Bond Strength and Fracture Toughness of Alkali Activated Self-Compacting Concrete Incorporating Metakaolin or Nanosilica

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials

2.2. Mix Proportions

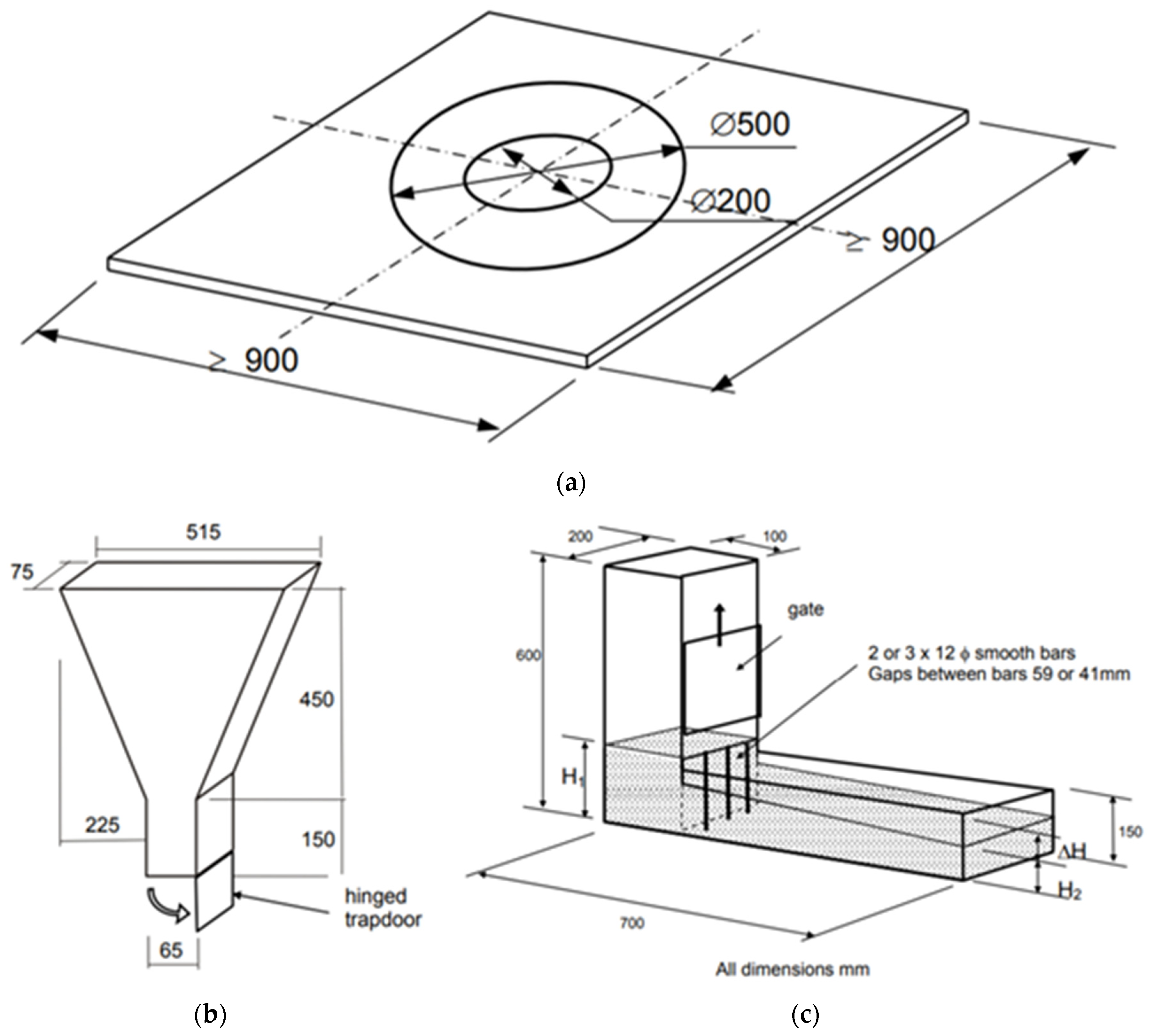

2.3. The Fresh Properties Tests of A-ASCCs

2.4. Curing Condition of the A-ASCC Specimens

2.5. The Hardened Properties Tests for A-ASCC

2.5.1. Compressive Strength

2.5.2. Flexural Tensile Strength

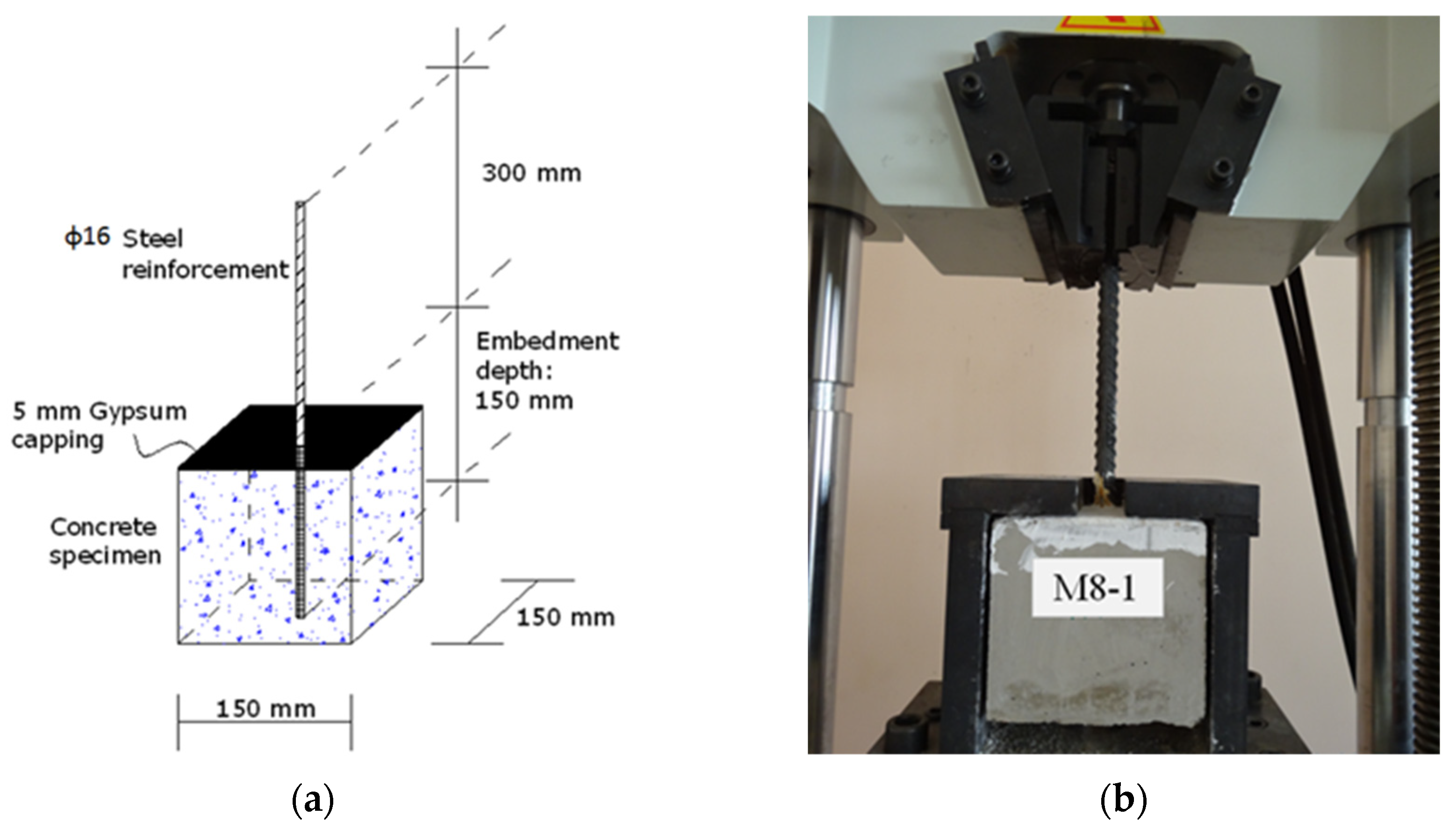

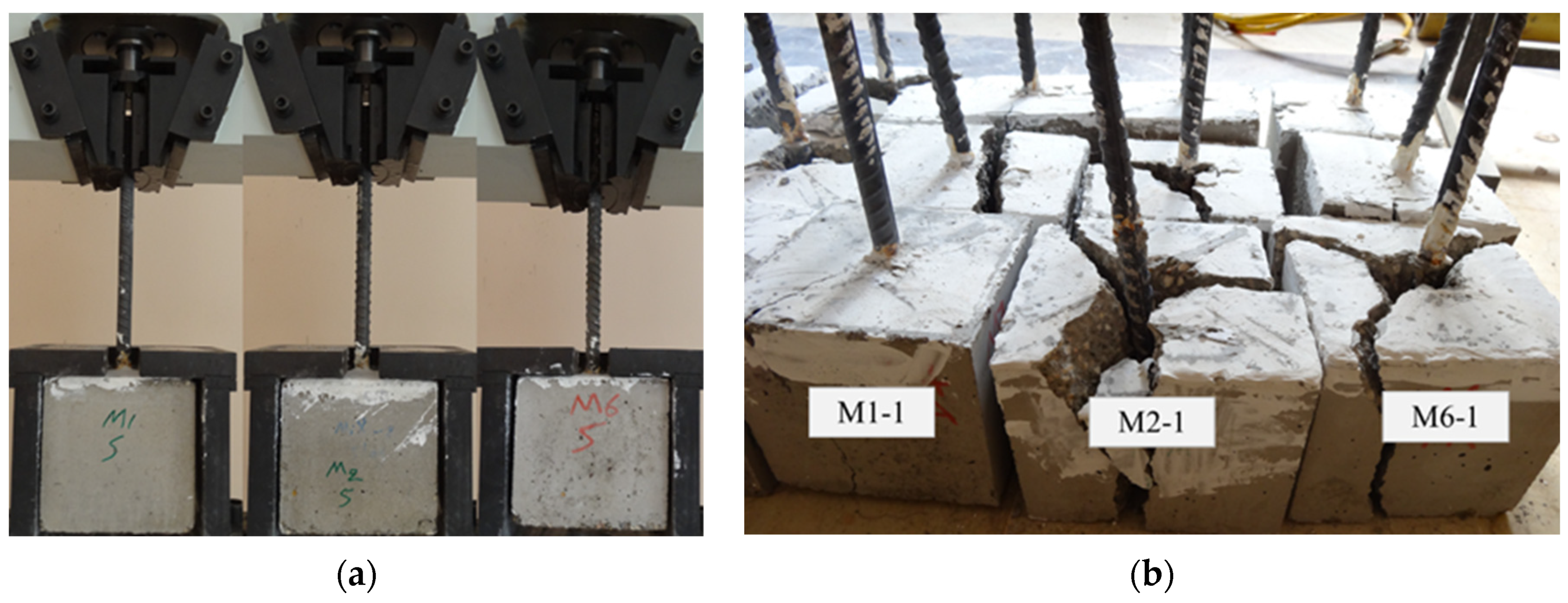

2.5.3. Pullout Test and Bond Strength of A-ASCC

3. Result and Discussions

