Simulation-Optimization for the Planning of Off-Site Construction Projects: A Comparative Study of Recent Swarm Intelligence Metaheuristics

Abstract

1. Introduction

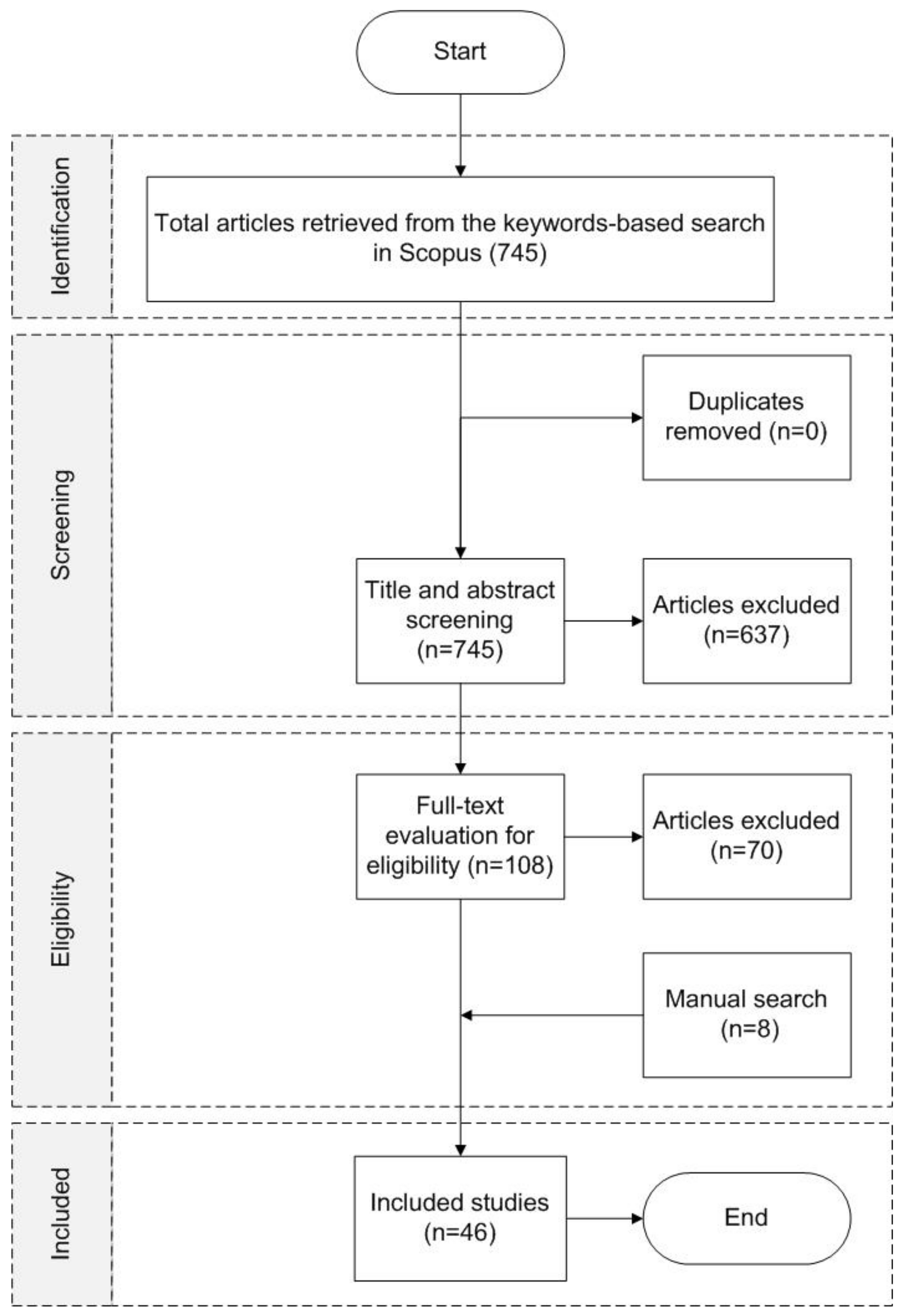

2. Literature Review of Simulation-Optimization (SO) in the Construction Research Field

3. Problem Statement and Formulation

3.1. Problem Description

3.2. Optimization Model Formulation

3.2.1. Model Parameters and Decision Variables

3.2.2. Objective Functions and Constraints

4. Solution Methods

4.1. The Adopted Simulation Optimization Approach

4.1.1. Simulation Model Development

4.1.2. Swarm Intelligence Metaheuristics

Firefly Algorithm (FA)

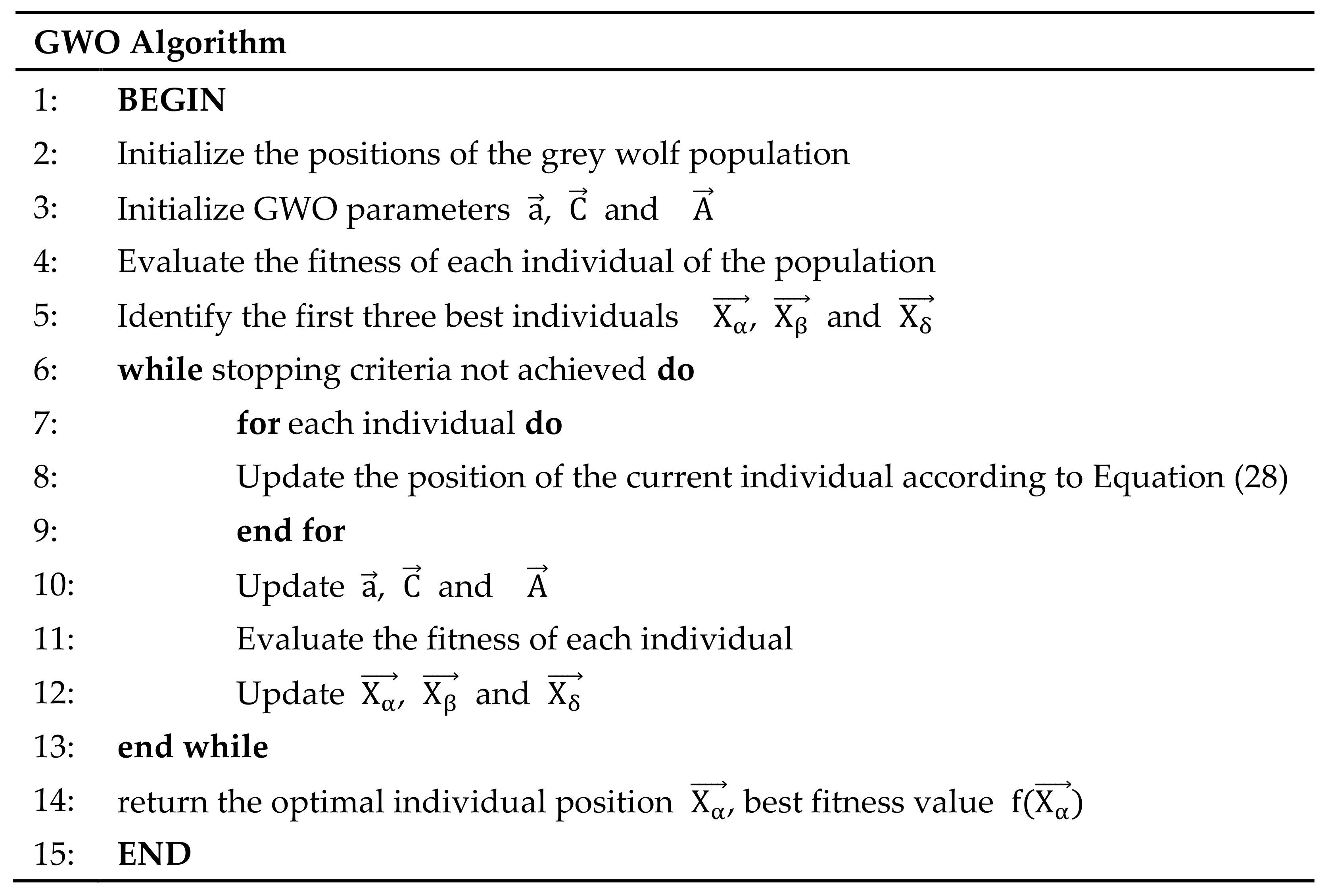

Grey Wolf Optimization (GWO) Algorithm

Novel Bat Algorithm (NBA)

