2.4. Financial Calculations for Landfills and WWTPs

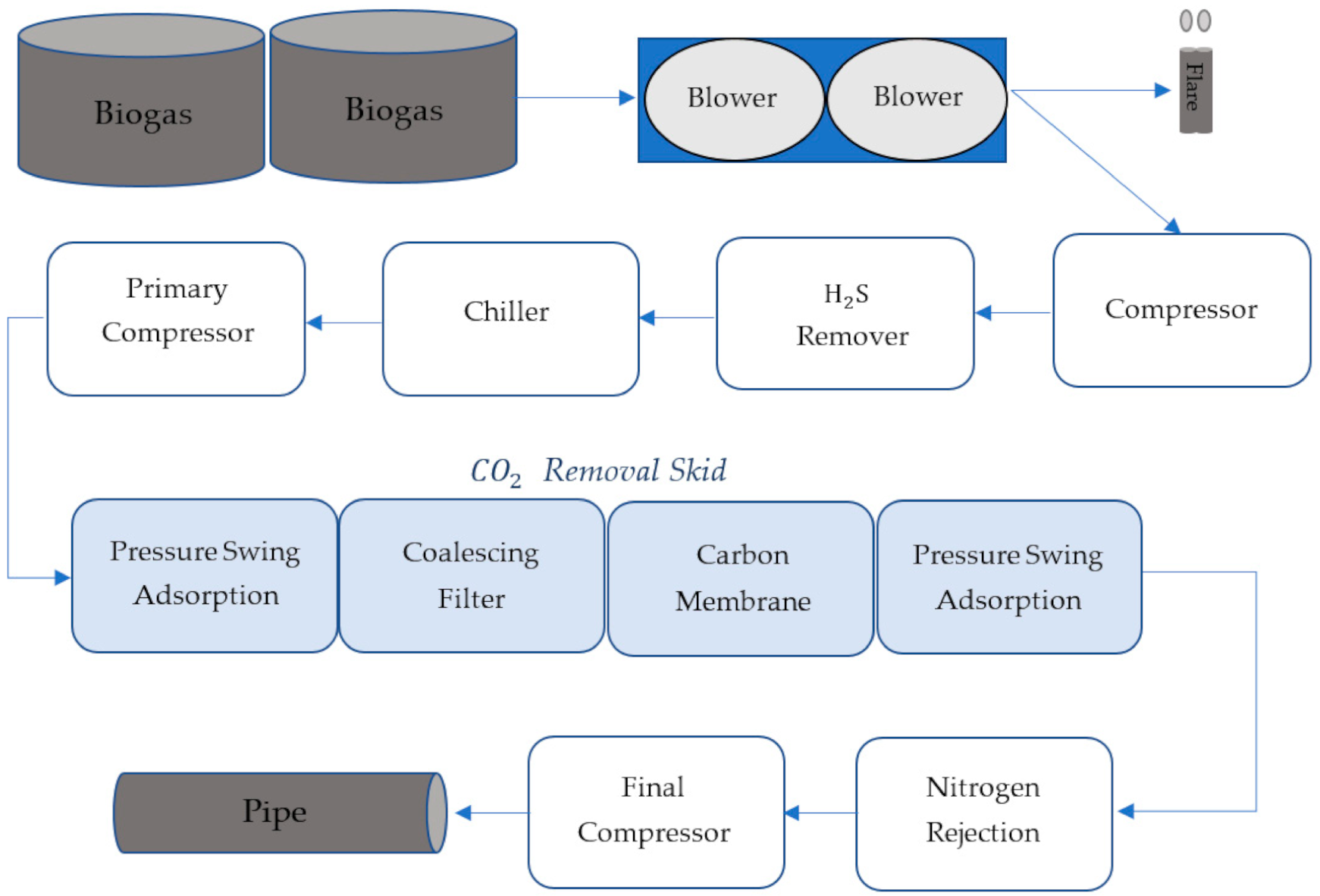

The costs of renewable natural gas projects can be broken out into capital investment and operating and maintenance (O&M) costs. The capital investment includes compressors, gas separators, and dryers for pipeline quality gas [

