Abstract

The use of mulching in agriculture suppresses the weeds around crop plants, enhances the nutrients status of soil, controls the soil structure and temperature, and reduces soil water evaporation. Excessive use of low-density polyethylene mulches is contributing to the accumulation of high amounts of plastic wastes, an environmental problem for agricultural ecosystems. Fragments of plastic from such wastes can be found in soils, in water resources, and in organisms, including humans. The objective of this work was to study the economic viability of the use of different hydromulches in an artichoke crop. Three blends were prepared by mixing paper pulp (recycled from used paper) and cardboard (from paper mills) with different additives: wheat straw (WS), rice hulls (RH), and substrate used for mushroom cultivation (MS). These were compared with low-density polyethylene (Pe), a treatment without mulching on bare soil where hand weeding was performed (HW), and a treatment without mulching on bare soil where herbicide was applied (H). The results indicate that the use of hydromulch in an artichoke crop represents a good alternative for reducing plastic waste in agriculture. The net profits of the hydromulch treatments (MS, WS, RH) were higher than for HW and H, and slightly lower than for Pe. The most profitable treatment was Pe (€0.69 m−3), followed by RH (€0.59 m−3), WS (€0.58 m−3), MS (€0.47 m−3), HW (€0.36 m−3), and H (€0.32 m−3). A sensitivity analysis showed a probability of negative results of 0.04 in Pe, 0.13 in SM, 0.08 in WS, and 0.07 in RH, so the probability that the grower will make a profit is greater than 0.9 with the use of mulch (except mushroom substrate) or polyethylene.

1. Introduction

One of the great advances with regard to improving agronomic yields in crops in areas where water and the environmental conditions are limiting has been the use of plastic films for mulching [1,2,3]. In the 1950s, plastic mulches began to be used, due to their ability to increase the soil temperature [4]. Soil covers enhance total yields, control soil erosion, and suppress weed growth [1,5,6,7,8]. In addition, mulches, by influencing the temperature and improving the physical structure of the soil, produce a microclimate that improves the productivity in the use of water and fertilizers [9] and modifies the energy balance of the soil [10].

The most used mulching material is low-density polyethylene (LDPe) since, among its physical properties, it exhibits good impact resistance, very good processability, thermal and chemical resistance, flexibility, and impermeability to water, in addition to being a cheap material [6]. However, the use of LDPe provokes serious environmental concerns, because its manufacture requires fossil fuels and, since it is non-biodegradable, it causes a residue problem and has detrimental effects on the ecosystem [11,12,13,14].

Excessive use of LDPe mulches is leading to the accumulation of high amounts of plastic wastes, an environmental problem for agricultural ecosystems. After their use, most of these mulches (around 80%) accumulate in landfills or in natural ecosystems [15]. Pieces of plastic from such wastes can be found in soils, water resources, and organisms, including humans [16,17,18,19,20], with effects on the environment and on human health [21,22,23]. The risks in terrestrial systems are less evident than in aquatic ones, since the waste is either buried or burned; however, in the aquatic environment it floats and travels long distances, or is deposited on the seabed [24].

Recycling rates for mulches are significantly lower than the global plastic recycling rate, and are estimated to be below 30% [25]. Furthermore, the problem is aggravated since the fragments that remain after the use of the mulch are difficult to collect and are of low value [24].

Today, one of the new objectives of many governments is the transition to a more circular economic model, where the value of products, materials, and resources is maintained in the economy for as long as possible, and the generation of waste is minimized, reducing adverse health and environmental impacts [26].

In this respect, the use of low-cost and available organic agricultural residues has been proposed for the production of biodegradable mulch materials [27,28], as a way to make weed management practices cost-effective, labor-efficient, and environmentally sound [29].

Hydromulches have been proposed as an alternative to plastic mulches made of LDPe. Hydromulch can be defined as a mixture of water with some type of lignocellulosic material or polymers, plus other additives suitable for the particular purpose, which is applied not as a film but as a liquid [30].

Hydromulching can be useful for the suppression of weed growth, where mechanical and chemical weeding are very difficult [31,32]. Hydromulches can persist for a long time on the ground, although this depends on environmental factors (temperature and moisture) [33].

In recent years, some studies have been published in relation to the effect of hydromulching on the soil, but very few have dealt with its application in agriculture and the potential benefits for weed control, yield, and sustainability.

The specific aim of this work is to contribute new data to the literature by comparing the economic outcomes of two different forms of artichoke cultivation: with mulch (one plastic and three hydromulches) and without mulch (with and without herbicide). For each of these, the yields of two consecutive years will be valued, according to the market prices, to obtain the income, which will be compared with the operational costs to determine the viability of each alternative. Finally, a sensitivity analysis will determine the variability of the results obtained and the probabilities that the grower will incur losses or not.

2. Materials and Methods

The hydromulches consisted of different mixtures (blends). Recycled paper pulp and paper pinus pulp were used as the basic components and sodium silicate was used as a matrix for the hydromulch samples. To prepare the blends, in addition to paper pulp, the following crop products were used: wheat straw (WH), used mushroom (Agaricus bisporus) substrate (MS), and rice husk (RH). Three random cultivation blocks were established, with five treatments each: two-color low-density Pe (white/black, top/bottom), the three hydromulches (WS, RH, and MS), a treatment without mulching on bare soil where hand weeding was carried out (HW), and a treatment without mulching on bare soil where an herbicide was used (H). Each block comprised 25 plants.

Plants of artichoke (Cynara candunculus var. scolymus L.) cv. Symphony (Nunhens-BASF), grown from seed, were cultivated at the IMIDA agricultural experimental farm, located in Murcia (Spain) (latitude 37°45′ N, longitude 0°59′ W). They were transplanted on 8 August in the first year (2019) and on 1 August in the second (2020), the final harvests taking place on 28 and 16 March, respectively. The crop density was 5000 plants/ha. A standard nutrient solution for artichoke was used, applied through an underground drip irrigation system at a depth of 5 cm, with emitters of 4 L/h. The trials were conducted following the agricultural practices commonly used in commercial artichoke production in this area. Herbicide was applied four times in each of the two years of study, the herbicides employed being Assistan® 40SC, Reglone®, and Lentagam®.

Twelve and 10 harvests were carried out in the first and second years of study, respectively: the artichokes were harvested at their optimum collection time and weighed individually.

2.1. Economic Analysis

A cost–benefit analysis determines the benefit by comparison of the income and the costs of an investment project. As in other works [34], an operational structure representative of southeastern Spain was used. Income was obtained as the product of the weekly yield (for each of the two years analyzed) and the average weekly price. Information on the market prices for artichokes was obtained from CARM [35] and the average market prices from 2000 to 2020 were used, as well as their variability, measured as the standard deviation during said period, for the subsequent sensitivity analysis.

The costs are the averages of the values for the two years studied. The costs per hectare were estimated, separating the structure costs from the annual costs, in line with other studies [36,37]. Among the structure costs, a toolshed (with a useful life of 25 years), an irrigation pumping head (15 years), a localized irrigation network (10 years), a regulating reservoir (30 years), and various auxiliary materials (5 years) were considered. For all these costs, only the annual depreciation was allocated, obtained as the ratio between the acquisition price and the useful life. In addition, the two years of cultivation were considered, so the costs of preparation and planting as well as of the mulching materials and their installation were distributed between the two years. The costs of the mulching materials were obtained using the amount (kg) needed to cover one square meter and the square meters that needed to be covered in one hectare (4600 m2). The annual costs were classified into weeding, herbicides, phytosanitary, fertilizers, irrigation water, etc. With regard to herbicides, where appropriate, 4 treatments were carried out and the amount of herbicide used was measured. Five phytosanitary treatments were carried out each year. The cost of water was €0.24 m−3, based on the average cost of recent years, and 5250 m3 ha−1 were used. This cost is similar to that used in other studies, such as that of García-García et al. [38], who considered a water cost of €0.23 m−3. The cost of water shows great volatility by area [39] and can reach €0.26 m−3 [40]. The harvesting costs were based on the weight (kg) of artichokes collected, considering a cost of €0.13 kg−1. For the fixed personnel expenses, it was considered that one employee can manage 20 ha, while the hourly cost of the operators was established at €7.50 h−1 and that of the tractor at €36 h−1.

2.2. Productivity and Efficiency Analysis

For the analysis of the productivity with regard to the use of water, the water productivity in Euros per cubic meter of water [41,42]) was calculated. Also, the yield, the income per cubic meter, and the net profit per cubic meter were determined. Finally, the maximum price of water that the operation could support without incurring losses—The water viability threshold (WVT)—Was obtained [43,44].

Regarding the employment, the NAJ (number of agricultural jobs) per hectare and per cubic hectometer was calculated. To determine the employment generated, the labor used in different tasks, including the handling of machinery, was calculated. One unit of NAJ corresponds to 1840 h.

The envelopment DEA-CCR model has been used to analyse the efficiency of each technology considering water and labour efficiency as input variables [45]

where Y is the output matrix for the six used technologies (production in kilos and net revenues have been considered), X is the input matrix (considering water and working hours), is the weighted or intensity vector (nx1), , ( is the intensity of unit j) and denotes the punctuation of technical efficiency of unit 0.

