Validation of a Simulation-Based Pre-Assessment Process for Solar Photovoltaic Technology Implemented on Rooftops of South African Shopping Centres

Abstract

1. Introduction

2. Literature Review

2.1. Existing Process in Constructing a PV System

- preliminary project assessment;

- project site survey;

- feasibility study or preliminary design, and report;

- advertisement in a tender process and proposal generation;

- contract award negotiations;

- final design;

- project integration into existing infrastructure;

- system commissioning, test and verification;

- final test and acceptance or performance verification; and

- system maintenance.

2.1.1. Preliminary Project Assessment and Project Site Survey

2.1.2. Feasibility Study or Preliminary Design

- The existing load demand of the consumer must be investigated. If the possibility arises that the PV system may surpass the maximum load demand, then control systems must be implemented to avoid feedback into the grid. In South Africa, feedback is only permitted under certain conditions [27].

- The existing electrical network of the consumer must be investigated and, if required, amended. In the case of renovations, electrical networks are not commonly addressed, resulting in that tie-in points do not accommodate the electricity supply. Therefore, contingencies must be made in the case of a system update [28].

- In line with current legislation pertaining to consumers who produce their electricity, PV systems are restricted to 1MVA without obtaining a generation license in South Africa [18].

- In the case of power disruptions due to load shedding (a controlled mechanism implemented by the South African utility because of inadequate electricity supply [2,29,30]) or system malfunction, shopping centres utilize multiple backup generators. When a PV system is designed for the relevant shopping centre, integration with the backup generators must be considered. Diesel generators must operate at 60–75% of their rated power to prevent bore glazing of the piston sleeves [31]. When bore glazing occurs, the honing marks of the bore are smoothed over, resulting in a reduced seal between the piston rings and the cylinder bore, the result being that combustion gases mix with the oil deposits [32].

