Clear waters and lush mountains are invaluable assets. Reducing the exploitation of natural resources is of great significance to global environmental protection. Transportation is a resource-intensive industry, in which the construction of transportation infrastructure consumes a lot of mineral resources. Seeking effective substitutes for ore resources has great potential for reducing mine development and promoting the sustainable development of society [

1,

2,

3,

4]. Steel slag is a by-product of the steelmaking process. It is a lumpy substance formed by the combination of residual flux and metal oxide in the steelmaking furnace after cooling, iron removal, and crushing. About 0.15 t of steel slag is produced for every 1 t of steel produced [

5]. China is the world’s largest steel producer, with annual steel production accounting for about 50% of global steel production capacity. In the past two years, the average annual discharge of steel slag is 100 million tons. The major industrial countries in the world have adopted the comprehensive utilization of steel slag as a strategy for green development [

6]. Steel slag has the advantages of high strength, wear resistance, slip resistance, high basicity, and low cost, and has the potential for large-scale utilization in pavements [

7,

8].

Some research results have been obtained on the application of steel slag in road engineering, mainly involving two aspects: conventional performance and functional performance. Conventional properties are stiffness indicators of SSAMs, such as fatigue properties, expansion properties, aging properties, and other mechanically related properties. For example, Kavussi [

9] studied the fatigue behavior of asphalt mixtures with electric arc furnace (EAF) steel slag as coarse aggregate in aged and unaged states. The four-point bending fatigue test showed that although the addition of EAF steel slag into the asphalt mixture improved the fatigue life of the sample, it had no obvious effect on the asphalt mixture in the aging state. To further improve the fatigue performance of the SSAM, Cao [

10] modified the surface of the steel slag with cement paste and studied the fatigue life of the SSAM under soaking conditions. The results showed that the fatigue life of the modified SSAM was 23% higher than that of the original SSAM. The dense layer formed on the surface of the steel slag by the cement hydration products prevents the water from invading the steel slag, thereby improving the fatigue performance. Although the physical properties of steel slag meet the application requirements of asphalt mixtures, due to its angular shape, asphalt mixtures using steel slag as aggregates are prone to expansion and are affected by void problems. Mineral aggregates cannot be completely replaced with steel slag [

11]. To reduce the volume expansion characteristics of steel slag and make full use of cold abandoned steel slag, Zhang [

