Research on Blank Optimization Design Based on Low-Carbon and Low-Cost Blank Process Route Optimization Model

Abstract

1. Introduction

2. Literature Review

2.1. The Application of a Low-Carbon Emission Model

2.2. The Solutions of Carbon Emission Reduction

2.3. Research Gaps

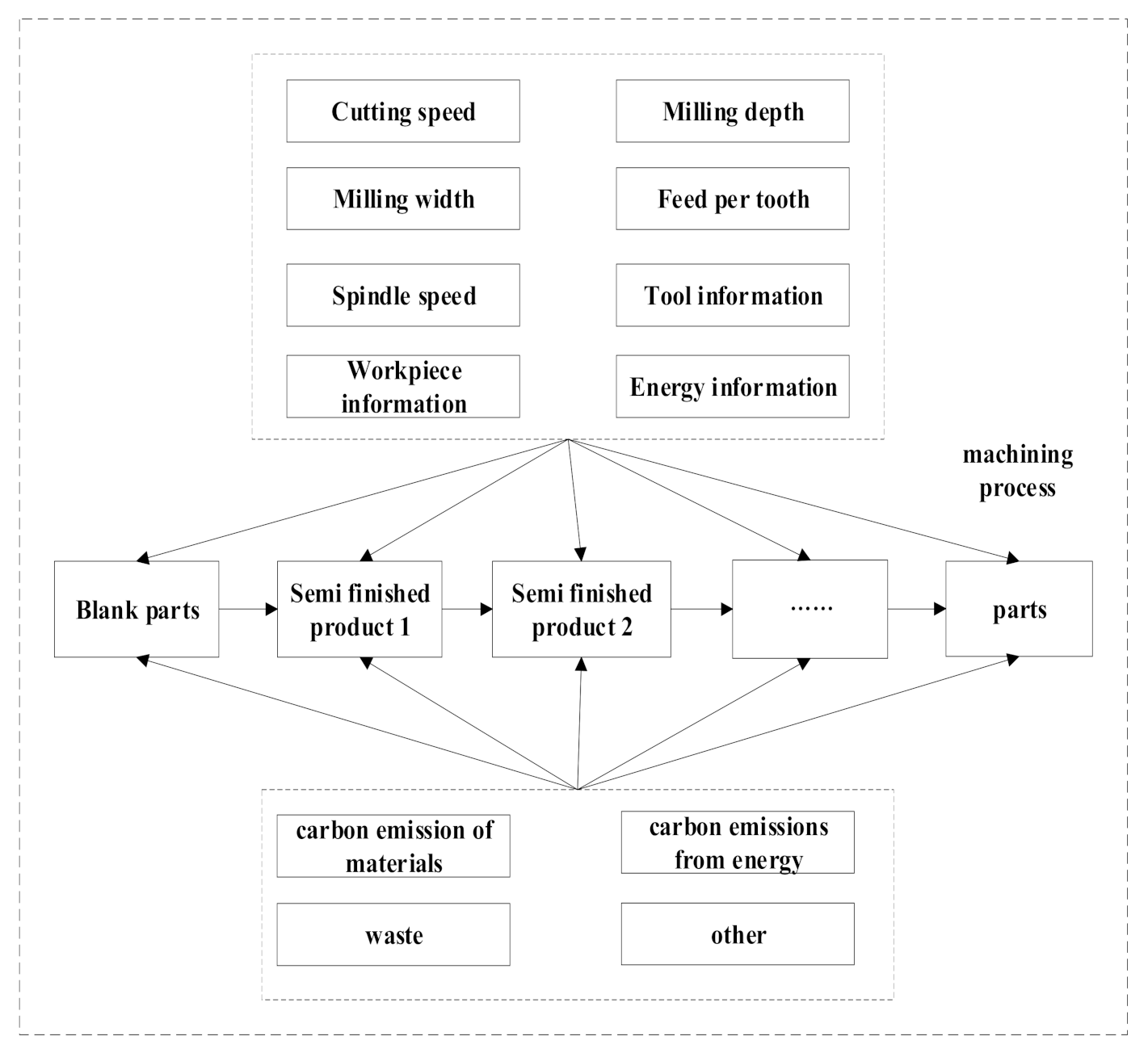

3. Establishment of Multi-Objective Optimization Model

3.1. Low-Carbon Objective Function

3.1.1. Carbon Emission of Materials in the Machining Process

3.1.2. Carbon Emission of Energy Consumption

- (1)