2.1.3. Advertisement in a Tender Process and Proposal Generation

2.1.4. Contract Award Negotiations

2.1.5. Final Design

2.1.6. Project Integration into Existing Infrastructure

2.1.7. System Commissioning, Test and Verification

2.1.8. Final Test and Acceptance or Performance Verification

2.1.9. System Maintenance

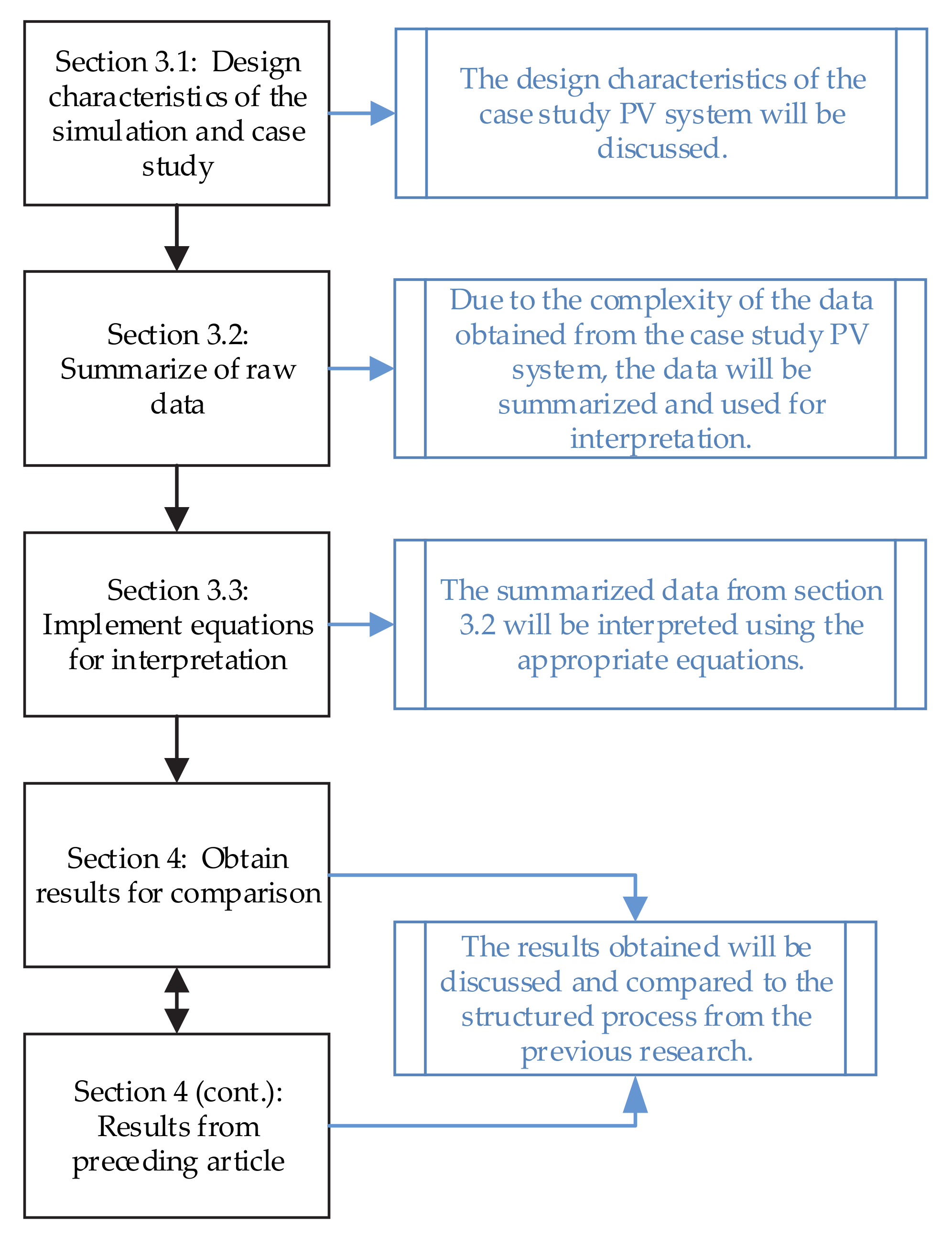

2.2. Results from Preceding Research Article

2.2.1. Literature Relating to Simulations of PV Systems

2.2.2. Pre-Assessment Process Derived from the Preceding Research Article

3. Experimental Methodology

3.1. Design Characteristics of the Simulation and Case Study

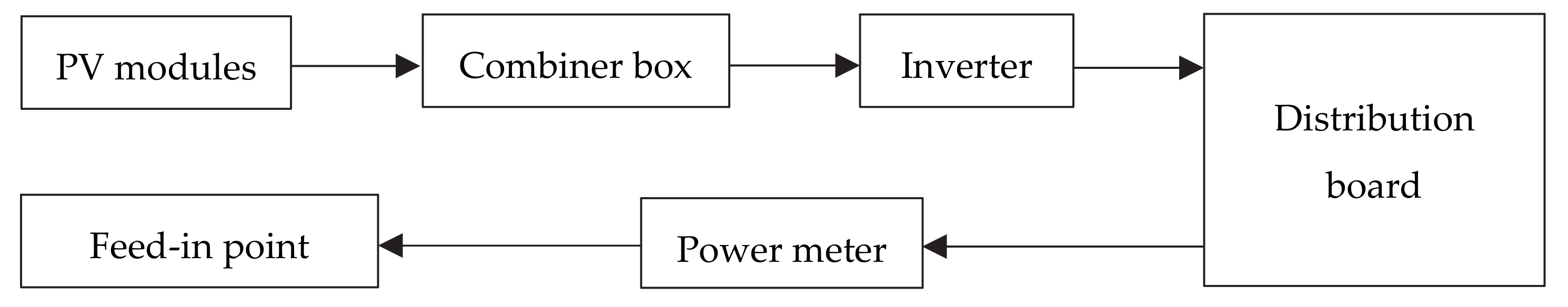

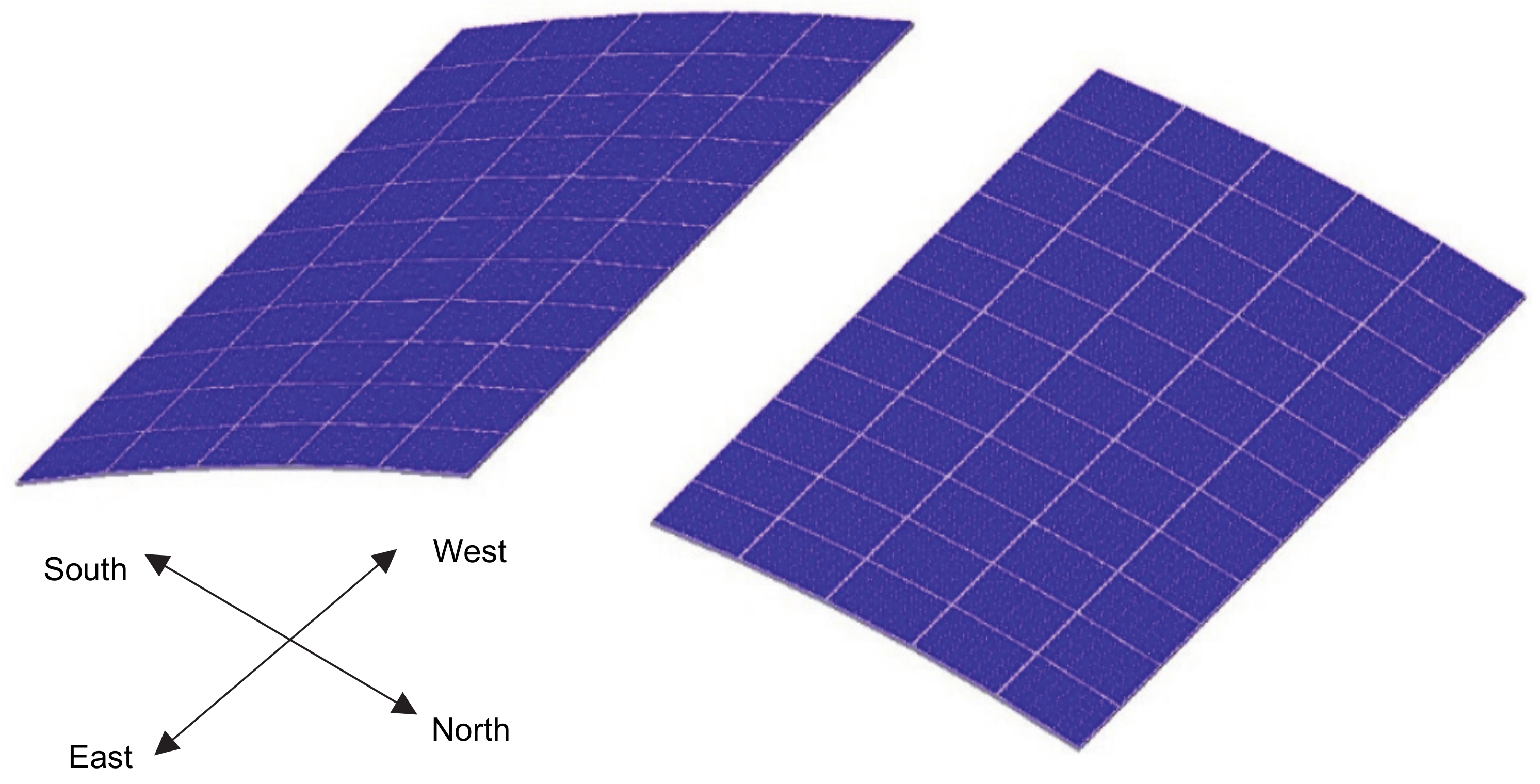

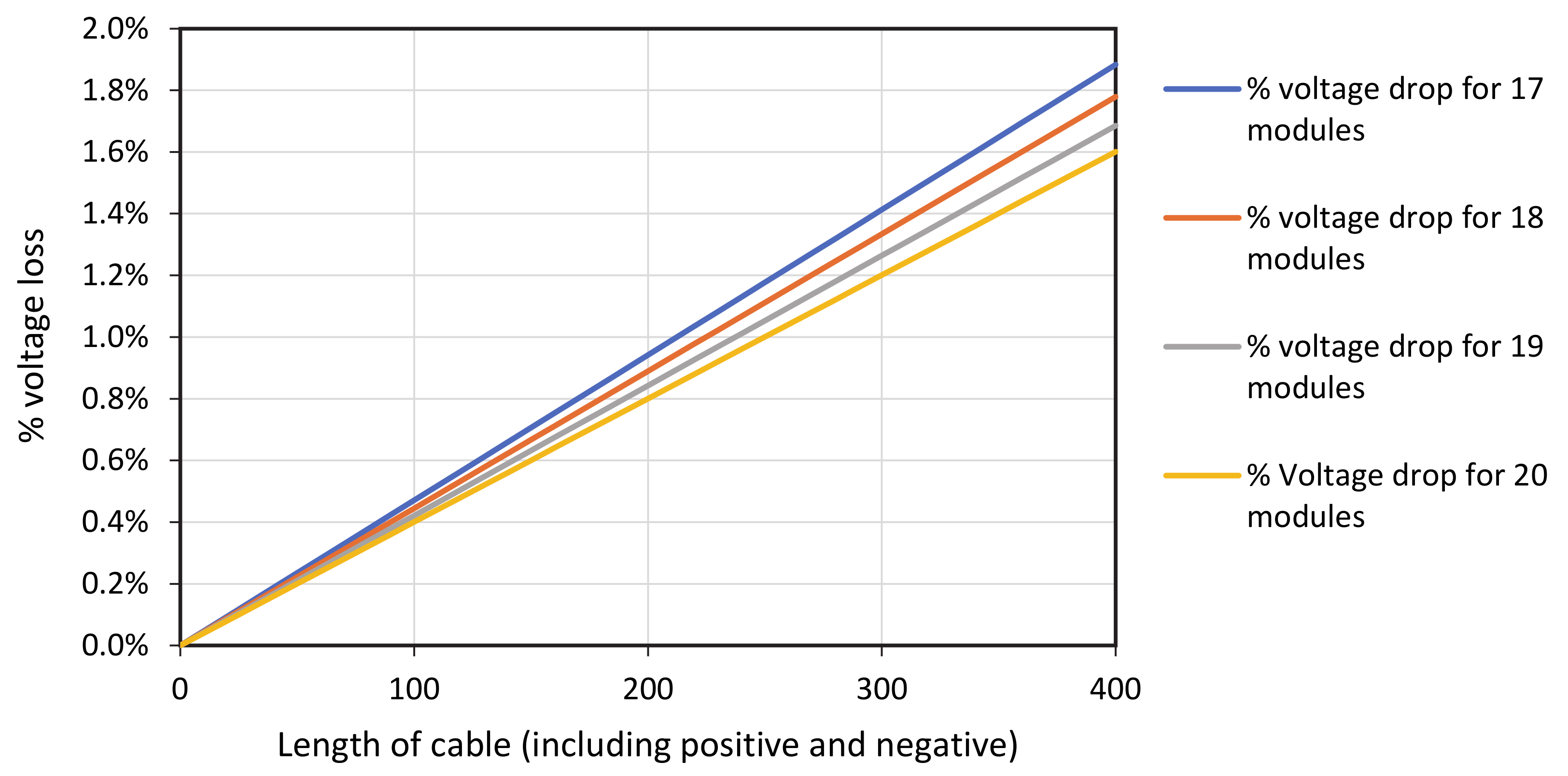

- The PV modules are connected in various series and parallel combinations to form an array, each set of series PV modules being described as a string. The system was rated to 924.48 kWp and encompasses 2889 × 320 Wp modules. Each string consisted of 17 or 18 modules whereby it was ensured that parallel strings consist of the same number of modules in series. The PV modules were connected such that each string’s modules were at the same inclination in each parallel combination.

