Metrology Process to Produce High-Value Components and Reduce Waste for the Fourth Industrial Revolution

Abstract

:1. Introduction

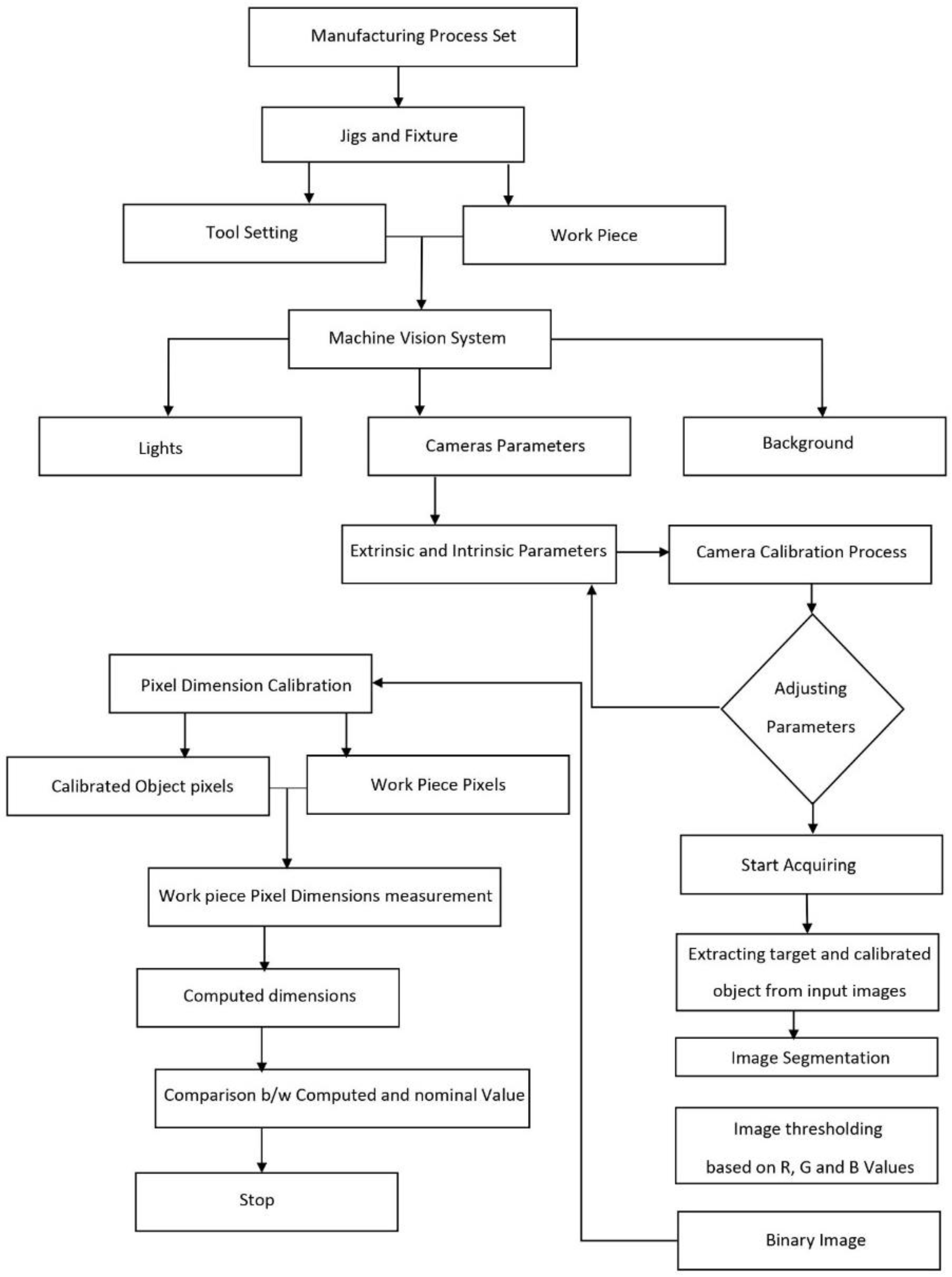

2. Methodology

2.1. Design of Experiment

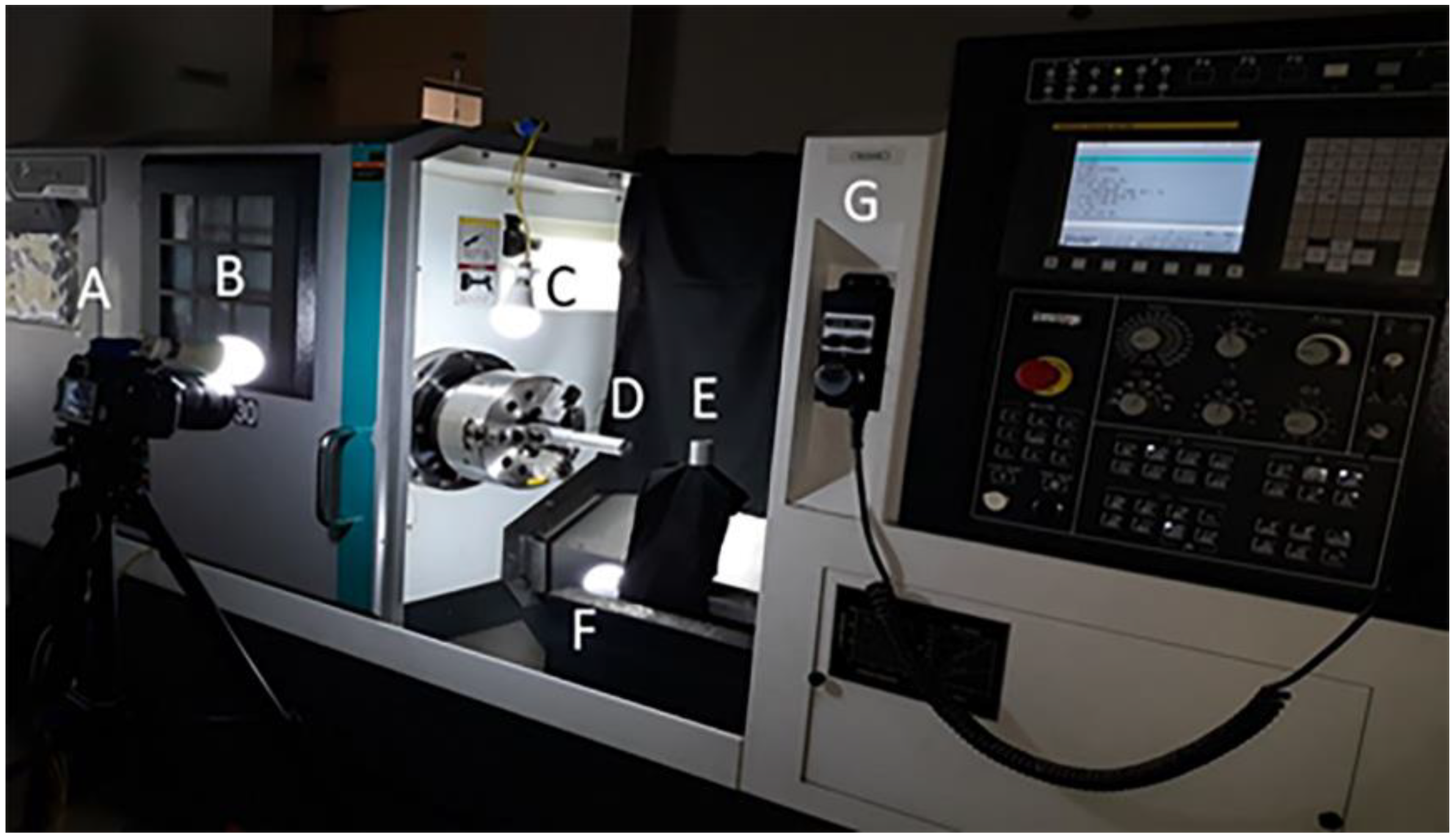

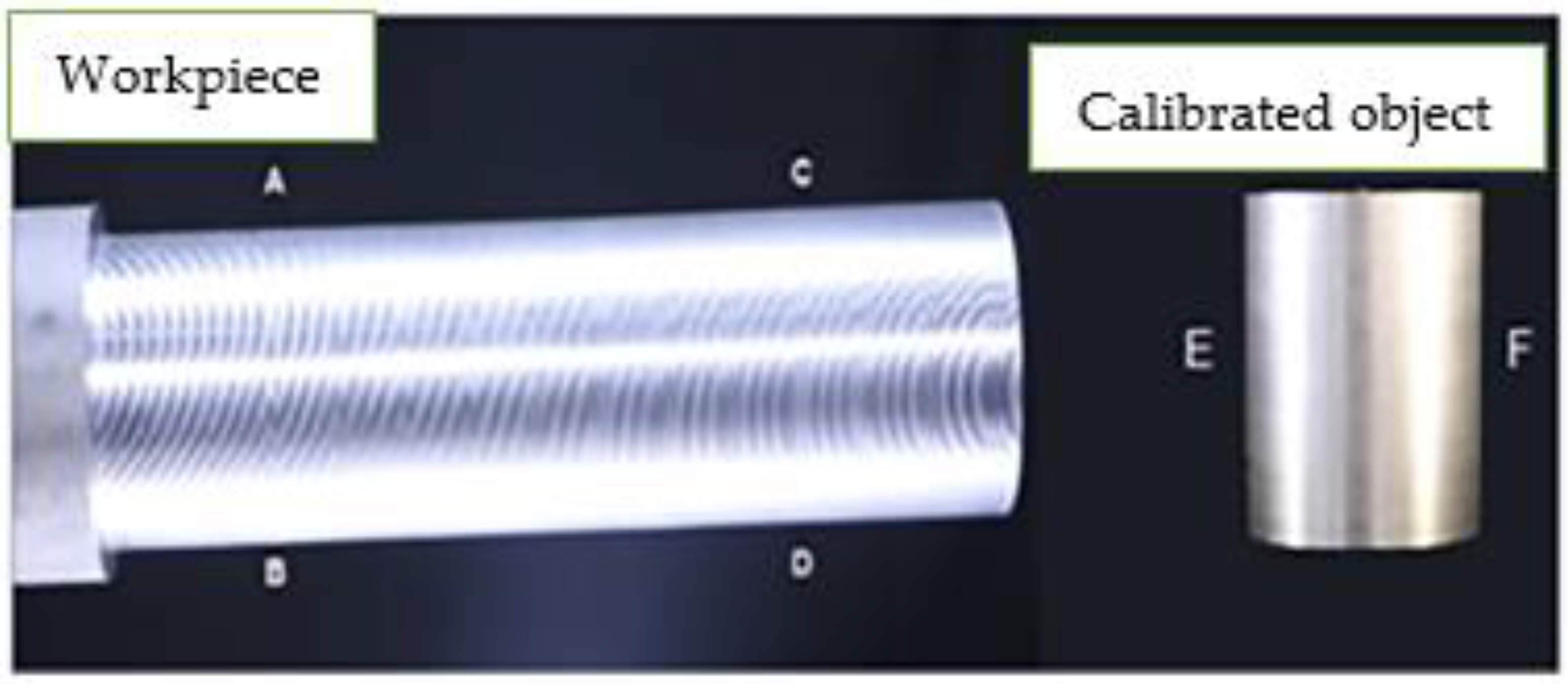

2.2. Experimental Setup

2.3. Machining Operation

2.4. Camera Calibration

2.5. Data Acquisition

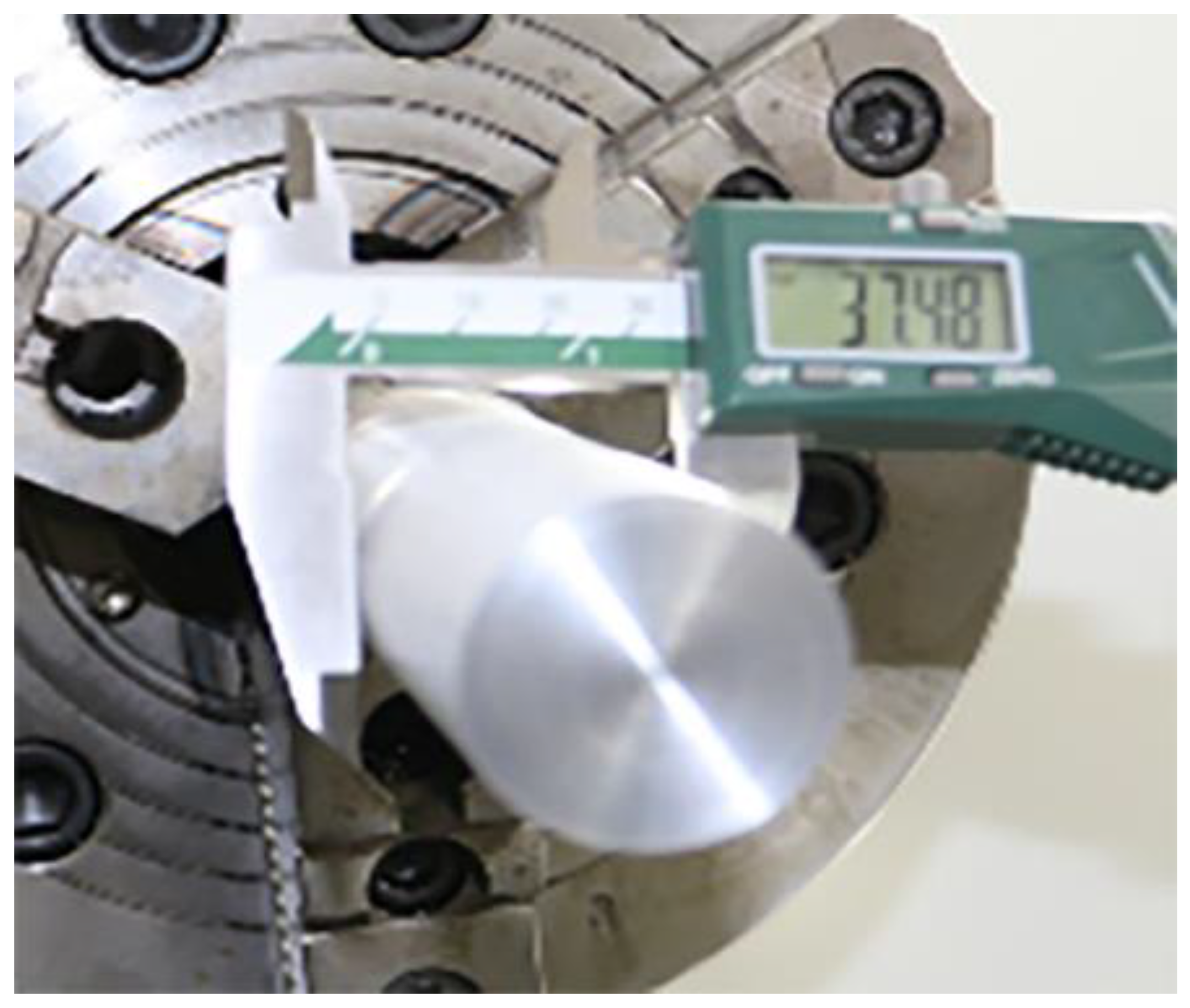

2.6. Manual Measurement

3. Metrology Results

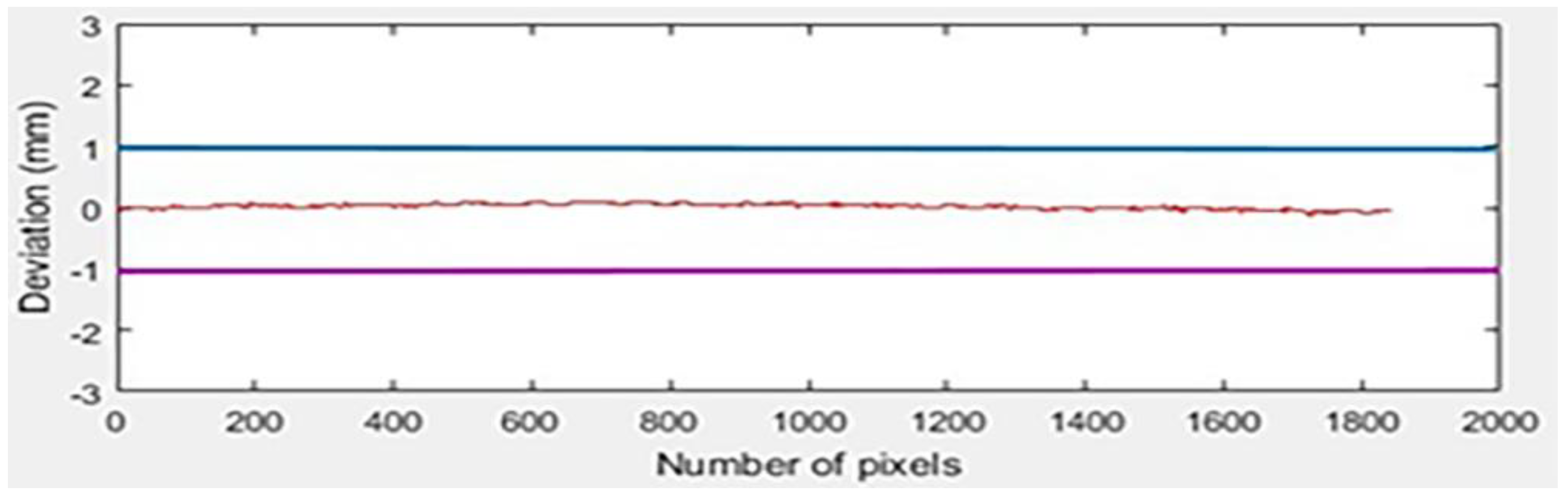

Graph Results Discussion

4. Statistical Analysis

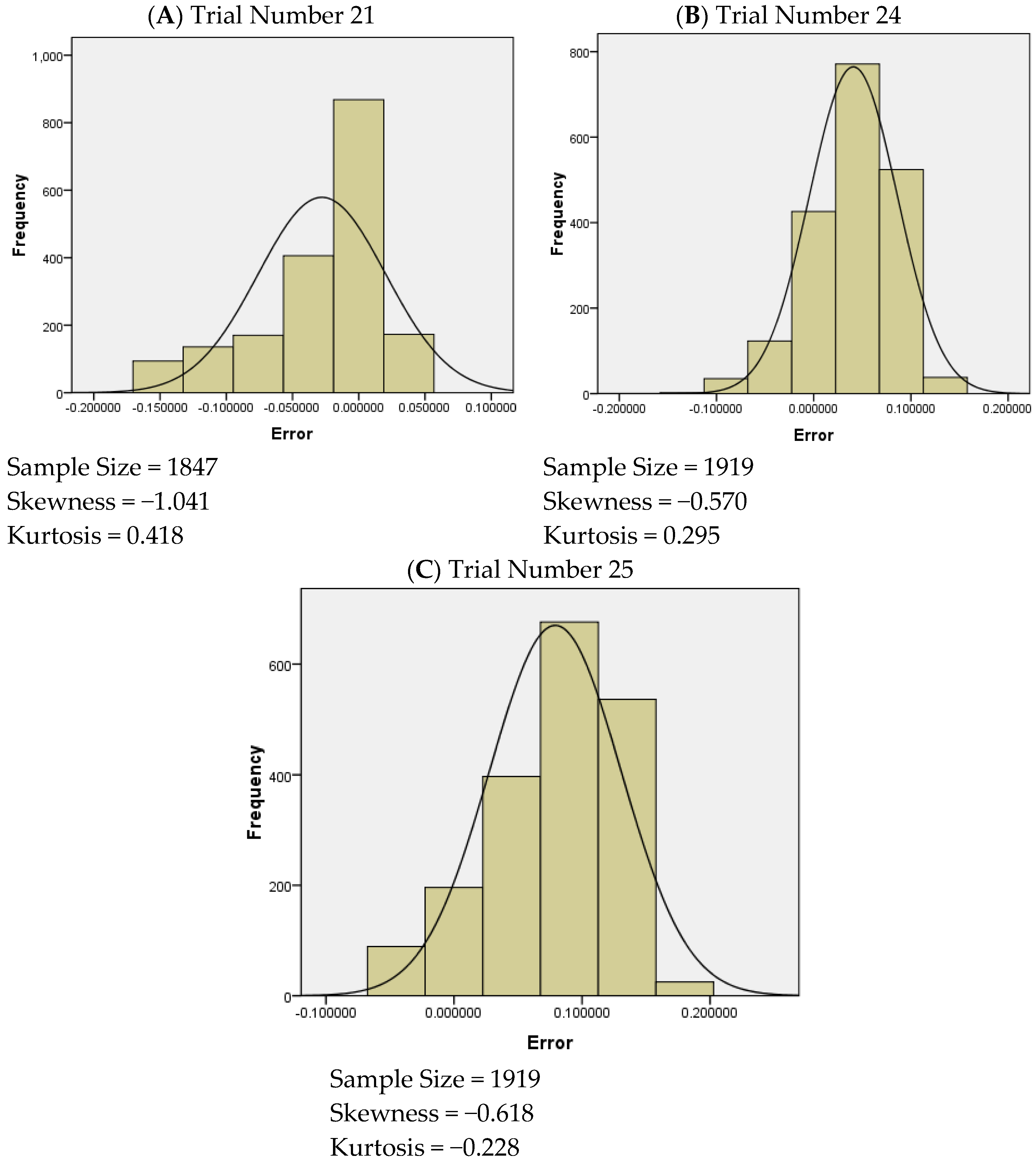

4.1. Descriptive Statistical Analysis

4.2. Measure of Central Tendency

4.3. Measure of Location

4.4. Measure of Dispersion

4.5. Shape of Distribution

4.6. Statistical Inference

