Innovative Renewable Technology Integration for Nearly Zero-Energy Buildings within the Re-COGNITION Project

Abstract

1. Introduction

- Section 2 introduces the Re-COGNITION project and details innovative technologies developed within the European project;

- Section 3 formulates the mathematical optimization problem used to obtain the outcomes;

- Section 4 includes a multi-energy system description and exposes the case study;

- Section 5 presents and discusses the simulation results;

- Section 6 draws conclusions obtained from the study and discusses future research work.

2. Re-COGNITION Project

- −

- Implement a number of different technological configurations that include renewable energy sources (such as solar, wind and bioenergy) and storage systems.

- −

- Develop software to improve self-consumption in the building/building block.

- −

- Develop a platform for the best design of the renewable technology configuration and the optimal management of the technologies installed during the operations.

2.1. Micro Combined Heat and Power Unit (mCHP)

2.2. Lightweight Photovoltaic (LW-PV)

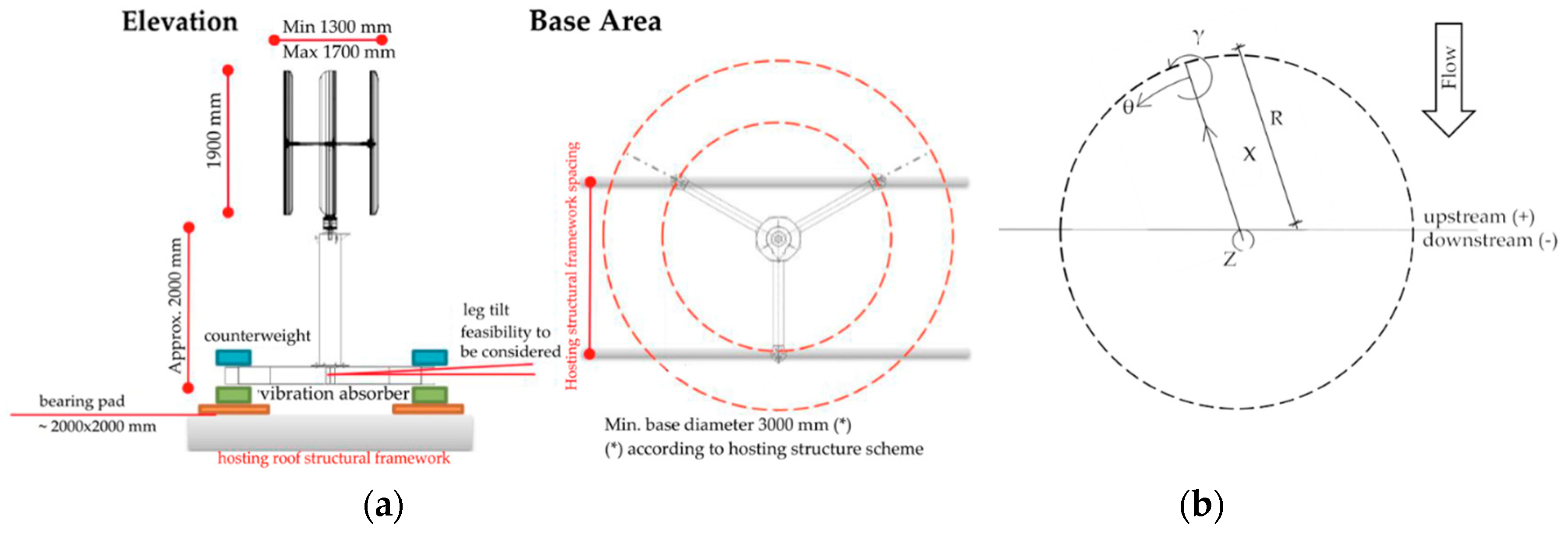

2.3. Vertical Axis Wind Turbine (VAWT)

2.4. Latent Heat Thermal Storage (LHTS)

3. Methodology

- Select the set of technologies that ensures minimal operational costs and simultaneously keeps the investment cost as low as possible.

- Find the optimal scheduling for the selected technologies.

3.1. Formulation of the Optimization Problem

- -

- Binary and integer variables are introduced to obtain the technologies selection and size of the installed units related to their capital cost.

- -

- The efficiencies of the production and conversion technologies depend on the operating conditions. Consequently, the correlation between the source and energy carrier produced is nonlinear.

- The input power of the conversion technologies—xop,c;

- The stored energy of the storage technologies—xop,st;

- The imported and exported electrical power from/to the grid—xop,grid;

- The size of some conversion technologies—xdes,size;

- The number of some system components—xdes,num;

- The on/off status of storage technologies—xdes,st.

3.2. Mathematical Models of Energy System Components

- Micro combined heat and power unit (mCHP): The relations between input and output powers are described as nonlinear equations. The nominal coefficients of performance are listed in Table 1.

- Lightweight photovoltaic modules (LW-PV): The generated electrical power is calculated using Equation (8), which expresses the PV output power as a function of irradiance and temperature. The normal operating condition temperature (NOCT) of the PV module was used to determine the cell temperature of PV module (Tcel), with the relation by Ross expressed in Equation (9) [36].

- 3.

- Vertical axis wind turbine (VAWT): The power generated by the VAWT was obtained by means of the wind turbine’s power curve, presented in Figure 2a, which relates its power production to the wind speed at the hub height.

- 4.

- Thermal solar (TS): The output power of the system is presented in Equation (10), which is the basic equation for the steady-state model according to the ISO 9806 standard [37].

- 5.

- Energy storage systems: Matrix Ast in Equation (4) includes in the model two linear inequity constraints for each timestep for both storage systems:

- −

- The stored energy is limited by the capacity of each storage system;

- −

- The available output power is limited by previously stored energy.

- Thermal storage: The model of the charging and discharging phase of a LHTS is dynamic and non-linear [38]. The thermal power absorbed or released is strongly dependent on the state of charge of the unit. The thermal power at a specific timestep depends on the state of charge. This is estimated through the interpolation of a thermo-fluid dynamic simulation of the storage. The equation is listed below.

- Electric storage: Concerning batteries, the constraints for the charging and discharging rates are imposed. The maximum hourly power charging rate is set as 20% of the battery capacity, whereas the maximum hourly power discharging rate is 50% of the battery capacity.

- 6.

- Traditional technologies: The components are modeled using proper efficiency values. Performance coefficients are listed in Table 1.

4. System Description

4.1. Technologies

- -

- Biogas-fueled micro-combined heat and power unit (mCHP)

- -

- Gas heat only boiler (HOB)

- -

- Electric heat pump (EHP)

- -

- Electric chiller (EC)

- -

- Absorption chiller (AC)

- -

- Building integrated photovoltaic (LW-PV)

- -

- Vertical axis wind turbine (VAWT)

- -

- Thermal solar collector (TS)

- -

- Possibility to buy/sell from/to the utility grid

- -

- Energy storage systems

- -

- Latent heat thermal energy storage (LHTS)

- -

- Battery energy storage system (BESS)

- −

- VAWT, LW-PV and mCHP directly support the attached AC loads, charge the electric energy storage, feed the electric heat pump and the electric chiller, or sell electricity to the utility grid;

- −

- Micro-CHP, HOB, EHP and TS are activated when heat production is required or to charge the thermal storage; *-

- −

- The cooling need is covered by electrically driven technologies (electric chiller or electric heat pump) and thermally driven technologies (absorption chiller). In the following paragraph, the main characteristics of each technology are presented, highlighting the innovative aspects compared to traditional solutions. Some basic technical data are listed in Table 1.

- −

- Heat only boiler (HOB): A traditional condensing gas HOB is considered for space heating. The maximum thermal power is 200 kW.

- −

- Electric heat pump (EHP) in heating mode: The EHP is a traditional air heat pump with a maximum thermal power of 180 kW. In this study, the proposed heat pump can work in a cooling or heating state simultaneously (four-pipe system heat pump).

- −

- Thermal solar (TS): Solar collectors convert solar radiation into thermal energy. In this study, a commercial flat plate collector was analyzed. It had an area of 2.30 m2 and it was fitted with a collection system with highly selective aluminum sheeting laser welded to a copper heat exchanger with a harp. An available area of 60 m2 was considered for the installation.

- −

- Electric chiller (EC): The electric chiller is a standard compression machine with a nominal power of 25 kW. Its nominal coefficient of performance is 3.58.

