Optimization of International Roughness Index Model Parameters for Sustainable Runway

Abstract

1. Introduction

2. Methodology

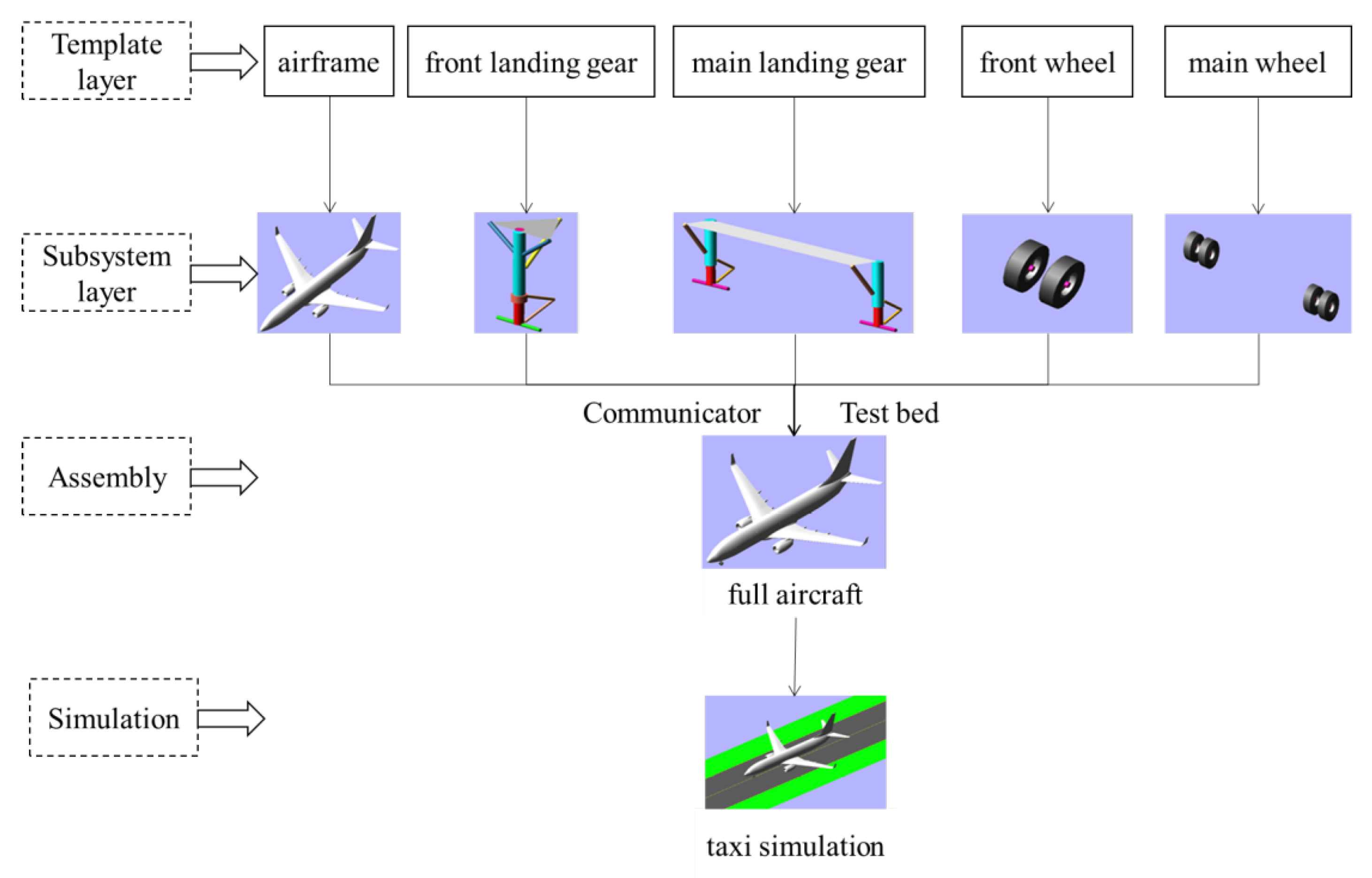

2.1. ADAMS/Aircraft Virtual Prototype Modeling Method

- Build the components in the template file.

- Define the quality property of the components.

- Build the required motion joints, hardpoints, etc.

- Build the mechanical elements and create and assign the property files.

- Build the communicator.

- Generate the subsystems.

- Construct the assembly.

