Sustainable Manufacturing 4.0—Pathways and Practices

Abstract

:1. Introduction

2. Methods

2.1. Search Strategy

2.2. Data Collection and Analysis

3. Results and Discussion

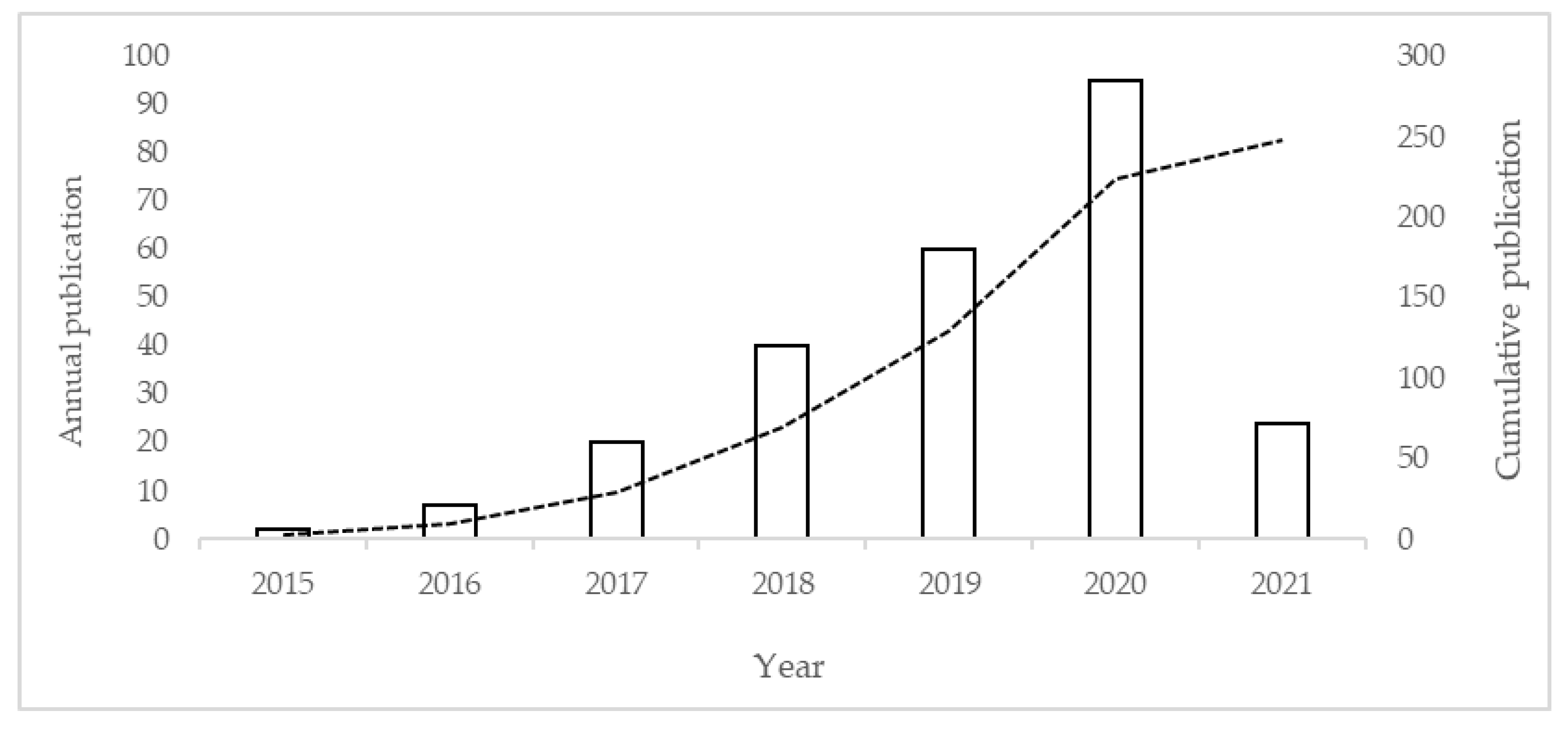

3.1. Growth of Research Interest

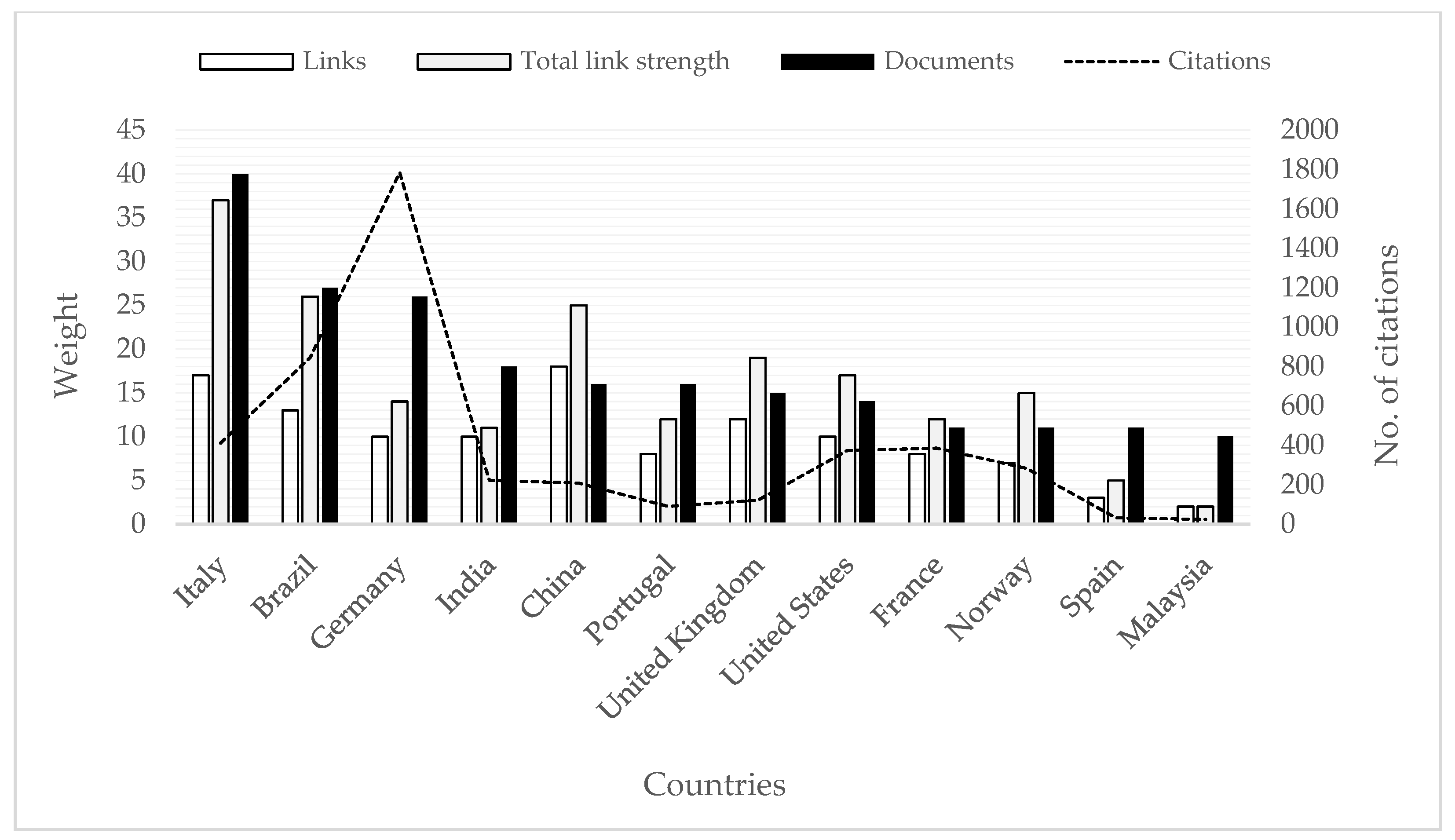

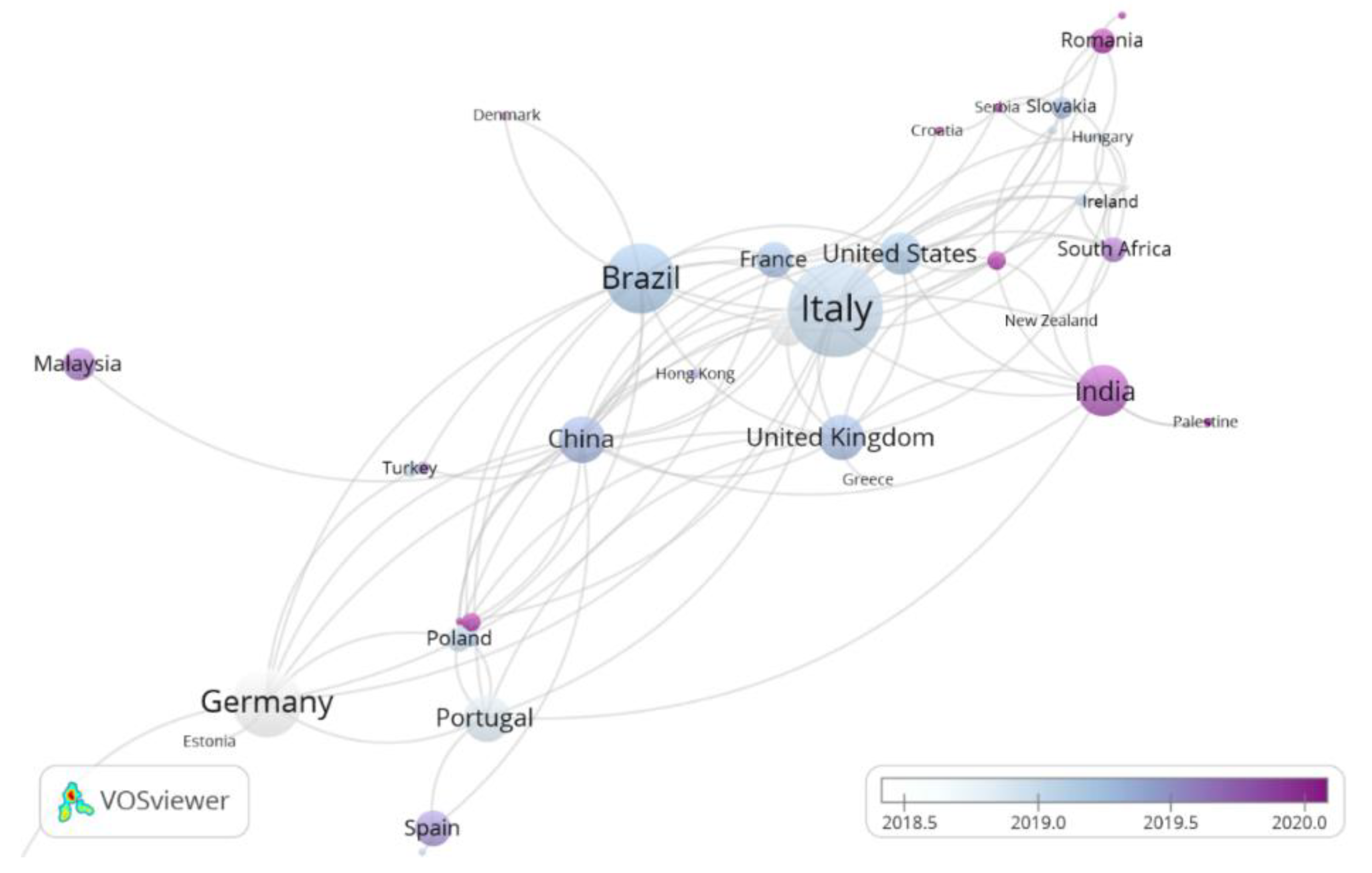

3.2. Leading Countries, Productive Institutions, and International Collaboration

3.3. Most Proactive Journals, Highly Cited Articles, and Prolific Authors

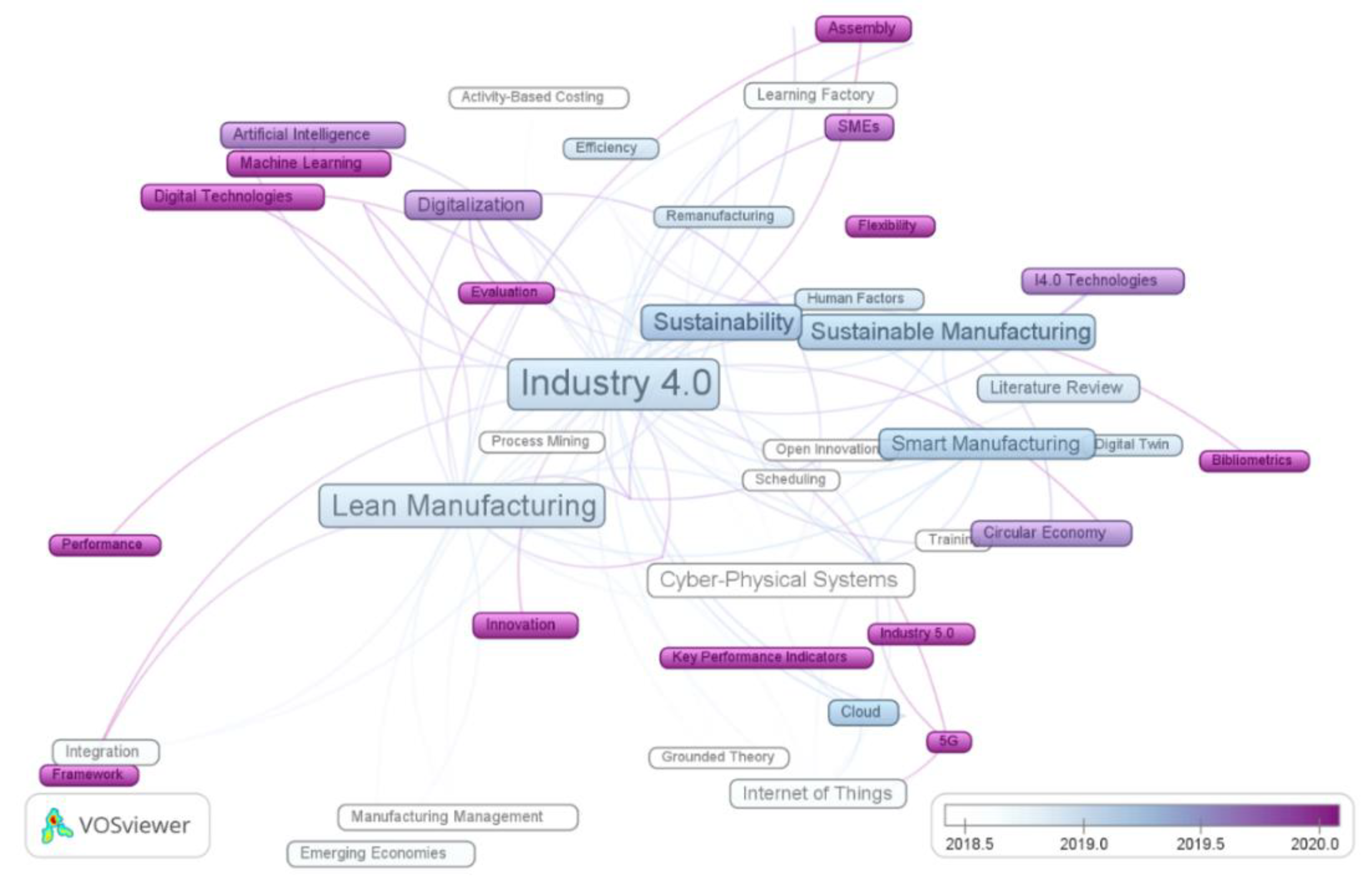

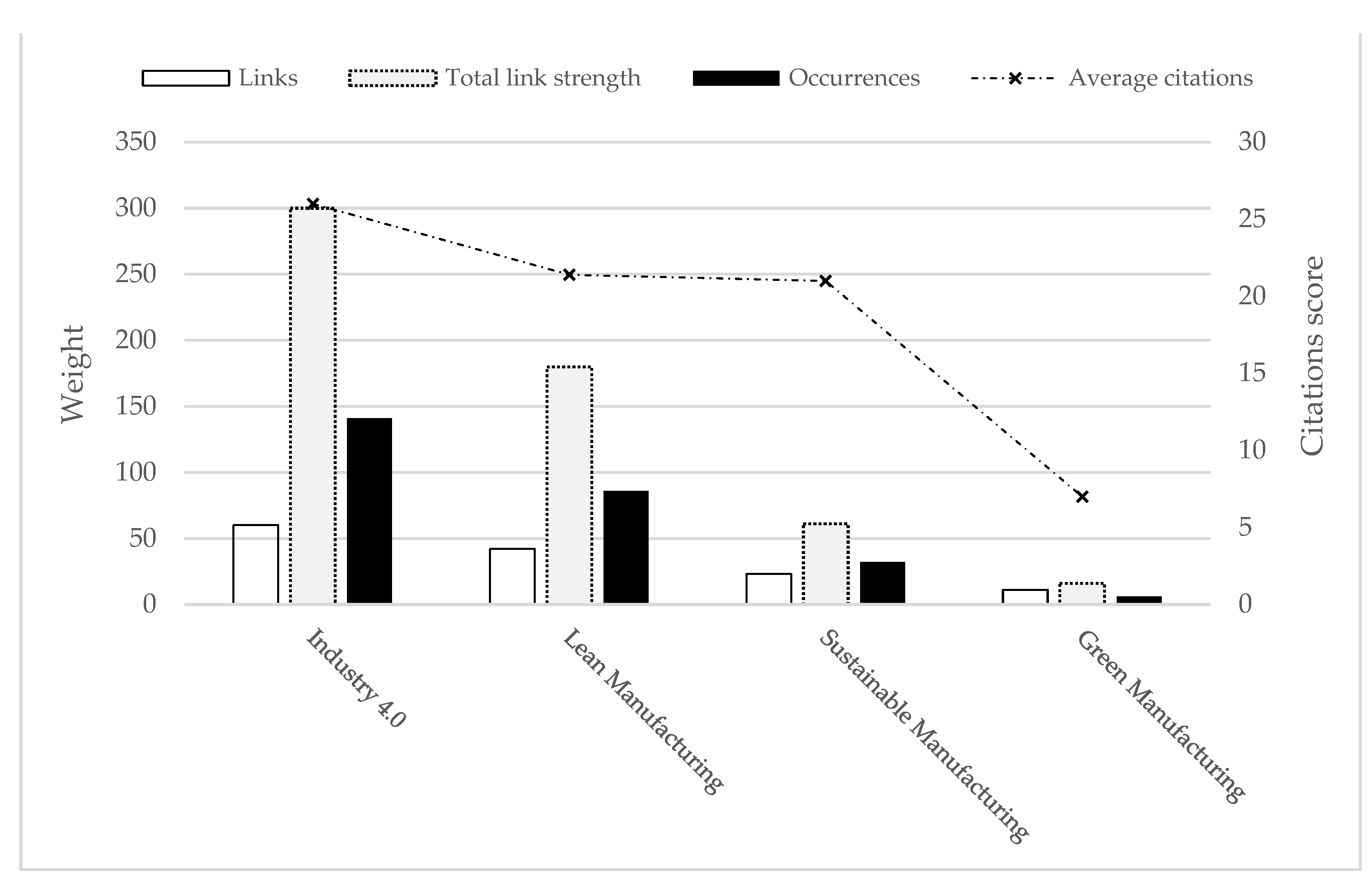

3.4. Topmost Keywords and Influential Publications Distributed to Major Keywords

| Rank | Authors | Year | Title | Source Title | Times Cited | Document Type |

|---|---|---|---|---|---|---|

| 1. | [37] | 2016 | Industry 4.0 implies lean manufacturing: Research activities in industry 4.0 function as enablers for lean manufacturing | Journal of Industrial Engineering and Management | 275 | Article |

| 2. | [7] | 2015 | Lean Automation enabled by Industry 4.0 Technologies | IFAC-PapersOnLine | 249 | Conference Paper |

| 3. | [30] | 2018 | The link between industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda | International Journal of Production Research | 220 | Article |

| 4. | [29] | 2018 | Implementation of industry 4.0 and lean production in Brazilian manufacturing companies | International Journal of Production Research | 199 | Article |

