Abstract

Industrial symbiosis (IS) can contribute to achieving a win-win situation between industry and environment for local and regional circular economies. Many authors have recognized that a variety of barriers can hinder the implementation of IS. However, there is very limited research on quantitatively evaluating the IS barriers. In this paper, we propose a model which combines the Analytic Hierarchy Process (AHP) and the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) to evaluate the IS barriers semi-quantitatively. This model assists in identifying and prioritizing the fundamental barriers for implementation of IS in a comprehensive manner. An operating IS, the Hai Hua Group (HHG), in Shandong Province, China is used as a case study to test the proposed model. The results show that the top four generic barriers are technological barriers, economic barriers, safety barriers, and informational barriers. More specifically, the barriers are information platforms, human safety and health, technology involved with extending industrial chains, product added value, and costs. The paper concludes by discussing managerial implications for promoting the establishment and operation of IS.

Keywords:

industrial symbiosis; industrial ecology; barriers; circular economy; case study; AHP; TOPSIS; model 1. Introduction

Industrial symbiosis (IS) has been well-recognized as a key subfield of industrial ecology (IE) [1,2]. A widely cited definition of IS is presented by Chertow [1]:“engaging traditionally separate entities in a collective approach to competitive advantage involving physical exchange of materials, energy, water, and by-products. The keys to IS are collaboration and the synergistic possibilities offered by geographic proximity” (p. 314). IS research is flourishing and has covered a broad range of topics and cases [3]. IS helps to increase the industrial system’s circularity [4] and is considered to be a circular economic business model [5]. It can often create economic, environmental, and social benefits [4,6,7], which assists in promoting local and regional sustainable development [8]. In recent years, IS has been considered to be a core strategy [6,9,10] and a key practical approach to promote the circular economy (CE) [4,11]. Fraccascia and Yazan [11] have argued that the catalytic role of IS in achieving a circular economy should be encouraged. In China, IS has been incorporated into national policies that were specifically formulated for CE, and has been identified as a key element for promoting national CE development [12], especially at the mesolevel [13].

A variety of barriers have been identified [3,4,6,9,14,15,16,17], which will influence the viability of IS and eco-industrial development [1]. Barriers for IS have been identified as one of the key topics which current IS research addresses [18] and are in urgent need of being examined [4,6].

The operation of IS remains a complex and dynamic process [2,19], which requires continuous improvement [2,20]. Cervo et al. [4] stressed that the “creation of a symbiosis is a multi-step process that goes from the identification of an opportunity to its implementation and operation” (p. 6). When organizations implement IS, it is important to start from understanding the barriers that they could face [21]. For operating industrial symbioses, there are still barriers hindering their full potential development [15,17,22]. Barriers can arise at different phases of the symbiotic development and the importance of a barrier will vary at different stages of the process [2,15]. Thus, it is imperative to prioritize the barriers which hinder the implementation and development of IS [2,15,20,23]. This will provide guidance for the realization of IS projects [18] and assist stakeholders and IS practitioners to create policies aiming at the fundamental barriers to improve the development of IS [14], which could also facilitate the transition to CE. However, the IS literature consists mostly of qualitative studies. There is very little research of a quantitative nature assessing the barriers for operating industrial symbioses.

To fill the research gap, this paper aims to uncover the nature of the various barriers and identify their significance in a semi-quantitative manner. A hierarchical evaluation model which combines the Analytic Hierarchy Process (AHP) and Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) is utilized in this study to systematically evaluate the barriers. An operating IS, the IS of Hai Hua Group (HHG) of China is taken as a case study to test the proposed model. The study results should provide managers with insights for addressing barriers to improve the operation of IS. In this paper, we have included eco-industrial parks (EIPs) in the discussion of IS because most EIP projects and studies have focused on symbiotic relationships among industries.

The paper is structured as follows: Section 2 presents an extensive literature review covering identification and classification of IS barriers. Section 3 describes the research methodology. Section 4 discusses the IS of HHG as an example to test the model presented in Section 3 to uncover the priority of various IS barriers and identify the fundamental IS barriers of HHG. Finally, some conclusions are drawn in Section 5.

2. Literature Review

2.1. Identification of IS Barriers

In general, the current research on identifying barriers related to IS can be mainly divided into three groups, i.e., specific barriers, generic barriers, and evaluation of barriers using mathematical methods, which is summarized in Table 1.

2.1.1. Identification of Specific Barriers

Some researchers identified some specific barriers related to IS from different perspectives, such as institutional barriers [24,25,26], organizational perspective [3], environmental regulation barriers [27], and sectoral boundary barrier [28]. They are summarized in Table 1.

2.1.2. Identification of Generic Barriers

The generic barriers related to IS were also put forward by some researchers. Some of these studies chose some IS or EIP cases to identify barriers, such as the Kwinana and Gladstone of Australia [15,17], the industrial estates of Canada [29], the Ulsan EIP project of Korea [30], and the EIPs of China [31]. These generic barriers are listed in Table 1.

Table 1.

Identification of barriers related to IS.

Table 1.

Identification of barriers related to IS.

| Categorization of IS Barriers | Descriptions | References |

|---|---|---|

| Identification of specific barriers |

| [24,25,26] |

| [3] | |

| [32] | |

| [33] | |

| [34] | |

| [35] | |

| [27] | |

| [36] | |

| [28] | |

| [37] | |

| [38] | |

| [39] | |

| Identification of generic barriers |

| [40] |

| [17] | |

| [41] | |

| [29] | |

| [42] | |

| [30] | |

| [43] | |

| [31] | |

| [15] | |

| [44] | |

| [45] | |

| [14] | |

| Evaluation of barriers using mathematical methods |

| [15] |

| [31] | |

| [14] | |

| [23] |

2.1.3. Evaluation of Barriers Using Mathematical Methods

A few researchers have introduced mathematical methods to evaluate the barriers of IS. Golev et al. [15] proposed a qualitative method, the IS maturity grid, to analyze IS barriers. It was concluded that the method is helpful for determining the most critical nontechnical barriers which influence the development of a regional IS and identifying mitigation measures to remove the most critical identified barriers. Zhu et al. [31] introduced a factor analysis and cluster analysis to evaluate a number of barriers for EIP development of China. Bacudio et al. [14] adopted the Decision Making Trial and Evaluation Laboratory (DEMATEL) method to identify barriers and concluded that it assists in detecting which barriers can be categorized as cause or effect factors. Based on the work of Bacudio et al. [14], Promentilla et al. [23] proposed a methodological framework to analyze the barriers for an EIP in the Philippines. The related contents are also listed in Table 1.

2.2. Classification of IS Barriers

In the current IE field, the literature on barriers related to IS, which is briefly described in Section 2.1, can be arranged into seven generic categories. This is summarized in Table 2. Many barriers have been identified in the literature. These are referred to as specific barriers in this paper. We have attempted to combine these into generic categories.

2.2.1. Governmental Barriers

Many governmental actions maybe hinder the development of EIP [16,46]. Policies, regulations, and the institutional system of a government can influence IS [3,28]. Chiu and Geng [47] demonstrated that some policies restrict the development of IS because they do not coordinate with industrial innovation. Van Eijk [48] reported that circularity is not effectively incorporated into innovation policies. Lehtoranta et al. [49] put forward that policy documents rarely consider structural change within industries, cooperation among companies, and the colocation of plants, which, in turn, restricts the development of IS.

Regulations and laws can be a barrier for development of IS. They may prevent companies from being linked together [42], thus hindering regional IS development [17]. Regulatory barriers may result from “the jungle of environmental laws and regulations” [43] (p. 988) or “uncertainties in the legislative framework” [17] (p. 69). Gibbs and Deutz [50] found that “the regulation of wastes leaves little opportunity for product reuse as feedstocks” (p. 1693). LeBlanc et al. [29] found that “regulations tend not to support innovative business practices” (p. 13). Although redefining wastes as byproducts may be required for IS, it has proven to be complicated to transform wastes into by-products under current environmental regulations [27], which prevents the reuse of wastes [15]. Based on EU policy and legal framework, Watkins et al. [26] concluded that the current end-of-waste criteria of the Waste Framework Directive (WFD) do not support the development of IS. Singh et al. [51] reported that “there is a lack of clarity on various areas of European Union legislation such as re-use and recovery” (p. 101752). Regulations may also impede transportation and reuse of wastes [45,52]. Van Beers et al. [17] mentioned strict transportation procedures and requirements that need to be applied for a byproduct that is classified as a controlled waste. Desrochers [38] mentioned that it is prohibited to export wastes categorized as “hazardous waste” to the United States under the Resource Conservation and Recovery Act (RCRA). Papathanasoglou et al. [25] reported that industrial units belonging to certain categories are not permitted to be located in the same industrial area in terms of the existing institutional framework in Greece, which restricts the shift towards the establishment of IS. Furthermore, Papathanasoglou et al. [25] argued that besides barriers of IS resulting from implementation of the current regulations, lack of comprehensive and specialized legislation hinders the development of IS as well.

In addition, closely related to the context of China, the planned economic system that was previously chosen by the Chinese government resulted in sectoral boundary barriers, which impeded the development of IS [28].

2.2.2. Economic Barriers

Economic considerations are a critical factor for the success of IS [2,41,53,54]. The existing pricing mechanism for waste products can be a barrier to IS [15]. Ayres [55] argued that “many industrial wastes cannot be economically recycled” (p. 428). Thus, from a company perspective, waste exchange relationships might be economically unsound or risky, which restricts potential IS activities [43,50,56]. Salmi et al. [27] argued that transportation of waste, especially hazardous waste and potential impurities, would result in a high risk cost. This will cause companies to give up utilizing wastes as raw materials, which impedes the development of IS [3,27]. Some researchers considered that a large investment in new techniques and infrastructure related to IS would also prevent companies from implementing IS [3,49,57].

Companies need to be profitable. Some authors argued that economic barriers may inhibit the incentive to utilize waste without a reliable market for them, which would lead to unsatisfactory economic benefits [42,56]. Mangan and Olivetti [45] mentioned that companies are less likely to engage in IS without a clear demonstration of potential benefits.

