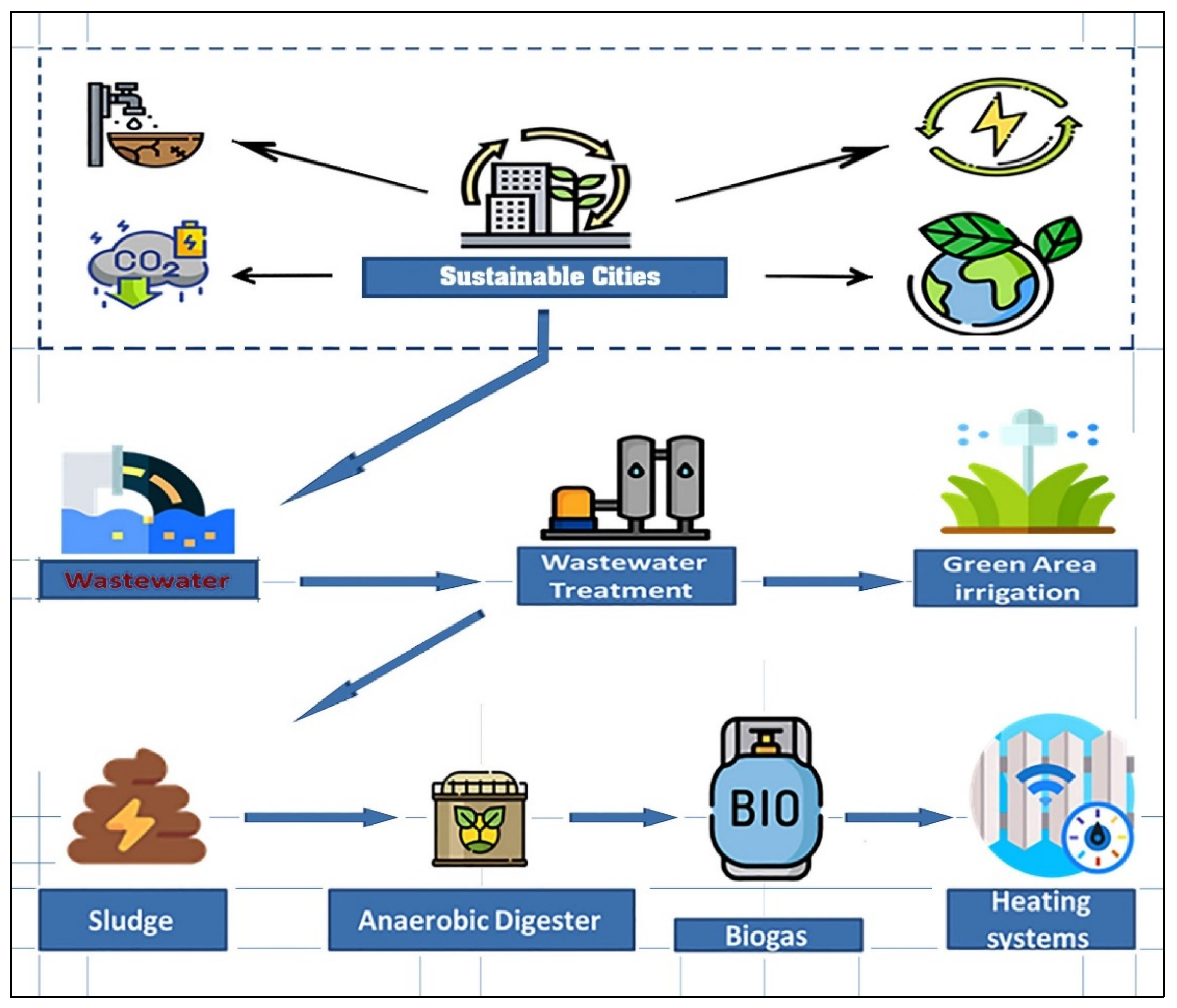

Sustainability of Egyptian Cities through Utilizing Sewage and Sludge in Softscaping and Biogas Production