Whale Optimization Algorithm (WOA)

Salp Swarm Algorithm (SSA)

Parameter Selection of the Metaheuristics

4.2. Reduction of the Computation Time

4.2.1. Common Random Numbers (CRN)

4.2.2. Parallel Computing

5. Model Implementation

6. Results and Discussion

6.1. Analysis of the Convergence Behaviour

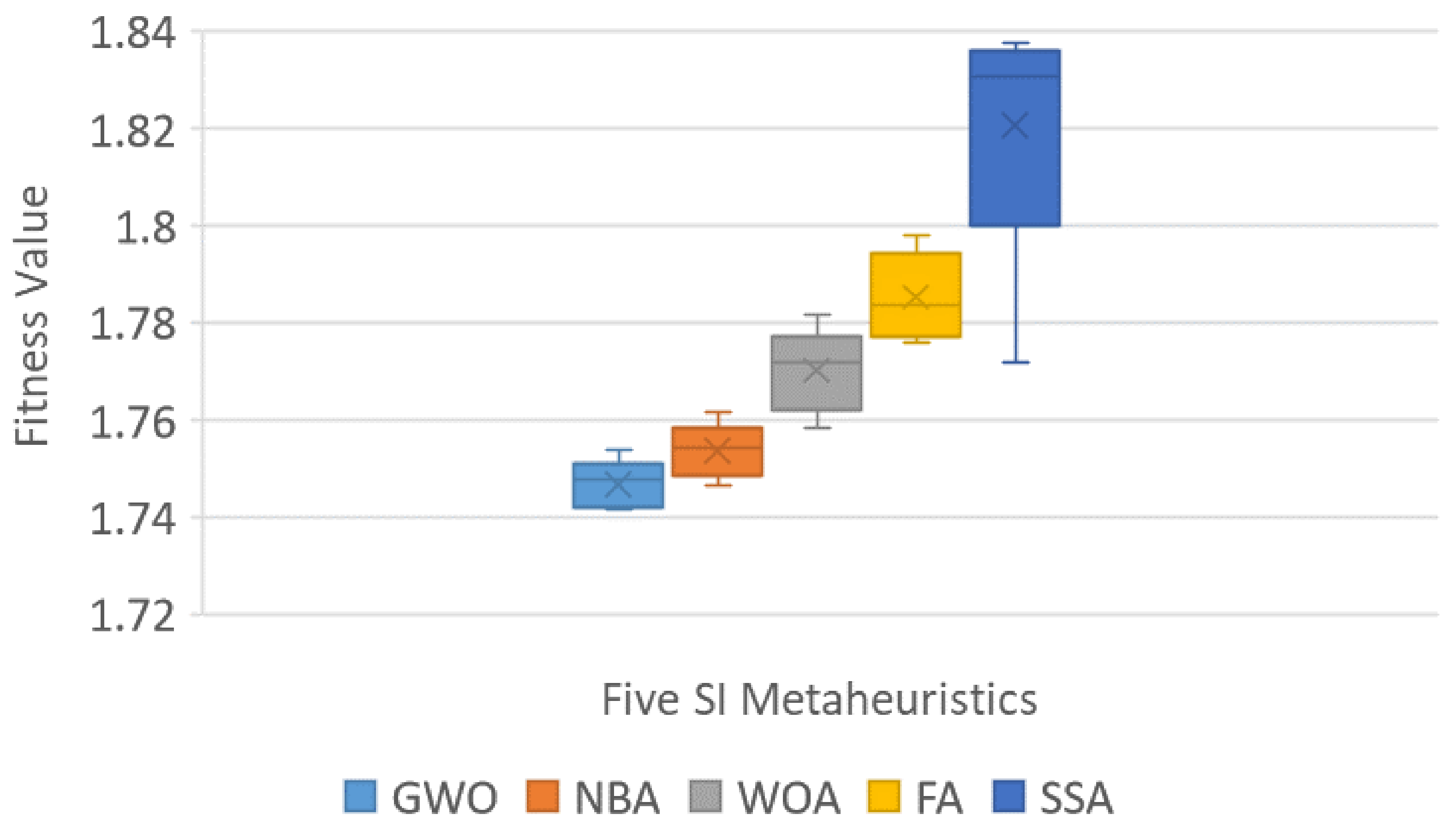

6.2. Statistical Results of the SI Metaheuristics

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hussein, M.; Zayed, T. Critical factors for successful implementation of just-in-time concept in modular integrated construction: A systematic review and meta-analysis. J. Clean. Prod. 2021, 284, 124716. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical evaluation of off-site construction research: A Scientometric analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Nam, S.; Yoon, J.; Kim, K.; Choi, B. Optimization of Prefabricated Components in Housing Modular Construction. Sustainability 2020, 12, 10269. [Google Scholar] [CrossRef]

- Chen, W.; Zhao, Y.; Yu, Y.; Chen, K.; Arashpour, M. Collaborative Scheduling of On-Site and Off-Site Operations in Prefabrication. Sustainability 2020, 12, 9266. [Google Scholar] [CrossRef]

- Wai, C.T.; Yi, P.W.; Olanrewaju, O.I.; Abdelmageed, S.; Hussein, M.; Tariq, S.; Zayed, T. A critical analysis of benefits and challenges of implementing modular integrated construction. Int. J. Constr. Manag. 2021, 1–24. [Google Scholar] [CrossRef]

- Kong, L.; Li, H.; Luo, H.; Ding, L.; Zhang, X. Sustainable performance of just-in-time (JIT) management in time-dependent batch delivery scheduling of precast construction. J. Clean. Prod. 2018, 193, 684–701. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Hill, C. Prefabrication, and Modularization: Increasing Productivity in the Construction Industry Smart Market Report; McGraw Hill Construction: New York, NY, USA, 2011. [Google Scholar]

- Xu, Z.; Zayed, T.; Niu, Y. Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- Salimi, S.; Mawlana, M.; Hammad, A. Performance analysis of simulation-based optimization of construction projects using High Performance Computing. Autom. Constr. 2018, 87, 158–172. [Google Scholar] [CrossRef]

- Jiang, W.; Wu, L. Flow shop optimization of hybrid make-to-order and make-to-stock in precast concrete component production. J. Clean. Prod. 2021, 297, 126708. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Barriers to the adoption of modular integrated construction: Systematic review and meta-analysis, integrated conceptual framework, and strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.; Yang, Y.; Tetteh, M.O. Building information modeling (BIM)-based modular integrated construction risk management—Critical survey and future needs. Comput. Ind. 2020, 123, 103327. [Google Scholar] [CrossRef]

- Hussein, M.; Eltoukhy, A.E.; Karam, A.; Shaban, I.A.; Zayed, T. Modelling in off-site construction supply chain management: A review and future directions for sustainable modular integrated construction. J. Clean. Prod. 2021, 310, 127503. [Google Scholar] [CrossRef]

- Feng, C.-W.; Liu, L.; Burns, S. Stochastic Construction Time-Cost Trade-Off Analysis. J. Comput. Civ. Eng. 2000, 14, 117–126. [Google Scholar] [CrossRef]

- Issa, U.H.; Eid, M.A. An application of genetic algorithms to time-cost-quality trade-off in construction industry. Civ. Environ. Res. 2013, 3, 11–19. Available online: https://www.iiste.org/Journals/index.php/CER/article/view/8635#google_vignette (accessed on 7 December 2021).