25]. It is important to note that the cost of upgrading for each landfill varies depending on the contents and impurities of gas from each location. For example, if there is high nitrogen content in the gas then an additional nitrogen rejection unit may be needed before the final compression stage. This would increase the capital expense by an additional USD 3 million [

25]. Additionally, operational expenses (OE

t) can vary from 15–20% depending on how much equipment is needed to convert biogas to RNG. If a facility has additional equipment in place due to different gas qualities, additional maintenance would be needed for that facility. The equipment is assumed to have a 20-year usable lifetime. Approximated costs for capital expenses (CE), annual O&M expenses without electricity expenses (O&M

t without EE

t), and annual electricity expenses (EE

t) are calculated based on biogas flow (landfill gas and WWTP biogas).

RNG Project Expenses are calculated in Equations (7)–(10):

The capital expense varies based on components that would need to be measured on a per case basis. Therefore, the calculation above is designed to give an estimate taking into consideration the amount of biogas coming in with the expectation that more gas flow means a higher chance of needing extra equipment. It factors in the SCFM when calculating potential equipment costs and SCFY when calculating annual operation and maintenance costs. It is based on a 2000 SCFM operation, which would estimate between USD 16 and USD 18 million in 2019 based on information provided from an RNG specific contractor [

25]. When making a formula to use universally based on SCFM, the upper range of the cost estimates was used to be conservative. This can be seen in Equation (7) (

). The true capital expense will change by year and location, so an estimate was used to calculate the costs. The O&M cost is taking into consideration the amount of biogas flowing per year. The more biogas being produced the more maintenance is necessary, so this formula scales with the size of production. The operating expense is charged at an operating and maintenance rate (m) of USD 0.22/1000 SCF [

25]. The electricity expense takes into consideration the cost on an industrial level per kilowatt hour and an average of how much electricity is estimated to be consumed per year based on the amount of gas flow. This is signified by k, which is 0.009 KWH per ft

3. The costs of electricity were calculated with the current price of electricity at the date in which this report was written (

.

It is also important to note that landfills require collection systems to collect the byproduct of their decomposing waste- biogas or landfill gas. LFG collection typically begins after a portion of the landfill, known as a “cell”, is closed to additional waste placement. Collection systems can be configured as either vertical wells or horizontal trenches [

12]. On average, one acre of a landfill requires one well. The cost of one well is about USD 19,500 per acre [

25], and the typical cost of maintenance for one well per year is USD 2250 [

25]. Costs can vary based on the depth that a collection well needs to go into the landfill. This report only focuses on candidate landfills, meaning that the wells are already in place and so the cost of the collection wells does not need to be included in the financial model.

