Inventory Models in a Sustainable Supply Chain: A Bibliometric Analysis

Abstract

:1. Introduction

2. Materials and Methods

3. Results

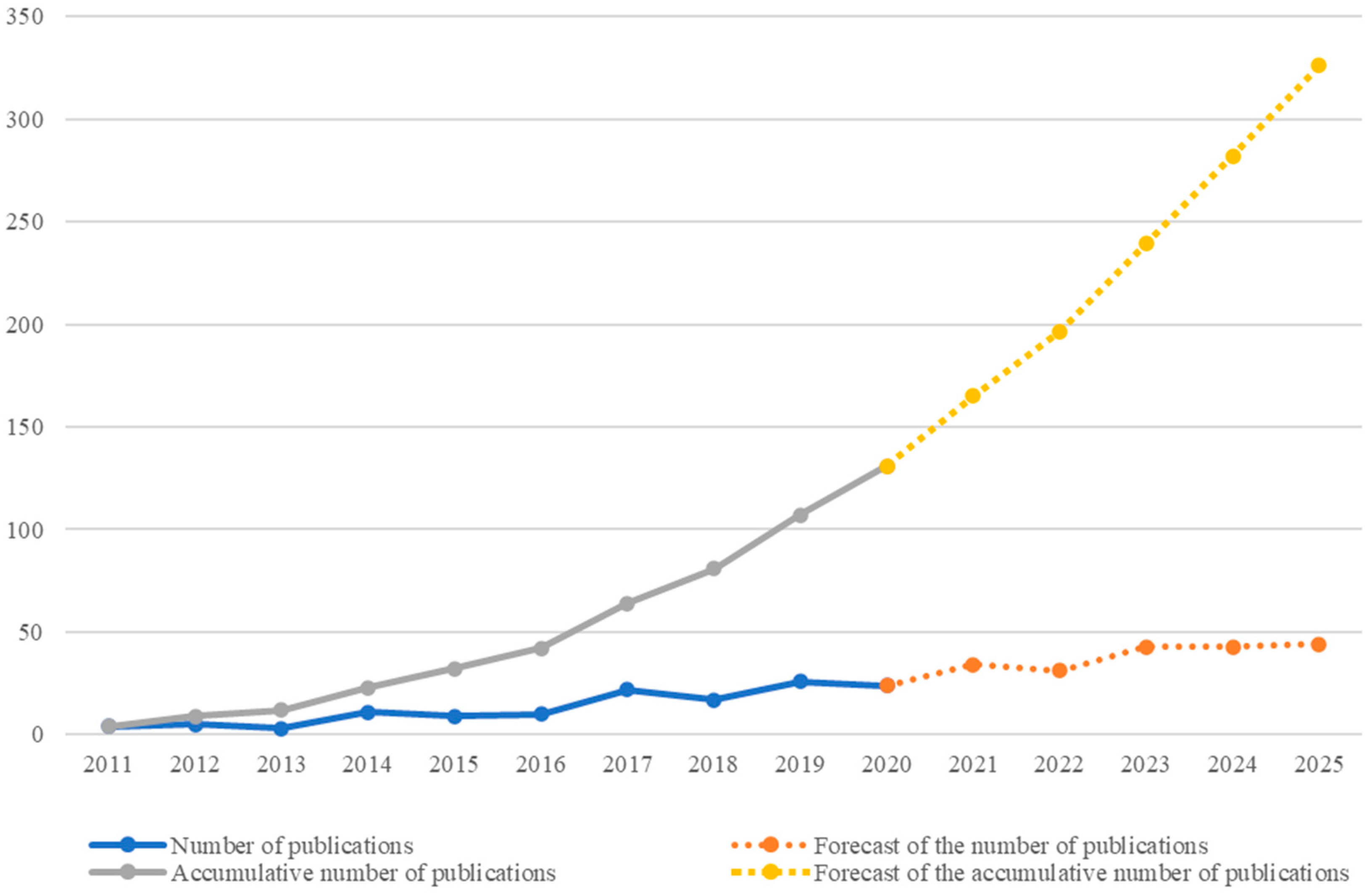

3.1. Publications by Year

3.2. Journals

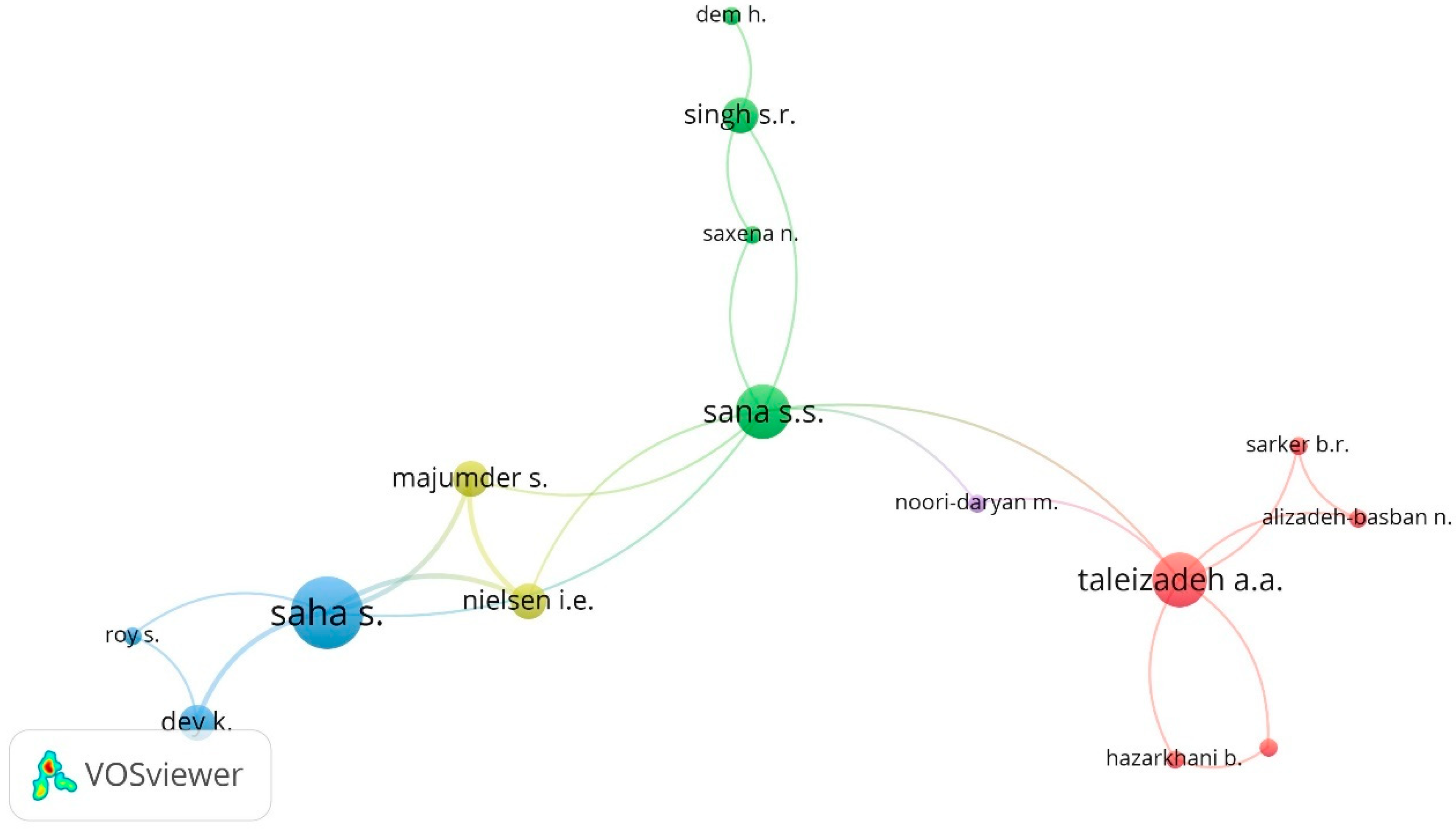

3.3. Authors

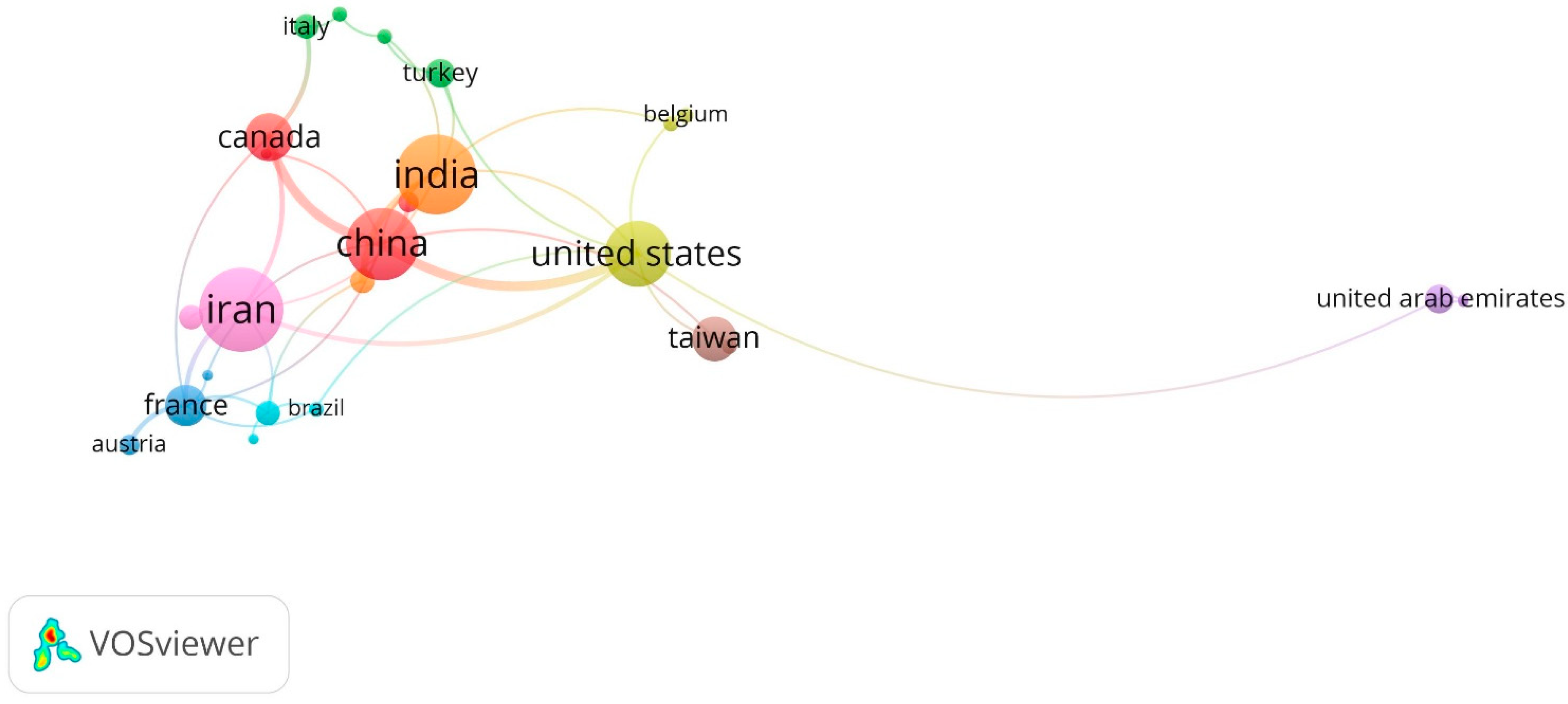

3.4. Countries, Institutions, Organizations

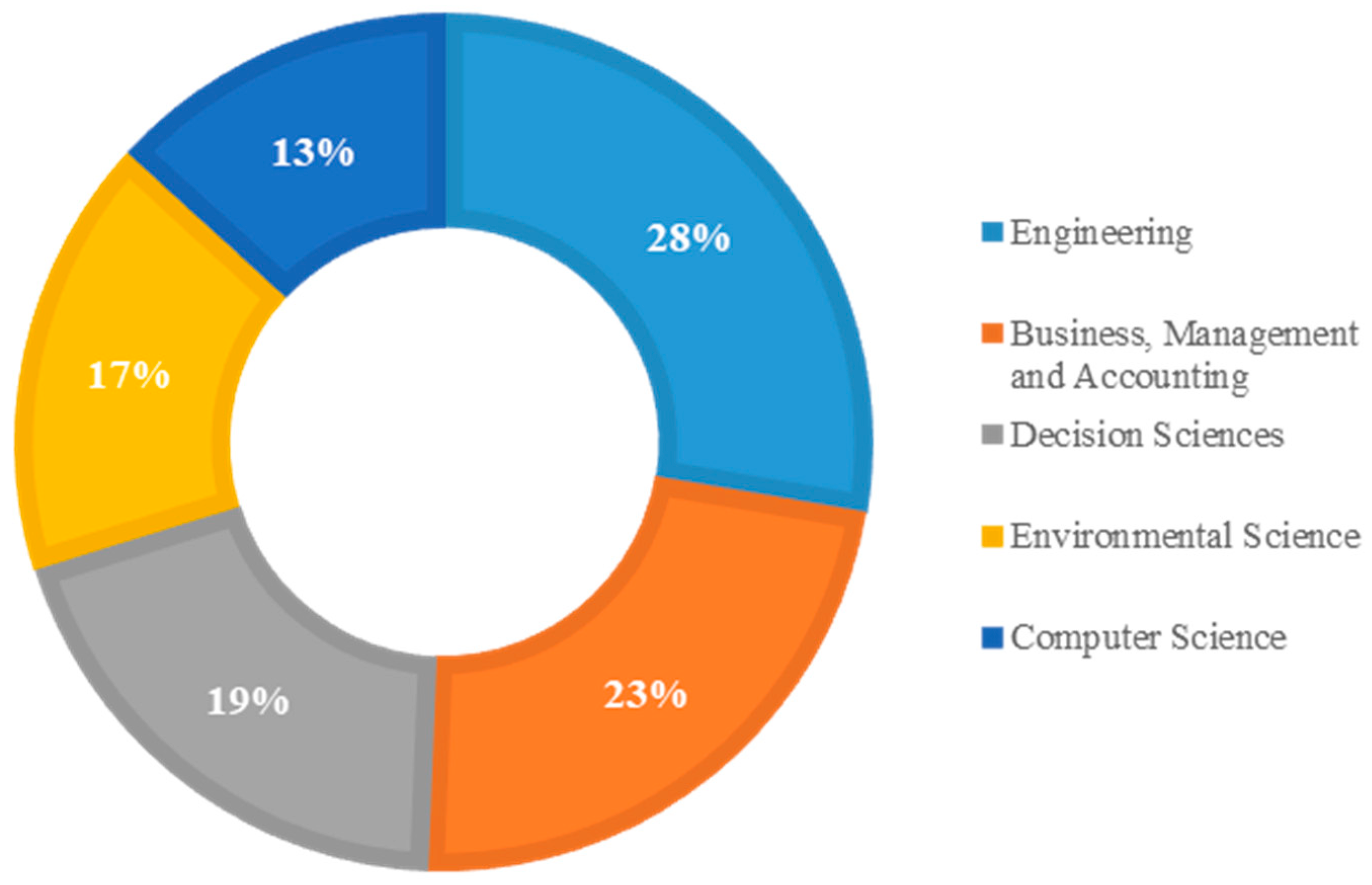

3.5. Analysis of Subject Categories

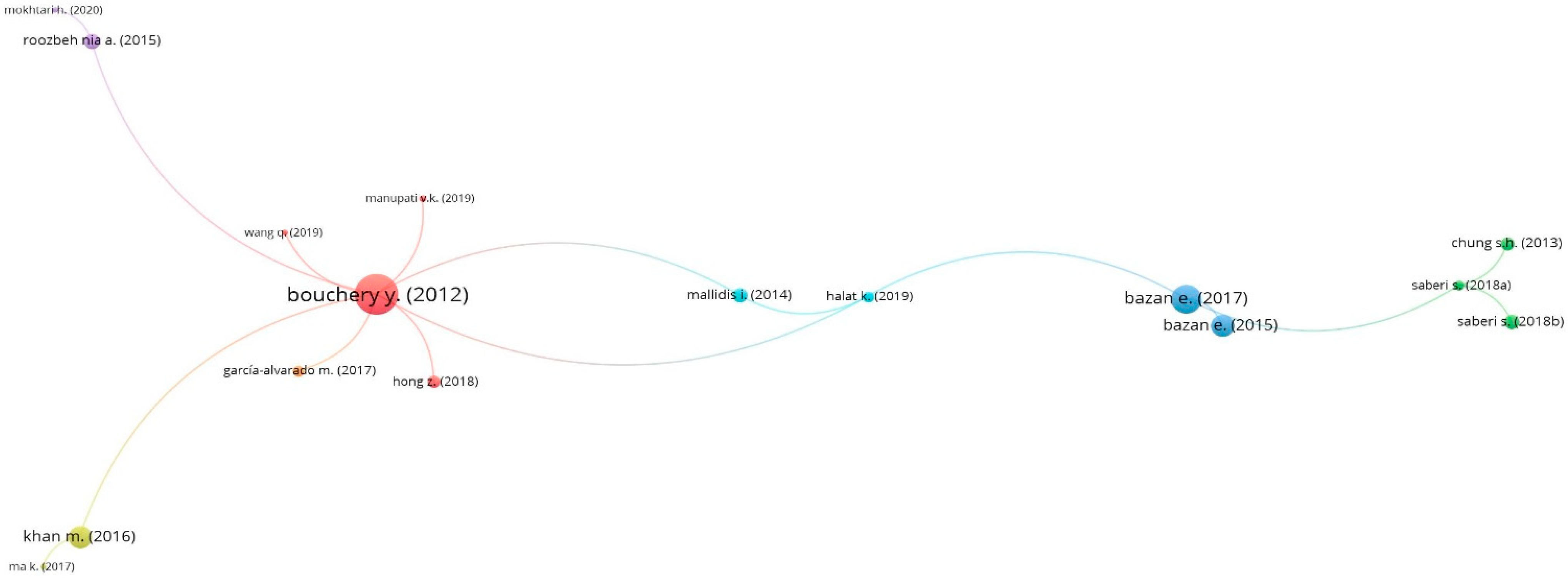

3.6. Analysis of Citations

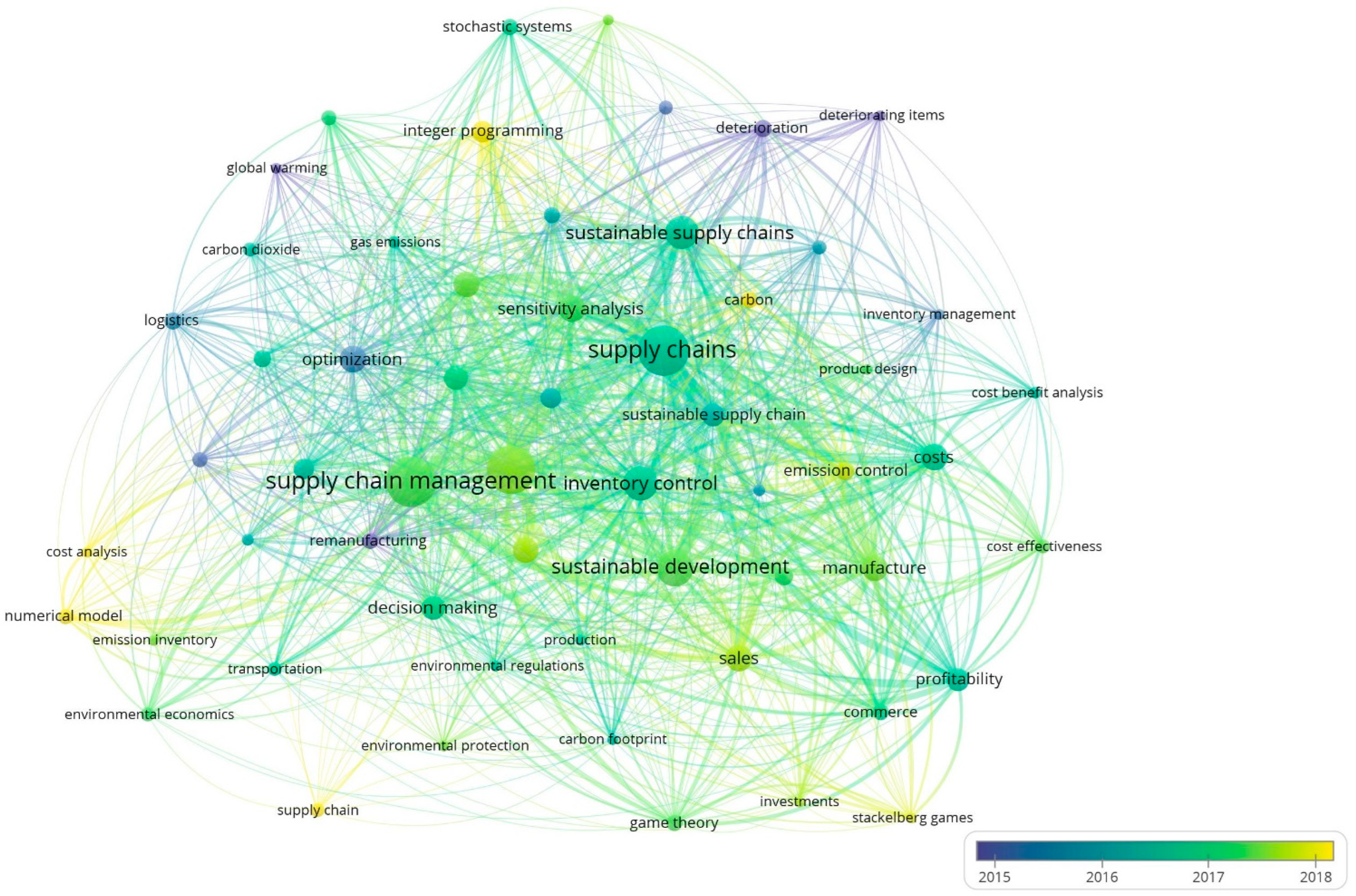

3.7. Term Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, B.; Pan, S.-Y.; Ke, R.-Y.; Wang, K.; Wei, Y.-M. An overview of climate change vulnerability: A bibliometric analysis based on Web of Science database. Nat. Hazards 2014, 74, 1649–1666. [Google Scholar] [CrossRef]

- Argumedo-García, M.; Salas-Navarro, K.; Acevedo-Chedid, J.; Ospina-Mateus, H. Bibliometric Analysis of the Potential of Technologies in the Humanitarian Supply Chain. J. Open Innov. Technol. Mark. Complex. 2021, 7, 232. [Google Scholar] [CrossRef]