| 5. | [35] | 2017 | Towards Lean Production in Industry 4.0 | Procedia Engineering | 180 | Conference Paper |

| 6. | [39] | 2017 | Industry 4.0 Impacts on Lean Production Systems | Procedia CIRP | 143 | Conference Paper |

| 7. | [42] | 2017 | Towards a lean automation interface for workstations | International Journal of Production Research | 99 | Article |

| 8. | [43] | 2020 | Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies | International Journal of Production Research | 69 | Article |

| 9. | [44] | 2017 | Review of Socio-technical Considerations to Ensure Successful Implementation of Industry 4.0 | Procedia Manufacturing | 65 | Article |

| 10. | [33] | 2019 | The interrelation between Industry 4.0 and lean production: an empirical study on European manufacturers | International Journal of Advanced Manufacturing Technology | 55 | Article |

| Rank | Authors | Year | Title | Source Title | Times Cited | Document Type |

|---|---|---|---|---|---|---|

| 1. | [38] | 2018 | China’s manufacturing locus in 2025: With a comparison of “Made-in-China 2025” and “Industry 4.0” | Technological Forecasting and Social Change | 257 | Article |

| 2. | [45] | 2018 | Green production planning and control for the textile industry by using mathematical programming and industry 4.0 techniques | Energies | 20 | Article |