- −

- Absorption chiller (AC): The absorption chiller can be driven by the heat recovered from mCHP, HOB and EHP, or by the heat from solar collectors. It is a single-stage absorption machine and its rated cooling capacity is 35 kW.

- −

- Electric heat pump (EHP) in cooling mode.

- −

- Battery energy storage system (BESS): Lithium-ion battery storage is mainly used for short-term electricity compensation due to its energy losses and high investment cost. Although it is not always cost-optimal for the system, co-siting renewables and storage turn out to be useful for fulfilling load profiles.

4.2. Case Study

- Politecnico di Torino in Turin, Italy (Lat/Lon: 45.081, 7.671).

- Electric Corby in Corby, United Kingdom (Lat/Lon: 52.496, 0.689)

- CERTH in Thessaloniki, Greece (Lat/Lon: 40.640, 22.939)

- Technical University of Cluj-Napoca in Cluj-Napoca, Romania (Lat/Lon: 46.770, 23.591)

Data Input

- −

- Meteorological data: Hourly wind, temperature and solar radiation profiles for the considered locations were obtained from PVGIS weather database [40] for a 24-h timespan. Typical days in January and July were chosen as heating and cooling design days, respectively.

- −

- −

- Typical residential thermal and power load profiles were obtained from the HOMER software. The cooling demand was derived from the electric consumption: The difference between power consumption in January and July was mostly attributable to summer air conditioning, since the machines delegated to this function were generally powered by electricity.

- −

- Investments costs for each technology are shown in Table 2 along with the references for the values assumed. The costs for the innovative technologies were given by the manufacturers or by considering cost of similar technologies currently marketed.