Abstract

1. Introduction

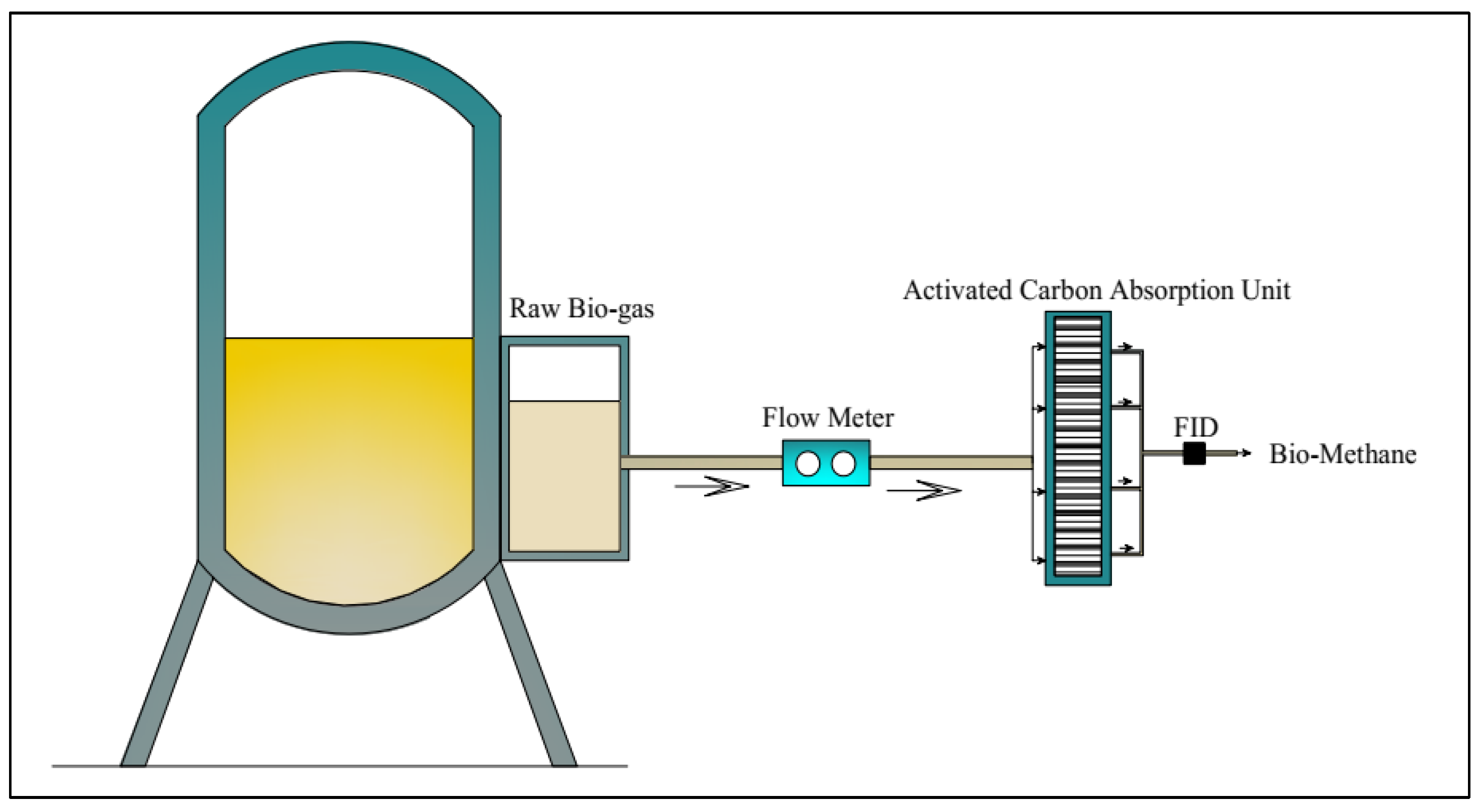

2. Literature Review

3. Materials and Methods

3.1. Description of the Existing Residual Community (Compound)

3.2. Description of Domestic Wastewater

3.3. Samples and Sampling

3.4. Description of the Wastewater Treatment Pilot

3.5. Description of the Anaerobic Digester (AD)

3.6. Experimental Methods

3.7. Preventing Corrosion in the Biogas Production Process

3.8. Chemical and Physical Parameters

4. Results and Discussion

4.1. Characteristics of Raw Municipal Wastewater

4.2. Performance of the Membrane Bioreactor Process

4.2.1. COD Removal

4.2.2. TSS Removal

4.2.3. Nitrogen Removal

4.2.4. Phosphorous Removal

4.2.5. The Effect of Settlement Time on Wastewater Concentrations

4.3. Performance of the Anaerobic Digester for Biogas Production

4.4. The Imagination of a Full-Scale Domestic Wastewater Treatment Plant

4.5. Suggestions for the Planning of the Irrigation Network

4.6. Dimensions of Planning for Sustainable City Development

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leyzerova, A.; Sharovarova, E.; Alekhin, V. Sustainable Strategies of Urban Planning. Procedia Eng. 2016, 150, 2055–2061. [Google Scholar] [CrossRef]

- Konbr, U. Sustainability of the Residential Zones in the New Urban Communities in Greater Cairo Region—An Approach for Sustainability Aspects Assessment. Ph.D. Thesis, Department of Architecture, Faculty of Engineering, Al-Azhar University, Cairo, Egypt, 2005. [Google Scholar] [CrossRef]

- Eldardiry, D.H.; Konbr, U. Using phenomenological theory for sustainable renovation of historical open spaces in Bahrain. Int. J. Sustain. Dev. Plan. 2022, 17, 559–568. [Google Scholar] [CrossRef]