3.1. The Fresh Properties of A-ASCC

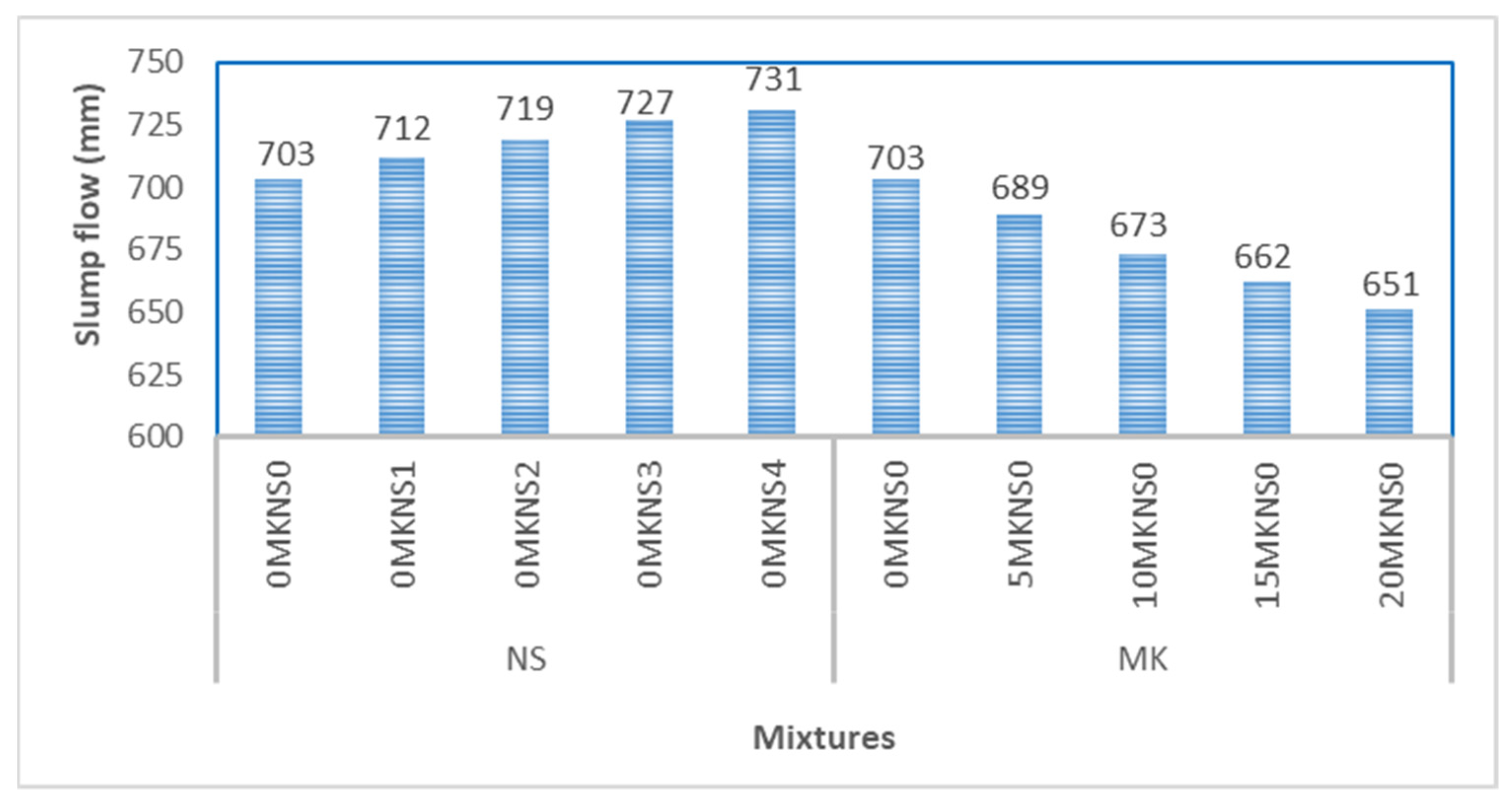

3.1.1. Slump Flow Test

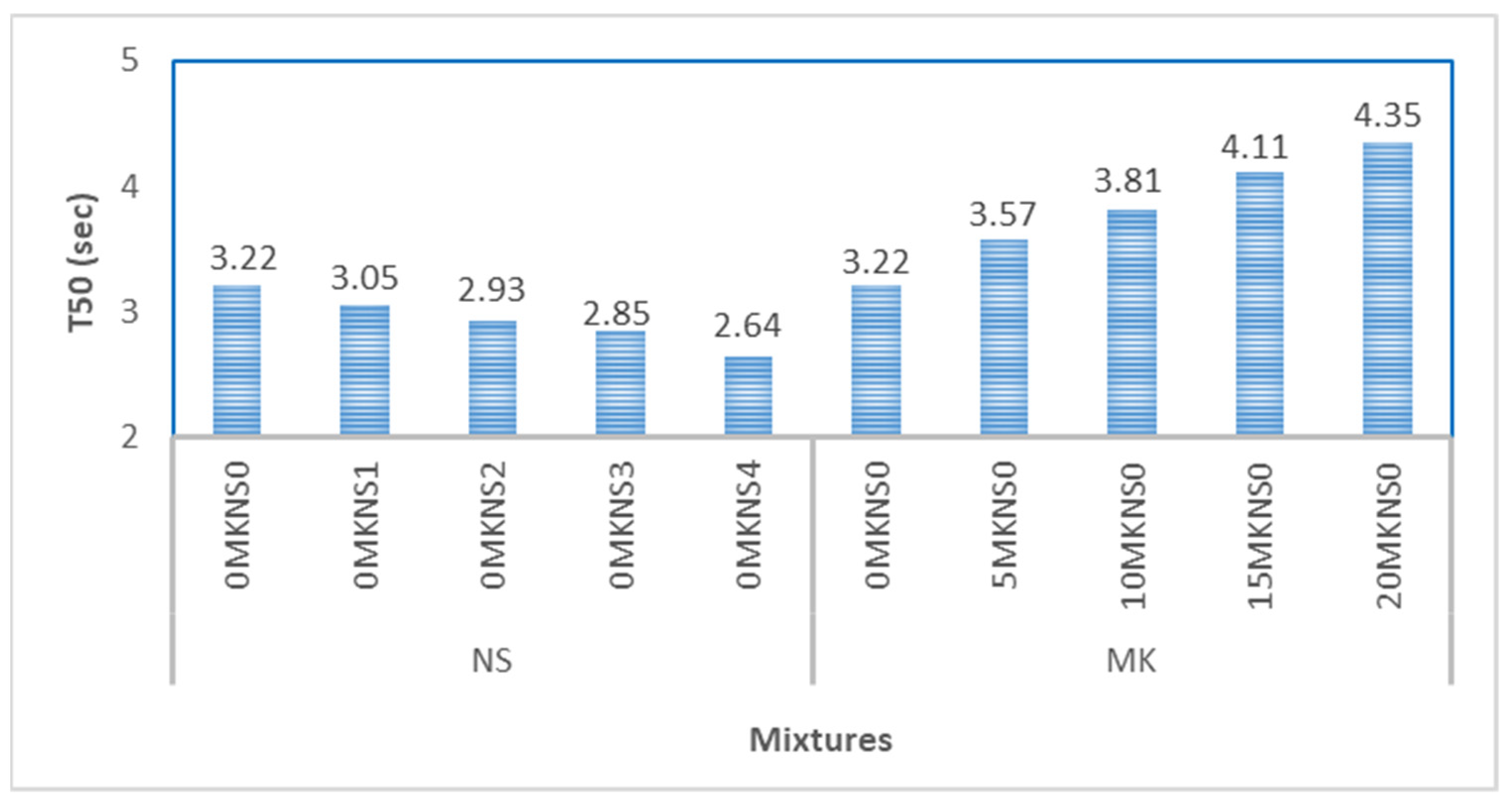

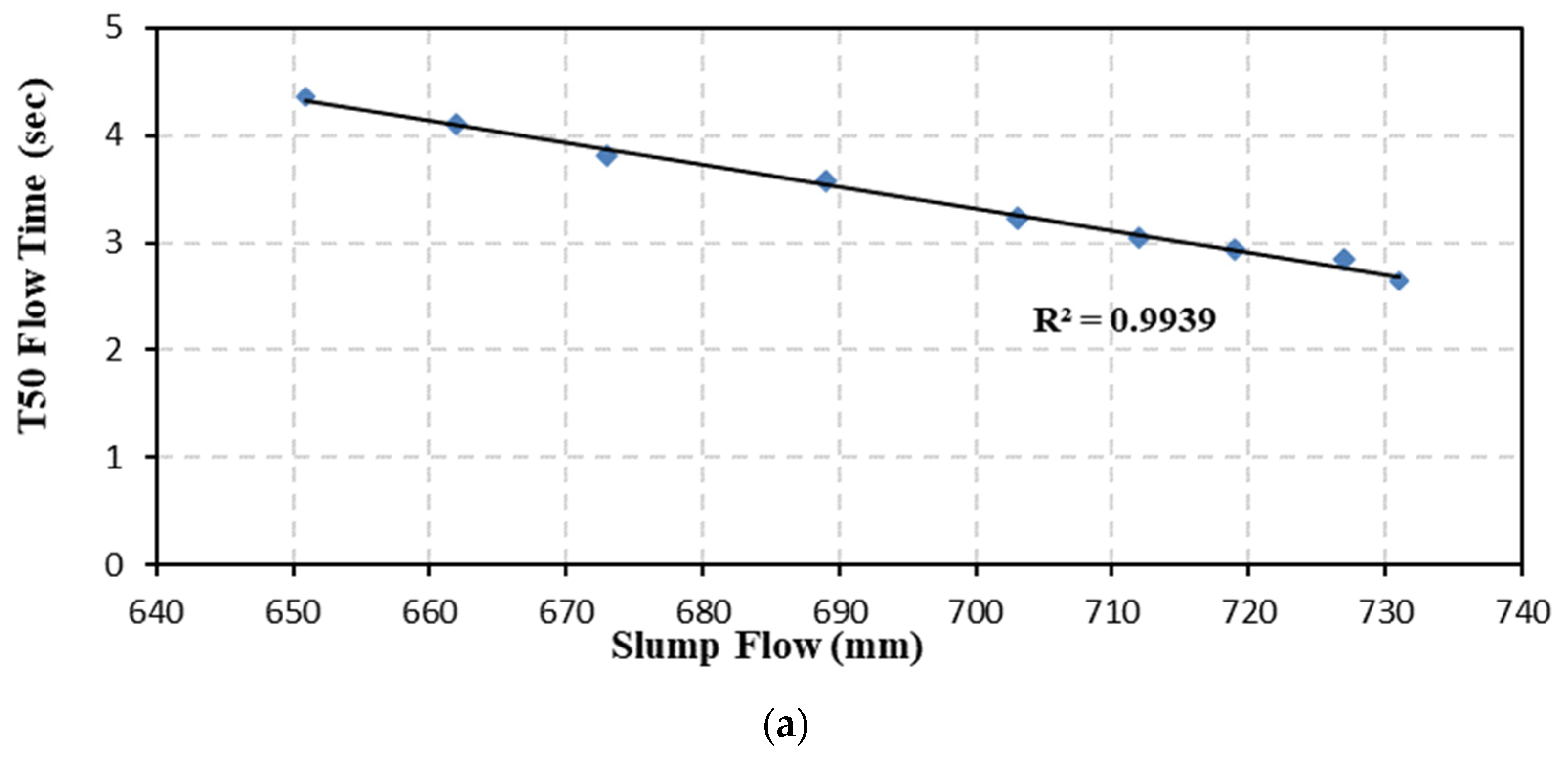

3.1.2. T50 Time Test

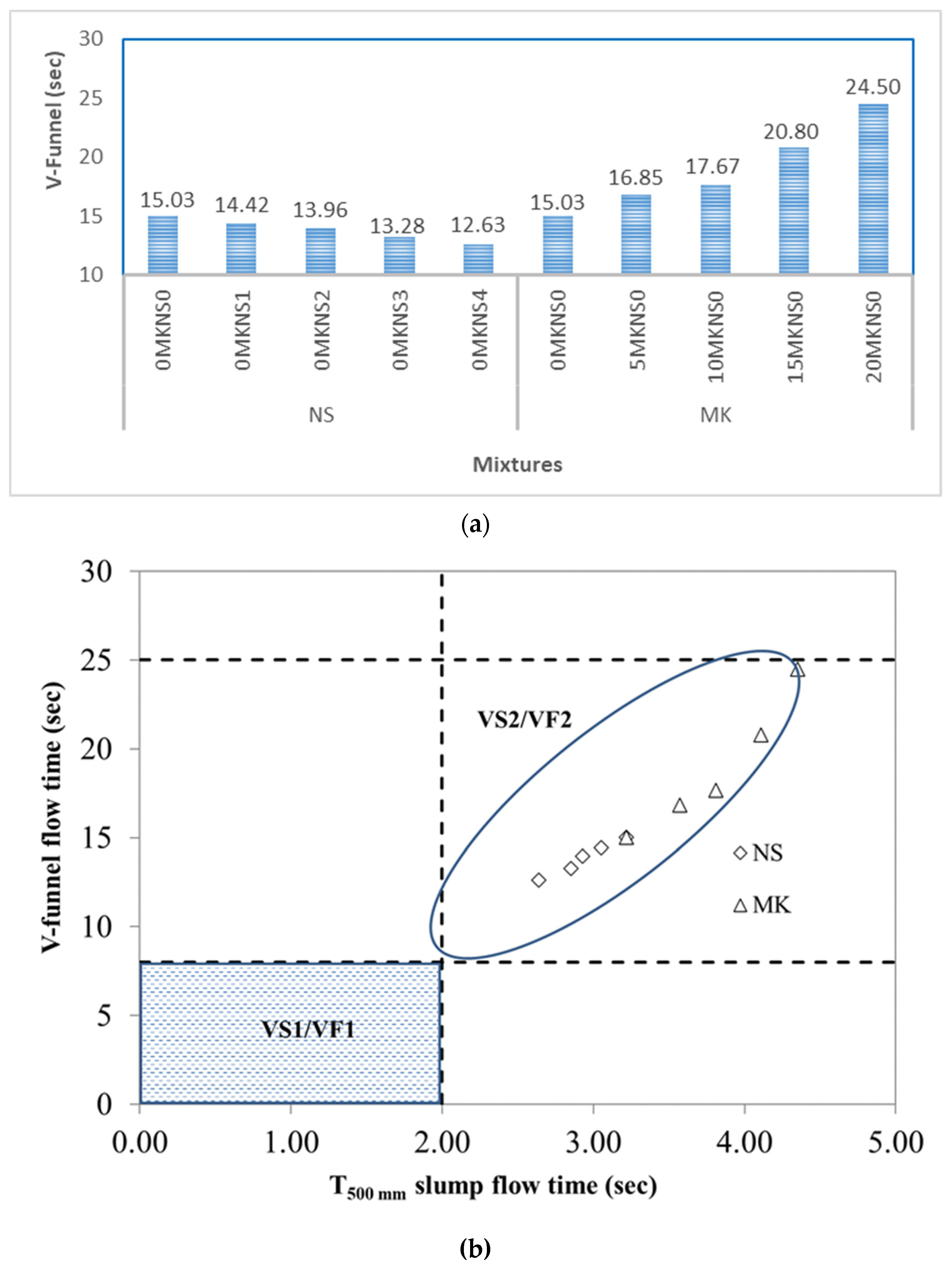

3.1.3. V-Funnel Flow Time of A-ASCC Mixes

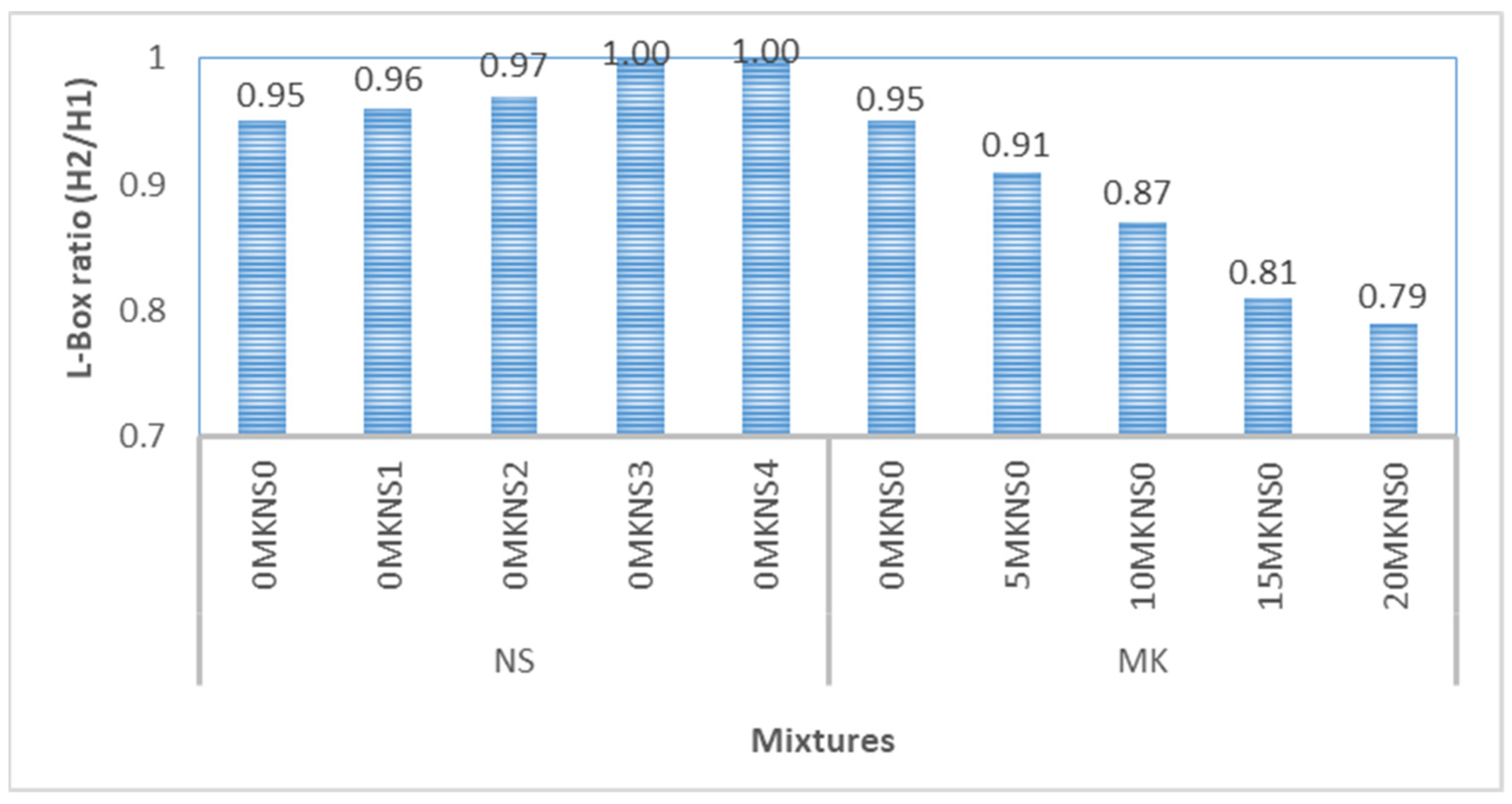

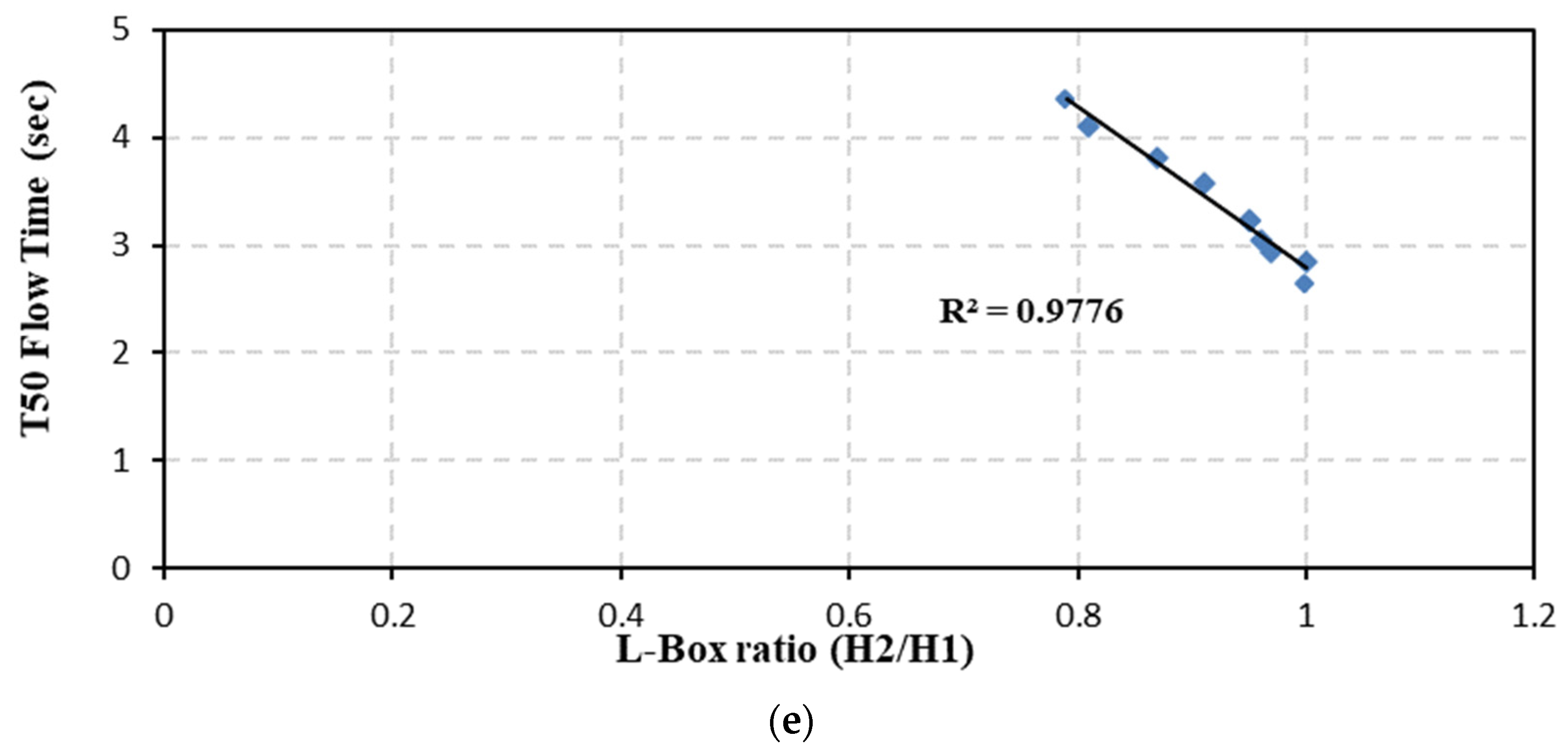

3.1.4. The L-Box Height Ratio of A-ASCC Mixtures

3.2. Hardened Performance of A-ASCC

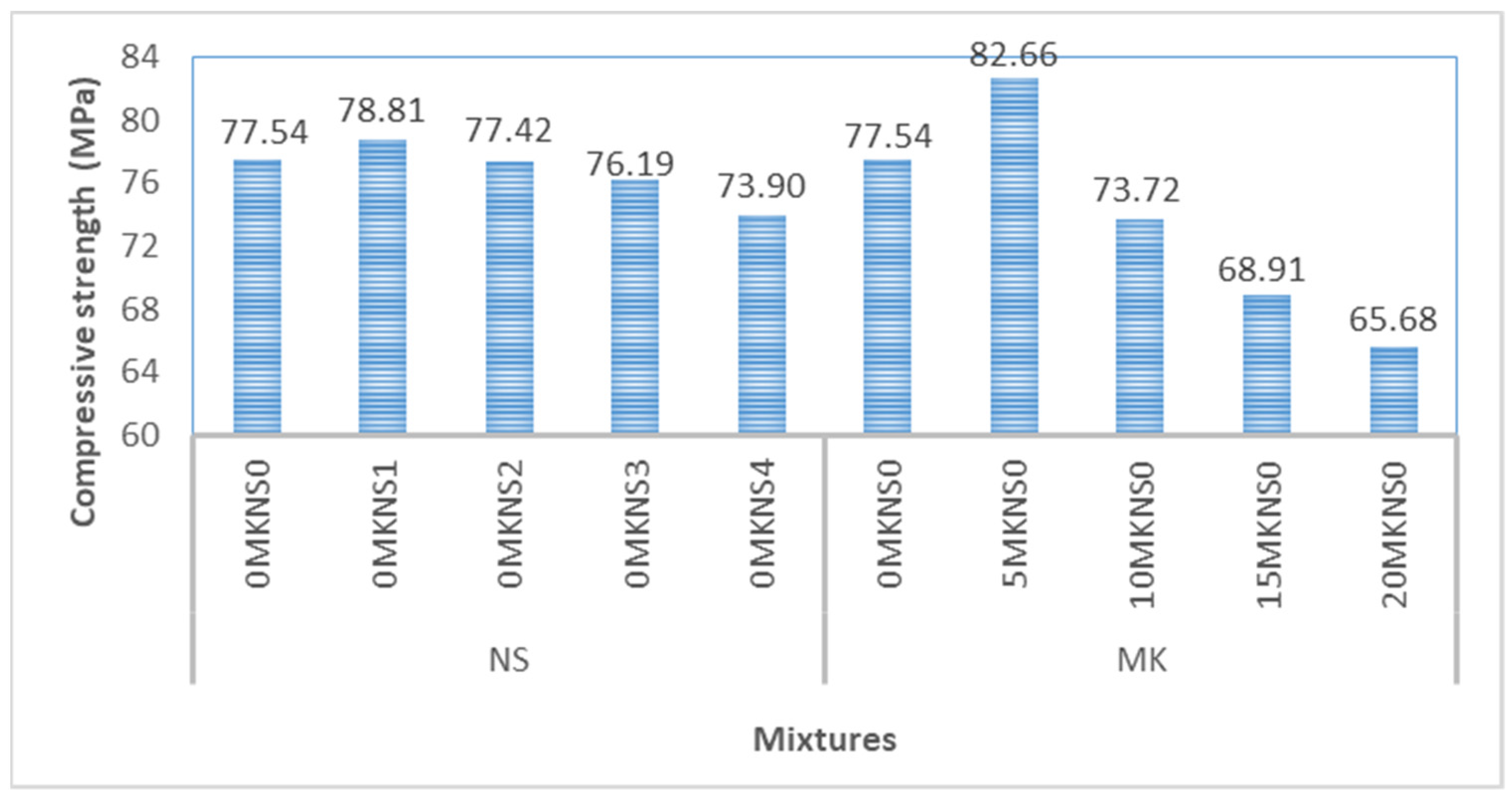

3.2.1. Compressive Strength

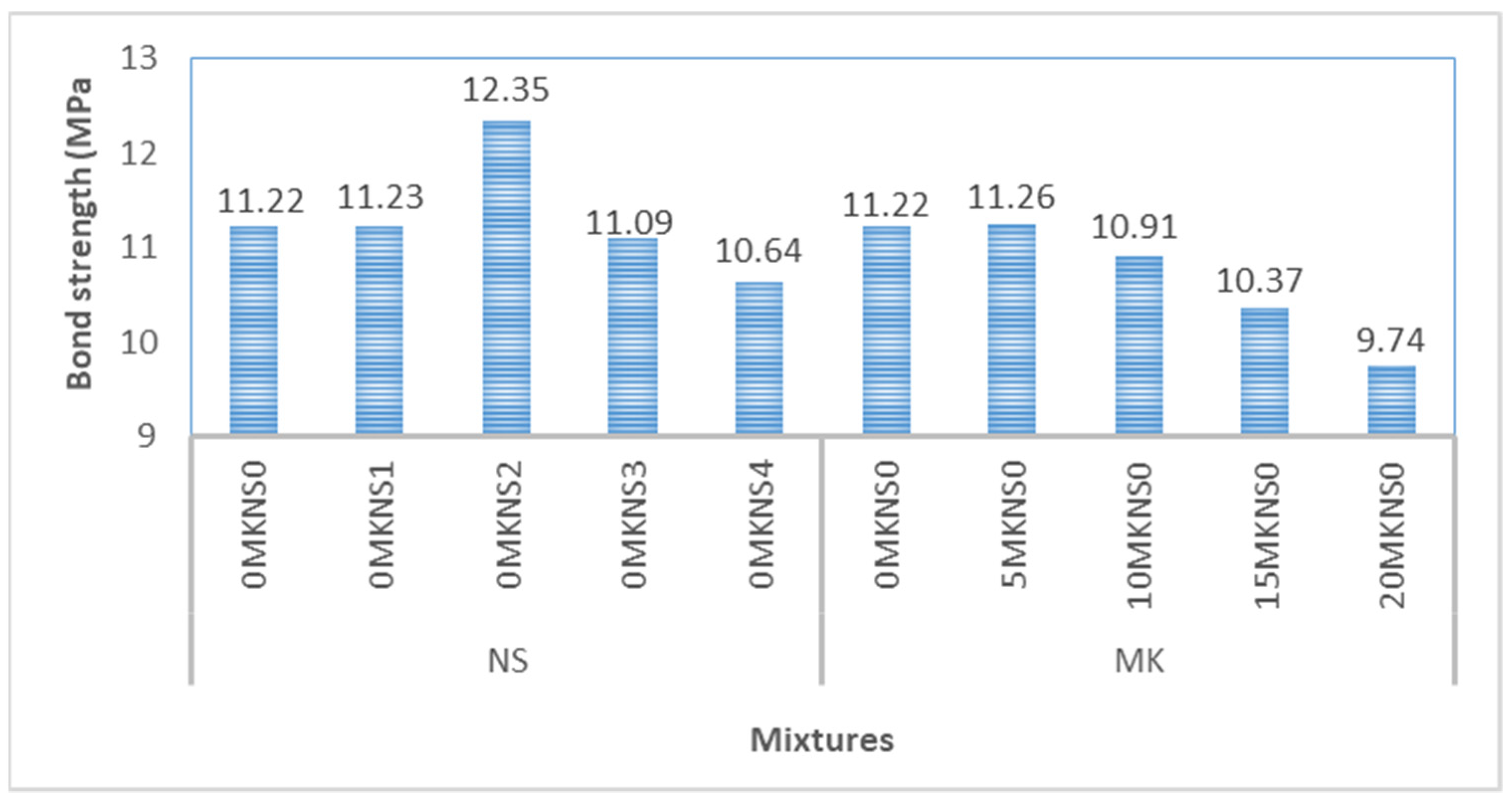

3.2.2. Bond Strength