- The no-load state is when the machine tool runs without load, it is composed of the no-load power of the transmission system and the loss power of the motor;

- (2)

- The load state is when the machine tool is in load processing state;

- (3)

- The accessory state is when the machine tool is in a load processing state, so there will be additional load power. The power of the additional load is composed of the power increased by the total power loss of the machine drive system and motor on the original no-load loss;

- (4)

- The tool changing state is when the machine tool is in the tool replacement stage.

3.2. Cost Function

3.3. Constrains

3.4. Conversion of Multiple Objective Functions

4. Combinatorial Optimization Algorithm

4.1. Intelligent Generation Algorithm of Workstep Chains

4.2. Adaptive Particle Swarm Optimization (APSO)

5. Case Study

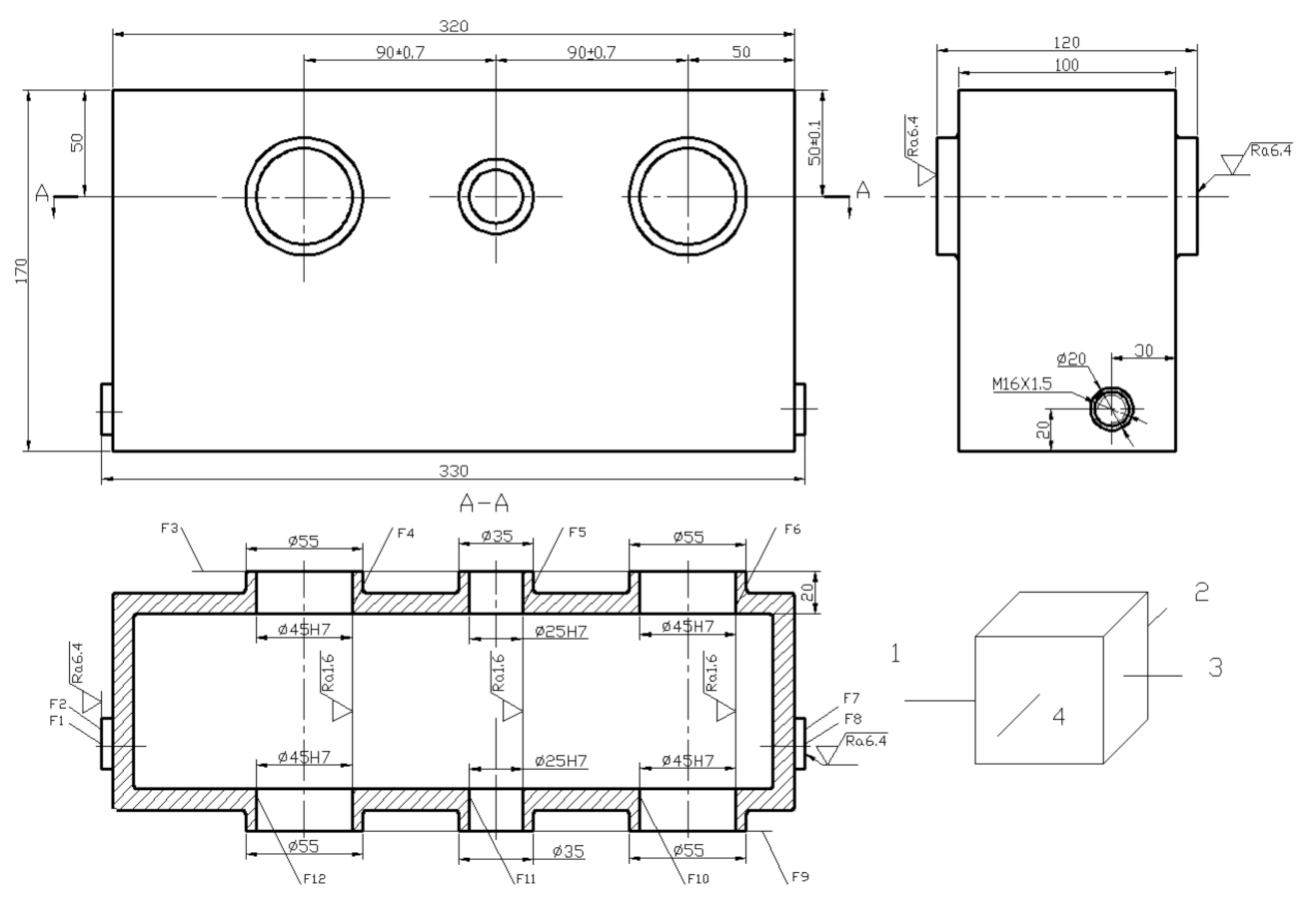

5.1. Analysis of Processing Characteristics

5.2. Process Route Optimization Based on Combinatorial Optimization Algorithm

- (1)

- number of machines, , number of jobs,

- (2)

- number of processes, , particle length, ,

- (3)

- the population size is 10, evolution times sets 50 times.

5.3. Analysis of Optimization Results and Discussion

5.3.1. Comparison of Optimization Results

5.3.2. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Zhai, X.Q.; An, Y.F. Analyzing influencing factors of green transformation in China’s manufacturing industry under environmental regulation: A structural equation model. J. Clean. Prod. 2020, 251, 119760. [Google Scholar] [CrossRef]

- Peng, B.H.; Zheng, C.Y.; Guo, W.; Ehsan, E. The Cultivation Mechanism of Green Technology Innovation in Manufacturing Industry: From the Perspective of Ecological Niche. J. Clean. Prod. 2019, 252, 119711. [Google Scholar] [CrossRef]