2.2.3. Technological Barriers

Concerns about the technical feasibility of waste exchange can be a barrier for IS [43,45]. Van Beers et al. [17] noted that IS concerns the capture, recovery, and reuse of byproducts. They reported that many potential IS opportunities have been prevented from being realized because of technology challenges, such as availability of (reliable) recovery technologies [17]. Liu et al. [58] mentioned some technical barriers associated with waste water regeneration and solid waste reutilization. Gibbs [42] perceived the possibility that local companies have no potential to ‘fit together’ as an example of technical barriers. In addition, lack of evaluation technique related to IS has received attention by some researchers. Costa et al. [59] emphasized lack of evaluation of the potential recycling function of manufacturing technologies already in place as a challenging technological barrier. Sakr et al. [40] considered that “the lack of local technical know-how capable of identifying and evaluating IS opportunities” (p. 1166) is an important technical issue.

2.2.4. Organizational Barriers

Heeres et al. [43] mentioned that the anticipated waste exchange might not conform to the current corporate organizational structure, which can be considered as an organizational barrier for IS. Walls and Paquin [3] argued that organizational structure can result in insufficient autonomy of subsidiaries for engaging in waste exchanges, thus limiting IS. For example, some researchers found that companies which are subsidiaries of national or international corporations may be “unable to alter materials linkages” [50] (p. 1693), or may lack interest in IS exchange [3,40]. This is considered to be a result of having limited decision-making powers [29,40,50]. Furthermore, Heeres et al. [43] found that in the case of the Fairfield EIP project, “absence of an entrepreneurs association that represents all Fairfield industries/companies” (p. 993) is one of the factors causing problems for this project.

The culture of an organization plays an important role in implementing IS practices. A shared vision and beliefs can form a common culture among actors of an IS [3,60,61]. Some researchers argued that organizational cultures with low levels of interfirm cooperation could cause a certain reluctance against taking part in symbiotic relationships [41], or could prevent companies from working across organizational borders [50].

In addition, Tudor et al. [54] postulated that “one of the main enterprises leaving or looking elsewhere for its materials/products” (p. 204) will influence the functioning of the entire chain in a small industrial network. Heeres et al. [43] found that in the Rietvelden/Vutter (RiVu) EIP project, having “few large, financially strong companies” (p. 993) is one of the barriers for this project.

2.2.5. Informational Barriers

Informational support assists in discovering IS opportunities through identification of possible compatible flows [2,20] and making decisions on the establishment of IS [62]. Heeres et al. [43] further suggested that informational barriers can be perceived as “the right people do not have the needed information at the right time” (p. 987). Gibbs [42] argued that it may be difficult to find new uses for waste products due to barriers such as poor information on the potential market and potential supply. Chertow [63] found that business managers “often lack access to information about their neighbors in different industries” (p. 24).

Heeres et al. [43] found that a communication platform is critical for EIP projects. Raabe et al. [39] considered that one major barrier faced by companies participating in IS is lack of information relating to possible and available byproducts. They suggested that a collaboration platform providing information could be helpful for companies engaging in a symbiosis [39].

In addition, there is difficulty in exchanging information between companies. LeBlanc et al. [29] found that some businesses, especially the large ones, “seemed hesitant to participate openly in eco-industrial activities because of the risks associated with sharing information with potential competitors” (p. 12). Based on the context of Egyptian industry, Sakr et al. [40] found that companies resist exchanging information “for fear that it may be used against them by the regulatory authorities” (p. 1163).

Table 2.

Classification of IS barriers.

Table 2.

Classification of IS barriers.

| Categories of Barriers | Type of Barrier | References |

|---|---|---|

| Governmental barriers |

| [3,47,49,64,65] |

| - | |

| [15,17,26,27,29,38,41,43,45,50,51,52,65,66] | |

| [25] | |

| [25,28,41] | |

| Economic barriers |

| [3,17,27,41,65] |

| [3,49,57] | |

| [42,45,56] | |

| Technological barriers |

| [17,58] |

| [40,42,59] | |

| Organizational barriers |

| [3,29,40,41,43,50] |

| [41,50] | |

| [43,54] | |

| Informational barriers |

| [39,41,42,43,56,63] |

| [29,40] | |

| Cognitive barriers |

| [22,29,34,37,39,40,45,64] |

| Motivational barriers |

| [42,43,44,49] |

| Safety barriers |

| [63] |

| [27,63] |

2.2.6. Cognitive Barriers

Cognition or perception is identified as one of the barriers for the development of IS by some researchers [45,64]. Mangan and Olivetti [45] pointed out that waste is often perceived as something with negative connotations by companies. This makes companies unwilling to focus on waste and participate in IS relationships [45]. Ehrenfeld and Gertler [64] argued that it is difficult for companies to integrate wastes into their strategic processes because wastes have a long history of being ignored. Notarnicola et al. [22] found that a main constraint for IS implementation is that the strategic approach of companies is highly oriented to the primary product with a focus on core business. In this circumstance, the waste is regarded as something to be disposed of quickly [22]. Some authors found that one of the barriers in enabling IS is that companies lack understanding of concepts, principles, potential benefits, and cooperation related to IS activities [29,34,37,39,40].

2.2.7. Motivational Barriers

Some researchers argued that there may be motivational barriers wherein stakeholders must be willing to cooperate [34,42,44]. In this respect, the barriers may be a lack of trust [42,43,44]. Gibbs [42] also noted that a lack of trust would inhibit the establishment of a symbiotic relationship. Compared with Dutch industry, Heeres et al. [43] found that when participating in EIP projects, US companies have more distrust towards the local government that acts as the EIP project promoter. Lehtoranta et al. [49] suggested that creation of trust is more challenging for larger regions when attempting to implement IS.

2.2.8. Safety Barriers

Chertow [63] argued that concern about the use of industrial byproducts, especially in symbioses involving agriculture, needs to be carefully examined because it is an important environmental and health issue. This means that an IS relationship focusing on utilizing wastes may be hindered if it can cause safety problems for environment and human health. Chertow [63] further pointed out that there is still no widely reported evidence of environmental health problems resulting from byproduct exchanges that has been found. In a case study of IS around the Gulf of Bothnia, Salmi et al. [27] found that while there were no significant technological barriers on utilization of wastes around that region, from an ecological point of view, they argued that the marine transport of hazardous materials across the open sea during winter is certainly risky and recommended that a risk assessment on marine transport should be conducted [27].

From the extensive literature review, it can be seen that the current research related to IS barriers is mainly qualitative. Evaluation of the IS barriers is still very limited. Only one paper was found examining the barriers using an operating IS as a case study [15]. Furthermore, the barriers evaluated are still focused on generic barriers. No literature has been found that utilizes a model designed as a hierarchical structure embracing both the generic and the specific IS barriers. In order to fill the current research gap, taking an operating IS as an example, this paper aims to semi-quantitatively evaluate and rank the IS barriers in order to reveal the degrees of importance of IS barriers in a comprehensive and systematic manner.