- To combine the various strings, a combiner box is used so that a single cable (pre MPPT) can be used to feed the electricity into the inverter. It also enables the integration of DC surge arrestors to protect the system from lightning.

- 18 × 49.9 kVA grid-tie inverters were installed in the system.

- Once the AC source had been created by the inverters, each cable from the inverters was fed into the distribution board.

- The distribution board allows for the combination of the inverters as well as encompassing the circuit breakers and surge arrestors.

- The feed from the distribution boards is then directed to the feed-in point where the power meter is located. In the case of legal disputes, the basis for the dispute is reliant on the data from the power meter.

- Thereafter, the electricity was fed into the microgrid of the shopping centre for consumption, noting that the maximum generation ability of the solar system will not surpass the maximum load demand of the shopping centre.

3.2. Summarizing of Raw Data

3.3. Equations for Interpretation

3.3.1. Load Demand Factor

- = Energy demand (W)

- = Number of days in the respective month

3.3.2. PV Module Factor

- = Yield from the string (kW)

- = Maximum power from the string (kWp)

- = Number of days for corresponding month

- = Rated power of PV modules (320 W)

- = Number of PV modules connected in series (17 or 18)

- = Number of strings connected in parallel

- = Average energy from MPPT (kWh)

- = Duration of operation (hour)