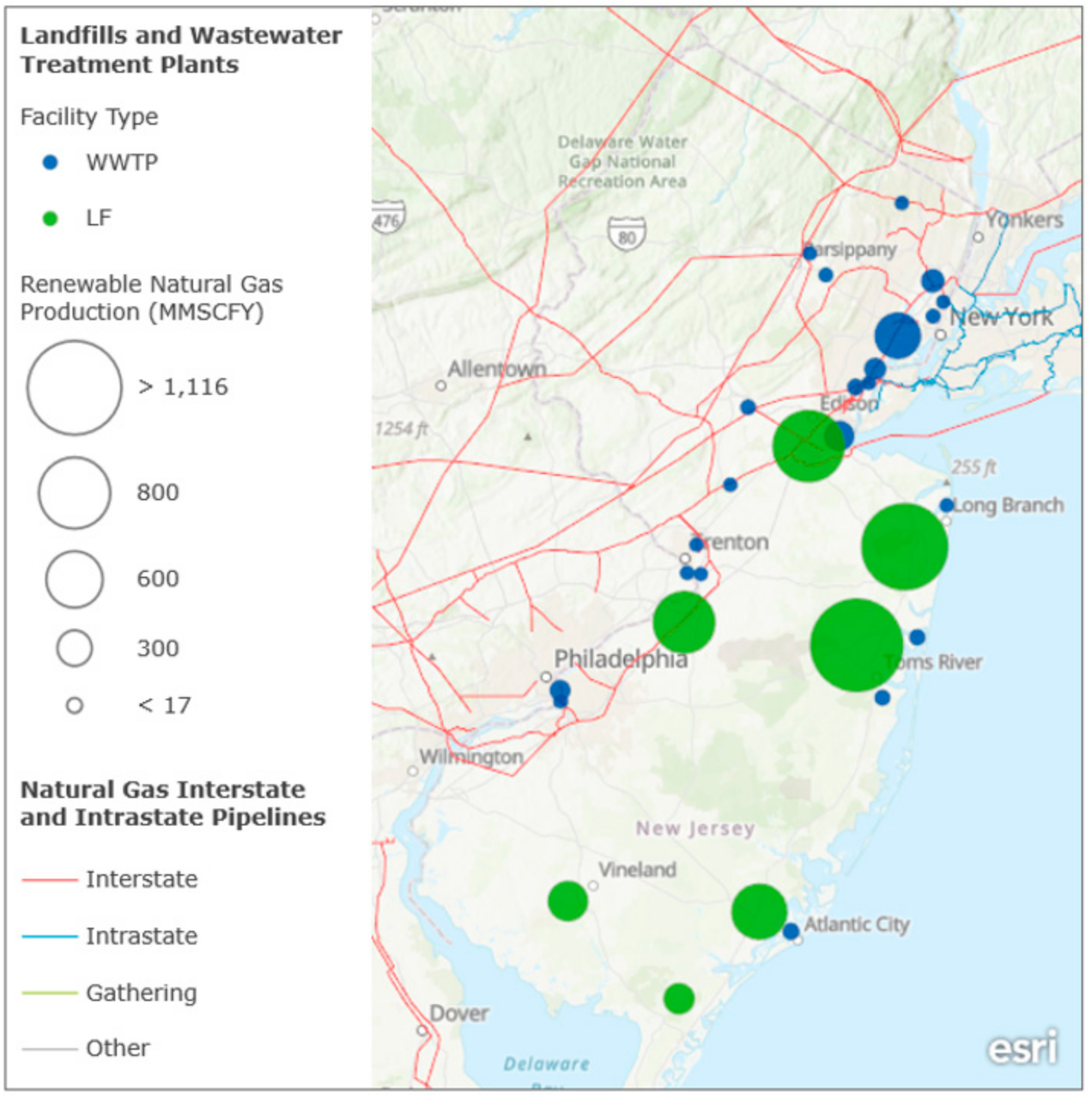

In addition, all RNG projects whether located at a landfill or WWTP would need to be connected to natural gas pipelines. Depending on the size of a pipeline and the location of the site, interconnection costs can be very expensive. The interconnection cost would be approximately USD 1.5–3 million per mile [

29], and so the farther the facility is from the existing natural gas pipeline, the more expensive the construction would be. In the case of this project, these expenses are not including in the financial analysis because the New Jersey Board of Public Utilities (NJBPU) helps to finance this construction [

46].

A payback period was calculated (Equation (11)) for all viable RNG locations including both WWTPs and landfills. This offered comparability with a universal measurement that did not discriminate between the two different types of projects. Once the total capital expenses, yearly operating expenses, and potential yearly revenue were calculated, the annual profit margin (

Equation (12)) for the landfills and WWTPs could be calculated in order to find the payback period for each of the facilitates. The payback period shows how many years it will take before the project turns a profit assuming all revenue goes towards paying off the project. It is a simplified calculation used to compare profitability across options. The following equations were used in these calculations:

