Evaluating Distribution Costs and CO2-Emissions of a Two-Stage Distribution System with Cargo Bikes: A Case Study in the City of Innsbruck

Abstract

:1. Introduction

1.1. Motivation and Goals

1.2. Related Literature

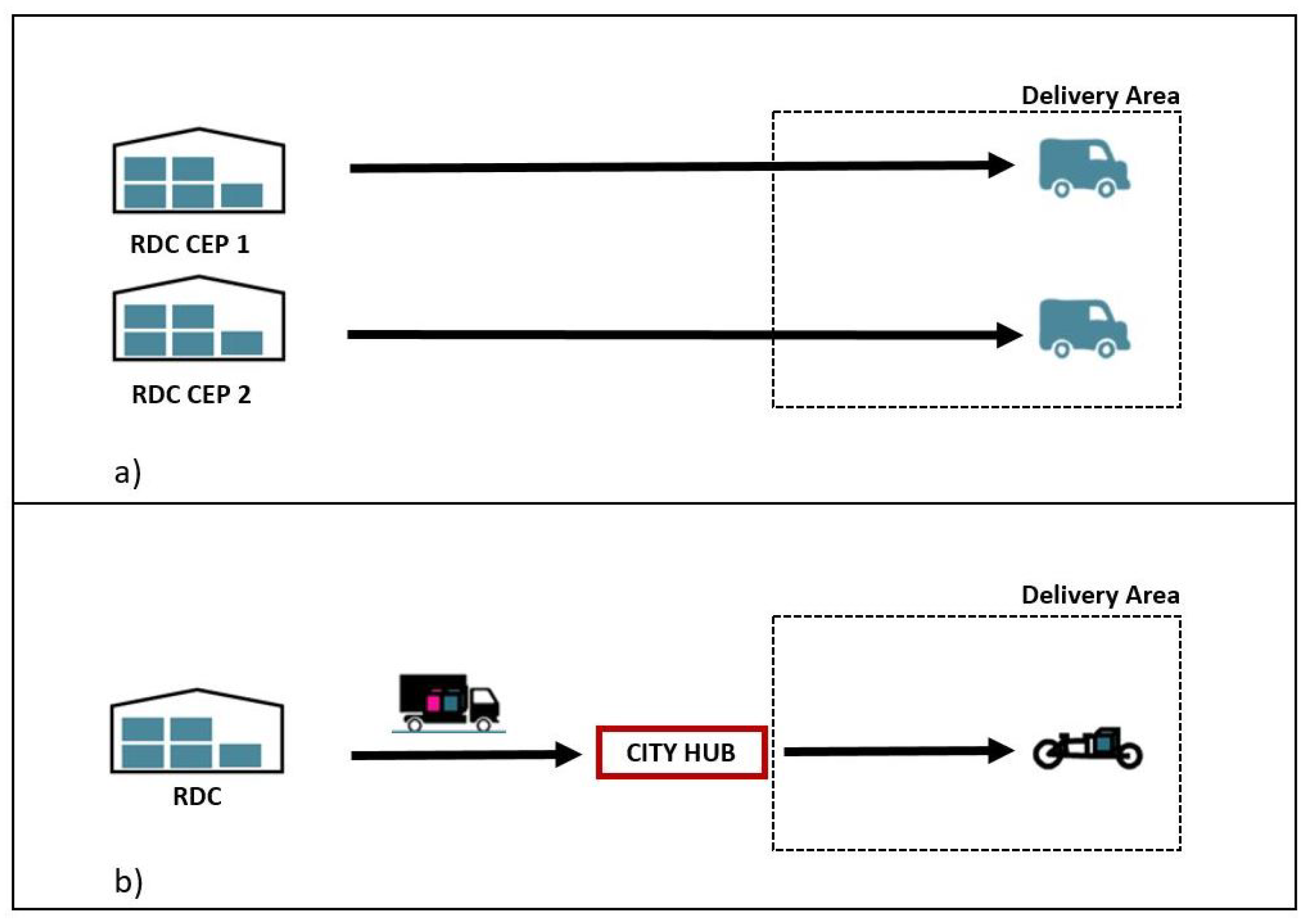

2. Two-Stage City Distribution System

2.1. Problem Description

2.2. Mathematical Model

2.3. Solution Method

3. Numerical Analysis

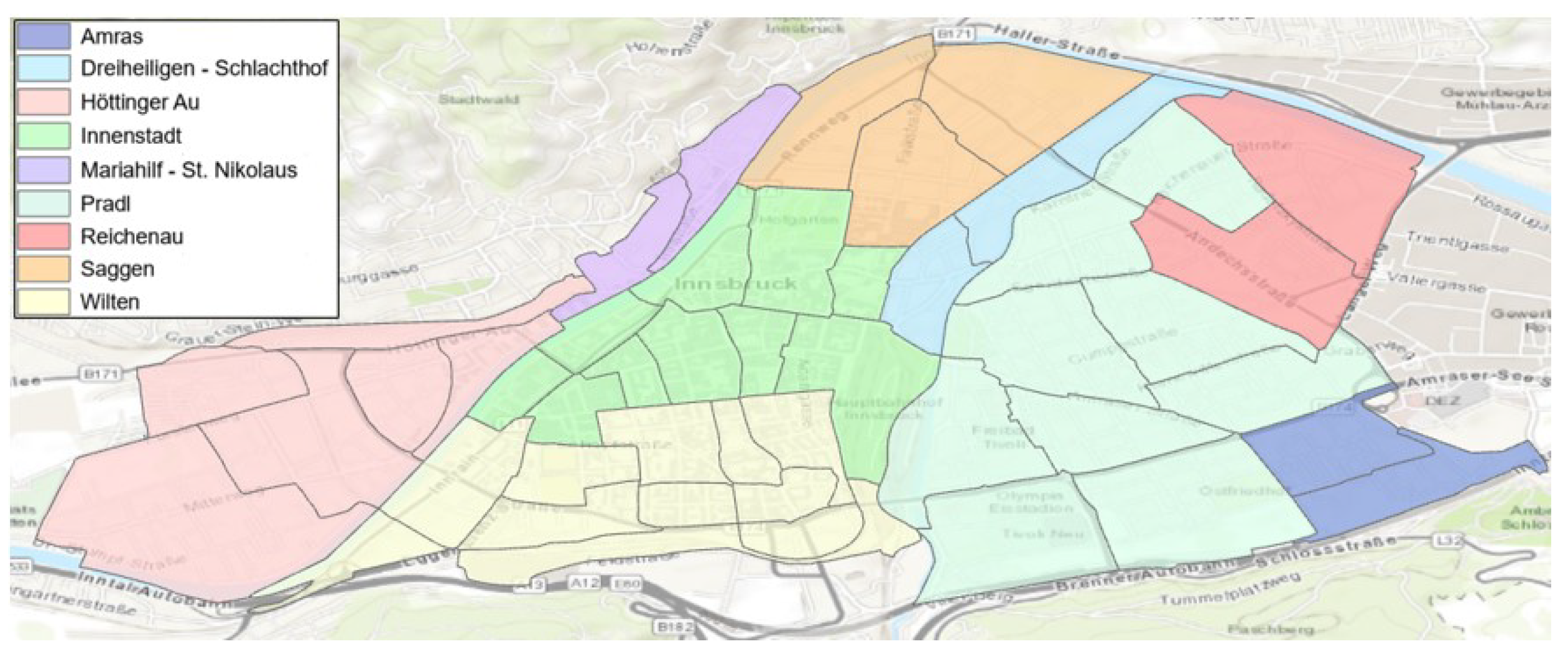

3.1. Scope of the Study and Data Description

3.2. Parameter Settings

4. Analysis Results

4.1. Last Mile Delivery Results

4.2. Sensitivity Analysis

4.3. Evaluation of the Two-Stage Distribution System

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| ArcGIS Parameter | Selected | Option |

|---|---|---|

| Time Field Units | Minutes | |

| Distance Field Units | Kilometers | |

| Impedance | Travel Time | |

| Type | Other | |

| Time Cost | Travel Time | |

| Distance Cost | Kilometers | |

| Cost Parameter, Travel Time, Vehicle Max. Speed | 25 | |

| Cost Parameter, Truck Travel Time, Vehicle Max. Speed | 0 | |

| Cost Parameter, Walk Time, Vehicle Max. Speed | 5 | |

| Any Hazmat Prohibited | Prohibited | |

| Avoid Carpool Roads | Prohibited | |

| Avoid Express Lanes | X | Prohibited |

| Avoid Ferries | Avoid | |

| Avoid Gates | X | Avoid |

| Avoid Limited Access Roads | X | Prohibited |

| Avoid Private Roads | X | Prefer (low) |

| Avoid Roads Unsuitable for Pedestrians | X | Avoid (high) |

| Avoid Stairways | X | Avoid (high) |

| Avoid Toll Roads | X | Prohibited |

| Avoid Toll Roads for Trucks | Avoid (high) | |

| Avoid Truck Restricted Roads | Avoid (high) | |

| Avoid Unpaved Roads | X | Avoid (low) |

| Axle Count Restriction | Prohibited, 0 | |

| Driving a Bus (Does not include roads where buses are prohibited. Using this restriction will also ensure that the results will honor one-way streets.) | Prefer (high) | |