| 3. | [46] | 2018 | Green production planning and control model with ABC under industry 4.0 for the paper industry | Sustainability (Switzerland) | 16 | Article |

| 4. | [47] | 2020 | Industry 4.0 and the circular economy: Resource melioration in logistics | Resources Policy | 15 | Article |

| 5. | [48] | 2016 | Toward dynamic energy management for green manufacturing systems | IEEE Communications Magazine | 11 | Article |

| 6. | [49] | 2017 | Enhancing the competitiveness of manufacturers through Small-scale Intelligent Manufacturing System (SIMS): A supply chain perspective | 2017 6th International Conference on Industrial Technology and Management, ICITM 2017 | 10 | Conference Paper |

| 7. | [50] | 2020 | Modified Carroll’s pyramid of corporate social responsibility to enhance organizational performance of SMEs industry | Journal of Cleaner Production | 8 | Article |

| 8. | [51] | 2019 | Business Logistics Optimization Using Industry 4.0: Current Status and Opportunities | IEEE International Conference on Industrial Engineering and Engineering Management | 5 | Conference Paper |

| 9. | [52] | 2021 | Leveraging Optimized and Cleaner Production through Industry 4.0 | Sustainable Production and Consumption | 3 | Article |

| 10. | [53] | 2021 | Industry 3.5 for optimizing chiller configuration for energy saving and an empirical study for semiconductor manufacturing | Resources, Conservation and Recycling | 2 | Article |

