A Review on the Effect of Mechanical Properties and Durability of Concrete with Construction and Demolition Waste (CDW) and Fly Ash in the Production of New Cement Concrete

Abstract

:1. Introduction

2. Importance of the Study

3. Factors That Influence the Properties of Concrete with Recycled Aggregate and Fly Ash

3.1. Properties of Construction and Demolition Waste That Influence New Concretes

3.1.1. Bulk Density and Water Absorption

- Recycled concrete aggregate for mixtures containing less than 10% ceramic and more than 90% concrete;

- Mixed recycled aggregate for mixtures containing less than 30% ceramic and between 70 and 90% concrete;

- Ceramic recycled aggregate for mixtures containing more than 30% ceramic and less than 70% concrete.

- (a)

- Class A—dry density between 2400 and 2600 kg/m3;

- (b)

- Class B—dry density between 2100 and 2300 kg/m3;

- (c)

- Class C—dry density between 1800 and 2000 kg/m3;

- (d)

- Class D—dry density lower than 1800 kg/m3.

3.1.2. Interfacial Transition Zones (ITZ)

3.1.3. Effect of the Recycled Aggregate Size on Strength and Elastic Modulus Properties

3.2. Fly Ash

3.2.1. Effect of Fly Ash on the Compression, Tensile and Flexural in Concretes

3.2.2. Bulk Density and Water Absorption

3.2.3. Physical and Mineralogical Properties of Fly Ash

4. Influence of Fly Ash Replacement in Concretes with Construction and Demolition Waste (CDW) in Concrete Properties

4.1. A General Overview

4.2. Mechanical Properties

4.2.1. Compressive Strength

4.2.2. Tensile Strength

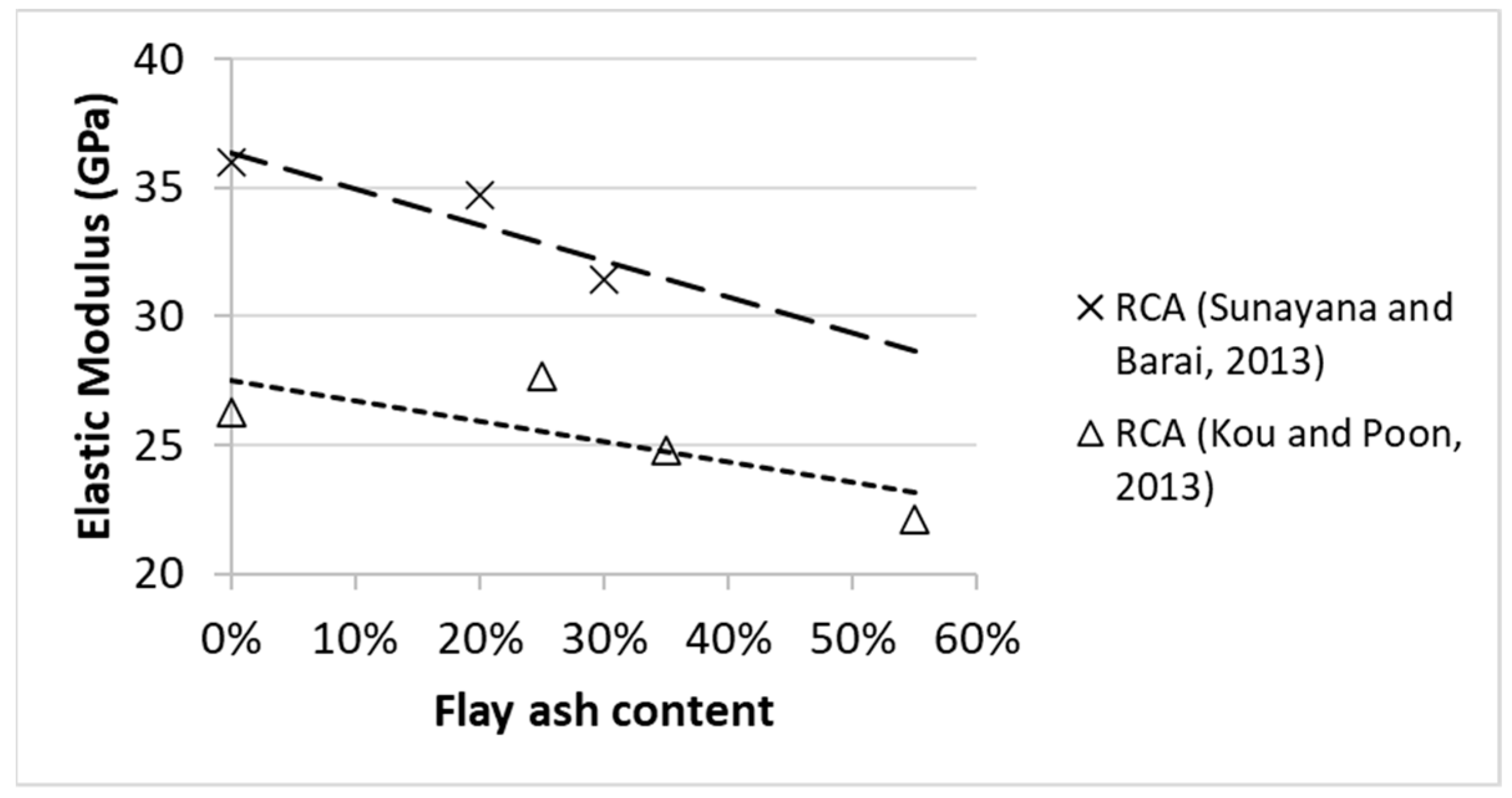

4.2.3. Elastic Modulus

- (a)

- Mix for 15 s the natural aggregates and recycled aggregate;

- (b)

- Add fly ash and mix for another 15 s;

- (c)

- Portland cement is added and mixed for another 30 s;

- (d)

- Add water and superplasticizer to the dry material and mix for another 60 s.