2.2. Boeing 737 Aircraft Virtual Prototype Model

2.2.1. Mass, Moment of Inertia, and Location of Center of Gravity of B737-800

2.2.2. Airframe Aerodynamics

2.2.3. Landing Gear Buffer System

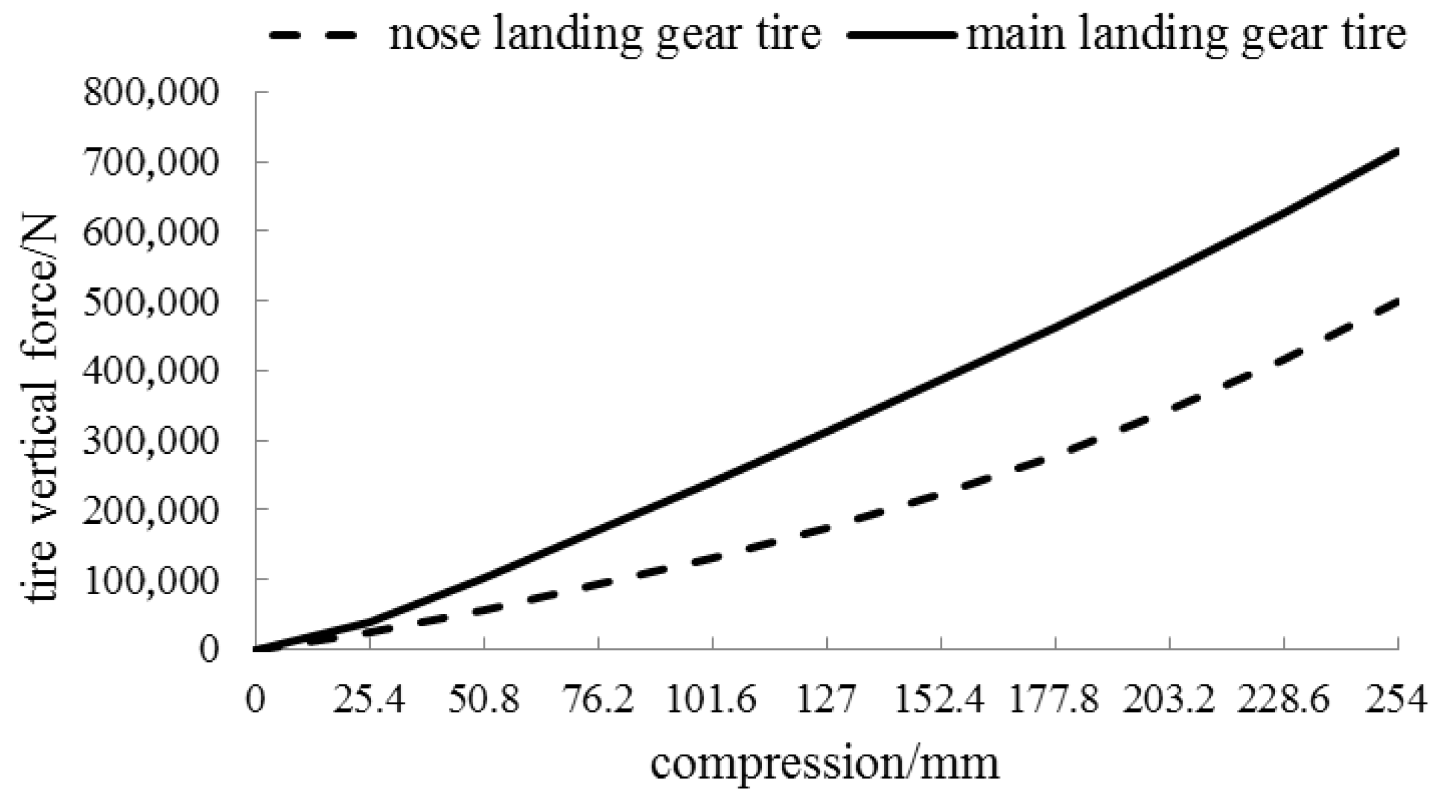

2.2.4. Wheels

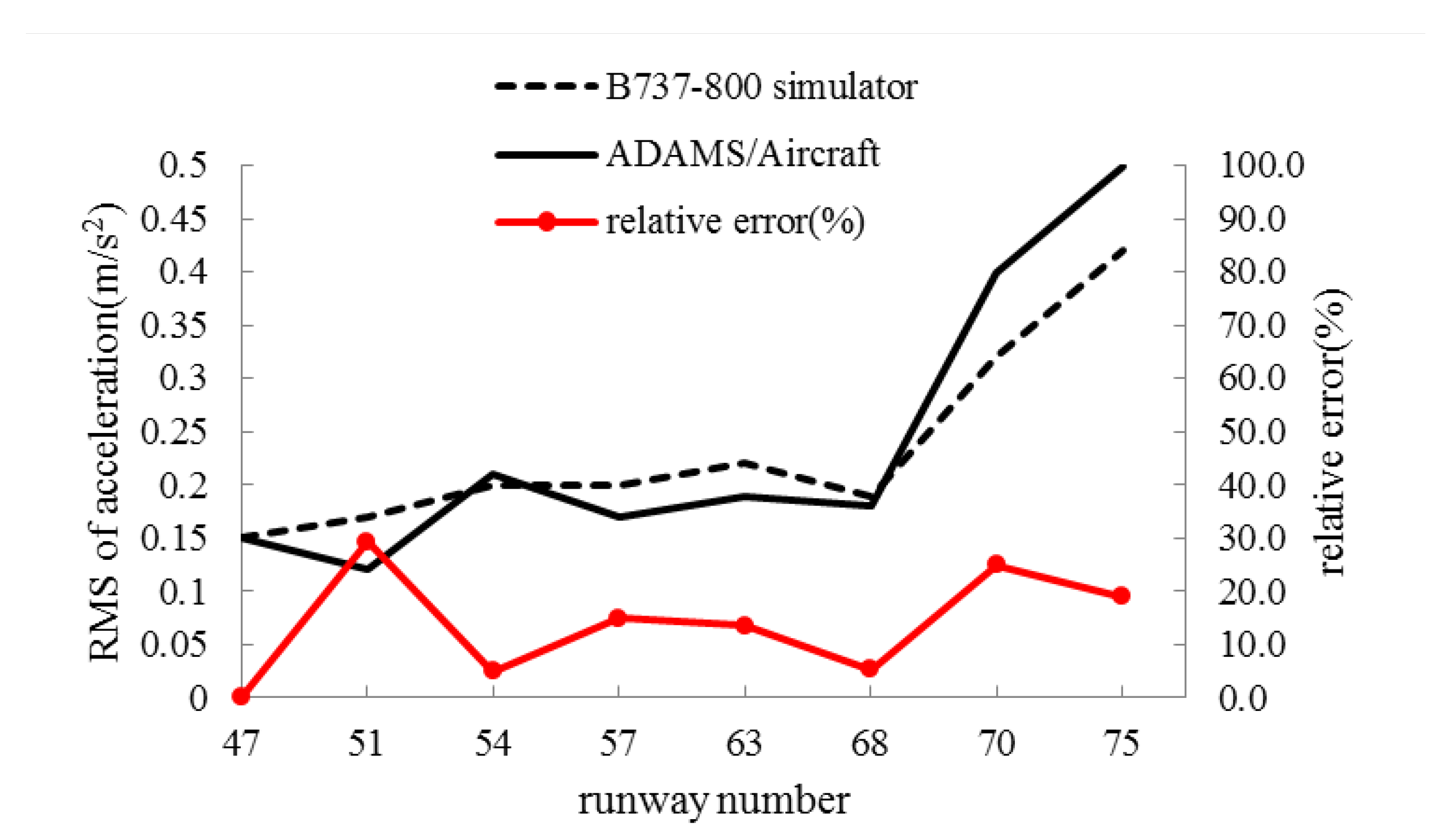

2.3. Verification of Virtual Prototype Model

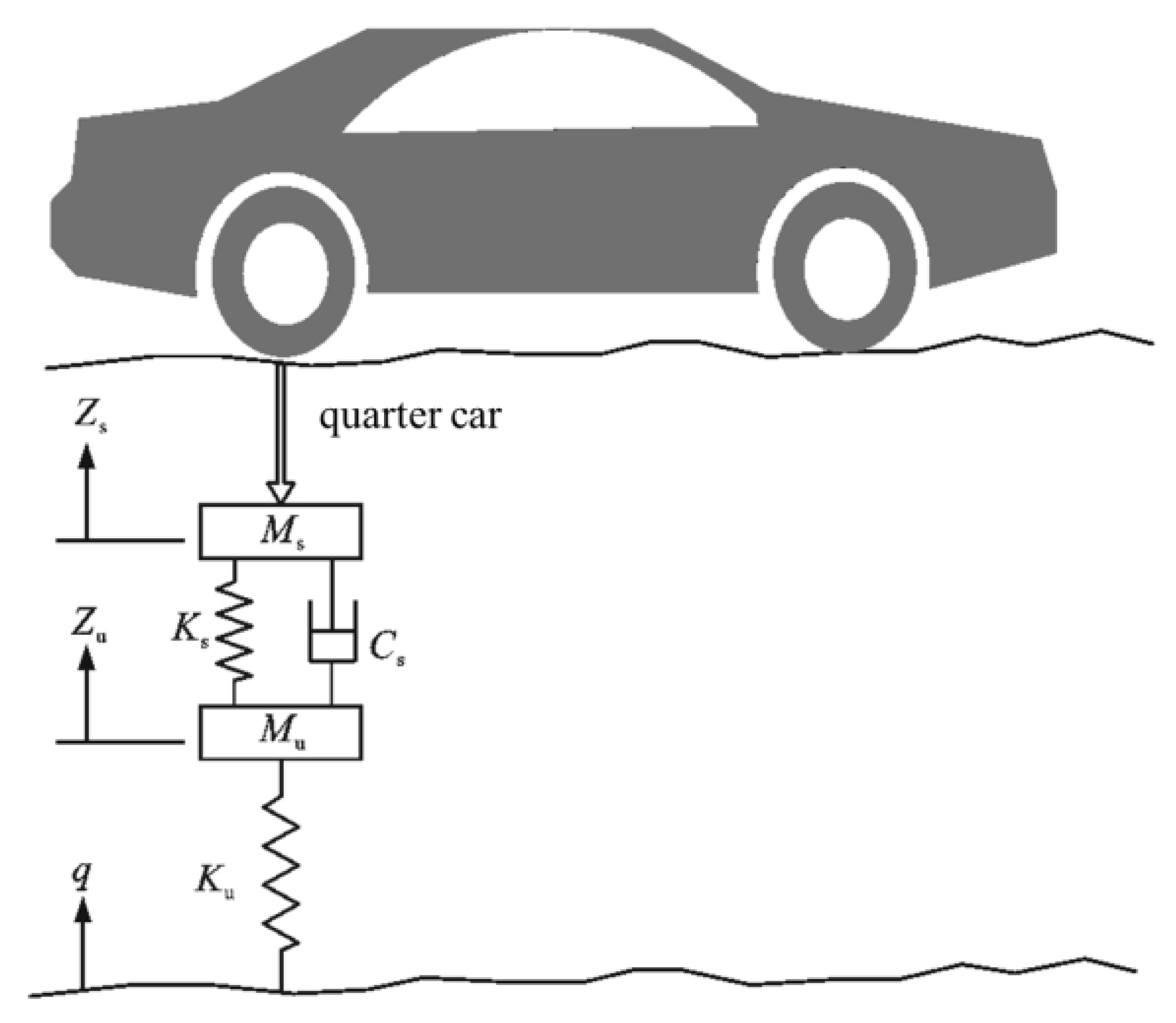

3. Frequency Response Function of IRI Model

4. Results and Discussion

4.1. Frequency Response Distribution of Aircraft

4.2. Frequency Response Curves of the IRI Model and Aircraft

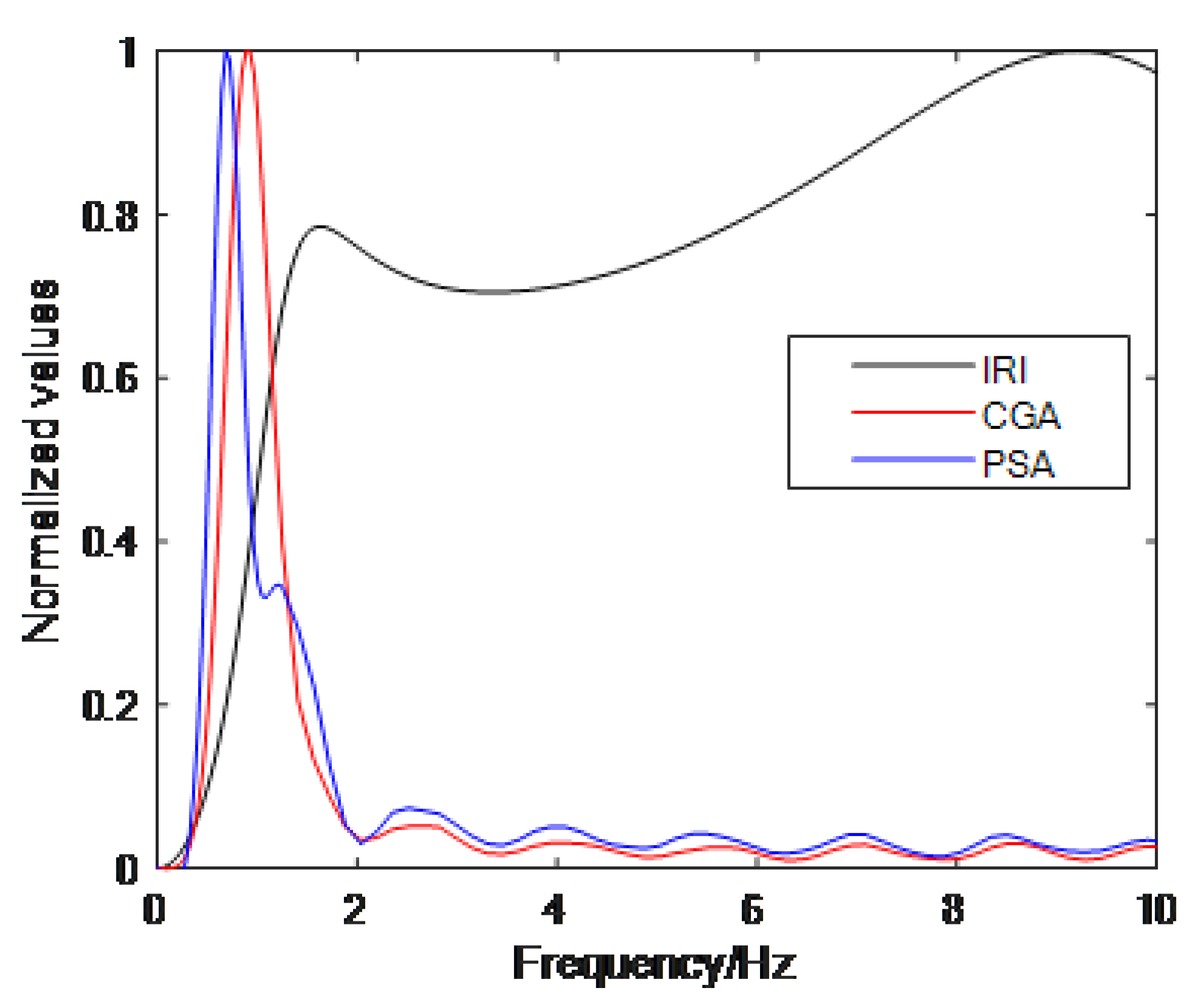

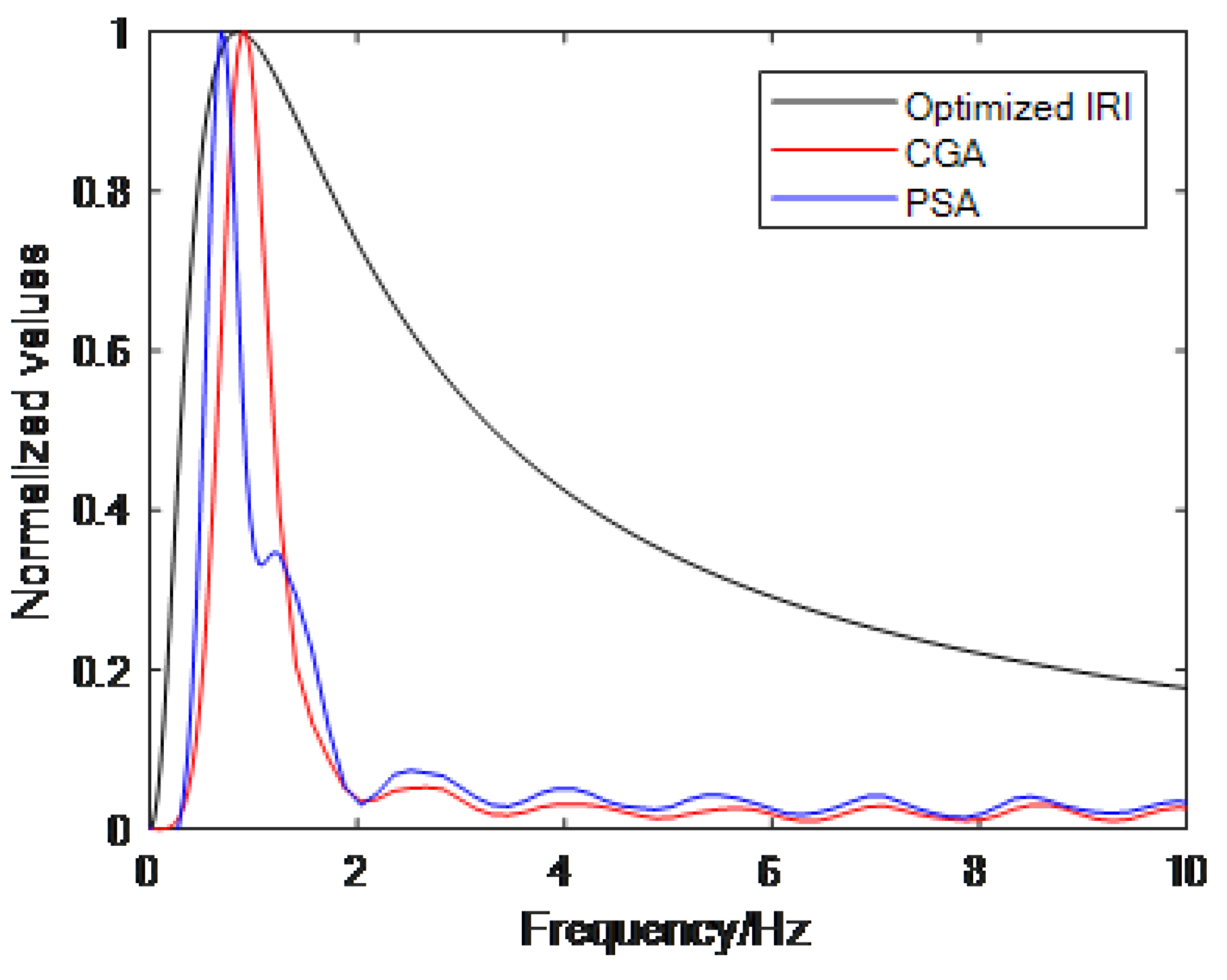

4.3. Parameter Optimization Based on Particle Swarm Optimization