- Navarro, K.S.; Chedid, J.A.; Florez, W.F.; Mateus, H.O.; Cárdenas-Barrón, L.E.; Sana, S.S. A collaborative EPQ inventory model for a three-echelon supply chain with multiple products considering the effect of marketing effort on demand. J. Ind. Manag. Optim. 2020, 16, 1613. [Google Scholar] [CrossRef]

- Ansari, Z.N.; Kant, R. Exploring the framework development status for sustainability in supply chain management: A systematic literature synthesis and future research directions. Bus. Strategy Environ. 2017, 26, 873–892. [Google Scholar] [CrossRef]

- Sarkar, B.; Ahmed, W.; Choi, S.-B.; Tayyab, M. Sustainable inventory management for environmental impact through partial backordering and multi-trade-credit-period. Sustainability 2018, 10, 4761. [Google Scholar] [CrossRef] [Green Version]

- Chibeles-Martins, N.; Pinto-Varela, T.; Barbosa-Póvoa, A.P.; Novais, A.Q. A multi-objective meta-heuristic approach for the design and planning of green supply chains-MBSA. Expert Syst. Appl. 2016, 47, 71–84. [Google Scholar] [CrossRef]

- Wang, X.; Cai, H.; Florig, H.K. Energy-saving implications from supply chain improvement: An exploratory study on China’s consumer goods retail system. Energy Policy 2016, 95, 411–420. [Google Scholar] [CrossRef]

- Nikolopoulou, A.; Ierapetritou, M.G. Optimal design of sustainable chemical processes and supply chains: A review. Comput. Chem. Eng. 2012, 44, 94–103. [Google Scholar] [CrossRef]

- Brandenburg, M.; Govindan, K.; Sarkis, J.; Seuring, S. Quantitative models for sustainable supply chain management: Developments and directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar]

- Pahl, J.; Voß, S. Integrating deterioration and lifetime constraints in production and supply chain planning: A survey. Eur. J. Oper. Res. 2014, 238, 654–674. [Google Scholar] [CrossRef]

- Duque-Uribe, V.; Sarache, W.; Gutiérrez, E.V. Sustainable supply chain management practices and sustainable performance in hospitals: A systematic review and integrative framework. Sustainability 2019, 11, 5949. [Google Scholar] [CrossRef] [Green Version]