4.3. Durability Properties

4.3.1. Water Absorption

4.3.2. Chloride Ingress

4.3.3. Carbonation Depth

4.3.4. Microstructural Analyses

5. General Analysis

6. Conclusions

- There are already several studies exploring the most suitable composition of concrete mixtures with construction and demolition waste and fly ash to reach a consensus on the most appropriate contents of these wastes to achieve results of mechanical properties and durability closer to the reference concretes;

- Although there is an intense debate regarding the use of construction and demolition waste for the production of new concretes due to the significant variability of this waste, many researchers agree that small amounts of substitution of natural aggregates by recycled aggregates are quite feasible;

- The addition of fly ash as a partial replacement for Portland cement in concretes with recycled aggregate from construction and demolition waste, besides improving the adverse effects caused by recycled aggregates in terms of mechanical properties and durability, can contribute significantly to reducing CO2 generation in the environment;

- The use of this solid waste in the production of concrete and mortar will make a significant contribution to reducing the consumption of natural resources as well as reducing production costs.

7. Suggestions for Further In-Depth Studies

- There is a need for an establishment of methodologies for cost evaluation per m3 of concretes with recycled aggregate and fly ash;

- A study of the mechanical properties and durability in concretes with recycled aggregate and fly ash under different environmental conditions;

- Further investigations are necessary to determine ranges for an adequate w/b ratio for concretes with recycled aggregate and fly ash, given the variability of the physical–chemical characteristics of such materials;

- As the curing temperature directly affects the chemical reactions of fly ash activation, an evaluation of the mechanical properties and durability of concretes with recycled aggregate and fly ash is necessary;

- Life cycle analysis (LCA) that includes the recycling or reuse process to incorporate the product in the construction process is needed in order to give information for the decision-making process.

- Prediction of compressive strength of concrete modified with fly ash: applications of neuro-swarm and neuro-imperialism models;

- Systematic multiscale models to predict the compressive strength of fly ash-based geopolymer concrete at various mixture proportions and curing regimes;

- Soft computing techniques: systematic multiscale models to predict the compressive strength of HVFA concrete based on mix proportions and curing times;

- ANN, M5P-tree, and nonlinear regression approach with statistical evaluations to predict the compressive strength of cement-based mortar modified with fly ash;

- Characterizing and modeling the mechanical properties of the cement mortar modified with fly ash for various water-to-cement ratios and curing times;

- Model technics to predict the impact of the particle size distribution (PSD) of the sand on the mechanical properties of the cement mortar modified with fly ash;

- Compare the cost and environmental effect of the use of demolition construction waste for the production of new concrete.

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar] [CrossRef]

- Lanz, B.; Dietz, S.; Swanson, T. Global Population Growth, Technology, and Malthusian Constraints: A Quantitative Growth Theoretic Perspective. Int. Econ. Rev. 2017, 58, 973–1006. [Google Scholar] [CrossRef] [Green Version]

- Dawson, I.G.J.; Johnson, J.E.V. Does Size Matter? A Study of Risk Perceptions of Global Population Growth. Risk Anal. 2017, 37, 65–81. [Google Scholar] [CrossRef] [PubMed]

- Meddah, M.S. Recycled aggregates in concrete production: Engineering properties and environmental impact. MATEC Web Conf. 2017, 101, 05021. [Google Scholar] [CrossRef]

- Dabhade, A.N.; Chaudari, S.R.; Gajbhaye, A.R. Effect of Flyash on Recycle Coarse Aggregate Concrete. Int. J. Civ. Eng. Res. 2014, 5, 2278–3652. Available online: http://www.ripublication.com/ijcer.htm (accessed on 8 November 2019).

- Silva, R.V.; de Brito, J.; Dhir, R.K. Performance of cementitious renderings and masonry mortars containing recycled aggregates from construction and demolition wastes. Constr. Build. Mater. 2016, 105, 400–415. [Google Scholar] [CrossRef]

- Zong, L.; Fei, Z.; Zhang, S. Permeability of recycled aggregate concrete containing fly ash and clay brick waste. J. Clean. Prod. 2014, 70, 175–182. [Google Scholar] [CrossRef]

- Ge, Z.; Wang, Y.; Sun, R.; Wu, X.; Guan, Y. Influence of ground waste clay brick on properties of fresh and hardened concrete. Constr. Build. Mater. 2015, 98, 128–136. [Google Scholar] [CrossRef]

- Ledesma, E.F.; Jiménez, J.R.; Ayuso, J.; Fernández, J.M.; de Brito, J. Maximum feasible use of recycled sand from construction and demolition waste for eco-mortar production—Part-I: Ceramic masonry waste. J. Clean. Prod. 2015, 87, 692–706. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Mirzahosseini, M.; Riding, K.A. Effect of curing temperature and glass type on the pozzolanic reactivity of glass powder. Cem. Concr. Res. 2014, 58, 103–111. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.Y.; Zeng, H.H.; Wu, J.Y. A study on the macro and micro properties of concrete with LCD glass. Constr. Build. Mater. 2014, 50, 664–670. [Google Scholar] [CrossRef]

- Guelmine, L.; Hadjab, H.; Benazzouk, A. Effect of elevated temperatures on physical and mechanical properties of recycled rubber mortar. Constr. Build. Mater. 2016, 126, 77–85. [Google Scholar] [CrossRef]

- Ghizdăveț, Z.; Ștefan, B.M.; Nastac, D.; Vasile, O.; Bratu, M. Sound absorbing materials made by embedding crumb rubber waste in a concrete matrix. Constr. Build. Mater. 2016, 124, 755–763. [Google Scholar] [CrossRef]

