3.2.2. Storage Stability Test

After production via wet method, the modified binders underwent a storage stability test in order to monitor the phase separation between binder and polymers since it is considered a critical aspect of modification results. This test highlights the capacity of a bitumen to be stored inside the tanks at storage and distribution terminal, before transportation to asphalt production plants, and it guarantees that either storage or handlings do not cause significant physical or chemical alterations of the binder itself. The outer portions, top and bottom, were taken for penetration, softening point, elastic recovery and dynamic viscosity tests.

The EN 13399 Standard provides for a maximum variation between the softening point of the top and bottom equal to 3 °C and a variation of the penetration value not greater than 5 0.1∙mm.

Storage stability is also the test that better indicates the compatibility between bitumen and polymer. In fact, if this is low, it is common for segregation effects to occur during the test during which the polymer tends to rise towards the top. This phenomenon determines a higher softening point at the top and a lower penetration index.

Table 9 details the storage stability results for the modified binders studied. Considering that storage stability requirement for PMBs is ΔTR&B ≤ 5 °C, the results obtained for the bitumen modified with 5% of Plasmix 50/50 clearly indicate that these samples are to be considered as unstable: unreacted polymer was detected in bitumen and macroscopic phase separation occurred during its storage at high temperatures, which leads to undesirable problems during transportation of the binder and storage in the plant. On the other hand, the experimental results for both the samples modified at 2% of Plasmix 50/50 show a significant stability, adequate for road application.

A possible solution for the instability when using high content of Plasmix 50/50 may be limiting to the minimum the time between the production of the blend and its use in plant or site (this process is called “terminal blend production”, in the case of modification of the bitumen with crumb rubber) [

34] or studying the introduction of adequate compatibilizers for improving the stability of the blend and to avoid phase separation during storage at high temperature or in absence of stirring. In any case, for proper evaluation of the sustainability of the production of these blends, the overall emissions related to each process necessary for producing them should be taken into consideration, since, for example, the extrusion and granulation processes as well as the possible use of additive for stability purposes are likely to produce not-negligible impacts in terms of air pollutants and emissions [

35]