- Zhang, Y.; Ng, S.T. An ant colony system based decision support system for construction time-cost optimization. J. Civ. Eng. Manag. 2012, 18, 580–589. [Google Scholar] [CrossRef]

- Yang, Q. Application of Time-Cost-Quality Tradeoff Optimization Model Based on Improved PSO Algorithm to Construction Project. In Proceedings of the 2009 Asia-Pacific Conference on Information Processing, Shenzhen, China, 18–19 July 2009; IEEE: Washington, DC, USA, 2009; Volume 2, pp. 298–301. [Google Scholar]

- De, P.; Dunne, E.J.; Ghosh, J.B.; Wells, C.E. The discrete time-cost tradeoff problem revisited. Eur. J. Oper. Res. 1995, 81, 225–238. [Google Scholar] [CrossRef]

- Aladini, K.; Afshar, A.; Kalhor, E. Discounted cash flow time-cost trade-off problem optimization, aco approach. Asian J. Civ Eng. Build. Hous. 2011, 12, 511–522. Available online: https://www.sid.ir/en/journal/ViewPaper.aspx?ID=248038 (accessed on 7 December 2021).

- Zareei, M.; Hassan-Pour, H.A. A multi-objective resource-constrained optimization of time-cost trade-off problems in scheduling project. Iran. J. Manag. Stud. 2015, 8, 653–685. [Google Scholar]

- Liu, Y.; Dong, J.; Shen, L. A Conceptual Development Framework for Prefabricated Construction Supply Chain Management: An Integrated Overview. Sustainability 2020, 12, 1878. [Google Scholar] [CrossRef]

- Borshchev, A. The Big Book of Simulation Modeling: Multimethod modeling with AnyLogic 6; AnyLogic North America: Oakbrook Terrace, IL, USA, 2013; ISBN 0989573176. [Google Scholar]

- Kim, T.; Kim, Y.-W.; Cho, H. Dynamic production scheduling model under due date uncertainty in precast concrete construction. J. Clean. Prod. 2020, 257, 120527. [Google Scholar] [CrossRef]

- Swisher, J.; Hyden, P.; Jacobson, S.; Schruben, L. A survey of simulation optimization techniques and procedures. In Proceedings of the 2000 Winter Simulation Conference Proceedings (Cat. No.00CH37165), Orlando, FL, USA, 10–13 December 2000; IEEE: Washington, DC, USA, 2000; Volume 1, pp. 119–128. [Google Scholar] [CrossRef]

- Juan, A.; Faulin, J.; Grasman, S.E.; Rabe, M.; Figueira, G. A review of simheuristics: Extending metaheuristics to deal with stochastic combinatorial optimization problems. Oper. Res. Perspect. 2015, 2, 62–72. [Google Scholar] [CrossRef]

- Mirjalili, S.; Lewis, A. The Whale Optimization Algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar] [CrossRef]

- Cheng, T.-M.; Feng, C.-W.; Chen, Y.-L. A hybrid mechanism for optimizing construction simulation models. Autom. Constr. 2005, 14, 85–98. [Google Scholar] [CrossRef]

- Marzouk, M.; Moselhi, O. Multiobjective Optimization of Earthmoving Operations. J. Constr. Eng. Manag. 2004, 130, 105–113. [Google Scholar] [CrossRef]

- Cheng, T.-M.; Feng, C.-W.; Hsu, M.-Y. An integrated modeling mechanism for optimizing the simulation model of the construction operation. Autom. Constr. 2006, 15, 327–340. [Google Scholar] [CrossRef]

- Marzouk, M.M.; Omar, O.A.; Hamid, M.S.A.; El-Said, M.E. An optimization algorithm for simulation-based planning of low-income housing projects. J. Adv. Res. 2010, 1, 291–300. [Google Scholar] [CrossRef][Green Version]

- Mawlana, M.; Hammad, A. Integrating Variance Reduction Techniques and Parallel Computing in Construction Simulation Optimization. J. Comput. Civ. Eng. 2019, 33, 04019026. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Zhang, H.; Tam, C.M.; Li, H.; Shi, J.J. Particle Swarm Optimization-Supported Simulation for Construction Operations. J. Constr. Eng. Manag. 2006, 132, 1267–1274. [Google Scholar] [CrossRef]

- Marzouk, M.; Said, H.; El-Said, M. Framework for Multiobjective Optimization of Launching Girder Bridges. J. Constr. Eng. Manag. 2009, 135, 791–800. [Google Scholar] [CrossRef]

- Nassar, K.; El Masry, M.; Sherif, Y. Multiobjective Optimization of Advanced Shoring Systems Used in Bridge Construction. In Computing in Civil Engineering (2011); American Society of Civil Engineers (ASCE): Reston, VA, USA, 2011; pp. 94–101. [Google Scholar]

- Mubarak, H.; Mansor, N.; Mokhlis, H.; Mohamad, M.; Mohamad, H.; Muhammad, M.; Al Samman, M.; Afzal, S. Optimum Distribution System Expansion Planning Incorporating DG Based on N-1 Criterion for Sustainable System. Sustainability 2021, 13, 6708. [Google Scholar] [CrossRef]

- Alali, M.; Shahooei, Z.; Bahramipanah, M. Resiliency-Oriented Optimization of Critical Parameters in Multi Inverter-Fed Distributed Generation Systems. Sustainability 2021, 13, 6699. [Google Scholar] [CrossRef]

- Shabbir, M.; Siddiqi, A.; Yapanto, L.; Tonkov, E.; Poltarykhin, A.; Pilyugina, A.; Petrov, A.; Foroughi, A.; Valiullina, D. Closed-Loop Supply Chain Design and Pricing in Competitive Conditions by Considering the Variable Value of Return Products Using the Whale Optimization Algorithm. Sustainability 2021, 13, 6663. [Google Scholar] [CrossRef]

- Qais, M.H.; Hasanien, H.M.; Alghuwainem, S. Enhanced salp swarm algorithm: Application to variable speed wind generators. Eng. Appl. Artif. Intell. 2019, 80, 82–96. [Google Scholar] [CrossRef]

- Sörensen, K. Metaheuristics-the metaphor exposed. Int. Trans. Oper. Res. 2015, 22, 3–18. [Google Scholar] [CrossRef]

- Hussein, M.; Zayed, T. Crane operations and planning in modular integrated construction: Mixed review of literature. Autom. Constr. 2021, 122, 103466. [Google Scholar] [CrossRef]

- Karam, A.; Hussein, M.; Reinau, K.H. Analysis of the barriers to implementing horizontal collaborative transport using a hybrid fuzzy Delphi-AHP approach. J. Clean. Prod. 2021, 321, 128943. [Google Scholar] [CrossRef]

- Tariq, S.; Hussein, M.; Wang, R.D.; Zayed, T. Trends and developments of on-site crane layout planning 1983–2020: Bibliometric, scientometric and qualitative analyses. Constr. Innov. 2021. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097-6. [Google Scholar] [CrossRef]

- Alzraiee, H.; Zayed, T.; Moselhi, O. Dynamic planning of construction activities using hybrid simulation. Autom. Constr. 2015, 49, 176–192. [Google Scholar] [CrossRef]

