Ultrasound-Assisted Vacuum Impregnation as a Strategy for the Management of Potato By-Products

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

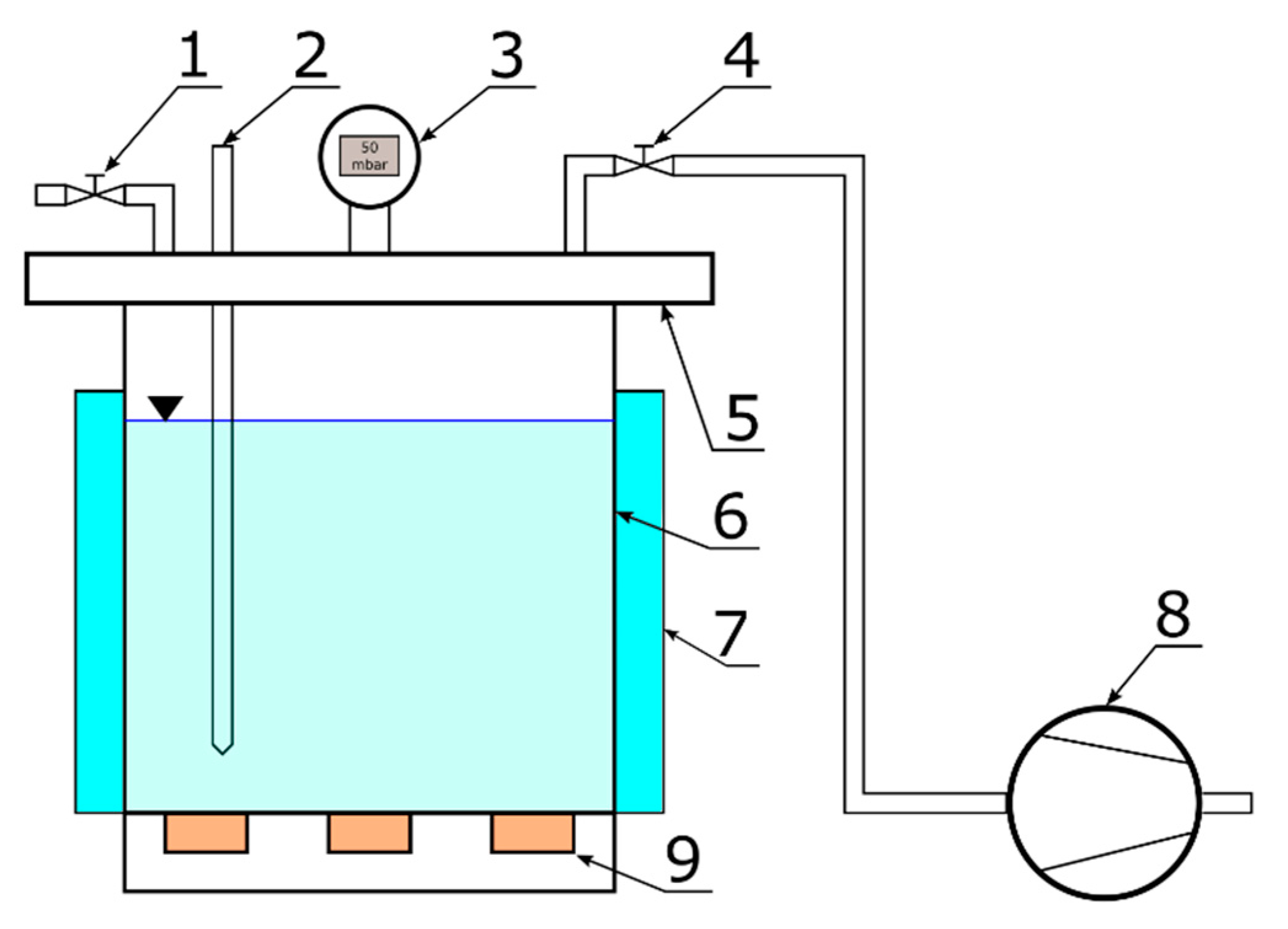

2.2. Vacuum Impregnation

2.3. Convective Drying

2.4. Evaluation of the Effectiveness of the Vacum Impregnation

2.5. Measurement of the Selected Product Quality Parameters

2.6. Statistical Analysis

3. Results and Discussion

3.1. Vacuum Impregnation Effectiveness

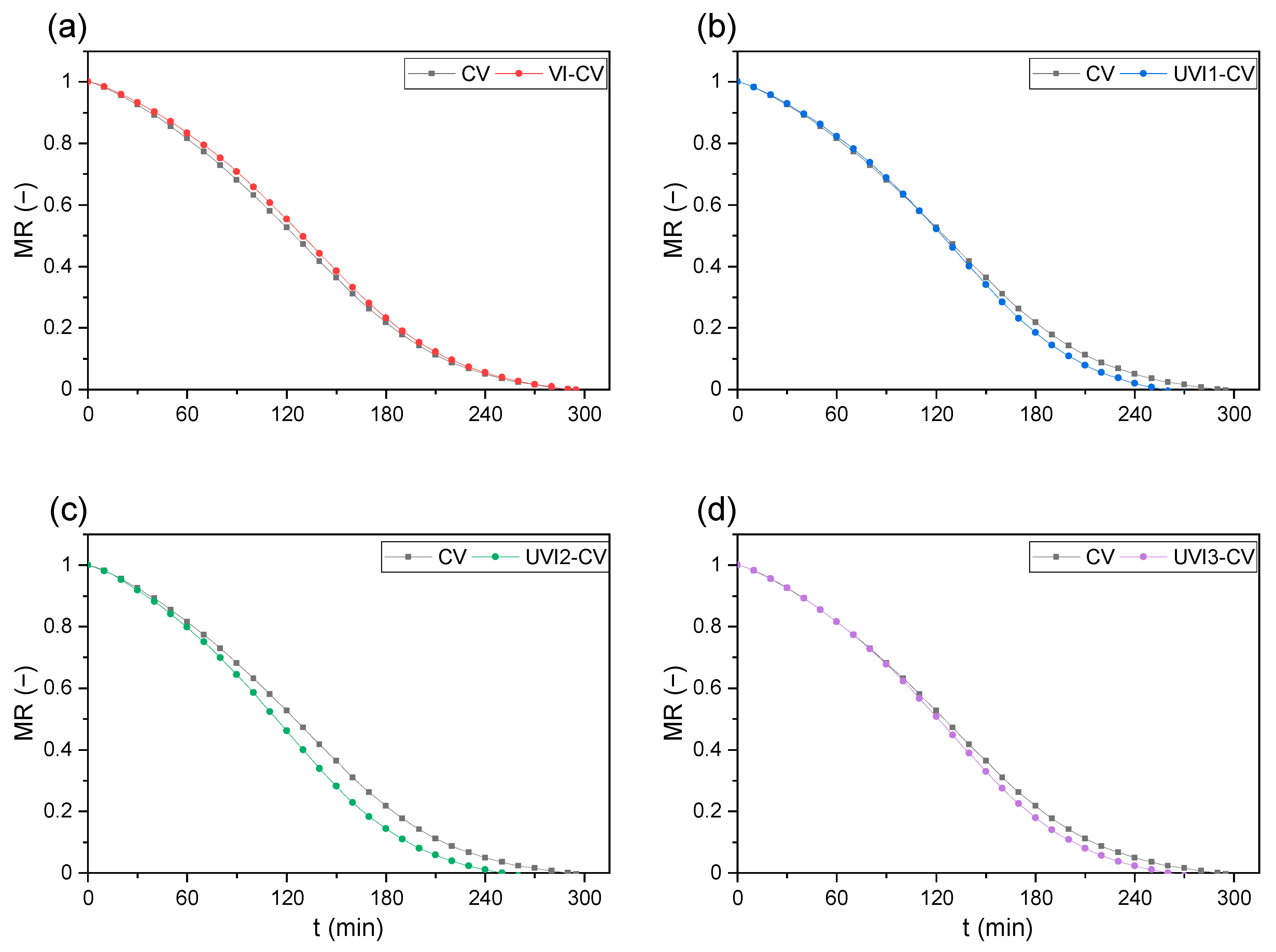

3.2. Convective Drying Kinetics

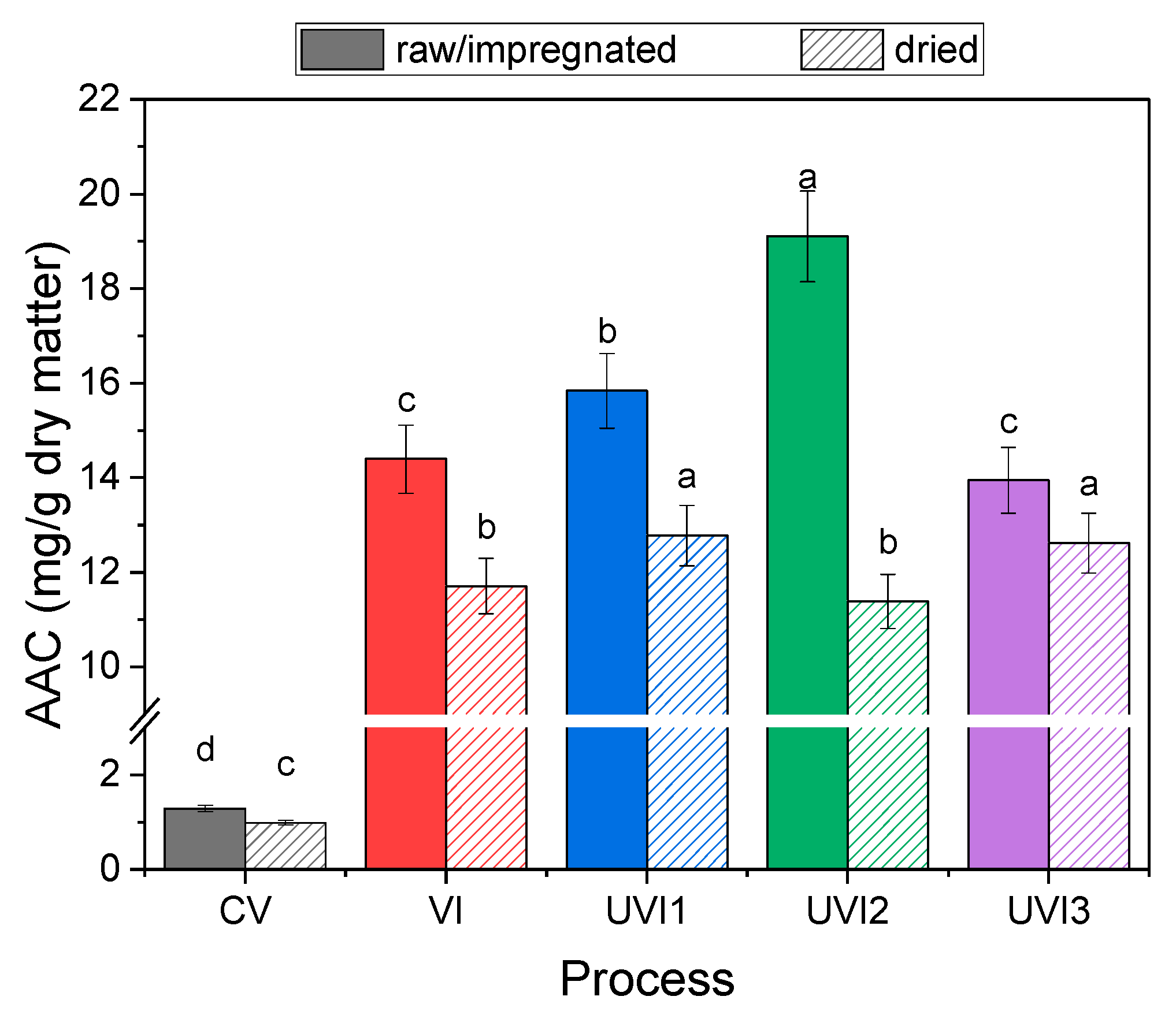

3.3. Quality Parameters

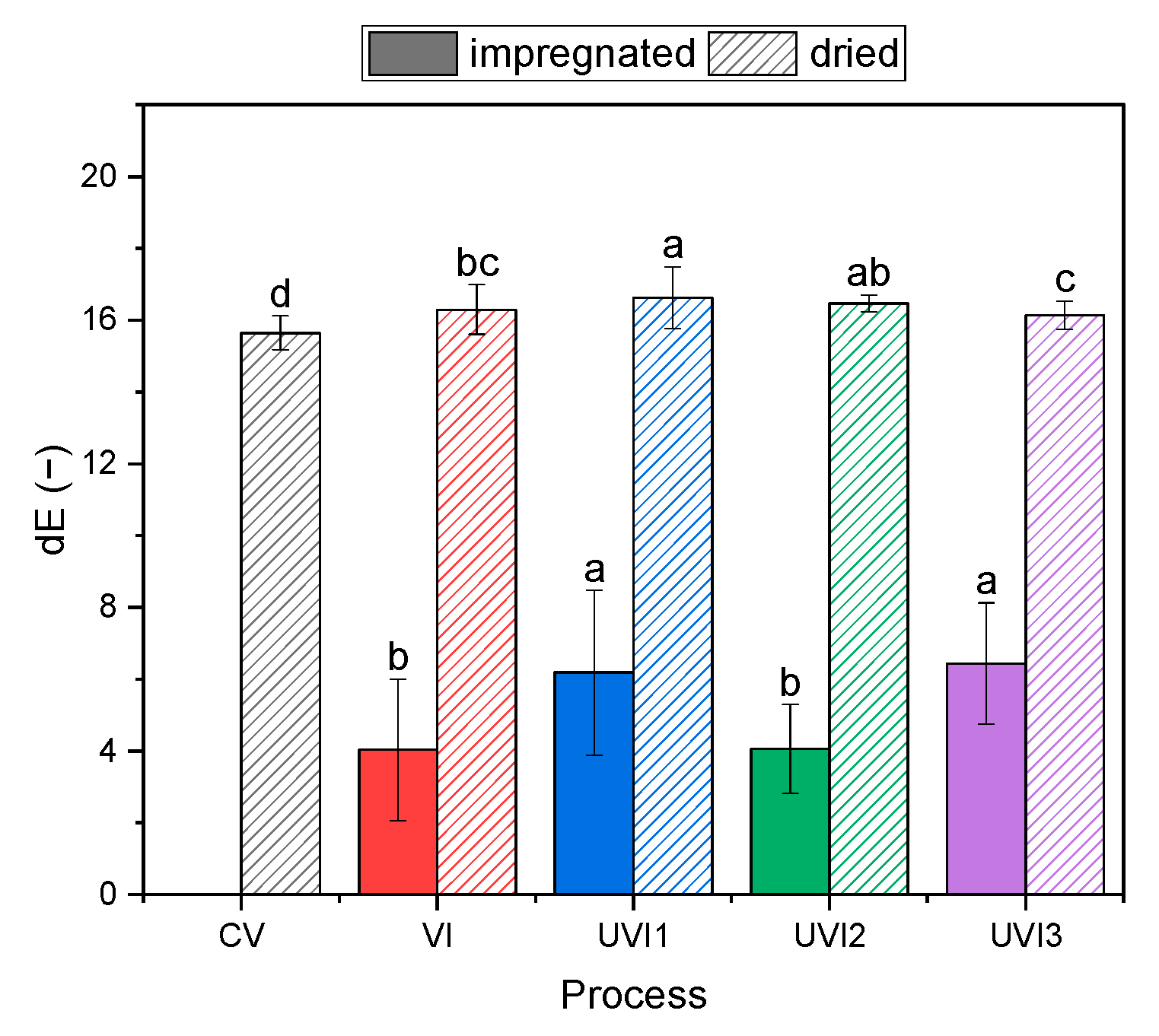

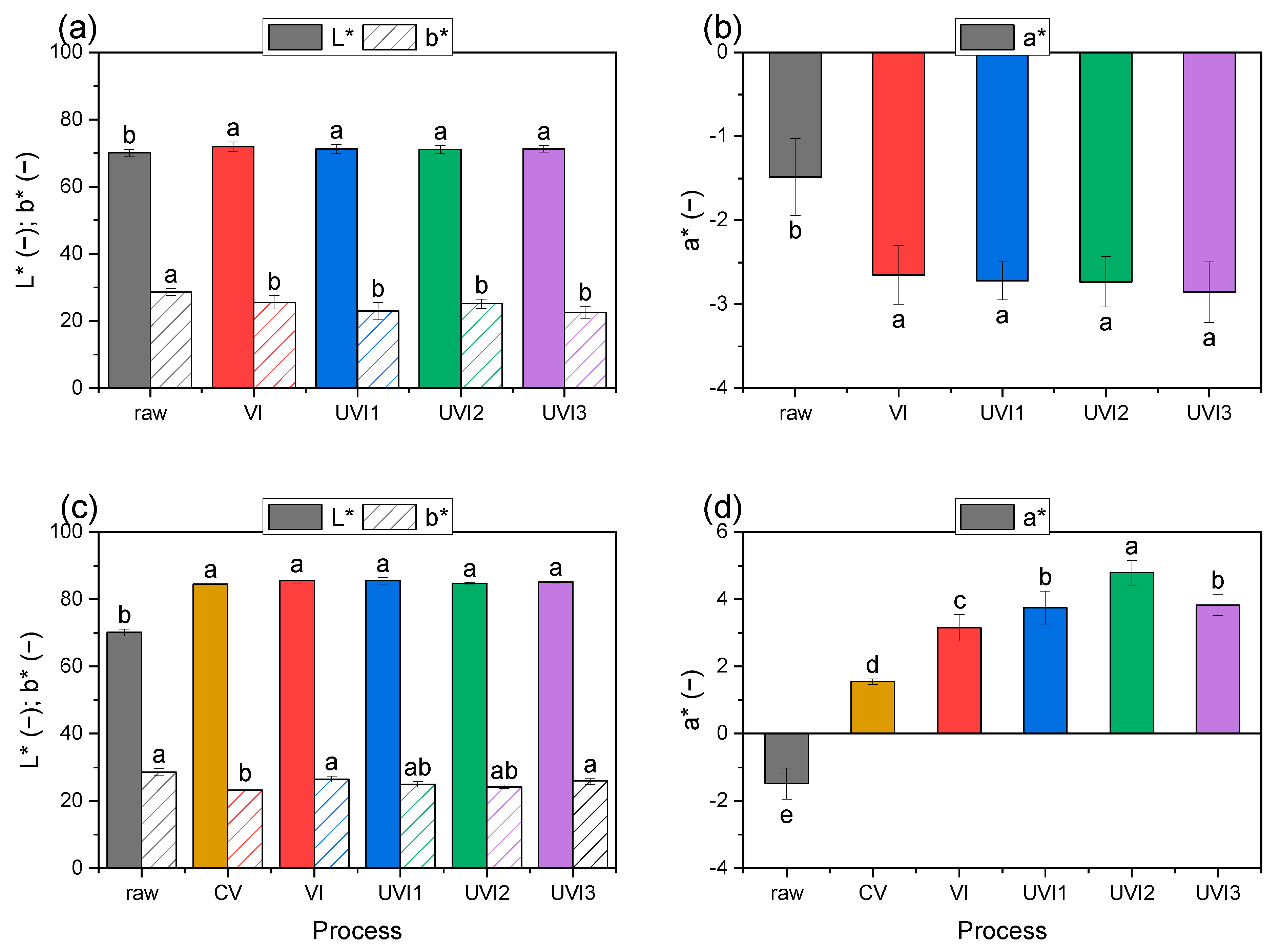

3.3.1. Color