| Driving a Taxi | Prefer (high) | |

| Driving a Truck | Prohibited | |

| Driving an Automobile | Prefer (low) | |

| Driving an Emergency Vehicle | Prohibited | |

| Height Restriction | Prohibited, 0 | |

| Kingpin to Rear Axle Length Restriction | Prohibited, 0 | |

| Length Restriction | Prohibited, 0 | |

| Preferred for Pedestrians | X | Prefer (medium) |

| Riding a Motorcycle | Prefer (high) | |

| Roads under Construction Prohibited | X | Avoid (high) |

| Semi or Tractor with One or More Trailers Prohibited | Prohibited | |

| Single Axle Vehicles Prohibited | Prohibited | |

| Tandem Axle Vehicles Prohibited | Prohibited | |

| Through Traffic Prohibited | X | Prefer (high) |

| Truck with Trailers Restriction | Prohibited, 0 | |

| Use Preferred Hazmat Routes | Prefer | |

| Use Preferred Truck Routes | Prefer | |

| Walking | Prohibited | |

| Weight per Axle Restriction | Prohibited, 0 | |

| Weight Restriction | Prohibited, 0 | |

| Width Restriction | Prohibited, 0 | |

| U-Turns (agility) | All | |

| Hierarchical road classification preferred | No | |

| Simplify Output Geometry (max allowable offset that simplified line can deviate from original line) | X | 10 m |

| Output Geometry | Along Network |

| ArcGIS Parameter | Selected | Option |

|---|---|---|

| Time Field Units | Minutes | |

| Distance Field Units | Kilometers | |

| Type | Driving | |

| Impedance | Travel Time | |

| Time Cost | Travel Time | |

| Distance Cost | Kilometers | |

| Cost Parameter, Travel Time, Vehicle Max. Speed | 0 | |

| Cost Parameter, Truck Travel Time, Vehicle Max. Speed | 0 | |

| Cost Parameter, Walk Time, Vehicle Max. Speed | 5 | |

| Any Hazmat Prohibited | Prohibited | |

| Avoid Carpool Roads | X | Prohibited |

| Avoid Express Lanes | X | Prohibited |

| Avoid Ferries | Avoid | |

| Avoid Gates | X | Avoid |

| Avoid Limited Access Roads | Avoid | |

| Avoid Private Roads | X | Avoid |

| Avoid Roads Unsuitable for Pedestrians | Avoid (high) | |

| Avoid Stairways | Avoid (high) | |

| Avoid Toll Roads | Avoid | |

| Avoid Toll Roads for Trucks | Avoid | |

| Avoid Truck Restricted Roads | Avoid (high) | |

| Avoid Unpaved Roads | X | Avoid (high) |

| Axle Count Restriction | Prohibited, 0 | |

| Driving a Bus (Does not include roads where buses are prohibited. Using this restriction will also ensure that the results will honor one-way streets.) | Prohibited | |

| Driving a Taxi | Prohibited | |

| Driving a Truck | Prohibited | |

| Driving an Automobile | Prohibited | |

| Driving an Emergency Vehicle | Prohibited | |

| Height Restriction | Prohibited, 0 | |

| Kingpin to Rear Axle Length Restriction | Prohibited, 0 | |

| Length Restriction | Prohibited, 0 | |

| Preferred for Pedestrians | Prefer (low) | |

| Riding a Motorcycle | Prohibited | |

| Roads under Construction Prohibited | X | Prohibited |

| Semi or Tractor with One or More Trailers Prohibited | Prohibited | |

| Single Axle Vehicles Prohibited | Prohibited | |

| Tandem Axle Vehicles Prohibited | Prohibited | |

| Through Traffic Prohibited | X | Avoid (high) |

| Truck with Trailers Restriction | Prohibited, 0 | |

| Use Preferred Hazmat Routes | Prefer | |

| Use Preferred Truck Routes | Prefer | |

| Walking | Prohibited | |

| Weight per Axle Restriction | Prohibited, 0 | |

| Weight Restriction | Prohibited, 0 | |

| Width Restriction | Prohibited, 0 | |

| U-Turns (agility) | Dead-Ends and Intersections | |

| Hierarchical road classification preferred | No | |

| Simplify Output Geometry (max allowable offset that simplified line can deviate from original line) | X | 10 m |

| Output Geometry | Along Network |

| Feature | Cargo Bike VRP | Van VRP | E-Van VRP |

|---|---|---|---|

| RouteName | Bike n | Van n | eVan n |

| Precedence | 1 | 1 | 1 |

| ServiceTime | 30 | 30 | 30 |

| TimeWindowStart | 09:00 | 06:00 | 06:00 |

| TimeWindowEnd | 12:30 | 12:00 | 12:00 |

| IsPaid | FALSE | FALSE | FALSE |

| Feature | Cargo Bike VRP | Van VRP | E-Van VRP |

|---|---|---|---|

| RouteName | Bike n | Van n | eVan n |

| DepotName | Main station, west station, fair, congress | RDC | RDC |

| ServiceTime | 10 | 30 | 30 |

| Feature | Cargo Bike VRP | Van VRP | E-Van VRP |

|---|---|---|---|

| Mode | Cargo bike cycling time (max 25 km/h) | Driving time | Driving time |

| Time Fields Unit | Minutes | Minutes | Minutes |

| Distance Fields Unit | Kilometers | Kilometers | Kilometers |

| Parameter | Literature | Chosen |

|---|---|---|

| Cargo bike speed | 8 km/h [43]; 12 km/h [14]; 15 km/h [5], [4], [25]; 16 km/h [44], [23]; 17.6 km/h [25]; 15–25 km/h [46]; 20 km/h [18], [3] | Average 18 km/h; Max. 25 km/h |