- Shitole, V.; Louis, J.; Tadepalli, P. Optimizing Earth Moving Operations Via Reinforcement Learning. In Proceedings of the 2019 Winter Simulation Conference (WSC), National Harbor, MD, USA, 8–12 December 2019; IEEE: Washington, DC, USA, 2019; pp. 2954–2965. [Google Scholar]

- Li, H.X.; Zhang, L.; Mah, D.; Yu, H. An integrated simulation and optimization approach for reducing CO 2 emissions from on-site construction process in cold regions. Energy Build. 2017, 138, 666–675. [Google Scholar] [CrossRef]

- Altaf, M.S.; Bouferguene, A.; Liu, H.; Al-Hussein, M.; Yu, H. Integrated production planning and control system for a panelized home prefabrication facility using simulation and RFID. Autom. Constr. 2018, 85, 369–383. [Google Scholar] [CrossRef]

- Chen, S.; Feng, K.; Lu, W. A Simulation-Based Optimisation for Contractors in Precast Concrete Projects. In 10th Nordic Conference on Construction Economics and Organization, Tallinn, Estonia, 7–8 May 2019; Lill, I., Witt, E., Eds.; Emerald Publishing Limited: Bingley, UK, 2019; Volume 2, pp. 137–145. [Google Scholar]

- Lamas-Rodríguez, A.; Pernas-Álvarez, J.; Taracido-López, I. Constrained-based discrete-event simulation of an assembly job shop in the offshore wind industry. In Proceedings of the 32nd European Modeling & Simulation Symposium (EMSS 2020), online, 16–18 September 2020; Cal-Tek Srl: Cosenza, Italy, 2020; pp. 62–91. [Google Scholar] [CrossRef]

- Robertson, B.; Srinivasan, R.; McFarlane, D. Dynamic Postponement in Off-Site/On-Site Construction Operations in the Face of On-Site Disruptions; Springer International Publishing: Cham, Switzerland, 2018; pp. 261–272. [Google Scholar] [CrossRef]

- Taghaddos, H.; Hermann, U.; Abourizk, S.; Mohamed, Y. Simulation-Based Scheduling of Modular Construction Using Multi-Agent Resource Allocation. In Proceedings of the 2010 Second International Conference on Advances in System Simulation, Nice, France, 22–27 August 2010; IEEE: Washington, DC, USA, 2010; pp. 115–120. [Google Scholar] [CrossRef]

- Altaf, M.S.; Al-Hussein, M.; Yu, H. Wood-Frame Wall Panel Sequencing Based on Discrete-Event Simulation and Particle Swarm Optimization. In Proceedings of the Proceedings of the 31st International Symposium on Automation and Robotics in Construction and Mining (ISARC), Sydney, Australia, 9–11 July 2014; International Association for Automation and Robotics in Construction (IAARC): Bratislava, Slovakia, 2014; pp. 254–261. [Google Scholar] [CrossRef]

- Yusuf, M.; Karam, A.; Eltawil, A. A Simulation based Optimization Study for Optimum Sequencing of Precast Components Considering Supply Chain Risks. In Proceedings of the 8th International Conference on Operations Research and Enterprise Systems, Prague, Czech Republic, 19–21 February 2019; SciTePress: Setúbal, Portugal, 2019; pp. 330–337. [Google Scholar] [CrossRef]

- Yusuf, M.; Karam, A.; Eltawil, A. A Stochastic Optimization Approach of Flow Shop Sequencing Problem for On-time Delivery of Precast Components. In Proceedings of the 8th International Conference on Operations Research and Enterprise Systems, Prague, Czech Republic, 19–21 February 2019; SciTePress: Setúbal, Portugal, 2019; pp. 245–252. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Gong, J. Framework for modeling operational uncertainty to optimize offsite production scheduling of precast components. Autom. Constr. 2018, 86, 69–80. [Google Scholar] [CrossRef]

- Taghaddos, H.; Eslami, A.; Hermann, U.; AbouRizk, S.; Mohamed, Y. Auction-based Simulation for Industrial Crane Operations. Autom. Constr. 2019, 104, 107–119. [Google Scholar] [CrossRef]

- Cheng, T.-M.; Yan, R.-Z. Integrating Messy Genetic Algorithms and Simulation to Optimize Resource Utilization. Comput. Civ. Infrastruct. Eng. 2009, 24, 401–415. [Google Scholar] [CrossRef]

- Liu, Y.; Mohamed, Y. Modelling industrial construction operations using a multi-agent resource allocation framework. Eng. Constr. Arch. Manag. 2012, 19, 406–427. [Google Scholar] [CrossRef]

- Yazdani, M.; Kabirifar, K.; Fathollahi-Fard, A.M.; Mojtahedi, M. Production scheduling of off-site prefabricated construction components considering sequence dependent due dates. Environ. Sci. Pollut. Res. 2021, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-T.; Hsie, M.; Hsiao, W.-T.; Wu, H.-T.; Cheng, T.-M. Optimizing the Schedule of Dispatching Earthmoving Trucks through Genetic Algorithms and Simulation. J. Perform. Constr. Facil. 2012, 26, 203–211. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Tran, D.-H. Integrating Chaotic Initialized Opposition Multiple-Objective Differential Evolution and Stochastic Simulation to Optimize Ready-Mixed Concrete Truck Dispatch Schedule. J. Manag. Eng. 2016, 32, 04015034. [Google Scholar] [CrossRef]

- Zhou, F.; Abourizk, S.M.; AL-Battaineh, H. Optimisation of construction site layout using a hybrid simulation-based system. Simul. Model. Pract. Theory 2009, 17, 348–363. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H. Simulation-based optimization for dynamic resource allocation. Autom. Constr. 2004, 13, 409–420. [Google Scholar] [CrossRef]

- Lu, M.; Lam, H.-C.; Dai, F. Resource-constrained critical path analysis based on discrete event simulation and particle swarm optimization. Autom. Constr. 2008, 17, 670–681. [Google Scholar] [CrossRef]

- Shin, Y.; Cho, H.; Kang, K.-I. Simulation model incorporating genetic algorithms for optimal temporary hoist planning in high-rise building construction. Autom. Constr. 2011, 20, 550–558. [Google Scholar] [CrossRef]

- Fayed, R.A.; Ezeldin, A.S. Simulation and optimization model for electrical substation construction. J. Inf Technol. Constr. 2018, 23, 215. [Google Scholar]

- Szczesny, K.; Hamm, M.; König, M. Adjusted recombination operator for simulation-based construction schedule optimization. In Proceedings of the 2012 Winter Simulation Conference (WSC), Berlin, Germany, 9–12 December 2012; IEEE: Washington, DC, USA, 2012; pp. 1–10. [Google Scholar]

- Cao, M.; Lu, M.; Zhang, J.-P. Concrete plant operations optimization using combined simulation and genetic algorithms. In Proceedings of the 2004 International Conference on Machine Learning and Cybernetics (IEEE Cat. No.04EX826), Shanghai, China, 26–29 August 2004; IEEE: Washington, DC, USA, 2005; Volume 7, pp. 4204–4209. [Google Scholar]

- Zankoul, E.; Khoury, H. Modeling, Animating, and Optimizing On-Shore Wind Farm Construction Operations. J. Comput. Civ. Eng. 2016, 30, 05016001. [Google Scholar] [CrossRef]

- Younes, A.; Marzouk, M. Tower cranes layout planning using agent-based simulation considering activity conflicts. Autom. Constr. 2018, 93, 348–360. [Google Scholar] [CrossRef]

- Feng, K.; Lu, W.; Chen, S.; Wang, Y. An Integrated Environment–Cost–Time Optimisation Method for Construction Contractors Considering Global Warming. Sustainability 2018, 10, 4207. [Google Scholar] [CrossRef]