5. Simulation Results

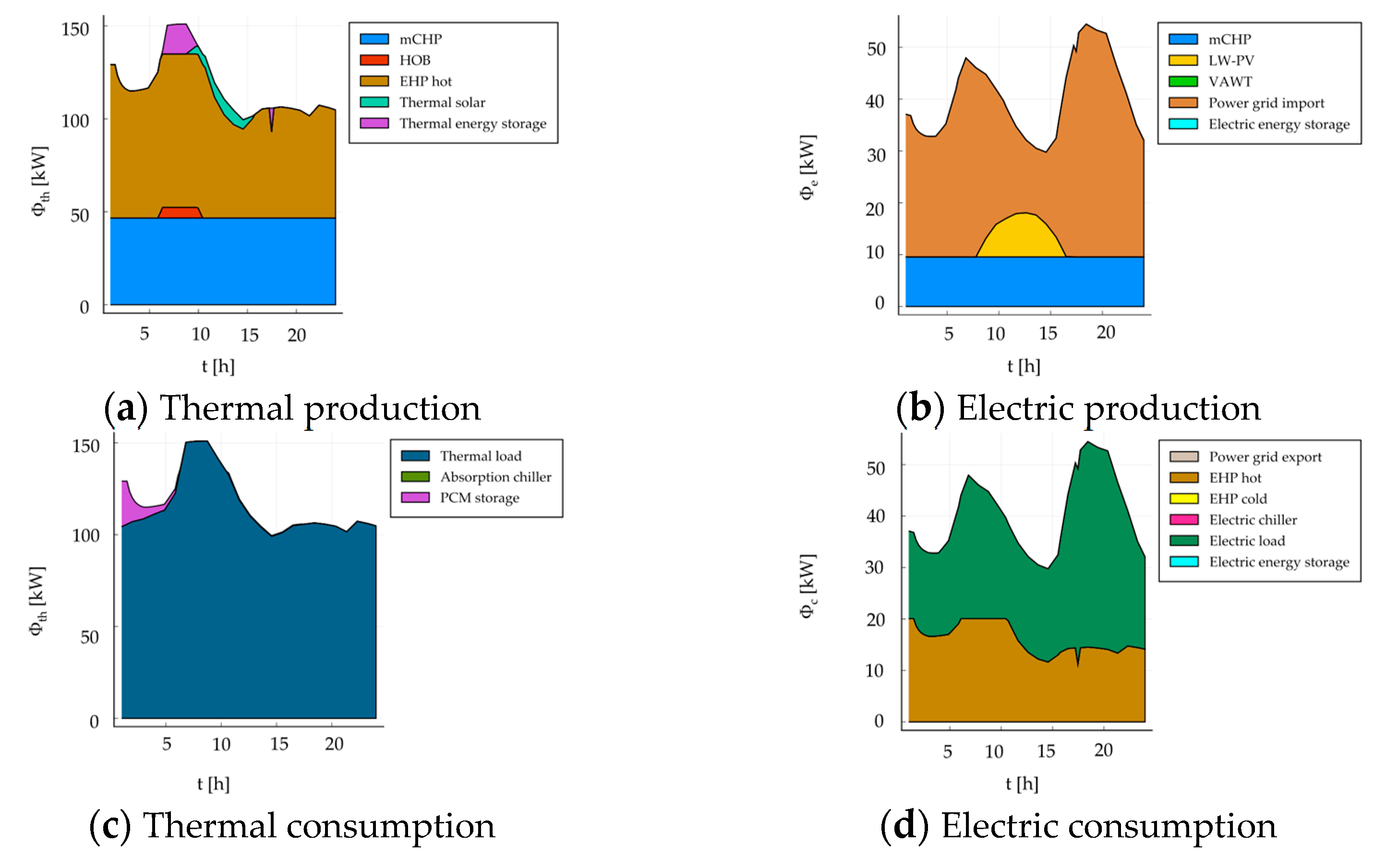

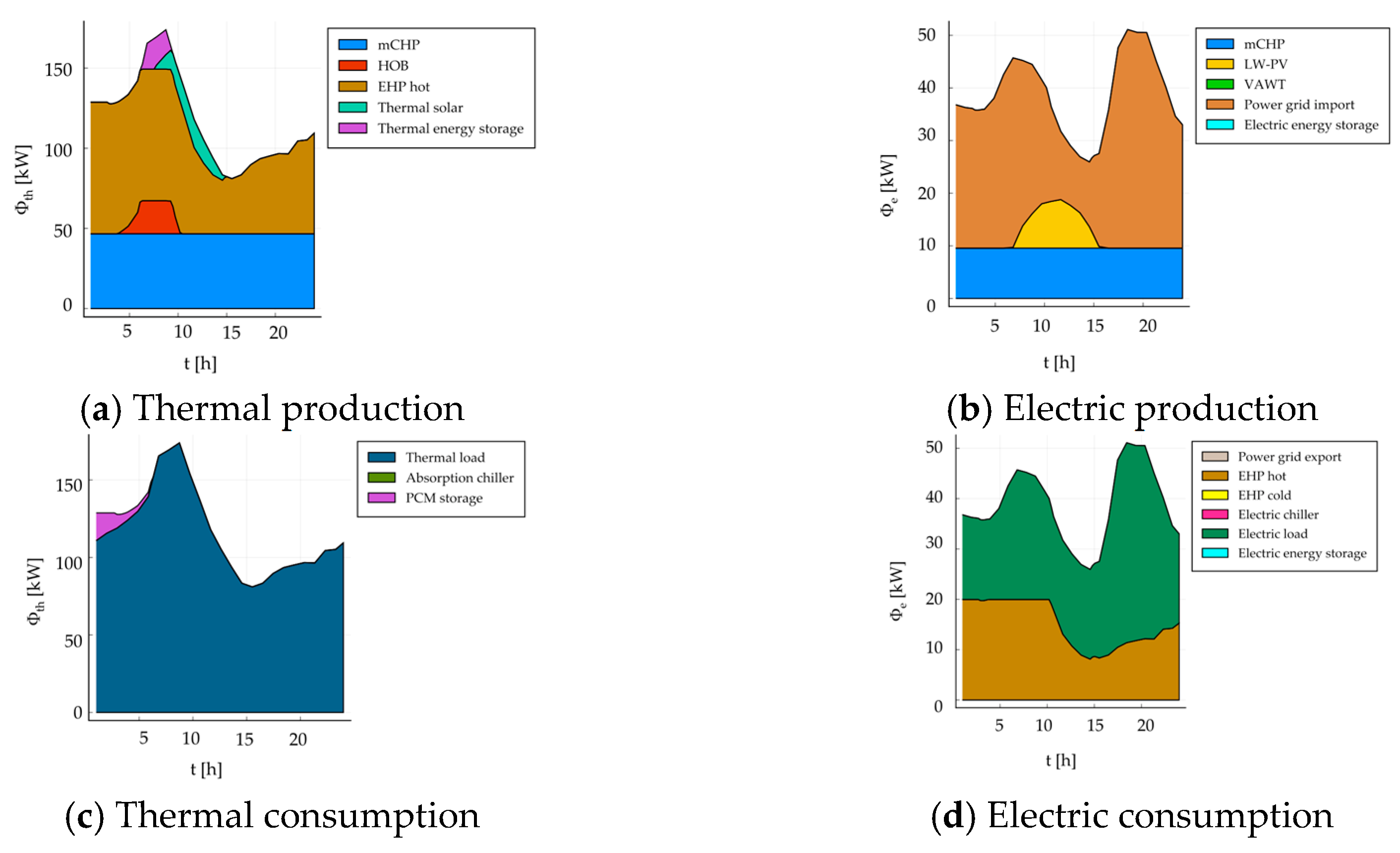

5.1. Pilot 1: Turin (Italy)

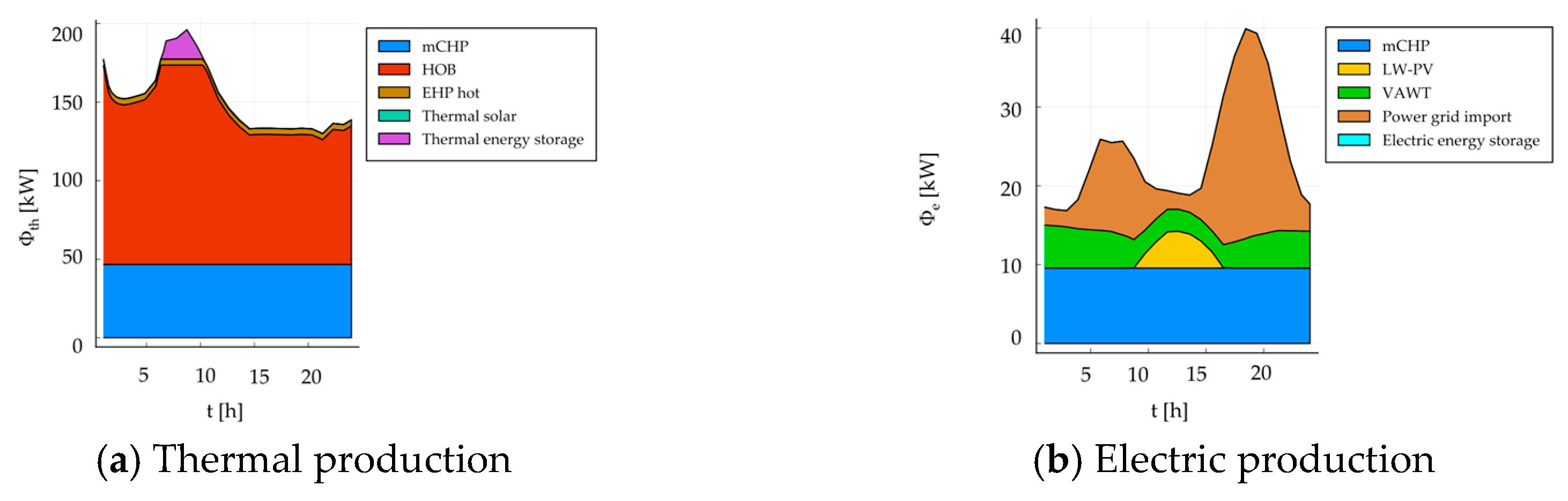

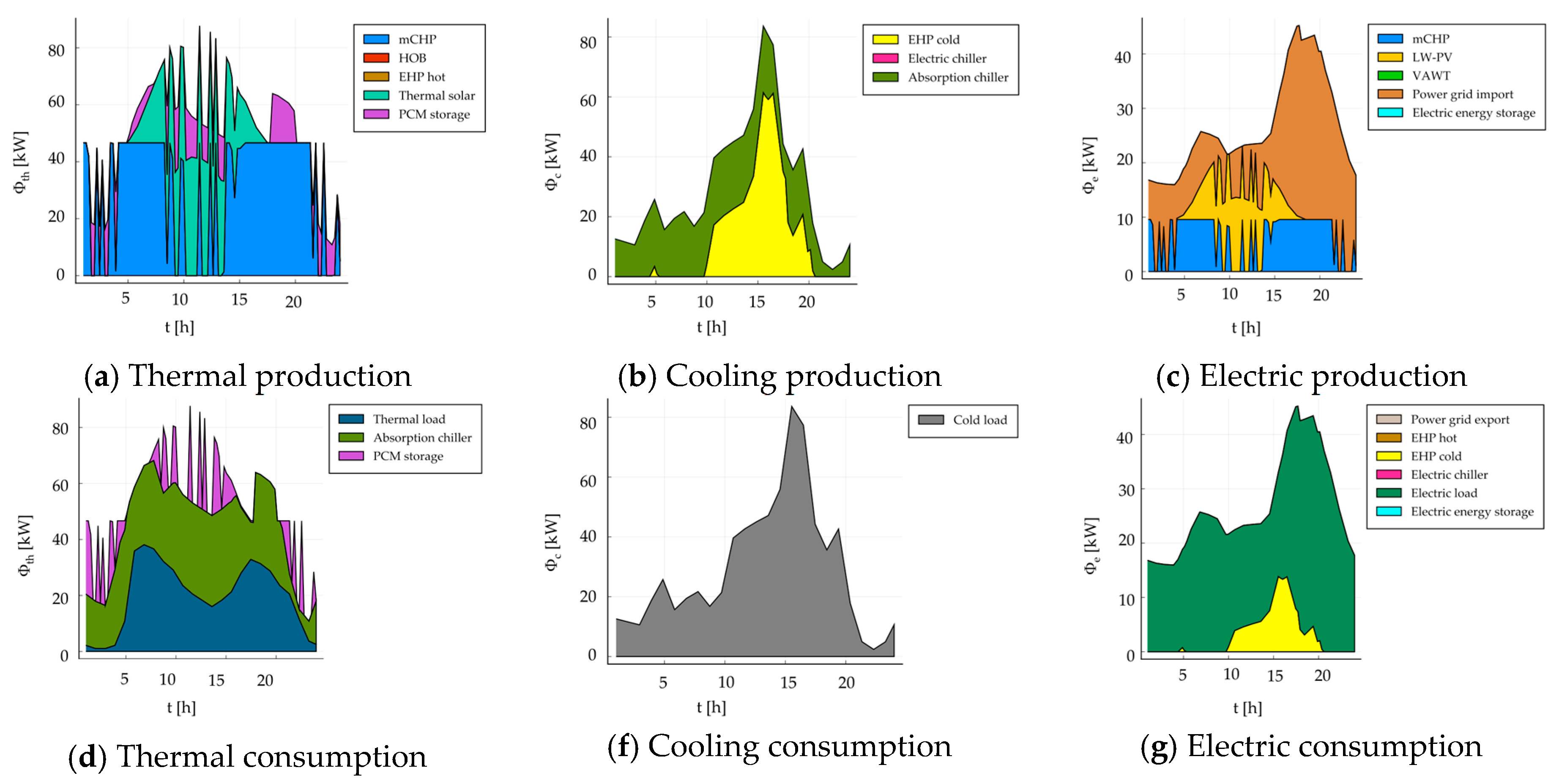

5.2. Pilot 2: Corby (United Kingdom)

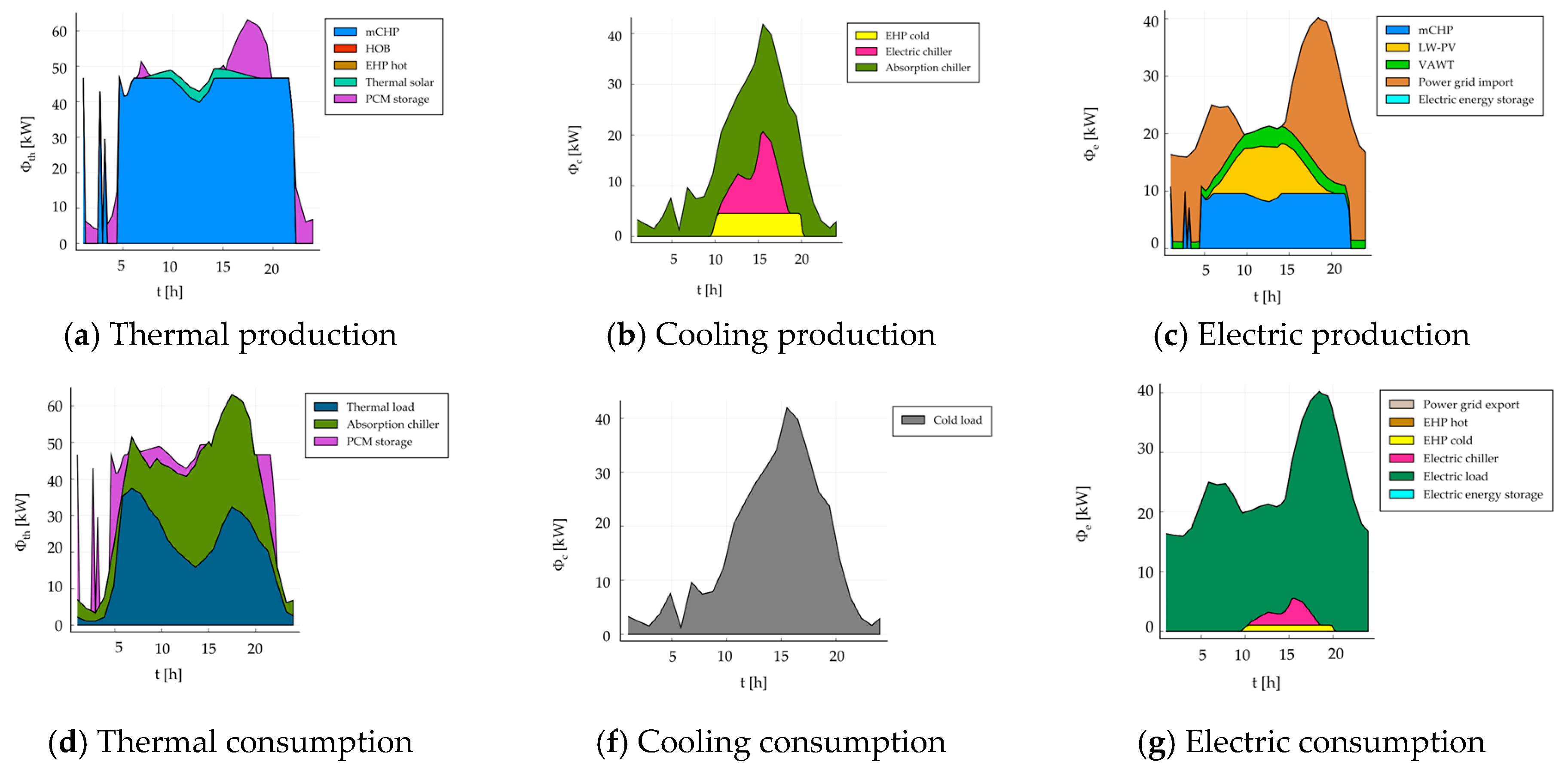

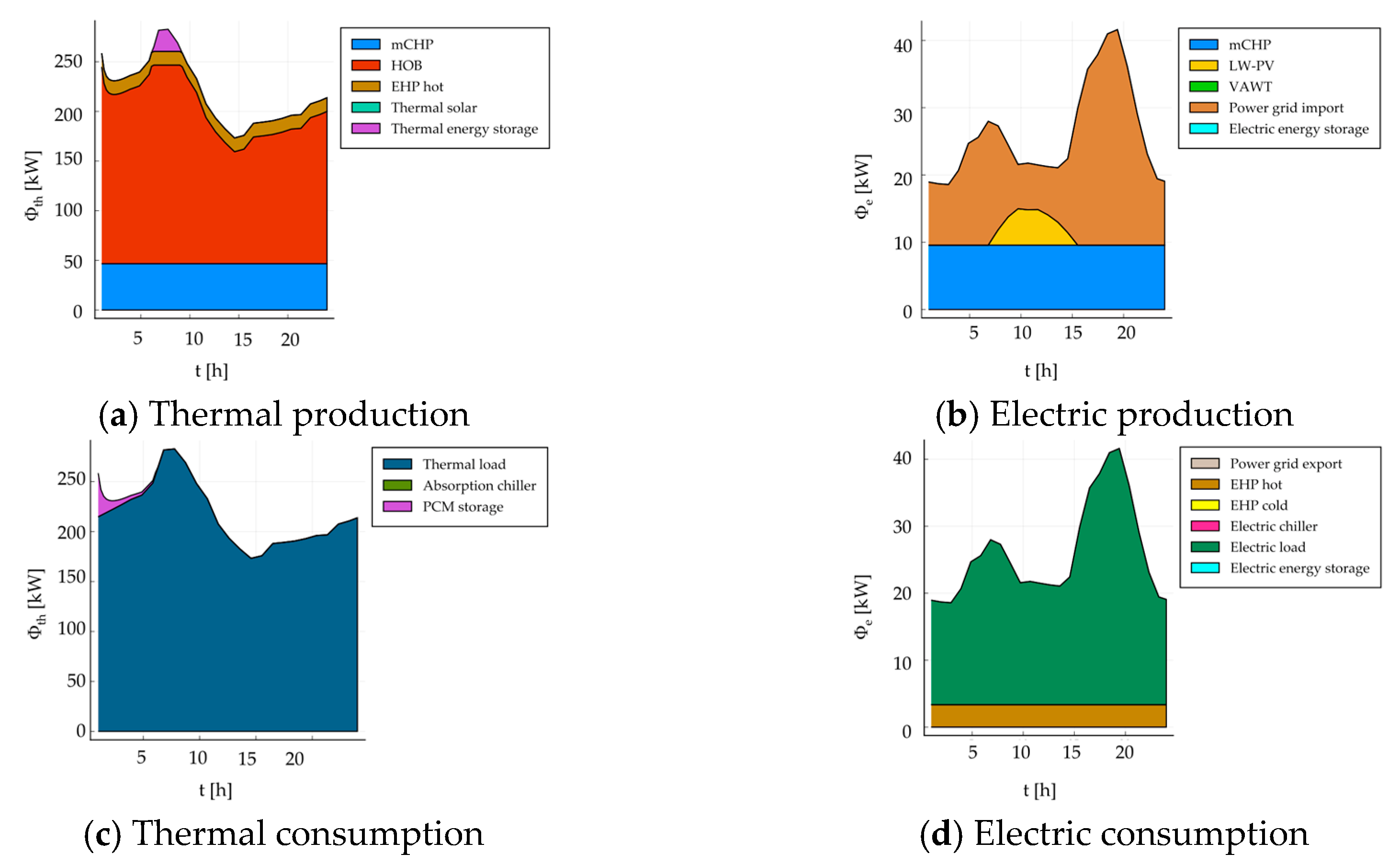

5.3. Pilot 3: Thessaloniki (Greece)

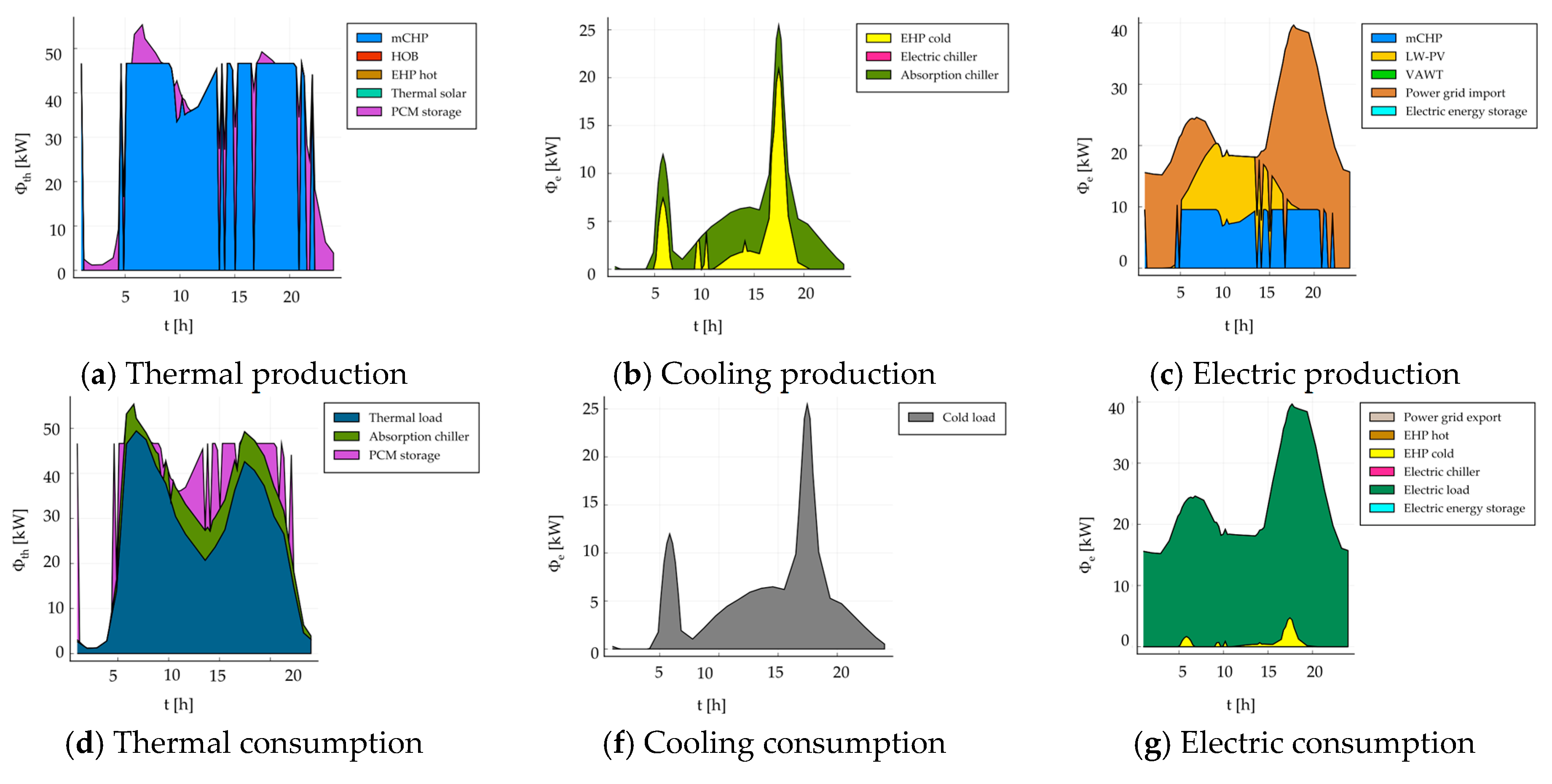

5.4. Pilot 4: Cluj-Napoca (Romania)

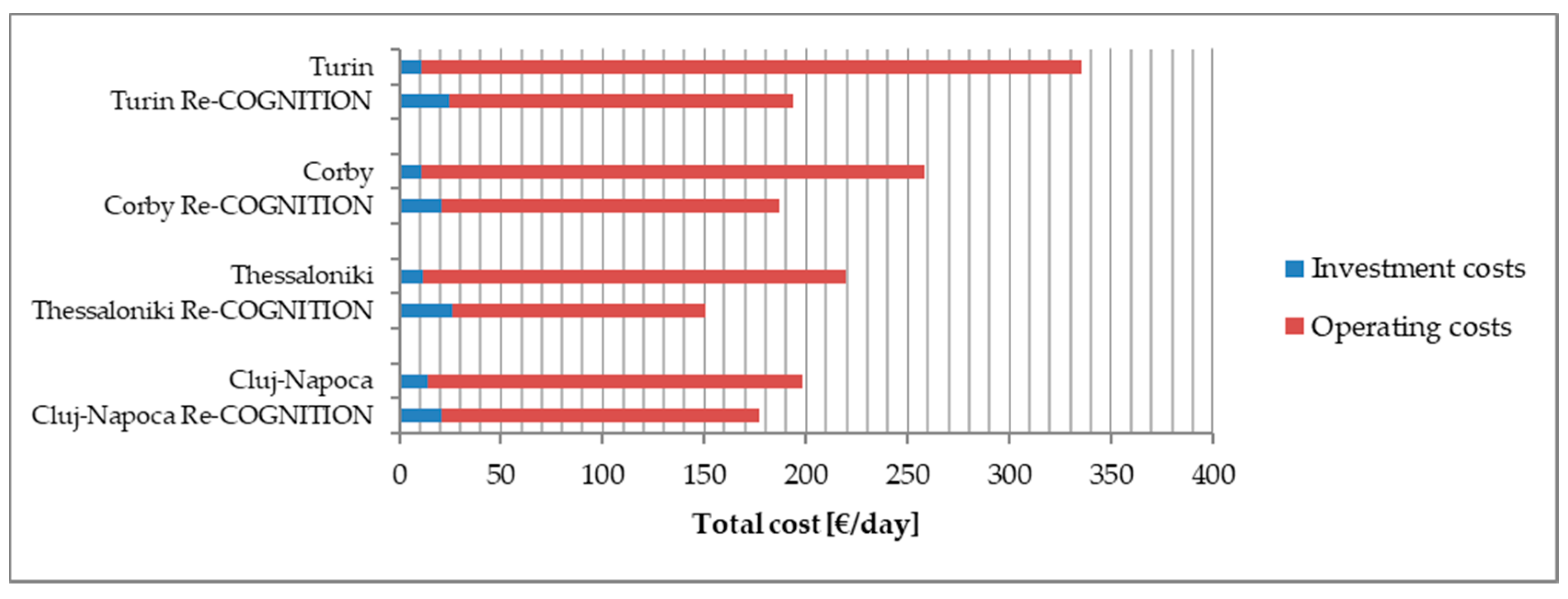

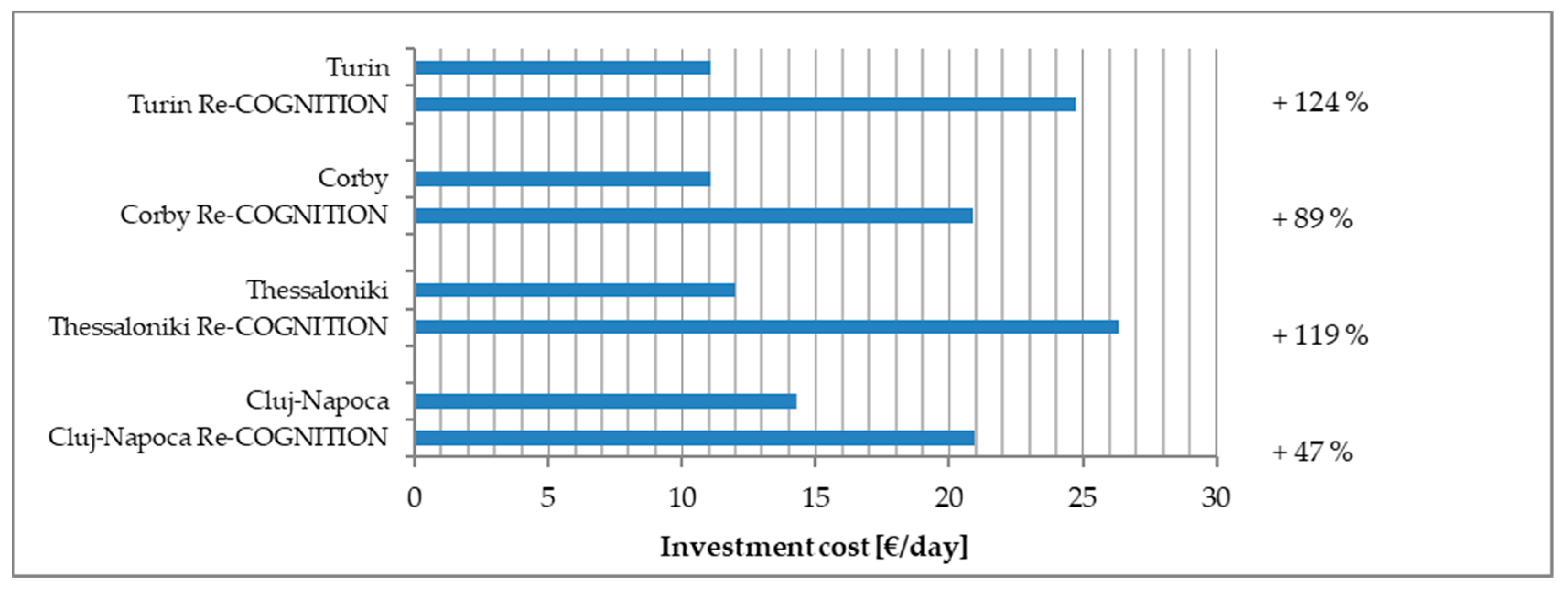

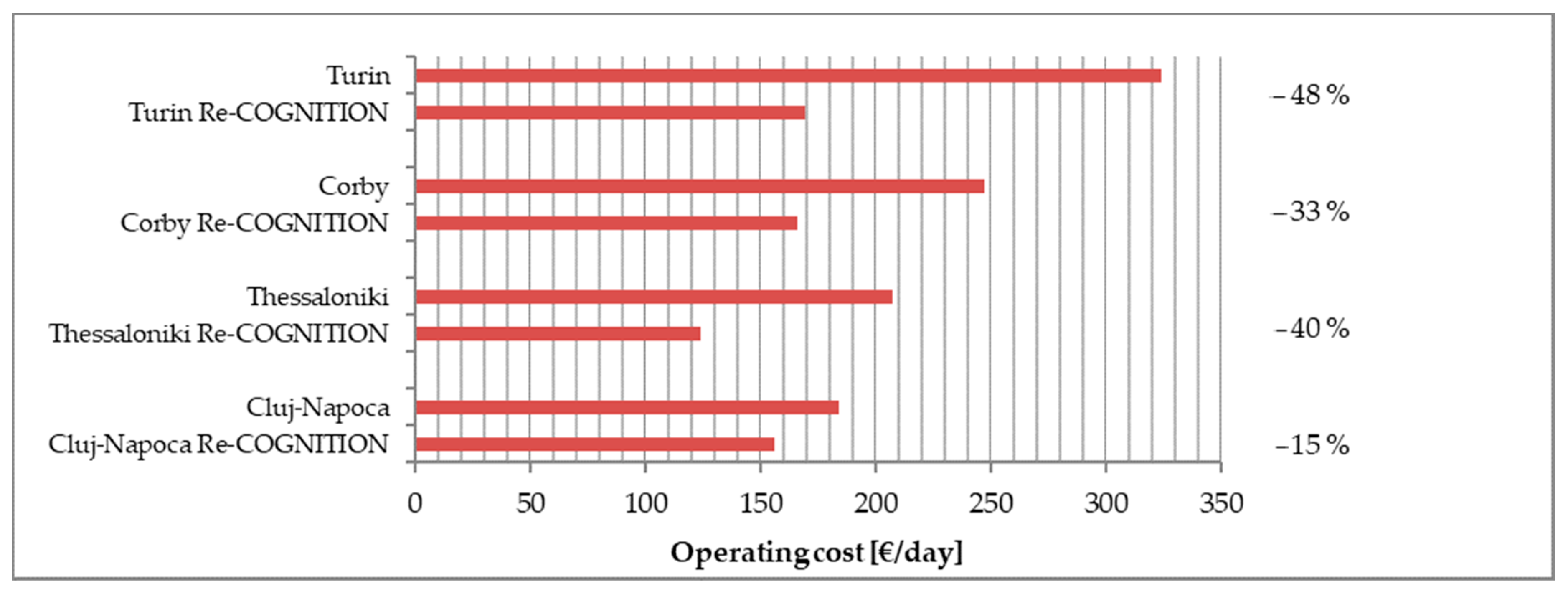

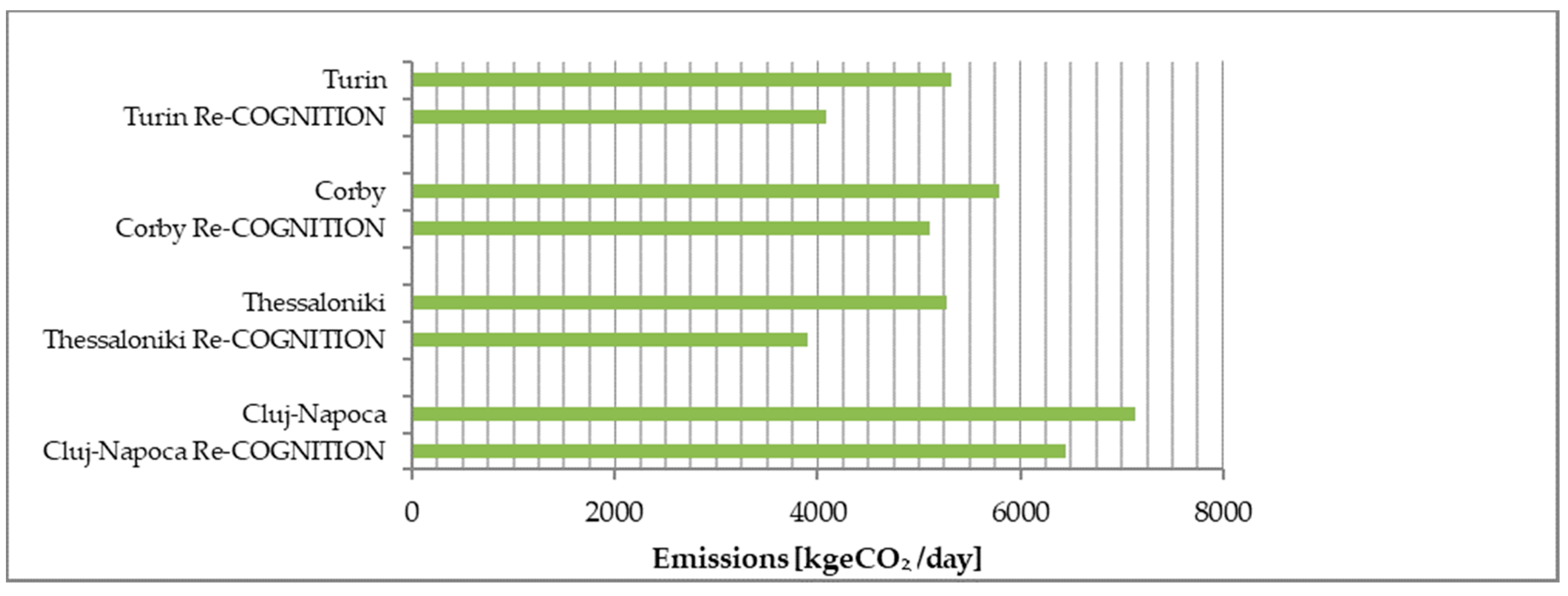

5.5. Pilot Comparison