3. Research Methodology

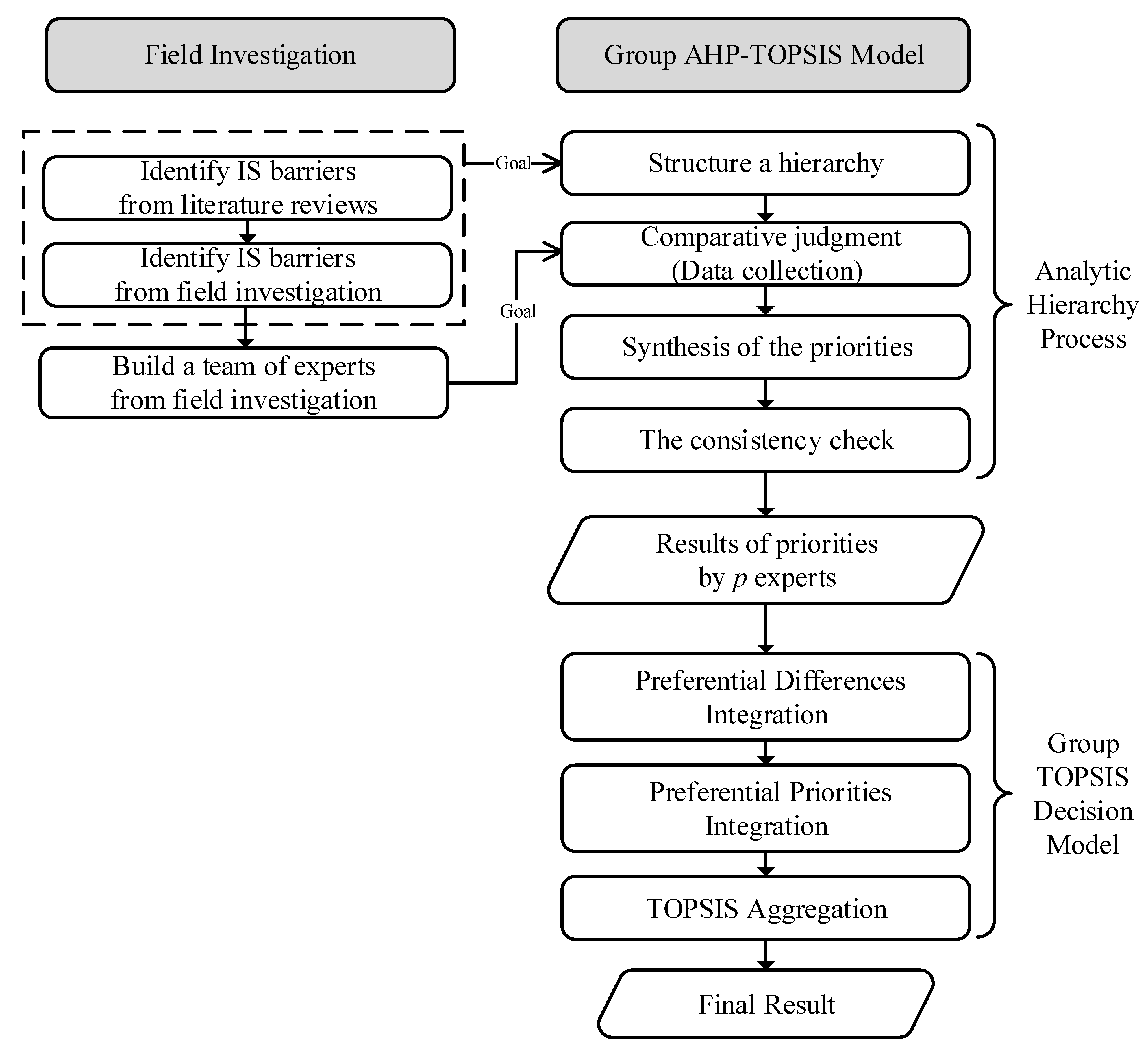

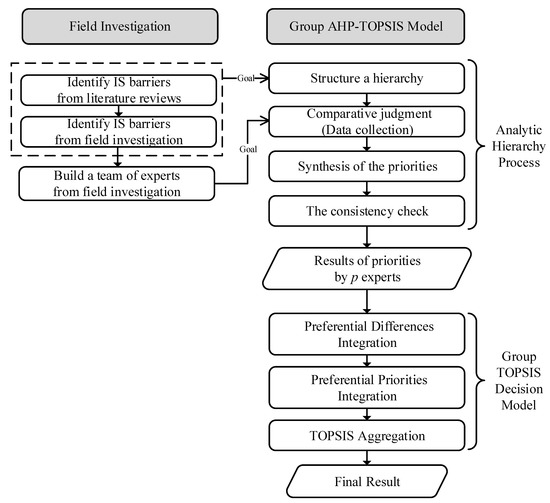

This paper presents a Group AHP-TOPSIS Model to systematically uncover the priority of various barriers for an operating IS. The structure of the method is shown in Figure 1. The main calculation steps are given in Supplemental Materials File S1.

Figure 1.

The flow chart of the Group AHP-TOPSIS Model.

3.1. Field Investigation

The field investigation on an IS aims at: (1) collecting the information on barriers from managers involved in the IS to ensure they are comprehensive; and (2) inviting experts from the IS to make pairwise comparisons. The process of conducting the field investigation involves the following two phases.

3.1.1. Phase One

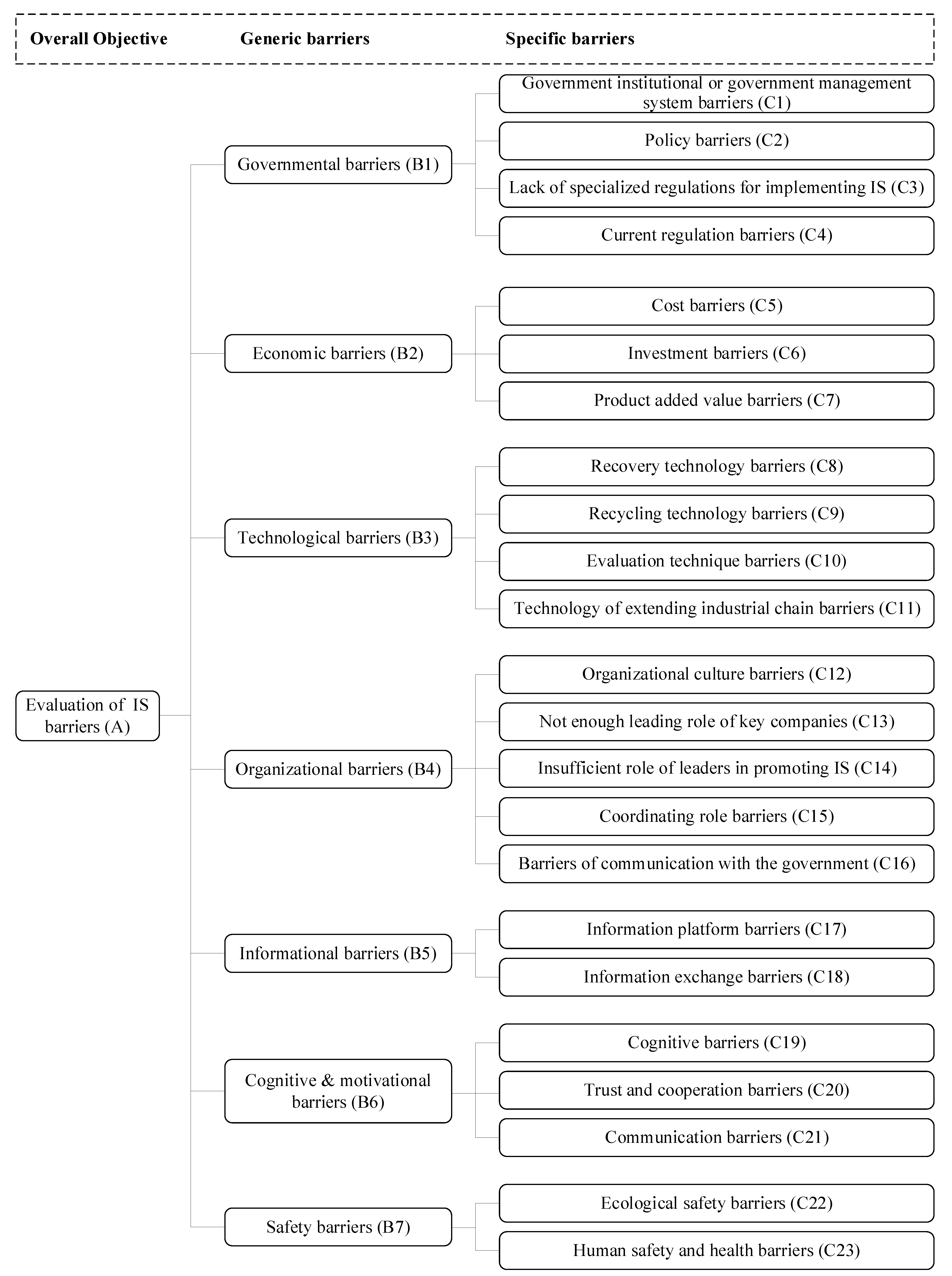

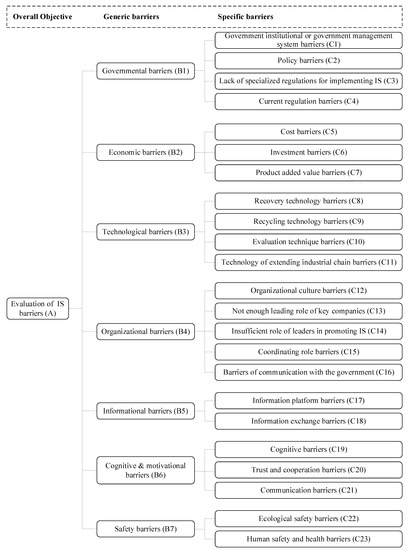

As shown in Section 2.1, an extensive review of the literature was conducted to identify IS barriers (Table 2). These IS barriers were then validated and refined through a field investigation on all the companies participating in the IS of HHG. These companies are the soda plant, the thermal power plant, the salt field, the bromine plant, the sodium bicarbonate plant, the potassium sulfate plant, the calcium chloride plant, the petrochemical company, and the chlor-alkali colophony plant. Interviewees were managers responsible for technology, finance, security, and environmental protection from the participating companies. All respondents had 5–10 years of experience and met the following conditions: (1) be familiar with IS, (2) be familiar with the evolution of IS in the group, and (3) be familiar with the cooperative relationships between the participating companies. Open-ended interviews were conducted in order to fully grasp the information on IS barriers of the HHG. Interviewees shared their judgments on barriers critical to hindering the establishment and operation of IS in HHG. After a brainstorming session, 7 generic barriers and 23 specific barriers were confirmed, which are shown in Figure 2.

Figure 2.

Hierarchical structure for IS barriers of HHG.

3.1.2. Phase Two

After phase one, the IS barriers reflecting the actual situation of an IS were identified and categorized. Based on this information, a hierarchy structure of the model for evaluating the IS barriers was built. In this phase, in order to more accurately assess the current barriers, experts from the IS of HHG were selected and invited to score the questionnaire on the IS barriers. A group composed of 25 experts selected by the HHG was formed. The experts selected met the conditions as laid out in Section 3.1.1 and all of them have more than 15 years of work experience. They are different from the managers interviewed in phase one of field investigation and would be invited to score the questionnaire on the IS barriers. They were from companies participating in the IS and the HHG, i.e., four from the HHG, four from the thermal power plant, two from the petrochemical plant, two from the sodium bicarbonate plant, two from the soda plant, two from the chlor-alkali company, two from the calcium chloride plant, two from the potassium sulfate plant, three from the bromide plant, and two from the salt field plant. Most of them are engineers. However, they have a comprehensive understanding of the IS in HHG, including many aspects such as technology, economy, and governmental regulations and policies. They agreed with the classification of the IS barriers in the context of HHG and would make pairwise comparisons of the IS barriers.

3.2. Group AHP-TOPSIS Model

3.2.1. Analytic Hierarchy Process

In this paper, the Analytic Hierarchy Process (AHP) method is incorporated into the model for evaluating the IS barriers. Created in the 1970s by the mathematician Thomas L. Saaty [67], AHP addresses how to determine the relative importance of a set of activities in a multi-criteria decision problem and then make choices based on the experts’ judgments [68,69]. It “makes it possible to incorporate judgments on intangible qualitative criteria alongside tangible quantitative criteria” [68] (p. 29) and has worldwide acceptance [70]. AHP has been widely used in many fields, including manufacturing systems, technology evaluation, strategy selection, firm’s competence evaluation, organizational performance evaluation, and sustainability evaluation [71]. It has many advantages, particularly ease of application, incorporating qualitative and subjective factors, and providing a methodology to measure the consistency of these judgments [72].

AHP can be used to quantify qualitative barriers, verify the consistency of expert judgments, and more accurately identify important barriers to a system. Some researchers have put forward several methods using AHP to evaluate the barriers related to the IE field, including barriers to sustainable consumption and production [73], green supply chain management [74], sustainable supply chain [75], and renewable energy development [76]. However, after a literature review, no studies have been found to examine IS barriers by applying AHP. This paper will explore the application of AHP to a semi-quantitative evaluation of the IS barriers.

