Performance Evaluation of Soft Computing for Modeling the Strength Properties of Waste Substitute Green Concrete

Abstract

1. Introduction

2. Methods and Datasets

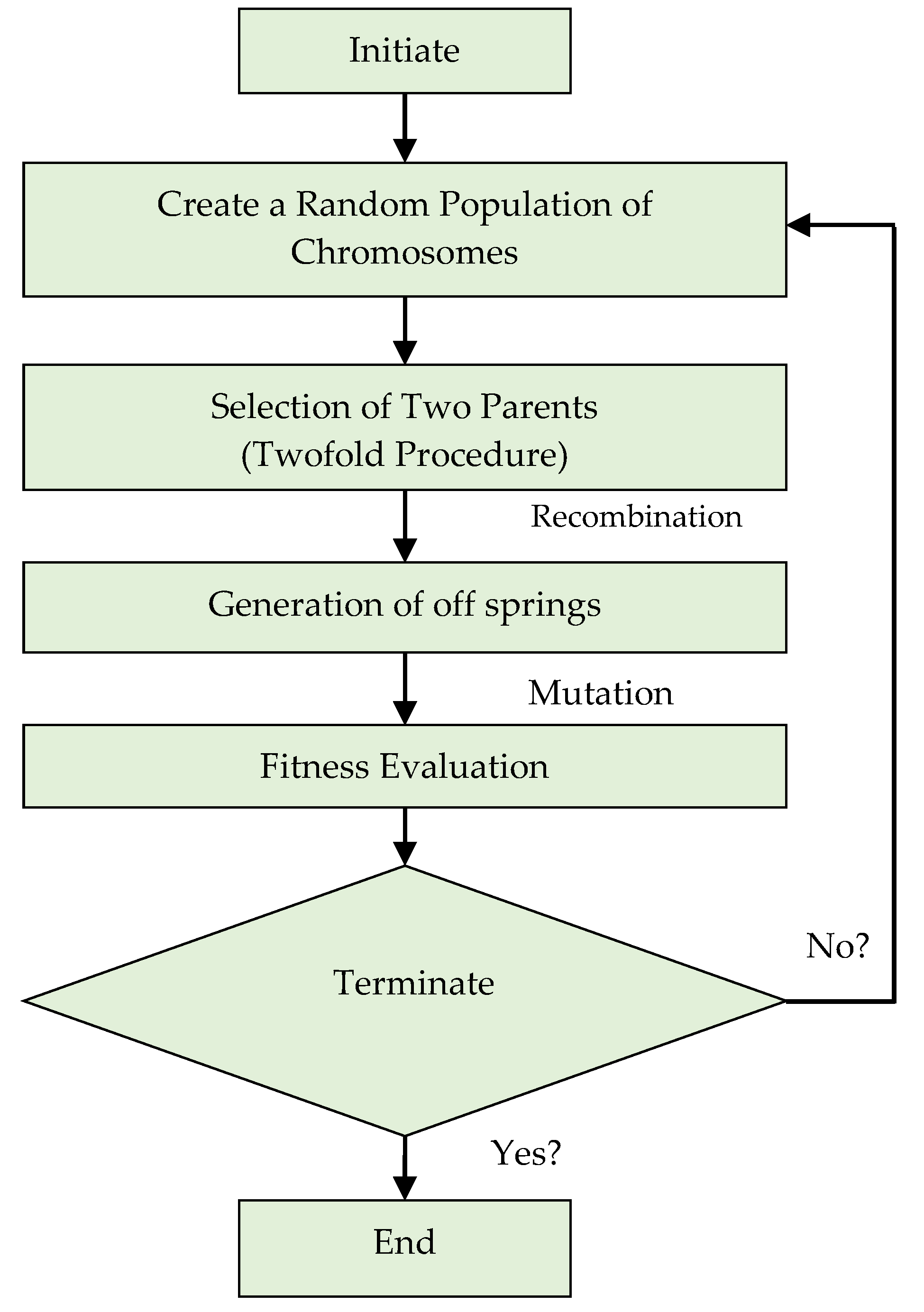

2.1. Multi Expression Programming

2.2. Modeling Dataset

2.3. Cross-Validation with k-Fold Algorithm

2.4. Performance Measures

3. Experimental Methods

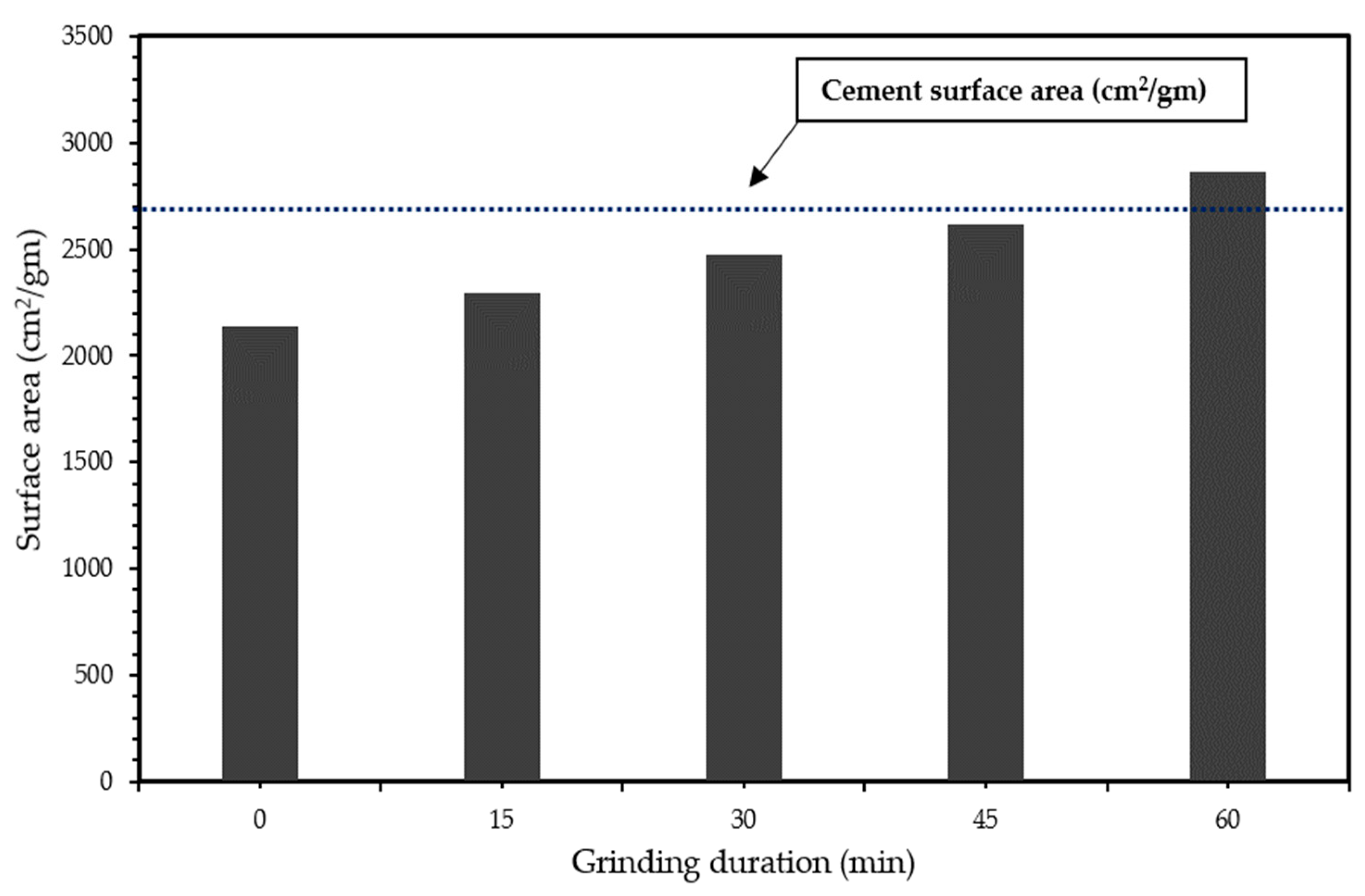

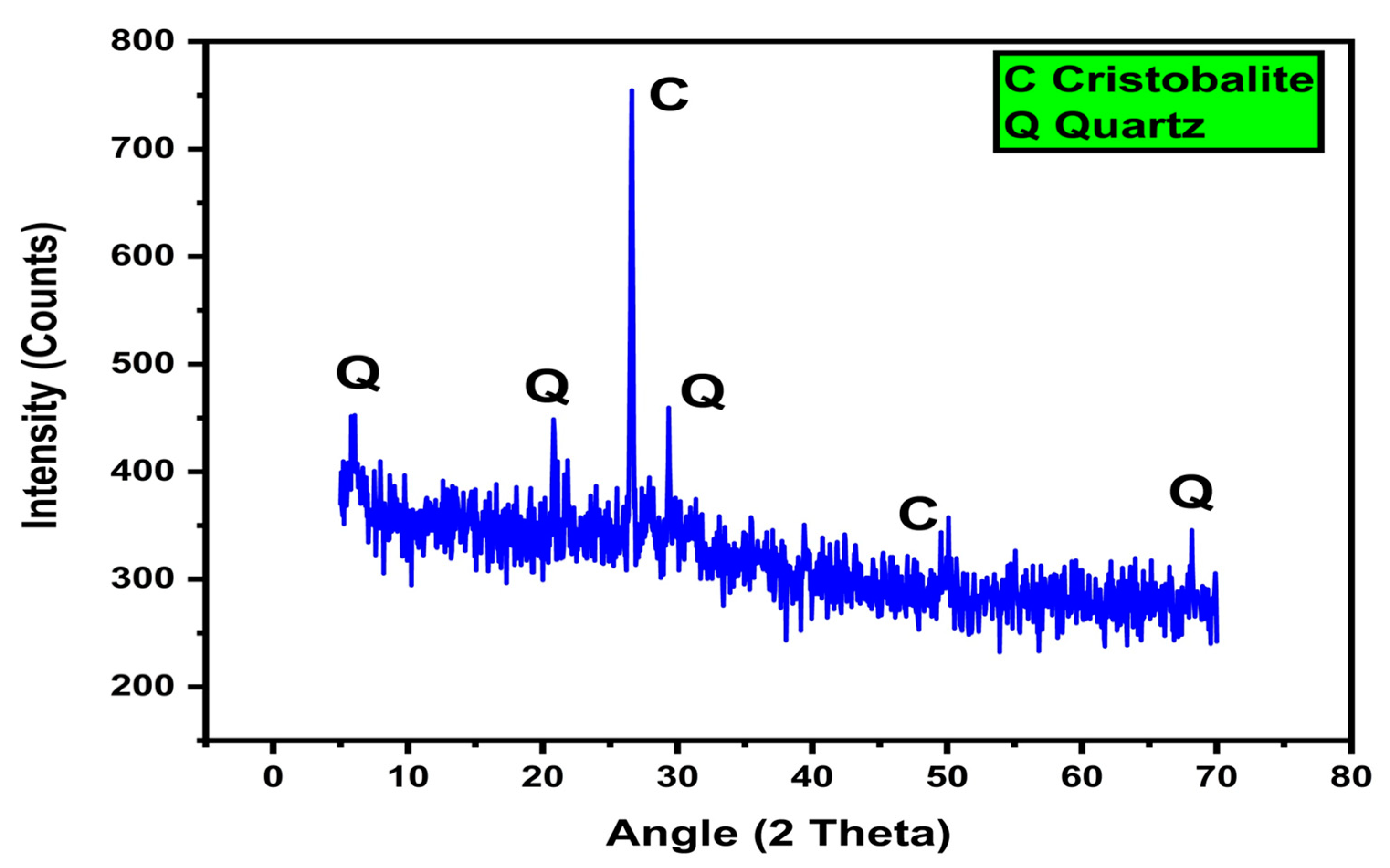

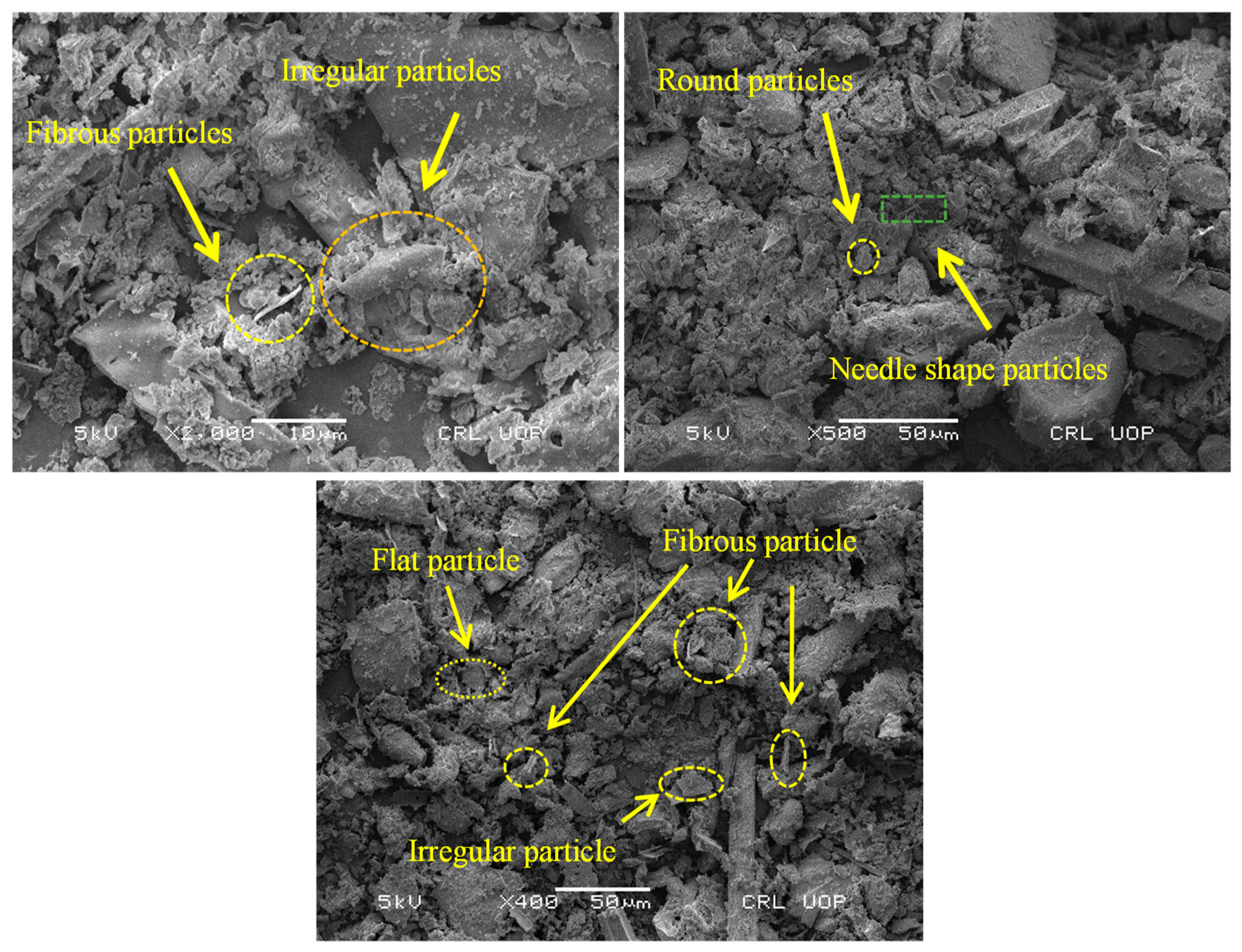

3.1. Sugarcane Bagasse Ash (SCBA) Characterization

3.2. Mix Proportions and Specimen Preparation

4. Results and Discussion

4.1. Mechanical Properties of SCBA Concrete

4.2. Modeling Results of SCBA Concrete

4.2.1. Formulation of Compressive Strength (CS)

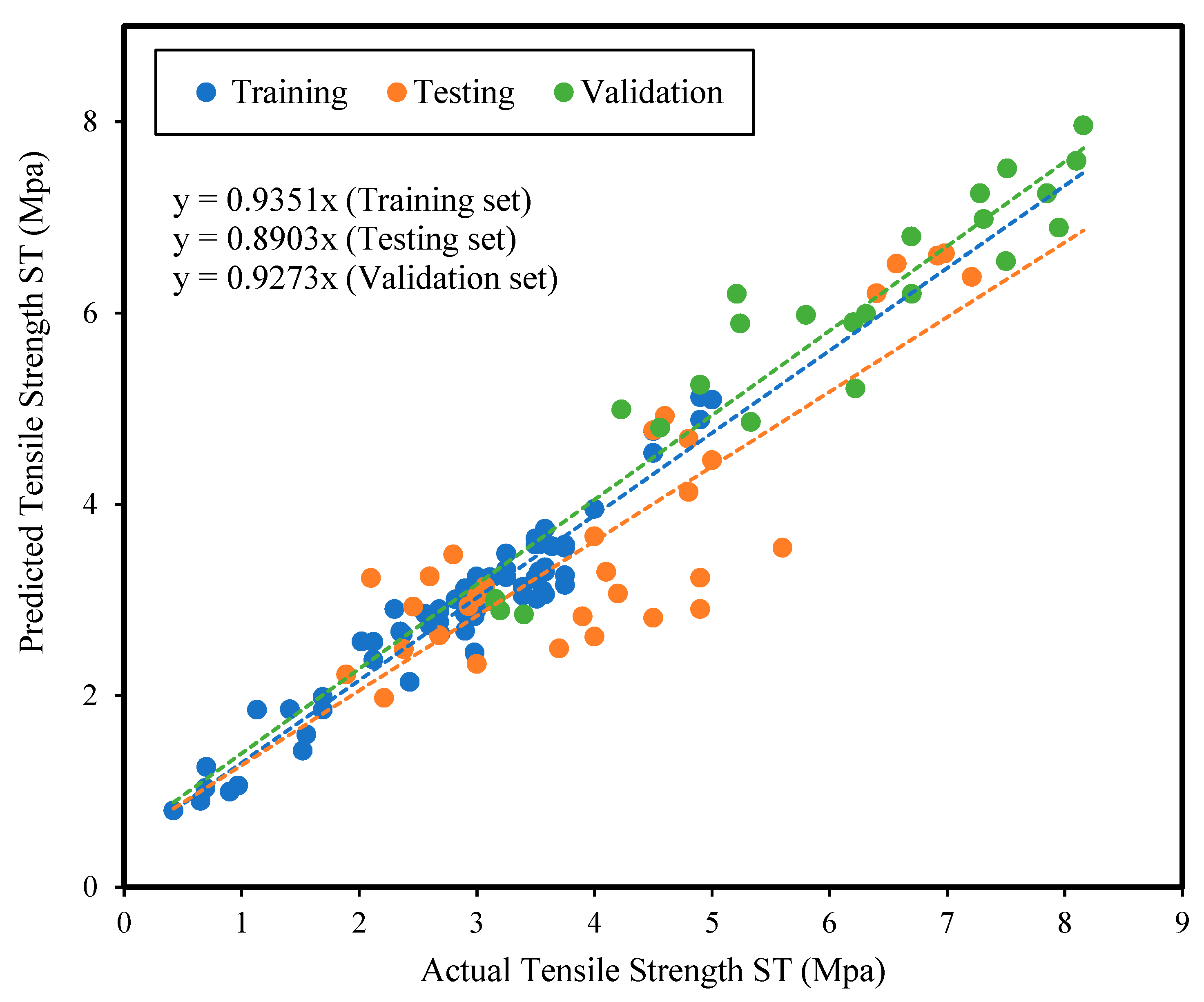

4.2.2. Formulation of Splitting Tensile Strength (ST)

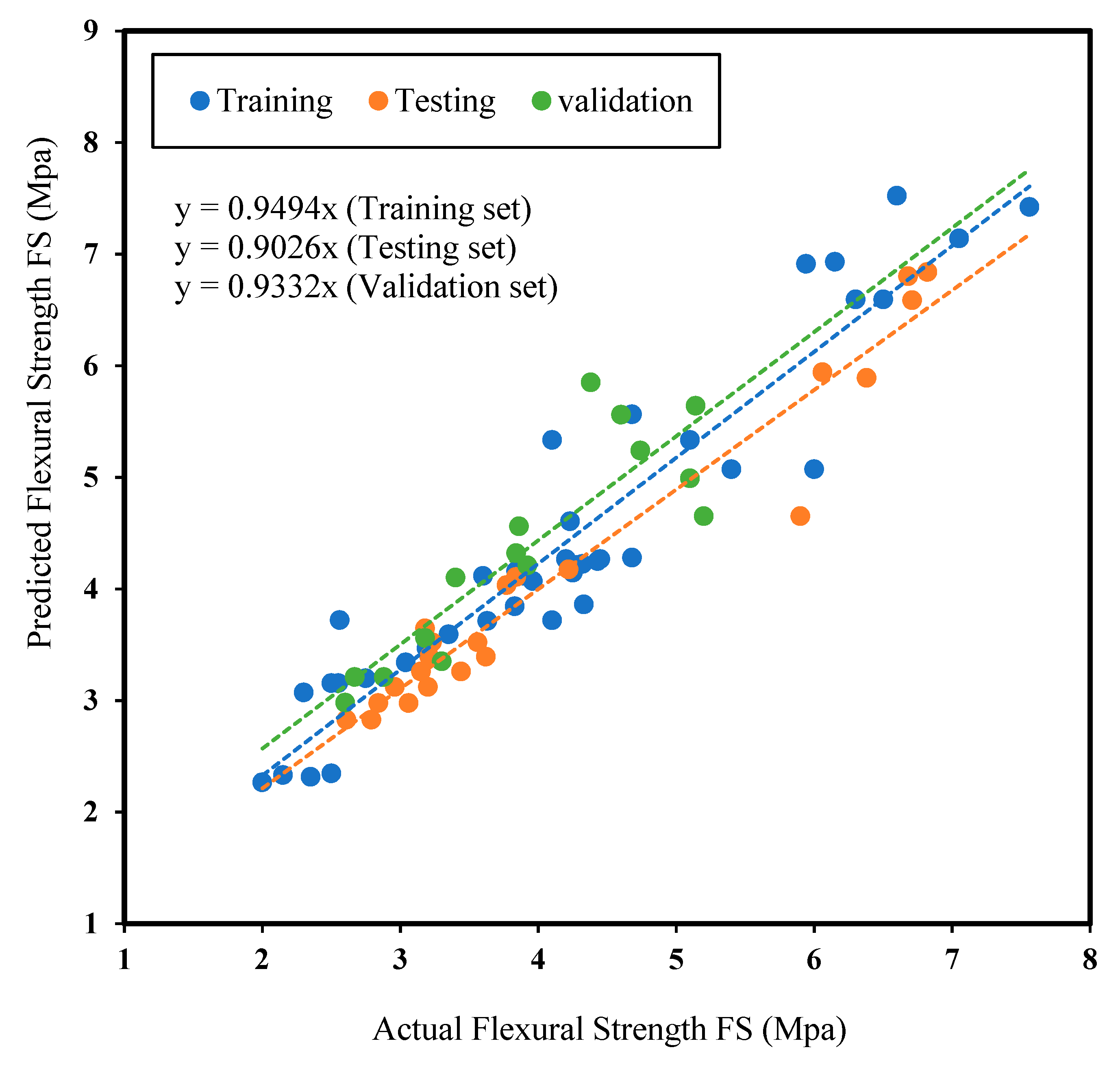

4.2.3. Formulation of Flexural Strength (FS)

