Discovering Energy Consumption Patterns with Unsupervised Machine Learning for Canadian In Situ Oil Sands Operations

Abstract

1. Introduction

- Assesses the impact of production regions and recovery methods on steam injection and oil production using clustering, unsupervised machine learning algorithms;

- Evaluates whether production regions have a relationship with solution gas production by an unsupervised machine learning method, namely association rules;

- Evaluates whether solvent co-injection with steam can reduce SORs and whether production regions have a relationship with solution gas production by an unsupervised machine learning method, namely association rules.

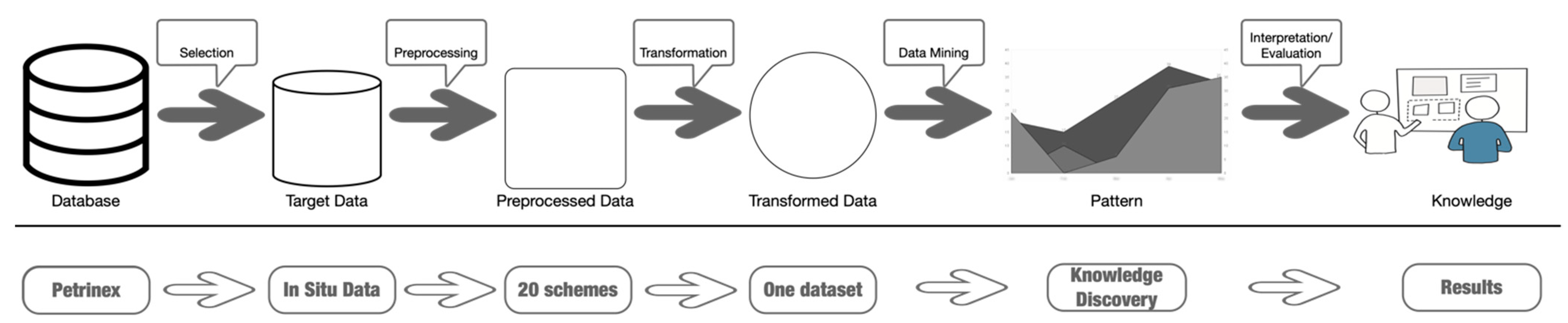

2. Materials and Methods

- Data selection: Relevant data are retrieved from the database, then a subset of data samples is selected to create a target dataset on which the discovery will be performed.

- Data pre-processing: Outliers, inconsistent, or missing data are removed.

- Data transformation: Appropriate data forms are created for mining. The task may consist of dimension reduction, data integration, and other steps.

- Data mining or pattern discovery: Interesting patterns are extracted. Data mining is an essential step in the process of KDD [37]. Data mining tasks are generally grouped as predictive or descriptive. The predictive task builds a model to predict the future with methods such as correlation and regression. The descriptive task characterises properties of the data with methods such as clustering, identifying frequent patterns, and understanding associations.

- Interpretation and evaluation: The mined patterns are interpreted and evaluated (commonly with pattern visualisation techniques).

2.1. Data Selection

- Under the reporting facility types, battery (BT) and injection facility (IF) were selected.

- Under the reporting facility subtypes, in situ oil sands and sulphur reporting at oil sands were selected.

- BT and IF were linked by 11,000 well IDs provided in the Well to Facility Link Report [39]. The paired injection wells and producing wells for the scheme had the same well IDs. Depending on the stage of production, the number of wells for each scheme ranged from 100 to over 600 wells. The linked BT and IF IDs formed a dataset for in situ oil sands extraction schemes only, which was the target dataset in this study. The linked BT and IF IDs for each scheme are provided in the Supplementary Material.

2.2. Data Preprocessing

2.3. Data Transformation

2.4. Data Mining

2.4.1. Clustering

- For K < K*, a (K + 1) cluster partition should be the K cluster partition with one of its clusters split into two. This would significantly decrease the total within-cluster variation ();

- For K > K*, both the K and (K + 1) cluster partitions will be equal to the right cluster partition with some of the right clusters split randomly, so that and are not significantly different.

2.4.2. Association Rule

2.5. Interpretation and Evaluation

- Ho: The antecedent (X) and the consequent (Y) are independent.

- Ha: The antecedent (X) and the consequent (Y) are not independent.