- Wang, Q.; Hu, Y.J.; Hao, J.; Lv, N.; Li, T.Y.; Tang, B.J. Exploring the influences of green industrial building on the energy consumption of industrial enterprises: A case study of Chinese cigarette manufactures. J. Clean. Prod. 2019, 231, 370–385. [Google Scholar] [CrossRef]

- Sun, Y.; Gong, Q.S.; Hu, M.M.; Yang, N. Multi-Objective Optimization of Workshop Scheduling with Multiprocess Route Considering Logistics Intensity. Processes 2020, 8, 838. [Google Scholar] [CrossRef]

- Ai, X.F.; Jiang, Z.G.; Zhang, H.; Wang, Y. Low-carbon product conceptual design from the perspectives of technical system and human use. J. Clean. Prod. 2020, 244, 118819. [Google Scholar] [CrossRef]

- Dowlatshahi, S. The role of logistics in concurrent engineering. Int. J. Prod. Econ. 1996, 44, 189–199. [Google Scholar] [CrossRef]

- Gutowski, T.; Dahmus, J.; Thiriez, A. Electrical energy requirements for manufacturing processes. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, Belgium, 31 May 2006–2 June 2006. [Google Scholar]

- Chirag, M.; Yuan, J.; Debangsu, B. Techno-economic optimization of shale gas to dimethyl ether production processes via direct and indirect synthesis routes. Appl. Energy 2019, 238, 119–134. [Google Scholar]

- Li, G.F.; Wang, S.X.; He, J.L.; Wu, K.; Zhou, C.Y. Compilation of load spectrum of machining center spindle and application in fatigue life prediction. J. Mech. Sci. Technol. 2019, 33, 1603–1613. [Google Scholar] [CrossRef]

- Jiang, Z.G.; Ding, Z.Y.; Zhang, H.; Cai, W.; Liu, Y. Data-driven ecological performance evaluation for remanufacturing process. Energy Convers. Manag. 2019, 198, 111844. [Google Scholar] [CrossRef]

- Stefano, P.; Riccardo, A.; Riccardo, M. Planning low carbon urban-rural ecosystems: An integrated transport land-use model. J. Clean. Prod. 2019, 235, 96–111. [Google Scholar]

- Avinash, V.; Adam, H. Demand side flexibility from residential heating to absorb surplus renewables in low carbon futures. Renew. Energy 2019, 138, 598–609. [Google Scholar]