The use of the DEA-CCR model for the efficiency analysis presents several limitations, such as the estimated frontier can be influenced by outliers, especially when the number of observations is too small; the model does not give information with regard to the theoretical optimum, and it is difficult to make estimations or to test hypothesis for the estimated parameters.

2.3. Sensitivity Analysis

In order to determine the effect of possible changes in the variables used on the results of this study, the Monte Carlo simulation was used. This methodology is based on the simultaneous change of all the variables that influence the variable under study; in this case, the yield per hectare. In this regard, the Monte Carlo simulation is especially suitable for the study of the effect of different variables on a given variable [46]. This methodology is much more complete than others such as the coefficient of variation used in Smith et al. [47] and Kiwia et al. [48]. For this, the distribution function of each of the variables was estimated and data were generated from this distribution. The generation of 40,000 iterations allowed the results obtained to be studied. In each iteration, the net return for each year was obtained as the difference between income and expenses. Income was considered as the product of the yield and prices. The yield was considered as a normal variable, its mean being the average of both years and with a standard deviation obtained from the experiment itself. For the prices, we proceeded in a similar way, but considering the information from the last 20 years. Regarding the costs, although the overheads were considered fixed, since they were incurred in the first planting and cannot be altered during the rest of the useful life, the annual costs were also considered normal, with the mean values used throughout the text and the standard deviation obtained from the information provided by the various sources. Combined with this analysis, the Value at Risk (VaR) was used to determine the probability that the profit of each alternative (Pe, H, HW, etc.) is positive (or, in general, greater than a previously defined value).

Although the VaR was originally designed for use in financial institutions, its use is currently spreading in other sectors such as agriculture, as can be seen in the work of Manfredo and Leuthold [49] and Brotons et al. [50], who calculated the VaR to quantify the market risk of cattle feeders. In this sense, if we assume that X is a random variable with a cumulative distribution function F (X) and let VaR be a fixed value such that

then VaR is defined as the inverse of the function of the cumulative distribution

So, the VaR is the lowest value of a variable for a certain level of confidence α; that is, the value for which the α% of the possible values of said variable are less than said value, and the (1 − α)% is greater.

The confidence level for which net income is equal to zero (I = 0), is the confidence level for which I = 0 can be obtained as the probability that I is lower or equal to zero.

2.4. Statistical Analysis

For the analysis of the yield and income of each treatment, the Levene test was used for the analysis of the homogeneity of variances. The non-existence of significant differences in the variance (p > 0.05) allowed the application of a one-way ANOVA to determine the existence of significant differences in yield and income among the treatments. When a difference was significant (p < 0.05), the treatment means were separated by Tukey’s honestly significant difference (HSD) multiple-range test, using lowercase letters to indicate significant differences between treatments. The statistical package used was SPSS 25 (Chicago, IL, USA).

3. Results and Discussion

Next, the income and expenses calculated for each of the treatments, the net yield, and the sensitivity analysis are shown.

3.1. Economic Analysis

3.1.1. Yield

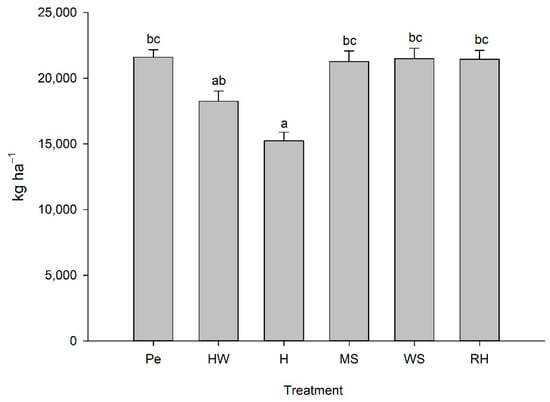

Table 1 and Table 2 show the weekly yield for each production system in each of the years under study. A weekly analysis is normally used for this kind of horticultural crop [51]. As can be seen, the yields were similar in the majority of treatments in the two years, being lower in the treatments without mulching: H (15% lower) and, especially, HW (29% lower). The hydromulches gave yields similar to those of the polythene and so they could be used without a significant yield loss.

Table 1.

Weekly yield of artichokes under different treatments in 2019 (kg ha−1).

Table 2.

Weekly yield of artichokes under different treatments in 2020 (kg ha−1).

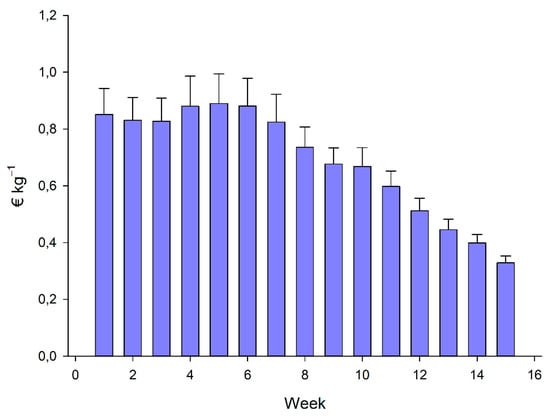

3.1.2. Income

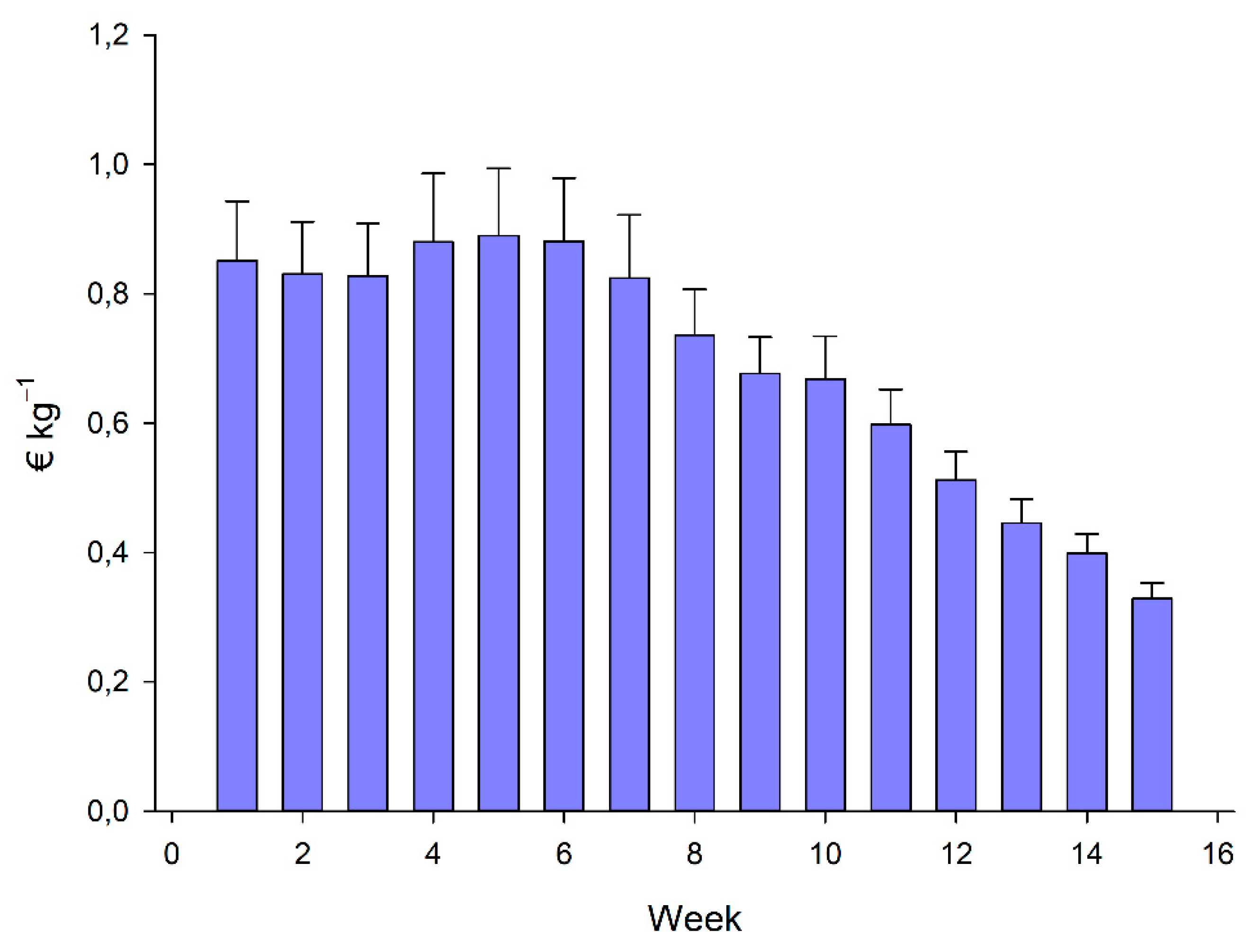

Given their variability throughout each season, a weekly study of the prices was chosen, in line with other work such as that of Heuvelink [51] or López-Marin et al. [34,52,53]. In the first place, the evolution of the artichoke prices [35] in the first weeks of the year, the time when harvesting took place in both years, was analyzed. As can be seen, the prices remained stable or showed a slight increase until mid-February (week 6), when they began to decrease, reaching €0.33 kg−1 in week 15, a price that is 61% lower than that at the beginning of the year (they did not vary greatly in the rest of the season). This decrease was motivated by the increase in supply, or, as Prestamburgo and Saccomandi [54] indicated, the greater the offer, the faster the decline in agricultural prices. This volatility in prices is transmitted along food supply chains, thereby exposing all chain actors to risk and uncertainty [55].