3. Results

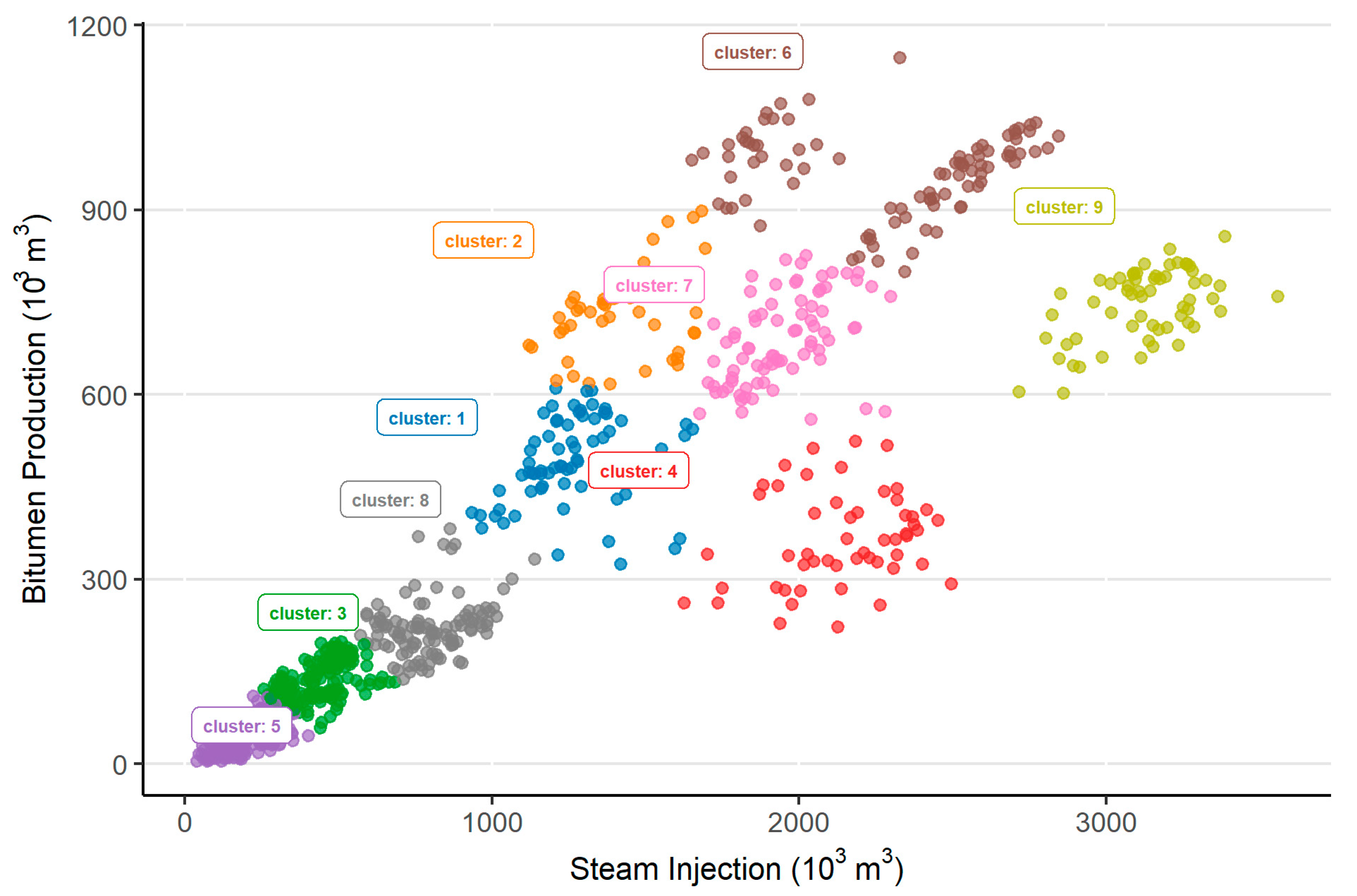

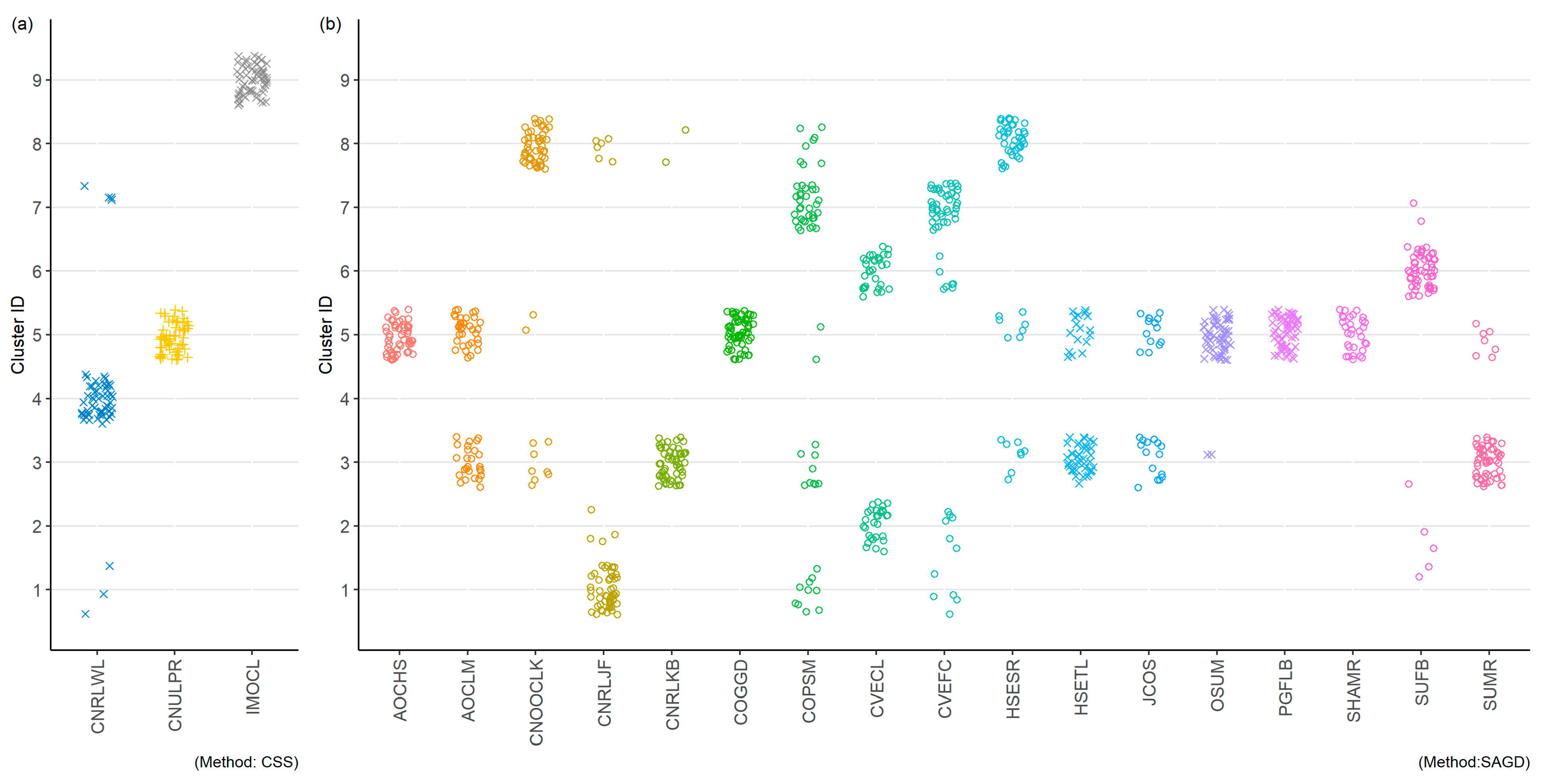

3.1. Clustering

3.2. Association Rule and Chi-Square Test

4. Discussion

4.1. Efficiency of Recovery Methods

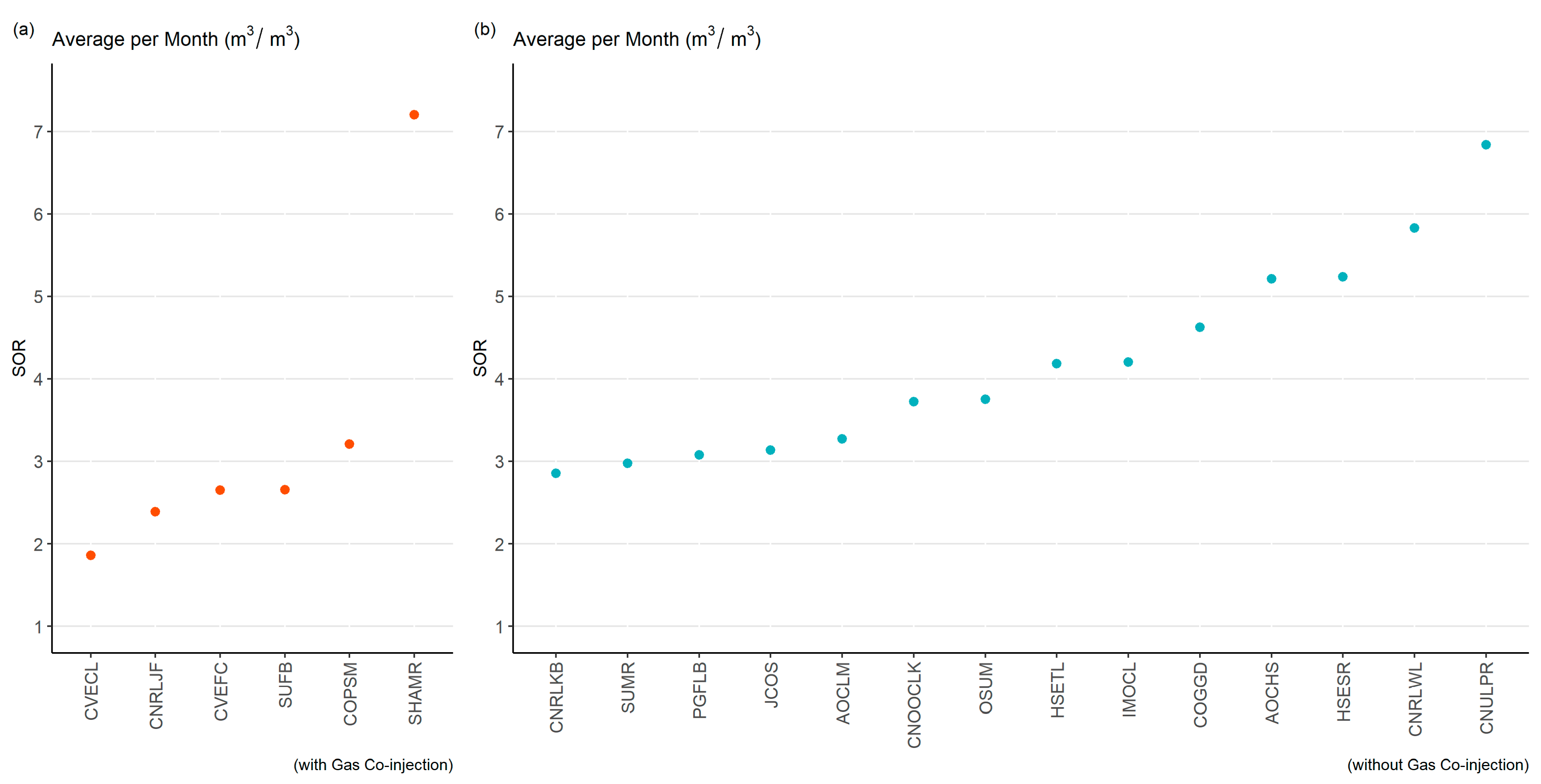

4.2. Solvent Co-Injection with Steam

4.3. Solution Gas and Production Region

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- McGlade, C.; Ekins, P. The geographical distribution of fossil fuels unused when limiting global warming to 2 °C. Nature 2015, 517, 187–190. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration (EIA). What Countries Are the Top Producers and Consumers of Oil? 2020. Available online: https://www.eia.gov/tools/faqs/faq.php?id=709&t=6 (accessed on 25 September 2020).

- U.S. Energy Information Administration (EIA). International Energy Statistics, Crude Oil Including Lease Condensate 2019. Available online: https://www.eia.gov/international/data/world/petroleum-and-other-liquids/annual-crude-and-lease-condensate-reserves?pd=5&p=0000000000000000000008&u=0&f=A&v=mapbubble&a=-&i=none&vo=value&vb=106&t=C&g=00000000000000000000000000000000000000000000000001&l=249-ruvvvvvfvtvnvv1vrvvvvfvvvvvvfvvvou20evvvvvvvvvvnvvvs0008&s=315532800000&e=1577836800000&ev=true (accessed on 3 December 2019).

- Masnadi, M.S.; El-Houjeiri, H.; Schunack, D.; Li, Y.; Englander, J.G.; Badahdah, A.; Monfort, J.-C.; Anderson, J.E.; Wallington, T.J.; Bergerson, J.A.; et al. Global carbon intensity of crude oil production. Science 2018, 361, 851–853. [Google Scholar] [CrossRef]

- Natural Resources Canada. Crude-Oil-Facts 2019. Available online: https://www.nrcan.gc.ca/science-data/data-analysis/energy-data-analysis/energy-facts/crude-oil-facts/20064 (accessed on 3 December 2019).