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rüßmann, M.; Markus, L.; Philipp, G.; Manuela, W.; Jan, J.; Pascal, E.; Michael, H. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Kang, C.W.; Ramzan, M.B.; Sarkar, B.; Imran, M. Effect of inspection performance in smart manufacturing system based on human quality control system. Int. J. Adv. Manuf. Technol. 2017, 94, 4351–4364. [Google Scholar] [CrossRef]

- Zhao, Y. An Integrated Process Planning System for Machining and Inspection. Ph.D. Thesis, University of Auckland, Auckland, New Zealand, 2009. [Google Scholar]

- Rezaei-Malek, M.; Tavakkoli-Moghaddam, R.; Siadat, A.; Dantan, J.-Y. A novel model for the integrated planning of part quality inspection and preventive maintenance in a linear-deteriorating serial multi-stage manufacturing system. Int. J. Adv. Manuf. Technol. 2018, 96, 3633–3650. [Google Scholar] [CrossRef] [Green Version]

- Wagner, R.; Haefner, B.; Lanza, G. Function-Oriented Quality Control Strategies for High Precision Products. Procedia CIRP 2018, 75, 57–62. [Google Scholar] [CrossRef]

- Syam, W.P.; Leach, R.; Rybalcenko, K.; Gaio, A.; Crabtree, J. In-process measurement of the surface quality for a novel finishing process for polymer additive manufacturing. Procedia CIRP 2018, 75, 108–113. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Siddiqi, M.U.R.; Ijomah, W.L.; Dobie, G.I.; Hafeez, M.; Pierce, S.G.; Ion, W.; Mineo, C.; MacLeod, C.N. Low cost three-dimensional virtual model construction for remanufacturing industry. J. Remanuf. 2018, 9, 129–139. [Google Scholar] [CrossRef] [Green Version]