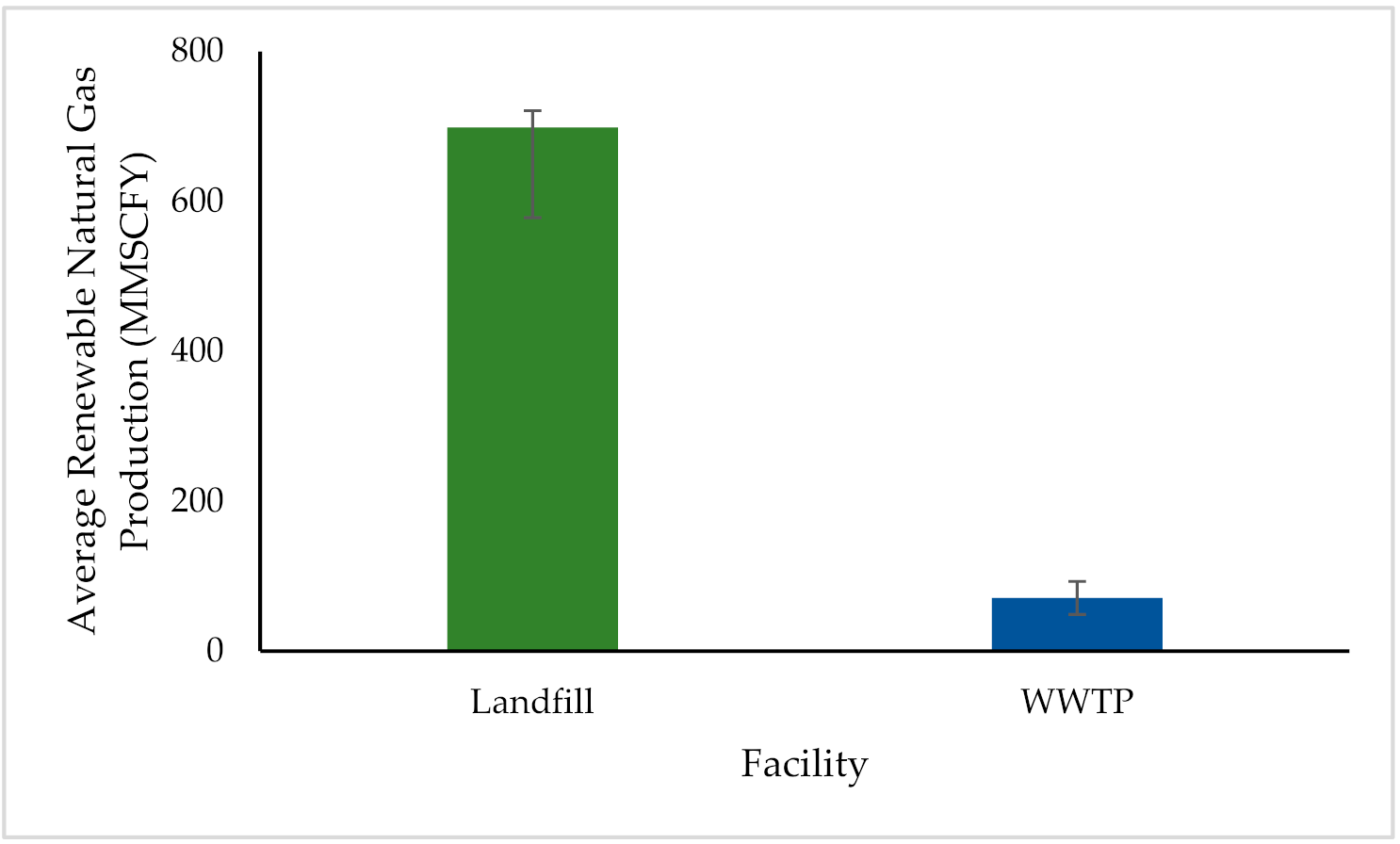

Internal rate of return (IRR) and net present value (NPV) models were also created to represent the potential outcomes for each of the seven viable landfills. The models only focused on the landfills because they were producing significantly more biogas which in turn meant these facilities should be more profitable. This was supported by the results of the initial payback period calculations that predated further modeling. The initial cash outflow is the capital investment. The models use the net cash flows of the annual retail sales revenue, the United States modified accelerated cost recovery system (MACRS) that acts as a tax shield on investments, and annual O&M expense including electricity. The projects were constructed on a 20-year timeline due to the projected lifetime of the machinery. The discount rate (