| Cargo bike capacity | 16 parcels [4]; 40 parcels [3], [22]; 1000 parcels for swap-containers [25]; 50 kg [46]; 50–250 kg [44]; 300–1300 L [23] | 40 parcels |

| Cargo bike battery range | 19–40 km [3]; 42 km [48]; 48 km [43]; 80 km [44] | 80 km |

| Time per day | 5 h [4]; 6 h [3]; 7h [43]; 7.5 h [22]; 8 h [5]; [44] | 8 h |

| Deliveries per day | Average: 77 orders [44]; Min: 80 orders [46]; Average: 100–150 parcels, Max: 200–250 parcels [45] | Max. 200 orders |

| Delivery service time | 2 min [46]; 2.5 min [14]; 3 min [22], [44]; 6–16 min [4] | 2 min |

| Depot service time | 24 min [22]; 96–132 min [44] | Start: 20 min; End: 10 min |

| Renewal depot service time | 1 min per parcel [44]; 5 min [14]; 24 min [22] | 10 min |

| Time-based costs | 13.90 €/h [43]; 16.70 €/h [44]; 18 €/h [4]; 18 €/h [14]; 21 €/h [26]; 21.44 €/h [3] | 20 €/h |

| Distance-based costs | 0.01 €/km [43], [52], [18]; 0.024 €/km [44]; 0.04 €/km [4] | 0.04 €/km |

| Fixed costs | 10 €/day [4]; 12.88 €/day [44]; 47 €/day, including operating costs [3] | 15 €/day |

References

- World Economic Forum. Supply Chain Decarbonization: The Role of Logistics and Transport in Reducing Supply Chain Carbon Emissions. 2009. Available online: http://www3.weforum.org/docs/WEF_LT_SupplyChainDecarbonization_Report_2009.pdf (accessed on 23 June 2021).

- Oliveira, C.M.; Albergaria De Mello Bandeira, R.; Vasconcelos Goes, G.; Schmitz Gonçalves, D.N.; D’Agosto, M.D. Sustainable Vehicles-Based Alternatives in Last Mile Distribution of Urban Freight Transport: A Systematic Literature Review. Sustainability 2017, 9, 1324. [Google Scholar] [CrossRef] [Green Version]

- Sheth, M.; Butrina, P.; Goodchild, A.; McCormack, E. Measuring delivery route cost trade-offs between electric-assist cargo bicycles and delivery trucks in dense urban areas. Eur. Transp. Res. Rev. 2019, 11, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Anderluh, A.; Hemmelmayr, V.; Nolz, P. Synchronizing vans and cargo bikes in a city distribution network. Cent. Eur. J. Oper. Res. 2017, 25, 345–376. [Google Scholar] [CrossRef] [Green Version]

- Leonardi, J.; Browne, M.; Allen, J. Before-After Assessment of a Logistics Trial with Clean Urban Freight Vehicles: A Case Study in London. Procedia-Soc. Behav. Sci. 2012, 39, 146–157. [Google Scholar] [CrossRef] [Green Version]

- Stadt Innsbruck. Statistische Stadtteile in Innsbruck. 2019. Available online: https://www.data.gv.at/katalog/dataset/75721d08-df07-4f6c-ae8d-b35e852ca163 (accessed on 22 April 2021).

- Stadt Innsbruck. Zählsprengel in Innsbruck. 2019. Available online: https://www.data.gv.at/katalog/dataset/gisibk-zspr (accessed on 22 April 2021).