- Cadavid-Giraldo, N.; Velez-Gallego, M.C.; Restrepo-Boland, A. Carbon emissions reduction and financial effects of a cap and tax system on an operating supply chain in the cement sector. J. Clean. Prod. 2020, 275, 122583. [Google Scholar] [CrossRef]

- Gaurav, J.; Soren, S.; Kapil, D.M. Life cycle assessment of sintering process for carbon footprint and cost reduction: A comparative study for coke and biomass-derived sintering process. J. Clean. Prod. 2020, 259, 120889. [Google Scholar]

- Yoshiyuki, M.; Keiichi, T.; Reijiro, T. Process Engineering Approach Towards Low Carbon Consumption in Carbon Cycle by Smart Iron Manufacture. ISIJ Int. 2015, 55, 365–372. [Google Scholar]

- Song, J.S.; Lee, K.M. Development of a low-carbon product design system based on embedded ghg emissions. Resour. Conserv. Recycl. 2010, 54, 547–556. [Google Scholar] [CrossRef]

- Xiu, F.Z.; Shu, Y.Z.; Zhi, Y.H.; Gang, Y.; Cheng, H.P.; Sa, R.N. Identification of connection units with high ghg emissions for low-carbon product structure design. J. Clean. Prod. 2012, 27, 118–125. [Google Scholar]

- Xu, F.; Gu, X.J.; Ji, Y.J.; Qi, G.N. The method of product conceptual design based on low-carbon constraint. J. Mech. Eng. 2013, 49, 58–65. [Google Scholar] [CrossRef]

- Rad-Tolouei, M.; Bidhendl, I.M. On the optimization of machining parameters for milling operations. Int. J. Mach. Tool. Manuf. 1997, 37, 1–16. [Google Scholar] [CrossRef]

- Eskicioglu, E.; Nisli, M. An application of geometric programming to single-pass turning operations. In Proceedings of the 25th International Machine Tool Design and Research, Birmingham, UK, 22–24 April 1985; Volume 21, pp. 428–435. [Google Scholar]

- Zainal, N.; Zain, A.M.; Radzi, N.H.; Othman, M.R. Glowworm swarm optimization (GSO) for optimization of machining parameters. J. Intell. Manuf. 2016, 27, 797–804. [Google Scholar] [CrossRef]

- Zarei, O.; Fesanghary, M.; Farshi, B.; Saffar, R.J.; Razfar, M.R. Optimization of multi-pass face-milling via harmony search algorithm. J. Mater. Process. Technol. 2009, 209, 2186–2192. [Google Scholar] [CrossRef]

- Esmaeil, S.; Milad, M.; Reza, G.; Saeed, K. Designing multi-layer quantum neural network controller for chaos control of rod-type plasma torch system using improved particle swarm optimization. Evol. Syst. 2019, 10, 317–331. [Google Scholar]

- Xiao, Y.M.; Zhang, H.; Jiang, Z.G.; Gu, Q.; Yan, W. Multiobjective optimization of machining center process route: Tradeoffs between energy and cost. J. Clean. Prod. 2021, 280, 1–15. [Google Scholar] [CrossRef]

- Yeh, F.H.; Li, C.L. Optimum blank design by the predictor-corrector scheme of SLM and FSQP in the deep drawing process of square cup with flange. Int. J. Adv. Manuf. Technol. 2007, 34, 277–286. [Google Scholar] [CrossRef]

- Wang, S.; Tao, F.; Shi, Y.; Wen, H. Optimization of vehicle routing problem with time windows for cold chain logistics based on carbon tax. Sustainability 2017, 9, 694. [Google Scholar] [CrossRef]

- Islam, M.Z.; Wahab, N.I.; Veerasamy, V.; Hizam, H.; Mailah, N.F.; Guerrero, J.M.; Mohd Nasir, M.N. A Harris Hawks optimization based single and multi-objective optimal power flow considering environmental emission. Sustainability 2020, 12, 5248. [Google Scholar] [CrossRef]