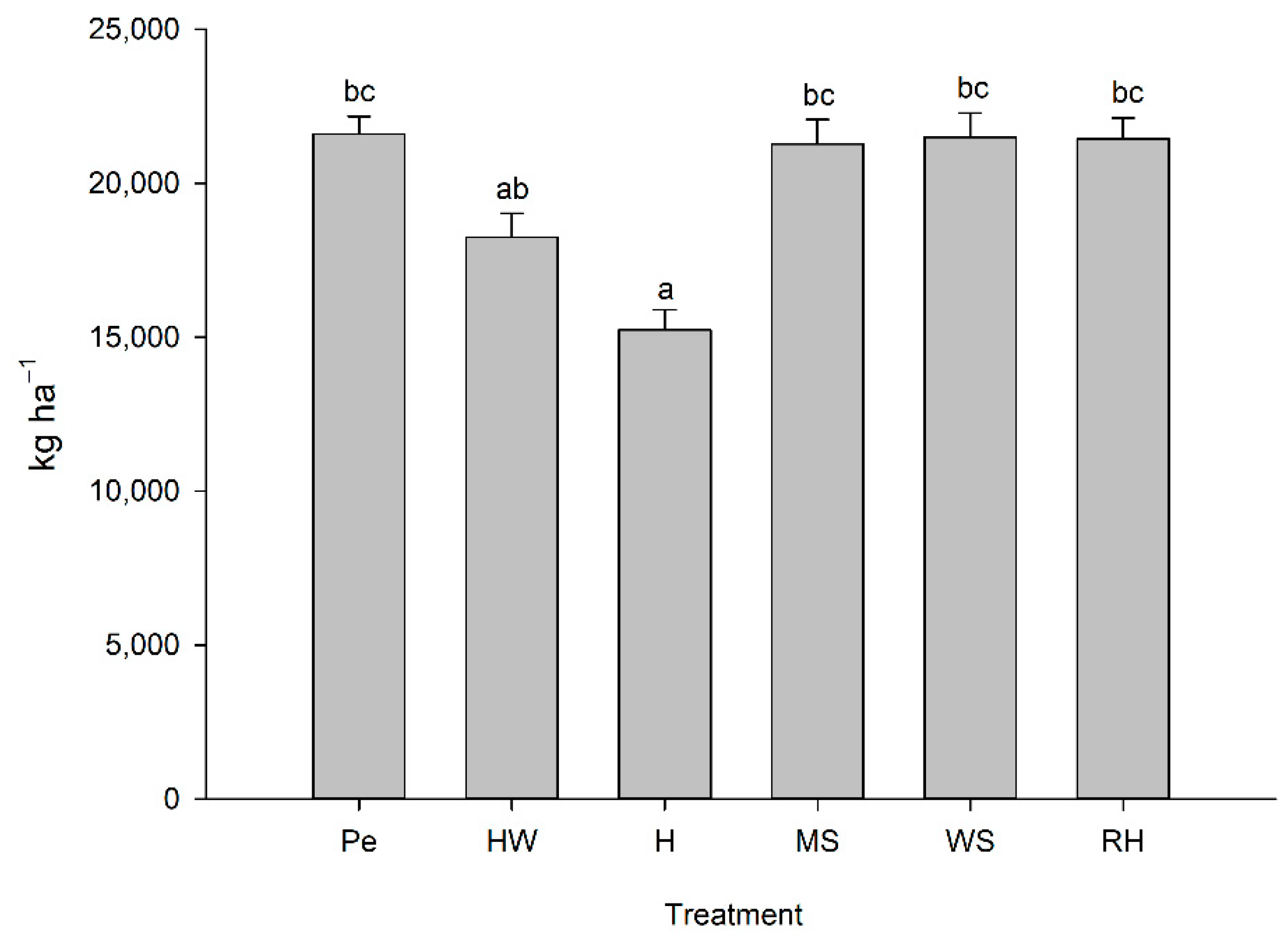

Figure 1 summarizes, by treatment, the annual profit (the average yield of the two years multiplied by the average prices of the period 2000–2020) and the average income, at the prevailing market prices (Figure 2). Regarding the yield, the Levene test was performed to study the homogeneity of the variances and had a significance level of 0.916, indicating that there were no significant differences, and the ANOVA was applied with p = 0.000, showing that there were differences among the treatments. The Tukey HSD test showed that treatments H and HW gave significantly worse yields than the other treatments, which did not differ significantly among themselves. The Levene’s test was carried out for income and showed that there were no differences among the variances, with a significance level of 0.738. From the ANOVA, it was concluded with p = 0.000 that there were differences among the treatments. The Tukey HSD test showed, as with the yield, that the H and HW treatments were clearly inferior to the rest regarding the income. This confirms that the temporal variability in the yield and price did not offset the differences in yield.

Figure 1.

Yield (mean ± SE) by treatment. Values with different letters differ significantly at the 95% level, according to Tukey’s HSD test. Pe: polyethylene, HW: hand weeding, H: herbicide, MS: substrate used for mushroom cultivation, WS: wheat straw, RH: rice hulls.

Figure 2.

Average weekly artichoke prices for the period 2000–2020. Means ± SE.

As mentioned in the previous section, it can be seen that weed removal by herbicide use (treatment H) or by hand (HW), in both cases without mulching, gave worse results: 15 and 29% lower, respectively.

3.1.3. Costs

Table 3 shows the costs of the structures, with their corresponding useful life and depreciation. The costs of preparation and planting have also been included since artichoke is a biennial crop, being replanted every two years. The importance of the structure costs is much lower in outdoor plantations than in greenhouse production, as reported in López Marín et al. [53].

Table 3.

Overhead costs a.

Table 4 shows the annual costs, the preparation costs being biennial since the plantation has a useful life of two years; so, only half of the €3706 ha−1 is considered (€1853 ha−1 year−1). In the tax costs, the Real Estate Tax was considered. The indirect costs are included in the purchase and sale prices, since, in general, farmers are covered by the special agricultural tax regime, and direct taxes are not included because they differ greatly from one taxpayer to another (especially regarding the tax on the income of individual persons).

Table 4.

Total and annual costs (€ ha−1).

- The herbicide costs were calculated according to Table 5. It shows the four treatments carried out (the values for the two years were practically identical, so only the average values are shown). These treatments were carried out between July and December (when the weeds had stopped growing) in each of the seasons.

Table 5. Herbicide treatments.

Table 5. Herbicide treatments. - The harvesting costs considered were €0.1 kg−1, regardless of the yield.

In summary, it can be seen that the MS treatment had the highest costs. Among the other treatments, the most important differences were due to the harvesting costs, which were higher in those treatments with higher yields, since a harvesting cost of €0.10 kg−1 was considered. In particular, the costs (without considering the structure costs) were lower for HW (8.60% lower than Pe) and H (25.07% lower than Pe) since mulch was not used. The treatments WS, RH, and MS had slightly higher costs than Pe (between 2.14 and 4.88%). Studies dealing with costs accounting in artichoke are practically non-existent. Among them, Sgroi et al. [57] reported costs on the island of Sicily of €17,119.75 ha−1, higher than those found in our study. As in that study, the variable costs in the present work were much higher than the fixed ones. García-García et al. [58] found that the fixed costs represented around 20–30% of the total costs, a percentage lower than that obtained here. In the present study, the distribution of costs among the fixed and variable was strongly influenced by the costs related to the plastic mulch and hydromulches, since, although in all cases the percentage of fixed costs was less than 60%, it was 41.32% for HW and 49.58% for H. This is due to the high percentage of the fixed costs that the hydromulch or polyethylene represents, as well as the manufacturing and removal costs, where appropriate. In addition, part of the personnel cost was considered as fixed.