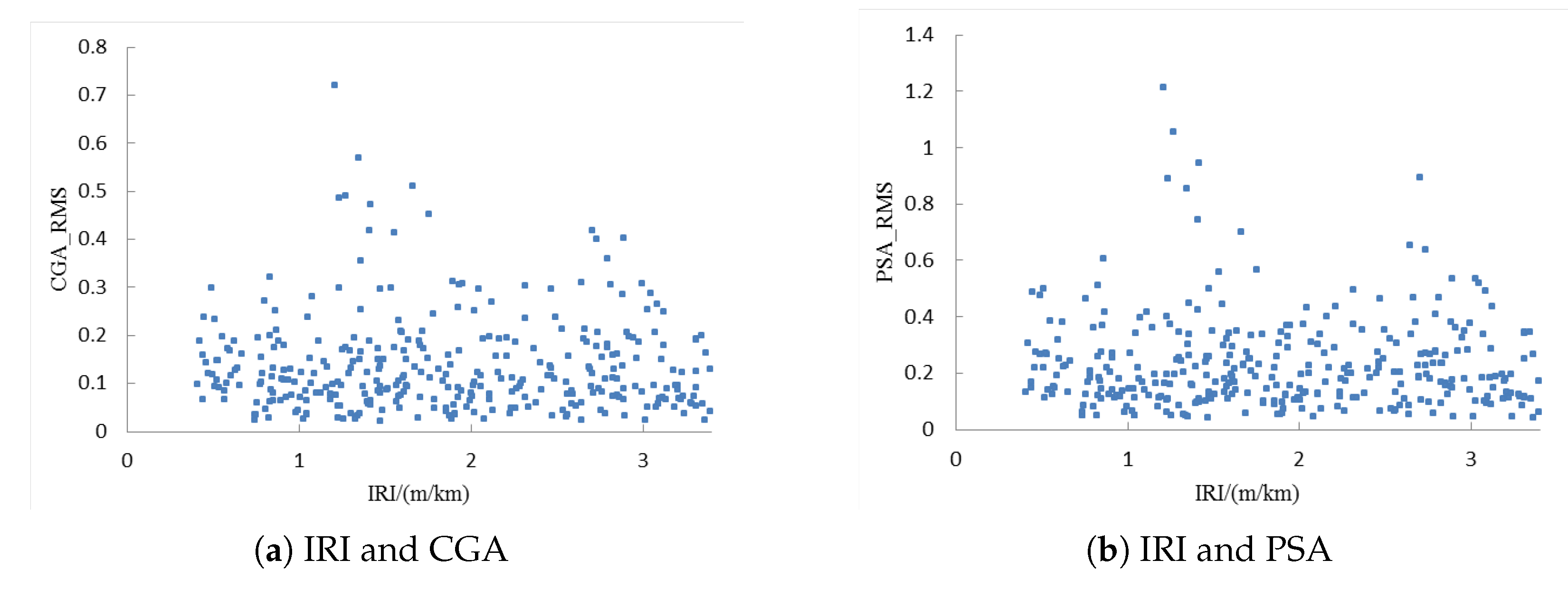

4.4. Case Study

5. Conclusions

- The B737-800 virtual prototype model developed and validated in this study is reliable and can represent aircraft dynamic responses to rough runways.

- The frequency response curves of the IRI model and aircraft model differ greatly, which indicates that the IRI cannot effectively represent the vibration responses of aircraft to runway roughness.

- PSO accelerates the efficiency of parameter optimization. The optimized IRI model approximates the vibration response characteristics of the aircraft better than the original IRI model (without optimized parameters).