- Wen, D.; Sun, X.; Liu, Y. Bibliometric analysis of supplier management: The theme and cluster perspectives. Sustainability 2020, 12, 2572. [Google Scholar] [CrossRef] [Green Version]

- Tang, Z.; Liu, X.; Wang, Y. Integrated optimization of sustainable transportation and inventory with multiplayer dynamic game under carbon tax policy. Math. Probl. Eng. 2020, 2020, 4948383. [Google Scholar] [CrossRef]

- Ghosh, A.; Jha, J.; Sarmah, S. Production-inventory models considering different carbon policies: A review. Int. J. Product. Qual. Manag. 2020, 30, 1–27. [Google Scholar] [CrossRef]

- Becerra, P.; Mula, J.; Sanchis, R. Green supply chain quantitative models for sustainable inventory management: A review. J. Clean. Prod. 2021, 328, 129544. [Google Scholar] [CrossRef]

- Pattnaik, S.; Nayak, M.M.; Abbate, S.; Centobelli, P. Recent trends in sustainable inventory models: A literature review. Sustainability 2021, 13, 11756. [Google Scholar] [CrossRef]

- Zhang, C.-T.; Liu, L.-P. Research on coordination mechanism in three-level green supply chain under non-cooperative game. Appl. Math. Model. 2013, 37, 3369–3379. [Google Scholar] [CrossRef]