- Pfaffenbichler, P. Umweltbelastung und Ressourcenverbrauch als Mögliche Auswirkung der Zunehmenden Nutzung des Onlinehandels durch die EinwohnerInnen der Stadt Wien (URANOS): Endbericht v1.0; Technische Universität Wien: Vienna, Austria, 2018. [Google Scholar]

- Savelsbergh, M.; van Woensel, T. City Logistics: Challenges and Opportunities: 50th Anniversary Invited Article. Transp. Sci. 2016, 50, 579–590. [Google Scholar] [CrossRef]

- Paddeu, D. Sustainable Solutions for Urban Freight Transport and Logistics: An Analysis of Urban Consolidation Centers. In Sustainable Freight Transport: Theory, Models, and Case Studies; Zeimpekis, V., Aktas, E., Bourlakis, M., Minis, I., Eds.; Springer: Cham, Switzerland, 2018; pp. 121–137. [Google Scholar] [CrossRef] [Green Version]

- Dolati Neghabadi, P.; Evrard Samuel, K.; Espinouse, M.L. Systematic literature review on city logistics: Overview, classification and analysis. Int. J. Prod. Res. 2019, 57, 865–887. [Google Scholar] [CrossRef]

- Enthoven, D.L.; Jargalsaikhan, B.; Roodbergen, K.J.; uit het Broek, M.A.J.; Schrotenboer, A.H. The two-echelon vehicle routing problem with covering options: City logistics with cargo bikes and parcel lockers. Comput. Oper. Res. 2020, 118, 104919. [Google Scholar] [CrossRef]

- Ehmke, J.F. Routing in City Logistics. In Integration of Information and Optimization Models for Routing in City Logistics; Ehmke, J.F., Ed.; Springer: Boston, MA, USA, 2012; pp. 119–156. [Google Scholar] [CrossRef]

- Arnold, F.; Cardenas, I.; Sörensen, K.; Dewulf, W. Simulation of B2C e-commerce distribution in Antwerp using cargo bikes and delivery points. Eur. Transp. Res. Rev. 2018, 10, 1–13. [Google Scholar] [CrossRef]

- Quak, H.; Tavasszy, L. Customized Solutions for Sustainable City Logistics: The Viability of Urban Freight Consolidation Centres. In Transitions Towards Sustainable Mobility: New Solutions and Approaches for Sustainable Transport Systems; van Nunen, J.A., Huijbregts, P., Rietveld, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 213–233. [Google Scholar] [CrossRef]

- Crainic, T.G.; Ricciardi, N.; Storchi, G. Models for Evaluating and Planning City Logistics Systems. Transp. Sci. 2009, 43, 432–454. [Google Scholar] [CrossRef] [Green Version]

- Nocera, S.; Cavallaro, F. A two-step method to evaluate the Well-To-Wheel carbon efficiency of Urban Consolidation Centres. Res. Transp. Econ. 2017, 65, 44–55. [Google Scholar] [CrossRef]

- Melo, S.; Baptista, P. Evaluating the impacts of using cargo cycles on urban logistics: Integrating traffic, environmental and operational boundaries. Eur. Transp. Res. Rev. 2017, 9, 30. [Google Scholar] [CrossRef] [Green Version]

- Quak, H.; van Duin, R.; Hendriks, B. Running an urban consolidation centre: Binnenstadservice 10 years back and forth. Transp. Res. Procedia 2020, 46, 45–52. [Google Scholar] [CrossRef]

- Anderluh, A.; Hemmelmayr, V.; Wakolbinger, T. Einsatz von Lastenfahrrädern zur innerstädtischen Güterlieferung: Ein Städtevergleich und Best Practice Empfehlungen für die Stadt Wien. 2016. Available online: https://www.wu.ac.at/fileadmin/wu/d/ri/scm/WU_Cargo_Bikes_Final_Report.pdf (accessed on 30 March 2021).

- Ranieri, L.; Digiesi, S.; Silvestri, B.; Roccotelli, M. A Review of Last Mile Logistics Innovations in an Externalities Cost Reduction Vision. Sustainability 2018, 10, 782. [Google Scholar] [CrossRef] [Green Version]

- Assmann, T.; Lang, S.; Müller, F.; Schenk, M. Impact Assessment Model for the Implementation of Cargo Bike Transshipment Points in Urban Districts. Sustainability 2020, 12, 4082. [Google Scholar] [CrossRef]

- Gruber, J.; Narayanan, S. Travel Time Differences between Cargo Cycles and Cars in Commercial Transport Operations. Transp. Res. Rec. J. Transp. Res. Board 2019, 2673, 623–637. [Google Scholar] [CrossRef] [Green Version]

- Blazejewski, L.; Sherriff, G.; Davies, N. Harnessing the potential of e-cargo bikes. Logist. Transp. Focus 2020, 22, 28–29. [Google Scholar]

- Mühlbauer, F.; Fontaine, P. A parallelised large neighbourhood search heuristic for the asymmetric two-echelon vehicle routing problem with swap containers for cargo-bicycles. Eur. J. Oper. Res. 2021, 289, 742–757. [Google Scholar] [CrossRef]

- van Heeswijk, W.; Larsen, R.; Larsen, A. An urban consolidation center in the city of Copenhagen: A simulation study. Int. J. Sustain. Transp. 2019, 13, 675–691. [Google Scholar] [CrossRef]

- Toth, P.; Vigo, D. The vehicle Routing Problem; SIAM Monographs on Discrete Mathematics and Applications, SIAM: Philadelphia, PA, USA, 2002. [Google Scholar]