- Khan, W.A.; Abbas, G.; Rahman, K.; Hussain, G.; Edwin, C.A. Functional Reverse Engineering of Machine Tools; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Boeckmans, B.; Tan, Y.; Welkenhuyzen, F.; Guo, Y.; Dewulf, W.; Kruth, J.-P. Roughness offset differences between contact and non-contact measurements. In Proceedings of the 15th International Conference of the European Society for Precision Engineering and Nanotechnology, Leuven, Belgium, 1–5 June 2015. [Google Scholar]

- Hill, S., Jr. Machine vision boosts assembly line quality. Qual. Manuf. Processes 2001, 40, 50–55. [Google Scholar]

- Lins, R.G.; Araujo, P.; Corazzim, M. In-process machine vision monitoring of tool wear for Cyber-Physical Production Systems. Robot. Comput. Manuf. 2019, 61, 101859. [Google Scholar] [CrossRef]

- Yang, Y.; Zha, Z.-J.; Gao, M.; He, Z. A robust vision inspection system for detecting surface defects of film capacitors. Signal Process. 2016, 124, 54–62. [Google Scholar] [CrossRef]

- Chauhan, V.; Surgenor, B. A comparative study of machine vision based methods for fault detection in an automated assembly machine. Procedia Manuf. 2015, 1, 416–428. [Google Scholar] [CrossRef] [Green Version]

- Chen, T.; Wang, Y.; Xiao, C.; Wu, Q.M.J. A machine vision apparatus and method for can-end inspection. IEEE Trans. Instrum. Meas. 2016, 65, 2055–2066. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, F.; He, Y. Automated status inspection of fastening bolts on freight trains using a machine vision approach. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 230, 1629–1641. [Google Scholar] [CrossRef]