The AHP method mainly embraces three steps [77]:

- (1)

- Structure a hierarchy: A complex decision problem is structured as a hierarchy, which involves decomposing the problem into its components. It helps to determine the importance of lower-level elements relative to an upper-level element [78]. Based on the extensive literature review and field investigation mentioned in Stage 1, the IS barriers were classified into a two-level hierarchy. The hierarchy structure and detailed information on the classification of IS barriers of HHG are respectively shown in Figure 2 and Table 3. As shown in Figure 2, the overall objective of evaluating IS barriers was represented by “A”. The generic category of barriers was listed as “B”, which was further divided into specific barriers listed as “C”. Such a hierarchy structure was composed of 7 generic barriers and 23 specific barriers.

Table 3. Classification of IS barriers of HHG.

Table 3. Classification of IS barriers of HHG. - (2)

- Comparative judgment: In order to collect the raw data required by the AHP, a team of experts was built as mentioned in Section 3.1.2. Firstly, the purpose of this research was introduced to them. Secondly, the meaning of various barriers and the method for rating the barriers were explained to them. Finally, based on their observation and experiences, the experts made pairwise comparison, i.e., at each level, these barriers should be pairwise compared in accordance with the hierarchy structure (Figure 2 and Table 3). This enables linguistic judgments to be converted into numerical scales [79], which are typically integers from one to nine [80]. Considering the complexity of 9 scales, we applied 1,3,5,7,9 scales [78]. According to Saaty [80], Table 4 shows the relationship scale when comparing barrier i to barrier j. Pairwise comparison also allows experts to focus on only the two factors being compared, which makes “the observation as free as possible from extraneous influences” [81] (p. 334).

Table 4. Relationship scale when comparing barrier i to barrier j.

Table 4. Relationship scale when comparing barrier i to barrier j. - (3)

- Synthesis of the priorities: The weight of each element is usually obtained by calculating the eigenvector (a property of a matrix that can be computed) of the judgment matrix, and the derived weights need to pass a consistency test [82]. The measure of consistency is obtained by the consistency index (CI) and consistency ratio (CR) [80]. Following Saaty [80], a consistency ratio (CR) less than 0.1 is acceptable. This threshold value has been widely adopted. However, according to the practical requirements, CR less than 0.2 could also be determined as an acceptable consistency level, which has been used in some studies such as Uzoka et al. [83] and Pauer et al. [84]. In our studies, a threshold value of 0.1 seemed too strict. Some experts felt confident about their judgments even though CR is between 0.1 and 0.2, as other studies have reported [85]. Thus, we adopt 0.2 as the threshold value of CR. Otherwise (CR > 0.2), the consistency needs to be improved [80] and the methods proposed by Kou [86] can be used [87,88]. Such a method only depends on the original matrix; it preserves most of the original information, enhances matrix consistency significantly, and improves the reliability of judgments [86].

Finally, the quantitative results of the importance of barriers given by each expert can be obtained.

3.2.2. Group TOPSIS Decision Model

After obtaining quantitative results of the importance of the barriers given by each expert, this paper applied the Group TOPSIS Decision Model proposed by Huang and Li [89] to aggregate these judgments.

To obtain a more convincing result, it is necessary to have more than one expert perform the pairwise comparisons in the AHP analysis, which “allows for multiple points of view and the knowledge of multiple subject matter experts to play a role in the final decision” [90] (p. 357). Generally, a consensus vote or mathematical aggregation can be applied to aggregate the opinions of experts [71]. The former requires the group to reach an agreement on the value of each entry in pairwise comparisons while the latter adopts mathematical models to aggregate results given by each expert. A consistent vote is “usually difficult to obtain with the increasing number of comparison matrices and related discussions” [71] (p. 14341). Problems such as “lengthy discussion, groupthink syndrome, unclear responsibility, minority dictatoriality and discontented compromise” (p. 446) make it ineffective [91]. In our study, the consensus vote is not appropriate because an operating IS usually contains several industries and more experts should be involved in the judgments. This makes it difficult to obtain a consensus on every aspect [91]. Second, in a decision situation, “the criteria to be considered are highly diverse and no single expert can be expected to have ‘expertise’ to comment on all such criteria” [92] (p. 256).

Therefore, we sought an appropriate mathematical model to aggregate the judgment of experts [71]. There are many mathematical models for aggregating experts’ judgments. Zadnik and Grošelj [93] claimed that the problem of selecting an appropriate aggregation method for aggregating individual judgments is still not fully solved although the group AHP has already been widely used. In recent years, some researchers have conducted extensive reviews of group aggregation methods in AHP, which systematically compared the characteristics of those mathematical models [94,95]. According to their research, the model proposed by Huang [89,91] was chosen as appropriate for our study because it takes two factors of “preferential differences” and “preferential priorities” into account.

The Group TOPSIS Decision Model involves the following three steps [89]:

- (1)

- Preferential differences integration: Preferential differences refer to “the differences of preferential weights among alternatives” for each expert [96] (p. 362). Ramanathan [92] stated that, when facing various factors, there is often no expert who can give a professional evaluation of all these criteria. If an expert is not able to or shows no interest in decisively distinguishing these alternatives, similar preferences may be chosen for all of them [89]. This means that experts give similar weights to barriers, thus there is little difference in weights among these barriers. Huang et al. [91] argued that “it is reasonable that an individual with greater preferential differences among alternatives would have more influence in a group than those who with less preferential differences, since the individual with greater preferential differences would fight for his/her choices, while the other members may be less insistent because of their similar perceptions of all alternatives” (p. 448). Basak [97] argued that “in any rational consensus, those who know more should, accordingly, influence the consensus more strongly than those who are less knowledgeable” (p. 103). Therefore, in our study, the preferential differences should also be considered. These people should have less influence on the result than others, making the result more accurate.

- (2)

- Preferential priorities integration: Preferential priorities refer to “the ranks of the alternatives” by each expert [96] (p. 362). Using the preferential priority assists in emphasizing “the importance of the best ranked alternative which is often much more important than other alternatives” [89] (p. 466), and has been demonstrated by Inti and Tandon [98]. In our study, considering the “preferential priorities” contributes to highlighting the IS barriers that are ranked ahead by the experts.From the above analysis, the two factors of “preferential differences” and “preferential priorities” are suitable for our research, because they assist in identifying the more important barriers for the development of an IS. The two factors have been considered to be “a more realistic and rational fashion” [96] (p. 362). Their meaning and significance have been confirmed [98,99]. It should be noticed that some additional factors, such as the risk attitudes of experts, may influence the process of aggregating preferences in practice [89]. If a judgment given by an expert is too far away from the majority, this expert will take up too much weight in the results, which will cause the results to be biased. To avoid this problem, three assumptions were adopted [89]: (i) All experts can express their preferences and make comparisons accordingly. (ii) All experts should be honest and will not deliberately overestimate or underestimate some alternatives. (iii) There is no monopoly and the experts have the same power.

- (3)

- TOPSIS aggregation: Accepting these assumptions, the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) method is adopted to aggregate the experts’ judgments based on the two factors above. As a popular Multi-Criteria Decision Making (MCDM) method, it has been widely used in many fields [100]. It is based upon the concept that “the chosen alternative should have the shortest distance from the positive ideal solution and the farthest from the negative ideal solution” [101] (p. 2). TOPSIS was extended by Huang and Li [89] to aggregate individual experts’ preferences. In our study, the chosen alternative is equal to the most important barrier for the operating IS. Moreover, every expert will provide a maximum weight and a minimum weight, which is equal to the positive ideal solution and the negative ideal solution, respectively. The TOPSIS method accounts for both the best and worst alternatives, i.e., the most important barrier should be closer to the maximum weight given by each expert, and should also be farther from the minimum weight given by every expert instead of only accounting for the former [102]. Therefore, it can avoid the problems that might occur with the common mean aggregation approaches [89]. The results indicate that most of the experts consider that one of these barriers should have a higher rank rather than a lower rank, and such a barrier is the most important barrier of the IS.

In the end, the weighted value of generic barriers under the overall objective and the weighted value of specific barriers under generic barriers can be achieved. The weighted value of the specific barriers under overall objective can be obtained by multiplying the weighted values of generic barriers with the weighted value of each specific barrier [70]. Thus, the quantitative evaluation of the IS barriers can be achieved by our model.

4. Case Study

4.1. Overview of Industrial Symbiosis of Hai Hua Group

With a feature of various material and energy flows, chemical industry is considered to be a key industry with strong potential for implementing IS and has often been emphasized in literature [3,4,41,56,103,104,105]. The IS of Hai Hua Group (HHG) is a chemical-industry-dominated IS. It is located in the Weifang Binhai Economic and Technological Development Zone (WBETDZ) in Shandong Province of China, which is currently the only national-level marine chemical EIP in China. The IS of HHG is the core component of this EIP. The establishment of the IS started with combining the salt and soda companies in 1995 [28]. After that, other symbiotic companies were introduced and it has now evolved over 25 years, thus becoming one of the most famous leading industrial symbioses in China.

Currently, the IS of HHG is composed of a salt field, a soda plant, a thermal power plant, a bromine plant, a sodium bicarbonate plant, a potassium sulfate plant, a calcium chloride plant, a petrochemical company, and a chlor-alkali colophony plant. Among these companies, the soda plant and the salt field are, respectively, China’s largest soda production company and one of the three major sea salt production bases. During its evolutionary process, the IS of HHG has been struggling to achieve a CE through continuous improvement. Being an operating chemical-industry-dominated IS with a relatively long evolutionary process, the IS of HHG is chosen as a case study and will be helpful to test the model proposed in this paper.

4.2. Group AHP-TOPSIS Model

4.2.1. AHP

As mentioned in Section 3, the questionnaires were designed and delivered to a group of 25 experts. A pairwise comparison was undertaken. After all the questionnaires were collected, according to Section 3.2.1, the weights of generic barriers, specific barriers, and the specific barriers’ degrees of importance corresponding to their generic barriers given by each expert were achieved, which are shown in Supplemental Materials File S2 (Tables S1–S3).