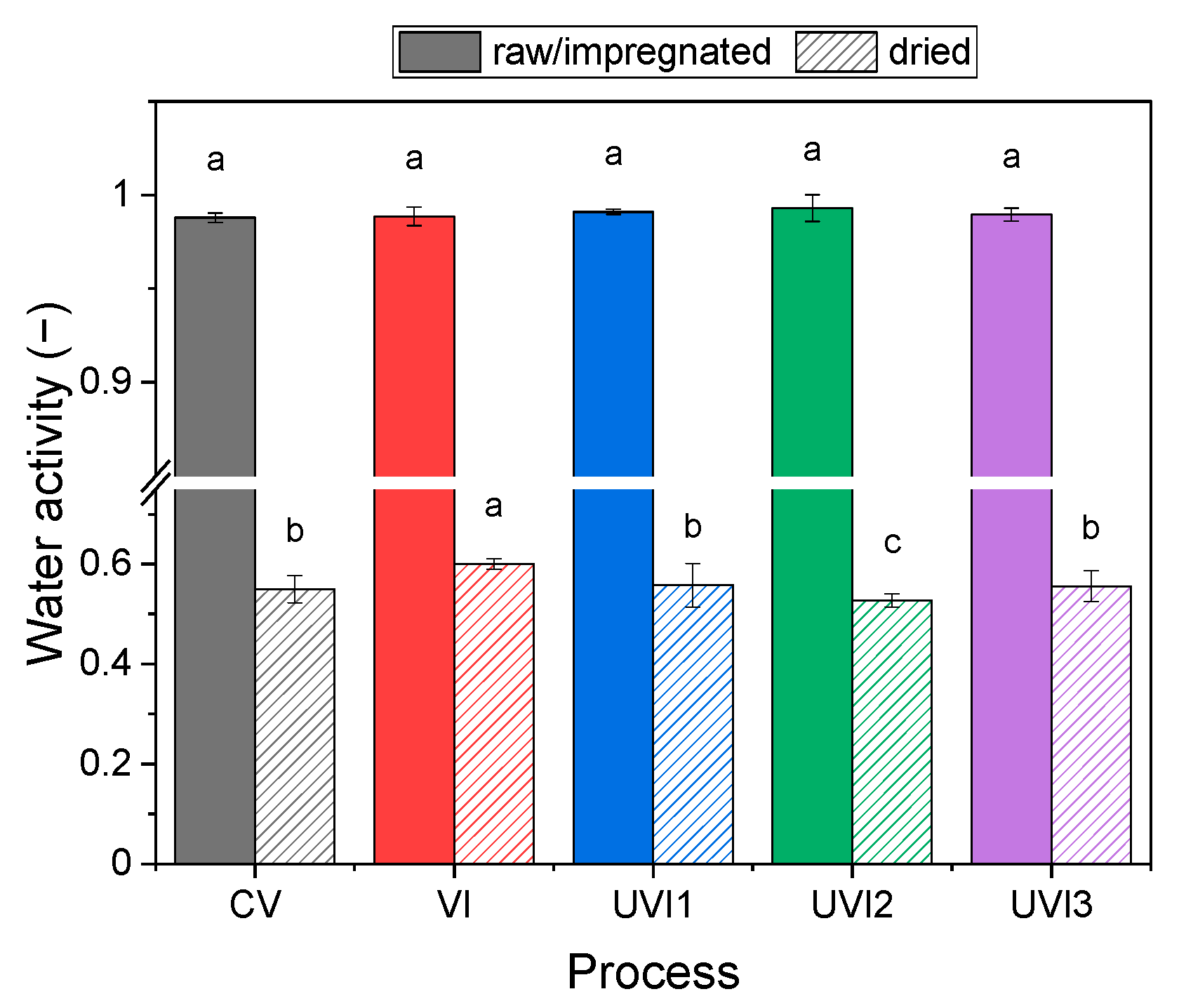

3.3.2. Water Activity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- KC, K.B.; Haque, I.; Legwegoh, A.; Fraser, E. Strategies to Reduce Food Loss in the Global South. Sustainability 2016, 8, 595. [Google Scholar] [CrossRef]

- Foley, J.A.; Ramankutty, N.; Brauman, K.A.; Cassidy, E.S.; Gerber, J.S.; Johnston, M.; Mueller, N.D.; O’Connell, C.; Ray, D.K.; West, P.C.; et al. Solutions for a cultivated planet. Nature 2011, 478, 337–342. [Google Scholar] [CrossRef] [PubMed]

- Thi, N.B.D.; Kumar, G.; Lin, C.-Y. An overview of food waste management in developing countries: Current status and future perspective. J. Environ. Manag. 2015, 157, 220–229. [Google Scholar] [CrossRef]