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Symbols and Parameters

| a1 | First order heat loss coefficient (W/m2 K) |

| a2 | Second order heat loss coefficient (W/m2 K) |

| ALW-PV | LW-PV area (m2) |

| G | Solar irradiance (W/m2) |

| Pbiogas-import | Imported biogas (kW) |

| Pc, AC | AC cooling power output (kW) |

| Pc, EC | EC cooling power output (kW) |

| Pc, EHP | EHP cooling power output (kW) |

| Pc, LOAD | Cooling load (kW) |

| Pe, EC | EC electric power input (kW) |

| Pe,grid-import | Imported electricity (kW) |

| Pe,grid-export | Exported electricity (kW) |

| Pe, LOAD | Electricity load (kW) |

| Pe, LW-PV | LW-PV electric power output (kW) |

| Pe, mCHP | mCHP electric power output (kW) |

| Pe, VAWT | VAWT electric power output (kW) |

| PLHTS | Charge/discharge power LHTS |

| PNG-import | Imported natural gas (kW) |

| Pth, AC | AC thermal power input (kW) |

| Pth, EHP | EHP thermal power output (kW) |

| Pth, HOB | HOB thermal power output (kW) |

| Pth, LOAD | Thermal load (kW) |

| Pth, mCHP | mCHP thermal power output (kW) |

| Pth, TS | TS thermal power output (kW) |

| NOCT | State of charge (-) |

| Tamb | Cell temperature at reference condition (°C) |

| Tcell | Temperature coefficient (1/K) |

| Tref | Cell temperature (°C) |

| xop | Operation variable |

| xdes | Design variable |

| LW-PV efficiency at STC (-) | |

| Zero loss efficiency (-) |

Abbreviations

| AC | Absorption chiller |

| BESS | Battery energy storage system |

| EC | Electric chiller |

| EHP | Electric heat pump |

| HOB | Only heat boiler |

| LHTS | Latent heat thermal energy storage |

| LW-PV | Lightweight photovoltaics |

| mCHP | Micro-combined heat and power unit |

| MILP | Mixed-integer linear programming |

| MINLP | Mixed-integer non-linear programming |

| NLP | Non-linear programming |

| nZEB | Nearly zero energy building |

| RES | Renewable energy sources |

| TS | Thermal solar |

| VAWT | Vertical axis wind turbine |

References and Note

- Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency (Text with EEA Relevance).