- Dimitriou, G.; Savva, P.; Petrou, M.F. Enhancing mechanical and durability properties of recycled aggregate concrete. Constr. Build. Mater. 2018, 158, 228–235. [Google Scholar] [CrossRef]

- Arulrajah, A.; Disfani, M.M.; Haghighi, H.; Mohammadinia, A.; Horpibulsuk, S. Modulus of rupture evaluation of cement stabilized recycled glass/recycled concrete aggregate blends. Constr. Build. Mater. 2015, 84, 146–155. [Google Scholar] [CrossRef]

- da Silva, S.R.; de Andrade, J.J. Investigation of mechanical properties and carbonation of concretes with construction and demolition waste and fly ash. Constr. Build. Mater. 2017, 153, 704–715. [Google Scholar] [CrossRef]

- Zieliński, K. Impact of Recycled Aggregates on Selected Physical and Mechanical Characteristics of Cement Concrete. Procedia Eng. 2017, 172, 1291–1296. [Google Scholar] [CrossRef]

- Bravo, M.; de Brito, J.; Pontes, J.; Evangelista, L. Durability performance of concrete with recycled aggregates from construction and demolition waste plants. Constr. Build. Mater. 2015, 77, 357–369. [Google Scholar] [CrossRef]

- Limbachiya, M.; Meddah, M.S.; Ouchagour, Y. Use of recycled concrete aggregate in fly-ash concrete. Constr. Build. Mater. 2012, 27, 439–449. [Google Scholar] [CrossRef]

- Lotfy, A.; Al-Fayez, M. Performance evaluation of structural concrete using controlled quality coarse and fine recycled concrete aggregate. Cem. Concr. Compos. 2015, 61, 36–43. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Influence of recycled aggregate on slump and bleeding of fresh concrete. Mater. Struct. 2007, 40, 981–988. [Google Scholar] [CrossRef]

- Bravo, M.; de Brito, J.; Evangelista, L.; Pacheco, J. Superplasticizer’s efficiency on the mechanical properties of recycled aggregates concrete: Influence of recycled aggregates composition and incorporation ratio. Constr. Build. Mater. 2017, 153, 129–138. [Google Scholar] [CrossRef]

- Wang, X.-Y.; Park, K.-B. Analysis of compressive strength development of concrete containing high volume fly ash. Constr. Build. Mater. 2015, 98, 810–819. [Google Scholar] [CrossRef]

- Chousidis, N.; Ioannou, I.; Rakanta, E.; Koutsodontis, C.; Batis, G. Effect of fly ash chemical composition on the reinforcement corrosion, thermal diffusion and strength of blended cement concretes. Constr. Build. Mater. 2016, 126, 86–97. [Google Scholar] [CrossRef]

- Zhao, Y.; Zeng, W.; Zhang, H. Properties of recycled aggregate concrete with different water control methods. Constr. Build. Mater. 2017, 152, 539–546. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Enhancing the durability properties of concrete prepared with coarse recycled aggregate. Constr. Build. Mater. 2012, 35, 69–76. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Aprianti, E.; Shafigh, P.; Bahri, S.; Farahani, J.N. Supplementary cementitious materials origin from agricultural wastes—A review. Constr. Build. Mater. 2015, 74, 176–187. [Google Scholar] [CrossRef]

- Acar, I.; Atalay, M.U. Characterization of sintered class F fly ashes. Fuel 2013, 106, 195–203. [Google Scholar] [CrossRef]

- Lima, C.; Caggiano, A.; Faella, C.; Martinelli, E.; Pepe, M.; Realfonzo, R. Physical properties and mechanical behaviour of concrete made with recycled aggregates and fly ash. Constr. Build. Mater. 2013, 47, 547–559. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Long-term mechanical and durability properties of recycled aggregate concrete prepared with the incorporation of fly ash. Cem. Concr. Compos. 2013, 37, 12–19. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Effect of ultrafine fly ash on the properties of concretes containing construction and demolition wastes as coarse aggregates. Struct. Concr. 2016, 17, 116–122. [Google Scholar] [CrossRef]

- Sunayana, S.; Barai, S.V. Recycled aggregate concrete incorporating fly ash: Comparative study on particle packing and conventional method. Constr. Build. Mater. 2017, 156, 376–386. [Google Scholar] [CrossRef]

- Geng, J.; Sun, J. Characteristics of the carbonation resistance of recycled fine aggregate concrete. Constr. Build. Mater. 2013, 49, 814–820. [Google Scholar] [CrossRef]

- Sim, J.; Park, C. Compressive strength and resistance to chloride ion penetration and carbonation of recycled aggregate concrete with varying amount of fly ash and fine recycled aggregate. Waste Manag. 2011, 31, 2352–2360. [Google Scholar] [CrossRef]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of incorporation of high volume of recycled concrete aggregates and fly ash on the strength and global warming potential of concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Payá, J.; Borrachero, M.V.; Monzó, J.; Peris-Mora, E.; Bonilla, M. Long term mechanical strength behaviour in fly ash/Portland cement mortars prepared using processed ashes. J. Chem. Technol. Biotechnol. 2002, 77, 336–344. [Google Scholar] [CrossRef]

- Sakai, E.; Miyahara, S.; Ohsawa, S.; Lee, S.H.; Daimon, M. Hydration of fly ash cement. Cem. Concr. Res. 2005, 35, 1135–1140. [Google Scholar] [CrossRef]

- Moon, G.D.; Oh, S.; Choi, Y.C. Effects of the physicochemical properties of fly ash on the compressive strength of high-volume fly ash mortar. Constr. Build. Mater. 2016, 124, 1072–1080. [Google Scholar] [CrossRef]