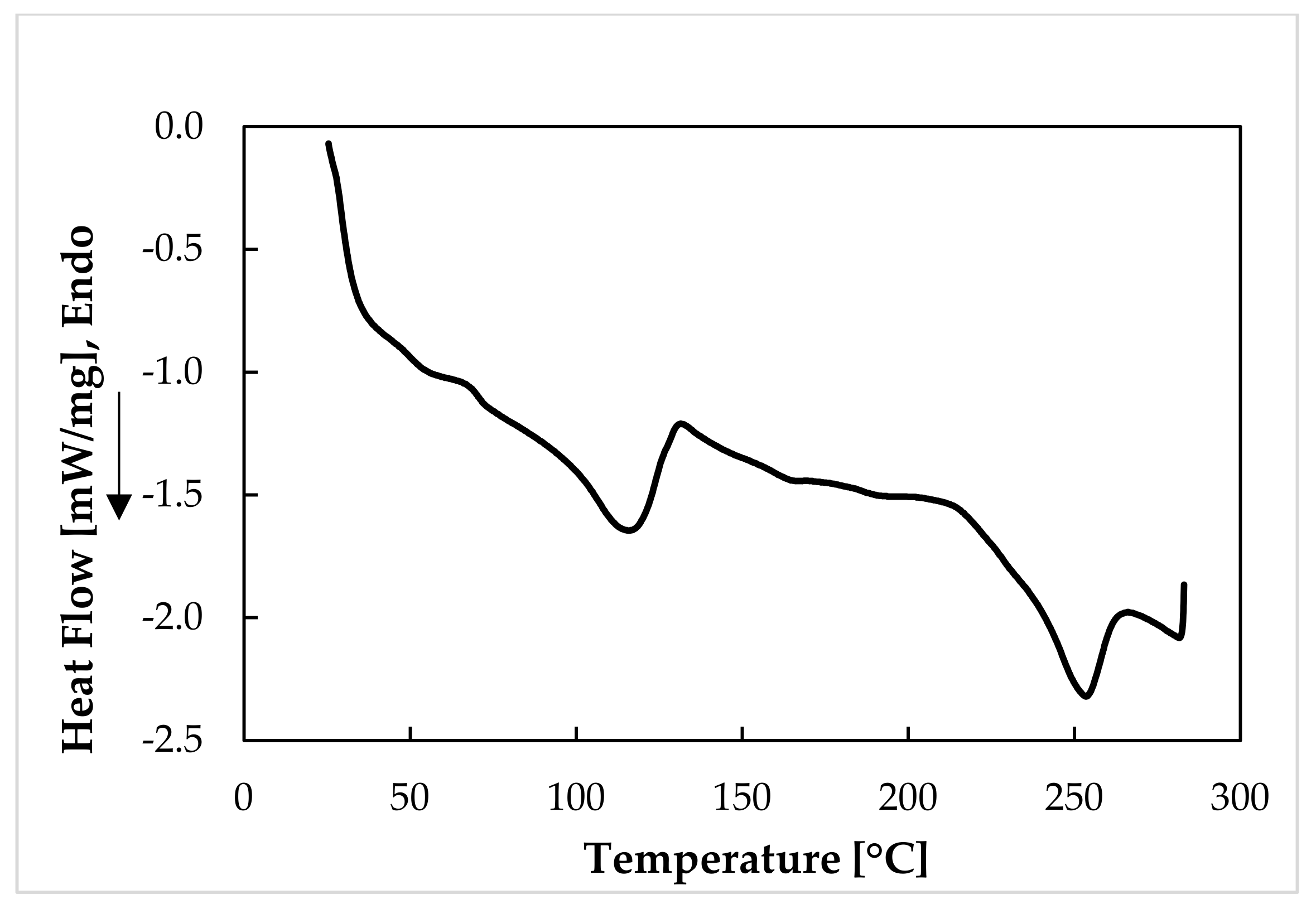

. 3.2.3. Morphology of the Modified Blends via Fluorescence Microscopy

Morphology of the modified blends produced was studied via fluorescence microscopy and micrographs were taken on the blends immediately after production and after storage at high temperatures according to the procedure of the stability tests, in accordance with EN 13399. The micrographs obtained qualitatively show the dispersion of the polymer in the bituminous matrix [

33]; at both dosages (2% and 5%), the dispersing phase remains the bitumen, while the Plasmix remains the dispersed phase.

In details,

Figure 6a proves that the 2% of Plasmix 50/50 is a dosage too low and it does not significantly affect the base bitumen, as it will be better proved by results of the rheological characterization given in the following paragraph of

Section 3.2.4. On the other hand, the dispersion of the 5% of Plasmix 50/50 is much more evident, with a homogenous distribution in the base bitumen, and this is also in line with the results of the rheological characterization, where substantial differences are detectable between the behavior of the base bitumen and that of the blend modified with the 5% of Plasmix 50/50, even though the phase inversion is not reached.

In terms of stability, after storage at high temperature, the blend with 2% of Plasmix 50/50 shows no substantial difference in morphology between the top and bottom section of the sample, thus proving a substantial stability, in line with the results provided in

Table 9. In the same way, the instability of the blend with 5% of Plasmix 50/50 can also be observed, since

Figure 6d,f—respectively taken on the top and bottom sections of the sample—very different from each other, thus proving the separation of the bitumen/plastic phases during the prolonged time at high temperature.