- Huang, Y.; Savelsbergh, M.; Zhao, L. Designing logistics systems for home delivery in densely populated urban areas. Transp. Res. Part B Methodol. 2018, 115, 95–125. [Google Scholar] [CrossRef]

- Hemmelmayr, V.C.; Cordeau, J.F.; Crainic, T.G. An adaptive large neighborhood search heuristic for Two-Echelon Vehicle Routing Problems arising in city logistics. Comput. Oper. Res. 2012, 39, 3215–3228. [Google Scholar] [CrossRef] [Green Version]

- Crainic, T.G.; Perboli, G.; Mancini, S.; Tadei, R. Two-echelon vehicle routing problem: A satellite location analysis. Procedia-Soc. Behav. Sci. 2010, 2, 5944–5955. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Yuan, J.; Lv, T.; Chang, X. The two-echelon time-constrained vehicle routing problem in linehaul-delivery systems considering carbon dioxide emissions. Transp. Res. Part D Transp. Environ. 2016, 49, 231–245. [Google Scholar] [CrossRef]

- Cattaruzza, D.; Absi, N.; Feillet, D. Vehicle routing problems with multiple trips. 4OR 2016, 14, 223–259. [Google Scholar] [CrossRef]

- Cattaruzza, D.; Absi, N.; Feillet, D. The multi-trip vehicle routing problem with time windows and release dates. Transp. Sci. 2016, 50, 676–693. [Google Scholar] [CrossRef] [Green Version]

- Hommen, M. Marktübersicht: Die Aktuellen Elektro-Transporter. 2021. Available online: https://www.adac.de/rund-ums-fahrzeug/elektromobilitaet/kaufen/e-transporter/ (accessed on 26 May 2021).

- Azi, N.; Gendreau, M.; Potvin, J.Y. An exact algorithm for a vehicle routing problem with time windows and multiple use of vehicles. Eur. J. Oper. Res. 2010, 202, 756–763. [Google Scholar] [CrossRef]

- Using ArcGIS Online Routing Services. 2021. Available online: https://pro.arcgis.com/en/pro-app/latest/help/analysis/networks/arcgis-online-services.htm (accessed on 24 May 2021).

- Vehicle Routing Problem Analysis Layer: ArcGIS Pro Documentation. 2021. Available online: https://pro.arcgis.com/en/pro-app/latest/help/analysis/networks/vehicle-routing-problem-analysis-layer.htm (accessed on 8 April 2021).

- About Esri: The Science of Where. 2021. Available online: https://www.esri.com/en-us/about/about-esri/overview (accessed on 24 May 2021).

- Anbuudayasankar, S.P.; Ganesh, K.; Mohapatra, S. (Eds.) Models for Practical Routing Problems in Logistics: Design and Practices; Springer: Cham, Switzerland, 2014. [Google Scholar]

- Glover, F.; Laguna, M. Tabu Search. In Handbook of Combinatorial Optimization; Du, D.Z., Pardalos, P.M., Eds.; Springer: Boston, MA, USA, 1998; pp. 2093–2229. [Google Scholar] [CrossRef]

- Stadt Innsbruck. Fahren in Fußgängerzonen. 2021. Available online: https://www.innsbruck.gv.at/page.cfm?vpath=umwelt–verkehr/fussgaengerinnen/fussgaengerzonen (accessed on 3 June 2021).

- Dag, R. KoMoDo—Paketauslieferung per Lastenrad Erfolgreich Erprobt. 2019. Available online: https://www.komodo.berlin/projektergebnisse (accessed on 11 March 2021).

- Tipagornwong, C.; Figliozzi, M. Analysis of Competitiveness of Freight Tricycle Delivery Services in Urban Areas. Transp. Res. Rec. J. Transp. Res. Board 2014, 2410, 76–84. [Google Scholar] [CrossRef] [Green Version]

- McLeod, F.N.; Cherrett, T.J.; Bektas, T.; Allen, J.; Martinez-Sykora, A.; Lamas-Fernandez, C.; Bates, O.; Cheliotis, K.; Friday, A.; Piecyk, M.; et al. Quantifying environmental and financial benefits of using porters and cycle couriers for last-mile parcel delivery. Transp. Res. Part D Transp. Environ. 2020, 82, 102311. [Google Scholar] [CrossRef]

- Weidemann, T. Warum Paketboten Immer Seltener Klingeln und Was du Dagegen tun Kannst. 2018. Available online: https://t3n.de/news/warum-paketboten-immer-seltener-klingeln-und-was-du-dagegen-tun-kannst-1097083/ (accessed on 2 May 2021).