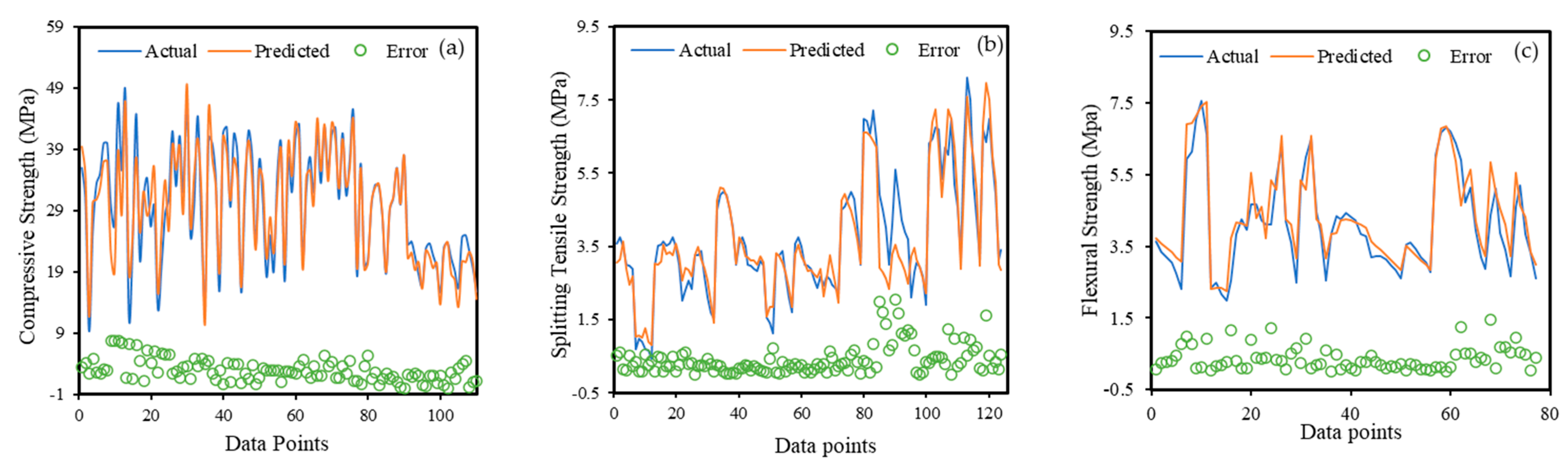

4.3. Models Error Assessment

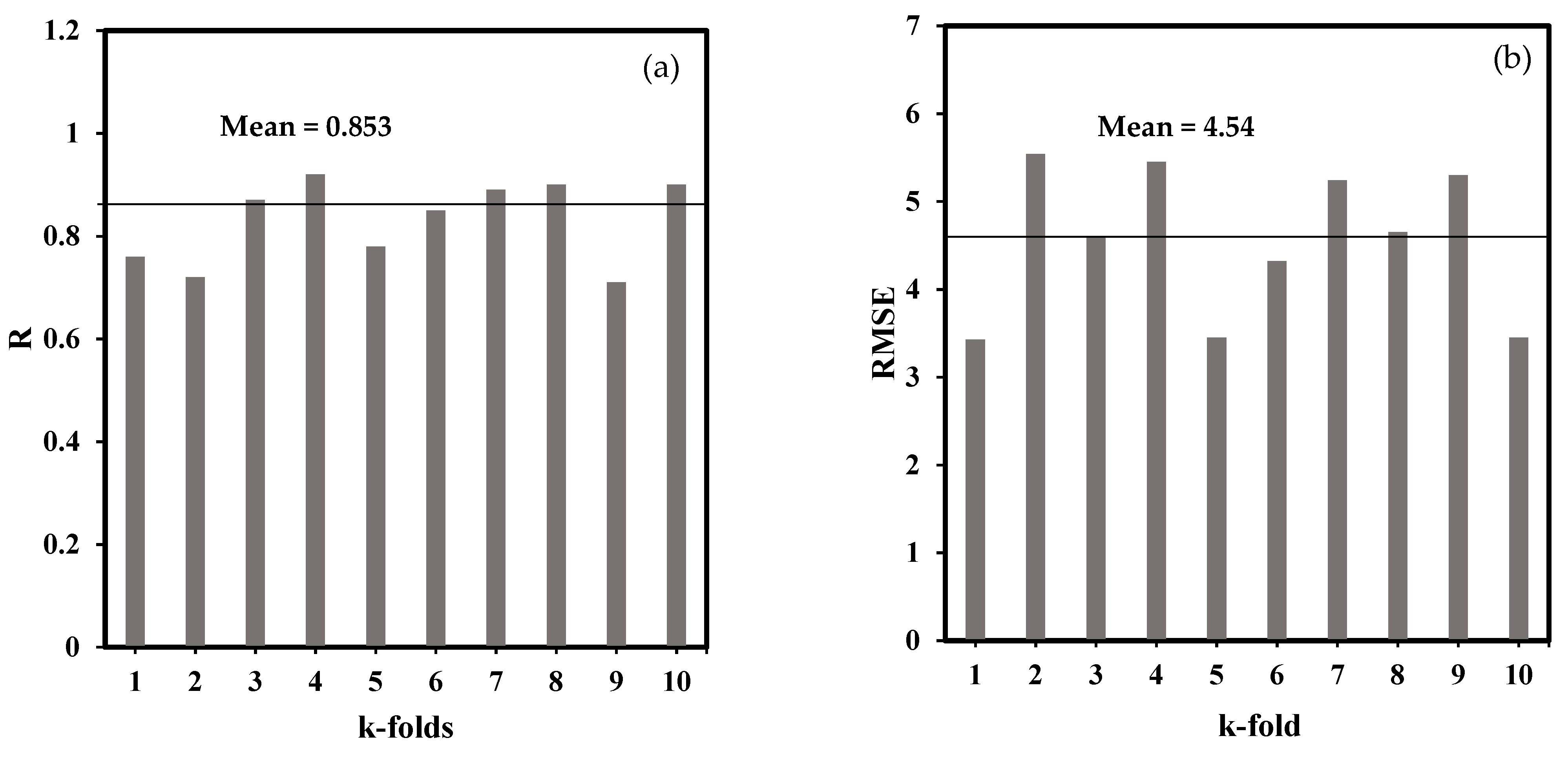

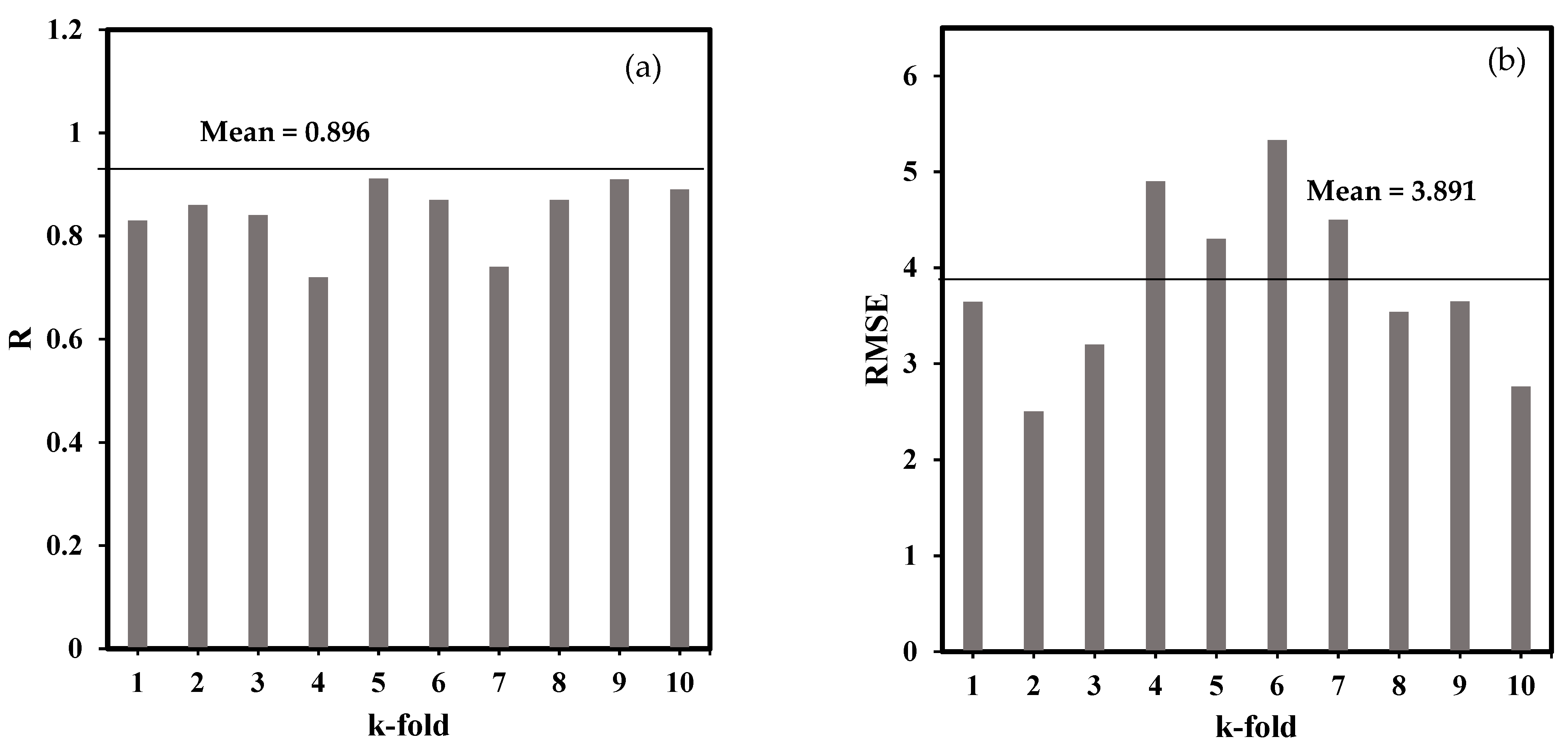

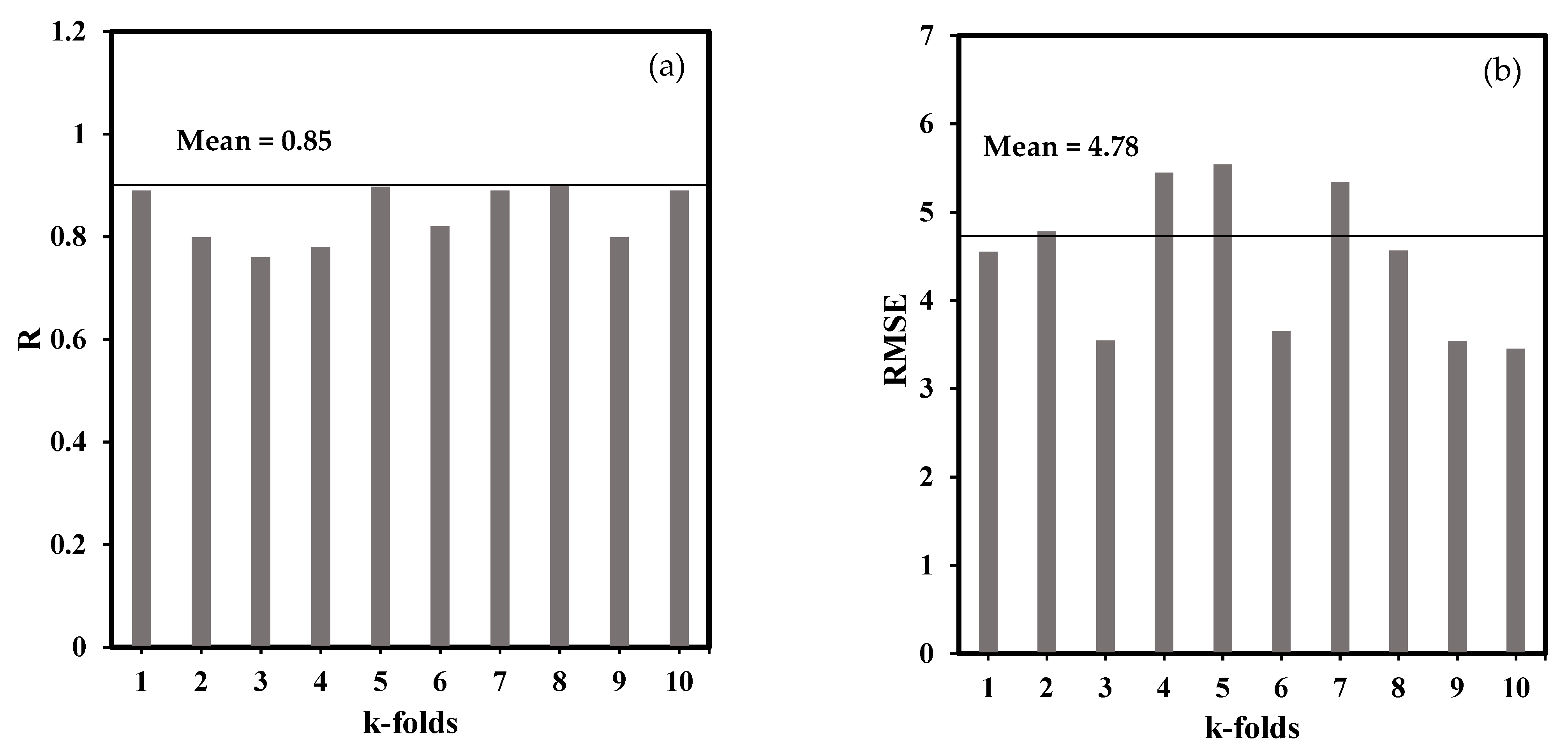

4.4. Model Cross-Validation Results

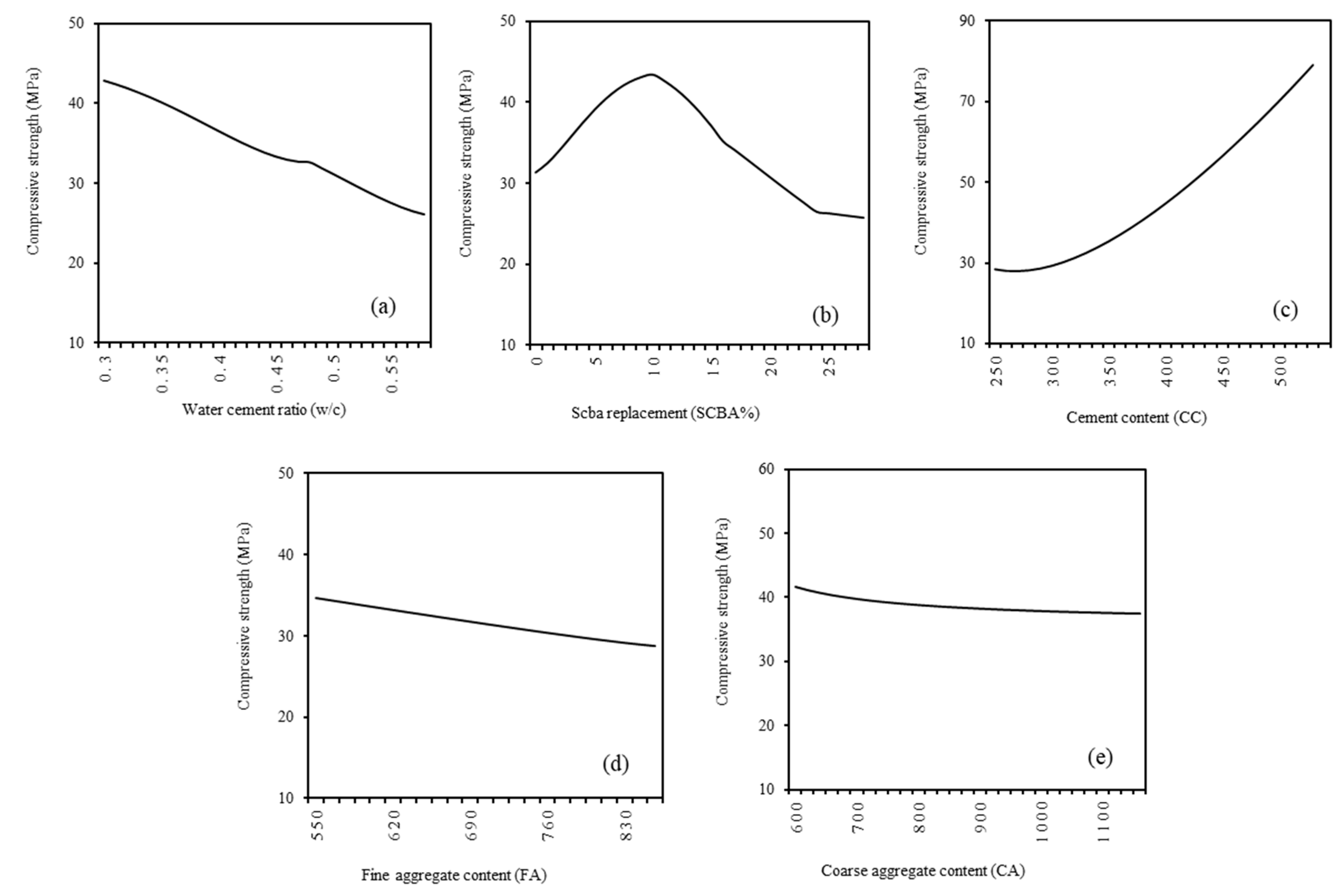

4.5. Parametric Analysis

5. Conclusions

- The SCBA showed good pozzolanic properties when processed, i.e., passed from sieve #200 and grinded up to cement fineness.

- Microfibrous structure and irregular shape particles were observed in the SEM images of processed SCBA.

- The concrete showed maximum strength when cement was replaced with 10% SCBA. Afterward, strength reduction was observed for higher replacement levels.

- The multi expression programming (MEP) was found to be very efficient in modeling the strength properties of SCBA concrete. The parametric study showed that the developed MEP models for SCBA concrete are accurate and revealed the effect of input parameters in the modeling output.