- Hamm, M.; Szczesny, K.; Nguyen, V.V.; Konig, M. Optimization of Construction Schedules with Discrete-Event Simulation Using an Optimization Framework. In Computing in Civil Engineering (2011); American Society of Civil Engineers (ASCE): Reston, VA, USA, 2011; pp. 682–689. [Google Scholar]

- Hsiao, W.-T.; Lin, C.-T.; Wu, H.-T.; Cheng, T.-M. A Hybrid Optimization Mechanism Used to Generate Truck Fleet to Perform Earthmoving Operations. In Instrumentation, Testing, and Modeling of Soil and Rock Behavior; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2011; pp. 151–159. [Google Scholar]

- Lu, M.; Dai, F.; Chen, W. Real-time decision support for planning concrete plant operations enabled by integrating vehicle tracking technology, simulation, and optimization algorithms. Can. J. Civ. Eng. 2007, 34, 912–922. [Google Scholar] [CrossRef]

- Yu, B.; Meng, X.; Liu, Q. Multi-objective optimisation of hot in-place recycling of asphalt pavement considering environmental impact, cost and construction quality. Int. J. Pavement Eng. 2020, 21, 1576–1584. [Google Scholar] [CrossRef]

- Szczesny, K.; König, M. Reactive scheduling based on actual logistics data by applying simulation-based optimization. Vis. Eng. 2015, 3, 10. [Google Scholar] [CrossRef]

- Dashti, M.S.; RezaZadeh, M.; Khanzadi, M.; Taghaddos, H. Integrated BIM-based simulation for automated time-space conflict management in construction projects. Autom. Constr. 2021, 132, 103957. [Google Scholar] [CrossRef]

- Yazdani, M.; Kabirifar, K.; Frimpong, B.E.; Shariati, M.; Mirmozaffari, M.; Boskabadi, A. Improving construction and demolition waste collection service in an urban area using a simheuristic approach: A case study in Sydney, Australia. J. Clean. Prod. 2021, 280, 124138. [Google Scholar] [CrossRef]

- Nadoushani, Z.S.M.; Nezhad, A.A.; Rey, D. Optimization of concrete placing operation based on competing carbon footprint, cost and production rate objectives. Eng. Constr. Arch. Manag. 2018, 25, 938–957. [Google Scholar] [CrossRef]

- Marzouk, M.; Azab, S.; Metawie, M. Framework for Sustainable Low-Income Housing Projects using Building Information Modeling. J. Environ. Inform. 2016, 28, 1–25. [Google Scholar] [CrossRef]

- Beißert, U.; König, M.; Bargstädt, H.-J. Soft Constraint-based simulation of execution strategies in building engineering. J. Simul. 2010, 4, 222–231. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.; Hu, Z.; Lu, M. Construction management utilizing 4D CAD and operations simulation methodologies. Tsinghua Sci. Technol. 2008, 13, 241–247. [Google Scholar] [CrossRef]

- Zivkovic, M.; Bacanin, N.; Venkatachalam, K.; Nayyar, A.; Djordjevic, A.; Strumberger, I.; Al-Turjman, F. COVID-19 cases prediction by using hybrid machine learning and beetle antennae search approach. Sustain. Cities Soc. 2021, 66, 102669. [Google Scholar] [CrossRef] [PubMed]

- Feng, K.; Chen, S.; Lu, W. Machine learning based construction simulation and optimization. In Proceedings of the 2018 Winter Simulation Conference (WSC), Gothenburg, Sweden, 9–12 December 2018; IEEE: Washington, DC, USA, 2018; pp. 2025–2036. [Google Scholar]

- Dorrah, D.H.; Marzouk, M. Integrated multi-objective optimization and agent-based building occupancy modeling for space layout planning. J. Build. Eng. 2021, 34, 101902. [Google Scholar] [CrossRef]

- Elbeltagi, E.; Hegazy, T.; Grierson, D. Comparison among five evolutionary-based optimization algorithms. Adv. Eng. Inform. 2005, 19, 43–53. [Google Scholar] [CrossRef]

- Elbehairy, H.; Elbeltagi, E.; Hegazy, T.; Soudki, K. Comparison of Two Evolutionary Algorithms for Optimization of Bridge Deck Repairs. Comput. Civ. Infrastruct. Eng. 2006, 21, 561–572. [Google Scholar] [CrossRef]

- El-Ghandour, H.A.; Elbeltagi, E. Comparison of Five Evolutionary Algorithms for Optimization of Water Distribution Networks. J. Comput. Civ. Eng. 2018, 32, 04017066. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Kashani, A.R. Construction Cost Minimization of Shallow Foundation Using Recent Swarm Intelligence Techniques. IEEE Trans. Ind. Inform. 2017, 14, 1099–1106. [Google Scholar] [CrossRef]

- Kaveh, A.; Seddighian, M.R. Domain decomposition of finite element models utilizing eight meta-heuristic algorithms: A comparative study. Mech. Based Des. Struct. Mach. 2020, 1–19. [Google Scholar] [CrossRef]

- Goodarzian, F.; Hosseini-Nasab, H.; Muñuzuri, J.; Fakhrzad, M.-B. A multi-objective pharmaceutical supply chain network based on a robust fuzzy model: A comparison of meta-heuristics. Appl. Soft Comput. 2020, 92, 106331. [Google Scholar] [CrossRef]

- Eltoukhy, A.E.; Chan, F.T.; Chung, S.H.; Niu, B.; Wang, X. Heuristic approaches for operational aircraft maintenance routing problem with maximum flying hours and man-power availability considerations. Ind. Manag. Data Syst. 2017, 117, 2142–2170. [Google Scholar] [CrossRef]

- Kaveh, A.; Hamedani, K.B.; Hosseini, S.M.; Bakhshpoori, T. Optimal design of planar steel frame structures utilizing meta-heuristic optimization algorithms. Structures 2020, 25, 335–346. [Google Scholar] [CrossRef]

- Alberdi, R.; Khandelwal, K. Comparison of robustness of metaheuristic algorithms for steel frame optimization. Eng. Struct. 2015, 102, 40–60. [Google Scholar] [CrossRef]

- Mostafa, S.; Kim, K.P.; Tam, V.W.Y.; Rahnamayiezekavat, P. Exploring the status, benefits, barriers and opportunities of using BIM for advancing prefabrication practice. Int. J. Constr. Manag. 2020, 20, 146–156. [Google Scholar] [CrossRef]

- Marler, R.T.; Arora, J.S. Function-transformation methods for multi-objective optimization. Eng. Optim. 2005, 37, 551–570. [Google Scholar] [CrossRef]

- Luo, H.; Liu, J.; Li, C.; Chen, K.; Zhang, M. Ultra-rapid delivery of specialty field hospitals to combat COVID-19: Lessons learned from the Leishenshan Hospital project in Wuhan. Autom. Constr. 2020, 119, 103345. [Google Scholar] [CrossRef] [PubMed]

- Eltoukhy, A.E.E.; Wang, Z.X.; Chan, F.T.S.; Chung, S.H.; Ma, H.-L.; Wang, X.P. Robust Aircraft Maintenance Routing Problem Using a Turn-Around Time Reduction Approach. IEEE Trans. Syst. Man, Cybern. Syst. 2020, 50, 4919–4932. [Google Scholar] [CrossRef]

- Eltoukhy, A.E.; Wang, Z.; Chan, F.T.; Fu, X. Data analytics in managing aircraft routing and maintenance staffing with price competition by a Stackelberg-Nash game model. Transp. Res. Part E Logist. Transp. Rev. 2019, 122, 143–168. [Google Scholar] [CrossRef]

- Amaran, S.; Sahinidis, N.V.; Sharda, B.; Bury, S.J. Simulation optimization: A review of algorithms and applications. Ann. Oper. Res. 2016, 240, 351–380. [Google Scholar] [CrossRef]

- Tekin, E.; Sabuncuoglu, I. Simulation optimization: A comprehensive review on theory and applications. IIE Trans. 2004, 36, 1067–1081. [Google Scholar] [CrossRef]

- Wang, L.-F.; Shi, L.-Y. Simulation Optimization: A Review on Theory and Applications. Acta Autom. Sin. 2013, 39, 1957–1968. [Google Scholar] [CrossRef]

- MATLAB. The MathWorks, Inc. 2005. Available online: http://www.mathworks.com (accessed on 7 December 2021).