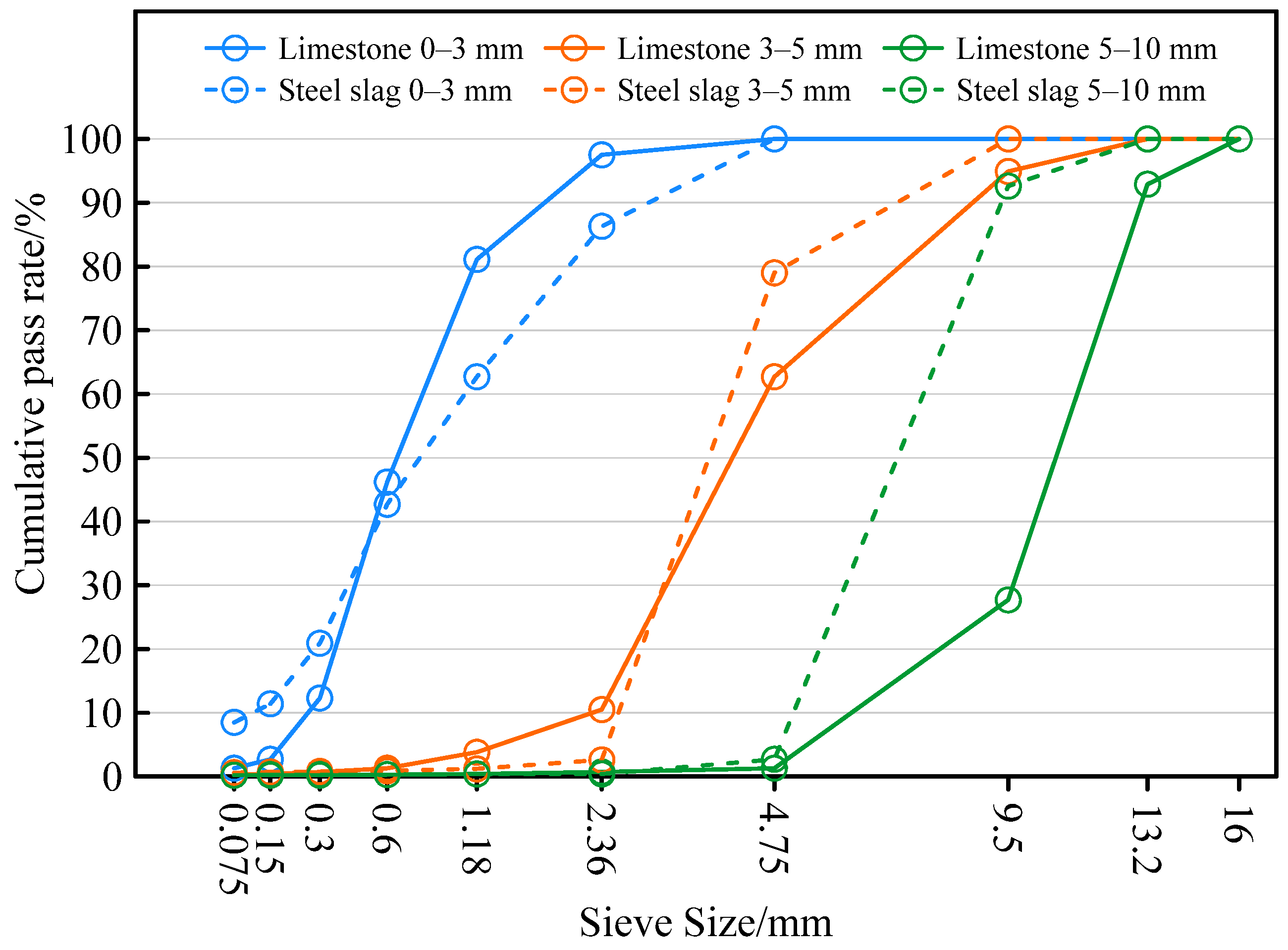

12] used limestone fine aggregate instead of steel slag fine aggregate to reduce the water swelling of cold abandoned SSAM. Masoudi [

13,

14] studied the long-term aging performance of the EAF steel slag warm mix asphalt mixture. Steel slag warm mix asphalt has better mechanical properties than limestone hot mix asphalt. The use of steel slag increases the aging index of the asphalt mixture and reduces the anti-aging ability of the asphalt mixture. In addition, the replacement of limestone aggregate with steel slag increases the optimal asphalt aggregate ratio by 0.45%. Zeng [

15] studied the nonlinear viscoelastic–plastic deformation characteristics of SSAMs and proposed a new integral viscoelastic–plastic constitutive model combining the Schapery model and the improved Schwartz model. The model can more accurately reflect the elastic, viscoelastic, and viscoplastic deformation of SSAM in the creep process. Ameri et al. [

16] studied the performance of steel slag in hot mix asphalt and warm mix asphalt. They showed that the hot mix asphalt mixture with steel slag instead of fine aggregate had the lowest elastic modulus and indirect tensile strength. However, using steel slag as coarse aggregate in warm mix asphalt improved the elastic modulus and indirect tensile strength of the mixture. Steel slag coarse aggregate is recommended for warm mix asphalt. To make full use of the coarse and fine aggregates of slag, Chen [

17] discussed the comprehensive utilization technology of steel slag and iron slag, and used steel slag coarse aggregate, iron slag fine aggregate, and steel slag powder to replace 100% limestone. Some performance indicators of the asphalt mixture prepared by combining high-viscosity asphalt and the secondary mixing process are significantly improved. The high-temperature flow times and low-temperature fracture energy were increased by 18% and 23%, respectively. There are many methods for evaluating the rutting resistance of asphalt mixtures, such as rutting test, dynamic modulus test, creep test, etc. [

18]. In addition, the rotary compaction process can also reflect the rutting resistance, more compaction times, and strong anti-rutting performance [

19]. Huang [

20] studied the compaction characteristics of steel slag porous asphalt mixture, and the results of rotary compaction showed that the number of compactions of porous asphalt mixture without steel slag was higher than that of steel slag porous asphalt mixture. It was indicated that the porous asphalt mixture without steel slag has a higher anti-rutting performance. However, Martinho’s [

21] research on the high-temperature performance of warm mix SSAM formed the opposite conclusion. In general, steel slag can improve the high-temperature performance of asphalt mixture. Liu [

22] evaluated the feasibility of the porous asphalt mixture containing steel slag in the seasonal freezing area, and the results showed that the addition of steel slag can improve the pavement performance of the porous asphalt mixture. When the coarse aggregates are steel slag, the overall performance of the porous asphalt mixture is optimal. Crisman [

23] compared the mechanical properties of rubber–asphalt mixture containing steel slag and ordinary asphalt mixture and found that the elastic modulus of steel slag rubber–asphalt mixture was higher than that of ordinary asphalt mixture at high temperature, but lower at low temperature. The permanent deformation resistance of steel slag rubber–asphalt mixture has been improved.