- Lin, Y.C.; Yeh, C.C.; Chen, W.H.; Liu, W.C.; Wang, J.J. The Use of Big Data for Sustainable Development in Motor Production Line Issues. Sustainability 2020, 12, 5323. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, F.; Wang, X. Multi-objective optimization of machining parameters considering energy consumption. Int. J. Adv. Manuf. Technol. 2013, 71, 1133–1142. [Google Scholar] [CrossRef]

- Jiang, Z.G.; Jiang, Y.; Wang, Y.; Zhang, H.; Cao, H.J.; Tian, G.D. A hybrid approach of rough set and case-based reasoning to remanufacturing process planning. J. Intell. Manuf. 2016, 30, 19–32. [Google Scholar] [CrossRef]

- Cai, W.; Lai, K.H.; Liu, C.H.; Wei, F.F.; Ma, M.D.; Jia, S.; Jiang, Z.G.; Lv, L. Promoting sustainability of manufacturing industry through the lean energy-saving and emission-reduction strategy. Sci. Total Environ. 2019, 665, 23–32. [Google Scholar] [CrossRef]

- Zhang, C.; Huang, H.H.; Zhang, L.; Bao, H.; Liu, Z.F. Low-carbon design of structural components by integrating material and structural optimization. Int. J. Adv. Manuf. Technol. 2018, 95, 4547–4560. [Google Scholar] [CrossRef]

- Park, H.S.; Nguyen, T.T.; Dang, X.P. Multi-objective optimization of turning process of hardened material for energy effificiency. Int. J. Precis. Eng. Man. 2016, 17, 1623–1631. [Google Scholar] [CrossRef]

- Mustapa, S.I.; Ayodele, B.V.; Mohamad Ishak, W.W.; Ayodele, F.O. Evaluation of Cost Competitiveness of Electric Vehicles in Malaysia Using Life Cycle Cost Analysis Approach. Sustainability 2020, 12, 5303. [Google Scholar] [CrossRef]

- Albertelli, P.; Keshari, A.; Matta, A. Energy oriented multi cutting parameter optimization in face milling. J. Clean. Prod. 2016, 137, 1602–1618. [Google Scholar] [CrossRef]

- Hu, T.M.; Sung, S.Y.; Sun, J.; Ai, X.W. A linear transform scheme for building weighted scoring rules. Intell. Data Anal. 2012, 16, 383–407. [Google Scholar] [CrossRef]

- Nabavi-KeriziH, S.H.; Abadi, M.; Kabir, E. A PSO-based weighting method for linear combination of neural networks. Comput. Electr. Eng. 2008, 36, 886–894. [Google Scholar] [CrossRef]

- Liu, X.J.; Yi, H.; Ni, Z.H. Application of ant colony optimization algorithm in process planning optimization. J. Intell. Manuf. 2013, 24, 1–13. [Google Scholar] [CrossRef]

- He, B.; Tang, W.; Huang, S.; Hou, S.; Cai, H. Towards low-carbon product architecture using structural optimization for lightweight. Int. J. Adv. Manuf. Technol. 2016, 83, 1419–1429. [Google Scholar] [CrossRef]

- Gao, W.Y.; Su, C. Analysis of earnings forecast of blockchain financial products based on particle swarm optimization. J. Comput. Appl. Math. 2020, 372, 112724. [Google Scholar] [CrossRef]

- Ding, Y.M.; Zhang, W.L.; Yu, L.; Lu, K.H. The accuracy and efficiency of GA and PSO optimization schemes on estimating reaction kinetic parameters of biomass pyrolysis. Energy 2019, 176, 582–588. [Google Scholar] [CrossRef]

- Dovie, D.B.; Dzodzomenyo, M.; Dodor, D.E.; Amoah, A.B.; Twerefou, D.K.; Codjoe, S.N.; Kasei, R.A. Multi-Vector Approach to Cities’ Transition to Low-Carbon Emission Developments. Sustainability 2020, 12, 5382. [Google Scholar] [CrossRef]

- Jurić, Ž.; Ljubas, D. Comparative Assessment of Carbon Footprints of Selected Organizations: The Application of the Enhanced Bilan Carbone Model. Sustainability 2020, 12, 9618. [Google Scholar] [CrossRef]