- Alexander, A.; Chambers, P. Assessment of seven Canadian rivers in relation to stages in oil sands industrial development, 1972–2010. Environ. Rev. 2016, 24, 484–494. [Google Scholar] [CrossRef]

- Banerjee, D. Oil Sands, Heavy Oil, & Bitumen: From Recovery to Refinery; PennWell Corporation: Tulsa, OK, USA, 2012. [Google Scholar]

- Giove, A.; Sciarrabba, T. In-Situ Bitumen Extraction; Oil Sands Mag: Calgary, AB, Canada, 2019. [Google Scholar]

- Brandt, A.R.; Englander, J.; Bharadwaj, S. The energy efficiency of oil sands extraction: Energy return ratios from 1970 to 2010. Energy 2013, 55, 693–702. [Google Scholar] [CrossRef]

- Englander, J.G.; Brandt, A.R.; Elgowainy, A.; Cai, H.; Han, J.; Yeh, S.; Wang, M.Q. Oil Sands Energy Intensity Assessment Using Facility-Level Data. Energy Fuels 2015, 29, 5204–5212. [Google Scholar] [CrossRef]

- Jordaan, S.M.; Keith, D.W.; Stelfox, B. Quantifying land use of oil sands production: A life cycle perspective. Environ. Res. Lett. 2009, 4, 024004. [Google Scholar] [CrossRef]

- Jordaan, S.M. Land and Water Impacts of Oil Sands Production in Alberta. Environ. Sci. Technol. 2012, 46, 3611–3617. [Google Scholar] [CrossRef] [PubMed]

- Goldenberg, S. Keystone XL Pipeline: Obama Rejects Controversial Project. 2012. Available online: https://www.theguardian.com/environment/2012/jan/18/obama-administration-rejects-keystone-xl-pipeline (accessed on 3 December 2019).

- Natural Resources Canada. Oil Sands: Economic Contributions 2016. Available online: https://www.nrcan.gc.ca/energy/publications/18756 (accessed on 28 September 2020).

- Zhang, Y.; Hu, J.; Zhang, Q. Simulation Study of CO2 Huff-n-Puff in Tight Oil Reservoirs Considering Molecular Diffusion and Adsorption. Energies 2019, 12, 2136. [Google Scholar] [CrossRef]

- Keshavarz, M. Analytical Modeling of Steam Injection and Steam-Solvent Co-Injection for Bitumen and Heavy Oil Recovery with Parallel Horizontal Wells. Ph.D. Thesis, University of Calgary, Calgary, AB, Canada, April 2019. [Google Scholar]

- Cenovus Energy. Cenovus Uses Solvents to Improve Its SAGD 2020. Available online: https://www.cenovus.com/technology/solvents.html (accessed on 11 August 2020).

- Oil Sands Advisory Group. The Oil Sands Advisory Group (“OSAG”) Recommendations on Implementation of the Oil Sands Emissions Limit Established by the Alberta Climate Leadership Plan (“ACLP”): Executive Summary; Oil Sands Advisory Group: Edmonton, AB, Canada, 2017. [Google Scholar]

- Government of Alberta. Capping Oil Sands Emissions 2020. Available online: https://www.alberta.ca/climate-oilsands-emissions.aspx (accessed on 30 September 2020).

- Alberta Energy Regulator. How to Submit Volumetric Data to the AER; Alberta Energy Regulato: Calgary, AB, Canada, 2019. [Google Scholar]

- Ge, Z.; Song, Z.; Ding, S.X.; Huang, B. Data Mining and Analytics in the Process Industry: The Role of Machine Learning. IEEE Access 2017, 5, 20590–20616. [Google Scholar] [CrossRef]

- Lv, Z.; Yan, X.; Jiang, Q. Batch process monitoring based on just-in-time learning and multiple-subspace principal component analysis. Chemom. Intell. Lab. Syst. 2014, 137, 128–139. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, G. Scale-sifting multiscale nonlinear process quality monitoring and fault detection. Can. J. Chem. Eng. 2015, 93, 1416–1425. [Google Scholar] [CrossRef]

- Yu, H.; Khan, F.; Garaniya, V. Nonlinear Gaussian Belief Network based fault diagnosis for industrial processes. J. Process. Control. 2015, 35, 178–200. [Google Scholar] [CrossRef]

- Thomas, M.C.; Zhu, W.; Romagnoli, J.A. Data mining and clustering in chemical process databases for monitoring and knowledge discovery. J. Process. Control. 2018, 67, 160–175. [Google Scholar] [CrossRef]