- Tsirigoti, D.; Zenginis, D.; Bikas, D. Sustainable Development Scenarios for Urban Blocks: Energy Renovation and Quality of Life in the Greek City. Environ. Sci. Proc. 2022, 15, 37. [Google Scholar] [CrossRef]

- Rose, G.; Stocker, M.; Ornetzeder, M. The Learning City: Temporary Housing Projects as Urban Niches for Sustainability Experiments. Sustainability 2022, 14, 5198. [Google Scholar] [CrossRef]

- Igliński, B.; Kiełkowska, U.; Piechota, G.; Skrzatek, M.; Cichosz, M.; Iwański, P. Can energy self-sufficiency be achieved? Case study of Warmińsko-Mazurskie Voivodeship (Poland). Clean Technol. Environ. Policy 2021, 23, 2061–2081. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Global Energy Transformation: A Roadmap to 2050. Available online: www.irena.org (accessed on 16 January 2021).

- Hakizimana, A. Novel Optimization Approaches for Integrated Design and Operation of Smart Manufacturing and Energy Systems. Ph.D. Thesis, Clemson University, Ann Arbor, MI, USA, 2019. [Google Scholar]

- Huang, Y.-F.; Chiueh, P.-T.; Kuan, W.-H.; Lo, S.-L. Product distribution and heating performance of lignocellulosic biomass pyrolysis using microwave heating. Energy Procedia 2018, 152, 910–915. [Google Scholar] [CrossRef]

- Kiddle, G.L.; Zari, M.P.; Blaschke, P.; Chanse, V.; Kiddle, R. An Oceania urban design agenda linking ecosystem services, nature-based solutions, traditional ecological knowledge and wellbeing. Sustainability 2021, 13, 12660. [Google Scholar] [CrossRef]

- Caposciutti, G.; Baccioli, A.; Ferrari, L.; Desideri, U. Biogas from Anaerobic Digestion: Power Generation or Biomethane Production? Energies 2020, 13, 743. [Google Scholar] [CrossRef]