- Flower, D.J.M.; Sanjayan, J.G. Chapter 1–Greenhouse Gas Emissions Due to Concrete Manufacture. In Handbook of Low Carbon Concrete; Nazari, A., Sanjayan, J.G., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 1–16. [Google Scholar] [CrossRef]

- Robalo, K.; Costa, H.; Carmo, R.d.; Júlio, E. Experimental development of low cement content and recycled construction and demolition waste aggregates concrete. Constr. Build. Mater. 2021, 273, 121680. [Google Scholar] [CrossRef]

- Martín-Morales, M.; Zamorano, M.; Ruiz-Moyano, A.; Valverde-Espinosa, I. Characterization of recycled aggregates construction and demolition waste for concrete production following the Spanish Structural Concrete Code EHE-08. Constr. Build. Mater. 2011, 25, 742–748. [Google Scholar] [CrossRef]

- Tu, T.Y.; Chen, Y.Y.; Hwang, C.L. Properties of HPC with recycled aggregates. Cem. Concr. Res. 2006, 36, 943–950. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Barbudo, A.; Agrela, F.; Beltrán, M.G.; Jiménez, J.R.; Galvín, A.P. Effect of cement addition on the properties of recycled concretes to reach control concretes strengths. J. Clean. Prod. 2014, 79, 124–133. [Google Scholar] [CrossRef]

- Kapoor, K.; Singh, S.P.; Singh, B. Durability of self-compacting concrete made with Recycled Concrete Aggregates and mineral admixtures. Constr. Build. Mater. 2016, 128, 67–76. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; de Rojas, M.I.S.; Frías, M. Influence of mixed recycled aggregate on the physical-mechanical properties of recycled concrete. J. Clean. Prod. 2014, 68, 216–225. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Lovato, P.S.; Possan, E.; Dal Molin, D.C.C.; Masuero, Â.B.; Ribeiro, J.L.D. Propriedades Mecânicas e de Durabilidade de Concretos com Agregados Reciclados. In Proceedings of the XII Congreso Latinoamericano de Patología y XIV Congreso de Calidad de la Construcción CONPAT, Cartagena, Colombia, 30 September–4 October 2013; pp. 1–10. [Google Scholar]

- Kisku, N.; Joshi, H.; Ansari, M.; Panda, S.K.; Nayak, S.; Dutta, S.C. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Constr. Build. Mater. 2017, 131, 721–740. [Google Scholar] [CrossRef]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of recycled concrete aggregate and their influence in new concrete production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Agrela, F.; de Juan, M.S.; Ayuso, J.; Geraldes, V.L.; Jiménez, J.R. Limiting properties in the characterisation of mixed recycled aggregates for use in the manufacture of concrete. Constr. Build. Mater. 2011, 25, 3950–3955. [Google Scholar] [CrossRef] [Green Version]

- Sharba, A.A.K.; Altemen, A.A.G.A.; Hason, M.M. Shear behavior of exploiting recycled brick waste and steel slag as an alternative aggregate for concrete production. Mater. Today Proc. 2021, 42, 2621–2628. [Google Scholar] [CrossRef]

- Zachariah, J.P.; Sarkar, P.P.; Pal, M. A study on the moisture damage and rutting resistance of polypropylene modified bituminous mixes with crushed brick aggregate wastes. Constr. Build. Mater. 2021, 269, 121357. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, J.; Pang, S.D.; Zhao, S. Durability and microstructural properties of concrete with recycled brick as fine aggregates. Constr. Build. Mater. 2020, 262, 120032. [Google Scholar] [CrossRef]

- Li, Y.; Yang, X.; Lou, P.; Wang, R.; Li, Y.; Si, Z. Sulfate attack resistance of recycled aggregate concrete with NaOH-solution-treated crumb rubber. Constr. Build. Mater. 2021, 287, 123044. [Google Scholar] [CrossRef]

- Jian, S.M.; Wu, B. Compressive behavior of compound concrete containing demolished concrete lumps and recycled aggregate concrete. Constr. Build. Mater. 2021, 272, 121624. [Google Scholar] [CrossRef]

- Sahoo, S.; Singh, B. Punching shear capacity of recycled-aggregate concrete slab-column connections. J. Build. Eng. 2021, 41, 102430. [Google Scholar] [CrossRef]

- Martínez-Lage, I.; Vázquez-Burgo, P.; Velay-Lizancos, M. Sustainability evaluation of concretes with mixed recycled aggregate based on holistic approach: Technical, economic and environmental analysis. Waste Manag. 2020, 104, 9–19. [Google Scholar] [CrossRef]

- Cantero, B.; del Bosque, I.F.S.; Matías, A.; Medina, C. Statistically significant effects of mixed recycled aggregate on the physical-mechanical properties of structural concretes. Constr. Build. Mater. 2018, 185, 93–101. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.F. Application of waste tire rubber and recycled aggregates in concrete products: A new compression casting approach. Resour. Conserv. Recycl. 2021, 167, 105353. [Google Scholar] [CrossRef]

- Feng, W.; Liu, F.; Yang, F.; Jing, L.; Li, L.; Li, H.; Chen, L. Compressive behaviour and fragment size distribution model for failure mode prediction of rubber concrete under impact loads. Constr. Build. Mater. 2021, 273, 121767. [Google Scholar] [CrossRef]

- Omoding, N.; Cunningham, L.S.; Lane-Serff, G.F. Effect of using recycled waste glass coarse aggregates on the hydrodynamic abrasion resistance of concrete. Constr. Build. Mater. 2021, 268, 121177. [Google Scholar] [CrossRef]

- Anupam, B.R.; Balan, L.A.; Sharma, S. Thermal and mechanical performance of cement concrete pavements containing PVC-glass mix. Road Mater. Pavement Des. 2021, 290, 123238. [Google Scholar] [CrossRef]