4. Results and Discussion

4.1. Load Demand Factor of Case Study

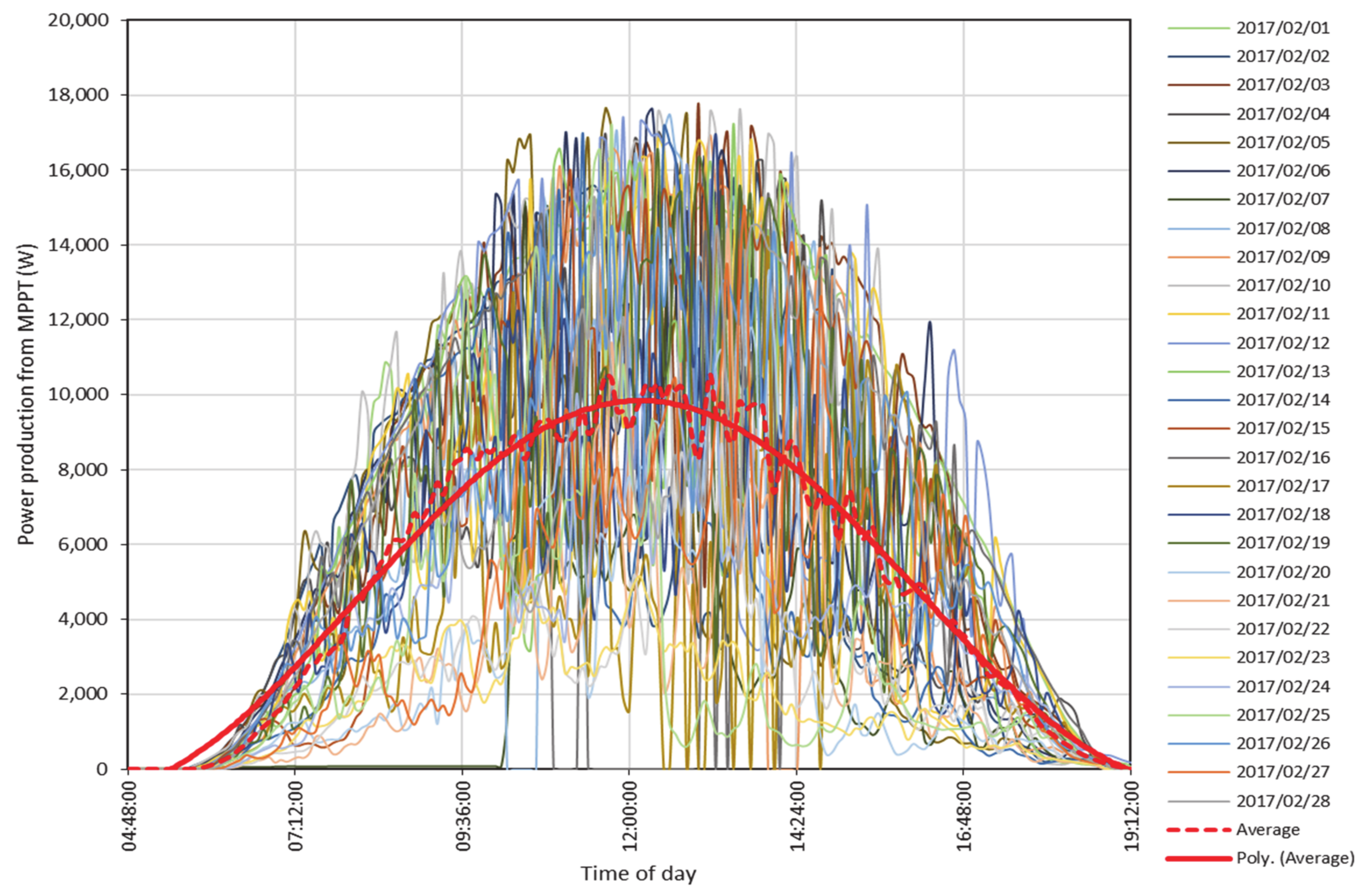

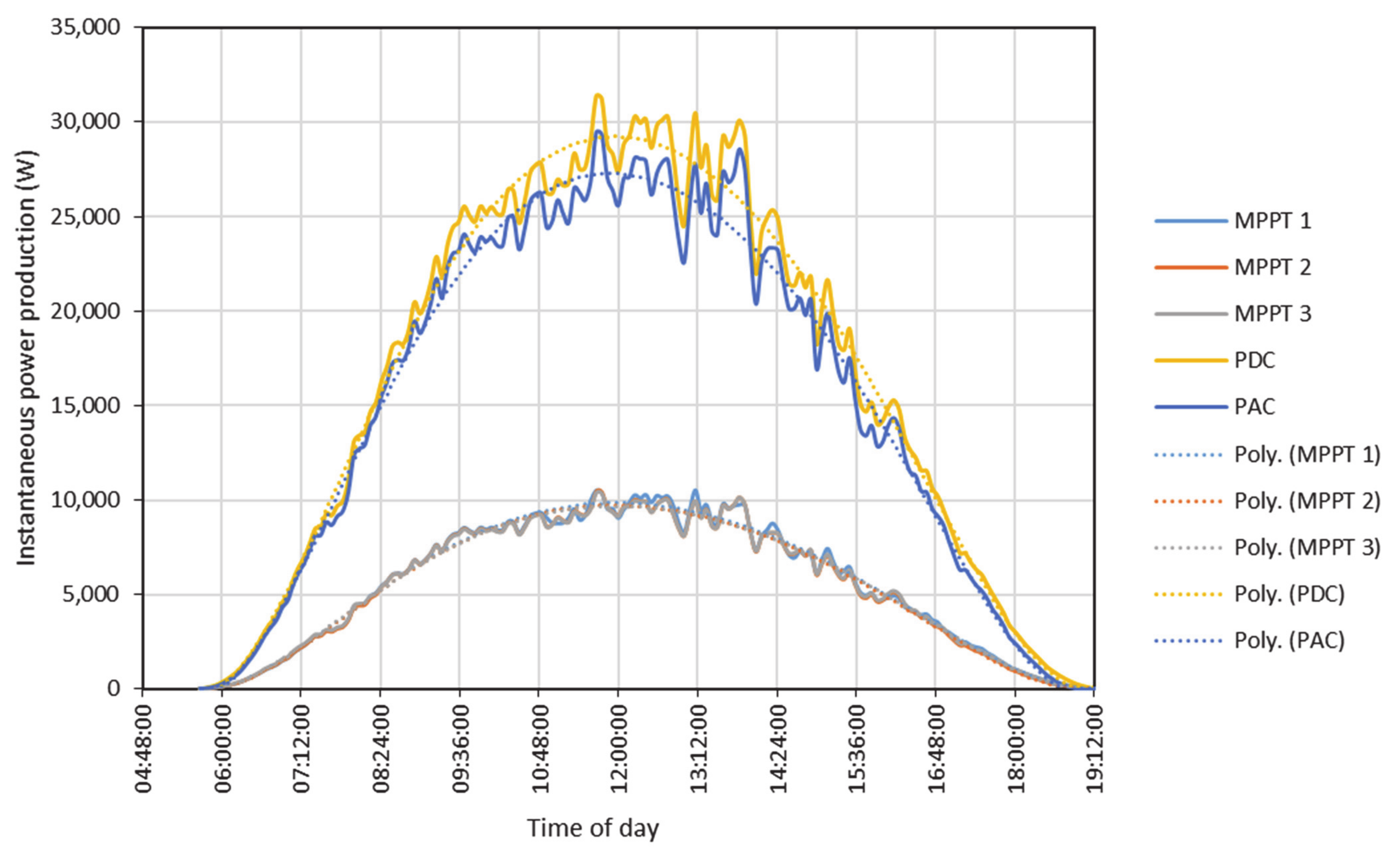

4.2. PV Module Factor

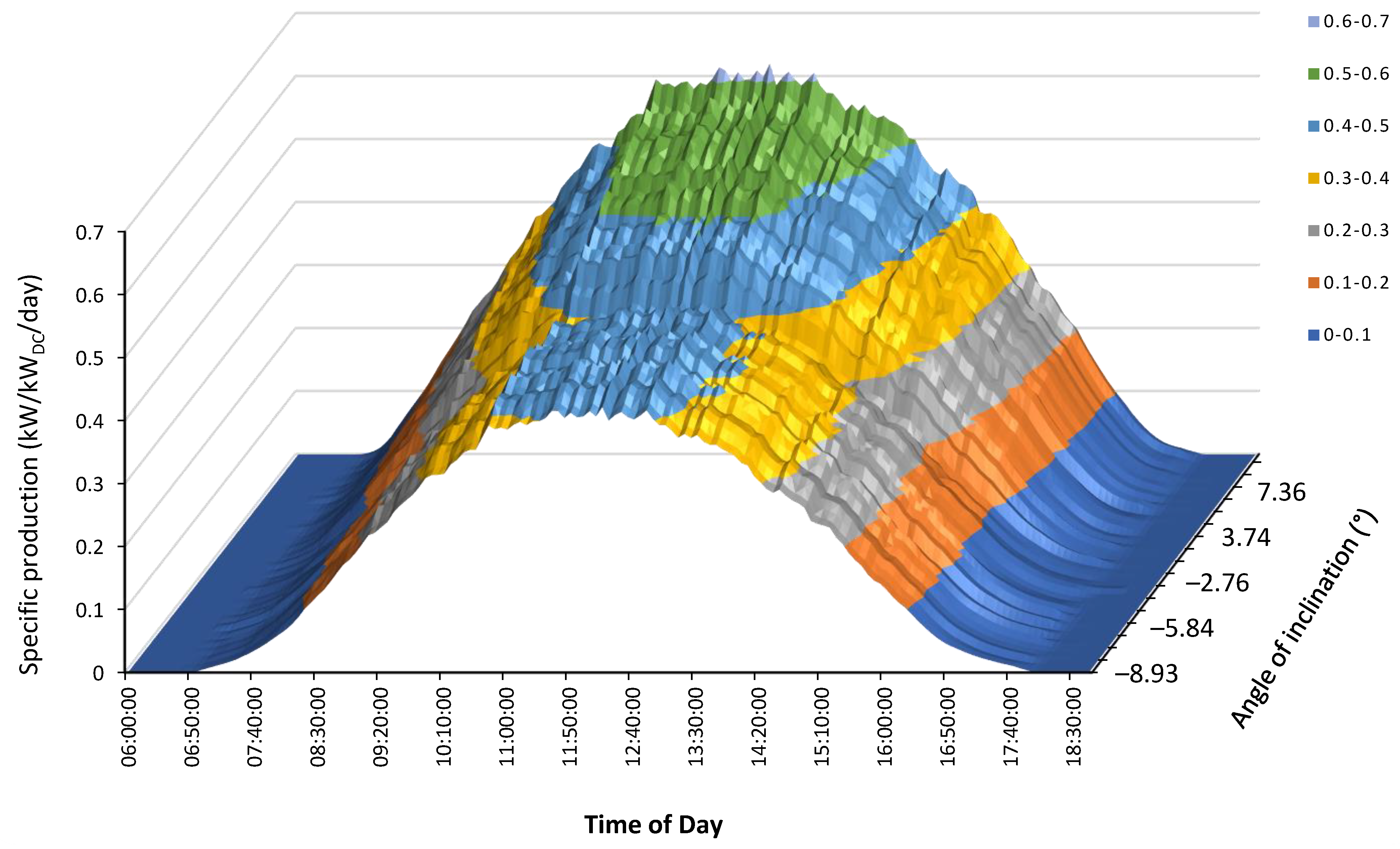

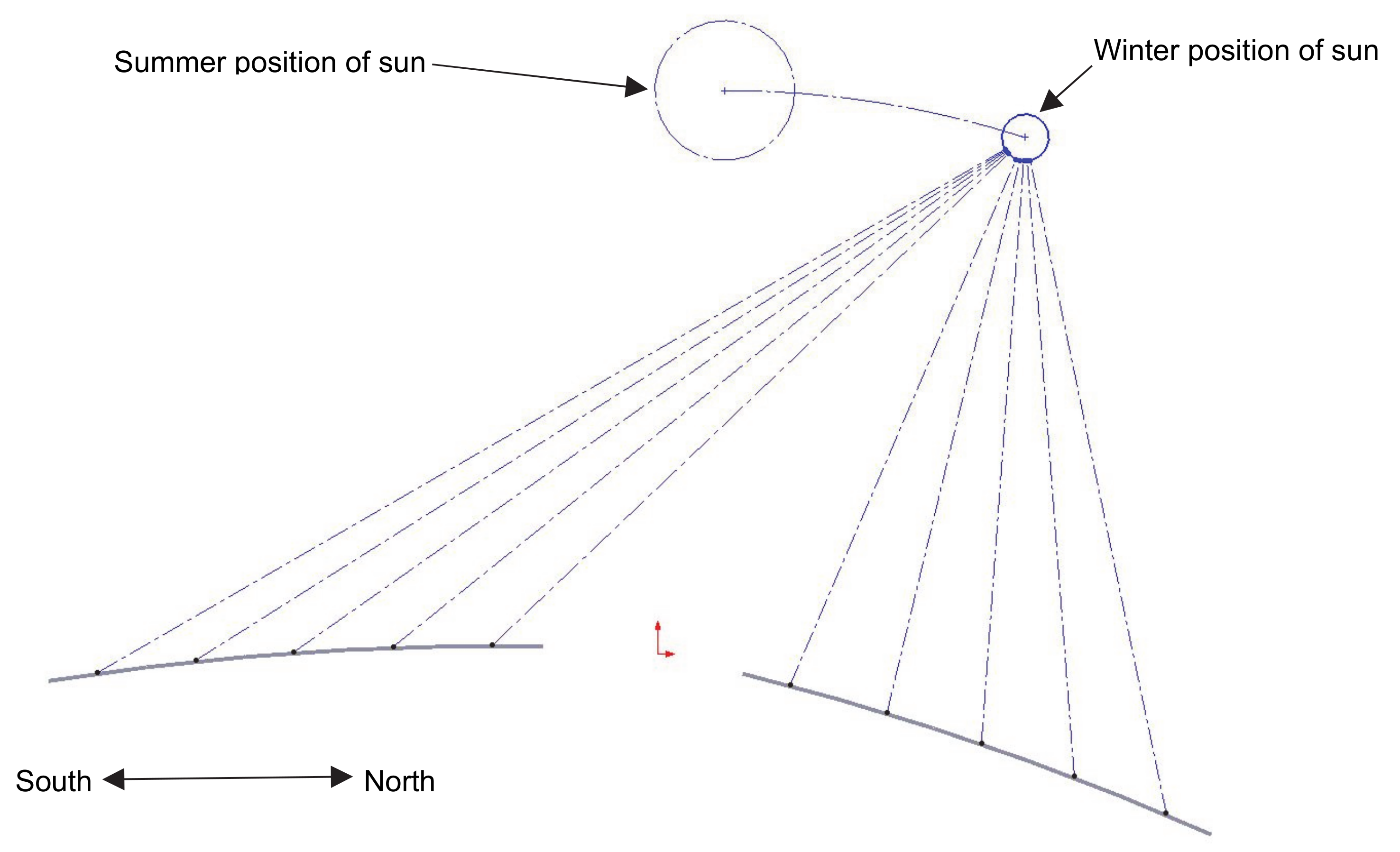

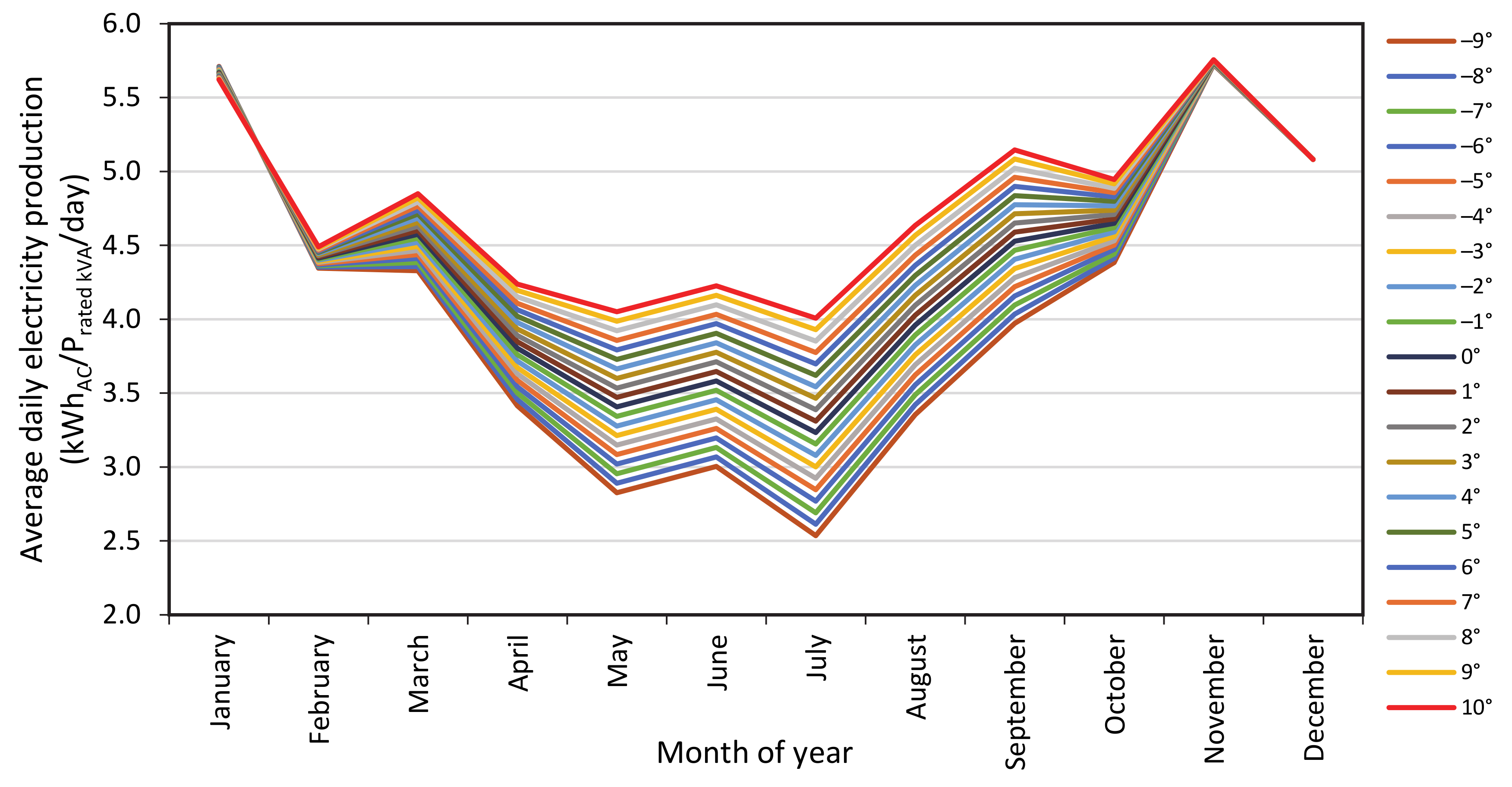

4.2.1. Electricity Production Variation Based on the Tilt

4.2.2. Electricity Production Loss due to PV Module Degradation

4.2.3. Array-to-Inverter Ratio (ATIR) Variation

4.3. Validation of Pre-Assessment Process

5. Conclusions

- Step 1: Analyse the existing load demand of the premises for the intended PV system. In doing so, design restrictions relating to the integration of the system into existing infrastructure is investigated. This research analysed the effect the PV system had on the case study load demand after construction was completed.

- Step 2: Analyse the effect of tilt and orientation. If it is analysed, then investors can design building architecture to optimize the electricity yield from the PV system. This is especially important when new buildings are being constructed.

- Step 3: Analyse the effect of module degradation on electricity yield. This is important if future electricity yield must be estimated. Module degradation has a detrimental effect on the yield of a PV system over a period. This will be especially useful when investors have to decide between investing immediately or waiting for improved technologies.