r) of 13% was used because this was the provided hurdle rate from New Jersey Natural Gas. The IRR and NPV models are designed to take into consideration the value of the investment if it was otherwise spent on an alternative project. High risk investments such as investing in a new energy source must meet higher yields to be worth the risk to investors. This means that a utility company would not pursue a project such as this unless the IRR was over 13%. With these factors considered, the NPV (Equation (13)) and IRR (Equation (14)) of each data set were calculated through 2016 Microsoft Excel’s formula for each. In the equations, T represents the number of time periods, t is the time period of each summation, and r signifies the discount rate. The equations also utilize the revenue (

and all costs

during the given time period.

In order to calculate the true revenue (

, Equation (15)), the IRR model had to be constructed first. The 2016 Microsoft Excel data tool “Goal Seek” was used to determine what the gas must be sold at per Therm in order to return the IRR value of 13%. Excel’s Goal Seek changes one factor in a formula in order to produce the end goal desired. This means for each landfill there would be a different price in order to make the project meet the 13% hurdle rate. The capital expense and annual operating expense will be the same no matter what the gas is sold for, so the price per Therm was used as the changing factor. In

Table 4, the prices vary from as low as USD 0.8063 per Therm to as high as USD 1.2126 per Therm. The average price is calculated to be USD 0.9499 per Therm, so this would become the standard retail price of RNG in order to meet required return levels. This average was used in all financial modeling, and it was retroactively filled into the payback period models to improve accuracy. Equation (15) uses this rate of USD 0.9499 per Therm (

to calculate the annual revenue of RNG projects. The amount of Therms produced each year at a given RNG project was calculated with Equation (16) to utilize in Equation (15) and utilizes the conversion rate of 10,000 Therms per 1 MMSCFY of RNG (

. This also means that projects that required a price higher than USD 0.9499 will not meet the hurdle rate, and therefore will not be accepted as options.

The incentive gap (Equation (17)) was calculated with consideration of the current natural gas rate (CR). Natural gas at the time of this study is being sold at an average price through NJNG of USD 0.4667 [

47]. Because the RNG needs to be sold at the retail rate (RR) of USD 0.9499 to meet the financial goals and the conventional natural gas is being sold at USD 0.4667, the incentive gap (IG) would be the difference between these two or USD 0.4832.

This means that the customer either has to pay an additional USD 0.4832 per Therm in order to be enrolled in the RNG option, or an incentive system must be in place to subsidize this extra cost.

Another option to offset the higher cost of RNG per Therm is renewable identification numbers (RINs). For the calculation of revenue that could potentially be brought in from RIN sales (Equation (18)), the units of a RIN must be understood. A RIN is measured in the equivalence of burning one gallon of ethanol fuel which is equivalent to 77,000 BTU [

48]. At the time of this report, RINs for renewable natural gas could have been sold or brought at USD 0.5864 per Therm according to the EPA’s RIN Trades [

49]. The RINs are classified by where they are sourced from with varying price ranges. Landfill gas related RINs fall under D5 classification. The price range for D5 class RINs are starting from USD 0.05 and ranges up to USD 2.00 per RIN [

49]. D5 RINs generated in 2018 are being sold in 2019 at an average price of USD 0.50 per RIN [

49]. RINs are currently generated for every gallon of renewable fuel produced. This is equivalent to USD 0.5864 per Therm (D

RIN). Since New Jersey does not currently accept RNG for heating purposes, regulations would have to change in order to take advantage of this. However, if this program was adjusted, this would eliminate the incentive gap.