- Mcbrien, M.; Serrenho, A.C.; Allwood, J.M. Potential for energy savings by heat recovery in an integrated steel supply chain. Appl. Therm. Eng. 2016, 103, 592–606. [Google Scholar] [CrossRef]

- Kitayama, S.; Natsume, S.; Yamazaki, K.; Han, J.; Uchida, H. Numerical optimization of blank shape considering flatness and variable blank holder force for cylindrical cup deep drawing. Int. J. Adv. Manuf. Technol. 2016, 85, 1–12. [Google Scholar] [CrossRef]

- Cheng, D.D.; Lu, X.; Sun, X.J. Multi-objective topology optimization of column structure for vertical machining center. CIRP Ann. Manuf. Technol. 2018, 78, 1021–1037. [Google Scholar] [CrossRef]

- Lu, Q.; Zhou, G.H.; Xiao, Z.D.; Chang, F.T.; Tian, C.L. A selection methodology of key parts based on the characteristic of carbon emissions for low-carbon design. Int. J. Adv. Manuf. Technol. 2018, 94, 3359–3373. [Google Scholar] [CrossRef]

- Jiang, Z.G.; Ding, Z.Y.; Liu, Y.; Wang, Y.; Hu, X.L.; Yang, Y.H. A data-driven based decomposition–integration method for remanufacturing cost prediction of end-of-life products. Robot Comput Integr Manuf. 2020, 61, 101838. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, L.; Feng, H.; Zhang, L.; Zhang, X.; Li, J. Modeling Method for Cost and Carbon Emission of Sheep Transportation Based on Path Optimization. Sustainability 2020, 12, 835. [Google Scholar] [CrossRef]

- Xu, Z.Z.; Wang, Y.S.; Teng, Z.R.; Zhong, C.Q.; Teng, H.F. Low-carbon product multi-objective optimization design for meeting requirements of enterprise, user and government. J. Clean. Prod. 2015, 103, 747–758. [Google Scholar] [CrossRef]

| Name | Name | ||

|---|---|---|---|

| 1.0000 | 0.4690 | ||

| 30.1530 |

| Regional/Name | Regional/Name | ||

|---|---|---|---|

| North China | 1.0580 | Central China | 0.9724 |

| Northeast China | 1.1280 | Southern China | 0.9183 |

| East China | 0.8095 | Northwest China | 0.9578 |

| Feature No. | Feature Description | Azimuth Plane | Feature No. | Feature Description | Azimuth Plane |

|---|---|---|---|---|---|

| F1 | End face | 1 | F7 | End face | 3 |

| F2 | M16 × 1.5 Threaded hole | 1 | F8 | M16 × 1.5 Threaded hole | 3 |

| F3 | End face | 2 | F9 | End face | 4 |

| F4 | Φ45Through hole | 2 | F10 | Φ45Through hole | 4 |

| F5 | Φ35Through hole | 2 | F11 | Φ35Through hole | 4 |

| F6 | Φ45Through hole | 2 | F12 | Φ45Through hole | 4 |

| Equipment Serial No. | Equipment Name | Equipment Power/kW |

|---|---|---|

| M01 | Ordinary lathe | 10 |

| M02 | CNC lathe | 22 |

| M03 | CNC vertical milling machine | 15 |

| M04 | Vertical milling machine | 11 |

| M05 | Radial drilling machine | 4 |

| M06 | Radial drilling machine | 3 |

| M07 | machining center | 18.5 |

| Cutting Tools Number | Tool Name | Life/min | Quality/g | The Main Purpose |

|---|---|---|---|---|

| T01 | Turning tool 1 | 60 | 9.5 | Turning |

| T02 | Turning tool 2 | 100 | 10.0 | Turning |

| T03 | Turning tool 3 | 90 | 9.0 | Turning |

| T04 | Milling cutter 1 | 240 | 7.5 | Milling |

| T05 | Milling cutter 2 | 180 | 50.0 | Milling |

| T06 | Drill 1 | 60 | 375.0 | Drilling |

| T07 | Drill 2 | 75 | 475.0 | Drilling |

| T08 | Tap | 75 | 275.0 | Tapping |

| Feature No. | Feature Info. | Processing Worsteps | Work Step Encoding | Machine Tool Equipment | Time/min |