- Step 4: Analyse the effect of varying the ATIR. Increased ATIR is important when considering the gains of electricity potential in the winter season. Return on investment losses incurred in the summer season, due to clipping, will be recuperated by the gains in the winter season since the tariffs are structured to be more expensive in winter.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

Abbreviations

References

- Lipp, J. Policy considerations for a sprouting UK green electricity market. Renew. Energy 2001, 24, 31–44. [Google Scholar] [CrossRef]

- Du Plooy, N.T.; Brent, A.C.; de Kock, I.H. Fostering Sustainable Energy Transitions for South Africa’s Electricity Sector: A set of Criteria; University of Stellenbosch: Stellenbosch, South Africa, 2017. [Google Scholar]

- Hadebe, D.; Hansa, A.; Ndlhovu, C.; Kibido, M. Scaling Up Renewables Through Regional Planning and Coordination of Power Systems in Africa—Regional Power System Planning to Harness Renewable Resources and Diversify Generation Portfolios in Southern Africa. Curr. Sustain. Energy Rep. 2018, 5, 224–229. [Google Scholar] [CrossRef]

- Andersen, T.B.; Dalgaard, C.-J.L. Power outages and economic growth in Africa. Energy Econ. 2013, 38, 19–23. [Google Scholar] [CrossRef]

- Bobo, A.; Pretorius, J.H.C.; Enslin, J.H.R. Effect on energy supply contribution by incorporating rooftop photovoltaic systems within the City of Johannesburg. In Proceedings of the 2017 IEEE AFRICON, Cape Town, South Africa, 18–20 September 2017; pp. 1032–1037. [Google Scholar] [CrossRef]

- Bohlmann, J.; Bohlmann, H.; Inglesi-Lotz, R.; Van Heerden, J. An economy-wide evaluation of new power generation in South Africa: The case of Medupi and Kusile. Energy Policy 2016, 97, 450–460. [Google Scholar] [CrossRef][Green Version]

- RSA Department of Energy. Integrated Resource Plan. Available online: http://www.energy.gov.za/IRP/overview.html (accessed on 14 October 2019).

- Jain, S.; Jain, P. The rise of Renewable Energy implementation in South Africa. Energy Procedia 2017, 143, 721–726. [Google Scholar] [CrossRef]

- RSA Department of Energy. Integrated Resource Plan 2019. Gov. Gaz. 2019, 4, 1–100. [Google Scholar]

- Jung, J.; Tyner, W.E. Economic and policy analysis for solar PV systems in Indiana. Energy Policy 2014, 74, 123–133. [Google Scholar] [CrossRef]

- Ferrara, C.; Philipp, D. Why Do PV Modules Fail? Energy Procedia 2011, 15, 379–387. [Google Scholar] [CrossRef]

- Centre for Renewable and Sustainable Energy Studies. New Solar Resource Maps for South Africa. 2014. Available online: http://www.crses.sun.ac.za/research-publications-resources (accessed on 12 December 2017).

- Gevorkian, P. Solar power system design. In Large-Scale Solar Power System Design: An Engineering Guide for Grid-Connected Solar Power Generation, 1st ed.; McGraw Hill Education: London, UK, 2011. [Google Scholar]

- Kotak, Y.; Gago, E.; Mohanty, P.; Muneer, T. Installation of roof-top solar PV modules and their impact on building cooling load. Build. Serv. Eng. Res. Technol. 2014, 35, 613–633. [Google Scholar] [CrossRef]

- Alghamdi, A.S. Potential for Rooftop-Mounted PV Power Generation to Meet Domestic Electrical Demand in Saudi Arabia: Case Study of a Villa in Jeddah. Energies 2019, 12, 4411. [Google Scholar] [CrossRef]

- Van Vuuren, D.J.; Marnewick, A.; Pretorius, J.H.C. A Theoretical Pre-Assessment of Solar Photovoltaic Electrical Production for Commercial Retail Centers. In Proceedings of the 18th IEEE EEEIC International Conference on Environment and Electrical Engineering, Palermo, Italy, 12–15 June 2018; IEEE: New York, NY, USA, 2018; p. 5. [Google Scholar]

- Mahmud, N.; Zahedi, A.; Rahman, S. An event-triggered distributed coordinated voltage control strategy for large grid-tied PV system with battery energy storage. In Proceedings of the 2017 Australasian Universities Power Engineering Conference, AUPEC, Melbourne, Australia, 19–22 November 2017; IEEE: New York, NY, USA, 2017; pp. 1–6. [Google Scholar]

- RSA Department of Energy. Annexure Schedule 2: Exemption from obligation to apply for and hold a licence. Gov. Gaz. 2016, 1482, 58–63. Available online: www.nersa.org.za (accessed on 20 June 2018).

- Van Vuuren, D.J.; Marnewick, A.; Pretorius, J.H.C. A proposed simulation-based theoretical preconstruction process: The case of solar photovoltaic technology in South African shopping centres. Renew. Sustain. Energy Rev. 2019, 113, 109295. [Google Scholar] [CrossRef]

- United Nations. Goal 7|Ensure Access to Affordable, Reliable, Sustainable and Modern Energy for All. 2021. Available online: https://sdgs.un.org/goals/goal7 (accessed on 4 February 2021).

- RSA Department of Energy. Integrated Resource Plan for Electricity 2010–2030. Gov. Gaz. 2011, 400, 1–72. [Google Scholar]

- Wahlström, Å.; Joosen, S.; Geurts, F.; Kleefkens, O.; Zavrl, M.S.; Hansen, K.; Norvaisa, E.; Makowska, N.; Despretz, H.; Ruud, S. Handbook for Performing Feasibility Studies of Alternative Energy Systems; Sentro European Project: Utrecht, The Netherlands, 2008. [Google Scholar]

- Gevorkian, P. Photovoltaic power system feasbility study. In Large-Scale Solar Power System Design: An Engineering Guide for Grid-Connected Solar Power Generation, 1st ed.; McGraw Hill Education: London, UK, 2011. [Google Scholar]

- Townsend, D. Environmental Impact Assessment (EIA). Enviropaedia: Rethink Reality. 2019. Available online: http://www.enviropaedia.com/topic/default.php?topic_id=92 (accessed on 23 June 2019).

- Veldhuis, H.; Reinders, A. Real-time irradiance simulation for PV products and building integrated PV in a virtual dynamic environment. In Proceedings of the 2011 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011; IEEE: New York, NY, USA, 2011; p. 193. [Google Scholar]

- Hwang, T.; Kim, J.T.; Chung, Y. Power performance of photovoltaic-integrated lightshelf systems. Indoor Built Environ. 2013, 23, 180–188. [Google Scholar] [CrossRef]

- Solareff (Pty) Ltd. Embedded Solar PV Generation in South Africa. 2016. Available online: http://www.solareff.co.za/assets/Uploads/Solareff-Info-Brochure-Regulatory-Position-July-2016.pdf (accessed on 20 March 2019).

- Sklar-Chik, M.D.; Brent, A.C. System Cost of Energy Generation Scenarios for South Africa: Understanding the Real Cost of Integrating Energy Generation Technologies; University of Stellenbosch: Stellenbosch, South Africa, 2017. [Google Scholar]

- Deloitte Ltd. An Overview of Electricity Consumption and Pricing in South Africa: An Analysis of the Historical Trends and Policies, Key Issues and Outlook in 2017; Deloitte Ltd.: Johannesburg, South Africa, 2017; pp. 1–86. [Google Scholar]

- Montmasson-Clair, G.; Kritzinger, K.; Scholtz, L.; Gulati, M. New Roles for South African Municipalities in Renewable Energy—A Review of Business Models. South African-German Energy Partnership: Pretoria, South Africa, 2017. [Google Scholar]

- Hamilton, J.; Negnevitsky, M.; Wang, X. Low load diesel perceptions and practices within remote area power systems. In Proceedings of the 2015 International Symposium on Smart Electric Distribution Systems and Technologies (EDST), Vienna, Austria, 8–11 September 2015; 2015; pp. 121–126. [Google Scholar] [CrossRef]

- Pumphrey, S.G. Bore Polishing in a Running Diesel Engine; Imperial College of Science and Technology: London, UK, 1982. [Google Scholar]

- Barker, I.C. Preliminaries and conditions. In A Practical Introduction to Facilities Management, 1st ed.; Whittles Publishing: Dunbeath, UK, 2013; p. 282. [Google Scholar]