- Nguyen, H.-C.; Nguyen, P.-L.; Lee, B.-R. A vision-based wheel disc inspection system. In Advances in Engineering Research and Application—Proceedings of the International Conference on Engineering Research and Applications, Thai Nguyen, Vietnam, 1–2 December 2018; Springer: Cham, Switzerland, 2018; pp. 109–115. [Google Scholar]

- Liu, L.; Zhou, F.; He, Y. Automated Visual Inspection System for Bogie Block Key Under Complex Freight Train Environment. IEEE Trans. Instrum. Meas. 2015, 65, 2–14. [Google Scholar] [CrossRef]

- Huang, S.-H.; Pan, Y.-C. Automated visual inspection in the semiconductor industry: A survey. Comput. Ind. 2015, 66, 1–10. [Google Scholar] [CrossRef]

- Spencer, B.F., Jr.; Hoskere, V.; Narazaki, Y. Advances in computer vision-based civil infrastructure inspection and monitoring. Engineering 2019, 5, 199–222. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Xu, W.H.; Xi, C.Z.; Liang, D.T.; Li, H.N. Automatic and Accurate Measurement of Microhardness Profile Based on Image Processing. IEEE Trans. Instrum. Meas. 2021, 70, 6006009. [Google Scholar] [CrossRef]

- Lee, Y.-C.; Wu, Y.-C.; Yeh, S.-S. Development of an On-Machine External Thread Measurement System for CNC Lathes Using Eye-in-Hand Machine Vision with Morphology Technology. Eng. Lett. 2021, 29, 1–12. [Google Scholar]

- Dayam, S.; Desai, K.A.; Kuttolamadom, M. In-Process Dimension Monitoring System for Integration of Legacy Machine Tools into the Industry 4.0 Framework. Smart Sustain. Manuf. Syst. 2021, 5, 20210021. [Google Scholar] [CrossRef]

- Siddiqi, M.U.R.; Corney, J.R.; Sivaswamy, G.; Amir, M.; Bhattacharya, R. Design and validation of a fixture for positive incremental sheet forming. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 232, 629–643. [Google Scholar] [CrossRef] [Green Version]

- Kamble, S.; Kasbe, A.; Bhanage, Y. A Case Study Approach of Quality Tools in Manufacturing Industry. Int. Res. J. Eng. Technol. 2019, 6, 1–10. [Google Scholar]

- Wuest, T.; Irgens, C.; Thoben, K.-D. An approach to monitoring quality in manufacturing using supervised machine learning on product state data. J. Intell. Manuf. 2013, 25, 1167–1180. [Google Scholar] [CrossRef]

- Hartman, D.A.; Dave, V.R.; Cola, M.J.; Carpenter, R.W. Method and Apparatus for In-Process Sensing of Manufacturing Quality. U.S. Patent 6,857,553, 22 February 2005. [Google Scholar]

- Zhang, F.; Wu, D.; Yang, J.; I Butt, S.; Yan, Y. High-definition metrology-based machining error identification for non-continuous surfaces. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 232, 2566–2576. [Google Scholar] [CrossRef]

- Jianming, W.; Gao, B.; Zhang, X.; Duan, X.; Li, X. Error correction for high-precision measurement of cylindrical objects diameter based on machine vision. In Proceedings of the 2015 12th IEEE International Conference on Electronic Measurement & Instruments (ICEMI), Qingdao, China, 16–18 July 2015; 3, pp. 1113–1117. [Google Scholar]

- Sun, Q.; Hou, Y.; Tan, Q.; Li, C. Shaft diameter measurement using a digital image. Opt. Lasers Eng. 2014, 55, 183–188. [Google Scholar] [CrossRef]

- Shiraishi, M.; Sumiya, H.; Aoshima, S. In-Process Diameter Measurement of Turned Workpiece with Curvatures by Using Sensor Positioning. J. Manuf. Sci. Eng. 2005, 128, 188–193. [Google Scholar] [CrossRef]

- Ayub, M.A.; Mohamed, A.B.; Esa, A.H. In-line Inspection of Roundness Using Machine Vision. Procedia Technol. 2014, 15, 807–816. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Tan, Q.; Zhang, Y. Shaft Diameter Measurement Using Structured Light Vision. Sensors 2015, 15, 19750–19767. [Google Scholar] [CrossRef] [Green Version]

- Pramanik, A. Problems and solutions in machining of titanium alloys. Int. J. Adv. Manuf. Technol. 2014, 70, 919–928. [Google Scholar] [CrossRef]

- You, S.H.; Lee, J.H.; Oh, S.H. A Study on Cutting Characteristics in Turning Operations of Titanium Alloy used in Automobile. Int. J. Precis. Eng. Manuf. 2019, 20, 209–216. [Google Scholar] [CrossRef] [Green Version]

- GreyRigge Associates Ltd. The Biotech Consultancy. Available online: http://www.greyrigge.com/services/biotech-consulting/design-experiments-doe/ (accessed on 17 May 2022).