- Yang, X.-S. Firefly Algorithms for Multimodal Optimization. In International Symposium on Stochastic Algorithms; Springer: Berlin/Heidelberg, Germany, 2009; pp. 169–178. [Google Scholar]

- Meng, X.-B.; Gao, X.; Liu, Y.; Zhang, H. A novel bat algorithm with habitat selection and Doppler effect in echoes for optimization. Expert Syst. Appl. 2015, 42, 6350–6364. [Google Scholar] [CrossRef]

- Zhong, M.; Long, W. Whale optimization algorithm with nonlinear control parameter. In Proceedings of the MATEC Web of Conferences, Chengdu, China, 16–17 December 2017; EDP Sciences: Les Ulis, France, 2017; Volume 139, p. 00157. [Google Scholar] [CrossRef]

- Kaveh, A.; Ghazaan, M.I. Enhanced whale optimization algorithm for sizing optimization of skeletal structures. Mech. Based Des. Struct. Mach. 2016, 45, 345–362. [Google Scholar] [CrossRef]

- Mirjalili, S.; Gandomi, A.H.; Mirjalili, S.Z.; Saremi, S.; Faris, H.; Mirjalili, S.M. Salp Swarm Algorithm: A bio-inspired optimizer for engineering design problems. Adv. Eng. Softw. 2017, 114, 163–191. [Google Scholar] [CrossRef]

- Wang, Q.; Guidolin, M.; Savic, D.; Kapelan, Z. Two-Objective Design of Benchmark Problems of a Water Distribution System via MOEAs: Towards the Best-Known Approximation of the True Pareto Front. J. Water Resour. Plan. Manag. 2015, 141, 04014060. [Google Scholar] [CrossRef]

- Stützle, T.; López-Ibáñez, M.; Pellegrini, P.; Maur, M.; de Oca, M.M.; Birattari, M.; Dorigo, M. Parameter Adaptation in Ant Colony Optimization. Auton. Search 2011, 191–215. [Google Scholar] [CrossRef]

- Law, A.M.; Kelton, W.D.; Kelton, W.D. Simulation Modeling and Analysis; McGraw-Hill: New York, NY, USA, 2000; Volume 3, ISBN 10: 0073401323. [Google Scholar]

- Kelton, W.D.; Sadowski, R.P.; Sturrock, D.T. Simulation with Arena; McGraw-Hill Higher Education: New York, NY, USA, 2003; ISBN 10: 0073401315. [Google Scholar]

- Crainic, T. Parallel Metaheuristics and Cooperative Search. In International Series in Operations Research & Management Science; Springer International Publishing: Cham, Switzerland, 2019; pp. 419–451. [Google Scholar]

- Barney, B. Introduction to Parallel Computing; Lawrence Livermore National Laboratory: Livermore, CA, USA, 2010; Volume 6, pp. 169–178. Available online: https://hpc.llnl.gov/training/tutorials/introduction-parallel-computing-tutorial (accessed on 7 December 2021).

- Gendreau, M.; Potvin, J.-Y. Handbook of Metaheuristics; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2010; Volume 2. [Google Scholar]

- Mawlana, M. Improving Stochastic Simulation-based Optimization for Selecting Construction Method of Precast Box Girder Bridges. Ph.D. Thesis, Concordia University, Montreal, Canada, 30 July 2015. Available online: https://spectrum.library.concordia.ca/980234/ (accessed on 7 December 2021).

- Abourizk, S.M.; Halpin, D.W. Statistical Properties of Construction Duration Data. J. Constr. Eng. Manag. 1992, 118, 525–544. [Google Scholar] [CrossRef]

- McCabe, B. In Construction engineering and project management III: Monte carlo simulation for schedule risks. In Proceedings of the 35th Conference on Winter Simulation: Driving Innovation, New Orleans, LA, USA, 7–10 December 2003; ACM Press: New York, NY, USA, 2003; pp. 1561–1565. [Google Scholar] [CrossRef]

- Faghihi, V.; Reinschmidt, K.F.; Kang, J.H. Objective-driven and Pareto Front analysis: Optimizing time, cost, and job-site movements. Autom. Constr. 2016, 69, 79–88. [Google Scholar] [CrossRef]

- Wood, D.A. Gas and oil project time-cost-quality tradeoff: Integrated stochastic and fuzzy multi-objective optimization applying a memetic, nondominated, sorting algorithm. J. Nat. Gas Sci. Eng. 2017, 45, 143–164. [Google Scholar] [CrossRef]

- Zhang, L.; Du, J.; Zhang, S. Solution to the Time-Cost-Quality Trade-off Problem in Construction Projects Based on Immune Genetic Particle Swarm Optimization. J. Manag. Eng. 2014, 30, 163–172. [Google Scholar] [CrossRef]

- April, J.; Glover, F.; Kelly, J.; Laguna, M. Simulation/optimization using real-world applications. In Proceeding of the 2001 Winter Simulation Conference (Cat. No.01CH37304), Arlington, VA, USA, 9–12 December 2001; IEEE: Washington, DC, USA, 2002; pp. 134–138. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017; ISBN 978-1-119-49244-3. [Google Scholar]

- Zhao, M.; Wang, X.; Yu, J.; Bi, L.; Xiao, Y.; Zhang, J. Optimization of Construction Duration and Schedule Robustness Based on Hybrid Grey Wolf Optimizer with Sine Cosine Algorithm. Energies 2020, 13, 215. [Google Scholar] [CrossRef]

- Zhang, J.; Zhong, D.; Zhao, M.; Yu, J.; Lv, F. An Optimization Model for Construction Stage and Zone Plans of Rockfill Dams Based on the Enhanced Whale Optimization Algorithm. Energies 2019, 12, 466. [Google Scholar] [CrossRef]

| Construction Method | Construction Application | Objective Function | Sim. M | Metaheuristic | Single Objective | Multi-Objective | Parallel Computing | VRT * | Reference |

|---|---|---|---|---|---|---|---|---|---|

| OSC | Onsite panelized construction | Minimize CO2 emissions from the on-site construction | DES | GA | ✓ | [48] | |||

| Production planning in Panelized construction | Minimize the production time | DES | PSO and SA | ✓ | [49] | ||||

| Planning of precast supply chain and construction configuration | Minimize project duration, costs and GHG emissions | DES | PSO | ✓ | [50] | ||||

| Job shop scheduling for construction of off-shore wind foundation | Minimize total tardiness and maximize total earliness | DES | OptQuest (scatter search) | ✓ | [51] | ||||

| Disruption management of OSC supply chain | Minimize total costs | DES | GA | ✓ | [52] | ||||

| Project scheduling and resource allocation in modular construction | Maximize welfare of stakeholders | DES | Heuristics (greedy and ascending-auctionalgorithm) | ✓ | [53] | ||||

| Production sequencing in wood Panelized construction | Minimize the makespan | DES | PSO | ✓ | [54] | ||||

| Production planning of precast components | Minimizeunit cost or maximize production rate | DES | GA | ✓ | [30] | ||||

| Planning of Precast beam bridge deck construction using launching gantry | Minimize project duration and costs | DES | ACO | ✓ | [35] | ||||