- Shokrollahi, A.; Tatar, A.; Safari, H. On accurate determination of PVT properties in crude oil systems: Committee machine intelligent system modeling approach. J. Taiwan Inst. Chem. Eng. 2015, 55, 17–26. [Google Scholar] [CrossRef]

- Ramirez, A.M.; Valle, G.A.; Romero, F.; Jaimes, M. Prediction of PVT Properties in Crude Oil Using Machine Learning Techniques MLT. SPE Lat. Am. Caribb. Pet. Eng. Conf. 2017. [Google Scholar] [CrossRef]

- An, J.; Mikhaylov, A.; Moiseev, N. Oil price predictors: Machine learning approach. Int. J. Energy Econ. Policy 2019, 9, 1–6. [Google Scholar] [CrossRef]

- Gumus, M.; Kiran, M.S. Crude oil price forecasting using XGBoost. In Proceedings of the 2017 International Conference on Computer Science and Engineering (UBMK), Antalya, Turkey, 5–8 October 2017; pp. 1100–1103. [Google Scholar] [CrossRef]

- You, J.; Ampomah, W.; Sun, Q.; Kutsienyo, E.J.; Balch, R.S.; Dai, Z.; Cather, M.; Zhang, X. Machine learning based co-optimization of carbon dioxide sequestration and oil recovery in CO2-EOR project. J. Clean. Prod. 2020, 260, 120866. [Google Scholar] [CrossRef]

- Krasnov, F.; Glavnov, N.; Sitnikov, A. A Machine Learning Approach to Enhanced Oil Recovery Prediction. Available online: https://www.researchgate.net/publication/321976616_A_Machine_Learning_Approach_to_Enhanced_Oil_Recovery_Prediction (accessed on 3 December 2019).

- Kurian, D.; Sattari, F.; Lefsrud, L.; Ma, Y. Using machine learning and keyword analysis to analyze incidents and reduce risk in oil sands operations. Saf. Sci. 2020, 130, 104873. [Google Scholar] [CrossRef]

- Kurian, D.; Ma, Y.; Lefsrud, L.; Sattari, F. Seeing the forest and the trees: Using machine learning to categorize and analyze incident reports for Alberta oil sands operators. J. Loss Prev. Process. Ind. 2020, 64, 104069. [Google Scholar] [CrossRef]

- Esmaeili, S.; Sarma, H.K.; Harding, T.; Maini, B.B. Effect of Temperature on Bitumen/Water Relative Permeability in Oil Sands. Energy Fuels 2020, 34, 12314–12329. [Google Scholar] [CrossRef]

- Li, C.; Jan, N.M.; Huang, B. Data analytics for oil sands subcool prediction—A comparative study of machine learning algorithms. IFAC-Pap 2018, 51, 886–891. [Google Scholar] [CrossRef]

- Gullo, F. From Patterns in Data to Knowledge Discovery: What Data Mining Can Do. Phys. Procedia 2015, 62, 18–22. [Google Scholar] [CrossRef]

- Han, J.; Pei, J.; Kamber, M. Data Mining: Concepts and Techniques; Elsevier: Waltham, MA, USA, 2011. [Google Scholar]

- Fayyad, U.M.; Piatetsky-Shapiro, G.; Smyth, P.; Uthurusamy, R. Advances in Knowledge Discovery and Data Mining; American Association for Artificial Intelligence: Menlo Park, CA, USA, 1996. [Google Scholar]

- Petrinex. Petrinex Public Data. Petrinex Public Data Web Portal 2019. Available online: https://www.petrinex.gov.ab.ca/PublicData (accessed on 2 December 2019).

- Government of Alberta. Oil and Gas Conservation Act, Oil Gas Conserv Act Oil Gas Conserv Rules Alta Regul 1511971 Amend Alta Regul 172019 2019. Available online: http://www.qp.alberta.ca/documents/Regs/1971_151.pdf (accessed on 17 November 2019).

- Alberta Energy Regulator. ST53: Alberta In Situ Oil Sands Production Summary 2020. Available online: https://www.aer.ca/providing-information/data-and-reports/statistical-reports/st53.html (accessed on 15 April 2020).

- Si, M. Data Mining and Unsupervised Machine Learning in Canadian In Situ Oil Sands Database for Knowledge Discovery and Carbon Cost Analysis. Available online: https://data.mendeley.com/datasets/8ngkgz69zb/3 (accessed on 3 December 2019).