3.2.3. Net Flexural Tensile Strength

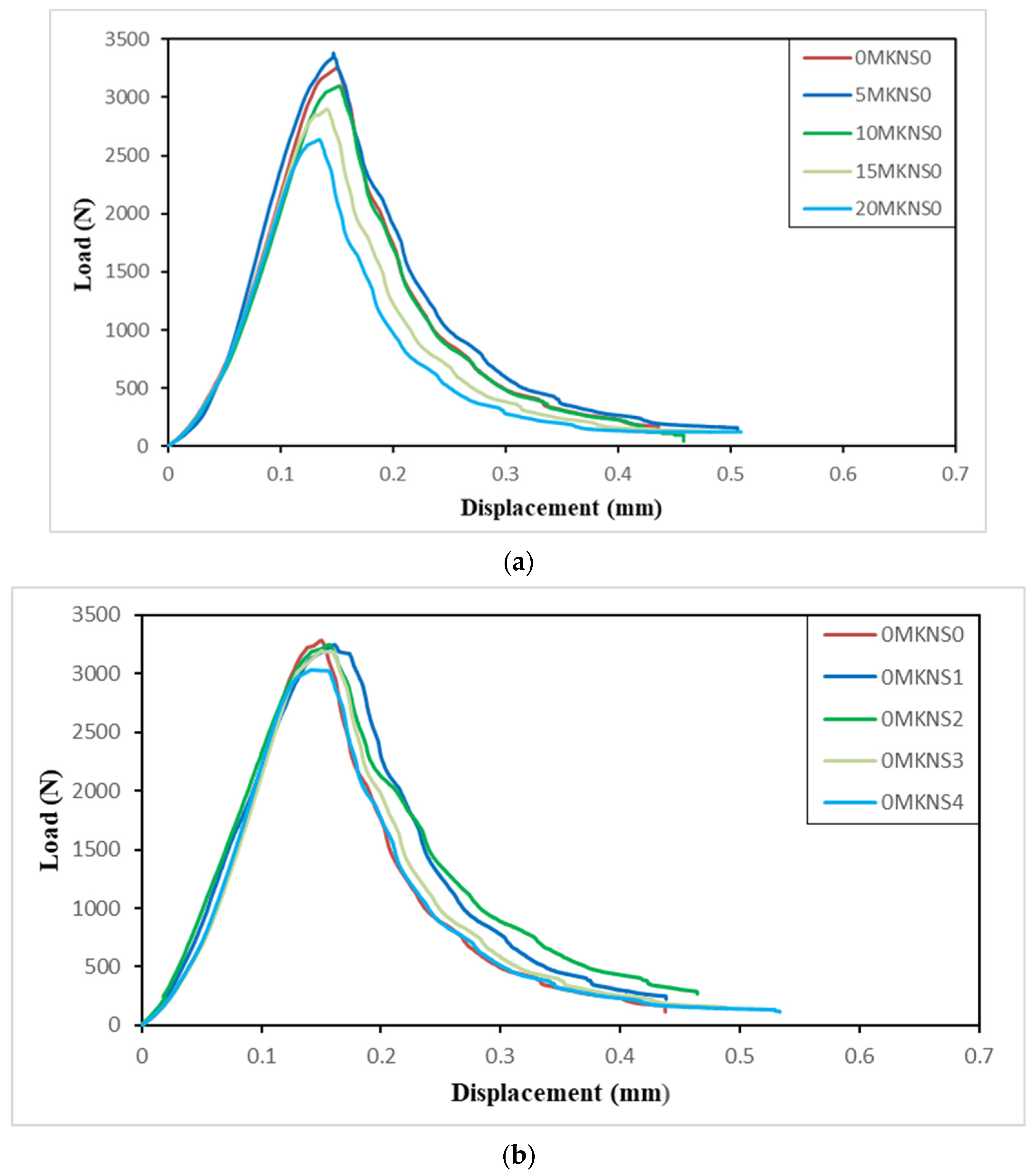

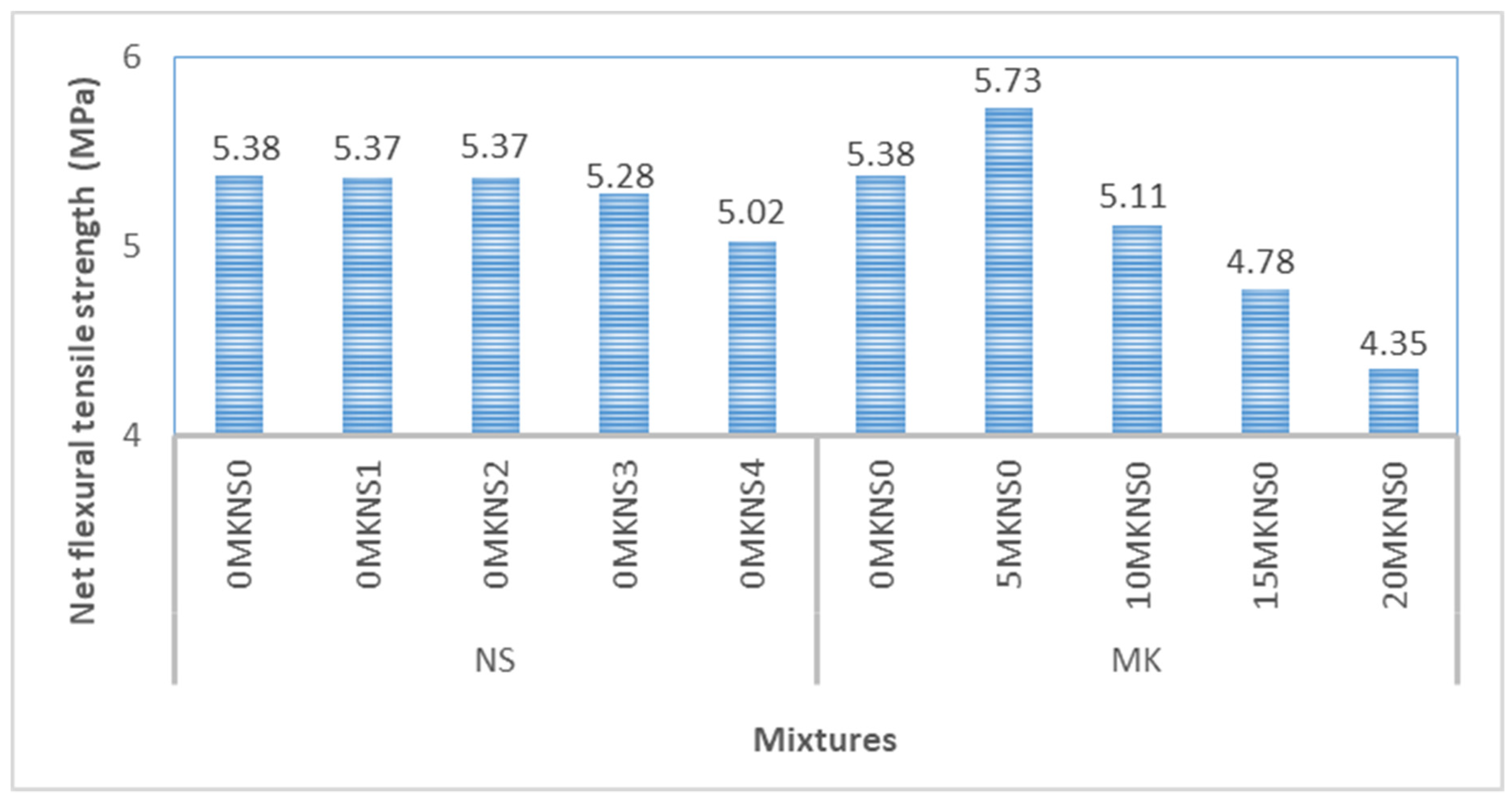

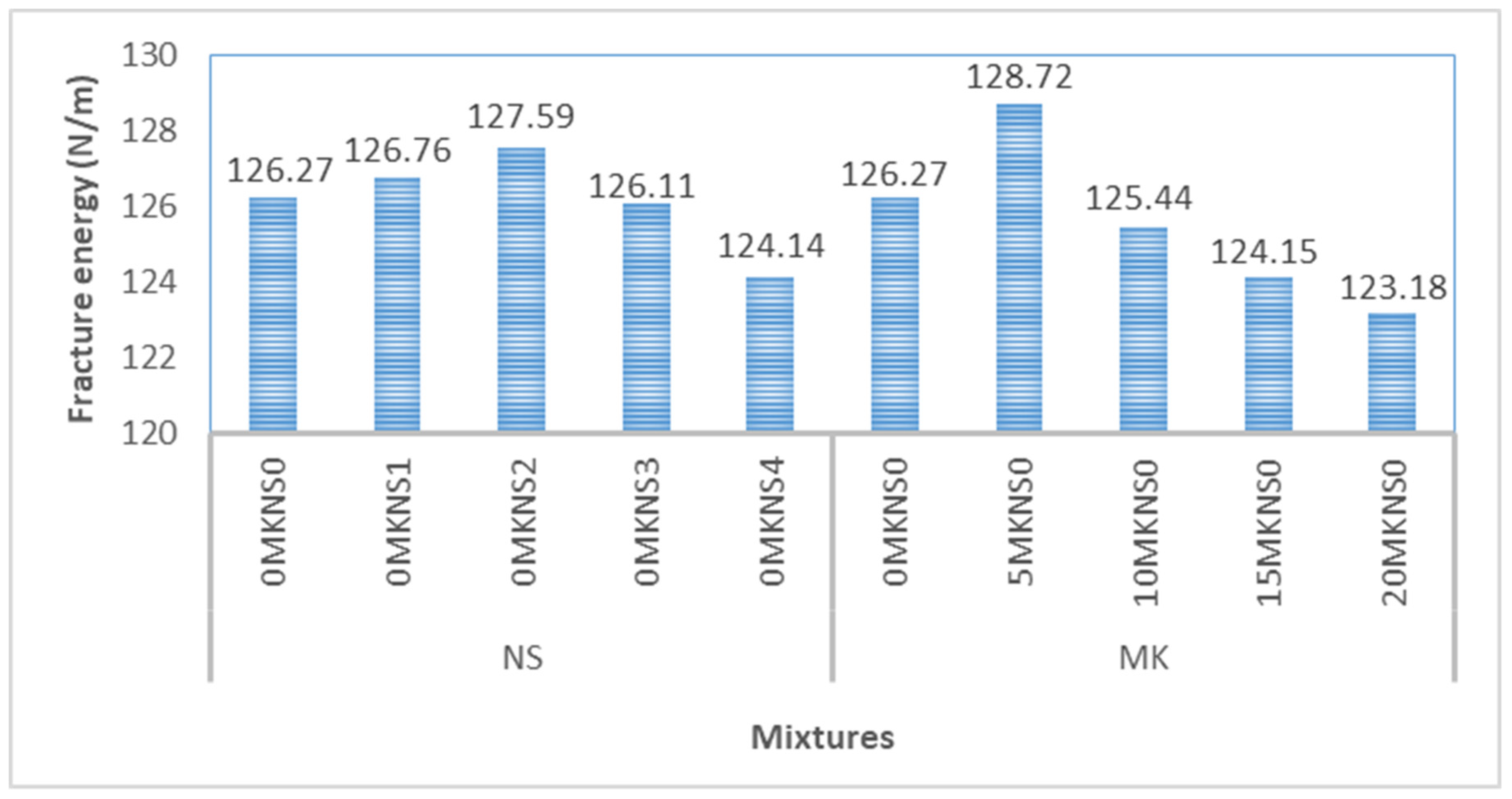

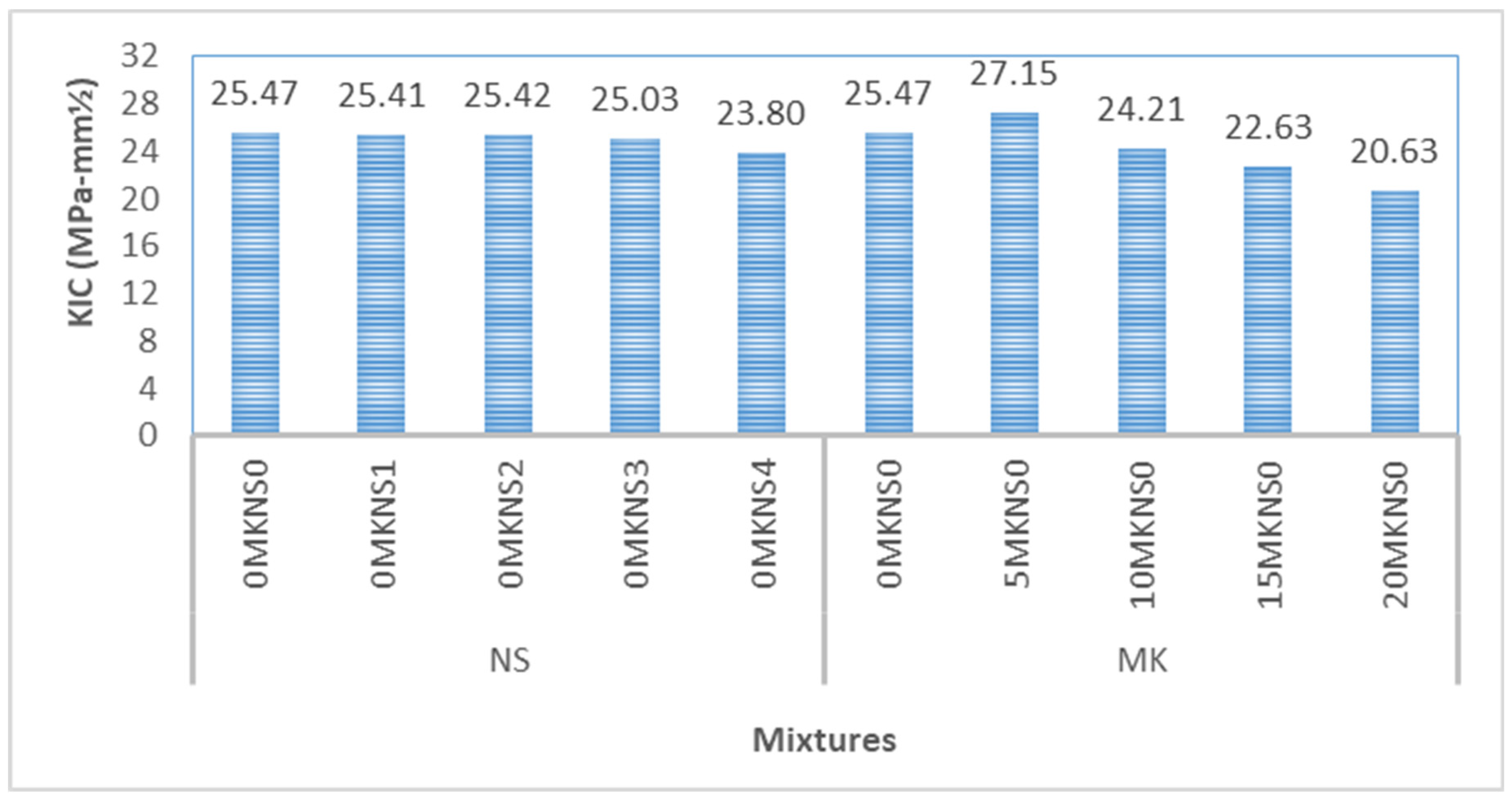

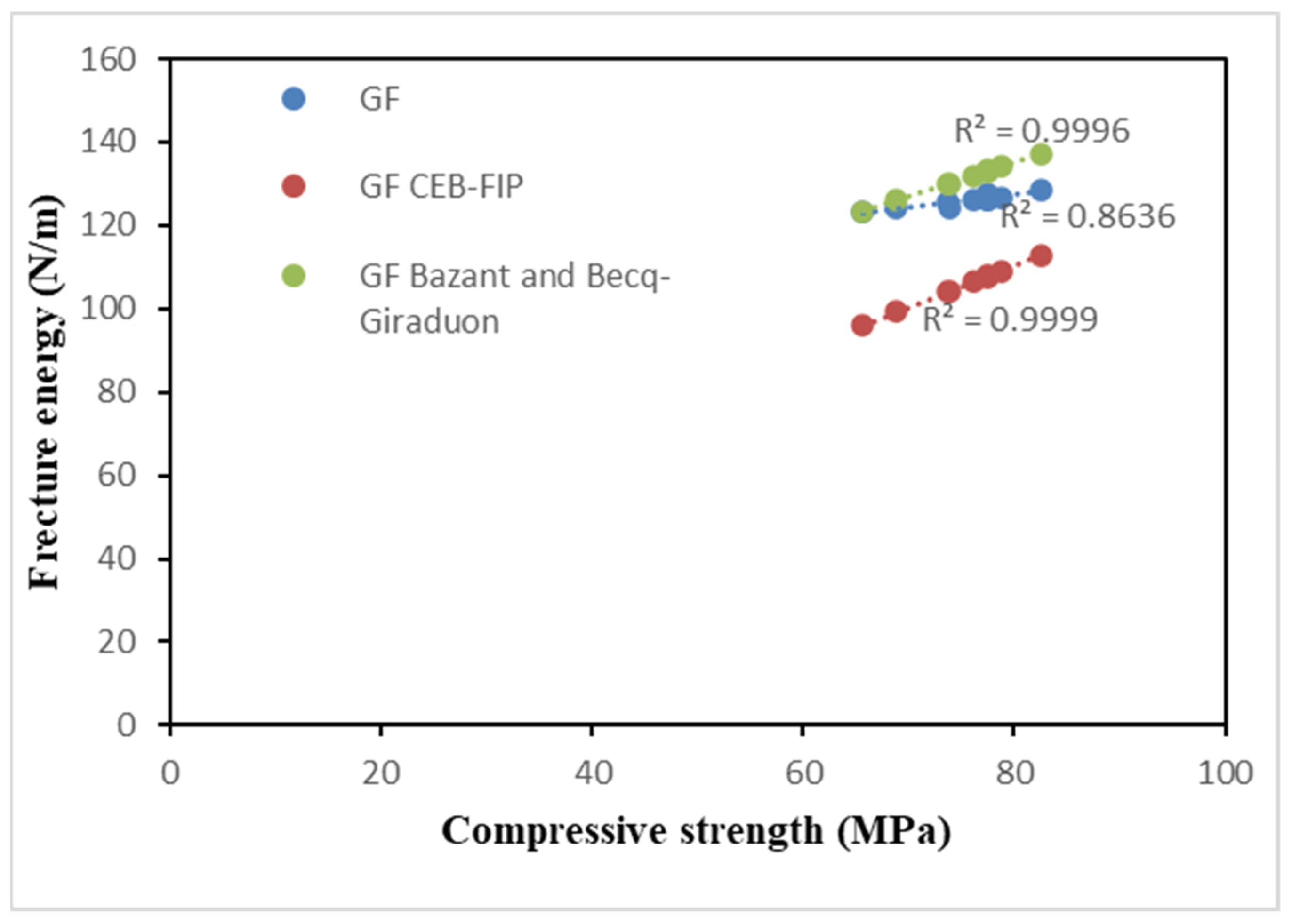

3.2.4. Fracture Performance

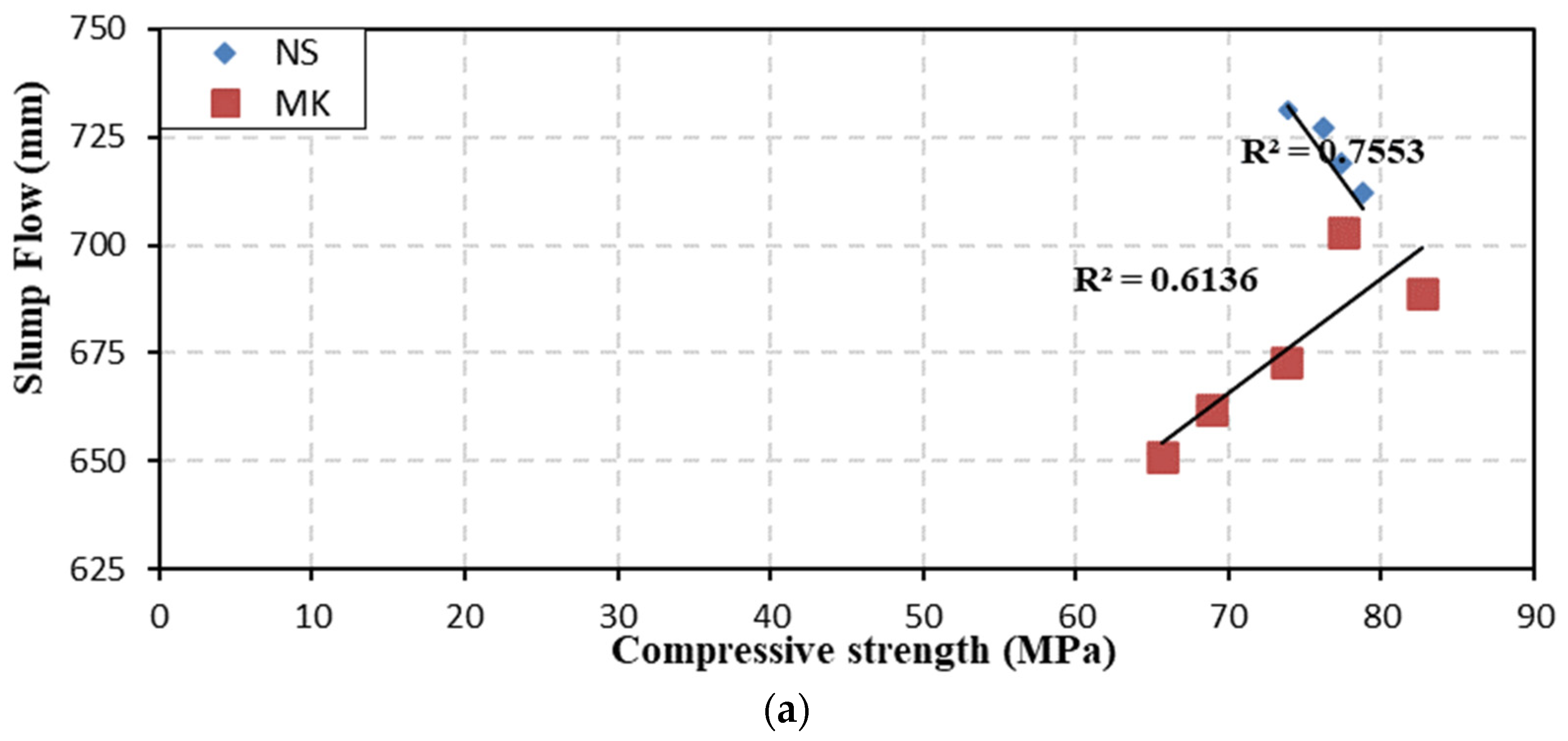

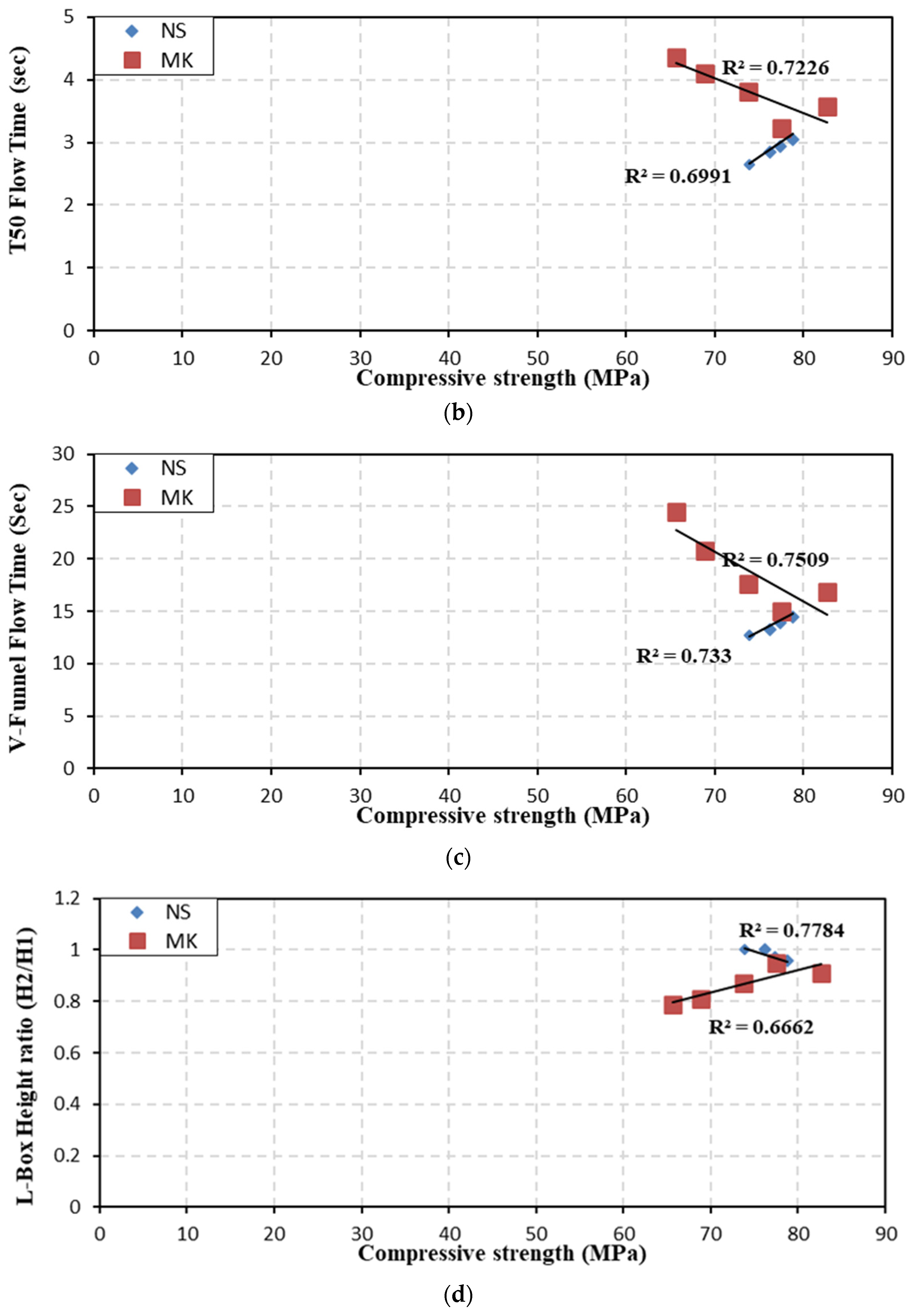

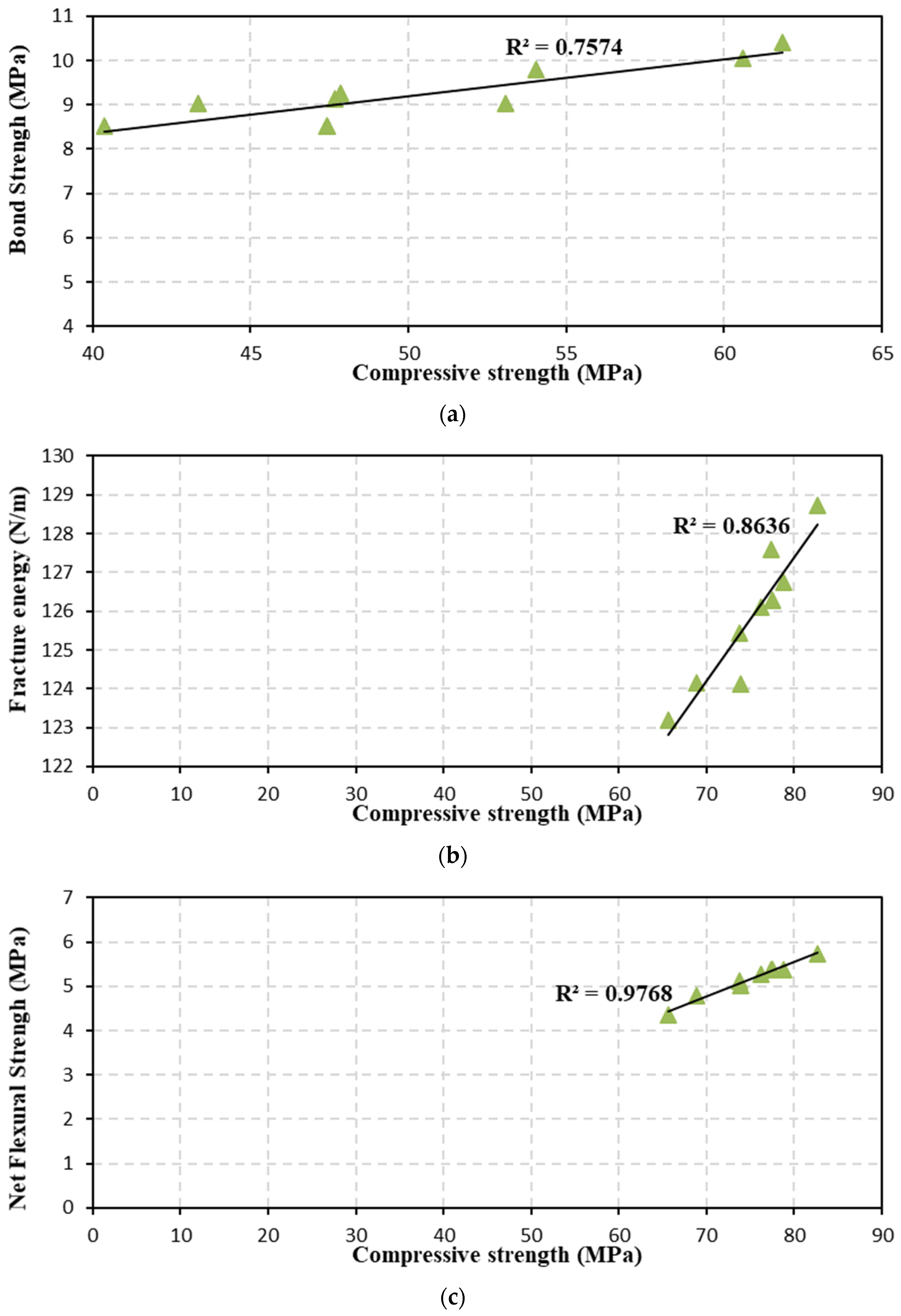

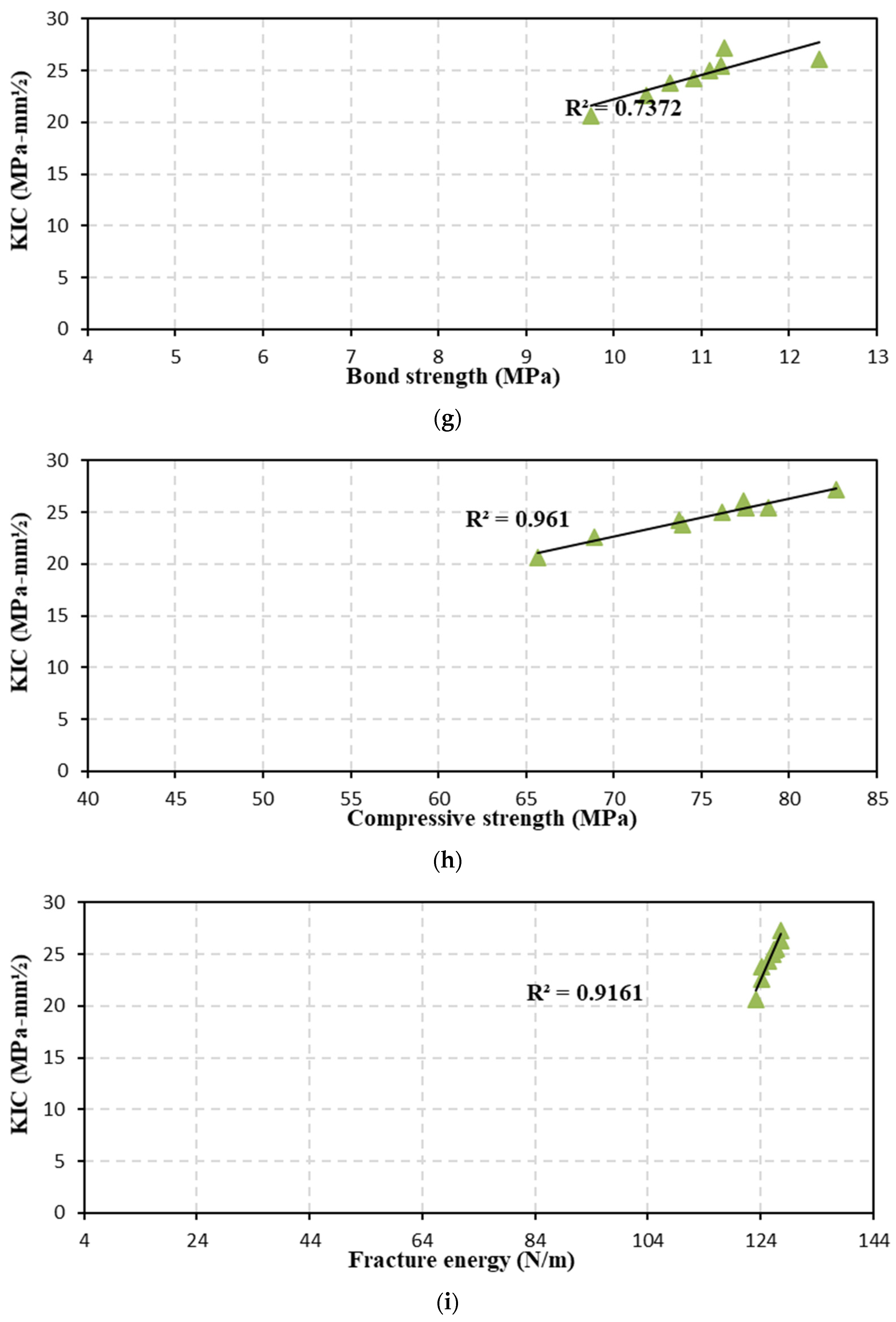

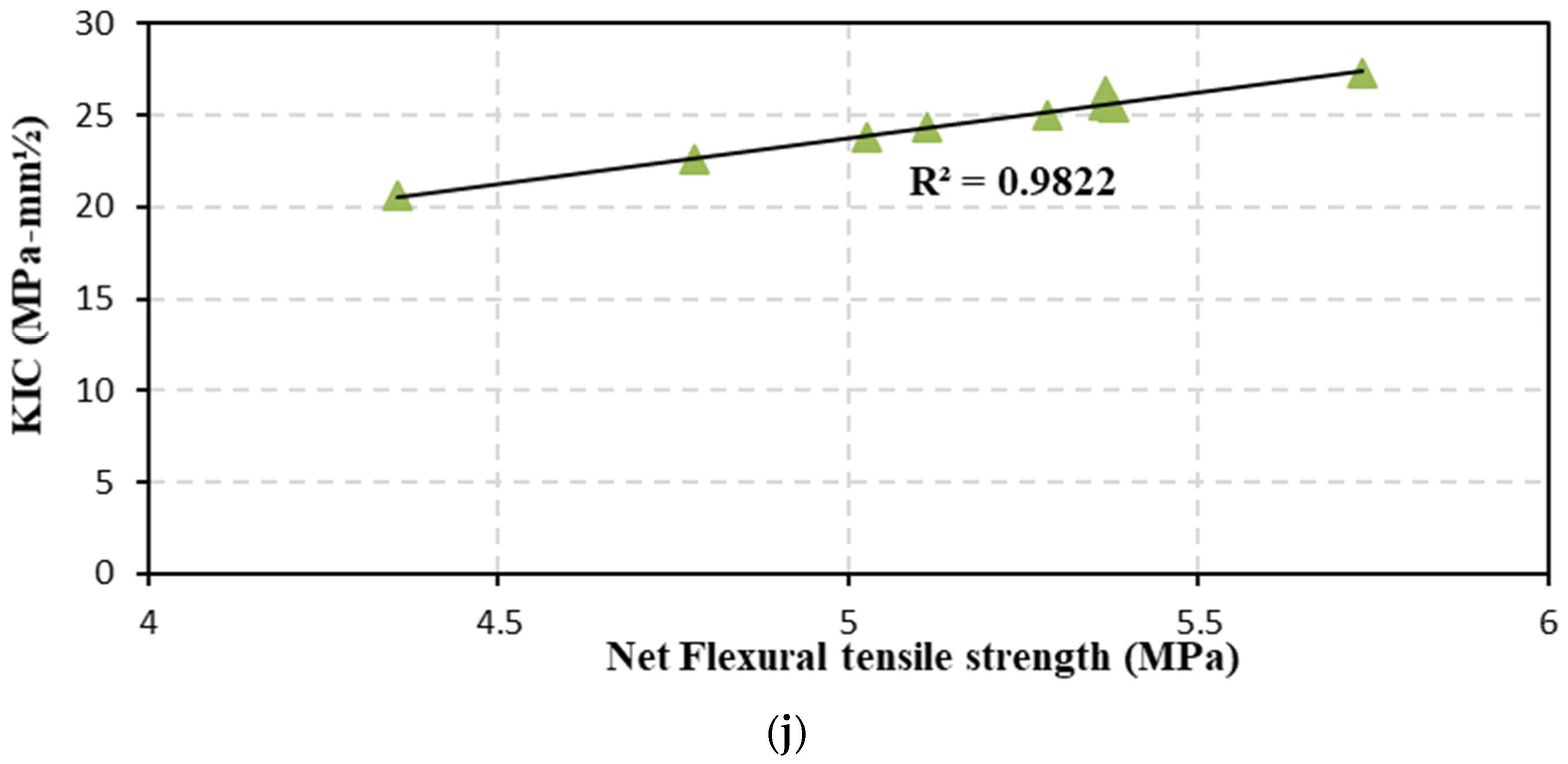

3.3. Relationship and Correlation among the Properties of A-ASCC

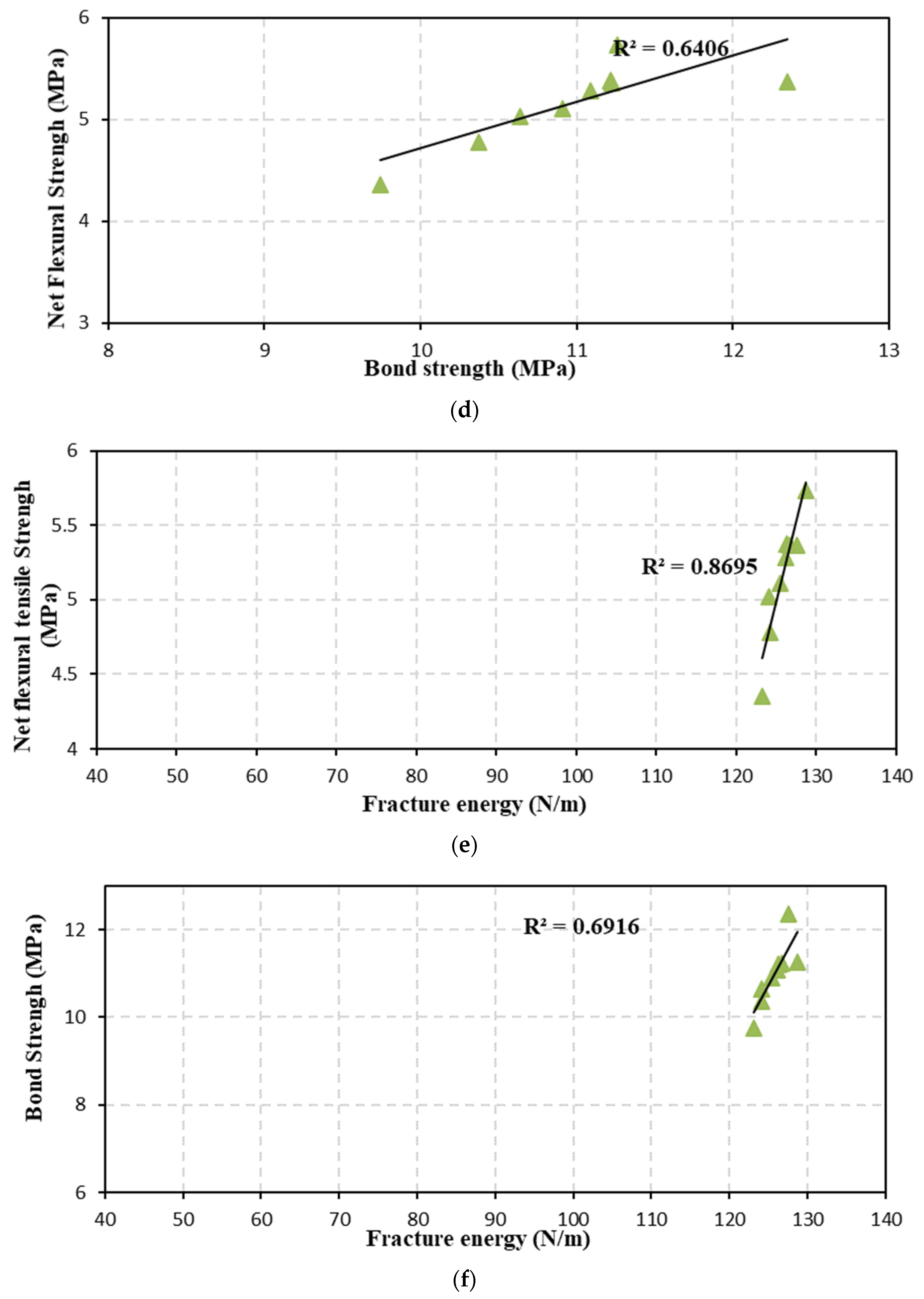