| Planning of Housing construction using precast components | Minimize project duration and costs | DES | GA | ✓ | [31] | ||||

| Production planning of precast components | Achieve On-time delivery and minimize production costs | DES | OptQuest | ✓ | [55,56] | ||||

| Planning of Precast full-span bridge deck construction using launching gantry | Minimize project duration and costs | DES | NSGA-II | ✓ | ✓ | [10] | |||

| Planning of Precast full-span bridge deck construction using launching gantry | Minimize project duration and costs | DES | fmGA | ✓ | ✓ | ✓ | [32] | ||

| Production scheduling of precast components | Minimize delivery penalty costs | DES | GA | ✓ | [57] * | ||||

| Crane operation and planning | Maximize the system’s social welfare | DES | Heuristic (Auction protocol) | ✓ | [58] * | ||||

| Resource assignment in precast production facilities | Maximize the production rate or minimize the system’s unit cost | DES | Messy GA | ✓ | [59] | ||||

| OSC | Resource allocation in industrial construction projects | Maximize the system’s social welfare | ABS | Heuristics (Greedy and dynamic programming algorithms) | ✓ | [60] | |||

| Production scheduling of precast components | Minimize inventory costs and delivery penalty costs | DES | GA, DE, and ICA | ✓ | [61] | ||||

| Traditional construction | Earthmoving operations | Minimize time and cost of earthmoving operations. | DES | GA | ✓ | [29] | |||

| Fleet management of earth moving trucks | Minimize the time of earthmoving operations. | DES | GA | ✓ | [62] | ||||

| Dispatch scheduling of concrete batch plants. | Minimize the idle time of trucks and construction sites. | DES | DE | ✓ | [63] | ||||

| Tunnel construction site layout | Minimize site layout costs | DES | GA | ✓ | [64] | ||||

| Resource allocation for bridge construction | Minimize project duration | DES | Heuristic | ✓ | [65] | ||||

| Activity scheduling and resource allocation | Minimize project duration | DES | PSO | ✓ | [66] | ||||

| Temporary hoist planning in high-rise building construction | Minimize the hoists’ rental costs | DES | GA | ✓ | [67] | ||||

| Construction of electrical substations | Minimize project duration | DES | GA | ✓ | [68] | ||||

| Scheduling of shell construction project | Minimize project duration | DES | EA | ✓ | [69] | ||||

| Concrete plant operation | Minimize site idle time and maximize plant utilization | DES | GA | ✓ | [70] | ||||

| On-shore wind farm construction planning | Minimize total construction costs | DES | OptQuest | ✓ | [71] | ||||

| Tower crane layout planning | Minimize hoisting time or total costs | ABS | OptQuest | ✓ | [72] | ||||

| Building construction planning | Minimize project duration, costs and environmental impact | DES | PSO | ✓ | [73] | ||||

| Scheduling of complex construction | Minimize the project duration and maximize resource utilizations | DES | NSGA-II | ✓ | ✓ | [74] | |||

| Fleet management of earth moving trucks | Minimize the operational time | DES | GA | ✓ | [75] | ||||

| Planning concrete plant operation | Minimize total operations inefficiencies | DES | PSO | ✓ | [76] | ||||

| Planning of hot in-place recycling of asphalt pavement | Minimize cost and environmental impact and maximize quality | DES | NSGA-II | ✓ | [77] | ||||

| Construction scheduling | Minimize project delay and resource costs | DES | NSGA-II | ✓ | [78] | ||||

| Sewer pipeline installation | Maximize system production rate or minimize the unit cost | DES | Hybrid heuristic-GA | ✓ | [28] | ||||

| Traditional construction | Planning of bridge deck construction using advanced shoring method | Minimize project duration and costs | DES | PSO | ✓ | [36] | |||

| Planning of concrete placement operation | Maximize productivityor minimize cost | DES | PSO | ✓ | [34] | ||||

| Time-space conflictplanning | Collision-free shortest path | DES | Rapidly-exploring Random Tree | ✓ | [79] | ||||

| Route planning for construction waste collection | Minimize travel time | MC | GA | ✓ | [80] | ||||

| Concrete placingoperation | Minimize carbon emissions and costs & Maximize the production rate | DES | Full enumeration | ✓ | [81] | ||||

| Sustainability of low-income housing projects | Minimize life cycle costs & Maximize LEED credit | DES & SD | NSGA-II | ✓ | [82] * | ||||

| Scheduling of execution processes in building projects | Minimize makespan | DES | GreedyRandomized Adaptive Search Procedure | ✓ | [83] | ||||

| Site layout planning and resource allocation | Minimize the project’s duration | DES | GA | ✓ | [84] |

| Indicies | |

| Prefabricated box girders; , is the set of girders. | |

| Production processes; , is the set of production processes. | |

| Logistics processes; , is the set of logistics processes. | |

| Installation processes; , is the set of installation processes. | |

| Equipment resources; , is the set of equipment. | |

| Human resources (i.e., crews); c , is the set of crews. | |

| Parameters | |

| Duration spent by a girder in a production process . | |

| Duration spent by a girder in a logistics process . | |

| Duration spent by a girder in an installation process . | |

| Time waited by a girder for a production process . | |

| Time waited by a girder for a logistics process . | |

| Time waited by a girder for an installation process . | |

| Daily indirect or overhead costs. | |

| Mobilization cost of an equipment used in a production process . | |

| Mobilization cost of an equipment used in a logistics process . | |

| Mobilization cost of an equipment used in an installation process . | |

| Mobilization cost of a crew working on a production process . | |

| Mobilization cost of a crew working on a logistics process . | |

| Mobilization cost of a crew working on an installation process . | |

| Fixed cost of an equipment used in a production process . | |

| Hourly cost of an equipment used in a production process . | |

| Hourly cost of an equipment used in a logistics process . | |

| Hourly cost of an equipment used in an installation process . | |

| Duration spent by an equipment working on production processes . | |

| Duration spent by an equipment working on logistics processes. | |

| Duration spent by an equipment working on installation processes . | |

| Hourly cost of crew working on a production process . | |

| Hourly cost of crew working on a logistics process . | |

| Hourly cost of crew working on an installation process . | |

| Duration spent by crew working on production processes . | |

| Duration spent by crew working on logistics processes. | |

| Duration spent by crew working on installation processes . | |

| Overtime cost adjustment factor of crew working on production processes . | |

| Overtime cost adjustment factor of crew working on logistics processes. | |

| Overtime cost adjustment factor of crew working on installation processes . | |

| Hourly storage cost. | |

| and | The maximum number of equipment available for production , logistics , and installation processes, respectively. |

| ,, and | The maximum number of crew available for production , logistics , and installation processes, respectively. |

| The minimum and maximum distances between the construction site and available locations for the production facility. | |

| The minimum and maximum storage capacity of the production yard. | |

| The minimum and maximum storage time of girders at the production yard. | |

| The minimum and maximum number of daily working hours. | |

| The minimum and maximum number of working days per week. | |

| Decision variables | |

| Number of daily working hours. | |

| Number of working days per week. | |

| Number of equipment resource used in a production process . | |

| Number of equipment resource used in a logistics process . | |

| Number of equipment resource used in an installation process . | |

| Number of crew working in a production process . | |

| Number of crew working in a logistics process . | |

| Number of crew working in an installation process . | |

| Storage capacity of the production yard. | |

| Storage time of girders at the production yard. | |

| The distance between the construction site and available locations to set up the production yard. | |

| Metaheuristic | Parameter | Parameter Tuning Method | Value or Range |

|---|---|---|---|

| FA | light absorption coefficient | Self-adaptive | (1–30) |

| constant number | Self-adaptive | (0.1–0.2) | |

| GWO | Parameter | Pre-scheduled | (2–0) |

| Coefficient | Pre-scheduled | (0–2) | |

| NBA | Constant | Offline (constant) | 0.99 |

| Constant | Offline (constant) | 0.9 | |

| Probability of habitat selection | Pre-scheduled (random number within the range) | (0.6–0.9) | |