- Yang, S.; Lu, J.X.; Poon, C.S. Recycling of waste glass in dry-mixed concrete blocks: Evaluation of alkali-silica reaction (ASR) by accelerated laboratory tests and long-term field monitoring. Constr. Build. Mater. 2020, 262, 120865. [Google Scholar] [CrossRef]

- Penacho, P.; de Brito, J.; Veiga, M.R. Physico-mechanical and performance characterization of mortars incorporating fine glass waste aggregate. Cem. Concr. Compos. 2014, 50, 47–59. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Sun, Z.; Lange, D.A.; Shah, S.P. Properties of interfacial transition zones in recycled aggregate concrete tested by nanoindentation. Cem. Concr. Compos. 2013, 37, 276–292. [Google Scholar] [CrossRef]

- Duan, P.; Shui, Z.; Chen, W.; Shen, C. Effects of metakaolin, silica fume and slag on pore structure, interfacial transition zone and compressive strength of concrete. Constr. Build. Mater. 2013, 44, 1–6. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Corr, D.J.; Shah, S.P. Effects of interfacial transition zones on the stress-strain behavior of modeled recycled aggregate concrete. Cem. Concr. Res. 2013, 52, 82–99. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, T.; Liu, H. Performance evolution of the interfacial transition zone (ITZ) in recycled aggregate concrete under external sulfate attacks and dry-wet cycling. Constr. Build. Mater. 2019, 229, 116938. [Google Scholar] [CrossRef]

- Kong, D.; Lei, T.; Zheng, J.; Ma, C.; Jiang, J.; Jiang, J. Effect and mechanism of surface-coating pozzalanics materials around aggregate on properties and ITZ microstructure of recycled aggregate concrete. Constr. Build. Mater. 2010, 24, 701–708. [Google Scholar] [CrossRef]

- Kang, M.; Weibin, L. Effect of the aggregate size on strength properties of recycled aggregate concrete. Adv. Mater. Sci. Eng. 2018, 2018. [Google Scholar] [CrossRef] [Green Version]

- Musa, M.F.; bin Saim, A.A. The Effect of Aggregate Size on the Strength of Concrete; Universiti Teknologi Malaysia: Skudai, Malaysia, 2017; Volume 10, pp. 9–11. Available online: http://sps.utm.my/thecolloquium/files/2017/09/TC-10-9-12.pdf (accessed on 9 May 2021).

- Myadraboina, H.; Setunge, S.; Patnaikuni, I. Pozzolanic Index and lime requirement of low calcium fly ashes in high volume fly ash mortar. Constr. Build. Mater. 2017, 131, 690–695. [Google Scholar] [CrossRef]

- Gunasekara, C.; Law, D.W.; Setunge, S.; Sanjayan, J.G. Zeta potential, gel formation and compressive strength of low calcium fly ash geopolymers. Constr. Build. Mater. 2015, 95, 592–599. [Google Scholar] [CrossRef]

- Kiattikomol, K.; Jaturapitakkul, C.; Songpiriyakij, S.; Chutubtim, S. A study of ground coarse fly ashes with different finenesses from various sources as pozzolanic materials. Composites 2001, 23, 335–343. [Google Scholar] [CrossRef]

- Blissett, R.S.; Rowson, N.A. A review of the multi-component utilisation of coal fly ash. Fuel 2012, 97, 1–23. [Google Scholar] [CrossRef]

- Durdziński, P.T.; Dunant, C.F.; Haha, M.B.; Scrivener, K.L. A new quantification method based on SEM-EDS to assess fly ash composition and study the reaction of its individual components in hydrating cement paste. Cem. Concr. Res. 2015, 73, 111–122. [Google Scholar] [CrossRef]

- Ramachandran, V.S.P. Concrete Admixtures Handbook—Properties, Science and Technology, 12th ed.; William Andrew: Park Ridge, NJ, USA, 1984; 180p. [Google Scholar]

- Shehata, M.H.; Thomas, M.D.A.; Bleszynski, R.F. The effects of fly ash composition on the chemistry of pore solution in hydrated cement pastes. Cem. Concr. Res. 1999, 29, 1915–1920. [Google Scholar] [CrossRef]

- de Grazia, M.T.; Goshayeshi, N.; Gorga, R.; Sanchez, L.F.M.; Santos, A.C.; Souza, D.J. Comprehensive semi-empirical approach to describe alkali aggregate reaction (AAR) induced expansion in the laboratory. J. Build. Eng. 2021, 40, 102298. [Google Scholar] [CrossRef]

- Mehta, P.K. Natural Pozzolan. In Suplementary Cementing Materials; Malhotra, V.M., Ed.; 1987; 427p, Available online: https://books.google.com/books/about/Supplementary_cementing_materials_for_co.html?id=PL9TAAAAMAAJ (accessed on 9 May 2021).

- Wang, Z.S. Influence of fly ash on the mechanical properties of frame concrete. Sustain. Cities Soc. 2011, 1, 164–169. [Google Scholar] [CrossRef]

- Oner, A.; Akyuz, S.; Yildiz, R. An experimental study on strength development of concrete containing fly ash and optimum usage of fly ash in concrete. Cem. Concr. Res. 2005, 35, 1165–1171. [Google Scholar] [CrossRef]

- Arezoumandi, M.; Looney, T.J.; Volz, J.S. Effect of fly ash replacement level on the bond strength of reinforcing steel in concrete beams. J. Clean. Prod. 2015, 87, 745–751. [Google Scholar] [CrossRef]

- Rao, B.H.; Dinakar, P.; Mohanty, A.N.; Reddy, M.S.; Pavithra, P.; Satpathy, B.K. A mix design procedure for geopolymer concrete with fly ash. J. Clean. Prod. 2016, 133, 117–125. [Google Scholar] [CrossRef]

