of the International Society for Optical Engineering, St. Petersburg, Russia, 12–17 June 2001; pp. 306–309. [Google Scholar] [CrossRef]

- Decree of the Representatives of the Russian Federation of October 22, 2012 N 1075 (as amended on 20 May 2022) on Pricing in the Field of Heat Supply. Available online: https://docs.cntd.ru/document/902148460 (accessed on 6 June 2022).

- Kolbantseva, D.; Treschev, D.; Trescheva, M.; Anikina, I.; Kolbantsev, Y.; Kalmykov, K.; Aleshina, A.; Kalyutik, A.; Vladimirov, I. Analysis of Technologies for Hydrogen Consumption, Transition and Storage at Operating Thermal Power Plants. Energies 2022, 15, 3671. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).