In terms of the functional utilization of steel slag, Li [

24] studied the effect of steel slag on the electrical conductivity of graphite–carbon fiber composite conductive asphalt concrete and found that 100% steel slag content increased the conductivity of the mixture to 0.125 S/m. The contribution of the three materials to the conductivity followed the order carbon fiber, graphite, and steel slag (from highest to lowest). Xiang [

25] studied the self-healing performance of SSAM under microwave heating conditions. The addition of steel slag can improve the healing effect of asphalt mixtures. The asphalt mixture of coarse stone and fine steel slag has a more uniform temperature distribution, and the healing effect is 1.11 times higher than that of asphalt mixtures without steel slag. Gao [

26] mixed steel slag into asphalt mixture for microwave deicing, measured the temperature distribution and ice melting effect of SSAM, and verified the feasibility of ice melting of SSAM.

To sum up, the application of steel slag in road engineering mainly focuses on the basic properties of SSAM, such as fatigue, expansion, aging, and mechanical properties. This is because the primary task of SSAM is to meet the requirements of engineering construction. There is still insufficient research on the functional aspects of SSAM. Whether it is electrical conductivity, self-healing performance, or ice-melting performance, these properties are all related, to some extent, to the thermal conductivity of SSAM. Existing research rarely considers the basic indicators of its thermal conductivity. Further research into the thermal conductivity of SSAM is required.