- Plevri, A.; Mamais, D.; Noutsopoulos, C. Anaerobic MBR technology for treating municipal wastewater at ambient temperatures. Chemosphere 2021, 275, 129961. [Google Scholar] [CrossRef]

- Makisha, N.; Semenova, D. Production of biogas at wastewater treatment plants and its further application. MATEC Web Conf. 2018, 144, 04016. [Google Scholar] [CrossRef]

- Ben Aim, R.M.; Semmens, M.J. Membrane bioreactors for wastewater treatment and reuse: A success story. Water Sci. Technol. 2003, 47, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Joshi, A.; Gupta, A.; Verma, S.; Ranjan Paul, A.; Jain, A.; Haque, N. Life Cycle Based Greenhouse Gas Footprint Assessment of a Smartphone. IOP Conf. Ser. Earth Environ. Sci. 2021, 795, 012028. [Google Scholar] [CrossRef]

- Cosenza, A.; Mannina, G.; Neumann, M.B.; Viviani, G.; Vanrolleghem, P.A. Biological nitrogen and phosphorus removal in membrane bioreactors: Model development and parameter estimation. Bioprocess Biosyst. Eng. 2013, 36, 499–514. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Gupta, A.; Verma, S.; Paul, A.R.; Jain, A.; Haque, N. Life Cycle Assessment Based Environmental Footprint of a Battery Recycling Process. In Intelligent Manufacturing and Energy Sustainability; Springer: Singapore, 2022; Volume 265, pp. 115–123. [Google Scholar]

- Delanka-Pedigo, H.M.K.; Munasinghe-Arachchige, S.P.; Abeysiriwardana-Arachchige, I.S.A.; Nirmalakhandan, N. Wastewater infrastructure for sustainable cities: Assessment based on UN sustainable development goals (SDGs). Int. J. Sustain. Dev. World Ecol. 2021, 28, 203–209. [Google Scholar] [CrossRef]

- Naidoo, D.; Nhamo, L.; Lottering, S.; Mpandeli, S.; Liphadzi, S.; Modi, A.T.; Trois, C.; Mabhaudhi, T. Transitional pathways towards achieving a circular economy in the water, energy, and food sectors. Sustainability 2021, 13, 9978. [Google Scholar] [CrossRef]

- Elghonaimy, I.H.; El-Dardiry, D.H. Comparative Study for Developing Closed Vernacular Settlements in Egypt. IJRDO J. Soc. Sci. Hum. Res. 2016, 1, 82–105. [Google Scholar] [CrossRef]

- Shiba, A.S.E. A Study of Spontaneous Architecture Environmental Characteristics and Treatments in Hot Dry Regions and their re-application in Contemporary Architecture Using Green Technology. Int. J. Adv. Sci. Technol. 2020, 29, 1819–1830. [Google Scholar]

- Konbr, U. Smart sustainable cities—Vision and reality. Resourceedings 2019, 2, 101–127. [Google Scholar] [CrossRef]

- IEA. Sustainable Development Strategy: Egypt Vision 2030—Policies—IEA. Available online: https://www.iea.org/policies/14823-sustainable-development-strategy-egypt-vision-2030 (accessed on 9 May 2022).

- Bohl, D.K.; Hanna, T.L.; Scott, A.C.; Moyer, J.D.; Hedden, S.G. Sustainable Development Goals Report: Egypt 2030; Frederick, S., Ed.; The University of Denver, School of International Studies; Pardee, Center for International Futures: Denver, CO, USA, 2018. [Google Scholar]

- Ministry of International Cooperation. Egypt National Review Report for Input to the 2016 HLPF; The Arab Republic of Egypt, National Voluntary Review on the Sustainable Development Goals, Input to the 2016 High-level Political Forum (HLPF) on Sustainable Development; Ministry of International Cooperation: Cairo, Egypt, 2016.