- Alghazali, H.H.; Myers, J.J. Shear behavior of full-scale high volume fly ash-self consolidating concrete (HVFA-SCC) beams. Constr. Build. Mater. 2017, 157, 161–171. [Google Scholar] [CrossRef]

- Komonweeraket, K.; Cetin, B.; Aydilek, A.H.; Benson, C.H.; Edil, T.B. Effects of pH on the leaching mechanisms of elements from fly ash mixed soils. Fuel 2015, 140, 788–802. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. Performance of sustainable concretes containing very high volume Class-F fly ash and ground granulated blast furnace slag. J. Clean. Prod. 2017, 162, 1407–1417. [Google Scholar] [CrossRef]

- Tosun-Felekoğlu, K.; Gödek, E.; Keskinateş, M.; Felekoğlu, B. Utilization and selection of proper fly ash in cost effective green HTPP-ECC design. J. Clean. Prod. 2017, 149, 557–568. [Google Scholar] [CrossRef]

- Wright, J.R.; Shafaatian, S.; Rajabipour, F. Reliability of chemical index model in determining fly ash effectiveness against alkali-silica reaction induced by highly reactive glass aggregates. Constr. Build. Mater. 2014, 64, 166–171. [Google Scholar] [CrossRef]

- Shafaatian, S.M.H.; Akhavan, A.; Maraghechi, H.; Rajabipour, F. How does fly ash mitigate alkali-silica reaction (ASR) in accelerated mortar bar test (ASTM C1567)? Cem. Concr. Compos. 2013, 37, 143–153. [Google Scholar] [CrossRef]

- Du, L.; Lukefahr, E.; Naranjo, A. Texas Department of Transportation Fly Ash Database and the Development of Chemical Composition–Based Fly Ash Alkali-Silica Reaction Durability Index. J. Mater. Civ. Eng. 2012, 25, 70–77. [Google Scholar] [CrossRef]

- Oey, T.; Timmons, J.; Stutzman, P.; Bullard, J.W.; Balonis, M.; Bauchy, M.; Sant, G. An improved basis for characterizing the suitability of fly ash as a cement replacement agent. J. Am. Ceram. Soc. 2017, 100, 4785–4800. [Google Scholar] [CrossRef]

- Aboustait, M.; Kim, T.; Ley, M.T.; Davis, J.M. Physical and chemical characteristics of fly ash using automated scanning electron microscopy. Constr. Build. Mater. 2016, 106, 1–10. [Google Scholar] [CrossRef]

- Schumacher, K.A.; Ideker, J.H. New Considerations in Predicting Mitigation of Alkali-Silica Reaction Based on Fly Ash Chemistry. J. Mater. Civ. Eng. 2014, 27, 04014144. [Google Scholar] [CrossRef]

- Gunasekara, C.; Law, D.W.; Setunge, S. Long term permeation properties of different fly ash geopolymer concretes. Constr. Build. Mater. 2016, 124, 352–362. [Google Scholar] [CrossRef]

- Du, W.; Zhang, C.-Y.; Kong, X.-M.; Zhuo, Y.-Q.; Zhu, Z.-W. Mercury release from fly ashes and hydrated fly ash cement pastes. Atmos. Environ. 2018, 178, 11–18. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Homwuttiwong, S.; Sirivivatnanon, V. Influence of fly ash fineness on strength, drying shrinkage and sulfate resistance of blended cement mortar. Cem. Concr. Res. 2004, 34, 1087–1092. [Google Scholar] [CrossRef]

- Tkaczewska, E. Effect of size fraction and glass structure of siliceous fly ashes on fly ash cement hydration. J. Ind. Eng. Chem. 2014, 20, 315–321. [Google Scholar] [CrossRef]

- Ma, Y.; Hu, J.; Ye, G. The effect of activating solution on the mechanical strength, reaction rate, mineralogy, and microstructure of alkali-activated fly ash. J. Mater. Sci. 2012, 47, 4568–4578. [Google Scholar] [CrossRef] [Green Version]

- Durdziński, P.T.; Snellings, R.; Dunant, C.F.; Haha, M.B.; Scrivener, K.L. Fly ash as an assemblage of model Ca-Mg-Na-aluminosilicate glasses. Cem. Concr. Res. 2015, 78, 263–272. [Google Scholar] [CrossRef]

- Shakr, N.; Salih, A.; Hamad, S.M.; Kurda, R. Comprehensive multiscale techniques to estimate the compressive strength of concrete incorporated with carbon nanotubes at various curing times and mix proportions. J. Mater. Res. Technol. 2021, 15, 6506–6527. [Google Scholar] [CrossRef]

- Barkhordari, M.S.; Armaghani, D.J.; Mohammed, A.S. Data-Driven Compressive Strength Prediction of Fly Ash Concrete Using Ensemble Learner Algorithms. Buildings 2022, 12, 132. [Google Scholar] [CrossRef]

- Shakr, N.; Mohammed, A.; Hamad, S.M.; Kurda, R. Electrical resistivity-Compressive strength predictions for normal strength concrete with waste steel slag as a coarse aggregate replacement using various analytical models. Constr. Build. Mater. 2022, 327, 127008. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- Lorca, P.; Calabuig, R.; Benlloch, J.; Soriano, L.; Payá, J. Microconcrete with partial replacement of Portland cement by fly ash and hydrated lime addition. Mater. Des. 2014, 64, 535–541. [Google Scholar] [CrossRef]

- Poon, C.S.; Lam, L.; Wong, Y.L. Study on high strength concrete prepared with large volumes of low calcium fly ash. Cem. Concr. Res. 2000, 30, 447–455. [Google Scholar] [CrossRef]

- Gonzalez-Corominas, A.; Etxeberria, M.; Poon, C.S. Influence of steam curing on the pore structures and mechanical properties of fly-ash high performance concrete prepared with recycled aggregates. Cem. Concr. Compos. 2016, 71, 77–84. [Google Scholar] [CrossRef]