- The case study results show that the correlation coefficient between the optimized IRI model and the aircraft vibration response is as high as 0.56. Compared with the original IRI model, the optimized IRI model shows a qualitative leap in terms of correlation coefficients.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gerardi, A.G. Dynamic Response of Aircraft to Pavement Unevenness; Transportation Research Board Special Report; TRB: Washington, DC, USA, 1978. [Google Scholar]

- Gervais, E.L. Runway roughness measurement, quantification and application: The Boeing approach. In Aircraft/Pavement Interaction: An Integrated System; ASCE: Reston, VA, USA, 1991; pp. 121–131. [Google Scholar]

- Civil Aviation Administration of China. MH/T 5024-2009, Technical Specifications of Aerodrome Pavement Evaluation and Management. 2009. Available online: https://www.docin.com/p-119165177.html (accessed on 13 February 2021).

- Transport Canada, Measurement and Evaluation of Runway Roughness. Civil Aviation, Standards. Advisory Circular AC 302-023, 16 September 2015. Available online: https://tc.canada.ca/sites/default/files/migrated/ac_302_023_issue_02.pdf (accessed on 13 February 2021).

- Hayhoe, G.F. Airport pavement rideability rating for maintenance evaluation. In Proceedings of the 2016 Airports Conference, Hershey, PA, USA, 21–23 March 2016; Volume 22. [Google Scholar]