- Sheth, S.; George, P.M. Experimental investigation, prediction and optimization of cylindricity and perpendicularity during drilling of WCB material using grey relational analysis. Precis. Eng. 2016, 45, 33–43. [Google Scholar] [CrossRef]

- Shakeri, Z.; Benfriha, K.; Shirinbayan, M.; Ghodsian, N.; Tcharkhtchi, A. Modeling and Optimization of Fused Deposition Modeling process parameters for cylindricity control by using Taguchi method. In Proceedings of the 2021 International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Port Louis, Mauritius, 7–8 October 2021; pp. 1–5. [Google Scholar]

- Reddy, M.S.; Selvan, C.P.; Sampath, S.; Pillai, S.R. Impact of process parameters on surface roughness of hastelloy using abrasive waterjet machining technology. Int. J. Recent Technol. Eng. 2019, 7, 419–425. [Google Scholar]

- Pham, H. (Ed.) Springer Handbook of Engineering Statistics; Springer: London, UK, 2006; Volume 49. [Google Scholar]

- Besterfield, D.H. Quality Control; Pearson Education India: Noida, India, 2004. [Google Scholar]

- Harun, A.; Harun, Y. Experimental and statistical investigation of the effect of cutting parameters on surface roughness, vibration and energy consumption in machining of titanium 6Al-4V ELI (grade 5) alloy. Measurement 2021, 167, 108465. [Google Scholar]

- Shi, M.; Xiong, J.; Zhang, G.; Zheng, S. Monitoring process stability in GTA additive manufacturing based on vision sensing of arc length. Measurement 2021, 185, 110001. [Google Scholar] [CrossRef]

- Walpole, R.E.; Myers, R.H.; Myers, S.L.; Ye, K. Probability and Statistics for Engineers and Scientists; Macmillan: New York, NY, USA, 1993; Volume 5. [Google Scholar]

| S. No | Distance between Workpiece and Camera (cm) | Distance between Workpiece and Light Source (cm) | RPM | ||

|---|---|---|---|---|---|

| Workpiece and Light 1 (Upper) Distance (cm) | Workpiece and Light 2 (Lower) Distance (cm) | Workpiece and Light 3 (Camera Front Light) Distance (cm) | |||

| 1 | 26.9 | 12 | 7 | 25 | 40 |

| 2 | 26.9 | 16 | 7 | 25 | 40 |

| 3 | 26.9 | 20 | 7 | 25 | 40 |

| 4 | 26.9 | 12 | 7 | 25 | 65 |

| 5 | 26.9 | 16 | 7 | 25 | 65 |

| 6 | 26.9 | 20 | 7 | 25 | 65 |

| 7 | 26.9 | 12 | 11 | 25 | 110 |

| 8 | 26.9 | 16 | 11 | 25 | 110 |

| 9 | 26.9 | 20 | 11 | 25 | 110 |

| 10 | 35 | 12 | 11 | 32.5 | 40 |

| 11 | 35 | 16 | 11 | 32.5 | 40 |

| 12 | 35 | 20 | 11 | 32.5 | 40 |

| 13 | 35 | 12 | 11 | 32.5 | 65 |

| 14 | 35 | 16 | 11 | 32.5 | 65 |

| 15 | 35 | 20 | 11 | 32.5 | 65 |

| 16 | 35 | 12 | 11 | 32.5 | 110 |

| 17 | 35 | 16 | 11 | 32.5 | 110 |

| 18 | 35 | 20 | 11 | 32.5 | 110 |

| 19 | 45 | 12 | 11 | 42.5 | 40 |

| 20 | 45 | 16 | 11 | 42.5 | 40 |

| 21 | 45 | 20 | 11 | 42.5 | 40 |

| 22 | 45 | 12 | 11 | 32.5 | 65 |

| 23 | 45 | 16 | 11 | 32.5 | 65 |

| 24 | 45 | 20 | 11 | 32.5 | 65 |

| 25 | 45 | 12 | 11 | 32.5 | 110 |

| 26 | 45 | 16 | 11 | 32.5 | 110 |

| 27 | 45 | 20 | 11 | 32.5 | 110 |

| S. No | Equipment | Model | Detail |

|---|---|---|---|

| 1 | Turning Center | FTC 30 | Feeler/250 diameter/650 length |

| 2 | Camera | Canon EOS 70D | f-18 mm -153 mm |

| 3 | Workpiece | Aluminum Alloy | A3035 |

| 4 | Calibrated Object | Aluminum Alloy | A3035 |

| 5 | Light Source | PC-12 | 12 W White Light |

| D21 | E21 | D24 | E24 | D25 | E25 | |

|---|---|---|---|---|---|---|

| Sample Size | 1847 | 1847 | 1919 | 1919 | 1919 | 1919 |

| Mean (mm) | 33.45 | −0.03 | 33.52 | 0.04 | 33.56 | 0.08 |

| Median (mm) | 33.48 | 0.00 | 33.53 | 0.05 | 33.57 | 0.09 |

| Mode (mm) | 33.48 | 0.00 | 33.53 | 0.05 | 33.57 | 0.09 |

| Standard Deviation (mm) | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Coefficient of Variation (mm) | 0.14 | 173.22 | 0.13 | 110.82 | 0.15 | 65.09 |