- Sazvar, Z.; Mirzapour Al-E-Hashem, S.; Baboli, A.; Jokar, M.A. A bi-objective stochastic programming model for a centralized green supply chain with deteriorating products. Int. J. Prod. Econ. 2014, 150, 140–154. [Google Scholar] [CrossRef]

- Panja, S.; Mondal, S.K. Analyzing a four-layer green supply chain imperfect production inventory model for green products under type-2 fuzzy credit period. Comput. Ind. Eng. 2019, 129, 435–453. [Google Scholar] [CrossRef]

- Chung, C.-J.; Wee, H.-M. Short life-cycle deteriorating product remanufacturing in a green supply chain inventory control system. Int. J. Prod. Econ. 2011, 129, 195–203. [Google Scholar] [CrossRef]

- Wee, H.-M.; Lee, M.-C.; Jonas, C.; Wang, C.E. Optimal replenishment policy for a deteriorating green product: Life cycle costing analysis. Int. J. Prod. Econ. 2011, 133, 603–611. [Google Scholar] [CrossRef]

- Lin, C.C.; Lin, C.W. Defective item inventory model with remanufacturing or replenishing in an integrated supply chain. Int. J. Integr. Supply Manag. 2011, 6, 254–269. [Google Scholar] [CrossRef]

- Widyadana, G.A.; Wee, H.M. An economic production quantity model for deteriorating items with multiple production setups and rework. Int. J. Prod. Econ. 2012, 138, 62–67. [Google Scholar] [CrossRef]

- Karimi, M.; Niknamfar, A.H.; Pasandideh, S.H.R. Two-stage single period inventory management for a manufacturing vendor under green-supplier supply chain. Int. J. Syst. Assur. Eng. Manag. 2017, 8, 704–718. [Google Scholar] [CrossRef]

- Khatua, D.; Roymahapatra, G.; Maity, K. A green supply chain production inventory model with uncertain holding cost. Int. J. Process Manag. Benchmarking 2017, 7, 277–304. [Google Scholar] [CrossRef]

- Bai, Q.; Chen, M.; Xu, L. Revenue and promotional cost-sharing contract versus two-part tariff contract in coordinating sustainable supply chain systems with deteriorating items. Int. J. Prod. Econ. 2017, 187, 85–101. [Google Scholar] [CrossRef]

- Yang, S.; Xiao, Y.; Zheng, Y.; Liu, Y. The green supply chain design and marketing strategy for perishable food based on temperature control. Sustainability 2017, 9, 1511. [Google Scholar] [CrossRef] [Green Version]

- Saxena, N.; Singh, S.R.; Sana, S.S. A green supply chain model of vendor and buyer for remanufacturing. RAIRO-Oper. Res. 2017, 51, 1133–1150. [Google Scholar] [CrossRef]

- Taleizadeh, A.A.; Alizadeh-Basban, N.; Sarker, B.R. Coordinated contracts in a two-echelon green supply chain considering pricing strategy. Comput. Ind. Eng. 2018, 124, 249–275. [Google Scholar] [CrossRef]

- Rani, S.; Ali, R.; Agarwal, A. Fuzzy inventory model for deteriorating items in a green supply chain with carbon concerned demand. Opsearch 2019, 56, 91–122. [Google Scholar] [CrossRef]

- García-Alvarado, M.; Paquet, M.; Chaabane, A.; Amodeo, L. Inventory management under joint product recovery and cap-and-trade constraints. J. Clean. Prod. 2017, 167, 1499–1517. [Google Scholar] [CrossRef] [Green Version]

- Martí, J.M.C.; Tancrez, J.-S.; Seifert, R.W. Carbon footprint and responsiveness trade-offs in supply chain network design. Int. J. Prod. Econ. 2015, 166, 129–142. [Google Scholar] [CrossRef]

- Sepehri, M.; Sazvar, Z. Multi-objective sustainable supply chain with deteriorating products and transportation options under uncertain demand and backorder. Sci. Iran. 2016, 23, 2977–2994. [Google Scholar] [CrossRef] [Green Version]

- Kang, K.; Hong, K.-s.; Kim, K.H.; Lee, C. Shipment consolidation policy under uncertainty of customer order for sustainable supply chain management. Sustainability 2017, 9, 1675. [Google Scholar] [CrossRef] [Green Version]

- Gautam, P.; Kishore, A.; Khanna, A.; Jaggi, C.K. Strategic defect management for a sustainable green supply chain. J. Clean. Prod. 2019, 233, 226–241. [Google Scholar] [CrossRef]

- Lu, X.; Shang, J.; Wu, S.-y.; Hegde, G.G.; Vargas, L.; Zhao, D. Impacts of supplier hubris on inventory decisions and green manufacturing endeavors. Eur. J. Oper. Res. 2015, 245, 121–132. [Google Scholar] [CrossRef]

- Mokhtari, H.; Rezvan, M.T. A single-supplier, multi-buyer, multi-product VMI production-inventory system under partial backordering. Oper. Res. 2020, 20, 37–57. [Google Scholar] [CrossRef]

- Bazan, E.; Jaber, M.Y.; Zanoni, S. Carbon emissions and energy effects on a two-level manufacturer-retailer closed-loop supply chain model with remanufacturing subject to different coordination mechanisms. Int. J. Prod. Econ. 2017, 183, 394–408. [Google Scholar] [CrossRef]

- Halat, K.; Hafezalkotob, A. Modeling carbon regulation policies in inventory decisions of a multi-stage green supply chain: A game theory approach. Comput. Ind. Eng. 2019, 128, 807–830. [Google Scholar] [CrossRef]

- Pan, J.; Chiu, C.-Y.; Wu, K.-S.; Yen, H.-F.; Wang, Y.-W. Sustainable Production–Inventory Model in Technical Cooperation on Investment to Reduce Carbon Emissions. Processes 2020, 8, 1438. [Google Scholar] [CrossRef]

- Taleizadeh, A.A.; Hazarkhani, B.; Moon, I. Joint pricing and inventory decisions with carbon emission considerations, partial backordering and planned discounts. Ann. Oper. Res. 2020, 290, 95–113. [Google Scholar] [CrossRef]

- Khan, M.; Hussain, M.; Saber, H.M. Information sharing in a sustainable supply chain. Int. J. Prod. Econ. 2016, 181, 208–214. [Google Scholar] [CrossRef]

- Cui, L.; Deng, J.; Liu, F.; Zhang, Y.; Xu, M. Investigation of RFID investment in a single retailer two-supplier supply chain with random demand to decrease inventory inaccuracy. J. Clean. Prod. 2017, 142, 2028–2044. [Google Scholar] [CrossRef]

- Ospina-Mateus, H.; Jiménez, L.A.Q.; Lopez-Valdes, F.J.; Salas-Navarro, K. Bibliometric analysis in motorcycle accident research: A global overview. Scientometrics 2019, 121, 793–815. [Google Scholar] [CrossRef]