- Filho, J.H. Sistemas Cimento, Cinza Volante e Cal Hidratada: Mecanismo de Hidratação, Microestrutura e Cabonatação do Concreto; Escola Politécnica da Universidade de Sâo Paulo: Sao Paulo, Brazil, 2008. [Google Scholar]

- Kou, S.C.; Poon, C.S.; Chan, D. Influence of fly ash as a cement addition on the hardened properties of recycled aggregate concrete. Mater. Struct. 2008, 41, 1191–1201. [Google Scholar] [CrossRef]

- Neville, A.M. Propriedades do Concreto, 2nd ed.; Editora Pini Ltd.: São Paulo, Brazil, 1997. [Google Scholar]

- Zhang, W.; Huang, Q.; Jiang, Z.; Dou, X.; Gu, X. Numerical analysis of the effect of coarse aggregate distribution on concrete carbonation. Constr. Build. Mater. 2012, 37, 27–35. [Google Scholar] [CrossRef]

- Supit, S.W.M.; Shaikh, F.U.A.; Sarker, P.K. Effect of ultrafine fly ash on mechanical properties of high volume fly ash mortar. Constr. Build. Mater. 2014, 51, 278–286. [Google Scholar] [CrossRef]

- Ann, K.Y.; Moon, H.Y.; Kim, Y.B.; Ryou, J. Durability of recycled aggregate concrete using pozzolanic materials. Waste Manag. 2008, 28, 993–999. [Google Scholar] [CrossRef]

- Khunthongkeaw, J.; Tangtermsirikul, S.; Leelawat, T. A study on carbonation depth prediction for fly ash concrete. Constr. Build. Mater. 2006, 20, 744–753. [Google Scholar] [CrossRef]

- Atiş, C.D. Accelerated carbonation and testing of concrete made with fly ash. Constr. Build. Mater. 2003, 17, 147–152. [Google Scholar] [CrossRef]

- Li, J.; Xiao, H.; Zhou, Y. Influence of coating recycled aggregate surface with pozzolanic powder on properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 1287–1291. [Google Scholar] [CrossRef]

- Sidorova, A.; Vazquez-Ramonich, E.; Barra-Bizinotto, M.; Roa-Rovira, J.J.; Jimenez-Pique, E. Study of the recycled aggregates nature’s influence on the aggregate-cement paste interface and ITZ. Constr. Build. Mater. 2014, 68, 677–684. [Google Scholar] [CrossRef]

- Juan-Valdés, A.; Rodríguez-Robles, D.; García-González, J.; Guerra-Romero, M.I.; Morán-del Pozo, J.M. Mechanical and microstructural characterization of non-structural precast concrete made with recycled mixed ceramic aggregates from construction and demolition wastes. J. Clean. Prod. 2018, 180, 482–493. [Google Scholar] [CrossRef]

| Recycled Aggregate | Bulk Density (kg/m3) | Water Absorption (%) | Authors |

|---|---|---|---|

| Brick | 974–2548 | 5.96–8.6 | Sharba et al. [54], Zachariah et al. [55], Dang et al. [56] |

| RCA 1 | 2265–2560 | 4.0–6.92 | Yang et al. [57], Jian and Wu [58], Sahoo and Singh [59] |

| MRA 2 | 1250–2340 | 5.0–8.79 | Martínez et al. [60], Cantero et al. [61], Silva et al. [17], Robalo et al. [42] |

| Rubber | 539–1050 | 0.9–1.7 | Kasmi et al. [62], Yang et al. [57], Feng et al. [63] |

| Glass | 800–880 | 0.002–0.4 | Omoding et al. [64], Balan et al. [65], Yang et al. [66] |

| Properties (%) | ABNT NBR 12653:2014 | ASTM C 618:2012 | |

|---|---|---|---|

| Class C | Class F | ||

| SiO2 + Al2O3 + Fe2O3 | ≥70.0 | ≥50.0 | ≥70.0 |

| SO3 | ≤5.0 | ≤5.0 | ≤5.0 |

| Humidity (%) | ≤3.0 | ≤3.0 | ≤3.0 |

| Loss to fire | ≤10.0 | ≤10.0 | ≤10.0 |

| Alkalis available in Na2O | ≤1.5 | ≤1.5 | ≤1.5 |

| Retained in the sieve 45 μm | ≤20% | ≤34% | ≤34% |

| Oxides | Class C (%) | Class F (%) | Authors |

|---|---|---|---|

| CaO | 16.28–29.21 | 0.87–13.52 | [25,76,87,88,89,90,91,92,93,94] |

| SiO2 | 27.05–37.67 | 49.2–70.70 | [25,76,87,88,89,90,91,92,93,94] |

| Al2O3 | 13.44–21.07 | 16.36–33.7 | [25,76,87,88,89,90,91,92,93,94] |

| Fe2O3 | 4.42–6.58 | 2.87–14.72 | [25,76,87,88,89,90,91,92,93,94] |

| MgO | 1.48–6.22 | 0.08–4.57 | [25,76,87,88,89,90,91,92,93,94] |

| K2O | 0.35–1.25 | 0.58–2.16 | [25,76,88,89,91,92,93,94] |

| Na2O | 0.33–1.91 | 0.0–2.82 | [25,76,88,91,92,93,94] |

| Na2Oeq | 0.50–1.43 | 1.16–4.24 | [76,87,88,89,93,94] |

| SO3 | 1.43–7.65 | 0.25–1.47 | [25,76,87,88,89,91,92,93,94] |

| LOI | 0.12–15.73 | 0.49–4.01 | [25,76,87,88,89,90,92,94] |

| Properties (%) | ABNT NBR 12653:2014 | ASTM C 618:2012 | |

|---|---|---|---|

| Class C | Class F | ||

| Retained in the sieve 45 μm (% max.) | 34 | 34 | 34 |

| Pozzolanic activity Index at 28 days (% min.) | 75 | 75 | 75 |

| Required water (% max.) | 110 | 105 | 105 |

| Properties | RCD Types | Replacements | Authors |

|---|---|---|---|

| Compressive strength | RCA 1 | (RA 4, 0% 50% 100%) (FA 5, 0% 30% 60%) | Kurad et al. [37] |