- Bas-Bellver, C.; Barrera, C.; Betoret, N.; Seguí, L. Turning Agri-Food Cooperative Vegetable Residues into Functional Powdered Ingredients for the Food Industry. Sustainability 2020, 12, 1284. [Google Scholar] [CrossRef]

- Schieber, A.; Stintzing, F.; Carle, R. By-products of plant food processing as a source of functional compounds—Recent developments. Trends Food Sci. Technol. 2001, 12, 401–413. [Google Scholar] [CrossRef]

- Gracia, A.; Gómez, M.I. Food Sustainability and Waste Reduction in Spain: Consumer Preferences for Local, Suboptimal, and/or Unwashed Fresh Food Products. Sustainability 2020, 12, 4148. [Google Scholar] [CrossRef]

- Wang, J.; Law, C.L.; Mujumdar, A.S.; Xiao, H.-W. The Degradation Mechanism and Kinetics of Vitamin C in Fruits and Vegetables During Thermal Processing. In Drying Technologies for Foods: Fundamentals and Applications; Nema, P.K., Kaur, B.P., Mujumdar, A.S., Eds.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2019; pp. 275–301. ISBN 9781138733084. [Google Scholar]

- Zhang, H.; Patel, J.; Bhunia, K.; Al-Ghamdi, S.; Sonar, C.R.; Ross, C.F.; Tang, J.; Sablani, S.S. Color, vitamin C, β-carotene and sensory quality retention in microwave-assisted thermally sterilized sweet potato puree: Effects of polymeric package gas barrier during storage. Food Packag. Shelf Life 2019, 21, 100324. [Google Scholar] [CrossRef]