- Perboli, G.; Rosano, M. Parcel delivery in urban areas: Opportunities and threats for the mix of traditional and green business models. Transp. Res. Part C Emerg. Technol. 2019, 99, 19–36. [Google Scholar] [CrossRef]

- Eigenbauer, A.; Urbantschitsch, W. Stromkennzeichnungsbericht 2020: Unsere Energie. Für klare Kennzeichnung. Available online: https://www.e-control.at/documents/1785851/1811582/E-Control-Stromkennzeichnungsbericht-2020.pdf/1f27276a-9743-4607-c163-59558b735b42?t=1604916217802 (accessed on 8 April 2021).

- Koning, M.; Conway, A. The good impacts of biking for goods: Lessons from Paris city. Case Stud. Transp. Policy 2016, 4, 259–268. [Google Scholar] [CrossRef]

- Klima-Kollekte Österreich. Kosten einer Tonne CO2. 2021. Available online: https://klima-kollekte.at/kompensieren/kosten-einer-tonne-co2 (accessed on 19 May 2021).

- Presse- und Informationsamt der Bundesregierung Deutschlands. Grundlage für CO2-Preis Steht. 2020. Available online: https://www.bundesregierung.de/breg-de/themen/klimaschutz/nationaler-emissionshandel-1684508 (accessed on 19 May 2021).

- Thomasson, E.; Alkousaa, R. FACTBOX-In Germany, Competition Heats Up between Two Logistics Giants. 2019. Available online: https://www.reuters.com/article/amazoncom-logistics-idUKL5N269413 (accessed on 11 May 2021).

- Wachotsch, U.; Kolodziej, A.; Specht, B.; Kohlmeyer, R.; Petrikowski, F. E-Rad Macht Mobil: Potenziale von Pedelecs und deren Umweltwirkung. 2014. Available online: https://www.umweltbundesamt.de/publikationen/e-rad-macht-mobil (accessed on 8 April 2021).

| Parameter | Cargo Bike | Van (Base Case) | E-Van (First Stage) | |

|---|---|---|---|---|

| Travel | Max Speed | 25 km/h | - | 100 km/h |

| Depots | Locations | Main St., West St. | RDC | RDC |

| Fair, Congress | ||||

| Routes | Earliest Start Time | 06:00:00 | 06:00:00 | - |

| Latest Start Time | 08:00:00 | 08:00:00 | - | |

| Start Depot Service Time | 20 min | 30 min | 30 min | |

| End Depot Service Time | 10 min | 10 min | 10 min | |

| Capacity | 40 parcels | 160 parcels | 160 parcels | |

| Fixed Cost | 15.00 € | 30.00 € | 40.00 € | |

| Cost Per Unit Time | 0.33 €/min | 0.33 €/min | 0.33 €/min | |

| Cost Per Unit Distance | 0.04 €/km | 0.14 €/km | 0.04 €/km | |

| Max. Total Distance | 80 km | 500 km | 200 km | |

| Max. Total Time | 480 min | 480 min | 480 min | |

| Orders | Service Time | 2 min | 4 min | 30 min |

| Number Parcels per Stop | 1.3 parcels | 1.8 parcels | 4154 parcels | |

| TW Start | - | (06:00:00) | - | |

| TW End | - | (10:30:00) | 06:00:00 | |

| Route Renewals | Service Time | 10 min | 30 min | 30 min |

| Depot | Main Station | West Station | Fair | Congress |

|---|---|---|---|---|

| Stop Count | 3193 | 3193 | 3193 | 3193 |

| Parcel Count | 4154 | 4154 | 4154 | 4154 |

| Total Number of Bikes | 23 | 24 | 24 | 24 |

| Avg. Order Count per Bike | 139 | 133 | 133 | 133 |

| Avg. Parcel Count per Bike | 180 | 173 | 173 | 173 |

| Avg. Number of Renewals | 4 | 3.8 | 3.8 | 3.8 |

| Total Cost | 3732.14 € | 3797.07 € | 3775.54 € | 3810.38 € |

| Time Cost | 3361.39 € | 3408.15 € | 3389.64 € | 3423.83 € |

| Distance Cost | 25.75 € | 28.92 € | 25.91 € | 26.56 € |

| Total Time | 181 h 16 m | 184 h 8 m | 183 h 12 m | 184 h 55 m |

| Avg. Time per Bike | 7 h 53 m | 7 h 40 m | 7 h 38 m | 7 h 42 m |

| Total Travel Time | 36 h 40 m | 38 h 32 m | 37 h 46 m | 39 h 29 m |

| Avg. Travel Time Per Bike | 1 h 36 m | 1 h 36 m | 1 h 34 m | 1 h 39 m |

| Total Distance | 643.7 km | 723.0 km | 647.6 km | 663.9 km |

| Avg. Distance per Bike | 28.0 km | 30.1 km | 27.0 km | 27.7 km |

| Parameter | Random Demand | Service Time: 3 min | Service Time: 3.5 min | Capacity: 30 parcels | Capacity: 50 parcels | Renewal Time: 20 min | Renewal Time: 5 min | Max. Time: 510 min | Fixed Cost: 20.00 € | Distance Cost: 0.01 € |