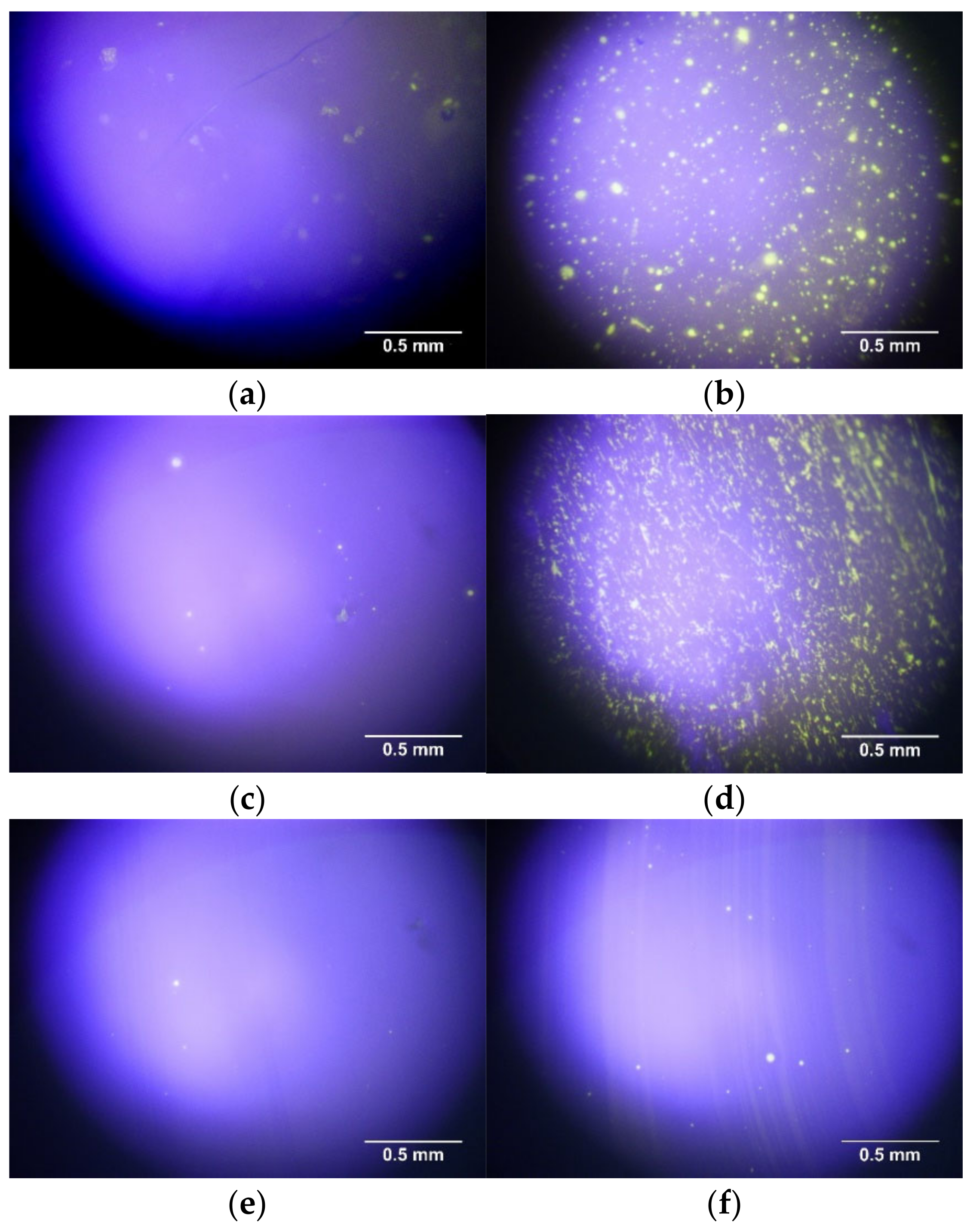

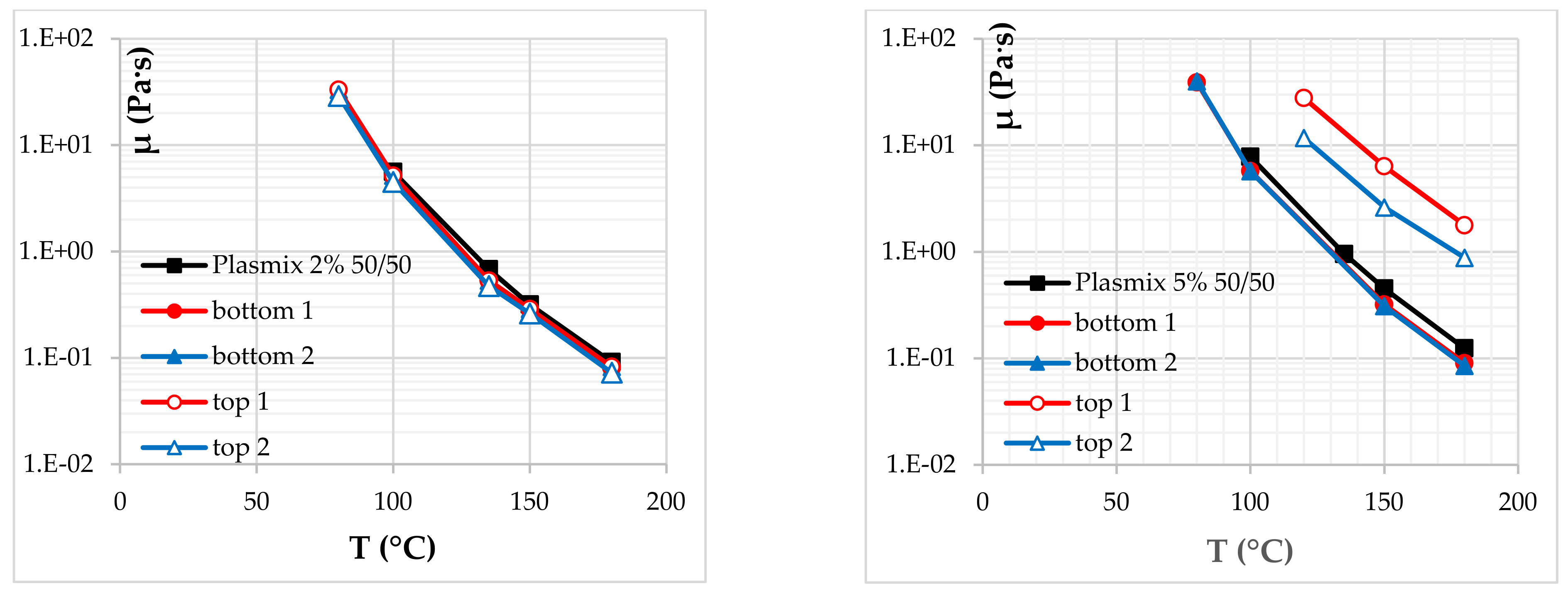

3.2.4. Rheological Characterization

Dynamic viscosity was determined for modified binders studied; the neat bitumen was also tested for comparison purposes.

Figure 6 depicts the results of the viscosity tests carried out.

As can be seen from

Figure 7, the viscosity of the plastic/bitumen blend increases with the content of Plasmix 50/50, as expected, in line with the results of the empirical tests, i.e., the increase in softening point and the decrease in penetration, given in

Table 7 and previously discussed. This increase is beneficial for the resistance (stiffness) at high temperature, which is particularly of interest in regions with warm climate, such as those in the Mediterranean area.

In any case, this increase in viscosity does not compromise the possibility of using the modified binders produced for road applications. In fact, for each sample, the viscosity value at 135 °C and the equiviscosity temperature were evaluated, as detailed in

Table 10. These viscosities are of interest at production level for bituminous mixtures, since the binder viscosity at 135 °C is prescribed to be less than 3 Pa·s [

36,

37,

38], for adequate pumpability from the storage tank to the mixing chamber in the plant. On the other hand, the equiviscosity temperature is the temperature at which the binder has a viscosity equal to 0.17 Pa·s, that is considered as the ideal one for a complete and effective coating of the aggregates during the mixing phase at the asphalt plant [

36,

37].