- I.E.A. Tracking Buildings 2020—Analysis. Available online: https://www.iea.org/reports/tracking-buildings-2020 (accessed on 2 February 2021).

- Kheiri, F. A review on optimization methods applied in energy-efficient building geometry and envelope design. Renew. Sustain. Energy Rev. 2018, 92, 897–920. [Google Scholar] [CrossRef]

- Méndez Echenagucia, T.; Capozzoli, A.; Cascone, Y.; Sassone, M. The early design stage of a building envelope: Multi-objective search through heating, cooling and lighting energy performance analysis. Appl. Energy 2015, 154, 577–591. [Google Scholar] [CrossRef]

- Tuhus-Dubrow, D.; Krarti, M. Genetic-algorithm based approach to optimize building envelope design for residential buildings. Build. Environ. 2010, 7, 1574–1581. [Google Scholar] [CrossRef]

- Baglivo, C.; Congedo, P.M.; Fazio, A.; Laforgia, D. Multi-objective optimization analysis for high efficiency external walls of zero energy buildings (zeb) in the mediterranean climate. Energy Build. 2014, 84, 483–492. [Google Scholar] [CrossRef]

- Li, H.; Wang, S. Coordinated optimal design of zero/low energy buildings and their energy systems based on multi-stage design optimization. Energy 2019, 189, 116–202. [Google Scholar] [CrossRef]

- Ferrara, M.; Fabrizio, E.; Virgone, J.; Filippi, M. A simulation-based optimization method for cost-optimal analysis of nearly zero energy buildings. Energy Build. 2014, 84, 442–457. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; De Masi, R.F.; Mauro, G.M.; Vanoli, G.P. Resilience of robust cost-optimal energy retrofit of buildings to global warming: A multi-stage, multi-objective approach. Energy Build. 2017, 153, 150–167. [Google Scholar] [CrossRef]

- Diakaki, C.; Grigoroudis, E.; Kabelis, N.; Kolokotsa, D.; Kalaitzakis, K.; Stavrakakis, G. A multi-objective decision model for the improvement of energy efficiency in buildings. Energy 2010, 35, 5483–5496. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, S.; Shan, K. Design optimization and optimal control of grid-connected and standalone nearly/net zero energy buildings. Appl. Energy 2015, 155, 463–477. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, C.; Liu, H.; Wang, J.; Yang, Z.; Jiang, Y. Smart energy systems: A critical review on design and operation optimization. Sustain. Cities Soc. 2020, 62, 102369. [Google Scholar] [CrossRef]

- Mazzoni, S.; Ooi, S.; Nastasi, B.; Romagnoli, A. Energy storage technologies as techno-economic parameters for master-planning and optimal dispatch in smart multi energy systems. Appl. Energy 2019, 254, 113682. [Google Scholar] [CrossRef]

- Rong, A.; Su, Y. Polygeneration systems in buildings: A survey on optimization approaches. Energy Build. 2017, 151, 439–454. [Google Scholar] [CrossRef]

- Di Somma, M.; Yan, B.; Bianco, N.; Luh, P.B.; Graditi, G.; Mongibello, L.; Naso, V. Multi-objective operation optimization of a distributed energy system for a large-scale utility customer. Appl. Therm. Eng. 2016, 101, 752–761. [Google Scholar] [CrossRef]

- Perera, A.; Attalage, R.; Perera, K.; Dassanayake, V. Designing standalone hybrid energy systems minimizing initial investment, life cycle cost and pollutant emission. Energy 2013, 54, 220–230. [Google Scholar] [CrossRef]

- Zhang, S.; Huang, P.; Sun, Y. A multi-criterion renewable energy system design optimization for net zero energy buildings under uncertainties. Energy 2016, 94, 654–665. [Google Scholar] [CrossRef]

- Strantzali, E.; Aravossis, K. Decision making in renewable energy investments: A review. Renew. Sustain. Energy Rev. 2016, 55, 885–898. [Google Scholar] [CrossRef]

- Ferrara, M.; Monetti, V.; Fabrizio, E. Cost-optimal analysis for nearly zero energy buildings design and optimization: A critical review. Energies 2018, 11, 1478. [Google Scholar] [CrossRef]

- Ashouri, A.; Fux, S.S.; Benz, M.J.; Guzzella, L. Optimal design and operation of building services using mixed-integer linear programming techniques. Energy 2013, 59, 365–376. [Google Scholar] [CrossRef]

- Shaterabadi, M.; Jirdehi, M.A.; Amiri, N.; Omidi, S. Enhancement the economical and environmental aspects of plus-zero energy buildings integrated with INVELOX turbines. Renew. Energy 2020, 153, 1355–1367. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, S.; Sun, Y.; Yan, C. Optimal scheduling of buildings with energy generation and thermal energy storage under dynamic electricity pricing using mixed-integer nonlinear programming. Appl. Energy 2015, 147, 49–58. [Google Scholar] [CrossRef]

- Bruno, J.; Fernandez, F.; Castells, F.; Grossmann, I. A rigorous minlp model for the optimal synthesis and operation of utility plants. Chem. Eng. Res. Des. 1998, 76, 246–258. [Google Scholar] [CrossRef]

- Arcuri, P.; Florio, G.; Fragiacomo, P. A mixed integer programming model for optimal design of trigeneration in a hospital complex. Energy 2007, 32, 1430–1447. [Google Scholar] [CrossRef]

- Sichilalu, S.M.; Xia, X. Optimal energy control of grid tied pv–diesel– battery hybrid system powering heat pump water heater. Sol. Energy 2015, 115, 243–254. [Google Scholar] [CrossRef]

- RE-COGNITION—Renewable Energy Technologies for Zero Energy Building. Available online: https://re-cognition-project.eu/ (accessed on 2 February 2021).

- Martins, A.; Chapuis, V.; Sculati-Meillaud, F.; Virtuani, A.; Ballif, C. Light and durable: Composite structures for building-integrated photovoltaic modules. Prog. Photovolt. Res. Appl. 2018, 26, 1–12. [Google Scholar] [CrossRef]

- Martins, A.; Chapuis, V.; Virtuani, A.; Ballif, C. Robust glass-free lightweight photovoltaic modules with improved resistance to mechanical loads and impact. IEEE J. Photovolt. 2019, 9, 245–251. [Google Scholar] [CrossRef]

- Martins, A.C. Thermo-mechanical stability of lightweight glass-free photovoltaic modules based on a composite substrate. Sol. Environ. Mater. Sol Cells 2018, 187, 82–90. [Google Scholar] [CrossRef]

- Virtuani, A.; Strepparava, D. Modelling the performance of amorphous and crystalline silicon in different typologies of building-integrated photovoltaic (bipv) conditions. Sol. Energy 2017, 146, 113–118. [Google Scholar] [CrossRef]

- CSEM. Available online: https://www.csem.ch (accessed on 2 February 2021).

- Morbiato, T. Passive Variable Geometry Turbine. Patent Deposit N. 102019000010479, 30 September 2019. [Google Scholar]

- Windcity. Available online: http://www.windcity.it/en/ (accessed on 2 February 2021).

- IEC 61400-2:2013. Wind Turbines—Part 2: Small Wind Turbines. Available online: https://webstore.iec.ch/publication/5433 (accessed on 2 February 2021).

- Kroger, O.; Coffrin, C.; Hijazi, H.; Nagarajan, H. Juniper: An Open-Source Nonlinear Branch-And-Bound Solver in Julia. In Integration of Constraint Programming, Artificial Intelligence, and Operations Research; Springer International Publishing: New York, NY, USA, 2018; pp. 377–386. [Google Scholar]

- Markvart, T. Solar Electricity, 2nd ed.; John Wiley & Sons Inc.: New York, NY, USA, 2000; Volume 6. [Google Scholar]

- ISO 9806:2017. Solar Energy—Solar Thermal Collectors—Test Methods. 2017. Available online: https://www.iso.org/obp/ui/#iso:std:iso:9806:ed-2:v1:en (accessed on 2 February 2021).