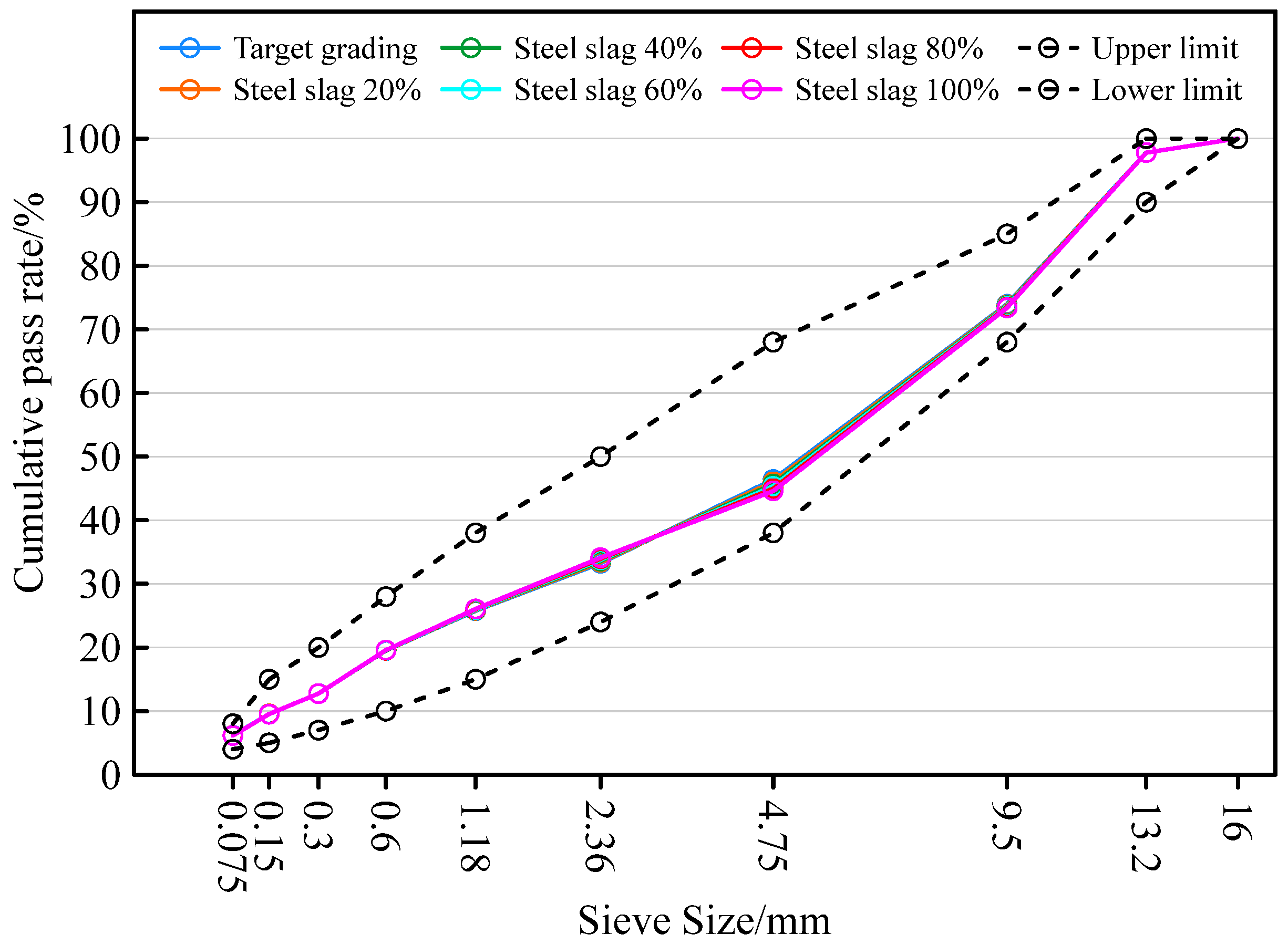

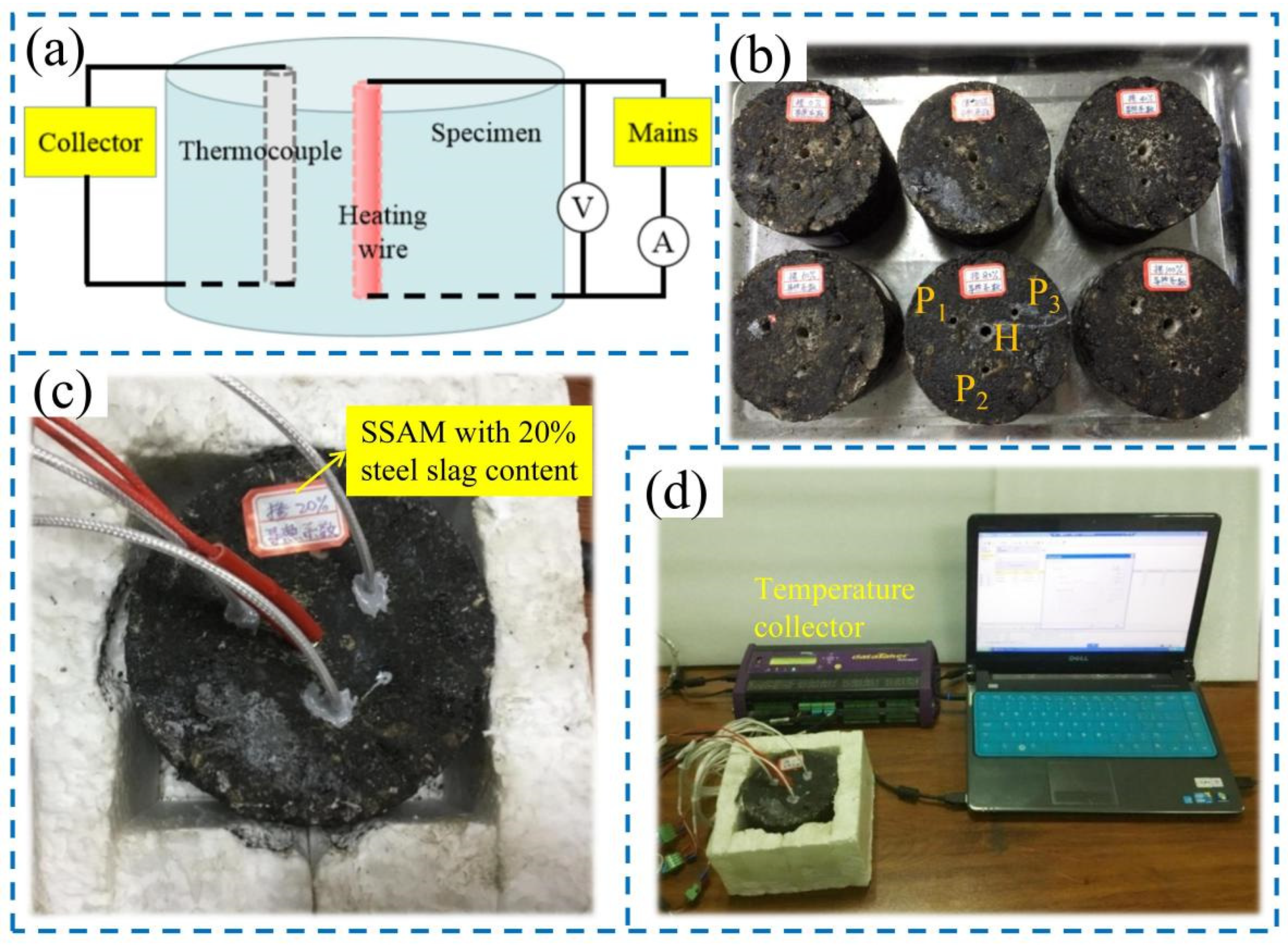

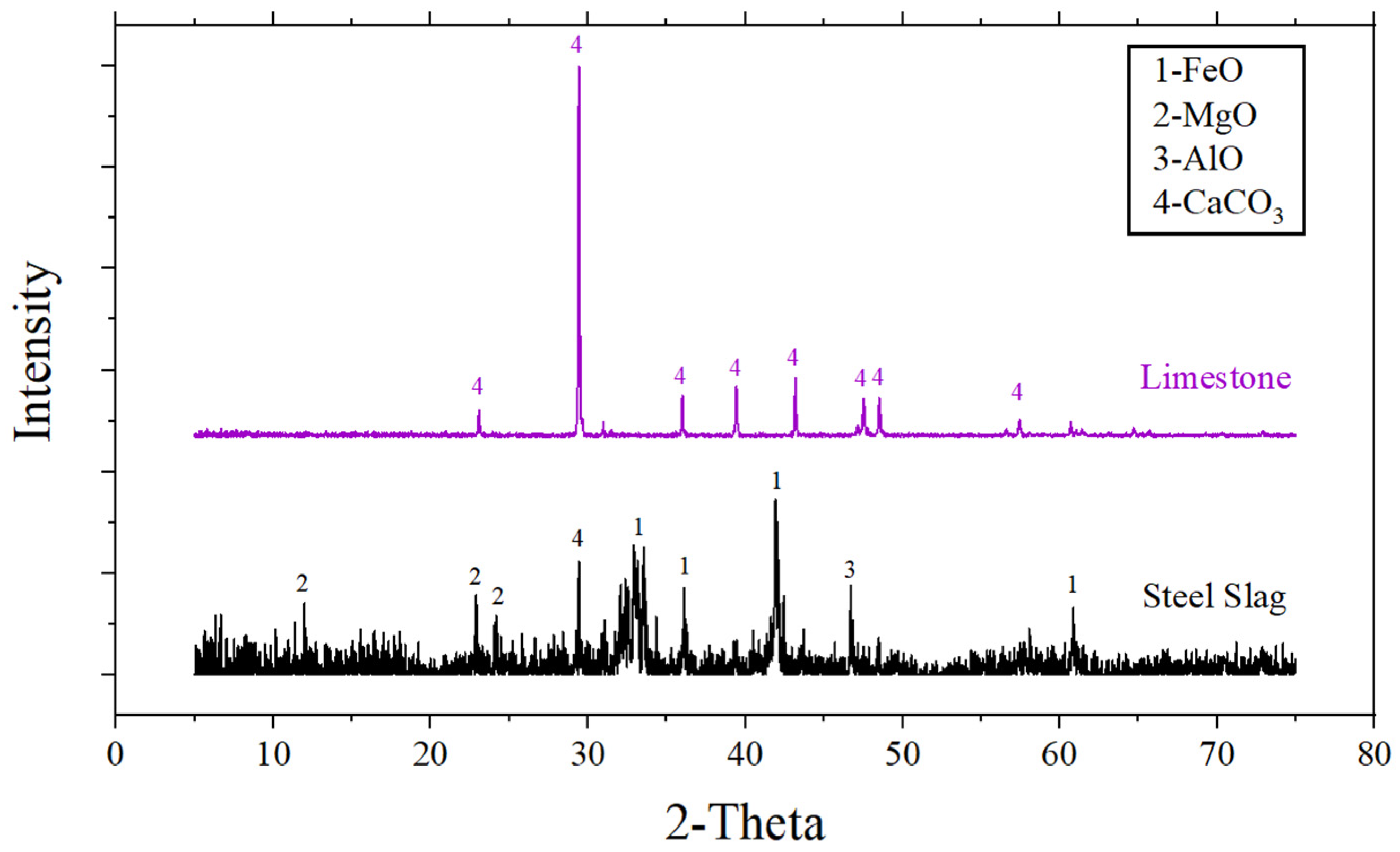

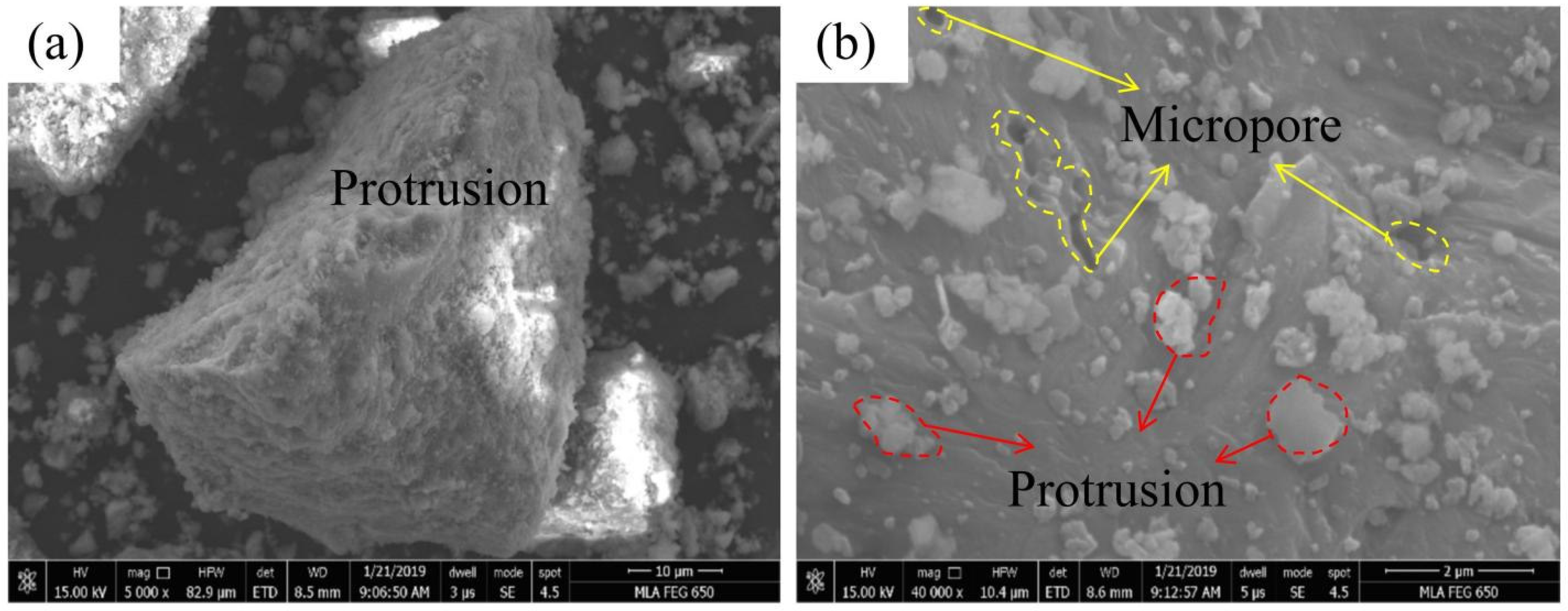

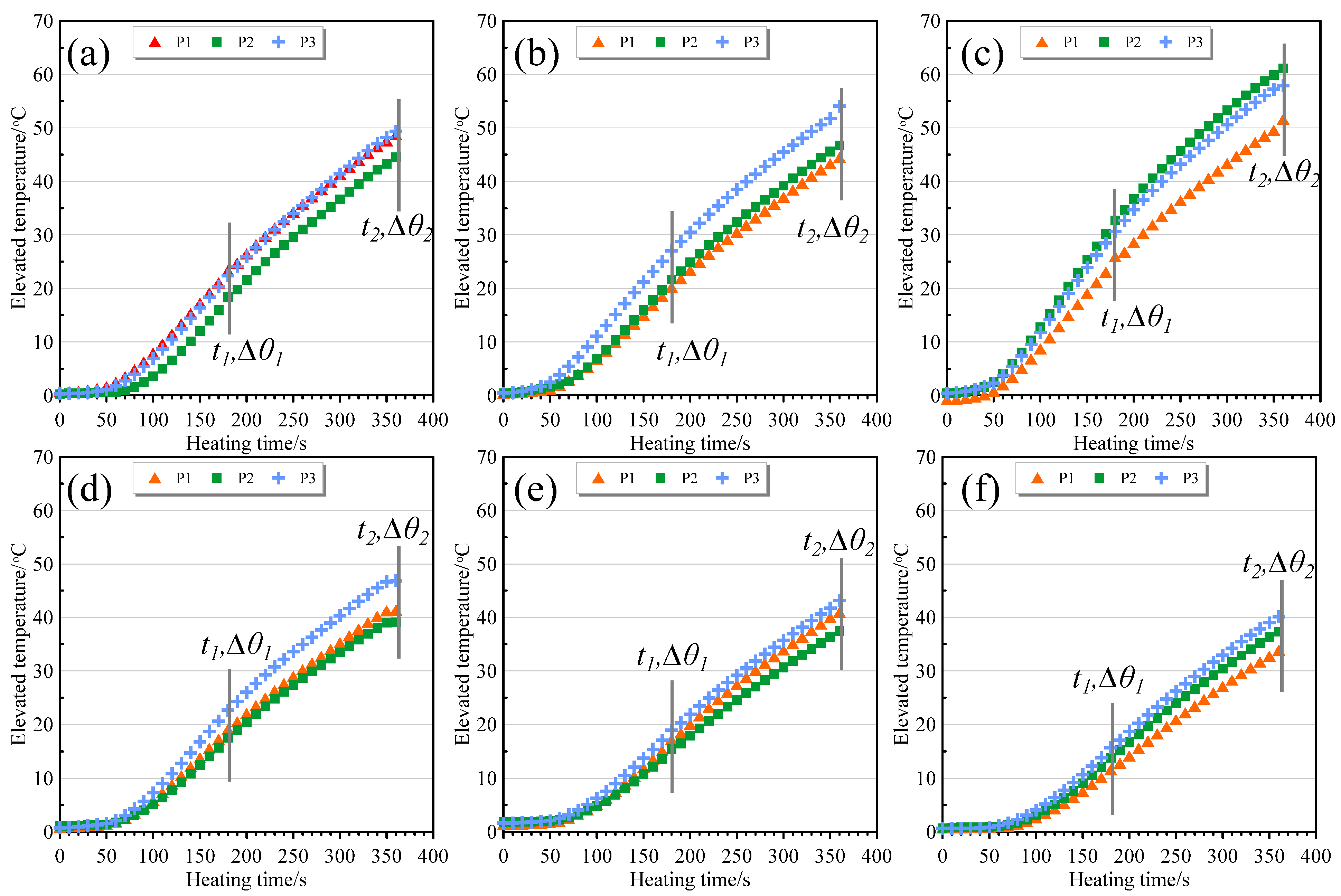

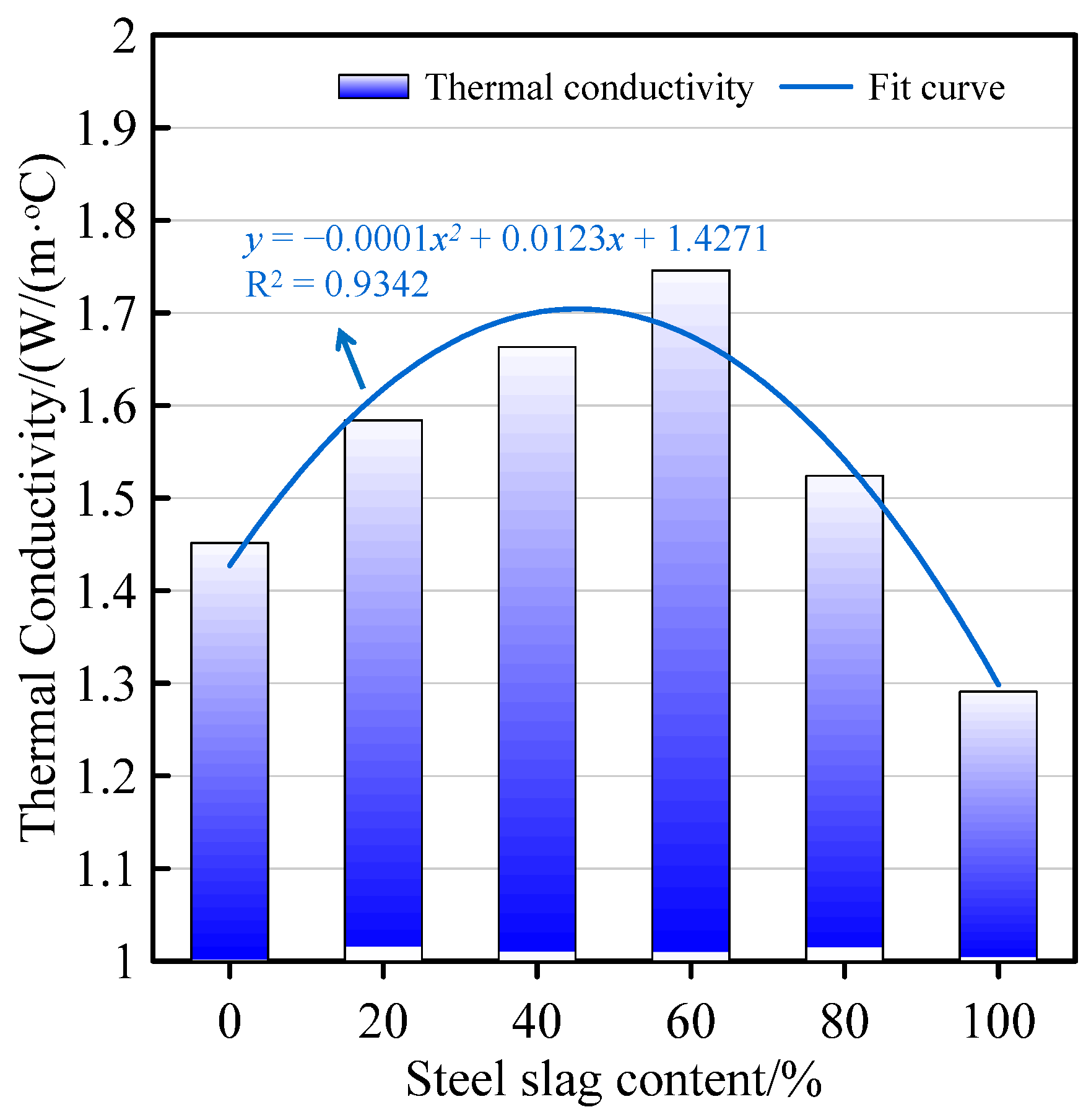