3.4. Statistical Analysis of the Experimental Result

4. Conclusions

- The addition of nanosilica increased the V-funnel flow time, L-box passage ability, T50 flow time, and slump flow in fresh state tests. The mixtures with the highest NS showed the largest improvement in fresh performance (4%). The addition of MK, on the other hand, reduced the fresh properties of A-ASCC; the minimum fresh properties were deducted by using 20% MK. Even in this case, the A-ASCC mixes satisfied the EF-NARC and TS 12350 flowability and passing ability standards.

- Adding additional NS and/or MK to the A-ASCC mixture improved the resistance to segregation and bleeding, whereas NS and/or MK-containing mixtures were shown to be more cohesive than non-NS and/or non-MK-containing mixes.

- Based on V-funnel and slump flow tests, EFNARC standards confirmed that all A-ASCC mixes were in the VS2/VF2 viscosity class, which has superior bleeding and segregation resistance and low formwork pressure.

- The addition of nanosilica (up to 2%), and MK (up to 5%), marginally improved the mechanical properties of A-ASCC, which were decreased with an increase in the NS ratio (more than 2%), and the MK ratio (more than 5%).

- The addition of NS and/or MK considerably increased the bond strength, flexural strength, fracture energy, and stress intensity factor of A-ASCC specimens. The specimens with concentrations of metakaolin (5%) and/or nanosilica (up to 2%) exhibited the best mechanical performance.

- The maximum bond strength was obtained by using NS and/or MK. The maximum improvement was 9.62% and 0.35% for specimens with 2% NS and 5% MK, respectively. As a result, it can be stated that the optimal NS and/or MK ratio for achieving the best fresh and hardened performance of GGBS-based A-ASCC was 2% and 5%, respectively.