|---|---|---|---|---|---|---|---|---|---|---|

| No. Bikes | 0.00 | 31.60 | 48.50 | 6.30 | −7.00 | 13.00 | −6.30 | −7.30 | 0.00 | 0.00 |

| Avg. no. Parcels | 0.00 | −24.00 | −32.00 | −5.90 | 7.60 | −11.00 | 6.80 | 8.00 | 0.00 | 0.00 |

| Avg. No. Renewals | −1.50 | −25.00 | −37.00 | 27.10 | −18.00 | −11.00 | 9.10 | 10.90 | 0.30 | 0.70 |

| Total Cost | 0.10 | 33.30 | 49.00 | 7.80 | −5.70 | 10.50 | −5.00 | −0.90 | 3.30 | −0.60 |

| Time Cost | 0.10 | 33.80 | 49.40 | 7.80 | −5.50 | 10.30 | −4.90 | −0.20 | 0.20 | 0.00 |

| Distance Cost | −0.90 | 2.30 | 0.50 | 20.60 | −15.00 | 0.90 | −1.50 | −0.30 | 0.10 | −74.00 |

| Total Time | 0.10 | 33.60 | 49.30 | 7.70 | −5.60 | 10.50 | −5.00 | −0.70 | 0.20 | 0.00 |

| Avg. Time per Bike | 0.10 | 1.60 | 0.60 | 1.30 | 1.50 | −2.30 | 1.50 | 7.20 | 0.20 | 0.00 |

| Total Travel Time | 0.90 | 3.10 | 0.70 | 19.30 | −13.00 | 2.20 | −0.50 | 0.30 | 0.70 | −0.50 |

| Avg. Travel Time per Bike | 0.90 | −21.00 | −32.00 | 12.20 | −6.70 | −9.60 | 6.30 | 8.30 | 0.70 | −0.50 |

| Total Distance | −0.90 | 2.30 | 0.50 | 20.60 | −15.00 | 0.90 | −1.50 | −0.30 | 0.10 | 3.30 |

| Avg. Distance per Bike | −0.90 | −22.00 | −32.00 | 13.50 | −8.80 | −10.00 | 5.20 | 7.60 | 0.10 | 3.30 |

| Hub Solution with Cargo Bikes and E-Vans | Basic System | ||||

|---|---|---|---|---|---|

| Depot | Main St. | West St. | Fair | Congress | |

| Nr. Bikes and Vans | 23 bikes, | 24 bikes, | 24 bikes, | 24 bikes, | 28 vans |

| 5 e-vans | 5 e-vans | 6 e-vans | 6 e-vans | ||

| Total Cost | 4639.16 € | 4705.67 € | 4763.83 € | 4781.36 € | 4860.81 € |

| Regular Time Cost | 4050.57 € | 4098.79 € | 4121.19 € | 4138.51 € | 3907.95 € |

| Distance Cost | 43.59 € | 46.88 € | 42.64 € | 42.86 € | 112.86 € |

| Emissions | 8.4 kgCO | 8.5 kgCO | 9.9 kgCO | 9.0 kgCO | 242 kgCO |

| Worst Case | Realistic Case | Best Case | |

|---|---|---|---|

| Average Parcel Count per Bike | 119 | 160 | 189 |

| Difference in Costs compared to the Basic System | −1372.09 € | 110.40 € | 695.29 € |

| CO-emissions Savings | 96.50% | 96.50% | 96.60% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Büttgen, A.; Turan, B.; Hemmelmayr, V. Evaluating Distribution Costs and CO2-Emissions of a Two-Stage Distribution System with Cargo Bikes: A Case Study in the City of Innsbruck. Sustainability 2021, 13, 13974. https://doi.org/10.3390/su132413974

Büttgen A, Turan B, Hemmelmayr V. Evaluating Distribution Costs and CO2-Emissions of a Two-Stage Distribution System with Cargo Bikes: A Case Study in the City of Innsbruck. Sustainability. 2021; 13(24):13974. https://doi.org/10.3390/su132413974

Chicago/Turabian StyleBüttgen, Anne, Belma Turan, and Vera Hemmelmayr. 2021. "Evaluating Distribution Costs and CO2-Emissions of a Two-Stage Distribution System with Cargo Bikes: A Case Study in the City of Innsbruck" Sustainability 13, no. 24: 13974. https://doi.org/10.3390/su132413974

APA StyleBüttgen, A., Turan, B., & Hemmelmayr, V. (2021). Evaluating Distribution Costs and CO2-Emissions of a Two-Stage Distribution System with Cargo Bikes: A Case Study in the City of Innsbruck. Sustainability, 13(24), 13974. https://doi.org/10.3390/su132413974