- Rokach, L.; Maimon, O. Clustering Methods. In Data Mining and Knowledge Discovery Handbook; Maimon, O., Rokach, L., Eds.; Springer: New York, NY, USA, 2005; pp. 321–352. [Google Scholar] [CrossRef]

- Guha, S.; Mishra, N. Clustering Data Streams. In Data Stream Manag; Garofalakis, M., Gehrke, J., Rastogi, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 169–187. [Google Scholar] [CrossRef]

- Hartigan, J.A. Clustering Algorithms; Wiley: New York, NY, USA, 1975. [Google Scholar]

- Bagui, S.; Dhar, P.C. Positive and negative association rule mining in Hadoop’s MapReduce environment. J. Big Data 2019, 6, 75. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Duan, L.; Bai, T.; Wang, X.; Zhang, Y.; Qin, G. Association Rule-Based Feature Mining for Automated Fault Diagnosis of Rolling Bearing. Shock. Vib. 2019, 2019, 1–12. [Google Scholar] [CrossRef]

- Brin, S.; Motwani, R.; Silverstein, C. Beyond market baskets: Generalizing association rules to correlations. In Proceedings of the 1997 ACM SIGMOD International Conference on Management of Data, New York, NY, USA, May 1997; pp. 265–276. [Google Scholar]

- Silverstein, C.; Brin, S.; Motwani, R. Beyond Market Baskets: Generalizing Association Rules to Dependence Rules. Data Min. Knowl. Discov. 1998, 2, 39–68. [Google Scholar] [CrossRef]

- Farouq, A. Application of Solvent Slugs in Thermal Recovery Operations; 1965. Available online: https://www.osti.gov/biblio/6685144 (accessed on 15 April 2020).

- Lechtenberg, H.J.; Gates, G.L.; Caraway, W.H.; Baptist, O.C. Field Study of Viscous Oil Production by Solvent Stimulation Wilmington; Bureau of Mines: Washington, DC, USA, 1972. [Google Scholar]

| Operation (In-Text Reference) * | Operator | Scheme Name | Region | Recovery (Extraction) Method |

|---|---|---|---|---|

| IMOCL | Imperial Oil Resources | Cold Lake | Cold Lake | CSS |

| SUFB | Suncor Energy Inc. | Firebag | Athabasca | SAGD |

| CNRLWL | Canadian Natural Resources Limited (CNRL) | Wolf Lake, Primrose, and Burnt Lake | Cold Lake | CSS |

| CVECL | Cenovus Energy Inc. | Christina Lake | Athabasca | SAGD |

| CVEFC | Cenovus Energy Inc. | Foster Creek | Athabasca | SAGD |

| COPSM | ConocoPhillips Canada Resources Corp. | Surmont | Athabasca | SAGD |

| CNOOCLK | CNOOC Petroleum North America ULC | Long Lake | Athabasca | SAGD |

| HSESR | Husky Oil Operations Limited | Sunrise | Athabasca | SAGD |

| CNRLJF | Canadian Natural Resources Limited | Jackfish | Athabasca | SAGD |

| HSETL | Husky Oil Operations Limited | Tucker Lake | Cold Lake | SAGD |

| CNRLKB | CNRL | Kirby | Athabasca | SAGD |

| AOCLM | Athabasca Oil Corporation | Leismer | Athabasca | SAGD |

| SHAMR | PetroChina Canada Ltd. | Mackay River | Athabasca | SAGD |

| AOCHS | Athabasca Oil Corporation | Hangingstone | Athabasca | SAGD |

| PGFLB | Pengrowth Energy Corporation | Lindbergh | Cold Lake | SAGD |

| CNULPR | Canadian Natural Upgrading Limited | Peace River | Peace River | CSS |

| SUMR | Suncor Energy Inc. | Mackay River | Athabasca | SAGD |

| COGGD | Connacher Oil and Gas Limited | Great Divide | Athabasca | SAGD |

| OSUM | Osum Production Corp. | Orion | Cold Lake | SAGD |

| JCOS | Japan Canada Oil Sands Limited | Hangingstone | Athabasca | SAGD |

| Operating Parameters | Units | Selection Method |

|---|---|---|

| Fuel Use | 103 m3 | ActivityID column select FUEL ProductID column select GAS |

| Flare Volume | 103 m3 | ActivityID column select FLARE ProductID column select GAS |

| Vented Gas Volume | 103 m3 | ActivityID column select VENT ProductID column select GAS |

| Oil Production Volume | m3 | ActivityID column select PROD ProductID column select OIL |

| Steam Injection Volume | m3 | ActivityID column select INJ ProductID column select STEAM |