4.2.2. Group TOPSIS Decision Model

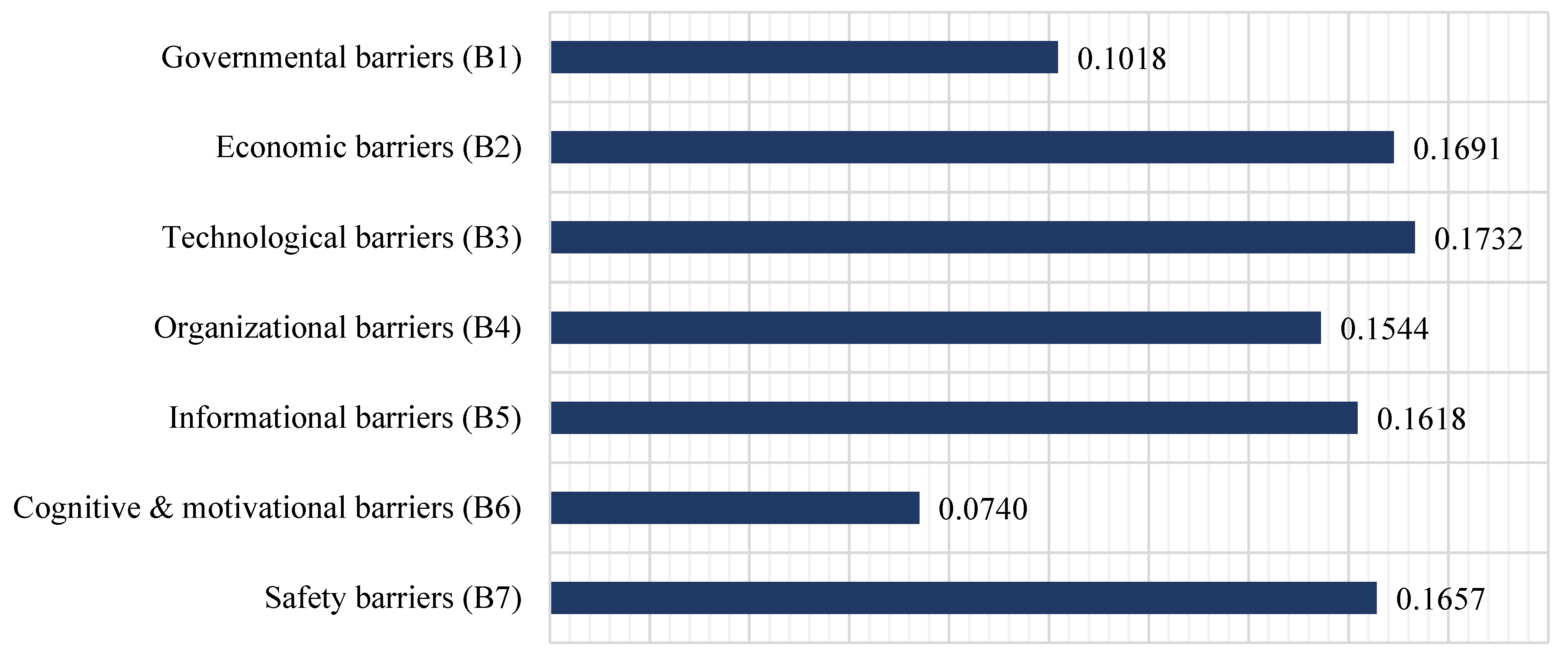

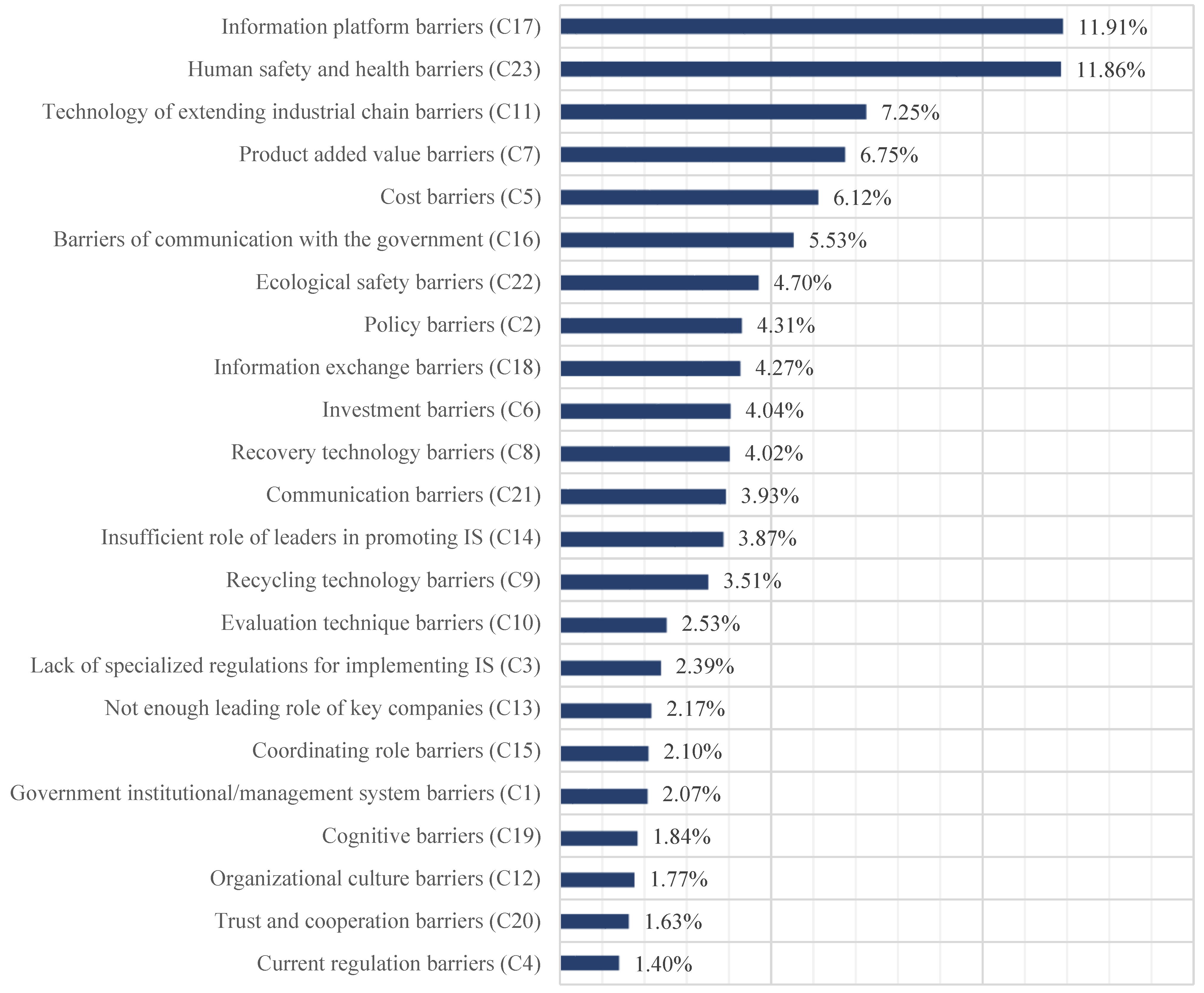

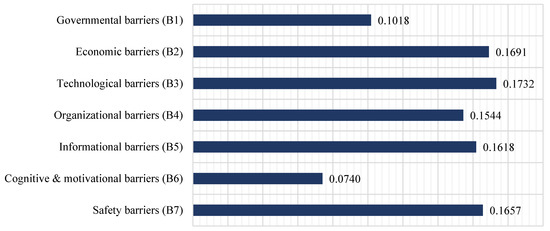

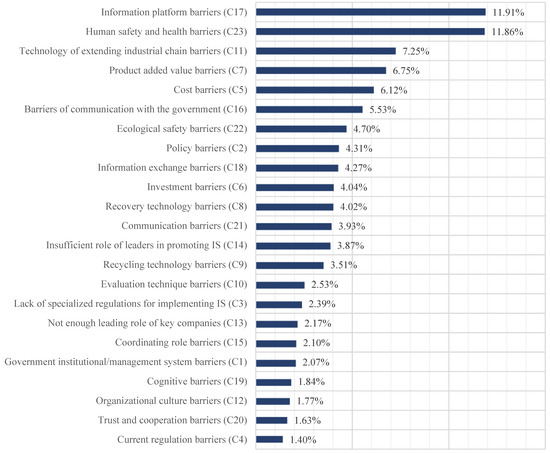

According to Section 3.2.2, the weights derived by AHP should be aggregated by Group TOPSIS Decision Model, including preferential differences integration, preferential priorities integration, and TOPSIS aggregation. These intermediate steps results are shown in Supplemental Materials File S3 (Tables S4 and S5). Finally, by TOPSIS aggregation, the degrees of importance of IS barriers have been quantitatively evaluated, including weights of generic barriers (Table 5 and Figure 3), specific barriers (Table 6 and Figure 4), and the specific barriers’ degrees of importance corresponding to their generic barriers (Table 6).

Table 5.

Rankings for generic barriers.

Figure 3.

Priority weighs for generic barriers.

Table 6.

Rankings for specific barriers.

Figure 4.

Priority weighs for specific barriers.

4.3. Results and Discussion

The results of the intermediate steps of AHP and Group-TOPSIS Decision Model are given in Supplemental Materials Files S2 and S3. In addition, through taking consideration of the two characteristics of preferential differences and preferential priorities in the model of this paper, the weighted value of each barrier can be distinguished more clearly. The results of preferential differences and preferential priorities are provided in Supplemental Materials File S3. The detailed discussion on preferential differences and preferential priorities is provided in Supplemental Materials File S4.

From Figure 3 and Table 5, it can be seen that the prioritization of the IS barriers of HHG has been performed by observing the highest weighted value of 7 generic barriers which shows that technological barriers (B3), economic barriers (B2), safety barriers (B7), informational barriers (B5), organizational barriers (B4), governmental barriers (B1), and cognitive and motivational barriers (B6) are in descending order. Furthermore, the global ranking for 23 specific barriers is shown in Figure 4 and Table 6. The discussion on the results is as follows.

4.3.1. Barriers Analysis

Technological Barriers (B3)

Technology plays a very important role for the establishment of IS relationships [17,61,106]. Technological barriers have often been considered as one of the key barriers that hinder companies’ transition towards a CE [21,107].