- The data analysis showed that all of the independent variables had a significant influence on the properties of A-ASCC (both fresh and hardened properties). The most critical components were shown to be the addition of nanosilica and metakaolin. The presence of metakaolin had a stronger impact on the specimens’ fresh performance (V-funnel flow time, L-box passage ability, T50 flow time, and slump flow) and compressive strength than the addition of nanosilica. The incorporation of NS and MK, on the other hand, was found to be the most important variable in the A-ASCC specimens’ flexural tensile strength, fracture energy, and bond strength performance.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdel-Gawwad, H.A.; Abo-El-Enein, S.A. A Novel Method to Produce Dry Geopolymer Cement Powder. HBRC J. 2016, 12, 13–24. [Google Scholar] [CrossRef] [Green Version]

- Mehta, P.K. Sustainable Cements and Concrete for the Climate Change Era—A Review. In Proceedings of the Second International Conference on Sustainable Construction Materials and Technologies, Aneona, Italy, 28–30 June 2010; Citeseer: Princeton, NJ, USA, 2010; pp. 28–30. [Google Scholar]

- Revathi, T.; Jeyalakshmi, R.; Rajamane, N.P. Study on the Role of N-SiO2 Incorporation in Thermo-Mechanical and Microstructural Properties of Ambient Cured FA-GGBS Geopolymer Matrix. Appl. Surf. Sci. 2018, 449, 322–331. [Google Scholar]

- Huntzinger, D.N.; Eatmon, T.D. A Life-Cycle Assessment of Portland Cement Manufacturing: Comparing the Traditional Process with Alternative Technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Li, C.; Gong, X.Z.; Cui, S.P.; Wang, Z.H.; Zheng, Y.; Chi, B.C. CO2 Emissions Due to Cement Manufacture. In Materials Science Forum; Trans Tech Publ.: Zurich, Switzerland, 2011; Volume 685, pp. 181–187. [Google Scholar]

- Peng, J.X.; Huang, L.; Zhao, Y.B.; Chen, P.; Zeng, L. Modeling of Carbon Dioxide Measurement on Cement Plants. In Advanced Materials Research; Trans Tech Publications: Zurich, Switzerland, 2013; Volume 610, pp. 2120–2128. [Google Scholar]

- Khayat, K.H. Workability, Testing, and Performance of Self-Consolidating Concrete. Mater. J. 1999, 96, 346–353. [Google Scholar]

- Van Jaarsveld, J.G.S.; Van Deventer, J.S.J. Effect of the Alkali Metal Activator on the Properties of Fly Ash-Based Geopolymers. Ind. Eng. Chem. Res. 1999, 38, 3932–3941. [Google Scholar] [CrossRef]

- García-Lodeiro, I.; Palomo, A.; Fernández-Jiménez, A.; Macphee, D.E. Compatibility Studies between NASH and CASH Gels. Study in the Ternary Diagram Na2O–CaO–Al2O3–SiO2–H2O. Cem. Concr. Res. 2011, 41, 923–931. [Google Scholar] [CrossRef]

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-Activated Fly Ashes: A Cement for the Future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer Concrete: A Review of Some Recent Developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Eren, N.A.; Alzeebaree, R.; Çevik, A.; Niş, A.; Mohammedameen, A.; Gülşan, M.E. Fresh and Hardened State Performance of Self-Compacting Slag Based Alkali Activated Concrete Using Nanosilica and Steel Fiber. J. Compos. Mater. 2021, 55, 4125–4139. [Google Scholar] [CrossRef]

- Belkowitz, J.S.; Belkowitz, W.L.B.; Nawrocki, K.; Fisher, F.T. Impact of Nanosilica Size and Surface Area on Concrete Properties. ACI Mater. J. 2015, 112, 419–427. [Google Scholar] [CrossRef]

- Dheyaaldin, M.H.; Mosaberpanah, M.A.; Alzeebaree, R. Performance of Fiber-Reinforced Alkali-Activated Mortar with/without Nano Silica and Nano Alumina. Sustainability 2022, 14, 2527. [Google Scholar] [CrossRef]

- Phoo-ngernkham, T.; Chindaprasirt, P.; Sata, V.; Hanjitsuwan, S.; Hatanaka, S. The Effect of Adding Nano-SiO2 and Nano-Al2O3 on Properties of High Calcium Fly Ash Geopolymer Cured at Ambient Temperature. Mater. Des. 2014, 55, 58–65. [Google Scholar] [CrossRef]

- Said, A.M.; Zeidan, M.S.; Bassuoni, M.T.; Tian, Y. Properties of Concrete Incorporating Nano-Silica. Constr. Build. Mater. 2012, 36, 838–844. [Google Scholar] [CrossRef]

- Jalal, M.; Pouladkhan, A.; Harandi, O.F.; Jafari, D. RETRACTED: Comparative Study on Effects of Class F Fly Ash, Nano Silica and Silica Fume on Properties of High Performance Self Compacting Concrete. In Construction and Building Materials; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Du, H.; Du, S.; Liu, X. Durability Performances of Concrete with Nano-Silica. Constr. Build. Mater. 2014, 73, 705–712. [Google Scholar] [CrossRef] [Green Version]

- Singh, N.B.; Saxena, S.K.; Kumar, M. Effect of Nanomaterials on the Properties of Geopolymer Mortars and Concrete. Mater. Today Proc. 2018, 5, 9035–9040. [Google Scholar] [CrossRef]

- Alzeebaree, R.; Çevik, A.; Mohammedameen, A.; Niş, A.; Gülşan, M.E. Mechanical Performance of FRP-Confined Geopolymer Concrete under Seawater Attack. Adv. Struct. Eng. 2019, 23, 1055–1073. [Google Scholar] [CrossRef]

- Naniz, O.A.; Mazloom, M. Effects of Colloidal Nano-Silica on Fresh and Hardened Properties of Self-Compacting Lightweight Concrete. J. Build. Eng. 2018, 20, 400–410. [Google Scholar] [CrossRef]

- Gülşan, M.E.; Alzeebaree, R.; Rasheed, A.A.; Niş, A.; Kurtoğlu, A.E. Development of Fly Ash/Slag Based Self-Compacting Geopolymer Concrete Using Nano-Silica and Steel Fiber. Constr. Build. Mater. 2019, 211, 271–283. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Panesar, D.K.; Sain, M. Properties of Nanofibre Reinforced Cement Composites. Constr. Build. Mater. 2014, 63, 119–124. [Google Scholar] [CrossRef]

- Çevik, A.; Alzeebaree, R.; Humur, G.; Niş, A.; Gülşan, M.E. Effect of Nano-Silica on the Chemical Durability and Mechanical Performance of Fly Ash Based Geopolymer Concrete. Ceram. Int. 2018, 44, 12253–12264. [Google Scholar] [CrossRef]

- Görhan, G.; Aslaner, R.; Sinik, O. The Effect of Curing on the Properties of Metakaolin and Fly Ash-Based Geopolymer Paste. Compos. Part B Eng. 2016, 97, 329–335. [Google Scholar] [CrossRef]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of Nano-SiO2 Addition on Properties of Hardened Cement Paste as Compared with Silica Fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Alzeebaree, R.; Gülsan, M.E.; Nis, A.; Mohammedameen, A.; Cevik, A. Performance of FRP Confined and Unconfined Geopolymer Concrete Exposed to Sulfate Attacks. Steel Compos. Struct. 2018, 29, 201–218. [Google Scholar] [CrossRef]

- Belkowitz, J.S.; Armentrout, D. An Investigation of Nano Silica in the Cement Hydration Process. Ph.D. Thesis, University of Denver, Denver, CO, USA, 2009. Volume 48. [Google Scholar]

- Quercia, G.; Brouwers, H.J.H. Application of Nano-Silica (NS) in Concrete Mixtures. In Proceedings of the 8th fib PhD Symposium in Kgs, Copenhagen, Denmark, 20–23 June 2010. [Google Scholar]

- Lahoti, M.; Wong, K.K.; Tan, K.H.; Yang, E.-H. Effect of Alkali Cation Type on Strength Endurance of Fly Ash Geopolymers Subject to High Temperature Exposure. Mater. Des. 2018, 154, 8–19. [Google Scholar] [CrossRef]

- Albegmprli, H.M.; Al-Qazzaz, Z.K.A.; Rejeb, S.K. Strength Performance of Alkali Activated Structural Lightweight Geopolymer Concrete Exposed to Acid. Ceram. Int. 2022, 48, 6867–6873. [Google Scholar] [CrossRef]

- Nazari, A.; Bagheri, A.; Sanjayan, J.G.; Dao, M.; Mallawa, C.; Zannis, P.; Zumbo, S. Thermal Shock Reactions of Ordinary Portland Cement and Geopolymer Concrete: Microstructural and Mechanical Investigation. Constr. Build. Mater. 2019, 196, 492–498. [Google Scholar] [CrossRef]

- Daniel, A.J.; Sivakamasundari, S.; Abhilash, D. Comparative Study on the Behaviour of Geopolymer Concrete with Hybrid Fibers under Static Cyclic Loading. Procedia Eng. 2017, 173, 417–423. [Google Scholar] [CrossRef]

- Kathirvel, P.; Kaliyaperumal, S.R.M. Influence of Recycled Concrete Aggregates on the Flexural Properties of Reinforced Alkali Activated Slag Concrete. Constr. Build. Mater. 2016, 102, 51–58. [Google Scholar] [CrossRef]

- He, J.; Jie, Y.; Zhang, J.; Yu, Y.; Zhang, G. Synthesis and Characterization of Red Mud and Rice Husk Ash-Based Geopolymer Composites. Cem. Concr. Compos. 2013, 37, 108–118. [Google Scholar] [CrossRef]

- Zabihi, S.M.; Tavakoli, H.; Mohseni, E. Engineering and Microstructural Properties of Fiber-Reinforced Rice Husk–Ash Based Geopolymer Concrete. J. Mater. Civ. Eng. 2018, 30, 4018183. [Google Scholar] [CrossRef]

- Heah, C.Y.; Kamarudin, H.; Al Bakri, A.M.M.; Binhussain, M.; Luqman, M.; Nizar, I.K.; Ruzaidi, C.M.; Liew, Y.M. Effect of Curing Profile on Kaolin-Based Geopolymers. Phys. Procedia 2011, 22, 305–311. [Google Scholar] [CrossRef] [Green Version]

- Okoye, F.N.; Durgaprasad, J.; Singh, N.B. Mechanical Properties of Alkali Activated Flyash/Kaolin Based Geopolymer Concrete. Constr. Build. Mater. 2015, 98, 685–691. [Google Scholar] [CrossRef]

- Weng, L.; Sagoe-Crentsil, K. Dissolution Processes, Hydrolysis and Condensation Reactions during Geopolymer Synthesis: Part I—Low Si/Al Ratio Systems. J. Mater. Sci. 2007, 42, 2997–3006. [Google Scholar] [CrossRef]

- Yao, X.; Zhang, Z.; Zhu, H.; Chen, Y. Geopolymerization Process of Alkali–Metakaolinite Characterized by Isothermal Calorimetry. Thermochim. Acta 2009, 493, 49–54. [Google Scholar] [CrossRef]

- Yunsheng, Z.; Wei, S. Semi-Empirical AM1 Calculations on 6-Memebered Alumino-Silicate Rings Model: Implications for Dissolution Process of Metakaoline in Alkaline Solutions. J. Mater. Sci. 2007, 42, 3015–3023. [Google Scholar] [CrossRef]

- Yunsheng, Z.; Wei, S.; Zongjin, L.; Yantao, J. Study of Polycondensation Process of Metakaolin-Based Geopolymeric Cement Using Semi-Empirical AM1 Calculations. Adv. Cem. Res. 2009, 21, 67–73. [Google Scholar] [CrossRef]

- Albidah, A.; Altheeb, A.; Alrshoudi, F.; Abadel, A.; Abbas, H.; Al-Salloum, Y. Bond Performance of GFRP and Steel Rebars Embedded in Metakaolin Based Geopolymer Concrete. In Structures; Elsevier: Amsterdam, The Netherlands, 2020; Volume 27, pp. 1582–1593. [Google Scholar]

- Muñiz-Villarreal, M.S.; Manzano-Ramírez, A.; Sampieri-Bulbarela, S.; Gasca-Tirado, J.R.; Reyes-Araiza, J.L.; Rubio-Ávalos, J.C.; Pérez-Bueno, J.J.; Apatiga, L.M.; Zaldivar-Cadena, A.; Amigó-Borrás, V. The Effect of Temperature on the Geopolymerization Process of a Metakaolin-Based Geopolymer. Mater. Lett. 2011, 65, 995–998. [Google Scholar] [CrossRef]

- Perera, D.S.; Uchida, O.; Vance, E.R.; Finnie, K.S. Influence of Curing Schedule on the Integrity of Geopolymers. J. Mater. Sci. 2007, 42, 3099–3106. [Google Scholar] [CrossRef]

- Rovnaník, P. Effect of Curing Temperature on the Development of Hard Structure of Metakaolin-Based Geopolymer. Constr. Build. Mater. 2010, 24, 1176–1183. [Google Scholar] [CrossRef]

- Mohseni, E. Assessment of Na2SiO3 to NaOH Ratio Impact on the Performance of Polypropylene Fiber-Reinforced Geopolymer Composites. Constr. Build. Mater. 2018, 186, 904–911. [Google Scholar] [CrossRef]

- Pires, E.F.C.; de Azevedo, C.M.C.; Pimenta, A.R.; da Silva, F.J.; Darwish, F.A.I. Fracture Properties of Geopolymer Concrete Based on Metakaolin, Fly Ash and Rice Rusk Ash. Mater. Res. 2017, 20, 630–636. [Google Scholar] [CrossRef] [Green Version]

- Xie, J.; Chen, W.; Wang, J.; Fang, C.; Zhang, B.; Liu, F. Coupling Effects of Recycled Aggregate and GGBS/Metakaolin on Physicochemical Properties of Geopolymer Concrete. Constr. Build. Mater. 2019, 226, 345–359. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Qiu, G.H.; Kodur, V.; Yuan, Z.S. Spalling Behavior of Metakaolin-Fly Ash Based Geopolymer Concrete under Elevated Temperature Exposure. Cem. Concr. Compos. 2020, 106, 103483. [Google Scholar] [CrossRef]

- Memon, F.A.; Nuruddin, M.F.; Khan, S.; Shafiq, N.; Ayub, T. Effect of Sodium Hydroxide Concentration on Fresh Properties and Compressive Strength of Self-Compacting Geopolymer Concrete. J. Eng. Sci. Technol. 2013, 8, 44–56. [Google Scholar]

- Olivia, M.; Nikraz, H. Properties of Fly Ash Geopolymer Concrete Designed by Taguchi Method. Mater. Des. 2012, 36, 191–198. [Google Scholar] [CrossRef] [Green Version]

- EFNARC. The European Guidelines for Self-Compacting Concrete: Specification, Production and Use. Eur. Guidel. Self Compact. Concr. 2005, 68. [Google Scholar]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. On the Development of Fly Ash-Based Geopolymer Concrete. Mater. J. 2004, 101, 467–472. [Google Scholar]

- Memon, F.A.; Nuruddin, M.F.; Demie, S.; Shafiq, N. Effect of Curing Conditions on Strength of Fly Ash-Based Self-Compacting Geopolymer Concrete. Int. J. Civ. Environ. Eng. 2011, 3, 183–186. [Google Scholar]

- ASTM C39/C39M-01; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PE, USA, 2003.

- RILEM 50-FMC Committee of Fracture Mechanics of Concrete. Determination of the Fracture Energy of Mortar and Concrete by Means of Three-Point Bend Tests on Notched Beams. Mater. Struct. 1985, 18, 285–290. [Google Scholar]

- Draft Recommendation: Determination of the Fracture Energy of Mortar and Concrete by Means of Three-Point Bend Tests on Notched Beams. Mater. Struct. 1985, 18, 484. [CrossRef] [Green Version]

- Peterson, P.E. Fracture Energy of Concrete: Method of Determination. Cem. Concr. Res. 1980, 10, 79–89. [Google Scholar] [CrossRef]

- RILEM TC. RC 6. In Recommendations for the Testing and Use of Constructions Materials Bond Test for Reinforcement Steel. 2. Pull-Out Test; RILEM: Champs-sur-Marne, France, 1996; p. 3. [Google Scholar]

- EN, B. 12350-8; Testing Self Compacting Concrete: Slump Flow Test. European Committee of Standardization: Brussels, Belgium, 2010.