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bahurudeen, A.; Marckson, A.V.; Kishore, A.; Santhanam, M. Development of Sugarcane Bagasse Ash Based Portland Pozzo-Lana Cement and Evaluation of Compatibility with Superplasticizers. Constr. Build. Mater. 2014, 68, 465–475. [Google Scholar] [CrossRef]

- He, Z.; Zhu, X.; Wang, J.; Mu, M.; Wang, Y. Comparison of CO2 Emissions from OPC and Recycled Cement Production. Constr. Build. Mater. 2019, 211, 965–973. [Google Scholar] [CrossRef]

- Mao, L.-X.; Hu, Z.; Xia, J.; Feng, G.-L.; Azim, I.; Yang, J.; Liu, Q.-F. Multi-Phase Modelling of Electrochemical Rehabilitation for ASR and Chloride Affected Concrete Composites. Compos. Struct. 2019, 207, 176–189. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Kanraj, D.; Dev, V.G.; Santhanam, M. Performance Evaluation of Sugarcane Bagasse Ash Blended Cement in Concrete. Cem. Concr. Compos. 2015, 59, 77–88. [Google Scholar] [CrossRef]

- Iqbal, M.F.; Liu, Q.-F.; Azim, I.; Zhu, X.; Yang, J.; Javed, M.F.; Rauf, M. Prediction of Mechanical Properties of Green Concrete Incorporating Waste Foundry Sand Based on Gene Expression Programming. J. Hazard. Mater. 2020, 384, 121322. [Google Scholar] [CrossRef]

- Frontera, P.; Malara, A.; Mistretta, M. Recent Trends in Sustainability Assessment of “Green Concrete”. In Smart Innovation, Systems and Technologies; Bevilacqua, C., Calabrò, F., Della Spina, L., Eds.; New Metropolitan Perspectives: Reggio di Calabria, Italy, 2020; Volume 178, pp. 1402–14127. [Google Scholar]

- Bajare, D.; Būmanis, G.; Upeniece, L. Coal Combustion Bottom Ash as Microfiller with Pozzolanic Properties for Traditional Concrete. Procedia Eng. 2013, 57, 149–158. [Google Scholar] [CrossRef]

- Pippo, W.A.A.; Luengo, C. Sugarcane Energy Use: Accounting of Feedstock Energy Considering Current Agro-Industrial Trends and Their Feasibility. Int. J. Energy Environ. Eng. 2013, 4, 10. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Fairbairn, E.M.; Tavares, L.M.; Oliveira, C.H. Influence of Mechanical Grinding on the Pozzolanic Activity of Residual Sugarcane Bagasse Ash. In Proceedings of the International RILEM Conference on the Use of Recycled Materials in Building and Structures, Barcelona, Spain, 8–11 November 2004; pp. 731–740. [Google Scholar]

- Pedersen, K.; Jensen, A.; Skjothrasmussen, M.; Damjohansen, K. A Review of the Interference of Carbon Containing Fly Ash with Air Entrainment in Concrete. Prog. Energy Combust. Sci. 2008, 34, 135–154. [Google Scholar] [CrossRef]

- Chusilp, N.; Jaturapitakkul, C.; Kiattikomol, K. Utilization of Bagasse Ash as a Pozzolanic Material in Concrete. Constr. Build. Mater. 2009, 23, 3352–3358. [Google Scholar] [CrossRef]