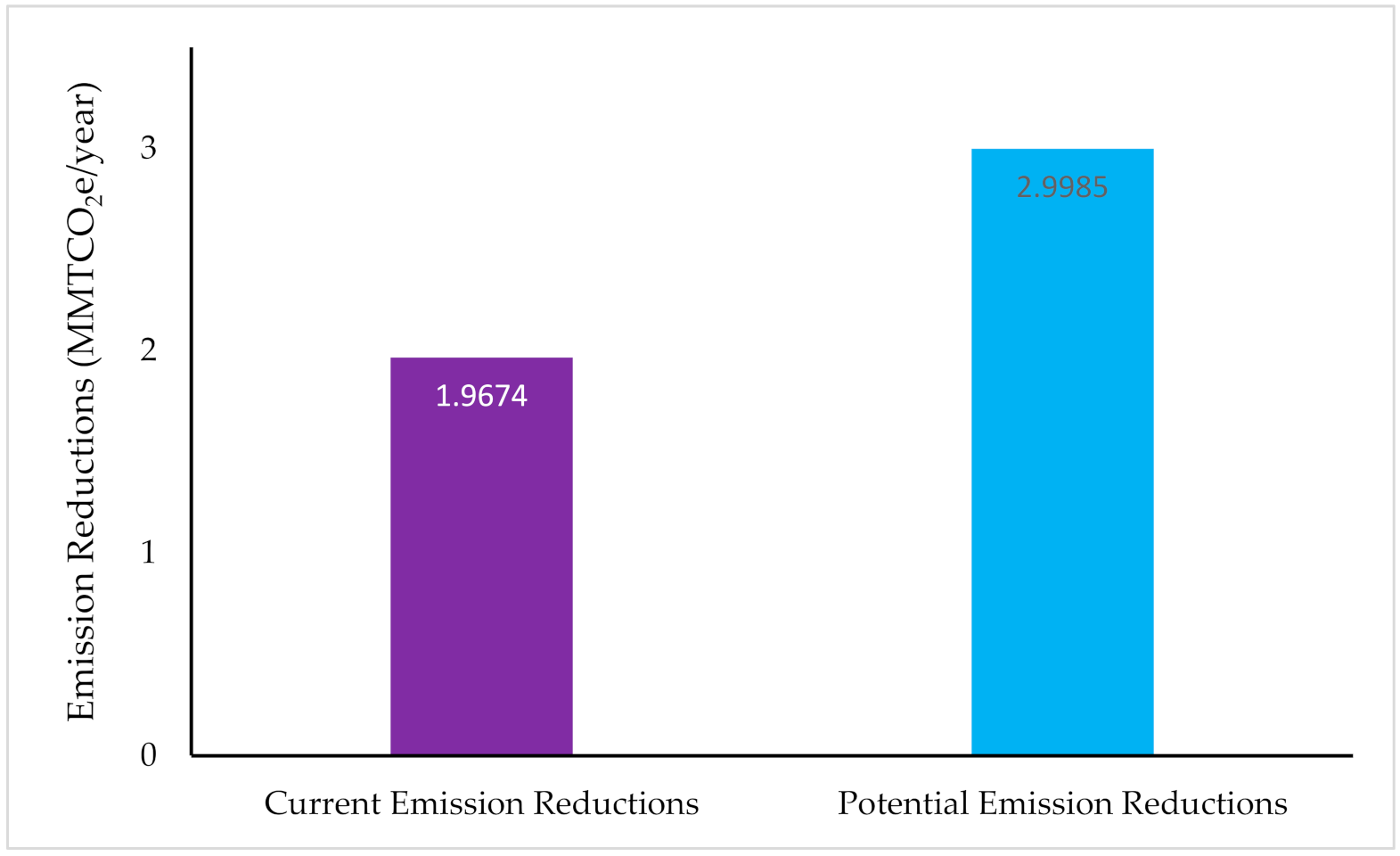

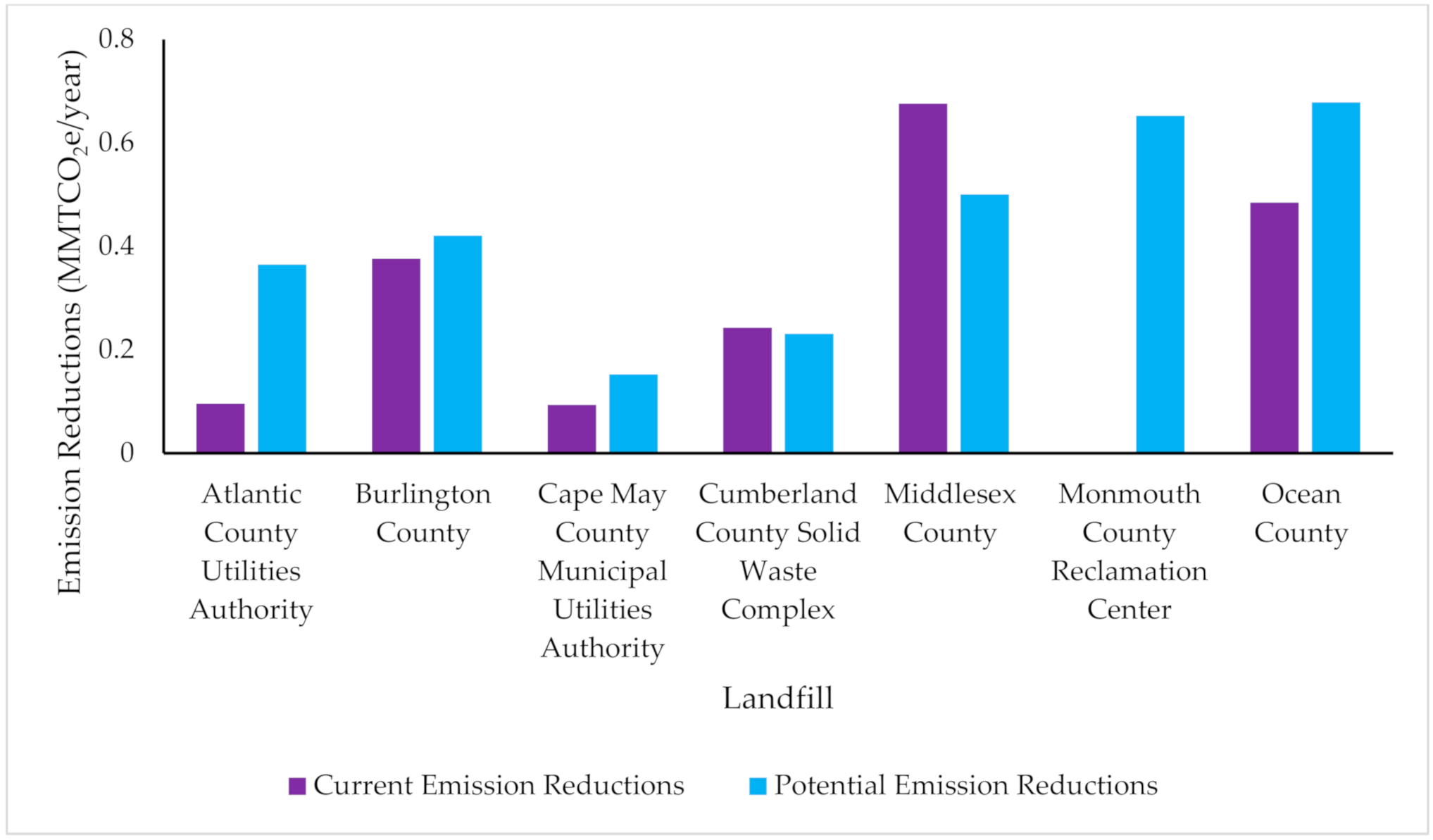

2.6. Current and Potential Emission Reductions from Renewable Natural Gas Projects at Landfills

Current emission reductions from ongoing electricity projects at landfills and potential emission reductions from possible RNG projects were compared for each landfill in order to gain better insight into RNG projects. Current emission reductions are based on the present gas to electricity projects of the viable landfills. These projects, found in the 2019 US EPA LMOP database, recorded the amount of landfill gas collected, megawatt (MW) generation of the project, direct methane reductions, and avoided carbon dioxide reductions each year [

52]. In order for the US EPA to calculate the current total emissions reductions, the MW generation of each project at each viable landfill was inputted into the US Environmental Protection Agency (EPA) Landfill Gas Energy Benefits calculator [

44]. MW generation is being used over LFG flow to project based on data availability from the EPA’s LMOP. These calculations provide an estimate of the potential methane emitted directly from the landfill, the offset of carbon dioxide from avoidance of fossil fuels, and the total emissions reduced by adding direct and avoided emissions. The equations used by the US EPA to calculate the direct emissions reductions (Equation (19)), avoided emissions reductions (Equation (20)), and total emissions reductions (Equation (21)) based on the MW capacity of the project can be found below.