- Veras, A.O.M.; Béttega, R.; Freire, F.B.; Barrozo, M.A.S.; Freire, J.T. Drying kinetics, structural characteristics and vitamin C retention of dedo-de-moça pepper (Capsicum baccatum) during convective and freeze drying. Braz. J. Chem. Eng. 2012, 29, 741–750. [Google Scholar] [CrossRef][Green Version]

- Weber, P.; Bendich, A.; Schalch, W. Vitamin C and human health—A review of recent data relevant to human requirements. Int. J. Vitam. Nutr. Res. 1996, 66, 19–30. [Google Scholar] [PubMed]

- Derossi, A.; De, T.; Severini, C. The Application of Vacuum Impregnation Techniques in Food Industry. In Scientific, Health and Social Aspects of the Food Industry; Valdez, B., Ed.; InTech: London, UK, 2012; ISBN 978-953-307-916-5. [Google Scholar]

- Chiralt, A.; Fito, P.; Barat, J.; Andrés, A.; González-Martínez, C.; Escriche, I.; Camacho, M. Use of vacuum impregnation in food salting process. J. Food Eng. 2001, 49, 141–151. [Google Scholar] [CrossRef]

- Radziejewska-Kubzdela, E.; Biegańska-Marecik, R.; Kidoń, M. Applicability of vacuum impregnation to modify physico-chemical, sensory and nutritive characteristics of plant origin products—A review. Int. J. Mol. Sci. 2014, 15, 16577–16610. [Google Scholar] [CrossRef]

- Fito, P.; Pastor, R. Non-diffusional mechanisms occurring during vacuum osmotic dehydration. J. Food Eng. 1994, 21, 513–519. [Google Scholar] [CrossRef]