- Hasan, N.M.S.; Sobuz, H.R.; Tamanna, N.; Slah, M. Properties of Concrete by Using Bagasse Ash and Recycle Aggregate. Concr. Res. Lett. 2014, 5, 768–785. [Google Scholar]

- Jagadesh, P.; Ramachandramurthy, A.; Murugesan, R. Evaluation of mechanical properties of Sugar Cane Bagasse Ash con-crete. Constr. Build. Mater. 2018, 176, 608–617. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Santhanam, M. Performance Evaluation of Sugarcane Bagasse Ash-Based Cement for Durable Concrete. In Proceedings of the 5th International Conference on the Durability of Concrete Structures, Purdue University, West Lafayette, IN, USA, 24–26 July 2014. [Google Scholar]

- Bahurudeen, A.; Wani, K.; Basit, M.A.; Santhanam, M. Assesment of Pozzolanic Performance of Sugarcane Bagasse Ash. J. Mater. Civ. Eng. 2016, 28, 04015095. [Google Scholar] [CrossRef]

- Rerkpiboon, A.; Tangchirapat, W.; Jaturapitakkul, C. Strength, Chloride Resistance, and Expansion of Concretes Containing Ground Bagasse Ash. Constr. Build. Mater. 2015, 101, 983–989. [Google Scholar] [CrossRef]

- Khan, M.I. Predicting properties of High Performance Concrete Containing Composite Cementitious Materials Using Artificial Neural Networks. Autom. Constr. 2012, 22, 516–524. [Google Scholar] [CrossRef]

- Dantas, A.T.A.; Leite, M.B.; Nagahama, K.D.J. Prediction of Compressive Strength of Concrete Containing Construction and Demolition Waste Using Artificial Neural Networks. Constr. Build. Mater. 2013, 38, 717–722. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Behnood, A.; Arashpour, M. Predicting the Compressive Strength of Normal and High-Performance Concretes Using ANN and ANFIS Hybridized with Grey Wolf Optimizer. Constr. Build. Mater. 2020, 232, 117266. [Google Scholar] [CrossRef]

- Parichatprecha, R.; Nimityongskul, P. Analysis of Durability of High Performance Concrete Using Artificial Neural Networks. Constr. Build. Mater. 2009, 23, 910–917. [Google Scholar] [CrossRef]

- Farooq, F.; Nasir Amin, M.; Khan, K.; Rehan Sadiq, M.; Faisal Javed, M.; Aslam, F.; Alyousef, R. A Comparative Study of Random Forest and Genetic Engineering Programming for the Prediction of Compressive Strength of High Strength Concrete (HSC). Appl. Sci. 2020, 10, 7330. [Google Scholar] [CrossRef]

- Zhang, J.; Li, D.; Wang, Y. Toward Intelligent Construction: Prediction of Mechanical Properties of Manufactured-Sand Concrete Using Tree-Based Models. J. Clean. Prod. 2020, 258, 120665. [Google Scholar] [CrossRef]

- Sun, Y.; Li, G.; Zhang, J.; Qian, D. Prediction of the Strength of Rubberized Concrete by an Evolved Random Forest Model. Adv. Civ. Eng. 2019, 2019, 5198583. [Google Scholar] [CrossRef]

- Chou, J.-S.; Chiu, C.-K.; Farfoura, M.; Al-Taharwa, I. Optimizing the Prediction Accuracy of Concrete Compressive Strength Based on a Comparison of Data-Mining Techniques. J. Comput. Civ. Eng. 2011, 25, 242–253. [Google Scholar] [CrossRef]

- Deng, F.; He, Y.; Zhou, S.; Yu, Y.; Cheng, H.; Wu, X. Compressive Strength Prediction of Recycled Concrete Based on Deep Learning. Constr. Build. Mater. 2018, 175, 562–569. [Google Scholar] [CrossRef]

- Ashteyat, A.; Obaidat, Y.T.; Murad, Y.Z.; Haddad, R. Compressive Strength Prediction of Lightweight Short Columns at Elevated Temperature Using Gene Expression Programing and Artificial Neural Network. J. Civ. Eng. Manag. 2020, 26, 189–199. [Google Scholar] [CrossRef]

- Behnood, A.; Golafshani, E.M. Predicting the Compressive Strength of Silica Fume Concrete Using Hybrid Artificial Neural Network with Multi-Objective Grey Wolves. J. Clean. Prod. 2018, 202, 54–64. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Sobhani, J.; Mirgozar, M. Modeling Compressive Strength of EPS Lightweight Concrete Using Regression, Neural Network And ANFIS. Constr. Build. Mater. 2013, 42, 205–216. [Google Scholar] [CrossRef]

- Öztaş, A.; Pala, M.; Özbay, E.; Kanca, E.; Çağlar, N.; Bhatti, M.A. Predicting the Compressive Strength and Slump of High Strength Concrete Using Neural Network. Constr. Build. Mater. 2006, 20, 769–775. [Google Scholar] [CrossRef]

- Nguyen, T.; Kashani, A.; Ngo, T.; Bordas, S. Deep Neural Network with High-Order Neuron for the Prediction of Foamed Concrete Strength. Comput. Civ. Infrastruct. Eng. 2019, 34, 316–332. [Google Scholar] [CrossRef]

- Getahun, M.A.; Shitote, S.M.; Gariy, Z.C.A. Artificial Neural Network Based Modelling Approach for Strength Prediction of Concrete Incorporating Agricultural and Construction Wastes. Constr. Build. Mater. 2018, 190, 517–525. [Google Scholar] [CrossRef]

- Javed, M.F.; Amin, M.N.; Shah, M.I.; Khan, K.; Iftikhar, B.; Farooq, F.; Aslam, F.; Alyousef, R.; Alabduljabbar, H. Applications of Gene Expression Programming and Regression Techniques for Estimating Compressive Strength of Bagasse Ash based Concrete. Crystals 2020, 10, 737. [Google Scholar] [CrossRef]

- Aslam, F.; Farooq, F.; Amin, M.N.; Khan, K.; Waheed, A.; Akbar, A.; Javed, M.F.; Alyousef, R.; Alabdulijabbar, H. Applications of Gene Expression Programming for Estimating Compressive Strength of High-Strength Concrete. Adv. Civ. Eng. 2020, 2020, 8850535. [Google Scholar] [CrossRef]

- Javed, M.F.; Farooq, F.; Memon, S.A.; Akbar, A.; Khan, M.A.; Aslam, F.; Alyousef, R.; Alabduljabbar, H.; Rehman, S.K.U. New Prediction Model for the Ultimate Axial Capacity of Concrete-Filled Steel Tubes: An Evolutionary Approach. Crystals 2020, 10, 741. [Google Scholar] [CrossRef]

- Oltean, M.; Grosan, C. A Comparison of Several Linear Genetic Programming Techniques. Complex Syst. 2003, 14, 285–314. [Google Scholar]

- Arabshahi, A.; Gharaei-Moghaddam, N.; Tavakkolizadeh, M. Development of Applicable Design Models for Concrete Columns Confined with Aramid Fiber Reinforced Polymer Using Multi-Expression Programming. Structures 2020, 23, 225–244. [Google Scholar] [CrossRef]

- Cramer, N.L. A Representation for the Adaptive Generation of Simple Sequential Programs. In Proceedings of the First International Conference on Genetic Algorithms, Carnegic-Mellon University Pittsburgh, Pittsburgh, PA, USA, 24–26 July 1985. [Google Scholar]

- Koza, J.R.; Koza, J.R. Genetic Programming: On the Programming of Computers by Means of Natural Selection; MIT Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Holland, J.H. Adaptation in Natural and Artificial Systems. Adapt. Nat. Artif. Syst. 1992, 561. [Google Scholar] [CrossRef]

- Sarıdemir, M. Prediction of Compressive Strength of Concretes Containing Metakaolin and Silica Fume by Artificial Neural Networks. Adv. Eng. Softw. 2009, 40, 350–355. [Google Scholar] [CrossRef]

- Nazari, A.; Torgal, F.P. Modeling the Compressive Strength of Geopolymeric Binders by Gene Expression Programming-GEP. Expert Syst. Appl. 2013, 40, 5427–5438. [Google Scholar] [CrossRef]

- Ferreira, C. Gene Expression Programming: Mathematical Modeling by an Artificial Intelligence; Springer: Amsterdam, The Netherlands, 2006; p. 21. [Google Scholar]

- Oltean, M.; Dumitrescu, D. Multi Expression Programming. Technical Report; Babeş-Bolyai University: Cluj-Napoca, Romania, 2002. [Google Scholar]

- Gandomi, A.; Faramarzifar, A.; Rezaee, P.G.; Asghari, A.; Talatahari, S. New Design Equations for Elastic Modulus of Concrete Using Multi Expression Programming. J. Civ. Eng. Manag. 2015, 21, 761–774. [Google Scholar] [CrossRef]

- Oltean, M.; Groşan, C. Evolving Evolutionary Algorithms Using Multi Expression Programming. In Proceedings of the Constructive Side-Channel Analysis and Secure Design; Springer International Publishing: Amsterdam, The Netherlands, 2003; pp. 651–658. [Google Scholar]