- Sayers, M.W. The International Road Roughness Experiment: Establishing Correlation and a Calibration Standard for Measurements; Technical Report; University of Michigan, Ann Arbor, Transportation Research Institute: Ann Arbor, MI, USA, 1986. [Google Scholar]

- Emery, S.; Hefer, A.; Horak, E. Roughness of runways and significance of appropriate specifications and measurement. In Proceedings of the 11th Conference on Asphalt Pavements for Southern Africa, Sun City, South Africa, 16–19 August 2015. [Google Scholar]

- Loprencipe, G.; Zoccali, P. Comparison of methods for evaluating airport pavement roughness. Int. J. Pavement Eng. 2019, 20, 782–791. [Google Scholar] [CrossRef]

- Chen, Y.; Chou, C. Effects of airport pavement-profile wavelength on aircraft vertical responses. Transp. Res. Rec. 2004, 1889, 83–93. [Google Scholar] [CrossRef]

- Ling, J.M.; Liu, S.F.; Yuan, J.; Yang, W.c. Applicability of IRI based evaluation of airport pavement roughness. J. Traffic Transp. Eng. 2017, 17, 20–27. [Google Scholar]

- Cardoso, S.H. Aircraft-based pavement surface roughness assessment. Transp. Res. Rec. 2007, 2007, 104–110. [Google Scholar] [CrossRef]

- Chen, Y.; Chou, C. Assessment of Aircraft’s Vertical Responses to Develop the Roughness Evaluation Index for Airport Pavement by; Citeseer: Princeton, NJ, USA, 2004. [Google Scholar]

- Woods, J.E. A Study of Airport Pavement-Aircraft Interaction Using Wavelet Analysis; The University of Texas at San Antonio: San Antonio, TX, USA, 2008. [Google Scholar]