- Elghonaimy, I.H.; AlSaeed, S. The Role of Theme Parks in Creating Sustainable Development. BAU J. Creat. Sustain. Dev. 2021, 3, 12. Available online: https://digitalcommons.bau.edu.lb/csdjournal/vol13/iss11/12 (accessed on 16 January 2022).

- Konbr, U.; Lebda, A. Criteria of sustainable interior design based on the green pyramid rating system. J. Eng. Res. 2019, 3, 48–60. [Google Scholar] [CrossRef]

- Picardo, A.; Soltero, V.M.; Peralta, M.E.; Chacartegui, R. District heating based on biogas from wastewater treatment plant. Energy 2019, 180, 649–664. [Google Scholar] [CrossRef]

- Lu, M.; Fu, G.; Osman, N.B.; Konbr, U. Green energy harvesting strategies on edge-based urban computing in sustainable internet of things. Sustain. Cities Soc. 2021, 75, 103349. [Google Scholar] [CrossRef]

- Shiba, A.S.E. Using Nanotechnology in Producing Organic Construction Materials. Int. J. Adv. Sci. Technol. 2020, 29, 8174–8185. [Google Scholar]

- Hrudka, J.; Stanko, Š.; Holubec, M. Analysis of flow and sedimentation processes in secondary sedimentation tank. Pollack Period 2017, 12, 79–89. [Google Scholar] [CrossRef]

- Wei, Z.; Zandi, Y.; Gholizadeh, M.; Selmi, A.; Roco-Videla, A.; Konbr, U. On the optimization of building energy, material, and economic management using soft computing. Adv. Concr. Constr. 2021, 11, 455–468. [Google Scholar] [CrossRef]

- Nawy. Cairo Festival City—New Cairo—Egypt. Available online: https://www.nawy.com/compound/187-cairo-festival-city/Townhouse (accessed on 16 January 2022).

- Maged, J.; Moussa, R.R.; Konbr, U. An Investigation into the Causes of Pedestrians’ Walking Difficulties in Cairo Streets. Civ. Eng. Archit. 2022, 10, 12–26. [Google Scholar] [CrossRef]

- El-Gohary, F.A.; Wahaab, R.A.; Nasr, F.A.; Ali, H.I. Three Egyptian industrial wastewater management programmes. Environmentalist 2002, 22, 59–65. [Google Scholar] [CrossRef]

- Naghizadeh, A.; Mahvi, A.H.; Mesdaghinia, A.R.; Alimohammadi, M. Application of MBR Technology in Municipal Wastewater Treatment. Arab. J. Sci. Eng. 2011, 36, 3–10. [Google Scholar] [CrossRef]

- Kurt, U.; Gonullu, M.T.; Ilhan, F.; Varinca, K. Treatment of Domestic Wastewater by Electrocoagulation in a Cell with Fe–Fe Electrodes. Environ. Eng. Sci. 2008, 25, 153–162. [Google Scholar] [CrossRef]

- Yang, Y.; Xia, S.; Hermanowicz, S. Full-scale engineering application of MBR system in municipal wastewater treatment plants around China’s Tai Lake Basin. Fresenius Environ. Bull. 2015, 24, 3616–3626. [Google Scholar]

- Shin, H.; Kang, S.; Lee, C.; Lim, J. Performance of a pilot scale membrane bioreactor coupled with SBR (SM-SBR)—Experiences in seasonal temperature changes. Water Supply 2004, 4, 135–142. [Google Scholar] [CrossRef]

- Bornare, J.B.; Adhyapak, U.S.; Minde, G.P.; Kalyan Raman, V.; Sapkal, V.S.; Sapkal, R.S. Submerged anaerobic membrane bioreactor for wastewater treatment and energy generation. Water Sci. Technol. 2015, 71, 1654–1660. [Google Scholar] [CrossRef] [PubMed]