| Rank | Authors | Year | Title | Source Title | Times Cited | Document Type |

|---|---|---|---|---|---|---|

| 1. | [19] | 2016 | Opportunities of Sustainable Manufacturing in Industry 4.0 | Procedia CIRP | 674 | Conference Paper |

| 2. | [10] | 2018 | When titans meet—Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors | Technological Forecasting and Social Change | 214 | Article |

| 3. | [5] | 2020 | Sustainable manufacturing in Industry 4.0: an emerging research agenda | International Journal of Production Research | 101 | Article |

| 4. | [54] | 2017 | On sustainable production networks for industry 4.0 | Entrepreneurship and Sustainability Issues | 71 | Article |

| 5. | [55] | 2018 | Manufacturing in the fourth industrial revolution: A positive prospect in Sustainable Manufacturing | Procedia Manufacturing | 66 | Conference Paper |

| 6. | [56] | 2018 | Biologicalisation: Biological transformation in manufacturing | CIRP Journal of Manufacturing Science and Technology | 56 | Article |

| 7. | [57] | 2017 | Enabling Circular Economy Through Product Stewardship | Procedia Manufacturing | 44 | Article |

| 8. | [58] | 2018 | Maintenance for Sustainability in the Industry 4.0 context: a Scoping Literature Review | IFAC-PapersOnLine | 43 | Conference Paper |

| 9. | [59] | 2019 | Industry 4.0—challenges to implement circular economy | Benchmarking | 32 | Article |

| 10. | [60] | 2018 | Exploring gamification to support manufacturing education on industry 4.0 as an enabler for innovation and sustainability | Procedia Manufacturing | 31 | Conference Paper |