Finally, given that this is an incipient technology, research should focus on obtaining cheaper mulches that can compete with polyethylene or even be cheaper. Public policies should be reoriented towards such materials that can become highly competitive and that benefit the environment in a double sense: they allow a reuse of “waste” and they contribute to a lower consumption of plastics in agriculture

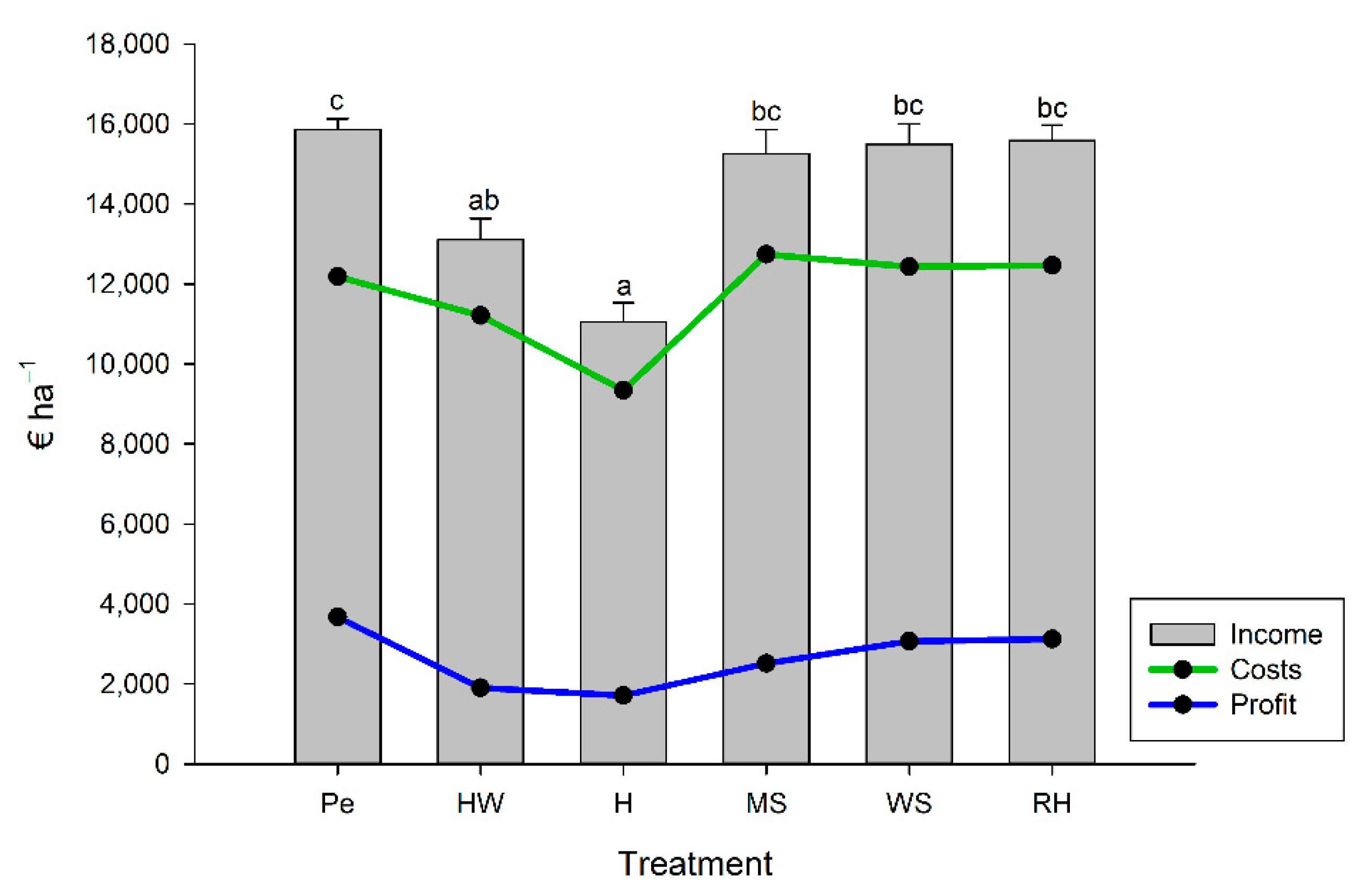

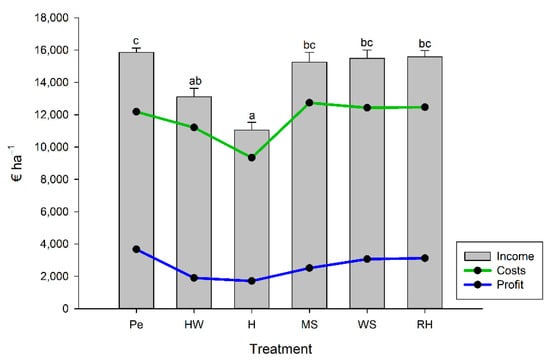

3.1.4. Net Profit

Figure 3 shows the net profit, obtained as the difference between the income and total costs (structure plus annual). The net profit was highest for Pe: for WS and RH it was lower than for Pe, by 16.54% and 14.95%, respectively, and it was lowest for HW and H (53.37 and 31.56% lower, respectively). For H, the yield was lower than for the rest of the treatments and, although it had the lowest costs, the net profit was also lower. With regard to the HW treatment, although the yield was quite high, the high costs of weeding prevented a high net profit from being obtained. The profit was higher with the WS and RH hydromulches. The higher costs observed for MS are due to the costs of the transport from the site of generation of the waste to the application area. This suggests that the mulch should be applied in areas close to the generation of the waste to avoid the costs of the transport and the pollution it generates.

Figure 3.

Income (mean ± SE), total costs, and net profit. Different letters indicate significant differences at the 95% level, according to Tukey’s HSD test. Pe: polyethylene, HW: hand weeding, H: herbicide, MS: substrate used for mushroom cultivation, WS: wheat straw, RH: rice hulls.

The average sale price was between €0.72 and €0.73 kg−1 (Table 6). The differences among the treatments were due to the distinct temporal distributions of the harvest. The unit cost was calculated as the ratio between the total cost and the yield, so that lower prices are indicative of higher yields and vice versa. The average cost was lowest for Pe (€0.56 kg−1), while it was highest for HW and H (€0.61 kg−1). The difference between the average sale price and the unit cost is the unit margin for the grower.

Table 6.

Average income and total and unit costs.

3.2. Productivity

3.2.1. Water Productivity

The productivity (in kilos) has been used on a widespread basis—for example, by Azorín et al. [43] and Goldhamer et al. [59], for the cultivation of almonds in Spain and California, respectively, and by Goldhamer et al. [60] and Dichio [61], for peach cultivation in California and Italy, respectively. For the Sao Francisco Valley (Brazil), Bassoi et al. [62] calculated the water productivity for different irrigation strategies such as partial root zone drying and regulated deficit irrigation. Alkhamis et al. [63] and Neal [64], for herbaceous crops, and García et al. [58], for artichoke, also did so. Table 7 shows the indicators of the productivity of water use. The productivity values of the hydromulches (WS, RH, and MS) are similar to those obtained for Pe.

Table 7.

Indexes of water use productivity.

The highest productivity in euros (€ m−3) was obtained in Pe (€2.98 m−3), followed by RH (€2.92 m−3) and WS (€2.91 m−3). These values are somewhat higher than that obtained by García et al. [58] for artichoke (€2.40 m−3), but are less than the €5.00 m−3 they achieved for strawberry. Other crops show much lower productivity: such as corn (€0.20 m−3 and €0.70 m−3).

Although the indicators productivity in kilos (kg m−3) and productivity in euros (€ m−3) may indicate that a crop has an efficient production, this does not mean that it is economically so. It is necessary to analyze the net profit that the activity generates per cubic meter of water consumed.

In this case, the most profitable treatment was Pe (€0.69 m−3), followed by RH (€0.59 m−3), WS (€0.58 m−3), MS (€0.47 m−3), HW (€0.36 m−3) and H (€0.32 m−3). In any case, all these values are higher than those reported by García et al. [58] (€0.32, €−0.01, and €0.10 m−3) and are also higher than the values reached for herbaceous crops such as rice (€0.02 m−3) or grain corn (€0.034 m−3) [65].

Mulching improves the soil moisture regime by limiting the evaporation rate of water at the surface; in general, mulching gives higher soil moisture contents compared to bare soil [66,67], which means that the yields are lower in treatments without mulching, as happened in our work.

The power of plastic mulches to retain soil moisture is greater than that of organic mulches [68]. However, in our work, in both growing cycles, there were no statistical differences between the hydromulches and the treatment with plastic. This may have been because these organic mulches (hydromulches), with the intervention of the soil moisture and temperature, affected the dynamics of the soil organic matter, augmenting the contents of dissolved organic carbon (C) and nitrogen (N) through the decomposition of plant materials, as has been found with other organic mulches [69,70].

The WVT shows the maximum price of water that the grower could bear and the strategies which are profitable for each price. In the treatment with herbicide, the grower could only withstand a maximum price of €0.65 m−3 (assuming that the rest of the costs remain constant). By contrast, in the WS and RH treatments the grower could withstand prices of up to €0.91 and €0.92 m−3, respectively; this indicates that in periods of scarcity, when the price of water is very high, the grower could bear such prices. The highest price could be borne in Pe (€1.02 m−3). In this regard, García et al. [58] obtained lower maximum prices (between €0.17 and €0.53 m−3, depending on the form of irrigation).

3.2.2. Generation of Employment

These types of indicators are used in agricultural policy [71,72,73]. The National Hydrological Plan of Spain [74] estimates a water productivity in the Segura basin (within which this work was carried out) of between 24 and 62 NAJ hm−3 for horticultural and fruit crops and 190 NAJ hm−3 for greenhouse grown crops. For the cultivation of artichoke, García et al. [64] obtained values between 26 and 45 NAJ hm−3. Table 8 shows the results obtained for the two indicators: the employment generated per hectare and per hectometer consumed. The highest generation of employment was achieved in Pe (71.14 NAJ hm−3), the lowest corresponding to H (45.36 NAJ hm−3).

Table 8.

Generation of employment.

The efficiency analysis was done solving optimization program (1) and the results are presented in Table 9. Technologies Pe, WS y RH are inefficient. As a result, Pe can be replaced by W or RH without loss of efficiency. In order to obtain the maximum efficiency in the remaining technologies, HW should reduce the input consumption by 7.52% considering the output obtained (radial reduction) and additionally (addition movement) reducing the input working hours by 700 h and increasing the production by 404 kg. The analysis for the remaining inefficient technologies (H and MS) is similar.