As said, the addition of Plasmix 50/50 increased the viscosity of the blends produced, but in any case, the requirement at 135 °C is fully satisfied, at both Plasmix dosages.

As far as the equiviscosity temperature is concerned, for the blend with addition of 5% of Plasmix 50/50, results prove an ideal mixing temperature about 15 °C higher than that of the neat bitumen, while at 2% of Plasmix 50/50, comparison with the neat bitumen used as reference, allows one to conclude that this dosage does not significantly affect the equiviscosity temperature (the difference between the results is lower than 5%) and, therefore, the energy needed in the production process in asphalt plant.

The results obtained for the blend with 2% of Plasmix 50/50 prove that, compared with the one with 5% Plasmix 50/50, the first is convenient from the technical, environmental and economical point of view; at lower mixing temperature there is lower risk of premature ageing of the binder as well as a lower need of energy for the production itself (lower costs and lower impacts).

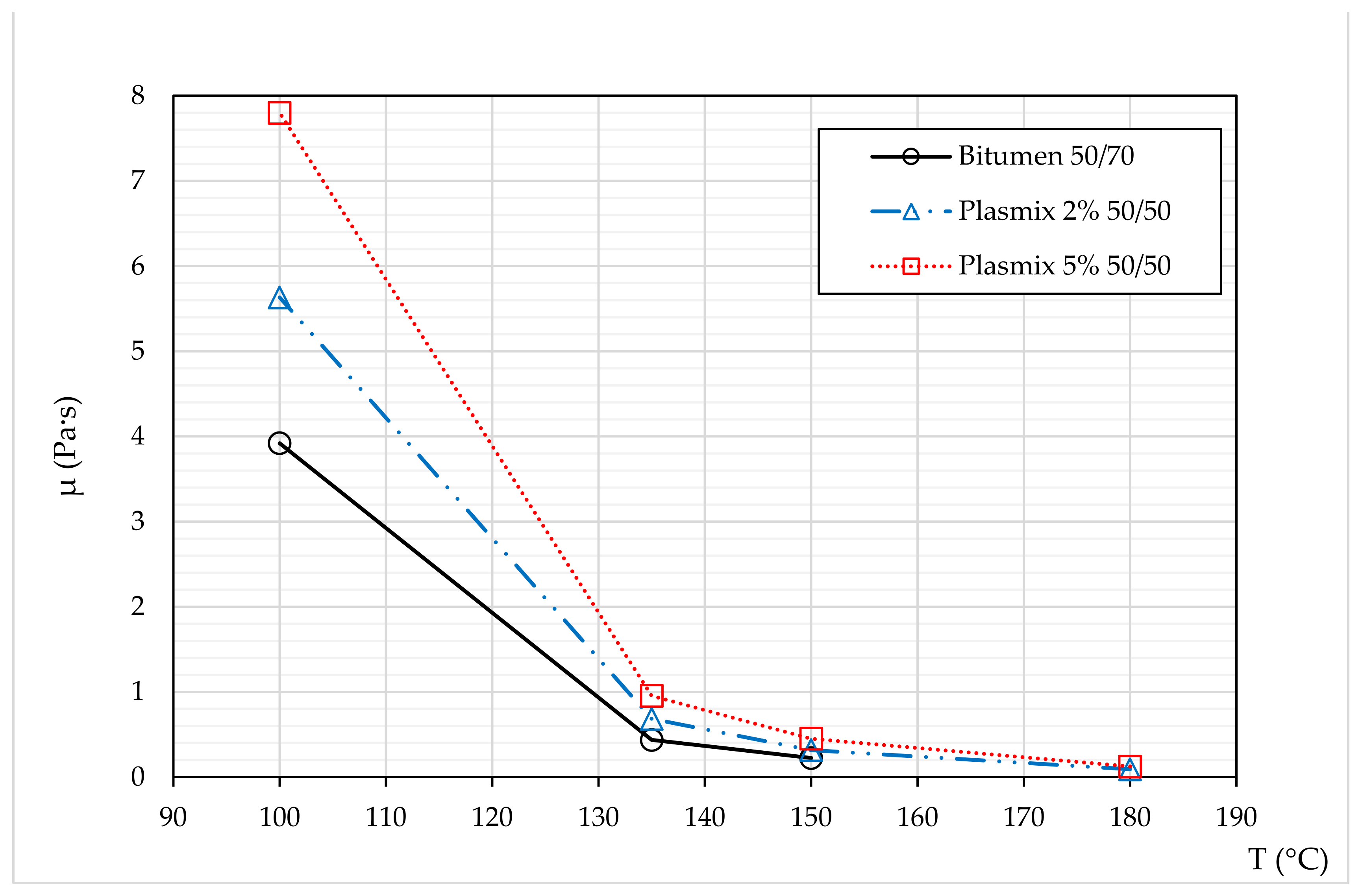

The viscosity tests were also carried out on the samples, subject to storage stability procedure, i.e., taken on the top and bottom of the sections of the tubes used in accordance with EN 13399 Standard. Results are provided in

Figure 8, where the viscosity of the modified blend is compared with that of the top and bottom sections taken after storage at high temperature. Two replicates were carried out for each test; due to the low repeatability for the blend with 5% of Plasmix 50/50, the replicates could not be averaged, thus proving the high heteromogeneity of the samples. This means that the bitumen blend with 5% of Plasmix 50/50 is not stable enough to be safely subjected to the handling and transportation operations, from the production site to the asphalt plant. On the other hand, the results for the top and bottom section of the blend with 2% of Plasmix 50/50 after prolonged storage at high temperature, show high repeatability and are comparable with the viscosity of the modified blend before storage, thus proving its adequacy for road application. These results are fully in line with those of the storage stability evaluated via softening point and penetration variations, but better depict the rheological behavior and, thus, the risk of instability of the bitumen polymer blends.