From Figure 3 and Table 5, it is shown that technological barriers (B3) rank first among all the generic barriers, receiving the highest weighted value. This means that technological barriers are the most important barriers to the IS of HHG and should be given the highest importance to be managed, or, if not, eliminated. Similarly, Zhu et al. [31] found that technological barriers are the most prevalent barrier for EIP implementation.

From Table 6, it can be seen that among all the specific barriers of technological barriers (B3), the order of the weighted value from high to low is technology of extending industrial chain barriers (C11) > recovery technology barriers (C8) > recycling technology barriers (C9) > evaluation technique barriers (C10). C11 is significantly higher than C8, C9, and C10. This indicates that technology for extending industrial chain barriers (C11) are the highest priority barriers of the technological barriers to the IS of HHG and should be given the most attention to be managed or eliminated. Some researchers mentioned that the value chain of raw chemical materials should be extended as much as possible for chemical industrial parks implementing industrial ecology strategies [105,108]. This would be beneficial to establish a circular business model [109]. Currently, the main products of HHG can be utilized as raw materials for other products to some extent. For example, salt is the raw material for producing soda and chlor-alkali products, and soda can be utilized for producing sodium bicarbonate, which refers to the IS relationships established between the salt field and the soda plant, the salt field and chlor-alkali colophony plant, and the soda plant and the sodium bicarbonate plant. However, during the investigation, some interviewees pointed out that in general, the IS of HHG still has lack of technologies which could utilize the current main products to further produce products with higher added value, leading to the improvement of economic benefit. This restricts the establishment of new IS relationships to some degree.

The recovery technology barriers (C8) rank second in the specific barriers of B3. Some interviewees provided an example related to C8. There is often great potential for establishing IS relationships between companies through utilizing waste heat. In the IS of HHG, it has been found that the waste ammonia liquid generated in the production of the soda plant contains a great amount of waste heat. However, there is still no technique which can effectively recover the waste heat, which restricts the utilization of waste heat and establishment of new IS relationships. The score of recycling technology barriers (C9) is less than but very close to that of C8. Recycling technologies assist in creating new synergy opportunities [56] and are often crucial to the establishment of “scavenger” companies [106,110,111]. A “scavenger” company refers to those companies who utilize other companies’ wastes [7,112]. It is a key component in a CE [113]. However, recycling often “requires a technology-intensive process” [114] (p. 732). From the investigation, it showed that the most important recycling technology barrier in the IS of HHG is lack of technologies capable of fully utilizing the caustic sludge, which is the main solid waste generated in soda production. This will restrict the establishment of a new IS relationship between the soda plant and a “scavenger” company utilizing the caustic sludge of the soda plant. Evaluation technique barriers (C10) receive the lowest weighted value among the specific barriers of technology barriers. Evaluation technique assists in identifying and evaluating potential IS opportunities [40]. Some interviewees suggested that information technology needs to play a more important role in identifying and evaluating potential IS opportunities in the future in the HHG.

Economic Barriers (B2)

The weighted value received by economic barriers (B2) is 0.1691, which ranks second among all the generic barriers. It is very close to that of technological barriers (B3) (0.1732). This means that economic barriers are a very important barrier for the IS of HHG.

Among all the specific barriers of B2, the order of the weighted value from high to low is C7 > C5 > C6. This indicates that product added value (C7) is the highest priority barrier and should be given the most attention when managing or eliminating economic barriers. C7 means that if it is difficult for an IS project to realize product added value, this may hinder the establishment of new IS relationships. For chemical industrial parks, achieving the added value of raw chemical materials through extending the value chain should be encouraged when implementing IS [105]. Some respondents pointed out that the current main products of HHG, such as soda, can be utilized as a raw material for further producing sodium bicarbonate. However, the added value of the sodium bicarbonate is not high. Thus it can be seen that although soda and sodium bicarbonate have potential for further extending the industrial chain, the low product added value will hinder the establishment of related new IS relationships.

The weighted value of cost barriers (C5) is 0.3619. It is lower than that of product added value barriers (C7) (0.3993), but is very similar. Furthermore, both of them are much higher than investment barriers (C6). This means that cost barriers (C5) and product added value barriers (C7) are also very important barriers to be addressed when eliminating economic barriers. Scavengers ensure resources are utilized efficiently [3]. However, reusing of many wastes is difficult to be achieved because it would lead to a high production cost, which would “require financial subsidies to ensure their economic viability” [107] (p. 268). During the process of investigation, many respondents mentioned that the calcium chloride plant and potassium sulfate plant, which act as two critical scavenger companies for the IS of HHG, respectively utilize the waste ammonia liquid produced by the soda plant and the bittern brine generated in the salt field as raw materials. However, this often leads to a relatively higher production cost for both of the two companies. Especially for the calcium chloride plant, in recent years, it has been facing fierce market competition because its production cost is higher than that of plants producing calcium chloride with waste acid. Thus, the respondents argued that the establishment and operation of such scavenger companies are critical for the stable operation of the whole IS of HHG. However, the challenge of higher production cost for them will restrict the establishment of other new IS relationships focusing on scavenger companies.

Safety Barriers (B7)

The weighted value of safety barriers (B7) is 0.1657. It is lower than that of economic barriers (B2) (0.1691), but is very similar. This means that safety barriers and economic barriers are also very important barriers for the IS of HHG and should be emphasized.

Chemical industrial parks often face challenges of safety issues [105,115]. The potential risks and threats to human health and the environment should be a key issue to be considered when chemical industrial parks implement industrial ecology strategies [105]. From Table 6, it can be seen that among the specific barriers of safety barriers, the weighted value of human safety and health barriers (C23) is 0.7160, which is higher than that of C22, i.e., ecological safety barriers (0.2840). This indicates that in the current development of HHG, human safety and health should be of primary concern when considering new IS projects. During the investigation, some interviewees stressed that in view of the IS in HHG, which is a chemical-industry-dominated IS, the potential safety issues need to be fully considered when establishing new IS relationships.

Some researchers argued that environmental or health issues need to be carefully examined for IS [27,63]. However, in the current IE field, few articles have discussed the relationship between safety issues and IS. In this paper, we found that safety barriers are very important for the IS of HHG. This finding confirmed the opinions of Chertow [63] and Salmi et al. [27], which show that the relationship between safety issues (including human safety and health and ecological safety) and IS is an important research topic to be examined. Although the finding is related to the chemical industry in this case, in fact, many industrial symbioses involve chemical companies or chemical products. Therefore, safety barriers deserve to be considered in other industrial symbioses.

Informational Barriers (B5)

The weighted value of informational barriers (B5) is 0.1618, which ranks fourth among all the generic barriers. Among the specific barriers of informational barriers, the weighted value of information platform barriers (C17) is 0.7539, which is far higher than that of information exchange barriers (C18, 0.2641). This indicates that information platform barriers should be given the highest importance. Mirata [41] considered that informational support must be a continuous process because it can both assist the functioning of existing IS and help new ones to be established. Golev et al. [15] found that even for companies that have existing IS relationships, it is not easy to obtain information available for investigating new potential symbiotic links. Establishment of an information platform is crucial for IS [2,43,56,116], which would help to carry out information dissemination [2], share information and enhance communication [13], and discover potential IS opportunities [2]. In the IS of HHG, many interviewees pointed out that in terms of information, although the HHG has established various information systems, there is still no information platform focusing on matters related to IS. This is identified as a main barrier among informational barriers. Therefore, an online platform collecting information related to IS needs to be established in the IS of HHG. In addition, in terms of information exchange, some respondents mentioned that the form of information exchange should be extended, such as encouraging ordinary employees to suggest potential new IS relationships.

In another study on assessing barriers of an operating IS, in Gladstone, Australia, informational barriers were detected as the most significant barriers among seven categories of IS barriers [15]. In our study, from Figure 4, it can be seen that information platform barriers rank first among all the 23 specific barriers. The informational barriers rank fourth among all the generic barriers, which shows that they are not as important as the case of Gladstone. This may relate to the organizational form of HHG. In this case, all the companies participating in the IS belong to the group. As the parent company, the HHG can play an important role in ensuring that information is shared among all the companies. However, comparing the weighted value of informational barriers (B5) with that of safety barriers (B7, 0.1657), economic barriers (B2, 0.1691), and technological barriers (B3, 0.1732), which rank third, second, and first place, respectively, it can be seen that it is similar. This indicates that safety barriers (B7) can also be considered to be a very important barrier.

As mentioned above, this paper finds that information platform is the most important specific barrier to the IS of HHG. Many researchers have pointed out that IS often suffers from informational barriers [11,15,40,117] and emphasized the importance of an information platform for IS [2,43,56]. Therefore, this is viewed as an important finding of our study.

Organizational Barriers (B4)

The weighted value of organizational barriers (B4) is 0.1544, which ranks fifth among all the generic barriers. From Table 6, it can be seen that the order of the weighted value of its corresponding specific barriers from high to low is barriers of communication with the government (C16) > insufficient role of leaders in promoting IS (C14) > not enough leading role of key companies (C13) > coordinating role barriers (C15) > organizational culture barriers (C12).

Barriers of communication with the government (C16) rank first in all the specific organizational barriers of organizational barriers. The development of IS can be fostered by positive feedback loops between government, industry, and stakeholders [3,118,119]. Through investigation, it was found that the HHG, which acts as the organization creating the IS, has not done enough to communicate with the local government, i.e., the management committee of WBETDZ, on the development of IS. For example, some respondents mentioned that the HHG needs to communicate with the management committee of WBETDZ on challenges for the IS in a timely manner and seek potential help from the government. This finding proves the viewpoints of Mirata [41], who argues that scope of communication actions should not be limited to companies participating in the IS, and ought to be expanded to feedback channels reaching to governmental authorities.

The score for insufficient role of leaders in promoting IS (C14) is 0.2506, which ranks second of all the specific barriers of organizational barriers. Some researchers use the word “champions” to describe key actors who are within IS systems and have the ability and energy to promote the development of IS [40,41,120,121]. Leadership plays a key role in organizational change [62,122]. During the evolutionary process of IS, the key leaders of HHG, acting as “champions”, played important roles in promoting its development. With enthusiasm for IS, they greatly contributed to the establishment of many IS relationships. After they retired, the HHG continued to implement development plans based on the culture of IS. For example, after being acquired by the China National Offshore Oil Corporation (CNOOC), the HHG put forward and is implementing a development plan which integrates the petrochemical industry and salt chemical industry. However, through investigation, it appears that the pressure directly from the leaders of the HHG is not as strong as it was in the earlier stages.