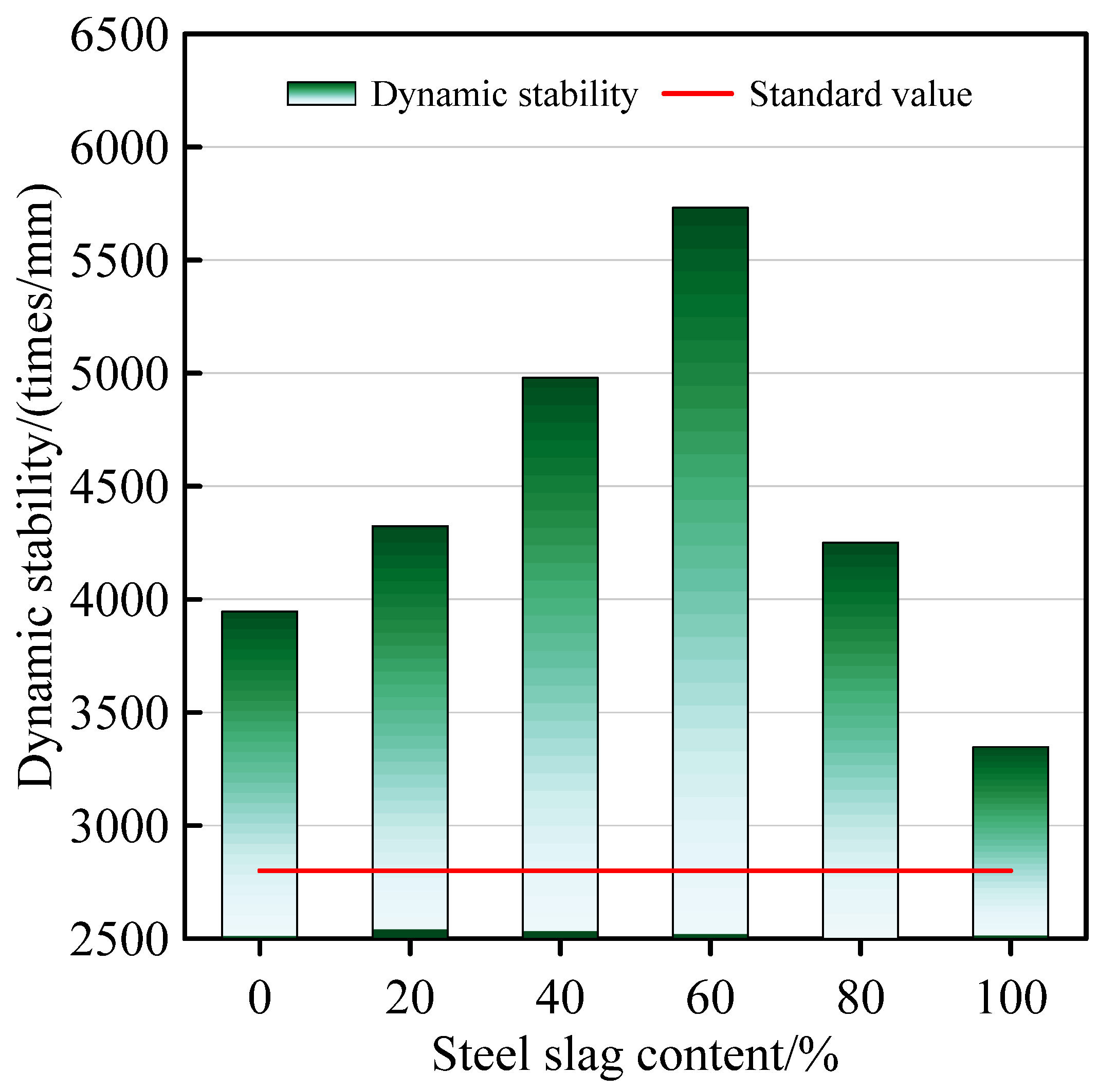

Consequently, the goal of this paper is to study the thermal conductivity of SSAM, as well as the road performance of SSAMs with different thermal conductivity. It is expected that SSAM can meet the requirements of road performance while exerting thermal conductivity. Therefore, the thermal conductivity of steel slag was first qualitatively evaluated from a microscopic perspective. Second, the SSAM was prepared according to the principle of equal volume replacement and the heating test was conducted. The thermal conductivity of SSAM was quantitatively evaluated with the thermal coefficient as an index. Afterward, to prove the accuracy of the measured data, the thermal coefficient was estimated by the theoretical calculation method. Finally, the volume indices of the asphalt mixtures with different thermal conductivity were tested, and the road performances of the SSAM was verified.