Table 9.

Efficiency and addition input and output variables.

Lastly, Table 10 shows the percentages of input and output potential improvement for the inefficient technologies. For obtaining the efficiency in H technology a 29.09 or 15.80% reduction in water and working hours is required. A similar interpretation can be used for HW and MS.

Table 10.

Potential improvement.

The analysis of the efficiency must be understood in a relative way. The aim of this section was to show the fact that treatments HW, H and MS are not effective with regard to Pe, WS and RH. However, further analysis with many more data will be required to check the efficiency of the former treatments.

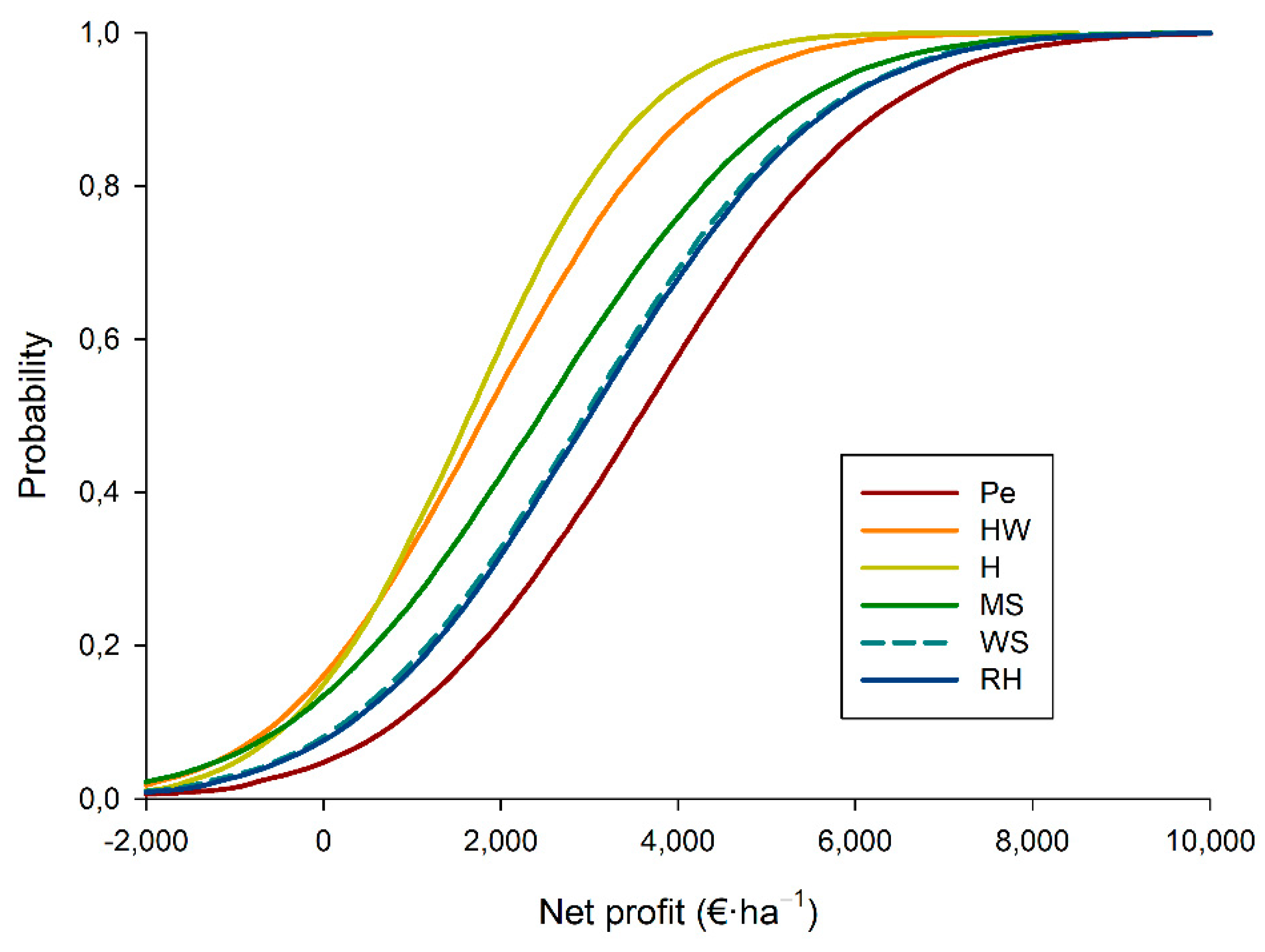

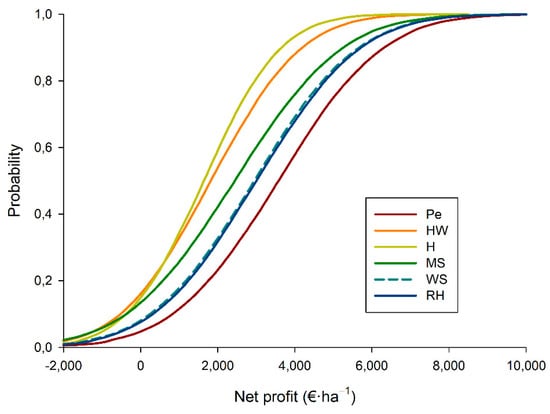

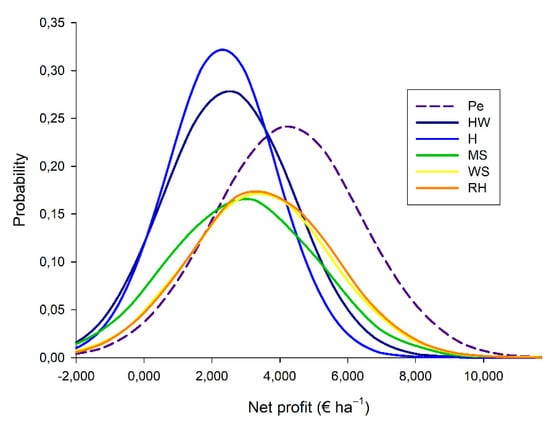

3.3. Sensitivity Analysis

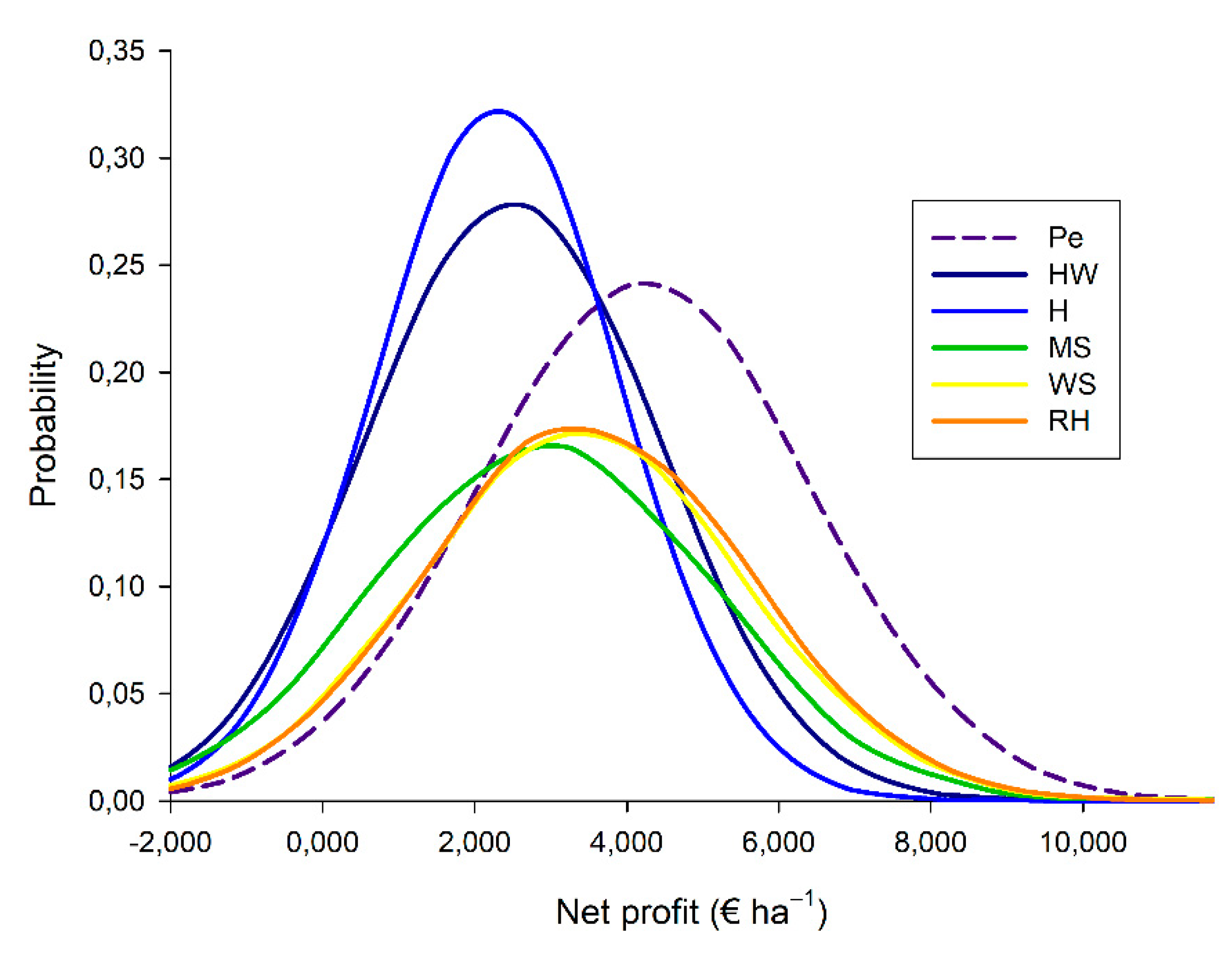

The variables that influence the net profit were found to be normal, with the means and standard deviations shown in this work. Figure 4 shows the results obtained, using these variables, from the Monte Carlo simulation, which can be easily implemented in a spreadsheet [75,76]. It displays the probability that the net income is equal to or less than each of the values of the x axis. The probability of obtaining negative results is 0.04 in Pe, 0.13 in SM, 0.08 in WS, and 0.07 in RH—so the probability that the grower will obtain benefits is greater than 0.9 when using mulch (except mushroom substrate) or polyethylene—while in HW and H the probability of obtaining negative results is 0.16 and 0.14, respectively. When analyzing the chances of obtaining a high net profit—for example, €4000, which is approximately the average net profit of the Pe—the probability that the yield does not reach this figure is 0.58 in Pe. Among the hydromulches it is 0.76, 0.69, and 0.68 for SM, WS, and RH, respectively; that is, this value will not be reached so often. Contrastingly, for the HW and H treatments values of 0.88 and 0.93, respectively, were obtained. This shows that a net profit of €4000 can reasonably be expected, even if the variables were to suffer alterations with respect to the initial values considered. López-Marín et al. [77] used this approach to compare the NPV with other methodologies such as the decoupled net present value and the use of decreasing discount functions such as the gamma function, given the existence of high initial costs that must be periodified during the useful life of the greenhouse. A similar methodology was applied by Smith et al. [78], who used descending cumulative probability curves for 10-year disease loss and control costs for five different control strategies used in the sensitivity analysis. The probability distribution of maize yields in relation to the target yield was used by Kiwia et al. [48].

Figure 4.

Probability of obtaining lower net revenues. Pe: polyethylene, HW: hand weeding, H: herbicide, MS: substrate used for mushroom cultivation, WS: wheat straw, RH: rice hulls.

Future research should address possible cost reductions in mulch manufacture, so that the costs of the grower are reduced. This would imply a reduction in the probability of incurring losses.

In Figure 5, the density function shows a higher concentration of income for Pe, HW, and H around the mean, with the distribution for treatment Pe being a little more shifted to the right; that is, the probability of getting high profits is superior. For treatments MS, WH, and RH, the distributions show greater dispersion and are somewhat shifted to the right; that is, the probability of obtaining high yields is greater. However, it should be noted that the probabilities of obtaining very high values with these latter three treatments (above €7000 ha−1) are similar to that of the Pe treatment.

Figure 5.

Density function of the net revenue. Pe: polyethylene, HW: hand weeding, H: herbicide, MS: substrate used for mushroom cultivation, WS: wheat straw, RH: rice hulls.

4. Conclusions

Hydromulches are a good alternative for artichoke cultivation, for the reduction of plastic waste. In addition, their costs may be reduced by the mechanization of the installation process on the ground. Their use can reduce the carbon footprint, and is more sustainable and profitable as well as being ecofriendly. It is a technique that can be easily used in many other horticultural crops, although the availability in the area where the hydromulch will be used of the plant waste used to make it is important for its economic viability.

The main conclusions of the study are:

- The yields, which showed little variability between the two years analyzed, were lower in the treatments without mulch: H (15% lower) and especially HW (29% lower). Therefore, the use of mulch increases the yield in a similar way to polyethylene, but also has environmental advantages.

- The sale prices remained practically stable until they began to decrease in mid-February, reaching €0.33 kg−1 in April, 61% lower than at the beginning of the year.