- Reyes, J.; Solano-Charris, E.; Montoya-Torres, J. The storage location assignment problem: A literature review. Int. J. Ind. Eng. Comput. 2019, 10, 199–224. [Google Scholar] [CrossRef]

- Meza-Peralta, K.; Gonzalez-Feliu, J.; Montoya-Torres, J.R.; Khodadad-Saryazdi, A. A unified typology of urban logistics spaces as interfaces for freight transport: A Systematic Literature Review. Supply Chain. Forum Int. J. 2020, 21, 274–289. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Yu, Z.; Golpira, H.; Sharif, A.; Mardani, A. A state-of-the-art review and meta-analysis on sustainable supply chain management: Future research directions. J. Clean. Prod. 2021, 278, 123357. [Google Scholar] [CrossRef]

- Martínez, J.M.G.; Carracedo, P.; Comas, D.G.; Siemens, C.H. An analysis of the blockchain and COVID-19 research landscape using a bibliometric study. Sustain. Technol. Entrep. 2022, 1, 100006. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Guerrero-Bote, V.P.; Moya-Anegón, F. A further step forward in measuring journals’ scientific prestige: The SJR2 indicator. J. Informetr. 2012, 6, 674–688. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Yang, W.; Yuan, Y.; Zhou, R. An integrated carbon policy-based interactive strategy for carbon reduction and economic development in a construction material supply chain. Sustainability 2017, 9, 2107. [Google Scholar] [CrossRef] [Green Version]

- Ma, K.; Wang, L.; Chen, Y. A collaborative cloud service platform for realizing sustainable make-to-order apparel supply chain. Sustainability 2018, 10, 11. [Google Scholar] [CrossRef] [Green Version]

- Lee, A.H.; Kang, H.-Y.; Ye, S.-J.; Wu, W.-Y. An integrated approach for sustainable supply chain management with replenishment, transportation, and production decisions. Sustainability 2018, 10, 3887. [Google Scholar] [CrossRef] [Green Version]

- Bouchery, Y.; Ghaffari, A.; Jemai, Z.; Dallery, Y. Including sustainability criteria into inventory models. Eur. J. Oper. Res. 2012, 222, 229–240. [Google Scholar] [CrossRef] [Green Version]

- Hoen, K.; Tan, T.; Fransoo, J.C.; van Houtum, G.-J. Effect of carbon emission regulations on transport mode selection under stochastic demand. Flex. Serv. Manuf. J. 2014, 26, 170–195. [Google Scholar] [CrossRef] [Green Version]

- Abdallah, T.; Diabat, A.; Simchi-Levi, D. Sustainable supply chain design: A closed-loop formulation and sensitivity analysis. Prod. Plan. Control. 2012, 23, 120–133. [Google Scholar] [CrossRef]

- Bazan, E.; Jaber, M.Y.; El Saadany, A.M. Carbon emissions and energy effects on manufacturing–remanufacturing inventory models. Comput. Ind. Eng. 2015, 88, 307–316. [Google Scholar] [CrossRef]

- Zhao, Y.; Choi, S.; Wang, X.; Qiao, A.; Wang, S. Production and Low-carbon Investment Analysis in Make-to-stock Supply Chain. Eng. Lett. 2017, 25, 1–10. [Google Scholar]

- Nielsen, I.E.; Majumder, S.; Sana, S.S.; Saha, S. Comparative analysis of government incentives and game structures on single and two-period green supply chain. J. Clean. Prod. 2019, 235, 1371–1398. [Google Scholar] [CrossRef]

- Manupati, V.K.; Jedidah, S.J.; Gupta, S.; Bhandari, A.; Ramkumar, M. Optimization of a multi-echelon sustainable production-distribution supply chain system with lead time consideration under carbon emission policies. Comput. Ind. Eng. 2019, 135, 1312–1323. [Google Scholar] [CrossRef]

- Rout, C.; Paul, A.; Kumar, R.S.; Chakraborty, D.; Goswami, A. Cooperative sustainable supply chain for deteriorating item and imperfect production under different carbon emission regulations. J. Clean. Prod. 2020, 272, 122170. [Google Scholar] [CrossRef]

- Diabat, A.; Al-Salem, M. An integrated supply chain problem with environmental considerations. Int. J. Prod. Econ. 2015, 164, 330–338. [Google Scholar] [CrossRef]

- Hong, Z.; Dai, W.; Luh, H.; Yang, C. Optimal configuration of a green product supply chain with guaranteed service time and emission constraints. Eur. J. Oper. Res. 2018, 266, 663–677. [Google Scholar] [CrossRef]

- Lee, C.; Realff, M.; Ammons, J. Integration of channel decisions in a decentralized reverse production system with retailer collection under deterministic non-stationary demands. Adv. Eng. Inform. 2011, 25, 88–102. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, J.; Zhao, N.; Zhu, Q. Inventory control and supply chain management: A green growth perspective. Resour. Conserv. Recycl. 2019, 145, 78–85. [Google Scholar] [CrossRef]

- Lieckens, K.T.; Colen, P.J.; Lambrecht, M.R. Network and contract optimization for maintenance services with remanufacturing. Comput. Oper. Res. 2015, 54, 232–244. [Google Scholar] [CrossRef]

- Baek, S.H.; Kim, J.S. Efficient Algorithms for a Large-Scale Supplier Selection and Order Allocation Problem Considering Carbon Emissions and Quantity Discounts. Mathematics 2020, 8, 1659. [Google Scholar] [CrossRef]

- Sadeghi Rad, R.; Nahavandi, N. A novel multi-objective optimization model for integrated problem of green closed loop supply chain network design and quantity discount. J. Clean. Prod. 2018, 196, 1549–1565. [Google Scholar] [CrossRef]

- Jabarzadeh, Y.; Yamchi, H.R.; Kumar, V.; Ghaffarinasab, N. A multi-objective mixed-integer linear model for sustainable fruit closed-loop supply chain network. Manag. Environ. Qual. Int. J. 2020, 31, 1351–1373. [Google Scholar] [CrossRef]

- Garcia-Alvarado, M.; Paquet, M.; Chaabane, A. Joint strategic and tactical planning under the dynamics of a cap-and-trade scheme. IFAC-Pap. 2016, 49, 622–627. [Google Scholar] [CrossRef]

- Tang, J.; Ji, S.; Jiang, L. The design of a sustainable location-routing-inventory model considering consumer environmental behavior. Sustainability 2016, 8, 211. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Fei, W.; Zhou, E.; Gajpal, Y.; Chen, X. The Impact of Lead Time Uncertainty on Supply Chain Performance Considering Carbon Cost. Sustainability 2019, 11, 6457. [Google Scholar] [CrossRef] [Green Version]