- Chiralt, A.; Fito, P. Transport Mechanisms in Osmotic Dehydration: The Role of the Structure. Food Sci. Technol. Int. 2003, 9, 179–186. [Google Scholar] [CrossRef]

- Witrowa-Rajchert, D. Study on changes in the plant tissue volume during rehydration. Acta Agroph. 2003, 2, 867–878. [Google Scholar]

- Kowalski, S.J.; Szadzińska, J. Convective-intermittent drying of cherries preceded by ultrasonic assisted osmotic dehydration. Chem. Eng. Process. Process Intensif. 2014, 82, 65–70. [Google Scholar] [CrossRef]

- Zielinska, M.; Markowski, M. Effect of microwave-vacuum, ultrasonication, and freezing on mass transfer kinetics and diffusivity during osmotic dehydration of cranberries. Dry. Technol. 2018, 36, 1158–1169. [Google Scholar] [CrossRef]

- Musielak, G.; Mierzwa, D.; Kroehnke, J. Food drying enhancement by ultrasound—A review. Trends Food Sci. Technol. 2016, 56, 126–141. [Google Scholar] [CrossRef]

- Mashkour, M.; Maghsoudlou, Y.; Kashaninejad, M.; Aalami, M. Effect of ultrasound pretreatment on iron fortification of potato using vacuum impregnation. J. Food Process. Preserv. 2018, 42, e13590. [Google Scholar] [CrossRef]

- Yılmaz, F.M.; Ersus Bilek, S. Ultrasound-assisted vacuum impregnation on the fortification of fresh-cut apple with calcium and black carrot phenolics. Ultrason. Sonochem. 2018, 48, 509–516. [Google Scholar] [CrossRef]

- Awad, T.S.; Moharram, H.A.; Shaltout, O.E.; Asker, D.; Youssef, M.M. Applications of ultrasound in analysis, processing and quality control of food: A review. Food Res. Int. 2012, 48, 410–427. [Google Scholar] [CrossRef]

- Labuza, T.P.; Tannenbaum, S.R.; Karel, M. Water content and stability of low-moisture & intermediate-moisture foods. Food Technol. 1970, 25, 35–42. [Google Scholar]

- Maltini, E.; Torreggiani, D.; Venir, E.; Bertolo, G. Water activity and the preservation of plant foods. Food Chem. 2003, 82, 79–86. [Google Scholar] [CrossRef]

- Barbosa de Lima, A.G.; Da Silva, J.V.; Pereira, E.M.A.; dos Santos, I.B.; de Lima, W.B. Drying of Bioproducts: Quality and Energy Aspects. In Drying and Energy Technologies; Delgado, J., Barbosa de Lima, A., Gilson, Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 1–18. ISBN 978-3-319-19767-8. [Google Scholar]

- Abdelaziz, E.A.; Saidur, R.; Mekhilef, S. A review on energy saving strategies in industrial sector. Renew. Sustain. Energy Rev. 2011, 15, 150–168. [Google Scholar] [CrossRef]

- Plattes, M.; Köhler, C.; Gallé, T. Disequilibrium calorimetry for determination of ultrasonic power in sonochemistry. MethodsX 2017, 4, 274–278. [Google Scholar] [CrossRef]

- Kowalski, S.J.; Pawłowski, A. Intensification of apple drying due to ultrasound enhancement. J. Food Eng. 2015, 156, 1–9. [Google Scholar] [CrossRef]

- Kurilich, A.C.; Jeffery, E.H.; Juvik, J.A.; Wallig, M.A.; Klein, B.P. Antioxidant capacity of different broccoli (Brassica oleracea) genotypes using the oxygen radical absorbance capacity (ORAC) assay. J. Agric. Food Chem. 2002, 50, 5053–5057. [Google Scholar] [CrossRef]

- Hironaka, K.; Kikuchi, M.; Koaze, H.; Sato, T.; Kojima, M.; Yamamoto, K.; Yasuda, K.; Mori, M.; Tsuda, S. Ascorbic acid enrichment of whole potato tuber by vacuum-impregnation. Food Chem. 2011, 127, 1114–1118. [Google Scholar] [CrossRef]

- Tiwari, B.K.; Patras, A.; Brunton, N.; Cullen, P.J.; O’Donnell, C.P. Effect of ultrasound processing on anthocyanins and color of red grape juice. Ultrason. Sonochem. 2010, 17, 598–604. [Google Scholar] [CrossRef]

- Nowacka, M.; Fijalkowska, A.; Dadan, M.; Rybak, K.; Wiktor, A.; Witrowa-Rajchert, D. Effect of ultrasound treatment during osmotic dehydration on bioactive compounds of cranberries. Ultrasonics 2018, 83, 18–25. [Google Scholar] [CrossRef]

- Witrowa-Rajchert, D.; Radecka-Wierzbicka, M. Wpływ Techniki Suszenia Konwekcyjnego na Wybrane Wyznaczniki Jakości Suszonej Tkanki Roślinnej. Available online: http://yadda.icm.edu.pl/yadda/element/bwmeta1.element.baztech-834dfd78-2b56-4b37-a35f-8702db7b43ec (accessed on 19 March 2021).