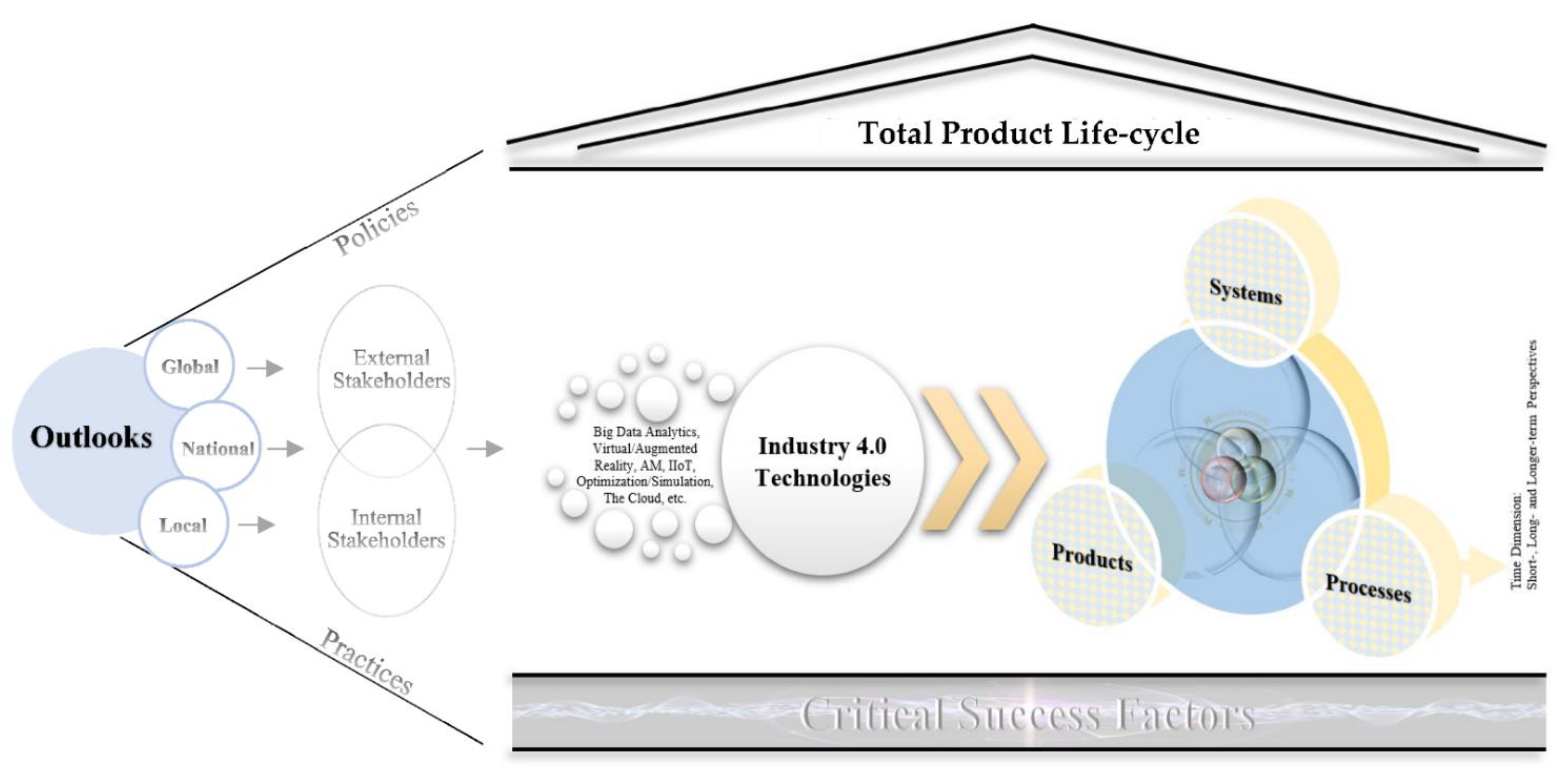

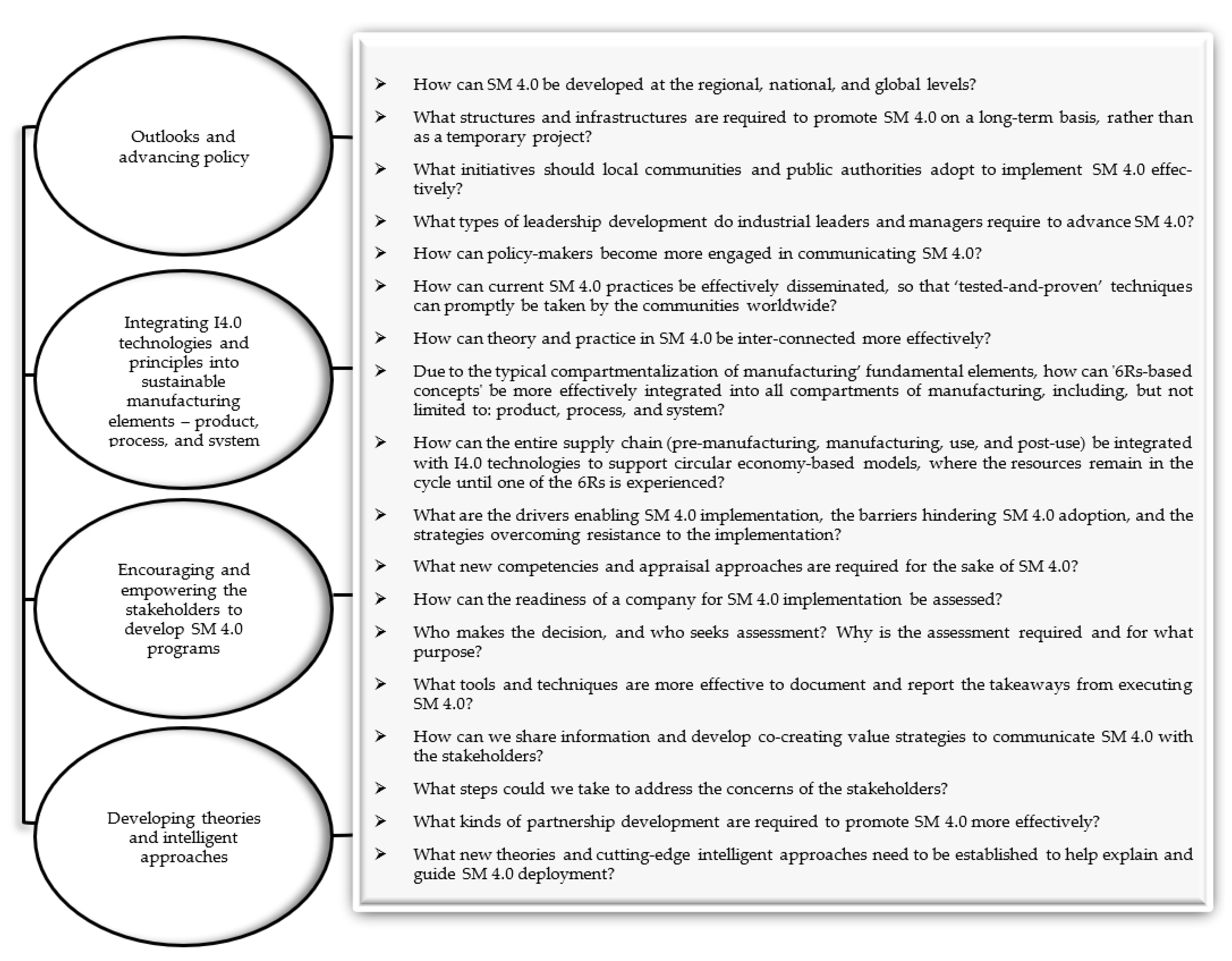

4. Pathways for Further Practices

- 1. Big Data Analytics—capable of improving direct/indirect costs, waste and emissions, and product end-of-life management at the product level [18,59,74,75]; energy consumption and environmental impact at the process level [9,18,76,77]; and net profit, operational performance, material use and efficiency, energy use and efficiency, and water use and efficiency at the system level [4,9,18].

- 2. Virtual and Augmented Reality—capable of improving product quality and durability, functional performance, and safety and health impact at the product level [18,77,78]; manufacturing cost, personnel health, and operational safety at the process level [4,18,79]; and net profit, operational performance, health and safety, and stakeholder engagement at the system level [18,80].

- 3. Optimization and Simulation—capable of improving functional performance at the product level [18,81]; manufacturing cost, energy consumption, environmental impact, personnel health, and operational safety at the process level [18,74,77]; and capital charge, manufacturing cost, operational performance, material use and efficiency, energy use and efficiency, water use and efficiency, waste and emission, and stakeholder engagement at the system level [4,18,82].

- 4. Additive Manufacturing—capable of improving initial investments, material use and efficiency, energy use and efficiency at the product level [4,18,19,75,83]; personnel health and operational safety at the process level [4,18]; and net profit, operational performance, health and safety, and stakeholder engagement at the system level [18,74].

- 5. Cloud—capable of improving functional performance, product end-of-life management, and safety and health impact at the product level [18,84]; manufacturing cost and waste management at the process level [18,77]; and net profit, manufacturing cost, operational performance, health and safety, and stakeholder engagement at the system level [18,74,85].

- 6. Industrial Internet of Things—capable of improving benefits and losses, product quality and durability, and product end-of-life management at the product level [8,18,78,84]; manufacturing cost, waste management, personnel health, operational safety at the process level [4,18,59,76,81]; and net profit, capital charge, operational performance, health and safety, and stakeholder engagement at the system level [18,59,76,86].

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries; Boston Consult, Group 9: Boston, MA, USA, 2015; pp. 54–89. [Google Scholar]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar] [CrossRef] [Green Version]

- Dalenogarea, L.S.; Beniteza, G.B.; Ayalab, N.F.; Franka, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Wee, D.; Kelly, R.; Cattel, J.; Breunig, M. Industry 4.0: How to Navigate Digitization of the Manufacturing Sector; McKinsey Company: Chicago, IL, USA, 2015. [Google Scholar]

- Machado, C.G.; Winroth, M.P.; Da Silva, E.H.D.R. Sustainable manufacturing in Industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Sartal, A.; Bellas, R.; Mejías, A.M.; García-Collado, A. The sustainable manufacturing concept, evolution and opportunities within Industry 4.0: A literature review. Adv. Mech. Eng. 2020, 12. [Google Scholar] [CrossRef]

- Kolberg, D.; Zühlke, D. Lean Automation enabled by Industry 4.0 Technologies. IFAC-PapersOnLine 2015, 48, 1870–1875. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef] [Green Version]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Luo, Z.; Wamba, S.F.; Roubaud, D. Can big data and predictive analytics improve social and environmental sustainability? Technol. Forecast. Soc. Chang. 2019, 144, 534–545. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Godinho Filho, M. When titans meet—Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Chang. 2018, 132, 18–25. [Google Scholar] [CrossRef]

- World Commission on Environment and Development. Our Common Future. (The Brundtland Report); Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Jawahir, I.; Dillon, O., Jr. Sustainable manufacturing processes: New challenges for developing predictive models and optimization techniques. In Proceedings of the First International Conference on Sustainable Manufacturing 2007, Montreal, QC, Canada, 18–19 October 2007. [Google Scholar]

- Gholami, H.; Jamil, N.; Zakuan, N.; Saman, M.Z.M.; Sharif, S.; Awang, S.R.; Sulaiman, Z. Social Value Stream Mapping (Socio-VSM): Methodology to Societal Sustainability Visualization and Assessment in the Manufacturing System. IEEE Access 2019, 7, 131638–131648. [Google Scholar] [CrossRef]

- Jamil, N.; Gholami, H.; Saman, M.Z.M.; Streimikiene, D.; Sharif, S.; Zakuan, N. DMAIC-based approach to sustainable value stream mapping: Towards a sustainable manufacturing system. Econ. Res.-Ekonomska Istraživanja 2020, 33, 331–360. [Google Scholar] [CrossRef]

- Jawahir, I.; Bradley, R. Technological Elements of Circular Economy and the Principles of 6R-Based Closed-loop Material Flow in Sustainable Manufacturing. Procedia CIRP 2016, 40, 103–108. [Google Scholar] [CrossRef] [Green Version]

- Jayal, A.D.; Badurdeen, F.; Dillon, O.W., Jr.; Jawahir, I.S. Sustainable manufacturing: Modeling and optimization challenges at the product, process and system levels. CIRP J. Manuf. Sci. Technol. 2010, 2, 144–152. [Google Scholar] [CrossRef]

- Badurdeen, F.; Jawahir, I. Strategies for Value Creation Through Sustainable Manufacturing. Procedia Manuf. 2017, 8, 20–27. [Google Scholar] [CrossRef]

- Enyoghasi, C.; Badurdeen, F. Industry 4.0 for sustainable manufacturing: Opportunities at the product, process, and system levels. Resour. Conserv. Recycl. 2021, 166, 105362. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Piwowar-Sulej, K.; Krzywonos, M.; Kwil, I. Environmental entrepreneurship—Bibliometric and content analysis of the subject literature based on H-Core. J. Clean. Prod. 2021, 295, 126277. [Google Scholar] [CrossRef]

- Abu, F.; Gholami, H.; Saman, M.Z.M.; Zakuan, N.; Sharif, S.; Streimikiene, D. Pathways of lean manufacturing in wood and furniture industries: A bibliometric and systematic review. Holz als Roh- Werkst. 2021, 79, 753–772. [Google Scholar] [CrossRef]

- Lee, J.K.Y.; Gholami, H.; Saman, M.Z.M.; Bin Ngadiman, N.H.A.; Zakuan, N.; Mahmood, S.; Omain, S.Z. Sustainability-Oriented Application of Value Stream Mapping: A Review and Classification. IEEE Access 2021, 9, 68414–68434. [Google Scholar] [CrossRef]

- Elsevier. Scopus Content Coverage Guide 2021. Available online: https://www.elsevier.com/solutions/scopus/content (accessed on 26 August 2021).