| D21 (mm) | E21 (mm) | D24 (mm) | E24 (mm) | D25 (mm) | E25 (mm) | |

|---|---|---|---|---|---|---|

| P00 = Minimum | 33.33 | −0.15 | 33.34 | −0.14 | 33.43 | −0.05 |

| P05 | 33.33 | −0.15 | 33.43 | −0.05 | 33.48 | 0.00 |

| P10 | 33.37 | −0.11 | 33.48 | 0.00 | 33.48 | 0.00 |

| P15 | 33.40 | −0.08 | 33.48 | 0.00 | 33.53 | 0.05 |

| P20 | 33.40 | −0.08 | 33.48 | 0.00 | 33.53 | 0.05 |

| P25 = Q1 = Lower Quartile | 33.44 | −0.04 | 33.48 | 0.00 | 33.53 | 0.05 |

| P30 | 33.44 | −0.04 | 33.48 | 0.00 | 33.53 | 0.05 |

| P35 | 33.44 | −0.04 | 33.53 | 0.05 | 33.53 | 0.05 |

| P40 | 33.44 | −0.04 | 33.53 | 0.05 | 33.57 | 0.09 |

| P45 | 33.48 | 0.00 | 33.53 | 0.05 | 33.57 | 0.09 |

| P50 = Q2 = Median | 33.48 | 0.00 | 33.53 | 0.05 | 33.57 | 0.09 |

| P55 | 33.48 | 0.00 | 33.53 | 0.05 | 33.57 | 0.09 |

| P60 | 33.48 | 0.00 | 33.53 | 0.05 | 33.57 | 0.09 |

| P65 | 33.48 | 0.00 | 33.53 | 0.05 | 33.57 | 0.09 |

| P70 | 33.48 | 0.00 | 33.53 | 0.05 | 33.57 | 0.09 |

| P75 = Q3 = Upper Quartile | 33.48 | 0.00 | 33.57 | 0.09 | 33.62 | 0.14 |

| P80 | 33.48 | 0.00 | 33.57 | 0.09 | 33.62 | 0.14 |

| P85 | 33.48 | 0.00 | 33.57 | 0.09 | 33.62 | 0.14 |

| P90 | 33.48 | 0.00 | 33.57 | 0.09 | 33.62 | 0.14 |

| P95 | 33.52 | 0.04 | 33.57 | 0.09 | 33.62 | 0.14 |

| P100 = Maximum | 33.52 | 0.04 | 33.62 | 0.14 | 33.66 | 0.18 |

| Trial (k) | Sample Size | Mean (mm) | Standard Deviation (mm) | Standard Error of Mean (mm) |

|---|---|---|---|---|

| 21 | 1847 | −0.0278 | 0.0482 | 0.0011 |

| 24 | 1919 | 0.0408 | 0.0452 | 0.0010 |

| 25 | 1919 | 0.0791 | 0.0515 | 0.0012 |

| Trial (k) | Value of t-Statistic | Degrees of Freedom | p-Value | Percentage % | Mean Difference (mm) | 99% Lower Confidence Limit (mm) | 99% Upper Confidence Limit (mm) |

|---|---|---|---|---|---|---|---|

| 21 | −24.810 | 1846 | 0.0000 | 0.083% | −0.0278 | −0.0307 | −0.0249 |

| 24 | 39.530 | 1918 | 0.0000 | 0.121% | 0.0408 | 0.0381 | 0.0434 |

| 25 | 67.304 | 1918 | 0.0000 | 0.236% | 0.0791 | 0.0761 | 0.0821 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Junaid, A.; Siddiqi, M.U.R.; Tariq, S.; Muhammad, R.; Paracha, U.; Ullah, N.; Al Ahmadi, A.A.; Suleman, M.; Habib, T. Metrology Process to Produce High-Value Components and Reduce Waste for the Fourth Industrial Revolution. Sustainability 2022, 14, 7472. https://doi.org/10.3390/su14127472

Junaid A, Siddiqi MUR, Tariq S, Muhammad R, Paracha U, Ullah N, Al Ahmadi AA, Suleman M, Habib T. Metrology Process to Produce High-Value Components and Reduce Waste for the Fourth Industrial Revolution. Sustainability. 2022; 14(12):7472. https://doi.org/10.3390/su14127472

Chicago/Turabian StyleJunaid, Ahmad, Muftooh Ur Rehman Siddiqi, Sundas Tariq, Riaz Muhammad, Ubaidullah Paracha, Nasim Ullah, Ahmad Aziz Al Ahmadi, Muhammad Suleman, and Tufail Habib. 2022. "Metrology Process to Produce High-Value Components and Reduce Waste for the Fourth Industrial Revolution" Sustainability 14, no. 12: 7472. https://doi.org/10.3390/su14127472

APA StyleJunaid, A., Siddiqi, M. U. R., Tariq, S., Muhammad, R., Paracha, U., Ullah, N., Al Ahmadi, A. A., Suleman, M., & Habib, T. (2022). Metrology Process to Produce High-Value Components and Reduce Waste for the Fourth Industrial Revolution. Sustainability, 14(12), 7472. https://doi.org/10.3390/su14127472