The score for lack of leadership role of key companies (C13) is 0.1406, which is lower than that of barriers of communication with the government (C16) and insufficient role of leaders in promoting IS (C14). Some researchers have emphasized the importance of “key companies” that can also be described as “anchor tenants” in an industrial ecosystem [53,106,123]. It would facilitate the establishment of more symbiotic links [53]. The soda plant and the thermal power plant are two key companies of the IS in HHG and many relationships have been established around them. Some interviewees mentioned that after implementing the strategy of integration of the petrochemical industry and salt chemical industry, there are potential new IS relationships around the petrochemical company. The latter should play a leading role in identifying and establishing these new IS relationships.

The score of coordinating role barrier (C15) is similar to that of lack of leadership role of key companies (C13). An IS coordination body needs to have a certain level of influential power on companies participating in the IS and plays a crucial role in facilitating the development and operation of the IS system [41]. Some interviewees mentioned that the HHG, as a parent company of all the companies participating in the IS, plays a critical role for coordinating the companies. However, it needs to play a bigger role in some aspects of coordination such as facilitating the information exchange between companies participating in the IS.

The score for organizational culture barriers (C12) is 0.1143, which ranks last among all the specific barriers of organizational barriers (B4). During the evolutionary process of the IS of HHG, a good organizational culture once formed. The result shows that the organizational culture still restricts the IS of HHG to some extent. Some interviewees mentioned that after the HHG was acquired by the CNOOC, although top managers have a deep understanding of the IS activities and IS and CE have been integrated into the strategy and goals, compared with the past, the current organizational culture related to IS needs to be improved within the companies of HHG, especially for new employees.

Governmental Barriers (B1)

The weighted value of governmental barriers (B1) is 0.1018, which ranks sixth among all the generic barriers. Among all the specific barriers of governmental barriers, the order of the weighted value from high to low is policy barriers (C2, 0.4234), lack of specialized regulations for implementing IS (C3, 0.2350), government institutional or government management system barriers (C1, 0.2038), and current regulation barriers (C4, 0.1379). It can be seen that policy barriers (C2) rank first and are much higher than the other three specific barriers of governmental barriers (B1). The role of policies for supporting IS has been specifically emphasized by some researchers [3,19,124]. Especially for scavenger and decomposer companies, it is often necessary to provide stimulative policies such as subsidies and low-interest loans to foster their development [62]. The main reasons that policy barriers are rated highly are that some incentive policies introduced by the government have not been continuously implemented for the IS of HHG. For example, the tax cuts and refund policies on calcium chloride introduced by the government once played a key role in encouraging the calcium chloride plant, which is a scavenger company, to effectively use the waste ammonia liquid discharged by the soda plant. However, that policy was cancelled afterwards and this will hinder the establishment of new IS relationships focusing on scavenger companies.

The score for lack of specialized regulations for implementing IS (C3) is 0.2350, which ranks second of all the specific barriers of governmental barriers (B1). Some interviewees mentioned that there is a lack of regulations specifically supporting the establishment of IS and this finding is in line with other results in the Greece study on IS [25].

The score for government institutional or government management system barriers (C1) is 0.2038, which is similar to that of lack of specialized regulations for implementing IS (C3). Through investigation, it was found that in the government of the region where HHG is located, there is still no functional department that is especially responsible for promoting and regulating IS. Currently, the environmental protection bureau is in charge of EIP management. The development and reform bureau is responsible for circular transformation for industrial parks, which is relevant to EIP. However, in terms of government institutional or government management system, there is lack of effective coordination in managing IS between the two government departments.

The score for current regulation barriers (C4) is 0.1379 and ranks last among all the specific barriers of governmental barriers (B1). Current environmental regulations often prevent the utilization of wastes in order to ensure public safety [15,125]. Some interviewees mentioned that current regulations on hazardous waste management are very strict. Companies need to be very careful about waste utilization. This restricts the reuse of wastes and thus hinders the establishment of new potential IS relationships to some extent.

Cognitive and Motivational Barriers (B6)

The weighted value of cognitive and motivational barriers (B6) is 0.0740, which is far below the other six generic barriers and indicates that it is the least important barrier to the IS of HHG.

Among all the specific barriers of B6, the order of the weighted value from high to low is communication barriers (C21, 0.5311), cognitive barriers (C19, 0.2482), and trust and cooperation barriers (C20, 0.2207). The score of C21 is much higher than that of C19 and C20. This shows that communication is the most important barrier. Through investigation, some respondents mentioned that communication especially aimed at IS among participating companies needs to be further strengthened.

In addition, although cognitive and motivational barriers exist to some extent for the IS of HHG, this also indicates that through an approximately 25 years of evolutionary process, a certain foundation for the cognitive and motivational aspects of IS has been established for the IS of HHG, which makes cognitive and motivational the least important barriers. Furthermore, from Figure 4, it can be seen that trust and cooperation barriers rank almost the last among the 23 specific barriers. This is consistent with the findings from the case study of Gladstone in Australia, which is also an operating IS and indicates that cooperation barriers were also identified as the least significant [15]. Other research related to IS barriers found that lack of awareness of IS concepts is one of the key barriers which might be potentially encountered when designing and implementing EIPs [14,23]. Thus, it can be seen that the cognitive and motivational barriers are often very important barriers for an IS which is at the planning and early implementation stage. However, for an operating IS with a relatively long evolution process such as the IS of HHG in this paper and Gladstone of Australia, the degree of importance of cognitive and motivational barriers for IS is much lower. This means that the importance of barriers will be different at different stages of the evolutionary process of an IS, which is supported by other researchers’ viewpoint [2].

In general, among all the generic barriers of the IS of HHG, technological barriers rank first. Economic barriers and safety barriers rank second and third, respectively. Their weighted values are very close to those of technological barriers. Thus, they can be considered to be very important barriers. Informational barriers rank fourth. However, their weighted value is very close to that of safety barriers, which rank third. Therefore, informational barriers can also be considered to be very important barriers. Organizational barriers rank fifth. The gap between the weighted value of organizational barriers and that of the top four generic barriers is not very big. Thus, organizational barriers can be considered to be an important barrier to some extent. Governmental barriers rank sixth. The weighted value of governmental barriers is much lower than that of the top five generic barriers. It can be considered to be a barrier with a medium degree of importance for the current IS of HHG. Cognitive and motivational barriers rank the last and are much lower than other generic barriers. This shows that the degree of importance of cognitive and motivational barriers is the lowest for the IS of HHG.

From the case study of IS barriers of the HHG, it is indicated that many barriers will directly or indirectly impact the establishment and operation of scavenger companies. For example, the results show that cost barriers (C5), policy barriers (C2), and recycling technology barriers (C9) directly impede the development of scavenger companies in the IS of HHG and the transition towards a CE. This further demonstrates that scavenger and decomposer companies play a key role in the development of IS and the achievement of the goal of a CE. This finding is supported by some literature [112,113] and this paper further provides empirical evidence from the perspective of IS barriers. In the future, the barriers focusing on scavenger and decomposer companies can be explored and evaluated, which could be an interesting research topic.

4.3.2. Managerial Implications

Removing or managing the key barriers is of great significance for promoting the establishment and operation of IS [28]. From the perspective of managing the operation of IS, it is necessary to understand the impact of the IS barriers, which will help in creating an action plan to remove these barriers and achieve the objective of continuous improvement. This paper should be helpful for managers, decision-makers, and policy planners to encourage the effective operation of IS, especially in China and perhaps other countries.

First, from the generic barriers perspective, it allows managers or governmental agencies dealing with IS to achieve a holistic understanding of IS barriers and then focus on the barriers as a group. For example, from the results of this paper, managers or governmental agencies can observe the rankings of seven generic barriers and identify the very important generic barriers, i.e., technological barriers, economic barriers, safety barriers, and informational barriers. Then, in order to manage or remove these generic barriers, such as the most important barrier, i.e., the technological barriers, managers or governmental agencies in charge of technology might look into the technological barriers and figure out how to manage or remove them.

Second, it also assists managers in confirming the degrees of importance of various barriers and identifying the key barriers at the specific barriers level. For example, the top five specific barriers in this paper are information platform barriers, human safety and health barriers, technology of extending industrial chain barriers, product added value barriers, and cost barriers. These barriers should be given high importance to be eliminated at the specific barriers level.

Third, it can further facilitate the determination of the relative importance of the specific barriers within the categories of generic barriers. For example, for technological barriers, which is the most important generic barrier, technology of extending industrial chain is the highest priority specific barrier among technological barriers and is significantly higher than the other specific barriers of technological barriers, i.e., recovery technology barriers, recycling technology barriers, and evaluation technique barriers. This means technology of extending industrial chain barriers should be afforded more attention. From the above analysis, it can be seen that managers could develop a comprehensive plan to manage or remove barriers and also develop more specific measures aiming at removing the key barriers. The priorities of the IS barriers identified in the paper have been accepted by most of the managers of HHG.

5. Conclusions

This paper proposed a Group AHP-TOPSIS Model to semi-quantitatively evaluate the barriers which impede the implementation of IS. The model is designed as a two-level hierarchical structure, which assists in identifying the degrees of importance of generic barriers and the specific barriers corresponding to their generic barriers. This helps to uncover the barriers of IS in a more comprehensive manner.

Taking HHG as a case study, it is found that a variety of barriers exist for this operating IS, which hinders the establishment and operation of IS and transition to CE. Applying this model to HHG demonstrates that it assists in prioritizing the different barriers. It shows that at the generic barriers level, the top four degrees of importance of generic barriers are technological barriers, economic barriers, safety barriers, and informational barriers. Technological barriers are the most important generic barrier for the IS of HHG and should be given the most attention to be managed or eliminated. The top five specific barriers are information platform barriers, human safety and health barriers, technology of extending industrial chain barriers, product added value barriers, and cost barriers. Information platform barriers are the most important specific barrier and should be emphasized. The work of this paper is one of the first to be undertaken to examine the barriers to an operating IS using mathematical methods with a case study. It provides empirical evidence for the study of IS barriers and should be helpful for managers, decision-makers, and policy planners to understand the IS barriers, focus on several critical barriers, and set comprehensive efforts for improving the operation of an IS, which could facilitate the transition to a CE.