- Kaliś, K. Dwukierunkowe działanie witamyny C a degradacja i suplementacja. Postępy Hig. Med. Doświadczalnej 2015, 69, 1239–1244. [Google Scholar] [CrossRef]

- Fernandes, F.A.N.; Rodrigues, S. Application of Ultrasound and Ultrasound-Assisted Osmotic Dehydration in Drying of Fruits. Dry. Technol. 2008, 26, 1509–1516. [Google Scholar] [CrossRef]

- Karathanos, V.T.; Kanellopoulos, N.K.; Belessiotis, V.G. Development of porous structure during air drying of agricultural plant products. J. Food Eng. 1996, 29, 167–183. [Google Scholar] [CrossRef]

- Pasławska, M.; Nawirska-Olszańska, A.; Stępień, B.; Klim, A. The Influence of Vacuum Impregnation on Nutritional Properties of Fluidized Bed Dried Kale (Brassica oleracea L. Var. Acephala) Leaves. Molecules 2018, 23, 2764. [Google Scholar] [CrossRef]

- Fontana, A.J. Understanding the importance of water activity in food. Cereal Foods World 2000, 45, 7–10. [Google Scholar]

- Beuchat, L.R. Microbial stability as affected by water activity. Cereal Foods World 1981, 26, 345–349. [Google Scholar]

- Beuchat, L.R. Influence of Water Activity on Growth, Metabolic Activities and Survival of Yeasts and Molds. J. Food Prot. 1983, 46, 135–141. [Google Scholar] [CrossRef]

| Process | Duration (min) | Ultrasound | |

|---|---|---|---|

| Vacuum Period | Relaxation Period | ||

| VI | 30 | 30 | - |

| UVI1 | 30 | 30 | during vacuum period |

| UVI2 | 30 | 30 | during relaxation period |

| UVI3 | 30 | 30 | during vacuum and relaxation periods |

| Process | DR 10 (g/min) | Change (%) | DT (min) | Change (%) | SEC 10 (MJ/kg) | Change (%) |

|---|---|---|---|---|---|---|

| CV | 4.81 ± 0.24 c | - | 290 ± 14.5 a | - | 1.60 ± 0.08 c | - |

| VI-CV | 4.84 ± 0.15 c | 0.70% | 290 ± 6.9 a | −0.06% | 1.57 ± 0.07 c | −1.15% |

| UVI1-CV | 5.50 ± 0.01 ab | 14.43% | 252 ± 3.4 b | −13.01% | 1.40 ± 0.02 ab | −12.84% |

| UVI2-CV | 5.56 ± 0.09 a | 15.63% | 247 ± 3.7 c | −14.71% | 1.38 ± 0.01 b | −13.98% |

| UVI3-CV | 5.44 ± 0.08 b | 13.15% | 255 ± 0.2 b | −12.04% | 1.43 ± 0.01 a | −10.56% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mierzwa, D.; Szadzińska, J.; Radziejewska-Kubzdela, E.; Biegańska-Marecik, R. Ultrasound-Assisted Vacuum Impregnation as a Strategy for the Management of Potato By-Products. Sustainability 2021, 13, 3437. https://doi.org/10.3390/su13063437

Mierzwa D, Szadzińska J, Radziejewska-Kubzdela E, Biegańska-Marecik R. Ultrasound-Assisted Vacuum Impregnation as a Strategy for the Management of Potato By-Products. Sustainability. 2021; 13(6):3437. https://doi.org/10.3390/su13063437

Chicago/Turabian StyleMierzwa, Dominik, Justyna Szadzińska, Elżbieta Radziejewska-Kubzdela, and Róża Biegańska-Marecik. 2021. "Ultrasound-Assisted Vacuum Impregnation as a Strategy for the Management of Potato By-Products" Sustainability 13, no. 6: 3437. https://doi.org/10.3390/su13063437

APA StyleMierzwa, D., Szadzińska, J., Radziejewska-Kubzdela, E., & Biegańska-Marecik, R. (2021). Ultrasound-Assisted Vacuum Impregnation as a Strategy for the Management of Potato By-Products. Sustainability, 13(6), 3437. https://doi.org/10.3390/su13063437