|---|---|---|---|---|---|

| F1 | End face | Rough turning | 01 | M01T01 | 2.0 |

| M01T02 | 2.1 | ||||

| M02T02 | 2.1 | ||||

| M02T03 | 2.1 | ||||

| M01T01 | 2.0 | ||||

| Semi-finish turning | 02 | M01T02 | 2.1 | ||

| M02T02 | 2.2 | ||||

| M02T03 | 2.1 | ||||

| Finish turning | 03 | M01T02 | 2.1 | ||

| M02T02 | 2.2 | ||||

| M02T03 | 2.1 | ||||

| F2 | M16 Thread | Rough turning | 04 | M01T01 | 2.0 |

| M01T02 | 2.0 | ||||

| M02T02 | 2.0 | ||||

| M02T03 | 2.1 | ||||

| M01T01 | 2.0 | ||||

| Semi-finish turning | 05 | M01T02 | 2.1 | ||

| M02T02 | 2.0 | ||||

| M02T03 | 2.2 | ||||

| Finish turning | 06 | M01T02 | 2.1 | ||

| M02T02 | 2.0 | ||||

| M02T03 | 2.1 | ||||

| F3 | End face | Rough turning | 07 | M01T01 | 2.2 |

| M01T02 | 2.2 | ||||

| M02T02 | 2.0 | ||||

| Semi-finish turning | 08 | M01T02 | 2.0 | ||

| M02T02 | 2.1 | ||||

| M02T03 | 2.0 | ||||

| Finish turning | 09 | M01T02 | 2.2 | ||

| M02T02 | 2.0 | ||||

| M02T03 | 2.1 | ||||

| F4 | Φ45 Through hole | Rough turning | 10 | M01T01 | 2.2 |

| M01T02 | 2.2 | ||||

| M02T02 | 2.0 | ||||

| Finish turning | 11 | M01T01 | 2.3 | ||

| M01T02 | 2.25 | ||||

| F5 | Φ35 Through hole | Rough turning | 12 | M01T01 | 1.2 |

| M01T02 | 1.2 | ||||

| M02T02 | 1.1 | ||||

| Finish turning | 13 | M01T01 | 1.2 | ||

| M01T02 | 1.3 | ||||

| M02T02 | 1.15 | ||||

| F6 | Φ45 Through hole | Rough turning | 14 | M01T01 | 1.0 |

| M01T02 | 1.2 | ||||

| Rough turning | 15 | M02T02 | 1.1 | ||

| M02T03 | 1.1 | ||||

| M01T01 | 1.3 | ||||

| Finish turning | 16 | M01T02 | 1.3 | ||

| M02T02 | 1.2 | ||||

| M02T03 | 1.1 | ||||

| F7 | End face | Rough milling | 17 | M03T04 | 1.0 |

| M04T05 | 1.0 | ||||

| M07T04 | 1.1 | ||||

| M07T05 | 1.2 | ||||

| M03T04 | 1.2 | ||||

| Finish milling | 18 | M04T05 | 1.1 | ||

| M07T04 | 1.2 | ||||

| M07T05 | 1.3 | ||||

| F8 | M16 Thread | Rough milling | 19 | M03T04 | 2.5 |

| M04T05 | 2.6 | ||||

| M07T04 | 2.4 | ||||

| Finish milling | 20 | M07T05 | 2.5 | ||

| M03T04 | 2.6 | ||||

| M04T05 | 2.6 | ||||

| M07T04 | 2.4 | ||||

| M07T05 | 2.4 | ||||

| F9 | End face | Finish turning | 21 | M01T01 | 3.2 |

| M01T02 | 3.3 | ||||

| M02T02 | 3.1 | ||||

| M02T03 | 3.2 | ||||

| F10 | Φ45 Through hole | Drilling | 22 | M05T06 | 2.9 |

| M06T07 | 2.8 | ||||

| M07T06 | 3.2 | ||||

| M07T07 | 3.0 | ||||

| 23 | M05T06 | 1.7 | |||

| M05T07 | 1.8 | ||||

| M06T07 | 1.6 | ||||

| M07T06 | 1.8 | ||||

| M07T07 | 1.7 | ||||

| F11 | Φ35 Through hole | Rough turning | 24 | M01T01 | 2.2 |

| M01T02 | 2.2 | ||||

| Semi-finish turning | 25 | M02T02 | 2.0 | ||

| M01T02 | 2.0 | ||||

| M02T02 | 2.1 | ||||

| M02T03 | 2.0 | ||||

| M01T02 | 2.2 | ||||

| M02T03 | 2.1 | ||||

| Finish turning | 26 | M01T02 | 2.2 | ||

| M01T01 | 1.2 | ||||