- Harper, W.; Bernhardt, M.; Newfield, C. Membrane bioreactor biomass characteristics and microbial yield at very low mean cell residence time. Water SA 2007, 32, 193–198. [Google Scholar] [CrossRef][Green Version]

- Fenu, A.; Thoeye, C.; Guglielmi, G.; Jimenez, J.; Spèrandio, M.; Saroj, D.; Lesjean, B.; Brepols, C.; Nopens, I. 6.26—Activated Sludge Model-Based Modeling of Membrane Bioreactor Processes: A Critical Review with Special Regard to MBR Specificities. In Comprehensive Biotechnology, 2nd ed.; Academic Press: Burlington, ON, Canada, 2011; pp. 305–327. [Google Scholar]

- Jover-Smet, M.; Martín-Pascual, J.; Trapote, A. Model of Suspended Solids Removal in the Primary Sedimentation Tanks for the Treatment of Urban Wastewater. Water 2017, 9, 448. [Google Scholar] [CrossRef]

- Karagiannidis, A.; Samaras, P.; Kasampalis, T.; Perkoulidis, G.; Ziogas, P.; Zorpas, A. Evaluation of sewage sludge production and utilization in Greece in the frame of integrated energy recovery. Desalin. Water Treat. 2011, 33, 185–193. [Google Scholar] [CrossRef]

- Maragkaki, A.E.; Fountoulakis, M.; Gypakis, A.; Kyriakou, A.; Lasaridi, K.; Manios, T. Pilot-scale anaerobic co-digestion of sewage sludge with agro-industrial by-products for increased biogas production of existing digesters at wastewater treatment plants. Waste Manag. 2017, 59, 362–370. [Google Scholar] [CrossRef]

- Wagner, J.; Rosenwinkel, K.-H. Sludge production in membrane bioreactors under different conditions. Water Sci. Technol. 2000, 41, 251–258. [Google Scholar] [CrossRef]

- Egyptian Code of Practice for the Reuse of Treated Wastewater for Agricultural Purposes; The Ministry of Housing Utilities and Urban Communities: Cairo, Egypt, 2005.

- Ali, M.N.; Shiba, A.S.E. Grey water treatment, reused and benefit of the heat capacity of water to improve the environmental performance of internal space. J. Xi’an Univ. Archit. Technol. 2020, XII, 983–992. [Google Scholar] [CrossRef]