- Organic mulching had the highest costs (up to 5% higher than Pe) since the costs of the mulching materials were higher than for Pe. Research should now focus on reducing these costs in order to make such materials economically competitive with plastics.

- The net profits with the mulching materials MS, WS, and RH were higher than for HW and H, but lower than for Pe. The profitability of the use of mulching materials may be reduced by the cost of transport if they are not available near the site of cultivation. It is clear that, if the objective is to reduce the environmental impact of the use of plastics and other polluting elements, the use of mulch should be carried out close to where the corresponding waste is generated to avoid the occurrence of externalities due to its transport.

- Pe gave the highest productivity in the use of water, regarding yield and income, followed by WS and RH. When considering the productivity in euros, the most profitable treatments were RH and WS. The profit per cubic meter was lower for Pe due to the high acquisition costs of this material. The highest generation of employment (greatest number of jobs) corresponded to Pe (71.14 NAJ hm−3) and the lowest to H (45.36 NAJ hm−3).

- According to the sensitivity analysis, the probability of negative results is 0.04 in Pe, 0.13 in SM, 0.08 in WS, and 0.07 in RH; so, the probability that the grower will obtain a profit is greater than 0.9 when using mulch (except mushroom substrate) or polyethylene. A future reduction in mulch costs would greatly reduce the probability that the grower will make a loss.

New work is required to corroborate the reasons for the agronomic differences among the different mulches, as well as studies on the decomposition of hydromulch remains (the C and N cycles in soil, and the availability of C and N to plant roots) and evaporation. Such work will reveal the system that is most effective and profitable, due to both the reduced evaporation and the enhanced bioavailability of nutrients resulting from the decomposition and mineralization of the mulch organic matter. The mulching materials selected in this way, and originating close to the site of cultivation, will be the most sustainable, both economically and environmentally.

Author Contributions

Conceptualization, J.L.-M., M.R., and J.M.B.-M.; methodology, J.L.-M. and J.M.B.-M.; software, J.L.-M. and J.M.B.-M.; validation, J.L.-M., M.R., M.C.P., F.M.d.A., and J.M.B.-M.; formal analysis, J.L.-M., A.G., and J.M.B.-M.; investigation, J.L.-M., M.R., and J.M.B.-M.; resources, J.L.-M., M.R., and J.M.B.-M.; data curation, J.L.-M., F.M.d.A., and J.M.B.-M.; writing—original draft preparation, J.L.-M., M.C.P., and J.M.B.-M.; writing—review and editing, J.L.-M. and J.M.B.-M.; supervision, J.L.-M., A.G., F.M.d.A., and J.M.B.-M.; project administration, J.L.-M.; funding acquisition, J.L.-M. and J.M.B.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministerio de Economía y Competitividad, INIA RTA RTA2015-00047-C05-02. For her predoctoral contract, M. Romero-Muñoz is grateful to the INIA-CCAA system (FPI-BES-2017-082758), under cofunding from the European Social Fund.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest and the funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- Kader, M.A.; Senge, M.; Mojid, M.A.; Ito, K. Recent advances in mulching materials and methods for modifying soil environment. Soil Tillage Res. 2017, 168, 155–166. [Google Scholar] [CrossRef]

- Gao, H.; Yan, C.; Liu, Q.; Ding, W.; Chen, B.; Li, Z. Effects of plastic mulching and plastic residue on agricultural production: A meta-analysis. Sci. Total Environ. 2019, 651, 484–492. [Google Scholar] [CrossRef]

- Emmert, E.M. Black polyethylene for mulching vegetables. Proc. Am. Soc. Hort. Sci. 1957, 69, 464–469. [Google Scholar]

- Scarascia-Mugnozza, G.; Schettini, E.; Vox, G.; Malinconico, M.; Immirzi, B.; Pagliara, S. Mechanical properties decay and morphological behaviour of biodegradable films for agricultural mulching in real scale experiment. Polym. Degrad. Stabil. 2006, 91, 2801–2808. [Google Scholar] [CrossRef]

- Haapala, T.; Palonen, P.; Korpela, A.; Ahokas, J. Feasibility of paper mulches in crop production: A review. Agric. Food Sci. 2014, 23, 60–79. [Google Scholar] [CrossRef]

- Martin-Closas, L.; Costa, J.; Pelacho, A.M. Agronomic Effects of Biodegradable Films on Crop and Field Environment. In Soil Degradable Bioplastics for a Sustainable Modern Agriculture; Malinconico, M., Ed.; Springer: Berlin, Germany, 2017. [Google Scholar]

- Pardo, G.; Gómez, M.I.; Cirujeda, A.; Martínez, Y. Economic Costs of Sharing the Harvester in the Control of an Invasive Weed. Sustainability 2020, 12, 9046. [Google Scholar] [CrossRef]

- Hayes, D.G.; Wadsworth, L.C.; Sintim, H.Y.; Flury, M.; English, M.; Schaeffer, S.; Saxton, A.M. Effect of diverse weathering conditions on the physicochemical properties of biodegradable plastic mulches. Polym. Test. 2017, 62, 454–467. [Google Scholar] [CrossRef]

- Tarara, J.M. Microclimate modification with plastic mulch. Hort. Sci. 2000, 35, 222–228. [Google Scholar] [CrossRef]