- Basson, H.; Pretorius, J. Risk mitigation of performance ratio guarantees in commercial photovoltaic systems. Renew. Energy Power Qual. J. 2016, 120–125. [Google Scholar] [CrossRef]

- Bayer, B.; Schäuble, D.; Ferrari, M. International experiences with tender procedures for renewable energy—A comparison of current developments in Brazil, France, Italy and South Africa. Renew. Sustain. Energy Rev. 2018, 95, 305–327. [Google Scholar] [CrossRef]

- Gevorkian, P. Solar power system economics. In Large-Scale Solar Power Systems—Construction and Economics; Cambridge University Press: Cambridge, UK, 2012; pp. 37–70. [Google Scholar]

- Basson, H.A. Risk Mitigation of Performance Ratio Guarantees; University of Johannesburg: Johannesburg, South Africa, 2015. [Google Scholar]

- Gevorkian, P. Solar power system cost analysis. In Large-Scale Solar Power System Design: An Engineering Guide for Grid-Connected Solar Power Generation; McGraw Hill Professional: London, UK, 2011. [Google Scholar]

- Cavinato, J.L.; Flynn, A.E.; Kauffman, R.G. Outsourcing: Challanges and opportunities. In Supply Management Handbook, 7th ed.; McGraw Hill Education: London, UK, 2006. [Google Scholar]

- Ransome, S. Modelling inaccuracies of PV energy yield simulations. In Proceedings of the 33rd Photovolatic Specialists Conference, San Diego, CA, USA, 11–16 May 2008; 2008; 44, pp. 1–5. [Google Scholar] [CrossRef]

- Shrivastava, R.L.; Kumar, V.; Untawale, S.P. Modeling and simulation of solar water heater: A TRNSYS perspective. Renew. Sustain. Energy Rev. 2017, 67, 126–143. [Google Scholar] [CrossRef]

- Després, J.; Hadjsaid, N.; Criqui, P.; Noirot, I. Modelling the impacts of variable renewable sources on the power sector: Reconsidering the typology of energy modelling tools. Energy 2015, 80, 486–495. [Google Scholar] [CrossRef]

- Fan, Y.; Xia, X. A multi-objective optimization model for energy-efficiency building envelope retrofitting plan with rooftop PV system installation and maintenance. Appl. Energy 2017, 189, 327–335. [Google Scholar] [CrossRef]

- Bhattacharyya, S.C.; Timilsina, G.R. A review of energy system models. Int. J. Energy Sect. Manag. 2010, 4, 494–518. [Google Scholar] [CrossRef]

- Chiodi, A.; Deane, M.; Gargiulo, M.; Ó’Gallachóir, B. Modelling Electricity Generation–Comparing Results: From a Power Systems Model and an Energy Systems Model; Environmental Research Institute: Cork, UK, 2011. [Google Scholar]

- Dondariya, C.; Porwal, D.; Awasthi, A.; Shukla, A.K.; Sudhakar, K., Sr.; Manohar, S.R.M.; Bhimte, A. Performance simulation of grid-connected rooftop solar PV system for small households: A case study of Ujjain, India. Energy Rep. 2018, 4, 546–553. [Google Scholar] [CrossRef]

- Al Siyabi, I.; Al Mayasi, A.; Al Shukaili, A.; Khanna, S. Effect of Soiling on Solar Photovoltaic Performance under Desert Climatic Conditions. Energies 2021, 14, 659. [Google Scholar] [CrossRef]

- Corba, Z.; Popadic, B.; Milicevic, D.; Dumnic, B.; Katic, V.A. A Long-Term Condition Monitoring and Performance Assessment of Grid Connected PV Power Plant with High Power Sizing Factor under Partial Shading Conditions. Energies 2020, 13, 4810. [Google Scholar] [CrossRef]

- Dobreva, P.; Van Dyk, E.E.; Vorster, F.J. Energy Yield Modelling of Pv Systems Operating in Namibian Conditions. In Proceedings of the 3rd Southern African Solar Energy Conference, Spier, South Africa, 11–13 May 2015. [Google Scholar]

- Wittmer, B.; Mermoud, A. A Tool to Optimize the Layout of Ground-Based PV Installations Taking into Account the Economic Boundary Conditions. In Proceedings of the 29th European Photovoltaic Solar Energy Conference, Amsterdam, The Netherlands, 22–26 September 2014; Available online: https://www.pvsyst.com/wp-content/uploads/2019/01/PVsyst_paper_EU_PVSEC_214_distribution.pdf (accessed on 15 July 2018).

- Malvoni, M.; Fiore, M.; Maggiotto, G.; Mancarella, L.; Quarta, R.; Radice, V.; Congedo, P.; De Giorgi, M. Improvements in the predictions for the photovoltaic system performance of the Mediterranean regions. Energy Convers. Manag. 2016, 128, 191–202. [Google Scholar] [CrossRef]

- Cheng, C.; Jimenez, C.S.S.; Lee, M.-C. Research of BIPV optimal tilted angle, use of latitude concept for south orientated plans. Renew. Energy 2009, 34, 1644–1650. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Balamurugan, M.; Narendiran, S. A Novel Control Strategy of Battery Management for Grid Connected Photovoltaic System; VIT University: Vellore, India, 2017. [Google Scholar]

- Climate & Weather Averages in Johannesburg, South Africa. 2018. Available online: https://www.timeanddate.com/weather/south-africa/johannesburg/climate (accessed on 8 November 2018).

- Seneviratne, M. Commercial buildings, hospitals and institutional buildings. In A Practical Approach to Water Conservation for Commercial and Industrial Facilities, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 267–290. [Google Scholar]

- Hafez, A.; Soliman, A.; El-Metwally, K.; Ismail, I. Tilt and azimuth angles in solar energy applications—A review. Renew. Sustain. Energy Rev. 2017, 77, 147–168. [Google Scholar] [CrossRef]

- Benghanem, M. Optimization of tilt angle for solar panel: Case study for Madinah, Saudi Arabia. Appl. Energy 2011, 88, 1427–1433. [Google Scholar] [CrossRef]

- Eskom Ltd. Tariffs & Charges Booklet 2020/21. 2020. Available online: http://www.eskom.co.za/CustomerCare/TariffsAndCharges/Pages/Tariffs_And_Charges.aspx (accessed on 10 October 2020).

- Dhoke, A.; Sharma, R.; Saha, T.K. PV module degradation analysis and impact on settings of overcurrent protection devices. Sol. Energy 2018, 160, 360–367. [Google Scholar] [CrossRef]

- Changwoon, H.; Nochang, P.; Jaeseong, J. Lifetime prediction of silicon PV module ribbon wire in three local weathers. In Photovoltaic Module Reliability Workshop; Keti: Ansan, Korea, 2012; pp. 307–319. [Google Scholar]

- CanadianSolar. Canadian Solar MaxPower CS6U-315|320|325|330P Datasheet; Canadian Solar: Guelph, ON, Canada, 2016. [Google Scholar]

- Silvestre, S.; Tahri, A.; Tahri, F.; Benlebna, S.; Chouder, A. Evaluation of the performance and degradation of crystalline silicon-based photovoltaic modules in the Saharan environment. Energy 2018, 152, 57–63. [Google Scholar] [CrossRef]

- Jordan, D.C.; Kurtz, S.R. Photovoltaic Degradation Rates-an Analytical Review. Prog. Photovolt. Res. Appl. 2013, 21, 12–29. [Google Scholar] [CrossRef]

- De Lia, F.; Castello, S.; Abenante, L. Modules after 22-year continuous field exposure. In 3rd World Conference on Photovoltaic Energy Conversion; IEEE: New York, NY, USA, 2003; pp. 2105–2108. [Google Scholar]

- Hussin, M.; Omar, A.; Shaari, S.; Sin, N.M. Review of state-of-the-art: Inverter-to-array power ratio for thin–Film sizing technique. Renew. Sustain. Energy Rev. 2017, 74, 265–277. [Google Scholar] [CrossRef]

- Serameng, T.J.; Van Dyk, E.E.; Roro, K.T. Validation of PVSyst for different photovoltaic module technologies and system design configurations of PV systems operating in central part of South Africa. In 4th Southern African Solar Energy Conference (SASEC); Sasec: Stellenbosch, South Africa, 2016; pp. 1–6. [Google Scholar]

- KBE Berlin. KBE Solar DB EN 50618. 2019. Available online: https://www.kbe-elektrotechnik.com/fileadmin/KBE_B/Broschueren/Solarbroschuere_DB_EN_50618_H1Z2Z2-K_.pdf (accessed on 15 May 2019).