- Treitl, S.; Nolz, P.C.; Jammernegg, W. Incorporating environmental aspects in an inventory routing problem. A case study from the petrochemical industry. Flex. Serv. Manuf. J. 2014, 26, 143–169. [Google Scholar] [CrossRef]

- Wanke, P.; Correa, H.; Jacob, J.; Santos, T. Including carbon emissions in the planning of logistic networks: A Brazilian case. Int. J. Shipp. Transp. Logist. 2015, 7, 655–675. [Google Scholar] [CrossRef]

- Zhao, Q.; Wen, Z.; Toppinen, A. Constructing the embodied Carbon flows and emissions landscape from the perspective of supply chain. Sustainability 2018, 10, 3865. [Google Scholar] [CrossRef] [Green Version]

- Nolz, P.C.; Absi, N.; Feillet, D. A stochastic inventory routing problem for infectious medical waste collection. Networks 2014, 63, 82–95. [Google Scholar] [CrossRef]

- Zheng, M.; Li, W.; Liu, Y.; Liu, X. A Lagrangian heuristic algorithm for sustainable supply chain network considering CO2 emission. J. Clean. Prod. 2020, 270, 122409. [Google Scholar] [CrossRef]

- Ali, S.S.; Paksoy, T.; Torğul, B.; Kaur, R. Reverse logistics optimization of an industrial air conditioner manufacturing company for designing sustainable supply chain: A fuzzy hybrid multi-criteria decision-making approach. Wirel. Netw. 2020, 26, 5759–5782. [Google Scholar] [CrossRef]

- Shaik, J.H.; Reddy, A.; Chowdary, N.; Jahnavi, Y. Is financial and sustainability performance associated with stock performance? A panel data analysis of bse telecom index companies. Int. J. Civ. Eng. Technol. 2018, 9, 256–263. [Google Scholar]

- Niranjan, T.; Parthiban, P.; Sundaram, K.; Jeyaganesan, P.N. Designing a omnichannel closed loop green supply chain network adapting preferences of rational customers. Sādhanā 2019, 44, 60. [Google Scholar] [CrossRef] [Green Version]

- Gholipour, S.; Ashoftehfard, A.; Mina, H. Green supply chain network design considering inventory-location-routing problem: A fuzzy solution approach. Int. J. Logist. Syst. Manag. 2020, 35, 436–452. [Google Scholar] [CrossRef]

- Haftor, D.M.; Climent, R.C.; Lundström, J.E. How machine learning activates data network effects in business models: Theory advancement through an industrial case of promoting ecological sustainability. J. Bus. Res. 2021, 131, 196–205. [Google Scholar] [CrossRef]

- United Nations. RES/70/1. Transforming Our world: The 2030 Agenda for Sustainable Development. Available online: http://www.un.org/ga/search/view_doc.asp?symbol=A/RES/70/1&Lang=E (accessed on 2 July 2021).

| Groups | Search Items |

|---|---|

| Inventory models | “Inventory model” or “inventory” or “EPQ model” or “EOQ model” or “emission inventory” or “inventory control” or “stock control” or “stock” or “stock accuracy” |

| Sustainable supply chain | “Sustainable supply chain” or “green supply chain” or “green supplier” or “sustainable performance” or “sustainable logistics” or “Sustainable Supply Chain Management” |

| Search equation | TITLE-ABS-KEY (“inventory model” or “inventory” or “EPQ model” or “EOQ model” or “emission inventory” or “inventory control” or “stock control” or “stock” or “stock accuracy”) and TITLE-ABS-KEY (“sustainable supply chain” or “green supply chain” or “green supplier” or “sustainable performance” or “sustainable logistics” or “Sustainable Supply Chain Management”)) and (exclude (pubyear, 2021)) |

| No. | Journal | Publisher | No. of Publications | SJR- 2020 | H-Index 2020 | Subject Area and Category |

|---|---|---|---|---|---|---|

| 1 | Sustainability | Multidisciplinary Digital Publishing Institute (MDPI) | 15 | 0.612 | 85 | Energy Engineering and Power Technology (Q2), Renewable Energy, Sustainability, and the Environment (Q2), Environmental Science (miscellaneous) (Q2), Management, Monitoring, Policy and Law (Q2), Geography, Planning and Development (Q1). |

| 2 | Journal of Cleaner Production | Elsevier | 13 | 1.937 | 200 | Environmental Science (miscellaneous) (Q1), Industrial and Manufacturing Engineering (Q1), Renewable Energy, Sustainability, and the Environment (Q1), Strategy and Management (Q1). |

| 3 | International Journal of Production Economics | Elsevier | 11 | 2.406 | 185 | Business, Management, and Accounting (miscellaneous) (Q1), Economics and Econometrics (Q1), Industrial and Manufacturing Engineering (Q1), Management Science and Operations Research (Q1). |

| 4 | Computers and Industrial Engineering | Elsevier | 7 | 1.315 | 128 | Computer Science (miscellaneous) (Q1), Engineering (miscellaneous) (Q1). |

| 5 | European Journal of Operational Research | Elsevier | 6 | 2.161 | 260 | Computer Science (miscellaneous) (Q1), Information Systems and Management (Q1), Management Science and Operations Research (Q1), Modeling and Simulation (Q1). |

| 6 | IFAC-Papers Online | IFAC Secretariat | 4 | 0.308 | 72 | Control and Systems Engineering (Q3). |

| 7 | Advances in Mathematics Scientific Journal | Researchpublication | 3 | 0.060 | 5 | Mathematics (miscellaneous) (NO Q). |

| 8 | International Journal of Production Research | Taylor & Francis | 3 | 1.909 | 142 | Strategy and Management (Q1), Management Science and Operations Research (Q1), Industrial and Manufacturing Engineering (Q1). |

| 9 | Transportation Research Part E Logistics and Transportation Review | Elsevier | 3 | 2.042 | 110 | Business and International Management (Q1), Management Science and Operations Research (Q1), Civil and Structural Engineering (Q1), Transportation (Q1). |

| 10 | Flexible Services and Manufacturing Journal | Springer Nature | 2 | 0.934 | 46 | Management Science and Operations Research (Q1), Industrial and Manufacturing Engineering (Q1). |

| No. | Name of Author | Country of Author | Number of Publications | Number of Publications as the First Author |