- Sharifi, S.; Abrishami, S.; Gandomi, A.H. Consolidation Assessment Using Multi Expression Programming. Appl. Soft Comput. 2020, 86, 105842. [Google Scholar] [CrossRef]

- Mousavi, S.; Gandomi, A.; Alavi, A.; Vesalimahmood, M. Modeling of Compressive Strength of HPC Mixes Using a Combined Algorithm of Genetic Programming and Orthogonal Least Squares. Struct. Eng. Mech. 2010, 36, 225–241. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, B.; Wang, L.; Zhu, F. Predicting Cement Compressive Strength Using Double-Layer Multi-Expression Programming. In Proceedings of the Fourth International Conference on Computational and Information Sciences, Chongqing, China, 17–19 August 2012; pp. 94–97. [Google Scholar]

- Alavi, A.H.; Mollahasani, A.; Gandomi, A.H.; Bazaz, J.B. Formulation of Secant and Reloading Soil Deformation Moduli Using Multi Expression Programming. Eng. Comput. 2012, 29, 173–197. [Google Scholar] [CrossRef]

- Srinivasan, R.; Sathiya, K. Experimental Study on Bagasse Ash in Concrete. Int. J. Serv. Learn. Eng. Humanit. Eng. Soc. Entrep. 2010, 5, 60–66. [Google Scholar] [CrossRef]

- Patel, J.A.; Raijiwala, D. Experimental Study on Use of Sugar Cane Bagasse Ash in Concrete by Partially Replacement with Cement. Int. J. Innov. Res. Sci. Eng. Technol. 2015, 4, 2228–2232. [Google Scholar]

- Neeraja, D.; Jagan, S.; Kumar, S.; Mohan, P.G. Experimental Study on Strength Properties of Concrete by Partial Replacement of Cement with Sugarcane Bagasse Ash. Nat. Environ. Pollut. Technol. 2014, 13, 629. [Google Scholar]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Evaluation of Bagasse Ash as Supplementary Cementitious Material. Cem. Concr. Compos. 2007, 29, 515–524. [Google Scholar] [CrossRef]

- Subramani, T.; Prabhakaran, M. Experimental Study on Bagasse Ash in Concrete. Int. J. Appl. Innov. Eng. Manag. 2015, 4, 163–172. [Google Scholar]

- Rukzon, S.; Chindaprasirt, P. Utilization of Bagasse Ash in High-Strength Concrete. Mater. Des. 2012, 34, 45–50. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.D.M.R. Ultrafine Grinding of Sugar Cane Bagasse Ash for Appli-Cation as Pozzolanic Admixture in Concrete. Cem. Concr. Res. 2009, 39, 110–115. [Google Scholar] [CrossRef]

- Kumar, T.S.; Balaji, K.; Rajasekhar, K. Assessment of Sorptivity and Water Absorption of Concrete with Partial Replacement of Cement by Sugarcane Bagasse Ash (SCBA) and Silica Fume. Int. J. Appl. Eng. Res. 2016, 11, 5747–5752. [Google Scholar]

- Amin, N.-U. Use of Bagasse Ash in Concrete and Its Impact on the Strength and Chloride Resistivity. J. Mater. Civ. Eng. 2011, 23, 717–720. [Google Scholar] [CrossRef]

- Hailu, B.; Dinku, A. Application of Sugarcane Bagasse Ash as a Partial Cement Replacement Material. Zede J. 2012, 29, 1–12. [Google Scholar]

- Mangi, S.A.; Jamaluddin, N.; Ibrahim, M.H.W.; Abdullah, A.H.; Awal, A.S.M.A.; Sohu, S.; Ali, N. Utilization of Sugarcane Bagasse Ash in Concrete as Partial Replacement of Cement. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 271, p. 012001. [Google Scholar]

- Dhengare, S.W.; Raut, S.P.; Bandwal, N.V.; Khangan, A. Investigation into Utilization of Sugarcane Bagasse Ash as Supple-Mentary Cementitious Material in Concrete. Int. J. 2015, 109. [Google Scholar]

- Hussein, A.A.E.; Shafiq, N.; Nuruddin, M.F.; Memon, F.A. Compressive Strength and Microstructure of Sugar Cane Bagasse Ash Concrete. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 2569–2577. [Google Scholar] [CrossRef]

- Reddy, M.V.S.; Ashalatha, K.; Madhuri, M.; Sumalatha, P. Utilization of Sugarcane Bagasse Ash (SCBA) in Concrete by Partial Replacement of Cement. IOSR J. Mech. Civ. Eng. 2015, 12, 12–16. [Google Scholar]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Evaluation of Bagasse Ash as Corrosion Resisting Admixture for Carbon Steel in Concrete. Anti-Corros. Methods Mater. 2007, 54, 230–236. [Google Scholar] [CrossRef]

- Yashwanth, M.K.; GB, A.; Raghavendra, A.; Kumar, B.N. An Experimental Study on Alternative Cementitious Materials: Bagasse Ash as Partial Replacement for Cement in Structural Lightweight Concrete. Indian Concr. J. 2017, 91, 51–58. [Google Scholar]

- Shafiq, N.; Hussein, A.A.E.; Nuruddin, M.F.; Al Mattarneh, H. Effects of Sugarcane Bagasse Ash on the Properties of Concrete. In Proceedings of the Institution of Civil Engineers—Engineering Sustainability; Thomas Telford Ltd.: London, UK, 2018; Volume 171, pp. 123–132. [Google Scholar]

- Priya, K.L.; Ragupathy, R. Effect of Sugarcane Bagasse Ash on Strength Properties of Concrete. Int. J. Res. Eng. Technol. 2016, 5, 159–164. [Google Scholar]

- Praveenkumar, S.; Sankarasubramanian, G. Mechanical and Durability Properties of Bagasse Ash-Blended High-Performance Concrete. SN Appl. Sci. 2019, 1, 1664. [Google Scholar] [CrossRef]

- Xu, Q.; Ji, T.; Gao, S.-J.; Yang, Z.; Wu, N. Characteristics and Applications of Sugar Cane Bagasse Ash Waste in Cementitious Materials. Materials 2018, 12, 39. [Google Scholar] [CrossRef]

- Arenas-Piedrahita, J.; Montes-García, P.; Mendoza-Rangel, J.; Calvo, H.L.; Valdez-Tamez, P.; Martínez-Reyes, J. Mechanical and Durability Properties of Mortars Prepared with Untreated Sugarcane Bagasse Ash and Untreated Fly Ash. Constr. Build. Mater. 2016, 105, 69–81. [Google Scholar] [CrossRef]

- Cordeiro, G.; Filho, R.T.; Tavares, L.; Fairbairn, E. Experimental Characterization of Binary and Ternary Blended-Cement Concretes Containing Ultrafine Residual Rice Husk and Sugar Cane Bagasse Ashes. Constr. Build. Mater. 2012, 29, 641–646. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, G. Utilization of Waste Foundry Sand (WFS) in Concrete Manufacturing. Resour. Conserv. Recycl. 2011, 55, 885–892. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Roke, D.A. Assessment of Artificial Neural Network and Genetic Programming as Predictive Tools. Adv. Eng. Softw. 2015, 88, 63–72. [Google Scholar] [CrossRef]

- Raju, K.S.; Murty, M.R.; Rao, M.V.; Satapathy, S.C. Support Vector Machine with K-Fold Cross Validation Model for Software Fault Prediction. Int. J. Pure Appl. Math. 2018, 118, 321–334. [Google Scholar]

- Kohavi, R. A Study of Cross-Validation and Bootstrap for Accuracy Estimation and Model Selection; Ijcai: Montreal, QC, Canada, 1995. [Google Scholar]

- Azim, I.; Yang, J.; Javed, M.F.; Iqbal, M.F.; Mahmood, Z.; Wang, F.; Liu, Q.-F. Prediction Model for Compressive Arch Action Capacity of RC Frame Structures under Column Removal Scenario Using Gene Ex-pression Programming. Structures 2020, 25, 212–228. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Alavi, A.H.; MirzaHosseini, M.R.; Nejad, F.M. Nonlinear Genetic-Based Models for Prediction of Flow Number of Asphalt Mixtures. J. Mater. Civ. Eng. 2011, 23, 248–263. [Google Scholar] [CrossRef]

- Despotovic, M.; Nedic, V.; Despotovic, D.; Cvetanovic, S. Evaluation of Empirical Models for Predicting Monthly Mean Hori-Zontal Diffuse Solar Radiation. Renew. Sustain. Energy Rev. 2016, 56, 246–260. [Google Scholar] [CrossRef]

- Cordeiro, G.; Filho, R.T.; Fairbairn, E. Effect of Calcination Temperature on the Pozzolanic Activity of Sugar Cane Bagasse Ash. Constr. Build. Mater. 2009, 23, 3301–3303. [Google Scholar] [CrossRef]

- Bumanis, G.; Vitola, L.; Stipniece, L.; Locs, J.; Korjakins, A.; Bajare, D. Evaluation of Industrial by-Products as Pozzolans: A Road Map for Use in Concrete Production. Case Stud. Constr. Mater. 2020, 13, e00424. [Google Scholar] [CrossRef]