- Mansour, A.Z.; Ahmi, A.; Popoola, O.M.J.; Znaimat, A. Discovering the global landscape of fraud detection studies: A bibliometric review. J. Financ. Crime 2021. ahead-of-p. [Google Scholar] [CrossRef]

- Bernat, S.; Karabag, S.F. Strategic alignment of technology: Organising for technology upgrading in emerging economy firms. Technol. Forecast. Soc. Chang. 2019, 145, 295–306. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0. In Final Report of the Industrie 4.0 WG. 2013. Available online: https://www.din.de/blob/76902/e8cac883f42bf28536e7e8165993f1fd/recommendations-for-implementing-industry-4-0-data.pdf (accessed on 24 October 2021).

- Agenda 21. The United Nations Programme of Action from Rio; Unite Nations: New York, NY, USA, 1993. [Google Scholar]

- Gholami, H.; Saman, M.Z.M.; Sharif, S.; Khudzari, J.M.; Zakuan, N.; Streimikiene, D.; Streimikis, J. A General Framework for Sustainability Assessment of Sheet Metalworking Processes. Sustainability 2020, 12, 4957. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fettermann, D.C. Implementation of Industry 4.0 and lean production in Brazilian manufacturing companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Buer, S.-V.; Strandhagen, J.O.; Chan, F.T.S. The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef] [Green Version]

- Varela, L.; Araújo, A.; Ávila, P.; Castro, H.; Putnik, G. Evaluation of the Relation between Lean Manufacturing, Industry 4.0, and Sustainability. Sustainability 2019, 11, 1439. [Google Scholar] [CrossRef] [Green Version]

- Bag, S.; Pretorius, J.H.C. Relationships between industry 4.0, sustainable manufacturing and circular economy: Proposal of a research framework. Int. J. Organ. Anal. 2020. ahead-of-p. [Google Scholar] [CrossRef]

- Matteo, R.; Costa, F.; Tortorella, G.L.; Alberto, P.S. The interrelation between Industry 4.0 and lean production: An empirical study on European manufacturers. Int. J. Adv. Manuf. Technol. 2019, 102, 3963–3976. [Google Scholar]

- Powell, D.; Romero, D.; Gaiardelli, P.; Cimini, C.; Cavalieri, S. Towards Digital Lean Cyber-Physical Production Systems: Industry 4.0 Technologies as Enablers of Leaner Production. In Proceedings of the Advances in Production Management Systems: Smart Manufacturing for Industry 4.0, Seoul, Korea, 26–30 August 2018; Springer: Cham, Switzerland, 2018; Volume 536, pp. 353–362. [Google Scholar]

- Mrugalska, B.; Wyrwicka, M.K. Towards lean production in industry 4.0. Procedia Eng. 2017, 182, 466–473. [Google Scholar] [CrossRef]

- Ito, T.; Rahman, M.S.A.; Mohamad, E.; Rahman, A.A.A.; Salleh, M.R. Internet of things and simulation approach for decision support system in lean manufacturing. J. Adv. Mech. Des. Syst. Manuf. 2020, 14, JAMDSM0027. [Google Scholar] [CrossRef] [Green Version]

- Sanders, A.; Elangeswaran, C.; Wulfsberg, J.P. Industry 4.0 implies lean manufacturing: Research activities in industry 4.0 function as enablers for lean manufacturing. J. Ind. Eng. Manag. 2016, 9, 811–833. [Google Scholar] [CrossRef] [Green Version]

- Li, L. China’s manufacturing locus in 2025: With a comparison of “Made-in-China 2025” and “Industry 4.0”. Technol. Forecast. Soc. Chang. 2018, 135, 66–74. [Google Scholar] [CrossRef]

- Wagner, T.A.; Herrmann, C.; Thiede, S. Industry 4.0 Impacts on Lean Production Systems. Procedia CIRP 2017, 63, 125–131. [Google Scholar] [CrossRef]

- Pramanik, P.K.D.; Mukherjee, B.; Pal, S.; Upadhyaya, B.K.; Dutta, S. Ubiquitous Manufacturing in the Age of Industry 4.0: A State-of-the-Art Primer. Adv. Sustain. Environ. Hydrol. Hydrogeol. Hydrochem. Water Resour. 2019, 73–112. [Google Scholar] [CrossRef]

- de Miranda, S.S.F.; Aguayo-González, F.; Ávila-Gutiérrez, M.J.; Córdoba-Roldán, A. Neuro-Competence Approach for Sustainable Engineering. Sustainability 2021, 13, 4389. [Google Scholar] [CrossRef]

- Kolberg, D.; Knobloch, J.; Zühlke, D. Towards a lean automation interface for workstations. Int. J. Prod. Res. 2017, 55, 2845–2856. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int. J. Prod. Res. 2019, 58, 1319–1337. [Google Scholar] [CrossRef]

- Davies, R.; Coole, T.; Smith, A. Review of Socio-technical Considerations to Ensure Successful Implementation of Industry 4.0. Procedia Manuf. 2017, 11, 1288–1295. [Google Scholar] [CrossRef]

- Tsai, W.-H. Green Production Planning and Control for the Textile Industry by Using Mathematical Programming and Industry 4.0 Techniques. Energies 2018, 11, 2072. [Google Scholar] [CrossRef] [Green Version]

- Tsai, W.-H.; Lai, S.-Y. Green Production Planning and Control Model with ABC under Industry 4.0 for the Paper Industry. Sustainability 2018, 10, 2932. [Google Scholar] [CrossRef] [Green Version]

- Bag, S.; Yadav, G.; Wood, L.C.; Dhamija, P.; Joshi, S. Industry 4.0 and the circular economy: Resource melioration in logistics. Resour. Policy 2020, 68, 101776. [Google Scholar] [CrossRef]

- Oh, E.; Son, S.-Y. Toward dynamic energy management for green manufacturing systems. IEEE Commun. Mag. 2016, 54, 74–79. [Google Scholar] [CrossRef]

- Yu, H.; Solvang, W.D. Enhancing the competitiveness of manufacturers through Small-scale Intelligent Manufacturing System (SIMS): A supply chain perspective. In Proceedings of the 2017 6th International Conference on Industrial Technology and Management (ICITM), Cambridge, UK, 7–10 March 2017; pp. 101–107. [Google Scholar] [CrossRef] [Green Version]

- Lu, J.; Ren, L.; Zhang, C.; Rong, D.; Ahmed, R.R.; Streimikis, J. Modified Carroll’s pyramid of corporate social responsibility to enhance organizational performance of SMEs industry. J. Clean. Prod. 2020, 271, 122456. [Google Scholar] [CrossRef]

- Surajit, B.; Telukdarie, A. Business Logistics Optimization Using Industry 4.0: Current Status and Opportunities. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; pp. 1558–1562. [Google Scholar]

- Amjad, M.S.; Rafique, M.Z.; Khan, M.A. Leveraging Optimized and Cleaner Production through Industry 4.0. Sustain. Prod. Consum. 2021, 26, 859–871. [Google Scholar] [CrossRef]

- Chien, C.-F.; Chen, Y.-J.; Han, Y.-T.; Wu, Y.-C. Industry 3.5 for optimizing chiller configuration for energy saving and an empirical study for semiconductor manufacturing. Resour. Conserv. Recycl. 2020, 168, 105247. [Google Scholar] [CrossRef]

- Prause, G.; Atari, S. On sustainable production networks for Industry 4.0. Entrep. Sustain. Issues 2017, 4, 421–431. [Google Scholar] [CrossRef]