|---|---|---|---|---|

| 1 | Saha, S. | Denmark | 4 | 0 |

| 2 | Ajay, S.Y. | India | 3 | 3 |

| 3 | Baboli, A. | France | 3 | 0 |

| 4 | Jaber, M.Y. | Canada | 3 | 0 |

| 5 | Nolz, P.C. | Austria | 3 | 2 |

| 6 | Sana, S.S. | India | 3 | 0 |

| 7 | Sazvar, Z. | Iran | 3 | 2 |

| 8 | Taleizadeh, A.A. | Iran | 3 | 3 |

| 9 | Wee, H.M. | Taiwan | 3 | 1 |

| 10 | Absi, N. | France | 2 | 0 |

| No. | Institutions | Country | Number of Publications |

|---|---|---|---|

| 1 | University of Tehran | Iran | 8 |

| 2 | Islamic Azad University, Qazvin Branch | Iran | 5 |

| 3 | Sharif University of Technology | Iran | 5 |

| 4 | Wirtschaftsuniversität Wien | Austria | 3 |

| 5 | Indian Institute of Technology Kharagpur | India | 3 |

| No. | Funding | Country | Articles |

|---|---|---|---|

| 1 | National Natural Science Foundation of China | China | 15 |

| 2 | Natural Sciences and Engineering Research Council of Canada | Canada | 5 |

| 3 | European Commission | Belgium | 3 |

| 4 | Fundamental Research Funds for the Central Universities | China | 2 |

| 5 | Ministry of Human Resource Development | Saudi Arabia | 2 |

| 6 | Ministry of Science and Technology, Taiwan | Taiwan | 2 |

| 7 | National Office for Philosophy and Social Sciences | China | 2 |

| 8 | National Research Foundation of Korea | South Korea | 2 |

| 9 | Seventh Framework Programme | United Kingdom | 2 |

| 10 | University of Tehran | Tehran | 2 |

| No. | Citation | Title | Times Cited | Average Citations per Year | Institution | Journal | SJR-2020 | Country (1st Author) | Main Topic (Subject Area and Category) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Bouchery, Ghaffari, Jemai and Dallery [54] | Including sustainability criteria into inventory models. | 209 | 26.13 | Ecole Centrale Paris | European Journal of Operational Research | 2.161 | France | Mathematics: Modeling and Simulation, Decision Sciences: Management Science and Operations Research, Computer Science: General Computer Science, Decision Sciences: Information Systems and Management. |

| 2 | Hoen, Tan, Fransoo and van Houtum [55] | Effect of carbon emission regulations on transport mode selection under stochastic demand. | 150 | 18.75 | Eindhoven University of Technology | Flexible Services and Manufacturing Journal | 0.934 | Netherlands | Engineering: Industrial and Manufacturing Engineering, Decision Sciences: Management Science and Operations Research. |

| 3 | Zhang and Liu [17] | Research on coordination mechanism in three-level green supply chain under non-cooperative game. | 118 | 14.75 | Anhui Agricultural University | Applied Mathematical Modelling | 1.011 | China | Mathematics: Applied Mathematics, Mathematics: Modeling and Simulation. |

| 4 | Chung and Wee [20] | Short life-cycle deteriorating product remanufacturing in a green supply chain inventory control system. | 105 | 0.00 | Chung Yuan Christian University | International Journal of Production Economics | 2.406 | Taiwan | Economics, Econometrics, and Finance: Economics and Econometrics, Decision Sciences: Management Science and Operations Research, Business, Management, and Accounting: General Business, Management, and Accounting, Engineering: Industrial and Manufacturing Engineering. |

| 5 | Bazan, Jaber and Zanoni [38] | Carbon emissions and energy effects on a two-level manufacturer retailer closed-loop supply chain model with remanufacturing subject to different coordination mechanisms. | 104 | 26.00 | Ryerson University | International Journal of Production Economics | 2.406 | Canada | Economics, Econometrics, and Finance: Economics and Econometrics, Decision Sciences: Management Science and Operations Research, Business, Management, and Accounting: General Business, Management, and Accounting, Engineering: Industrial and Manufacturing Engineering. |

| 6 | Abdallah et al. [56] | Sustainable supply chain design: a closed-loop formulation and sensitivity analysis. | 95 | 11.88 | Masdar Institute of Science and Technology | Production Planning and Control | 1.331 | United Arab Emirates | Business, Management and Accounting: Strategy and Management, Decision Sciences: Management Science and Operations Research, Engineering: Industrial and Manufacturing Engineering, Computer Science: Computer Science Applications. |

| 7 | Pahl and Voß [10] | Integrating deterioration and lifetime constraints in production and supply chain planning: a survey. | 79 | 11.29 | University of Hamburg | European Journal of Operational Research | 2.161 | Germany | Mathematics: Modeling and Simulation, Decision Sciences: Management Science and Operations Research, Computer Science: General Computer Science, Decision Sciences: Information Systems and Management. |

| 8 | Bai, Chen and Xu [26] | Revenue and promotional cost-sharing contract versus two-part tariff contract in coordinating sustainable supply chain systems with deteriorating items. | 75 | 18.75 | Concordia University | International Journal of Production Economics | 2.406 | Canada | Economics, Econometrics and Finance: Economics and Econometrics, Decision Sciences: Management Science and Operations Research, Business, Management and Accounting: General Business, Management and Accounting, Engineering: Industrial and Manufacturing Engineering. |

| 9 | Bazan et al. [57] | Carbon emissions and energy effects on manufacturing–remanufacturing inventory models. | 68 | 11.33 | Ryerson University | Computers and Industrial Engineering | 1.315 | Canada | Engineering: General Engineering, Computer Science: General Computer Science. |

| 10 | Nikolopoulou and Ierapetritou [8] | Optimal design of sustainable chemical processes and supply chains: A review. | 67 | 7.44 | Rutgers University | Computers and Chemical Engineering | 1.017 | United States | Chemical Engineering: General Chemical Engineering, Computer Science: Computer Science Applications. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salas-Navarro, K.; Serrano-Pájaro, P.; Ospina-Mateus, H.; Zamora-Musa, R. Inventory Models in a Sustainable Supply Chain: A Bibliometric Analysis. Sustainability 2022, 14, 6003. https://doi.org/10.3390/su14106003

Salas-Navarro K, Serrano-Pájaro P, Ospina-Mateus H, Zamora-Musa R. Inventory Models in a Sustainable Supply Chain: A Bibliometric Analysis. Sustainability. 2022; 14(10):6003. https://doi.org/10.3390/su14106003

Chicago/Turabian StyleSalas-Navarro, Katherinne, Paula Serrano-Pájaro, Holman Ospina-Mateus, and Ronald Zamora-Musa. 2022. "Inventory Models in a Sustainable Supply Chain: A Bibliometric Analysis" Sustainability 14, no. 10: 6003. https://doi.org/10.3390/su14106003

APA StyleSalas-Navarro, K., Serrano-Pájaro, P., Ospina-Mateus, H., & Zamora-Musa, R. (2022). Inventory Models in a Sustainable Supply Chain: A Bibliometric Analysis. Sustainability, 14(10), 6003. https://doi.org/10.3390/su14106003