| Frequency of updating loudness and pulse emission rate | Offline (constant) | 4 | |

| Compensation rate for Doppler effect in echoes | Pre-scheduled (random number within the range) | (0.1–0.9) | |

| Inertia weight | Pre-scheduled | (0.5–0.9) | |

| Contraction–expansion coefficient | Pre-scheduled | (0.5–1) | |

| WOA | Parameter | Pre-scheduled | (2–0) |

| positive number to define the spiral shape | Self-adaptive | (0.5–2) | |

| SSA | Parameter | Pre-scheduled | (2–0) |

| Decision Variables | Solutions | |

| A | B | |

| NT | 2 | 1 |

| PYD | 50 | 50 |

| NRC | 4 | 9 |

| NIM | 5 | 5 |

| NOM | 4 | 3 |

| NPC | 4 | 5 |

| NSC | 3 | 2 |

| NFC | 4 | 8 |

| NCC | 5 | 7 |

| SM | 1 | 1 |

| OP | 7 | 7 |

| YS | 35 | 35 |

| ST | 6 | 11 |

| Objective Values | Solutions | |

| A | B | |

| Mean fitness value (10−4) | 18396.93 | 18626.14 |

| Variance of fitness value | 0.0033 | 0.0031 |

| Mean project duration (day) | 84.4 | 85.03 |

| Mean project costs ($) | 1645074 | 1650806 |

| Performance Measures | Before CRN | After CRN | ||||

|---|---|---|---|---|---|---|

| Fitness Value | Fitness Value | |||||

| 0.0054 | 3.7580 | 54,953.86 104 | 0.0028 | 2.2110 | 18,983.16 104 | |

| 0.0144 | 0.3799 | 4594.59 | 0.0103 | 0.2914 | 2700.43 | |

| −0.0477 | −0.0428 | −0.0793 | 0.5651 | 0.5080 | 0.6879 | |

| Activity | Duration (Minutes) (Triangular Distribution [Min, Mode, Max]) | Activity | Duration (Minutes) (Triangular Distribution [Min, Mode, Max]) |

|---|---|---|---|

| Reinforcement of bottom slab and webs | [640, 961, 1280] | Trailer loading | [30, 60, 90] |

| Loading the inner mold | [120, 300, 480] | Trailer haul | F (Distance, Speed) |

| Reinforcement of the top slab | [660, 984, 1300] | Trailer return | F (Distance, Speed) |

| Lift to the outer mold | [23, 45, 68] | Trolley loading | [30, 60, 90] |

| Concrete pouring | [520, 771, 1020] | Trolley haul | F (Distance, Speed) |

| Concrete curing | (600 or 1200) | Reposition of LG | [120, 240, 360] |

| Remove the inner mold | [90, 255, 420] | Pickup span | [30, 60, 90] |

| 1st pre-stressing | [120, 300, 480] | Erect span | [120, 240, 360] |

| Move to storage area | [30, 60, 90] | Trolley return | F (Distance, Speed) |

| 2nd pre-stressing | [120, 300, 480] | Grouting of bearing | [120, 240, 360] |

| Delay for storage time | Decision variable (ST) | Load transfer | [30, 60, 90] |

| Decision Variables | Minimum | Increment | Maximum |

|---|---|---|---|

| Number of trailers | 1 | 1 | 10 |

| Distance between the casting yard and the construction site | 10 | 10 | 100 |

| Number of rebar cage molds | 1 | 1 | 10 |

| Number of inner molds | 1 | 1 | 10 |

| Number of outer molds | 1 | 1 | 10 |

| Number of preparation crews | 1 | 1 | 10 |

| Number of pre-stressing crews | 1 | 1 | 10 |

| Number of reinforcement crews | 1 | 1 | 10 |

| Number of casting crews | 1 | 1 | 10 |

| Steaming machine for concrete curing | 0 (conventional curing) | 1 | 1 (accelerated curing) |

| Casting yard storage capacity | 35 | 5 | 50 |

| Storage time of the span in the casting yard in hours | 1 | 1 | 15 |

| Number of daily working hours | 8 | 1 | 12 |

| Number of working days per week | 5 | 1 | 7 |

| Solutions | Stroboscope | SimEvents | ||

|---|---|---|---|---|

| Duration (Days) | Cost (104$) | Duration (Days) | Cost (104$) | |

| 1 | 73 | 277 | 74 | 280 |

| 2 | 76 | 266 | 77 | 271 |

| 3 | 77 | 247 | 77 | 244 |

| 4 | 80 | 214 | 80 | 217 |

| 5 | 81 | 207 | 81 | 208 |

| 6 | 83 | 205 | 83 | 207 |

| 7 | 84 | 197 | 84 | 199 |

| 8 | 89 | 195 | 89 | 202 |

| 9 | 92 | 193 | 92 | 192 |

| 10 | 98 | 167 | 97 | 167 |

| Summary Statistics | NBA | GWO | FA | WOA | SSA |

|---|---|---|---|---|---|

| Minimum | 79 | 80 | 80 | 79 | 80 |

| Maximum | 84 | 83 | 84 | 84 | 85 |

| Mean | 82 | 81.8 | 82.2 | 81.4 | 81.4 |

| Standard deviation | 2.34 | 1.64 | 2.04 | 2.40 | 2.07 |

| Half-width | 2.91 | 2.04 | 2.54 | 2.99 | 2.57 |

| Percentage error (half-width/mean) | 3.55 | 2.49 | 3.09 | 3.67 | 3.16 |

| Summary Statistics | NBA | GWO | FA | WOA | SSA |

|---|---|---|---|---|---|

| Minimum | 157.80 | 158.35 | 160.71 | 158.26 | 164.69 |

| Maximum | 172.39 | 170.69 | 175.72 | 171.27 | 177.80 |

| Mean | 163.89 | 163.45 | 166.92 | 165.01 | 173.22 |

| Standard deviation | 6.84 | 6.45 | 7.30 | 7.01 | 5.11 |

| Half-width | 8.49 | 8.01 | 9.06 | 8.70 | 6.35 |

| Percentage error (half-width/mean) | 5.18 | 4.90 | 5.43 | 5.27 | 3.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussein, M.; Eltoukhy, A.E.E.; Darko, A.; Eltawil, A. Simulation-Optimization for the Planning of Off-Site Construction Projects: A Comparative Study of Recent Swarm Intelligence Metaheuristics. Sustainability 2021, 13, 13551. https://doi.org/10.3390/su132413551

Hussein M, Eltoukhy AEE, Darko A, Eltawil A. Simulation-Optimization for the Planning of Off-Site Construction Projects: A Comparative Study of Recent Swarm Intelligence Metaheuristics. Sustainability. 2021; 13(24):13551. https://doi.org/10.3390/su132413551

Chicago/Turabian StyleHussein, Mohamed, Abdelrahman E. E. Eltoukhy, Amos Darko, and Amr Eltawil. 2021. "Simulation-Optimization for the Planning of Off-Site Construction Projects: A Comparative Study of Recent Swarm Intelligence Metaheuristics" Sustainability 13, no. 24: 13551. https://doi.org/10.3390/su132413551

APA StyleHussein, M., Eltoukhy, A. E. E., Darko, A., & Eltawil, A. (2021). Simulation-Optimization for the Planning of Off-Site Construction Projects: A Comparative Study of Recent Swarm Intelligence Metaheuristics. Sustainability, 13(24), 13551. https://doi.org/10.3390/su132413551