- Colangelo, A.; Guelpa, E.; Lanzini, A.; Mancò, G.; Verda, V. Compact model of latent heat thermal storage for its integration in multi-energy systems. Appl. Sci. 2020, 10, 8970. [Google Scholar] [CrossRef]

- U.S. Department of Energy Commercial Reference Building Models of the National Building Stock. Available online: https://www.nrel.gov/docs/fy11osti/46861.pdf (accessed on 2 February 2021).

- Photovoltaic Geographical Information System (PVGIS)—EU Science Hub—European Commission. Available online: https://ec.europa.eu/jrc/en/pvgis (accessed on 2 February 2021).

- Eurostat, Natural Gas Prices for Household Consumers, Second Half 2019. Available online: https://ec.europa.eu/ (accessed on 2 February 2021).

- Eurostat. Electricity Price (Including Taxes) for Household Consumers, Second Half 2019. Available online: https://ec.europa.eu/ (accessed on 2 February 2021).

- Coelho, S.; Velazquez, S.; Abreu, F. Sewage biogas conversion into electricity by using small systems. In Survival and Sustainability; Springer: Berlin/Heidelberg, Germany, 2011; pp. 491–497. [Google Scholar]

- Gustafsson, M.; Dipasquale, C.; Poppi, S.; Bellini, A.; Fedrizzi, R.; Bales, C.; Ochs, F.; Sie, M.; Holmberg, S. Economic and environmental analysis of energy renovation packages for European office buildings. Energy Build. 2017, 148, 155–165. [Google Scholar] [CrossRef]

- ASHRAE. Ashrae Equipment Life Expectancy Chart. Available online: https://www.ashrae.org/ (accessed on 2 February 2021).

- Eicker, U.; Pietruschka, D.; Haag, M.; Schmitt, A. Systematic design and analysis of solar thermal cooling systems in different climates. Renew. Energy 2015, 80, 827–836. [Google Scholar] [CrossRef]

- Shirazi, A.; Taylor, R.A.; Morrison, G.L.; White, S.D. A comprehensive, multi-objective optimization of solar-powered absorption chiller systems for air-conditioning applications. Energy Convers. Manag. 2017, 132, 281–306. [Google Scholar] [CrossRef]

- Eicker, U.; Colmenar-Santos, A.; Teran, L.; Cotrado, M.; Borge-Diez, D. Economic evaluation of solar thermal and photovoltaic cooling systems through simulation in different climatic conditions: An analysis in three different cities in Europe. Energy Build. 2014, 70, 207–223. [Google Scholar] [CrossRef]

- Kouloumpis, V.; Sobolewski, R.A.; Yan, X. Performance and life cycle assessment of a small scale vertical axis wind turbine. J. Clean. Prod. 2020, 247, 119520. [Google Scholar] [CrossRef]

- Bava, F.; Furbo, S.; Perers, B. Simulation of a solar collector array consisting of two types of solar collectors, with and without convection barrier. Energy Procedia 2015, 70, 4–12. [Google Scholar] [CrossRef]

- Eicker, U.; Pietruschka, D. Design and performance of solar powered absorption cooling systems in office buildings. Energy Build. 2009, 41, 81–91. [Google Scholar] [CrossRef]

- IRENA. Thermal Energy Storage: Technology Brief. Available online: https://www.irena.org/publications/2013/Jan/Thermal-energy-storage (accessed on 2 February 2021).

- Zakeri, B.; Syri, S. Electrical energy storage systems: A comparative life cycle cost analysis. Renew. Sustain. Energy Rev. 2015, 42, 569–596. [Google Scholar] [CrossRef]

| Technology | Parameter | Value |

|---|---|---|

| mCHP | Nominal electric power | 3.2 kW |

| Nominal thermal power | 15.6 kW | |

| Net grid output efficiency (electrical) | 0.16 | |

| Total efficiency | 0.94 | |

| Reference temperature | 15 °C | |

| Reference pressure | 1.01325 bar | |

| Overall dimensions (h × w × d) | 940 × 600 × 1040 mm | |

| Weight | 205 kg | |

| HOB | Maximum output power | 200 kW |

| Thermal efficiency | 0.932 | |

| EHP | Maximum output power | 180 kW |

| Coefficient of performance (heating) | 4.11 | |

| Coefficient of performance (cooling) | 4.43 | |

| EC | Maximum output power | 200 kW |

| Coefficient of performance | 3.58 | |

| AC | Maximum output power | 25 kW |

| Coefficient of performance | 0.69 | |

| LW-PV | PV module efficiency (STC) | 0.18 |

| Temperature coefficient of power | −4 × 10−3 1/K | |

| Reference temperature | 25 °C | |

| NOCT | 48 °C | |

| VAWT | Nominal output power | 2 kW |

| Cut-in velocity | 1 m/s | |

| Height of the installed wind turbine | 25 m | |

| TS | η0—zero-loss efficiency | 0.18 |

| First order heat loss coefficient | 3.93 W/m2 K | |

| Second order heat loss coefficient | 0.0148 W/m2 K | |

| Input fluid temperature | 17 °C | |

| Output fluid temperature | 60 °C | |

| LHTS | Maximum capacity | 50 kWh |

| BESS | Maximum capacity | 26 kWh |

| Maximum power charge | 5.2 kW | |

| Maximum power discharge | 13 kW |

| Technology | Lifetime [Years] | Cost |

|---|---|---|

| mCHP | 10 [43] | EUR 1950/kW [43] |

| HOB | 12 [44] | EUR 180/kW [44] |

| EHP | 15 [44] | EUR 720/kW [44] |

| EC | 20 [45] | EUR 310/kW [46] |

| AC | 23 [45] | EUR 360/kW [47] |

| LW-PV | 20 [44,48] | EUR 2280/kW [44] |

| VAWT | 20 [49] | EUR 3600/kW |

| TS | 20 [48,50] | EUR 280/kW [51] |

| LHTS | 30 [52] | EUR 50/kWh [52] |

| BESS | 10 [53] | EUR 546/kWh [53] |

| Technology | Pilots | |||

|---|---|---|---|---|

| Turin | Corby | Thessaloniki | Cluj-Napoca | |

| mCHP | ✓ | ✓ | ✓ | ✓ |

| HOB | ✓ | ✓ | ✓ | ✓ |

| EHP | ✓ | ✓ | ✓ | ✓ |

| EC | 🗴 | ✓ | 🗴 | ✓ |

| AC | ✓ | ✓ | ✓ | ✓ |

| LW-PV | ✓ | ✓ | ✓ | ✓ |

| VAWT | 🗴 | ✓ | 🗴 | 🗴 |

| TS | ✓ | ✓ | ✓ | 🗴 |

| LHTS | ✓ | ✓ | ✓ | ✓ |

| BESS | 🗴 | 🗴 | 🗴 | 🗴 |

| Pilots | Typical Solution [EUR/Day] | Re-Cognition Proposal [EUR/Day] | % |

|---|---|---|---|

| Turin | 335.37 | 194.11 | −42% |

| Corby | 258.29 | 187.00 | −28% |

| Thessaloniki | 219.61 | 150.35 | −32% |

| Cluj-Napoca | 198.64 | 177.35 | −11% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mancò, G.; Guelpa, E.; Colangelo, A.; Virtuani, A.; Morbiato, T.; Verda, V. Innovative Renewable Technology Integration for Nearly Zero-Energy Buildings within the Re-COGNITION Project. Sustainability 2021, 13, 1938. https://doi.org/10.3390/su13041938

Mancò G, Guelpa E, Colangelo A, Virtuani A, Morbiato T, Verda V. Innovative Renewable Technology Integration for Nearly Zero-Energy Buildings within the Re-COGNITION Project. Sustainability. 2021; 13(4):1938. https://doi.org/10.3390/su13041938

Chicago/Turabian StyleMancò, Giulia, Elisa Guelpa, Alessandro Colangelo, Alessandro Virtuani, Tommaso Morbiato, and Vittorio Verda. 2021. "Innovative Renewable Technology Integration for Nearly Zero-Energy Buildings within the Re-COGNITION Project" Sustainability 13, no. 4: 1938. https://doi.org/10.3390/su13041938

APA StyleMancò, G., Guelpa, E., Colangelo, A., Virtuani, A., Morbiato, T., & Verda, V. (2021). Innovative Renewable Technology Integration for Nearly Zero-Energy Buildings within the Re-COGNITION Project. Sustainability, 13(4), 1938. https://doi.org/10.3390/su13041938