Direct Equivalent Emissions Reduced Calculations for Electricity Generation Projects:

Avoided Equivalent Emissions Reduced Calculations for Electricity Generation Projects:

The following are conversion factors used in the equations to convert to the proper units: 8760 h per year, 1000 KW per MW, 0.9072 metric tons per short ton (

, 2000 pounds per short ton (

, and 1,000,000 metric tons per million metric tons [

42]. In the Direct Emissions Reductions calculations (Equation (19)), the 0.93 in the numerator is the gross capacity factor (

which accounts for the energy loss during production because of inefficiencies with equipment or weather-related impacts [

41]. The following are heating values and rates used in the Direct Emissions Reduction Equation (19): 11,700 BTU per KWH (

and 1012 BTU per SCF of methane (

, and are used to convert the equation from units of power (watts) to units of heat (BTU). Additionally, the methane conversion of 0.0423 pounds of methane per SCF of methane (

is used to convert units of heat to methane. The

stands for Global Warming Potential of methane which refers to methane having 25 time the global warming potential than carbon dioxide as reported by the 2014 IPCC. This is used to convert from methane to carbon dioxide equivalents. In the Avoided Emissions Reductions calculations (Equation (20)), the 0.85 in the numerator refers to the net capacity factor (

for generation units of electricity projects and accounts for operating load, availability, and small loses. Additionally, the 1540 pounds per MWH is the regional grid factor (

for 2019 for the mid-Atlantic region and is based on the AVoided Emissions and geneRation Tool (AVERT) to calculate the avoided carbon dioxide emissions. More specifics about the creation of the equations can be found through the US EPA’s Landfill Gas Energy Benefits calculator [

44].

In order to find the potential emissions reductions of RNG projects, the same Landfill Gas Energy Benefits calculator was used [

44]. This time, however, the LFG collected (MMSCFD) was used to calculate the direct and avoided emissions. This operates under the assumption that RNG projects would utilize all LFG collected at each landfill. The equations used by the US EPA in their landfill gas benefits calculator to calculate the direct emissions reductions, avoided emissions reductions, and total emissions reductions based on the LFG can be found below.

Direct Equivalent Emissions Reduced Calculations for Direct-Use Projects:

Avoided Equivalent Emissions Reduced Calculations for Direct-Use Projects:

Many of the conversion factors, methane conversions, and heating values and rates from the first set of Direct and Avoided Emissions equations are used in the second set. Additional conversion factors used in these equations are: 365 days per year and 1,000,000 SCF per 1 MMSCF in the numerator [

42]. Both of the direct-use equations based on LFG collected also rely on the previously stated information that 50% of LFG is methane (

. The Avoided Emissions equation also utilizes the heating rate of 1050 BTU per 1 SCF of natural gas (

and the carbon dioxide conversion of 0.12037 pounds of carbon dioxide per 1 SCF of natural gas (

. These components allow for the conversion from heat units to SCF of natural gas to carbon dioxide. Additionally, the Avoided Emissions equation multiplies the MMSCFD of LFG by 0.9, which is the gross capacity factor (

for direct-use LFG projects. Further information about the creation of these equations can be found through the US EPA Landfill Gas Energy Benefits calculator spreadsheet [

44]. In order to determine the total emission reductions of RNG projects at WWTPs, we replaced the MMSCFD LFG with MMSCFD of biogas from WWTPs and changed the methane conversion factor of 0.5 SCF methane per SCF LFG to 0.63 SCF methane per SCSF biogas for both the direct and avoided emissions equations.