| Tank | Parameter | Value |

|---|---|---|

| Primary Sedimentation Tank | Water volume | 450 L |

| Length × width × depth | 1 × 1 × 0.5 m | |

| Hydraulic retention time | 2 and 3 h | |

| Aeration tank | Length × width × depth | 1 × 1 × 0.5 m |

| Water volume | 450 L | |

| Hydraulic retention time | 12 h | |

| Sludge Recirculation | 30% | |

| Air blower | Type | Lutz-Jecsco Memdos Smart lp5-Srepper pump |

| Rate of flow | 5.3 L/h | |

| Fiber membrane | Material | Polypropylene |

| Pore size | 0.1 µm |

| Digester Unit | Parameter | Value |

|---|---|---|

| Cylindrical digester | Diameter | 50 cm |

| Height | 20 cm | |

| Mixer | Shaft speed | 100 rpm |

| Gas meter | Type | Ritter TG5-model 5 |

| Temperature | Range | 32 ± 3 °C |

| Sludge | Hydraulic retention time | 20 days |

| Parameters | Unit | Samples | Average | Standard Deviation | |||

|---|---|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 4th | ||||

| COD | mg/L | 321 | 326 | 346 | 350 | 335.75 | 14.38 |

| BOD | mg/L | 260 | 254 | 267 | 249 | 257.50 | 7.77 |

| pH | - | 8.1 | 8.2 | 7.9 | 7.7 | 7.98 | 0.22 |

| TSS | mg/L | 126 | 120 | 122 | 125 | 123.25 | 2.75 |

| NH3-N | mg/L | 33.4 | 31 | 32.3 | 45 | 35.43 | 6.46 |

| TKN | mg/L | 45 | 52 | 46.5 | 67 | 52.63 | 10.04 |

| TP | mg/L | 6.9 | 7 | 6.7 | 7.2 | 6.95 | 0.21 |

| Treatment Stages | COD | BOD | PH | TSS | NH3-N | TN | TP | |

|---|---|---|---|---|---|---|---|---|

| All Parameters in mg/L | ||||||||

| 12 h cycle | Raw sample | 335.75 | 257.5 | 7.98 | 123.25 | 35.43 | 52.63 | 6.95 |

| After P.S.T for 2 h | 220 | 180 | 7.7 | 61.3 | 29 | 43.2 | 6.1 | |

| After P.S.T for 3 h | 198.1 | 153 | 7.7 | 50.5 | 24.4 | 42.1 | 5.6 | |

| After aeration (12 h) | 36 | 22.6 | 7.9 | 24.6 | 18.3 | 22.1 | 4.7 | |

| After MBRs unit | 26.8 | 18.6 | 7.9 | 4.9 | 3.8 | 5.7 | 1.3 | |

| After disinfection | 23.5 | 14.4 | 7.6 | 3.8 | 3.1 | 4.4 | 1.1 | |

| Removal efficiency (%) | 93 | 94.4 | --- | 96.9 | 91.4 | 91.6 | 84.1 | |

| Law 48 of the year 1982 | 100 | 60 | 6–9 | 60 | 40 | ---- | 10 | |

| Time (Day) | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

|---|---|---|---|---|---|---|---|---|---|---|

| Biogas rate (mL/day) | 28.07 | 24.21 | 21.86 | 22.93 | 45.00 | 51.86 | 53.14 | 53.81 | 54.21 | 60.00 |

| Tank | Parameter | Value |

|---|---|---|

| Primary Sedimentation Tank | Tank volume | 45 m3 |

| Hydraulic retention time | 2 h | |

| Aeration tank | Tank volume | 290 m3 |

| Number of tanks | 2 | |

| Hydraulic retention time | 12 h | |

| Sludge Recirculation | 30% | |

| Air blower | Type | Lutz-Jecsco Memdos Smart lp5-Srepper pump |

| Rate of flow | 50 L/h | |

| Fiber membrane | Material | Polypropylene |

| Pore size | 0.1 µm | |

| Anaerobic digester | Diameter | 60 cm |

| Height | 50 cm | |

| Shaft speed | 100 rpm | |

| Hydraulic retention time | 20 days |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konbr, U.; Bayoumi, W.; Ali, M.N.; Shiba, A.S.E. Sustainability of Egyptian Cities through Utilizing Sewage and Sludge in Softscaping and Biogas Production. Sustainability 2022, 14, 6675. https://doi.org/10.3390/su14116675

Konbr U, Bayoumi W, Ali MN, Shiba ASE. Sustainability of Egyptian Cities through Utilizing Sewage and Sludge in Softscaping and Biogas Production. Sustainability. 2022; 14(11):6675. https://doi.org/10.3390/su14116675

Chicago/Turabian StyleKonbr, Usama, Walid Bayoumi, Mohamed N. Ali, and Ahmed Salah Eldin Shiba. 2022. "Sustainability of Egyptian Cities through Utilizing Sewage and Sludge in Softscaping and Biogas Production" Sustainability 14, no. 11: 6675. https://doi.org/10.3390/su14116675

APA StyleKonbr, U., Bayoumi, W., Ali, M. N., & Shiba, A. S. E. (2022). Sustainability of Egyptian Cities through Utilizing Sewage and Sludge in Softscaping and Biogas Production. Sustainability, 14(11), 6675. https://doi.org/10.3390/su14116675