- Gregory, M.R. Environmental implications of plastic debris in marine settings-entanglement, ingestion, smothering, hangers-on, hitch-hiking and alien invasions. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2013–2025. [Google Scholar] [CrossRef]

- Teuten, E.L.; Saquing, J.M.; Knappe, D.R.; Barlaz, M.A.; Jonsson, S.; Björn, A.; Rowland, S.J.; Thopson, R.C.; Galloway, T.S.; Yamashita, R.; et al. Transport and release of chemicals from plastics to the environment and to wildlife. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2009, 364, 2027–2045. [Google Scholar] [CrossRef] [PubMed]

- Liu, E.K.; He, W.Q.; Yan, C.R. ‘White revolution’ to ‘white pollution’-agricultural plastic film mulch in China. Environ. Res. Lett. 2014, 9, 3. [Google Scholar] [CrossRef]

- He, L.; Gielen, G.; Bolan, N.S.; Zhang, X.; Qin, H.; Huang, H.; Wang, H. Contamination and remediation of phthalic acid esters in agricultural soils in China: A review. Agron. Sustain. Dev. 2015, 35, 519–534. [Google Scholar] [CrossRef]

- Steinmetz, Z.; Wollmann, C.; Schaefer, M.; Buchmann, C.; David, J.; Troger, J.; Munoz, K.; Fror, O.; Schaumann, G.E. Plastic mulching in agriculture. Trading short-term agronomic benefits for long-term soil degradation? Sci. Total Environ. 2016, 550, 690–705. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Dris, R.; Gasperi, J.; Mirande, C.; Mandin, C.; Guerrouache, M.; Langlois, V.; Tassin, B. A first overview of textile fibers, including microplastics, in indoor and outdoor environments. Environ. Pollut. 2017, 221, 453–458. [Google Scholar] [CrossRef] [PubMed]

- Huerta-Lwanga, E.; Vega, J.M.; Quej, V.K.; Angeles, J.D.L.; Sanchez, L.; Chi, C.; Segura, G.E.; Henny, G.; Van Der Ploeg, M.; Koel, A.A.; et al. Field evidence for transfer of plastic debris along a terrestrial food chain. Nat. Sci. Rep. 2017, 7, 14071. [Google Scholar] [CrossRef]

- Schwabl, P.; Köppel, S.; Königshofer, P.; Bucsics, T.; Trauner, M.; Reiberger, T.; Liebmann, B. Detection of various microplastics in human stool: A prospective case series. Ann. Intern. Med. 2019, 171, 453–457. [Google Scholar] [CrossRef] [PubMed]

- Wong, J.K.H.; Lee, K.K.; Tang, K.H.D.; Yap, P.S. Microplastics in the freshwater and terrestrial environments: Prevalence, fates, impacts and sustainable solutions. Sci. Total Environ. 2020, 719, 137512. [Google Scholar] [CrossRef]

- Li, W.C.; Tse, H.F.; Fok, L. Plastic waste in the marine environment: A review of sources, occurrence and effects. Sci. Total Environ. 2016, 566–567, 333–349. [Google Scholar] [CrossRef]

- Rodrigues, M.O.; Abrantes, N.; Gonçalves, F.J.M.; Nogueira, H.; Marques, J.C.; Gonçalves, A.M.M. Impacts of plastic products used in daily life on the environment and human health: What is known? Environ. Toxicol. Pharmacol. 2019, 72, 103239. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Fu, D.; Qi, H.; Lan, C.Q.; Yu, H.; Ge, C. Micro- and nano-plastics in marine environment: Source, distribution and threats—A review. Sci. Total Environ. 2020, 698, 134254. [Google Scholar] [CrossRef]

- Serrano-Ruiz, H.; Martin-Closas, L.; Pelacho, A.M. Biodegradable plastic mulches: Impact on the agricultural biotic environment. Sci. Total Environ. 2020, 750, 141228. [Google Scholar] [CrossRef] [PubMed]

- Plastics Europe, Association of Plastic Manufacturers. Plastics-The Facts. Available online: https://www.plasticseurope.org/application/files/6315/4510/9658/Plastics_the_facts_2018_AF_web.pdf (accessed on 5 November 2020).

- Circular Economy Research and Innovation-Connecting Economic and Environmental Gains; EU Publications, European Union: Luxembourg, 2017. [CrossRef]

- Franca, R.D.G.; Pinheiro, H.M.; Van Loosdrecht, M.C.M.; Lourenço, N.D. Stability of aerobic granules during long-term bioreactor operation. Biotechnol. Adv. 2018, 36, 228–246. [Google Scholar] [CrossRef]

- Liu, F.C.; Gao, D.Y.; Liu, D.C.; Gao, F.Y. Multi-functional Characteristics of Novel Biodegradable Mulching Films from Citric Acid Fermentation Wastes. Waste Biomass Valor. 2018, 9, 1379–1387. [Google Scholar] [CrossRef]

- Warnick, J.P.; Chase, C.A.; Rosskopf, E.N.; Simonne, E.H.; Scholberg, J.M.; Koenig, R.L.; Roe, N.E. Weed suppression with hydramulch, a biodegradable liquid paper mulch in development. Renew. Agric. Food Syst. 2006, 21, 216–223. [Google Scholar] [CrossRef]

- Cline, J.; Neilsen, G.; Hogue, E.; Kuchta, S.; Neilsen, D. Spray-on-mulch technology for intensively grown irrigated apple orchards: Influence on tree establishment, early yields, and soil physical properties. Hort. Technol. 2011, 21, 398–411. [Google Scholar] [CrossRef]

- Claramunt, J.; Mas, M.T.; Pardo, G.; Cirujeda, A.; Verdú, A.M.C. Mechanical characterization of blends containing recycled paper pulp and other lignocellulosic materials to develop hydromulches for weed control. Biosyst. Eng. 2020, 191, 35–47. [Google Scholar] [CrossRef]

- Mas, M.T.; Pardo, G.; Pueyo, J.; Verdú, A.M.C.; Cirujeda, A. Can Hydromulch Reduce the Emergence of Perennial Weeds? Agronomy 2021, 11, 393. [Google Scholar] [CrossRef]

- Immirzi, B.; Santagata, G.; Vox, G.; Schettini, E. Preparation, characterisation and field-testing of a biodegradable sodium alginate-based spray mulch. Biosyst. Eng. 2009, 102, 461–472. [Google Scholar] [CrossRef]

- Lopez-Marin, J.; Brotons-Martinez, J.M.; Galvez, A.; Porras, I. Pepper grafting (Capsicum annuum): Benefits and profitability. Itea Inf. Technol. Econ. Agric. 2016, 112, 127–146. [Google Scholar]

- CARM. Consejería de Agricultura de la Región de Murcia. Available online: https://caamext.carm.es/esamweb/faces/vista/seleccionPrecios (accessed on 15 December 2020).

- Engindeniz, S. Economic analysis of processing tomato growing: The case study of Torbali, west Turkey. Span. J. Agric. Res. 2007, 7, 7–15. [Google Scholar] [CrossRef]

- Engindeniz, S.; Tüzel, Y. The Determination of Cost and Profitability of Organic Vegetable Production in Greenhouse: A Case Study for Turkey, Organic Agriculture in the Mediterranean Basin. In Proceedings of the International Symposium Organic Agriculture, Agadir, Marocco, 7–10 October 2001; Hanafi, A., Kenny, L., Eds.; pp. 434–442. [Google Scholar]

- García-García, J. Estructura de Costes de las Orientaciones Productivas Agrícolas de la Región de Murcia: Horticultura al Aire Libre y Bajo Invernadero; Serie Técnica, Consejería de Agua, Agricultura, Ganadería, Pesca y Medio Ambiente: Murcia, Spain, 2020. [Google Scholar]

- García, J.G. Evaluación Económica y Eficiencia del Agua de Riego en Frutales de Regadío; Consejería de Agricultura y Agua: Murcia, Spain, 2007. [Google Scholar]

- Rigby, D.; Alcón, F.; Burton, M. Supply Uncertainty and the Economic Value of Irrigation Water EUR Rev. Agric. Econ. Eur. Rev. Agric. Econ. 2010, 37, 2010. [Google Scholar] [CrossRef]

- Hussain, I.; Turral, H.; Molden, D.; Ahmad, M. Measuring and Enhancing the Value of Agricultural Water in Irrigated River. Basins Irrig. Sci. 2007, 25, 263–282. [Google Scholar] [CrossRef]

- Salvador, R.; Martínez-Cob, A.; Cavero, J.; Playán, E. Seasonal On-Farm Irrigation Performance in the Ebro Basin (Spain): Crops and Irrigation Systems. Agric. Water Manag. 2011, 98, 577–587. [Google Scholar] [CrossRef]

- Azorín, P.R.; García, J.G.; Ordaz, P.B. Cost-Benefit Analysis of a Regulated Deficit-Irrigated Almond Or-chard under Subsurface Drip Irrigation Conditions in South-Eastern Spain. Irrig. Sci. 2006, 24, 175–184. [Google Scholar] [CrossRef]