- Major, W.; Matthew, J.; Hubbard, S.; Bullock, D. Evaluation of opportunities for connected aircraft data to identify pavement roughness at airports. Coll. Aviat. Rev. Int. 2018, 36. [Google Scholar] [CrossRef]

- Cheng, G.; Guo, W. Airport pavement roughness evaluation based on three-degree-of-freedom aircraft model. J. Nanjing Univ. Aeronaut. Astronaut. 2016, 48, 606–614. [Google Scholar]

- Kanazawa, H.; Su, K.; Noguchi, T.; Hachiya, Y.; Nakano, M. Evaluation of airport runway pavement based on pilots’ subjective judgement. Int. J. Pavement Eng. 2010, 11, 189–195. [Google Scholar] [CrossRef]

- Dong, Q.; Hachiya, Y.; Endo, K.; Himeno, K.; Kawamura, A.; Matsui, K. Airport pavement roughness evaluation based on aircraft response. In Health Monitoring and Smart Nondestructive Evaluation of Structural and Biological Systems III; International Society for Optics and Photonics: Bellingham, WA, USA, 2004; Volume 5394, pp. 118–126. [Google Scholar]

- Endo, K.; Himeno, K.; Kawamura, A.; Hachiya, Y.; Matsui, K. Evaluation of longitudinal runway profile and ride quality using wavelet analysis and brain waves. In Proceedings of the TRB 82nd Annual Meeting, Washington, DC, USA, 12–16 January 2003. [Google Scholar]

- Liu, S.; Ling, J.; Yuan, J.; Li, P.; Chen, J. Landing gear cumulative stroke-based runway roughness evaluation. In Proceedings of the 97th Annual Meeting of Transportation Research Board, Washington, DC, USA, 7–11 January 2018. [Google Scholar]

- Boeing Commercial Airplanes. 737 Airplane Characteristics for Airport Planning; Technical Report D6-58325-6; Boeing Commercial Airplanes: Seattle, WA, USA, 2020. [Google Scholar]

- Koşar, K.; Durmaz, S.; Jafarov, E.M. Longitudinal dynamics analysis of Boeing 747-400. In Proceedings of the 9th WSEAS International Conference on Automatic Control, Modelling and Simulation, Istanbul, Turkey, 27–29 May 2007; pp. 82–87. [Google Scholar]

- F.A.A. Surface Roughness Study Final Data Report Boeing 737-800; Federal Aviation Administration: Washington, DC, USA, 2015. [Google Scholar]

- Morris, G.J. Response of Several Turbojet Airplanes to Runway Roughness; National Aeronautics and Space Administration: Washington, DC, USA, 1970; Volume 5740. [Google Scholar]

- Cai, X.; Gao, L.; Li, F. Sequential approximation optimization assisted particle swarm optimization for expensive problems. Appl. Soft Comput. 2019, 83, 105659. [Google Scholar] [CrossRef]

| Mass | Estimated Moment of Inertia | Center of Gravity | ||

|---|---|---|---|---|

| MTW/kg | 78,472 | 3,394,953 | 13.60 m to nose landing gear | |

| MTOW/kg | 78,245 | 1,866,711 | ||

| MLW/kg | 65,317 | 5,097,558 | ||

| Aircraft | SPAN/m | MAC/m | Aspect Ratio | |

|---|---|---|---|---|

| B737-800 | 1341 | 35.79 | 3.79 | 9.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Y.; Liu, S.; Liu, L.; Xiang, P. Optimization of International Roughness Index Model Parameters for Sustainable Runway. Sustainability 2021, 13, 2184. https://doi.org/10.3390/su13042184

Tian Y, Liu S, Liu L, Xiang P. Optimization of International Roughness Index Model Parameters for Sustainable Runway. Sustainability. 2021; 13(4):2184. https://doi.org/10.3390/su13042184

Chicago/Turabian StyleTian, Yu, Shifu Liu, Le Liu, and Peng Xiang. 2021. "Optimization of International Roughness Index Model Parameters for Sustainable Runway" Sustainability 13, no. 4: 2184. https://doi.org/10.3390/su13042184

APA StyleTian, Y., Liu, S., Liu, L., & Xiang, P. (2021). Optimization of International Roughness Index Model Parameters for Sustainable Runway. Sustainability, 13(4), 2184. https://doi.org/10.3390/su13042184