This study still has limitations; future research can be further extended in the following aspects. First, the results of the study are from one single industrial symbiosis which is operating in China; more industrial symbioses from different countries should be investigated with this model in future research. Secondly, while this model focused on an operating symbiosis, it could be combined with the maturity grid proposed by Golev et al. [15], allowing researchers to delve into yet more detail. Thirdly, this paper focused on evaluating the barriers and did not put forward measures to manage or remove the barriers. The two-level hierarchy structure included in the model should be helpful to managers for identifying more targeted measures for managing or removing these barriers. In the future, the model can be further applied and tested on other cases.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su14116815/s1, including “Supplemental Materials File S1. main calculation steps of Group AHP-TOPSIS Decision Model”, “Supplemental Materials File S2. results of AHP procedure in case study”, “Supplemental Materials File S3. results of Group-TOPSIS Decision model in case study”, and “Supplemental Materials File S4. discussion of preferential differences & preferential priorities in case study”.

Author Contributions

Conceptualization, C.L.; methodology, T.Y., C.L. and W.L.; software, T.Y.; validation, T.Y.; formal analysis, C.L. and T.Y.; investigation, T.Y., J.Y. and C.L.; data curation, T.Y.; writing—original draft preparation, C.L. and T.Y.; writing—review and editing, R.P.C.; visualization, T.Y.; supervision, C.L.; project administration, C.L.; funding acquisition, C.L. All authors have read and agreed to the published version of the manuscript.

Funding

The financial support provided by the National Natural Science Foundation of China (41471458) is acknowledged.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We acknowledge the Environmental Protection Bureau of Weifang Binhai Economic and Technological Development Zone (WBETDZ), Hai Hua Group (HHG), and the companies involved in the case study for their great help.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chertow, M.R. INDUSTRIAL SYMBIOSIS: Literature and Taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef] [Green Version]

- Yeo, Z.; Masi, D.; Low, J.S.C.; Ng, Y.T.; Tan, P.S.; Barnes, S. Tools for Promoting Industrial Symbiosis: A Systematic Review. J. Ind. Ecol. 2019, 23, 1087–1108. [Google Scholar] [CrossRef] [Green Version]

- Walls, J.L.; Paquin, R.L. Organizational Perspectives of Industrial Symbiosis: A Review and Synthesis. Organ. Environ. 2015, 28, 32–53. [Google Scholar] [CrossRef]

- Cervo, H.; Ogé, S.; Maqbool, A.S.; Alva, F.M.; Lessard, L.; Bredimas, A.; Ferrasse, J.-H.; Van Eetvelde, G. A Case Study of Industrial Symbiosis in the Humber Region Using the EPOS Methodology. Sustainability 2019, 11, 6940. [Google Scholar] [CrossRef] [Green Version]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M.P. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2019, 23, 36–61. [Google Scholar] [CrossRef] [Green Version]

- Boom-Cárcamo, E.; Peñabaena-Niebles, R. Analysis of the Development of Industrial Symbiosis in Emerging and Frontier Market Countries: Barriers and Drivers. Sustainability 2022, 14, 4223. [Google Scholar] [CrossRef]

- Côté, R.P. Exploring the Analogy Further. J. Ind. Ecol. 2000, 3, 11–12. [Google Scholar] [CrossRef]

- Zhu, Q.; Côté, R.P. Integrating Green Supply Chain Management into an Embryonic Eco-Industrial Development: A Case Study of the Guitang Group. J. Clean. Prod. 2004, 12, 1025–1035. [Google Scholar] [CrossRef]

- Henriques, J.; Ferrão, P.; Castro, R.; Azevedo, J. Industrial Symbiosis: A Sectoral Analysis on Enablers and Barriers. Sustainability 2021, 13, 1723. [Google Scholar] [CrossRef]

- Mortensen, L.; Kørnøv, L. Critical Factors for Industrial Symbiosis Emergence Process. J. Clean. Prod. 2019, 212, 56–69. [Google Scholar] [CrossRef]

- Yazan, D.M.; Fraccascia, L. Sustainable Operations of Industrial Symbiosis: An Enterprise Input-Output Model Integrated by Agent-Based Simulation. Int. J. Prod. Res. 2018, 58, 392–414. [Google Scholar] [CrossRef]

- National Development and Reform Commission The Leading Action of Circular Development. Available online: http://www.gov.cn/xinwen/2017-05/04/content_5190902.htm (accessed on 23 April 2022).

- Geng, Y.; Sarkis, J.; Ulgiati, S. Sustainability, Well-Being, and the Circular Economy in China and Worldwide. Science 2016, 6278, 73–76. [Google Scholar]

- Bacudio, L.R.; Benjamin, M.F.D.; Eusebio, R.C.P.; Holaysan, S.A.K.; Promentilla, M.A.B.; Yu, K.D.S.; Aviso, K.B. Analyzing Barriers to Implementing Industrial Symbiosis Networks Using DEMATEL. Sustain. Prod. Consum. 2016, 7, 57–65. [Google Scholar] [CrossRef]

- Golev, A.; Corder, G.D.; Giurco, D.P. Barriers to Industrial Symbiosis: Insights from the Use of a Maturity Grid: Barriers to Industrial Symbiosis. J. Ind. Ecol. 2015, 19, 141–153. [Google Scholar] [CrossRef]

- Neves, A.; Godina, R.; Azevedo, S.G.; Pimentel, C.; Matias, J.C.O. The Potential of Industrial Symbiosis: Case Analysis and Main Drivers and Barriers to Its Implementation. Sustainability 2019, 11, 7095. [Google Scholar] [CrossRef] [Green Version]

- Van Beers, D.; Bossilkov, A.; Corder, G.; Berkel, R. Industrial Symbiosis in the Australian Minerals Industry: The Cases of Kwinana and Gladstone. J. Ind. Ecol. 2007, 11, 55–72. [Google Scholar] [CrossRef] [Green Version]

- Madsen, J.K.; Boisen, N.; Nielsen, L.U.; Tackmann, L.H. Industrial Symbiosis Exchanges: Developing a Guideline to Companies. Waste Biomass Valorization 2015, 6, 855–864. [Google Scholar] [CrossRef]

- Boons, F.; Chertow, M.; Park, J.; Spekkink, W.; Shi, H. Industrial Symbiosis Dynamics and the Problem of Equivalence: Proposal for a Comparative Framework. J. Ind. Ecol. 2016, 21, 938–952. [Google Scholar] [CrossRef]

- Grant, G.B.; Seager, T.P.; Massard, G.; Nies, L. Information and Communication Technology for Industrial Symbiosis. J. Ind. Ecol. 2010, 14, 740–753. [Google Scholar] [CrossRef]

- Ritzén, S.; Sandström, G.Ö. Barriers to the Circular Economy—Integration of Perspectives and Domains. Procedia CIRP 2017, 64, 7–12. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A. Industrial Symbiosis in the Taranto Industrial District: Current Level, Constraints and Potential New Synergies. J. Clean. Prod. 2016, 122, 133–143. [Google Scholar] [CrossRef]

- Promentilla, M.A.B.; Bacudio, L.R.; Benjamin, M.F.D.; Chiu, A.S.F.; Yu, K.D.S.; Tan, R.R.; Aviso, K.B. Problematique Approach to Analyse Barriers in Implementing Industrial Ecology in Philippine Industrial Parks. Chem. Eng. Trans. 2016, 52, 811–816. [Google Scholar] [CrossRef]

- Pajunen, N.; Watkins, G.; Husgafvel, R.; Heiskanen, K.; Dahl, O. The Challenge to Overcome Institutional Barriers in the Development of Industrial Residue Based Novel Symbiosis Products—Experiences from Finnish Process Industry. Miner. Eng. 2013, 46–47, 144–156. [Google Scholar] [CrossRef]

- Papathanasoglou, A.; Panagiotidou, M.; Valta, K.; Loizidou, M. Institutional Barriers and Opportunities for the Implementation of Industrial Symbiosis in Greece. Environ. Pract. 2016, 18, 253–259. [Google Scholar] [CrossRef]

- Watkins, G.; Husgafvel, R.; Pajunen, N.; Dahl, O.; Heiskanen, K. Overcoming Institutional Barriers in the Development of Novel Process Industry Residue Based Symbiosis Products—Case Study at the EU Level. Miner. Eng. 2013, 41, 31–40. [Google Scholar] [CrossRef]

- Salmi, O.; Hukkinen, J.; Heino, J.; Pajunen, N.; Wierink, M. Governing the Interplay between Industrial Ecosystems and Environmental Regulation. J. Ind. Ecol. 2012, 16, 119–128. [Google Scholar] [CrossRef]

- Liu, C.; Ma, C.; Zhang, K. Going beyond the Sectoral Boundary: A Key Stage in the Development of a Regional Industrial Ecosystem. J. Clean. Prod. 2012, 22, 42–49. [Google Scholar] [CrossRef]

- LeBlanc, R.; Tranchant, C.; Gagnon, Y.; Côté, R. Potential for Eco-Industrial Park Development in Moncton, New Brunswick (Canada): A Comparative Analysis. Sustainability 2016, 8, 472. [Google Scholar] [CrossRef] [Green Version]

- Park, H.-S.; Won, J.-Y. Ulsan Eco-Industrial Park: Challenges and Opportunities. J. Ind. Ecol. 2008, 11, 11–13. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Sarkis, J.; Lai, K.-H. Barriers to Promoting Eco-Industrial Parks Development in China: Perspectives from Senior Officials at National Industrial Parks. J. Ind. Ecol. 2015, 19, 457–467. [Google Scholar] [CrossRef]

- Wolf, A.; Eklund, M.; Soderstrom, M. Towards Cooperation in Industrial Symbiosis: Considering the Importance of the Human Dimension. Prog. Ind. Ecol. Int. J. 2005, 2, 185–199. [Google Scholar] [CrossRef]