- Agarwal, S. Pozzolanic Activity of Various Siliceous Materials. Cem. Concr. Res. 2006, 36, 1735–1739. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Santhanam, M. Influence of Different Processing Methods on the Pozzolanic Performance of Sugarcane Bagasse Ash. Cem. Concr. Compos. 2015, 56, 32–45. [Google Scholar] [CrossRef]

- Akram, T.; Memon, S.A.; Obaid, H. Production of Low Cost Self Compacting Concrete Using Bagasse Ash. Constr. Build. Mater. 2009, 23, 703–712. [Google Scholar] [CrossRef]

- Jagadesh, P.; Ramachandramurthy, A.; Murugesan, R.; Sarayu, K. Micro-Analytical Studies on Sugar Cane Bagasse Ash. Sadhana 2015, 40, 1629–1638. [Google Scholar] [CrossRef]

- De Souza, L.M.S.; Fairbairn, E.D.M.R.; Filho, R.D.T.; Cordeiro, G.C. Influence of Initial CaO/SiO 2 Ratio on the Hydration of Rice Husk Ash-Ca(Oh) 2 and Sugar Cane Bagasse Ash-Ca(Oh) 2 Pastes. Química Nova 2014, 37, 1600–1605. [Google Scholar] [CrossRef]

- Cordeiro, G.; Filho, R.T.; Tavares, L.; Fairbairn, E. Pozzolanic Activity and Filler Effect of Sugar Cane Bagasse Ash in Portland Cement and Lime Mortars. Cem. Concr. Compos. 2008, 30, 410–418. [Google Scholar] [CrossRef]

- Macedo, P.C.; Pereira, A.M.; Akasaki, J.L.; Fioriti, C.F.; Payá, J.; Pinheiro, J.L. Performance of Mortars Produced with the Incorporation of Sugar Cane Bagasse Ash. Rev. Ing. Construcción 2014, 29, 187–199. [Google Scholar] [CrossRef]

- Gholampour, A.; Gandomi, A.H.; Ozbakkaloglu, T. New Formulations for Mechanical Properties of Recycled Aggregate Concrete Using Gene Expression Programming. Constr. Build. Mater. 2017, 130, 122–145. [Google Scholar] [CrossRef]

- Du, H. Properties of Ultra-lightweight Cement Composites with Nano-Silica. Constr. Build. Mater. 2019, 199, 696–704. [Google Scholar] [CrossRef]

| Parameters | Setting |

|---|---|

| Number of subpopulations | 50 |

| Size of subpopulation | 250 |

| Code length | 40 |

| Crossover probability | 0.9 |

| Mathematical operators | +, −, ×, ÷ |

| Mutation probability | 0.01 |

| Tournament size | 4 |

| Operators | 0.5 |

| Variables | 0.5 |

| Number of generations | 1000 |

| Parameter | W/C | CC | SCBA% | FA | CA |

|---|---|---|---|---|---|

| Unit | – | Kg/m3 | % | Kg/m3 | Kg/m3 |

| Range | 0.3 | 444 | 50 | 614 | 772 |

| Min | 0.3 | 112 | 0 | 239 | 477 |

| Max | 0.6 | 555 | 50 | 853 | 1249 |

| Mean | 0.47 | 336.5 | 13.98 | 603.5 | 884.6 |

| SD | 0.074 | 98.5 | 10.46 | 232.1 | 392.3 |

| Composition | Percentage |

|---|---|

| SiO2 | 66.28 |

| Al2O3 | 8.36 |

| Fe2O3 | 1.39 |

| CaO | 9.06 |

| MgO | 5.56 |

| P2O5 | 2.46 |

| K2O | 3.52 |

| Na2O | 1.30 |

| TiO2 | 0.19 |

| MnO | 0.02 |

| LOI | 1.67 |

| Moisture content | 1.15 |

| Mix | Cement Kg/m3 | CA Kg/m3 | SCBA Kg/m3 | W/C | FA Kg/m3 | Water Kg/m3 | Density (Kg/m3) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | CA | FA | SCBA | |||||||

| CM | 366 | 1013.5 | 0 | 0.5 | 742.3 | 183 | 3150 | 2510 | 1680 | 2450 |

| 10BC | 329.4 | 1013.5 | 36.6 | 0.5 | 742.3 | 183 | ||||

| 20BC | 292.8 | 1013.5 | 73.2 | 0.5 | 742.3 | 183 | ||||

| 30BC | 256.2 | 1013.5 | 109.8 | 0.5 | 742.3 | 183 | ||||

| 40BC | 219.6 | 1013.5 | 146.4 | 0.5 | 742.3 | 183 | ||||

| Mix | Compressive Strength (MPa) | ||||

|---|---|---|---|---|---|

| 0BC | 10BC | 20BC | 30BC | 40BC | |

| Sample 1 | 23.5 | 23.9 | 21.5 | 18.5 | 16.7 |

| Sample 2 | 22.7 | 23.6 | 21.6 | 19.6 | 15.6 |

| Sample 3 | 22.9 | 23.7 | 21.2 | 19.1 | 16.4 |

| Sample 4 | 23.4 | 24.2 | 22.3 | 19.5 | 15.7 |

| Average | 23.1 | 23.8 | 21.6 | 19.1 | 16.1 |

| Splitting Tensile Strength (MPa) | |||||

| Sample 1 | 6.3 | 7.9 | 7.2 | 6.7 | 5.3 |

| Sample 2 | 6.2 | 7.8 | 7.3 | 5.6 | 4.7 |

| Sample 3 | 6.2 | 8.1 | 7.5 | 5.3 | 4.4 |

| Sample 4 | 6.7 | 8.1 | 7.5 | 5.8 | 4.9 |

| Average | 6.3 | 7.9 | 7.3 | 5.8 | 4.8 |

| Flexural Strength (MPa) | |||||

| Sample 1 | 4.7 | 5.1 | 3.9 | 3.1 | 2.8 |

| Sample 2 | 4.3 | 5.1 | 3.8 | 3.3 | 2.6 |

| Sample 3 | 4.6 | 5.2 | 3.8 | 3.3 | 2.6 |

| Sample 4 | 4.6 | 5.3 | 3.7 | 3.2 | 2.5 |

| Average | 4.5 | 5.1 | 3.8 | 3.2 | 2.6 |

| Models | Data | NSE | R | RMSE | MAE | RSE | RRMSE | ρ |

|---|---|---|---|---|---|---|---|---|

| CS | Training | 0.87 | 0.91 | 3.47 | 2.96 | 0.16 | 0.04 | 0.020 |

| Testing | 0.89 | 0.94 | 2.98 | 2.98 | 0.12 | 0.09 | 0.046 | |

| Validation | 0.89 | 0.93 | 2.87 | 1.67 | 0.15 | 0.04 | 0.020 | |

| ST | Training | 0.85 | 0.90 | 2.43 | 3.67 | 0.23 | 0.09 | 0.047 |

| Testing | 0.91 | 0.92 | 2.65 | 3.69 | 0.26 | 0.12 | 0.062 | |

| Validation | 0.90 | 0.92 | 3.25 | 3.98 | 0.31 | 0.10 | 0.052 | |

| FS | Training | 0.86 | 0.91 | 3.92 | 1.87 | 0.29 | 0.13 | 0.068 |

| Testing | 0.87 | 0.91 | 3.34 | 1.45 | 0.28 | 0.15 | 0.078 | |

| Validation | 0.86 | 0.93 | 3.67 | 2.87 | 0.19 | 0.16 | 0.079 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, M.I.; Amin, M.N.; Khan, K.; Niazi, M.S.K.; Aslam, F.; Alyousef, R.; Javed, M.F.; Mosavi, A. Performance Evaluation of Soft Computing for Modeling the Strength Properties of Waste Substitute Green Concrete. Sustainability 2021, 13, 2867. https://doi.org/10.3390/su13052867

Shah MI, Amin MN, Khan K, Niazi MSK, Aslam F, Alyousef R, Javed MF, Mosavi A. Performance Evaluation of Soft Computing for Modeling the Strength Properties of Waste Substitute Green Concrete. Sustainability. 2021; 13(5):2867. https://doi.org/10.3390/su13052867

Chicago/Turabian StyleShah, Muhammad Izhar, Muhammad Nasir Amin, Kaffayatullah Khan, Muhammad Sohaib Khan Niazi, Fahid Aslam, Rayed Alyousef, Muhammad Faisal Javed, and Amir Mosavi. 2021. "Performance Evaluation of Soft Computing for Modeling the Strength Properties of Waste Substitute Green Concrete" Sustainability 13, no. 5: 2867. https://doi.org/10.3390/su13052867

APA StyleShah, M. I., Amin, M. N., Khan, K., Niazi, M. S. K., Aslam, F., Alyousef, R., Javed, M. F., & Mosavi, A. (2021). Performance Evaluation of Soft Computing for Modeling the Strength Properties of Waste Substitute Green Concrete. Sustainability, 13(5), 2867. https://doi.org/10.3390/su13052867