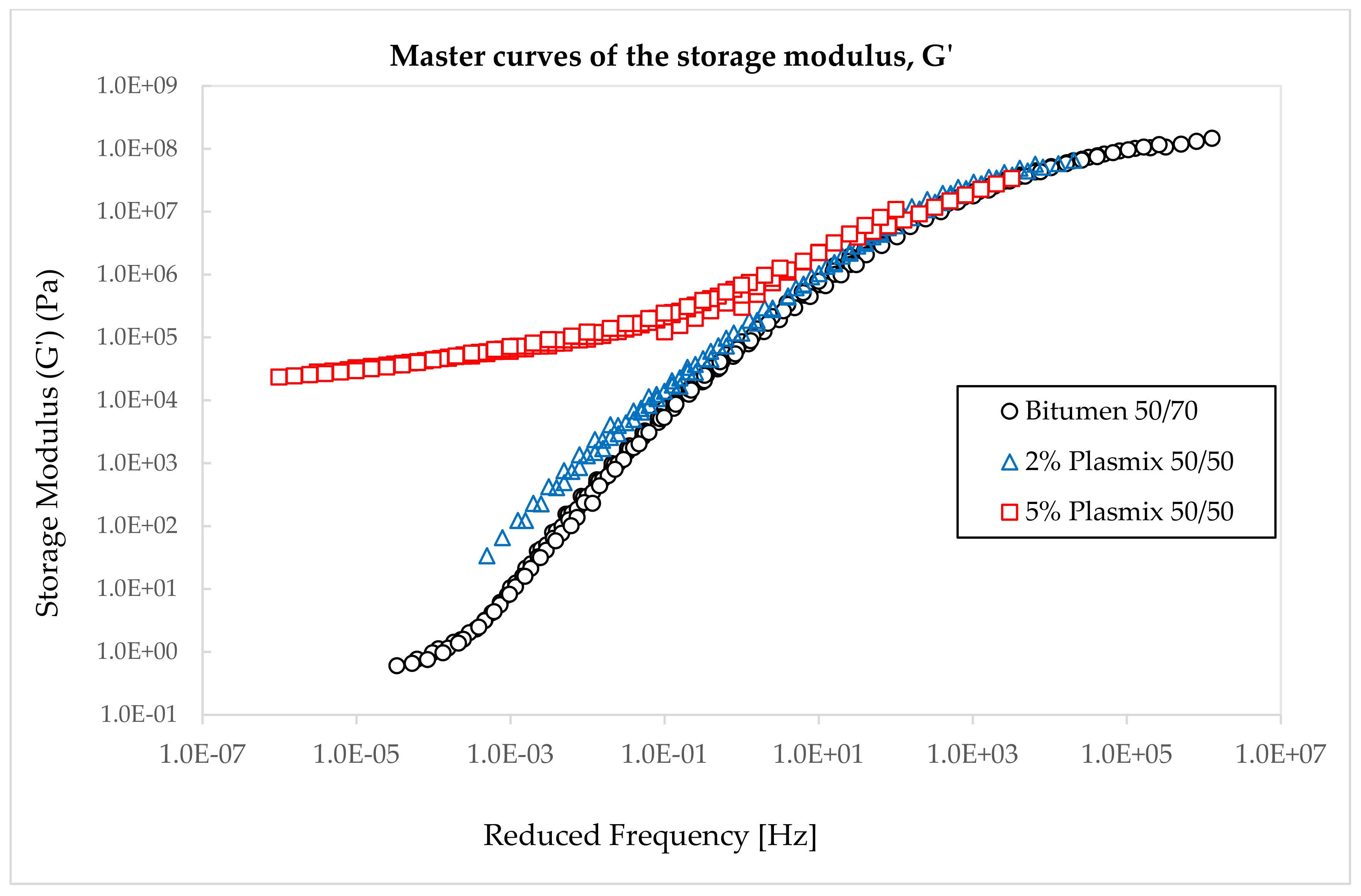

The results of the DSR test performed are given in

Figure 9 and

Figure 10, in terms of master curve of the storage modulus, G’, and Black diagram, respectively.

When analyzing the results obtained in terms of G’ master curve (see

Figure 9), one can conclude that after horizontal shifting at the reference temperature, using the shift factors according to Williams-Landel-Ferry (WLF) [

31], all the isotherms merge into a smooth curve, so that Time–Temperature Superposition Principle (TTSP) seems to be respected by the blends tested.

The bitumen modified with the 2% of Plasmix 50/50 does not exhibit a significant increase in elastic component, at the high testing frequencies (low temperature), but this increase became more appreciable at low frequencies (high temperature) [

33]; this behavior is favorable, since the material is not too rigid at low temperature, but it proves a higher stiffness at low temperature (thus offering a higher resistance to the loads). The blend modified with the 5% of Plasmix 50/50 shows a much more elastic behavior than the blend modified with the 2%, so that at very low frequencies—i.e., high service temperature—a plateau is reached, much higher than the corresponding one of the neat bitumen, that tends to zero.

The same results obtained during the frequency sweep tests at different temperatures can be directly plot in terms of Black diagrams (norm of G* vs. phase angle), as given in

Figure 10, with no need to invoke the TTSP. In this graph, the effect of Plasmix content is clear: at 2% of Plasmix 50/50, the behavior is still very similar to that of the neat binder, even if slightly shifted toward lower values of the phase angle (slight increase in elastic behavior). The addition of 5% of Plasmix 50/50 leads to a real modification of the binder, with a substantial change of its rheological behavior; the relevant increase in elastic behavior is proved by the decreased phase angles, with a plateau region typical of the formation of a polymer network in the blend [

39]. Furthermore, the TTSP is not valid for the blend with 5% of Plasmix 50/50 as it does not have a unique curve in the Black diagram. This evidence is known for Polymer Modified Bitumen (PMBs) as the Partial Time–Temperature Superposition Principle (PTTSP) [

40] since shifting procedures give continuous master curves as the one depicted in

Figure 9.