- Van Jaarsveld, J.G.S.; Van Deventer, J.S.J.; Lukey, G.C. The Characterisation of Source Materials in Fly Ash-Based Geopolymers. Mater. Lett. 2003, 57, 1272–1280. [Google Scholar] [CrossRef]

- Dheyaaldin, M.H.; Mosaberpanah, M.A.; Alzeebaree, R. Shrinkage Behavior and Mechanical Properties of Alkali Activated Mortar Incorporating Nanomaterials and Polypropylene Fibers. In Ceramic International; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Chithra, S.; Kumar, S.R.R.S.; Chinnaraju, K. The Effect of Colloidal Nano-Silica on Workability, Mechanical and Durability Properties of High Performance Concrete with Copper Slag as Partial Fine Aggregate. Constr. Build. Mater. 2016, 113, 794–804. [Google Scholar] [CrossRef]

- Madandoust, R.; Mousavi, S.Y. Fresh and Hardened Properties of Self-Compacting Concrete Containing Metakaolin. Constr. Build. Mater. 2012, 35, 752–760. [Google Scholar] [CrossRef]

- EN, B. 12350-9; Testing Self Compacting Concrete: V-Funnel Test. European Committee of Standardization: Brussels, Belgium, 2010.

- EN, B. 12350-10; Testing Self Compacting Concrete: L-Box Test. European Committee of Standardization: Brussels, Belgium, 2010.

- Nili, M.; Afroughsabet, V. Combined Effect of Silica Fume and Steel Fibers on the Impact Resistance and Mechanical Properties of Concrete. Int. J. Impact Eng. 2010, 37, 879–886. [Google Scholar] [CrossRef] [Green Version]

- Güneyisi, E.; Gesoǧlu, M.; Akoi, A.O.M.; Mermerdaş, K. Combined Effect of Steel Fiber and Metakaolin Incorporation on Mechanical Properties of Concrete. Compos. Part B Eng. 2014, 56, 83–91. [Google Scholar] [CrossRef]

- Saini, G.; Vattipalli, U. Assessing Properties of Alkali Activated GGBS Based Self-Compacting Geopolymer Concrete Using Nano-Silica. Case Stud. Constr. Mater. 2020, 12, e00352. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. The Role of SiO2 Nanoparticles and Ground Granulated Blast Furnace Slag Admixtures on Physical, Thermal and Mechanical Properties of Self Compacting Concrete. Mater. Sci. Eng. A 2011, 528, 2149–2157. [Google Scholar] [CrossRef]

- Adesina, A. Durability Enhancement of Concrete Using Nanomaterials: An Overview. In Materials Science Forum; Trans Tech Publ.: Zurich, Switzerland, 2019; Volume 967, pp. 221–227. [Google Scholar]

- Adesina, A. Nanomaterials in Cementitious Composites: Review of Durability Performance. J. Build. Pathol. Rehabil. 2020, 5, 1–9. [Google Scholar] [CrossRef]

- Alzeebaree, R.; Çevik, A.; Nematollahi, B.; Sanjayan, J.; Mohammedameen, A.; Gülcsan, M.E. Mechanical Properties and Durability of Unconfined and Confined Geopolymer Concrete with Fiber Reinforced Polymers Exposed to Sulfuric Acid. Constr. Build. Mater. 2019, 215, 1015–1032. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Bahrami, N.; Shoaei, P.; Moosaei, H.R.; Salemi, N. Performance of Sustainable High Strength Concrete with Basic Oxygen Steel-Making (BOS) Slag and Nano-Silica. J. Build. Eng. 2019, 25, 100791. [Google Scholar] [CrossRef]

- Alanazi, H.; Yang, M.; Zhang, D.; Gao, Z.J. Bond Strength of PCC Pavement Repairs Using Metakaolin-Based Geopolymer Mortar. Cem. Concr. Compos. 2016, 65, 75–82. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 2nd ed.; Geopolymer Institute: Saint Quentin, France, 2008. [Google Scholar]

- Kamarudin, H.; Al Bakri, A.M.; Binhussain, M.; Ruzaidi, C.M.; Luqman, M.; Heah, C.Y.; Liew, Y.M. Preliminary Study on Effect of NaOH Concentration on Early Age Compressive Strength of Kaolin-Based Green Cement. In Proceedings of the International Conference on Chemistry and Chemical Process IPCBEE, Bangkok, Thailand, 7–9 May 2011; Volume 10, pp. 18–24. [Google Scholar]

- Kurtouglu, A.E.; Alzeebaree, R.; Aljumaili, O.; Nis, A. Mechanical and Durability Properties of Fly Ash and Slag Based Geopolymer Concrete. In Advances of Concrete Construction; Techno Press: Daejeon, Korea, 2018. [Google Scholar]

- ACI 363R-92; State of the Art Report on High Strength Concrete. ACI Committee: Detroit, MI, USA, 1992; pp. 363R1–363R55.

- Committee Euro International Du Beton (CEB-FIB). CEB-FIB Model Code; Thomas Telford: London, UK, 1990. [Google Scholar]

| Component | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | K2O | Na2O | LOI | SG | BF (m2/kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| MK (%) | 1.287 | 50.995 | 42.631 | 2.114 | 0.127 | 0.439 | 0.337 | 0.284 | 1.640 | 2.54 | 18,000 |

| NS (%) | 99.800 | <1.000 | 2.20 | 15,000 | |||||||

| GGBS (%) | 34.128 | 36.412 | 11.379 | 1.681 | 10.310 | 0.478 | 3.641 | 0.361 | 1.65 | 2.79 | 418 |

| Sieve Size (mm) | 16 | 8 | 4 | 2 | 1 | 0.5 | 0.25 | Specific Gravity | Fineness Modules | Absorption |

|---|---|---|---|---|---|---|---|---|---|---|

| Coarse Aggregate | 100 | 31.0 | 1.5 | 0.75 | 0.25 | 0.25 | 0.65 | 2.72 | 5.65 | 2.4 |

| Fine Aggregate | 100 | 100 | 100 | 66.3 | 40.9 | 27.4 | 17.4 | 2.45 | 2.56 | 1.5 |

| Code of Mixture | Binder | Na2SO3 + NaOH | GGBS | NS | MK | Fine Agg. | Coarse Agg. | Molarity | SP | Extra Water |

|---|---|---|---|---|---|---|---|---|---|---|

| kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | % | % | ||

| 0MKNS0 | 500 | 250 | 500 | 0 | 0 | 803.00 | 777.27 | 12 | 7 | 9 |

| 0MKNS1 | 500 | 250 | 495 | 5 | 0 | 802.34 | 776.63 | 12 | 7 | 9 |

| 0MKNS2 | 500 | 250 | 490 | 10 | 0 | 801.69 | 776.00 | 12 | 7 | 9 |

| 0MKNS3 | 500 | 250 | 485 | 15 | 0 | 801.03 | 775.36 | 12 | 7 | 9 |

| 0MKNS4 | 500 | 250 | 480 | 20 | 0 | 800.37 | 774.73 | 12 | 7 | 9 |

| 0MKNS0 | 500 | 250 | 500 | 0 | 0 | 803.00 | 777.27 | 12 | 7 | 9 |

| 5MKNS0 | 500 | 250 | 475 | 0 | 25 | 801.64 | 775.95 | 12 | 7 | 9 |

| 10MKNS0 | 500 | 250 | 450 | 0 | 50 | 800.27 | 774.62 | 12 | 7 | 9 |

| 15MKNS0 | 500 | 250 | 425 | 0 | 75 | 798.90 | 773.30 | 12 | 7 | 9 |

| 20MKNS0 | 500 | 250 | 400 | 0 | 100 | 797.54 | 771.98 | 12 | 7 | 9 |

| Classification of Slump Flow (SF) | ||

|---|---|---|

| Class | SF diameter [cm] | |

| SF 1 | 55–65 | |

| SF 2 | 66–75 | |

| SF 3 | 76–85 | |

| Classification of Viscosity | ||

| Class | T50 [s] | V-funnel [s] |

| VS1/VF1 | ≤2 | ≤8 |

| VS2/VF2 | >2 | 9 to 25 |

| Classification of passing ability (PA) | ||

| PA1 | ≥0.8 with two rebar | |

| PA2 | ≥0.8 with three rebar | |

| Mixture | S-FLOW | L-BOX | V-FUNNEL | T-50 |

|---|---|---|---|---|

| 0MKNS0 | 703.00 | 0.95 | 15.03 | 3.22 |

| 0MKNS1 | 712.00 | 0.96 | 14.42 | 3.05 |

| 0MKNS2 | 719.00 | 0.97 | 13.96 | 2.93 |

| 0MKNS3 | 727.00 | 1.00 | 13.28 | 2.85 |

| 0MKNS4 | 731.00 | 1.00 | 12.63 | 2.64 |

| 5MKNS0 | 689.00 | 0.91 | 16.85 | 3.57 |

| 10MKNS0 | 673.00 | 0.87 | 17.67 | 3.81 |

| 15MKNS0 | 662.00 | 0.81 | 19.80 | 4.11 |

| 20MKNS0 | 651.00 | 0.79 | 24.50 | 4.35 |

| Mixtures | MK% | NS% | Compressive Strength (MPa) | Bond Strength (MPa) | Fracture Energy (N/m) | KIC (MPa-mm½) | Net Flexural Strength (MPa) | Displacement (mm) |

|---|---|---|---|---|---|---|---|---|

| 0MKNS0 | 0% | 0% | 77.54 | 11.22 | 126.27 | 25.47 | 5.38 | 0.43 |

| 0MKNS1 | 0% | 1% | 78.81 | 11.23 | 126.76 | 25.41 | 5.37 | 0.44 |

| 0MKNS2 | 0% | 2% | 77.42 | 12.35 | 127.59 | 25.42 | 5.37 | 0.46 |

| 0MKNS3 | 0% | 3% | 76.19 | 11.09 | 126.11 | 25.03 | 5.28 | 0.49 |

| 0MKNS4 | 0% | 4% | 73.9 | 10.64 | 124.14 | 23.80 | 5.02 | 0.53 |

| 0MKNS0 | 0% | 0% | 77.54 | 11.22 | 126.27 | 25.47 | 5.38 | 0.43 |

| 5MKNS0 | 5% | 0% | 82.66 | 11.26 | 127.61 | 27.15 | 5.73 | 0.50 |

| 10MKNS0 | 10% | 0% | 73.72 | 10.91 | 125.44 | 24.21 | 5.11 | 0.45 |

| 15MKNS0 | 15% | 0% | 68.91 | 10.37 | 124.15 | 22.63 | 4.78 | 0.48 |

| 20MKNS0 | 20% | 0% | 65.68 | 9.74 | 123.18 | 20.63 | 4.35 | 0.51 |

| Dependent Variable | Independent Variable | Sequential Sum of Squares | Mean Square | Computed F | p-Value | Significant | Contribution (%) |

|---|---|---|---|---|---|---|---|

| Compressive Strength | MK replacement level | 140.4 | 140.4 | 0.66 | 00 | Yes | 88.98 |

| NS replacement level | 9.8 | 9.8 | 10.0 | 0.00 | Yes | 6.21 | |

| Error | 7.58 | 4.8 | |||||

| Total | 157.78 | ||||||

| Bond Strength | MK replacement level | 1.48 | 1.48 | 25.21 | 0.001 | Yes | 57.4 |

| NS replacement level | 0.17 | 0.17 | 0.35 | 0.000 | Yes | 6.54 | |

| Error | 0.93 | 36 | |||||

| Total | 0.99980 | ||||||

| Fracture Toughness | MK replacement level | 9.3 | 9.3 | 9.9 | 0.001 | Yes | 67.14 |

| NS replacement level | 2.41 | 2.41 | 1.77 | 0.005 | Yes | 17.42 | |

| Error | 2.36 | 15.435 | |||||

| Total | 13.84 | ||||||

| KIC | MK replacement level | 20.16 | 20.16 | 11.64 | 0.001 | Yes | 85.52 |

| NS replacement level | 1.38 | 1.38 | 2.72 | 0.000 | Yes | 5.86 | |

| Error | 2 | 8.6 | |||||

| Total | 23.57 | ||||||

| Net Flexure Tensile Strength | MK replacement level | 0.9 | 0.9 | 11.82 | 0.001 | Yes | 64.77 |

| NS replacement level | 0.65 | 0.65 | 2.9 | 0.002 | Yes | 4.7 | |

| Error | 0.27 | 30.53 | |||||

| Total | 0.42 | ||||||

| Displacement | MK replacement level | 0.004 | 0.004 | 42.85 | 0.000 | Yes | 13 |

| NS replacement level | 0.006 | 0.006 | 53.57 | 0.00 | Yes | 20.35 | |

| Error | 0.02 | 66.62 | |||||

| Total | 0.03 | ||||||

| Slump Flow | MK replacement level | 409.6 | 409.6 | 52.96 | 0.000 | Yes | 44.61 |

| NS replacement level | 504.1 | 504.1 | 213 | 000 | Yes | 54.9 | |

| Error | 4.3 | 0.47 | |||||

| Total | 918 | ||||||

| L-Box Height Ratio | MK replacement level | 0.106 | 0.106 | 52.78 | 00 | Yes | 28.59 |

| NS replacement level | 0.185 | 0.185 | 149.1 | 00 | Yes | 49.85 | |

| Error | 0.08 | 21.57 | |||||

| Total | 0.37 | ||||||

| V-Funnel Flow Time | MK replacement level | 2.08 | 2.08 | 45.4 | 00 | Yes | 35.4 |

| NS replacement level | 3.52 | 3.52 | 792.3 | 00 | Yes | 59.82 | |

| Error | 0.28 | 4.76 | |||||

| Total | 5.89 | ||||||

| T-50 Flow Time | MK replacement level | 0.001 | 0.001 | 15.42 | 00 | Yes | 7.07 |

| NS replacement level | 0.002 | 0.002 | 36.75 | 00 | Yes | 9.62 | |

| Error | 0.0017 | 83.3 | |||||

| Total | 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alzeebaree, R. Bond Strength and Fracture Toughness of Alkali Activated Self-Compacting Concrete Incorporating Metakaolin or Nanosilica. Sustainability 2022, 14, 6798. https://doi.org/10.3390/su14116798

Alzeebaree R. Bond Strength and Fracture Toughness of Alkali Activated Self-Compacting Concrete Incorporating Metakaolin or Nanosilica. Sustainability. 2022; 14(11):6798. https://doi.org/10.3390/su14116798

Chicago/Turabian StyleAlzeebaree, Radhwan. 2022. "Bond Strength and Fracture Toughness of Alkali Activated Self-Compacting Concrete Incorporating Metakaolin or Nanosilica" Sustainability 14, no. 11: 6798. https://doi.org/10.3390/su14116798

APA StyleAlzeebaree, R. (2022). Bond Strength and Fracture Toughness of Alkali Activated Self-Compacting Concrete Incorporating Metakaolin or Nanosilica. Sustainability, 14(11), 6798. https://doi.org/10.3390/su14116798