| Gas Injection Volume | 103 m3 | ActivityID column select INJ ProductID column select GAS |

| Solution Gas Volume | 103 m3 | ActivityID column select PROD ProductID column select GAS |

| Other Solvent Injection Volume | m3 | ActivityID column select INJ ProductID column select C3-SP, COND, etc. |

| Rule | Criteria | Categorisation |

|---|---|---|

| SOR (Y) | SOR ≥ median | High SOR |

| SOR < median | Low SOR | |

| NCG/condensate/C3 injection (X) | Injection volume ≥ median | With co-injection |

| Injection volume < median | Without co-injection | |

| SGOR (Y) | SGOR ≥ median | High SGOR |

| SGOR < median | Low SGOR | |

| Production region (X) | Athabasca, Cold Lake, and Peace River | |

| Production Indicators | Cut-Off Values (Median) |

|---|---|

| NGC co-injection volume | 1456 103 m3 |

| SOR | 3.31 |

| SGOR | 0.01444 103 m3 solution gas/m3 of oil |

| Rule ID | Antecedent (X) | Consequent (Y) | Support | Confidence | Lift |

|---|---|---|---|---|---|

| 1 | With solvent co-injection | Low SOR | 19% | 93% | 1.9 |

| 2 | Without solvent co-injection | Low SOR | 31% | 39% | 0.8 |

| 3 | Method = CSS | Low SOR | 0% | 1% | 0.0 |

| 4 | Method = SAGD | Low SOR | 50% | 57% | 1.2 |

| 5 | Method = CSS | High SOR | 16% | 99% | 2.0 |

| 6 | Method = SAGD | High SOR | 34% | 40% | 0.8 |

| 7 | Region = Athabasca | Low SOR | 43% | 63% | 1.3 |

| 8 | Region = Cold Lake | Low SOR | 7% | 26% | 0.5 |

| 9 | Region = Peace River | Low SOR | 0% | 2% | 0.0 |

| 10 | Method = SAGD, without solvent co-injection | Low SOR | 37% | 48% | 0.8 |

| 11 | Method = SAGD, with solvent co-injection | Low SOR | 22% | 93% | 1.6 |

| 12 | Method = CCS, without solvent co-injection | Low SOR | 1% | 1% | 0.0 |

| 13 | Method = SAGD, with solvent co-injection, Region = Athabasca | Low SOR | 93% | 93% | 0.4 |

| 14 | Method = SAGD, with solvent co-injection, Region = Cold Lake | Low SOR | 0.4% | 100% | 0.4 |

| 15 | Method = SAGD, without solvent co-injection, Region = Athabasca | Low SOR | 38% | 50% | 0.6 |

| 16 | Method = SAGD, without solvent co-injection, Region = Cold Lake | Low SOR | 11% | 43% | 0.5 |

| 17 | Method = CSS | High SGOR | 16% | 100% | 2.0 |

| 18 | Method = SAGD | High SGOR | 34% | 39% | 0.8 |

| 19 | Method = SAGD, with solvent co-injection | High SGOR | 14% | 60% | 1.5 |

| 20 | Method = SAGD, without solvent co-injection | High SGOR | 26% | 34% | 0.9 |

| 21 | Without solvent co-injection, region = Athabasca | High SGOR | 12% | 20% | 1.7 |

| 22 | Without solvent co-injection, region = Cold Lake | High SGOR | 29% | 87% | 3.0 |

| 23 | Without solvent co-injection, region = Peace River | High SGOR | 7% | 100% | 15.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Si, M.; Bai, L.; Du, K. Discovering Energy Consumption Patterns with Unsupervised Machine Learning for Canadian In Situ Oil Sands Operations. Sustainability 2021, 13, 1968. https://doi.org/10.3390/su13041968

Si M, Bai L, Du K. Discovering Energy Consumption Patterns with Unsupervised Machine Learning for Canadian In Situ Oil Sands Operations. Sustainability. 2021; 13(4):1968. https://doi.org/10.3390/su13041968

Chicago/Turabian StyleSi, Minxing, Ling Bai, and Ke Du. 2021. "Discovering Energy Consumption Patterns with Unsupervised Machine Learning for Canadian In Situ Oil Sands Operations" Sustainability 13, no. 4: 1968. https://doi.org/10.3390/su13041968

APA StyleSi, M., Bai, L., & Du, K. (2021). Discovering Energy Consumption Patterns with Unsupervised Machine Learning for Canadian In Situ Oil Sands Operations. Sustainability, 13(4), 1968. https://doi.org/10.3390/su13041968