| MRA 2 | (RA 4, 0% 25% 50% 75% 100%) (FA 5, 0% 15% 20% 25% 30%) | da Silva and Andrade [17] | |

| RCA 1 | (RA 4, 0% 100%) (FA 5, 0% 20% 30%) | Sunayana and Barai [34] | |

| RCA 1 | (RA 4, 0% 25% 50%) (FA 5, 0% 10%) | Shaikh [33] | |

| RCA 1 | (RA 4, 0% 50% 100%) (FA 5, 0% 25% 35% 55%) | Kou and Poon [32] | |

| RMA 3 | (RA 4, 0% 30% 40% 50%) (FA 5, 0% 15%) | Zong, Fei, and Zhang [7] | |

| Tensile strength | MRA 2 | (RA 4, 0% 25% 50% 75% 100%) (FA 5, 0% 15% 20% 25% 30%) | da Silva and Andrade [17] |

| RCA 1 | (RA 4, 0% 25% 50%) (FA 5, 0% 10%) | Shaikh [33] | |

| RCA 1 | (RA 4, 0% 50% 100%) (FA 5, 0% 25% 35% 55%) | Kou and Poon [32] | |

| RCA 1 | (RA 4, 0% 100%) (FA 5, 0% 20% 30%) | Sunayana and Barai [34] | |

| Modulus of elasticity | RCA 1 | (FA 4, 0% 100%) (FA 5, 0% 20% 30%) | Sunayana and Barai [34] |

| RCA 1 | (RA 4, 0% 50% 100%) (FA 5, 0% 25% 35% 55%) | Kou and Poon [32] | |

| Carbonation coefficient (k) | RCA 1 | (RA 4, 0% 50% 100%) (FA 5, 0% 25% 35% 55%) | Kou and Poon [32] |

| RCA 1 | (RA 4, 0% 20% 40% 60% 80%) (FA 5, 0% 10% 20% 30%) | Geng and Sun [35] | |

| MRA 2 | (RA 4, 0% 25% 50% 75% 100%) (FA 5, 0% 15% 20% 25% 30%) | da Silva and Andrade [17] | |

| Sulfate resistance | RMA 3 | (RA 4, 0% 30% 40% 50%) (FA 5, 0% 15%) | Zong, Fei, and Zhang [7] |

| Permeability to chloride ions | RCA 2 | (RA 4, 0% 25% 50%) (FA 5, 0% 10%) | Shaikh [33] |

| RCA 2 | (RA 4, 0% 30% 60% 100%) (FA 5, 0% 15% 30%) | Sim and Park [36] | |

| Water absorption | MRA 3 | (RA 4, 0% 25% 50% 75% 100%) (FA 5, 0% 15% 20% 25% 30%) | da Silva and Andrade [17] |

| RCA 1 | (RA 4, 0% 25% 50%) (FA 5, 0% 10%) | Shaikh [33] | |

| RMA 3 | (RA 4, 0% 30% 40% 50%) (FA 5, 0% 15%) | Zong, Fei, and Zhang [7] |

| Mix | Relationship fc91/fc28 | ||

|---|---|---|---|

| w/b 0.4 | w/b 0.5 | w/b 0.6 | |

| R0F0 | 1.09 | 1.11 | 1.13 |

| R25F0 | 1.09 | 1.11 | 1.13 |

| R25F15 | 1.14 | 1.16 | 1.18 |

| R25F20 | 1.17 | 1.21 | 1.27 |

| R25F25 | 1.21 | 1.26 | 1.36 |

| R25F30 | 1.27 | 1.34 | 1.46 |

| Usage with 20% of Fly Ash | Replacement Rate | ||

|---|---|---|---|

| 0–25% | 25–50% | >50% | |

| Structural cement concrete (20–25 MPa) | X | ||

| Non-structural cement concrete (<20 MPa) | X | X | |

| Permeable cement concrete | X | X | |

| Mortars | X | X | |

| Paving (base, sub-base, and sub-bed reinforcement) | X | X | X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Da Silva, S.R.; Andrade, J.J.d.O. A Review on the Effect of Mechanical Properties and Durability of Concrete with Construction and Demolition Waste (CDW) and Fly Ash in the Production of New Cement Concrete. Sustainability 2022, 14, 6740. https://doi.org/10.3390/su14116740

Da Silva SR, Andrade JJdO. A Review on the Effect of Mechanical Properties and Durability of Concrete with Construction and Demolition Waste (CDW) and Fly Ash in the Production of New Cement Concrete. Sustainability. 2022; 14(11):6740. https://doi.org/10.3390/su14116740

Chicago/Turabian StyleDa Silva, Sérgio Roberto, and Jairo José de Oliveira Andrade. 2022. "A Review on the Effect of Mechanical Properties and Durability of Concrete with Construction and Demolition Waste (CDW) and Fly Ash in the Production of New Cement Concrete" Sustainability 14, no. 11: 6740. https://doi.org/10.3390/su14116740

APA StyleDa Silva, S. R., & Andrade, J. J. d. O. (2022). A Review on the Effect of Mechanical Properties and Durability of Concrete with Construction and Demolition Waste (CDW) and Fly Ash in the Production of New Cement Concrete. Sustainability, 14(11), 6740. https://doi.org/10.3390/su14116740