- Carvalho, N.; Chaim, O.; Cazarini, E.; Gerolamo, M. Manufacturing in the fourth industrial revolution: A positive prospect in Sustainable Manufacturing. Procedia Manuf. 2018, 21, 671–678. [Google Scholar] [CrossRef]

- Byrne, G.; Dimitrov, D.; Monostori, L.; Teti, R.; van Houten, F.; Wertheim, R. Biologicalisation: Biological transformation in manufacturing. CIRP J. Manuf. Sci. Technol. 2018, 21, 1–32. [Google Scholar] [CrossRef]

- Jensen, J.; Remmen, A. Enabling Circular Economy Through Product Stewardship. Procedia Manuf. 2017, 8, 377–384. [Google Scholar] [CrossRef]

- Franciosi, C.; Iung, B.; Miranda, S.; Riemma, S. Maintenance for Sustainability in the Industry 4.0 context: A Scoping Literature Review. IFAC-PapersOnLine 2018, 51, 903–908. [Google Scholar] [CrossRef]

- Rajput, S.; Singh, S.P. Industry 4.0—challenges to implement circular economy. Benchmarking Int. J. 2019, 28, 1717–1739. [Google Scholar] [CrossRef]

- Paravizo, E.; Chaim, O.C.; Braatz, D.; Muschard, B.; Rozenfeld, H. Exploring gamification to support manufacturing education on industry 4.0 as an enabler for innovation and sustainability. Procedia Manuf. 2018, 21, 438–445. [Google Scholar] [CrossRef]

- Joung, C.B.; Carrell, J.; Sarkar, P.; Feng, S.C. Categorization of indicators for sustainable manufacturing. Ecol. Indic. 2013, 24, 148–157. [Google Scholar] [CrossRef]

- Ragland, B. Measure, Metric or Indicator: What’s the Difference? Crosstalk 1995, 8, 29–30. [Google Scholar]

- Jawahir, I.S.; Wanigarathne, P.C.; Wang, X. Chapter 12: Product Design and Manufacturing Processes for Sustainability. In Mechanical Engineering Handbook, 3rd ed.; Kutz, M., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2006; Volume 3, pp. 414–443. [Google Scholar]

- Haapala, K.R.; Zhao, F.; Camelio, J.; Sutherland, J.W.; Skerlos, S.J.; Dornfeld, D.A.; Jawahir, I.S.; Clarens, A.F.; Rickli, J. A Review of Engineering Research in Sustainable Manufacturing. J. Manuf. Sci. Eng. 2013, 135, 041013. [Google Scholar] [CrossRef] [Green Version]

- Shuaib, M.; Seevers, D.; Zhang, X.; Badurdeen, F.; Rouch, K.E.; Jawahir, I. Product sustainability index (ProdSI) a metrics-based framework to evaluate the total life cycle sustainability of manufactured products. J. Ind. Ecol. 2014, 18, 491–507. [Google Scholar] [CrossRef]

- Razavi, S.; Jakeman, A.; Saltelli, A.; Prieur, C.; Iooss, B.; Borgonovo, E.; Plischke, E.; Piano, S.L.; Iwanaga, T.; Becker, W.; et al. The Future of Sensitivity Analysis: An essential discipline for systems modeling and policy support. Environ. Model. Softw. 2021, 137, 104954. [Google Scholar] [CrossRef]

- Lu, T.; Jawahir, I. Metrics-based Sustainability Evaluation of Cryogenic Machining. Procedia CIRP 2015, 29, 520–525. [Google Scholar] [CrossRef]

- Huang, A.; Badurdeen, F. Metrics-based approach to evaluate sustainable manufacturing performance at the production line and plant levels. J. Clean. Prod. 2018, 192, 462–476. [Google Scholar] [CrossRef]

- Huang, A.; Badurdeen, F. Sustainable Manufacturing Performance Evaluation at the Enterprise Level: Index- and Value-Based Methods. Smart Sustain. Manuf. Syst. 2017, 1, 178–203. [Google Scholar] [CrossRef]

- Saad, M.H.; Nazzal, M.A.; Darras, B.M. A general framework for sustainability assessment of manufacturing processes. Ecol. Indic. 2019, 97, 211–224. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A.; Kumar, V.; Chaikittisilp, S.; Tan, K.H. The effect of lean methods and tools on the environmental performance of manufacturing organisations. Int. J. Prod. Econ. 2018, 200, 170–180. [Google Scholar] [CrossRef]

- Vinodh, S.; Ben Ruben, R.; Asokan, P. Life cycle assessment integrated value stream mapping framework to ensure sustainable manufacturing: A case study. Clean Technol. Environ. Policy 2015, 18, 279–295. [Google Scholar] [CrossRef]

- Gholami, H.; Jamil, N.; Saman, M.Z.M.; Streimikiene, D.; Sharif, S.; Zakuan, N. The application of Green Lean Six Sigma. Bus. Strat. Environ. 2021, 30, 1913–1931. [Google Scholar] [CrossRef]

- Song, Z.; Moon, Y. Assessing sustainability benefits of cybermanufacturing systems. Int. J. Adv. Manuf. Technol. 2016, 90, 1365–1382. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Blunck, E.; Werthmann, H. Industry 4.0—An Opportunity to Realize Sustainable Manufacturing and Its Potential for a Circular Economy. In Proceedings of the DIEM—Dubrovnik International Economic Meeting, Dubrovnik, Croatia, 2–14 October 2017; Volume 3, pp. 644–666. Available online: https://hrcak.srce.hr/187419 (accessed on 29 August 2021).

- Carvalho, A.C.P.; Carvalho, A.P.P.; Carvalho, N.G.P. Chapter 3: Industry 4.0 Technologies: What Is Your Potential for Environmental Management? In Industry 4.0—Current Status and Future Trends; IntechOpen: London, UK, 2020; pp. 26–44. [Google Scholar]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Menon, S.; Shah, S.; Coutroubis, A. Impacts of I4. 0 on sustainable manufacturing to achieve competitive advantage. In Proceedings of the 8th International Conference on Operations and Supply Chain Management, Cranfield, UK, 9–12 September 2018. [Google Scholar]

- Rumsey, A.; Le Dantec, C.A. Manufacturing Change: The Impact of Virtual Environments on Real Organizations. In Proceedings of the 2020 CHI Conference on Human Factors in Computing Systems, Honolulu, HI, USA, 25–30 April 2020; ACM Press: New York, NY, USA, 2020. [Google Scholar]

- MacArthur, E.; Waughray, D. Intelligent Assets: Unlocking the Circular Economy Potential 2016; Ellen MacArthur Foundation: Cowes, UK, 2016. [Google Scholar]

- Hashemi, A.; Gholami, H.; Venkatadri, U.; Karganroudi, S.S.; Khouri, S.; Wojciechowski, A.; Streimikiene, D. A New Direct Coefficient-Based Heuristic Algorithm for Set Covering Problems. Int. J. Fuzzy Syst. 2021, 1–17. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Ivanov, D. New Drivers for Supply Chain Structural Dynamics and Resilience: Sustainability, Industry 4.0, Self-Adaptation. In International Series in Operations Research & Management Science; Springer: Singapore, 2017; pp. 293–313. [Google Scholar]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Sala, S.; Ciuffo, B.; Nijkamp, P. A systemic framework for sustainability assessment. Ecol. Econ. 2015, 119, 314–325. [Google Scholar] [CrossRef]

- Garetti, M.; Taisch, M. Sustainable manufacturing: Trends and research challenges. Prod. Plan. Control 2011, 23, 83–104. [Google Scholar] [CrossRef]

- Labuschagne, C.; Brent, A.; van Erck, R.P. Assessing the sustainability performances of industries. J. Clean. Prod. 2005, 13, 373–385. [Google Scholar] [CrossRef] [Green Version]