| M01T01 | 1.0 | ||||

| M01T02 | 1.2 | ||||

| M02T02 | 1.1 | ||||

| F12 | Φ45 Through hole | Rough turning | 27 | M01T01 | 2.2 |

| M01T02 | 2.2 | ||||

| M02T02 | 2.0 | ||||

| M01T02 | 2.0 | ||||

| Finish turning | 28 | M02T02 | 2.1 | ||

| M02T03 | 2.0 | ||||

| M01T02 | 2.2 | ||||

| M02T02 | 2.0 |

| Optimization Results | Low-Carbon as the Goal | Low-Cost as the Goal | Low-Carbon and Low-Cost as the Goal |

|---|---|---|---|

| Carbon emissions/kg | 5.68 | 6.87 | 6.15 |

| Cost/CNY | 35.84 | 33.42 | 34.06 |

| Processing Worsteps | Machine Tool Equipment | Feature Info. | Tool | Feature Info. |

|---|---|---|---|---|

| Milling | M07 | F8 M16 Thread | T05 | Rough milling F8 |

| Rough milling F7 | ||||

| F7 End face | T04 | Rough milling F7 | ||

| Rough milling F8 | ||||

| Turning | M01 | F1 End face | T01 | Rough turning F1 |

| F2 M16 Thread face | Rough turning F2 | |||

| F6 Φ45 Through hole face | Rough turning F6 | |||

| Turning | M01 | F3 End face | T01 | Rough turning F3 |

| F4 Φ45 Through hole | Rough turning F4 | |||

| F5 Φ35 Through hole | Rough turning F5 | |||

| Turning | M01 | F3 End face | T02 | Semi-finish turning F3 |

| F3 End face | Finish turning F3 | |||

| F4 Φ45 Through hole | Finish turning F4 | |||

| F5 Φ35 Through hole | Finish turning F5 | |||

| Turning | M01 | F1 End face | T03 | Semi-finish turning F1 |

| F1 M16 Thread | Semi-finish turning F1 | |||

| F1 End face | Finish turning F1 | |||

| F2 M16 Thread | Finish turning F2 | |||

| F9 End face | Finish turning F9 | |||

| F6 Φ45 Through hole | Finish turning F6 | |||

| Drilling | M06 | F10 Φ45 Through hole | T07 | Drill F10 |

| F11 Φ35 Through hole | Drill F11 | |||

| Tapping | M06 | F12 Φ45 Through hole | T08 | Tapping F12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Yan, W.; Wang, R.; Jiang, Z.; Liu, Y. Research on Blank Optimization Design Based on Low-Carbon and Low-Cost Blank Process Route Optimization Model. Sustainability 2021, 13, 1929. https://doi.org/10.3390/su13041929

Xiao Y, Yan W, Wang R, Jiang Z, Liu Y. Research on Blank Optimization Design Based on Low-Carbon and Low-Cost Blank Process Route Optimization Model. Sustainability. 2021; 13(4):1929. https://doi.org/10.3390/su13041929

Chicago/Turabian StyleXiao, Yongmao, Wei Yan, Ruping Wang, Zhigang Jiang, and Ying Liu. 2021. "Research on Blank Optimization Design Based on Low-Carbon and Low-Cost Blank Process Route Optimization Model" Sustainability 13, no. 4: 1929. https://doi.org/10.3390/su13041929

APA StyleXiao, Y., Yan, W., Wang, R., Jiang, Z., & Liu, Y. (2021). Research on Blank Optimization Design Based on Low-Carbon and Low-Cost Blank Process Route Optimization Model. Sustainability, 13(4), 1929. https://doi.org/10.3390/su13041929