- Rubicon, S.A. Solar PV Cable. 2019. Available online: https://www.rubiconsa.com/files/2019/03/Solar-Cable.pdf (accessed on 14 May 2019).

- Kumar, N.M.; Kumar, M.R.; Rejoice, P.R.; Mathew, M. Performance analysis of 100 kWp grid connected Si-poly photovoltaic system using PVsyst simulation tool. Energy Procedia 2017, 117, 180–189. [Google Scholar] [CrossRef]

- Tang, R.; Wang, S.; Shan, K. Optimal and near-optimal indoor temperature and humidity controls for direct load control and proactive building demand response towards smart grids. Autom. Constr. 2018, 96, 250–261. [Google Scholar] [CrossRef]

| Parameter: System Design Characteristics | ||

|---|---|---|

| Component Description | Name and Model/Quantity | Unit |

| Inverter | Kaco new energy Powador 60.0 TL3 | |

| Number of inverters | 18 | |

| Rated inverter power | 49.9 | kVA |

| PV module | Canadian Solar Inc. CS6X-320P | |

| Number of PV modules | 2 889 | W |

| Rated PV module power (1 module) | 320 | W |

| Latitude (within a 40 km radius of the case study) | 26°8′12.02″ S | |

| Longitude (within a 40 km radius of the case study) | 28°14′28.13″ E | |

| Plane tilt | −9 ≤ ≤ 10 | ° |

| Azimuth | 0 | ° |

| PV module fixation method | Rooftop, approximately 200 mm from the surface of the roof | |

| DC cable length | 50–200 (6 mm2 DC cable) | m |

| Approximate DC voltage loss at max load | 0.36–0.84 | % |

| AC cable length | 75–200 (4 × 95 mm2 × 4 core SWA ECC armoured cables) | m |

| Approximate AC voltage loss at max load | 3.54 | % |

| System logging component | Solar-log 2000 | |

| Parameter: System operating conditions | ||

| Installation date of system components | 1 August–30 November 2016 | |

| System commission date | 1 December 2016 | |

| Duration of system analysis | 24 months | |

| Start date of analysis | December 2016 (Month 1) | |

| Stop date of analysis | November 2018 (Month 24) | |

| Component Description | Name and Model/Quantity | Unit |

|---|---|---|

| Parameter: System | ||

| Inverter | Kaco new energy Powador 60.0 TL3 | |

| Number of inverters | 1 | |

| Rated inverter power | 49.9 | kVA |

| PV module | Canadian Solar Inc. CS6X-320P | |

| Rated PV module power | 320 | W |

| Number of PV modules in array | Varies as a variable | |

| Rated PV array power | Varies as a variable | W |

| Parameter: PV module fixation properties | ||

| Latitude (within a 40 km radius of the case study) | 26°8′12.02″ S | |

| Longitude (within a 40 km radius of the case study) | 28°14′28.13″ E | |

| Plane tilt | Varies as a variable | ° |

| Azimuth | Varies as a variable | ° |

| Data source in simulation | Meteonorm 7.2, Sat = 67% | |

| Parameter: Detailed losses | ||

| Constant loss factor | 15 | W/m2k |

| Wind loss factor | 0 | W/m2k/m/s |

| Global wiring resistance (calculated) | 226.5 | mOhm |

| Voltage drop across series diode | 0.7 | V |

| Voltage drop between inverter and injection | 1.7 | V |

| Module efficiency loss | −0.4 | % |

| Light-induced degradation | 2 | % |

| Module mismatch losses | 2.5 | % |

| String mismatch losses | 0.5 | % |

| Yearly loss factor through soiling | 3 | % |

| Incidence angle modifier losses | Definition as per PV module supplier | |

| Auxiliary power consumption | 5 | W |

| Duration of PV module degradation | Varies as a variable | |

| Average degradation factor | 0.4 | %/year |

| Imp RMS dispersion | 0.4 | %/year |

| Vmp RMS dispersion | 0.4 | %/year |

| System unavailability duration | 7.3 | days/year |

| Number of unavailability periods | 3 | periods/year |

| Steps in Process | Variations/Effect from the Case Study | Recommendations |

|---|---|---|

| Step 1: Analyse the existing load demand of the premises for the intended PV system | After analysis, it was found that the PV system affected the load demand of the case study. Due to the PV system, load demand decreased at 09:30 to approximately 16:30, after which the effect of the PV systems became limited. Furthermore, the presence of a PV system can reduce the existing load demand since cooling loads are decreased–however, this must be verified. | Design the size of the PV system according to load demand from the consumer, considering limiting factors such as generator integration between the PV system and the back-up generators and system registration requirements. |

| Step 2: Investigate the effect of tilt and orientation | Results from the case study indicate that the effect of tilt and orientation remained the same. There was a 0.68% variation between simulation and actual yield. | EPC company can warrant an electricity yield of 95% and higher from the results obtained through simulation. |

| Step 3: Investigate the effect of module degradation on electricity yield | PV module suppliers warrant an annual degradation of 0.7% per annum. Results from the case study reveal that module degradation was only 0.46% per annum. | EPC company can warrant module degradation of between 0.46% and 0.7% per annum. However, further analysis is recommended. |

| Step 4: Investigate the effect of varying the ATIR | This was not investigated in the research. However, based on the accuracy of the above results, the results from the simulations are valid. | PV systems can be designed so that ATIR is increased to approximately 1.5. Energy will be lost beyond an ATIR of 1.2 to reach a maximum of approximately 5% at an ATIR of 1.5. However, this will be offset due to module degradation after approximately 10.8 years. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

van Vuuren, D.J.; Marnewick, A.L.; Pretorius, J.H.C. Validation of a Simulation-Based Pre-Assessment Process for Solar Photovoltaic Technology Implemented on Rooftops of South African Shopping Centres. Sustainability 2021, 13, 2589. https://doi.org/10.3390/su13052589

van Vuuren DJ, Marnewick AL, Pretorius JHC. Validation of a Simulation-Based Pre-Assessment Process for Solar Photovoltaic Technology Implemented on Rooftops of South African Shopping Centres. Sustainability. 2021; 13(5):2589. https://doi.org/10.3390/su13052589

Chicago/Turabian Stylevan Vuuren, Dirk Johan, Annlizé L. Marnewick, and Jan Harm C. Pretorius. 2021. "Validation of a Simulation-Based Pre-Assessment Process for Solar Photovoltaic Technology Implemented on Rooftops of South African Shopping Centres" Sustainability 13, no. 5: 2589. https://doi.org/10.3390/su13052589

APA Stylevan Vuuren, D. J., Marnewick, A. L., & Pretorius, J. H. C. (2021). Validation of a Simulation-Based Pre-Assessment Process for Solar Photovoltaic Technology Implemented on Rooftops of South African Shopping Centres. Sustainability, 13(5), 2589. https://doi.org/10.3390/su13052589