- Bell, E.; Bryman, A.; Harley, B. Business Research Methods, 5th ed.; Oxford University Press Inc.: New York, NY, USA, 2018. [Google Scholar]

| No * | Keyword Search | Article | Conference Paper | Review Paper | Others | Total |

|---|---|---|---|---|---|---|

| (i) | “Sustainable production” | 4089 | 856 | 749 | 698 | 6392 |

| (i) | “Sustainable manufacturing” | 936 | 741 | 115 | 162 | 1954 |

| (i) | “Green production” | 624 | 147 | 66 | 60 | 897 |

| (i) | “Green manufacturing” | 601 | 487 | 46 | 106 | 1240 |

| (i) | “Lean production” | 1092 | 798 | 96 | 154 | 2140 |

| (i) | “Lean manufacturing” | 1778 | 1454 | 273 | 373 | 3878 |

| (ii) | “Fourth industrial revolution” | 1134 | 1160 | 127 | 258 | 2679 |

| (ii) | “4th industrial revolution” | 226 | 250 | 18 | 54 | 548 |

| (ii) | “Industry 4.0” | 3341 | 5191 | 345 | 1017 | 9894 |

| (ii) | “IR 4.0” | 69 | 53 | 7 | 1 | 130 |

| (ii) | “I4.0” | 144 | 216 | 25 | 24 | 409 |

| (iii) | Keywords’ combination | 96 | 119 | 13 | 20 | 248 |

| Affiliation | Country | National Context | No. of Documents | Total Citations | Most Cited Article (Times Cited) |

|---|---|---|---|---|---|

| Universidade Federal de Santa Catarina | Brazil | Emerging country | 9 | 334 | Tortorella and Fettermann [29] (199) |

| Norges teknisk-naturvitenskapelige universitet | Norway | Developed country | 8 | 268 | Buer et al. [30] (220) |

| Universidade do Minho | Portugal | Developed country | 6 | 69 | Varela et al. [31] (38) |

| University of Johannesburg | South Africa | Developing country | 6 | 61 | Bag and Pretorius [32] (31) |

| Universidade Federal de São Carlos | Brazil | Emerging country | 5 | 245 | Jabbour et al. [10] (214) |

| Politecnico di Milano | Italy | Developed country | 5 | 84 | Matteo et al. [33] (55) |

| Università degli Studi di Bergamo | Italy | Developed country | 5 | 43 | Powell et al. [34] (20) |

| Politechnika Poznanska | Poland | Developed country | 4 | 248 | Mrugalska and Wyrwicka [35] (180) |

| Universiti Teknikal Malaysia Melaka | Malaysia | Developing country | 4 | 5 | Ito et al. [36] (3) |

| Technical University of Berlin | Germany | Developed country | 3 | 690 | Stock and Seliger [19] (674) |

| Source Title | No. of Documents | Total Citations | Publication Year of Documents | Scopus Cite Score 2020 (Highest Percentile) | WoS Quartile 2020 (Impact Factor) | Total H-Index of Documents |

|---|---|---|---|---|---|---|

| Procedia Manufacturing | 15 | 280 | 2017–2020 | 13.1 (98%) | - | 7 |

| Procedia CIRP | 14 | 869 | 2015–-2020 | 3.3 (68%) | - | 5 |

| Sustainability | 14 | 145 | 2018–2021 | 3.9 (84%) | Q2 (3.251) | 5 |

| IFAC-PapersOnLine | 10 | 294 | 2015–2020 | 2.1 (43%) | - | 5 |

| Proceedings of The International Conference on Industrial Engineering and Operations Management | 9 | 22 | 2017–2021 | - | - | 2 |

| IFIP Advances in Information and Communication Technology | 8 | 42 | 2017–2021 | 1.0 (26%) | - | 3 |

| Proceedings of the Summer School Francesco Turco | 8 | 1 | 2018–2020 | - | - | 1 |

| International Journal of Production Research | 7 | 729 | 2017–2020 | 10.8 (97%) | Q1 (8.568) | 7 |

| Journal of Cleaner Production | 5 | 31 | 2020–2021 | 13.1 (98%) | Q1 (9.297) | 5 |

| IOP Conference Series: Materials Science and Engineering | 5 | 4 | 2017–2020 | 0.7 (23%) | - | 1 |

| Authors | Year of Publish | Title | Cites | Cites Per Year |

|---|---|---|---|---|

| Stock and Seliger [19] | 2016 | Opportunities of Sustainable Manufacturing in Industry 4.0 | 674 | 134.8 |

| Sanders et al. [37] | 2016 | Industry 4.0 implies lean manufacturing: Research activities in industry 4.0 function as enablers for lean manufacturing | 275 | 55 |

| Li [38] | 2018 | China’s manufacturing locus in 2025: With a comparison of “Made-in-China 2025” and “Industry 4.0” | 257 | 85.67 |

| Kolberg and Zühlke [7] | 2015 | Lean Automation enabled by Industry 4.0 Technologies | 249 | 41.5 |

| Buer et al. [30] | 2018 | The link between industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda | 220 | 73.33 |

| Jabbour et al. [10] | 2018 | When titans meet—Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors | 214 | 71.33 |

| Tortorella and Fettermann [29] | 2018 | Implementation of industry 4.0 and lean production in Brazilian manufacturing companies | 199 | 66.33 |

| Mrugalska and Wyrwicka [35] | 2017 | Towards Lean Production in Industry 4.0 | 180 | 45 |

| Wagner et al. [39] | 2017 | Industry 4.0 Impacts on Lean Production Systems | 143 | 35.75 |

| Machado et al. [5] | 2020 | Sustainable manufacturing in Industry 4.0: an emerging research agenda | 101 | 101 |

| Author Name | Institutions | Country | No. of Documents | Total Citations |

|---|---|---|---|---|

| Tortorella, G.L. | Universidade Federal de Santa Catarina | Brazil | 8 | 328 |

| Powell, Daryl John | Norges teknisk-naturvitenskapelige universitet | Norway | 5 | 44 |

| Gaiardelli, Paolo | Università degli Studi di Bergamo | Italy | 5 | 43 |

| Costa, Federica | Politecnico di Milano | Italy | 4 | 71 |

| Iung, Benoît | Université de Lorraine | France | 3 | 144 |

| Facchini, Francesco | Politecnico di Bari | Italy | 3 | 78 |

| Bag, Surajit | College of Business and Economics | South Africa | 3 | 53 |

| Bauer, Dennis | Universität Stuttgart | Germany | 3 | 3 |

| Draghici, Viorel Petrut | Fraunhofer Institute for Manufacturing Engineering and Automation IPA | Germany | 3 | 3 |

| Ciano, Maria Pia | Università Carlo Cattaneo | Italy | 3 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gholami, H.; Abu, F.; Lee, J.K.Y.; Karganroudi, S.S.; Sharif, S. Sustainable Manufacturing 4.0—Pathways and Practices. Sustainability 2021, 13, 13956. https://doi.org/10.3390/su132413956

Gholami H, Abu F, Lee JKY, Karganroudi SS, Sharif S. Sustainable Manufacturing 4.0—Pathways and Practices. Sustainability. 2021; 13(24):13956. https://doi.org/10.3390/su132413956

Chicago/Turabian StyleGholami, Hamed, Falah Abu, Jocelyn Ke Yin Lee, Sasan Sattarpanah Karganroudi, and Safian Sharif. 2021. "Sustainable Manufacturing 4.0—Pathways and Practices" Sustainability 13, no. 24: 13956. https://doi.org/10.3390/su132413956

APA StyleGholami, H., Abu, F., Lee, J. K. Y., Karganroudi, S. S., & Sharif, S. (2021). Sustainable Manufacturing 4.0—Pathways and Practices. Sustainability, 13(24), 13956. https://doi.org/10.3390/su132413956