- García, J.G.; Romero, P.; Botía, P.; García, F. Análisis Económico del Cultivo de Almendro en Riego Deficitario Controlado (RDC). Frutic. Prof. 2005, 154, 43–50. [Google Scholar]

- Cooper, W.W.; Seiford, L.M.; Tone, K. Data Eneloment Analysis. A Comprehensive Test with Models, Applications, Refrences and DEA-Software; Kluwer Academic Publishers: Boston, MA, USA, 2000. [Google Scholar]

- Wagner, H.M. Global sensitivity analysis. Oper. Res. 1995, 43, 948–969. [Google Scholar] [CrossRef]

- Smith, A.; Snapp, S.; Chikowo, R.; Thorne, P.; Bekunda, M.; Glover, J. Measuring sustainable intensification in smallholder agroecosystems: A review. Glob. Food Secur. 2017, 12, 127–138. [Google Scholar] [CrossRef]

- Kiwia, A.; Kimani, D.; Harawa, R.; Jama, B.; Sileshi, G.W. Sustainable Intensification with Cereal-Legume Intercropping in Eastern and Southern Africa. Sustainability 2019, 11, 2891. [Google Scholar] [CrossRef]

- Manfredo, M.R.; Leuthold, R.M. Value-at-Risk Analysis: A Review and the Potential for Agricultural Applications. Rev. Agric. Econ. 1999, 21, 99–111. [Google Scholar] [CrossRef]

- Brotons-Martínez, J.M.; Martin-Gorriz, B.; Torregrosa, A.; Porras, I. Economic evaluation of mechanical harvesting of lemons. Outlook Agric. 2018, 47, 44–50. [Google Scholar] [CrossRef]

- Heuvelink, E. Growth, development and yield of a tomato crop–periodic destructive measurements in a greenhouse. Sci. Hortic. 1995, 61, 77–99. [Google Scholar] [CrossRef]

- Lopez-Marin, J.; Galvez, A.; Porras, I.; Brotons-Martinez, J.M. Use of a PSNM to Increase Precocity and Its Benefits in Greenhouse-Grown Sweet pepper. J. Agric. Sci. Technol. 2017, 19, 1005–1018. [Google Scholar]

- Lopez-Marin, J.; Rodriguez, M.; Del Amor, F.M.; Galvez, A.; Brotons-Martinez, J.M. Cost-benefit Analysis of Tomato Crops under Different Greenhouse Covers. J. Agric. Sci. Technol. 2019, 21, 235–248. [Google Scholar]

- Prestamburgo, M.; Saccomandi, V. Economia Agraria; Etas libri Mondadori: Milano, Italy, 1995. [Google Scholar]

- Assefa, T.T.; Meuwissen, M.P.M.; Lansink, A.G.J.M. Price Volatility Transmission in Food Supply Chains: A Literature Review. Agribusiness 2016, 31, 3–13. [Google Scholar] [CrossRef]

- AEAA, Anuario estadístico Agrario de Aragón. Available online: https://www.aragon.es/-/anuario-estadistico-agrario (accessed on 15 February 2021).

- Sgroi, F.; Foder, M.; Di Trapani, A.M.; Tudisca, S.; Testa, R. Profitability of Artichoke Growing in the Mediterranean Area. Hortscience 2015, 50, 1349–1352. [Google Scholar] [CrossRef]

- García, J.; Contreras-López, J.; Usai, F.; Visani, D.C. Economic Assessment and Socio-Economic Evaluation of Water Use Efficiency in Artichoke Cultivation. Open J. Account. 2013, 2, 45–52. [Google Scholar] [CrossRef][Green Version]

- Goldhamer, D.A.; Viveros, M.; Salinas, M. Regulated Deficit Irrigation in Almonds: Effects of Variations in Applied Water and Stress Timing on Yield and Yield Components. Irrig. Sci. 2006, 24, 101–114. [Google Scholar] [CrossRef]

- Goldhamer, D.A.; Salinas, M.; Crisosto, C.; Day, K.R.; Soler, M.; Moriana, A. Effects of Regulated Deficit Irrigation and Partial Root Zone Drying on Late Harvest Peach Tree Performance. Acta Hortic. 2002, 592, 343–350. [Google Scholar] [CrossRef]

- Dichio, B.; Xiloyannis, C.; Sofo, A.; Montanaro, G. Effects of Post-Harvest Regulated Deficit Irrigation on Carbohydrate and Nitrogen Partitioning, Yield Quality and Vegetative Growth of Peach Trees. Plant. Soil 2007, 290, 127–137. [Google Scholar] [CrossRef]

- Bassoi, L.H.; Dantas, B.F.; Lima, J.M.P.; Lima, M.A.C.; Leao, P.C.S.; Silva, D.J.; Maia, J.L.T.; Souza, C.R.; Silva, J.A.M.; Ramos, M.M. Preliminary Results of a Long-Term Experiment about RDI and PRD Irrigation Strategies in Wine Grapes in Sao Francisco Valley, Brasil. Acta Hortic. 2007, 754, 275–282. [Google Scholar] [CrossRef]

- Alkhamisi, S.A.; Abdelrahman, H.A.; Ahmed, M.; Goosen, M.F.A. Assessment of Reclaimed Water Irrigation on Growth, Yield, and Water-Use Efficiency of Forage Crops. Appl. Water Sci. 2011, 1, 57–65. [Google Scholar] [CrossRef]

- Neal, J.S.; Fulkerson, W.J.; Sutton, B.G. Differences in Water-Use Efficiency among Perennial Forages Used by the Dairy Industry under Optimum and Deficit Irrigation. Irrig. Sci. 2011, 29, 213–232. [Google Scholar] [CrossRef]

- Jalota, S.K.; Sood, A.; Vitale, J.D.; Srinivasan, R. Simulated Crop Yields Response to Irrigation Water and Economic Analysis: Increasing Irrigated Water Use Efficiency in the Indian Punjab. Agron. J. 2007, 99, 1073–1084. [Google Scholar] [CrossRef]

- Chakraborty, D.; Nagarajan, S.; Aggarwal, P.; Gupta, V.K.; Tomar, R.K.; Garg, R.N.; Sahoo, R.N.; Sarkar, A.; Chopra, U.K.; Sarma, K.S.S.; et al. Effect of mulching on soil and plant water status, and the growth and yield of wheat (Triticum aestivum L.) in a semi-arid environment. Agric. Water Manag. 2008, 95, 1323–1334. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, R.Y.; Ma, B.L.; Xiong, Y.C.; Qiang, S.C.; Wang, C.L. Ridge-furrow with full plastic film mulching improves water use efficiency and tuber yields of potato in a semiarid rainfed ecosystem. Field Crop. Res. 2014, 161, 137–148. [Google Scholar] [CrossRef]

- Chakraborty, R.C.; Sadhu, M.K. Effect of mulch type and color on growth and yield of tomato (Lycopersicon esculentum). Indian J. Agric. Sci. 1994, 64, 608–612. [Google Scholar]

- Chantigny, M.H. Dissolved and water-extractable organic matter in soils: A review on the influence of land use and management practices. Geoderma 2003, 113, 357–380. [Google Scholar] [CrossRef]

- Huang, Z.; Xu, Z.; Chen, C. Effect of mulching on labile soil organic matter pools, microbial community functional diversity and nitrogen transformations in two hardwood plantations of subtropical Australia. Appl. Soil Ecol. 2008, 40, 229–239. [Google Scholar] [CrossRef]

- Ward, F.A.; Michelsen, A. The Economic Value of Water in Agriculture: Concepts and Policy Applications. Water Policy 2002, 4, 423–446. [Google Scholar] [CrossRef]

- Hellegers, P.J.G.J.; Soppe, R.; Perry, C.J.; Bastiaanssen, W.G.M. Combining Remote Sensing and Economic Analysis to Support Decisions that Affect Water Productivity. Irrig. Sci. 2009, 27, 243–251. [Google Scholar] [CrossRef]

- EEC. Hacia un Sector Vitivinícola Europeo. European Commission Report. 2006. Available online: http://ec.europa.eu/spain/pdf/sectorvitivinicola_es.pdf (accessed on 10 October 2020).

- CES (Consejo Económico y Social de Murcia). Informe Sobre la Situación Hidrológica y Socioeconómica en la Cuenca del Segura en el Nuevo Contexto del Plan Hidrológico Nacional. 2000. Available online: http://www.cesmurcia.org/informes/a_2000/phn/2-2000.pdf (accessed on 7 September 2020).

- Savage, S.; Scholtes, S.; Zweidler, D. Probability Management. OR/MS Today 2006, 33, 21–28. [Google Scholar] [CrossRef]

- Savage, S.; Scholtes, S.; Zweidler, D. Probability Management (Part 2). OR/MS Today 2006, 33, 60–66. [Google Scholar]

- López-Marín, J.; Gálvez, A.; del Amor, F.M.; Brotons, J.M. The Financial Valuation Risk in Pepper Production: The Use of Decoupled Net Present Value. Mathematics 2021, 9, 13. [Google Scholar] [CrossRef]

- Smith, R.L.; Sanderson, M.W.; Jones, R.; N’Guessan, Y.; Renter, D.; Larson, R.; White, B.J. Economic risk analysis model for bovine viral diarrhea virus biosecurity in cow-calf herds. Prev. Vet. Med. 2014, 113, 492–503. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).