Health-Related Parameters for Evaluation Methodologies of Human Operators in Industry: A Systematic Literature Review

Abstract

1. Introduction

- What are the tools and methodologies used to evaluate the health parameters considered for evaluation of the working conditions of the operators in industry?

- Which methods are proposed to mitigate the impact of the working conditions on operators and their health?

- How are these methods integrated into an industrial environment?

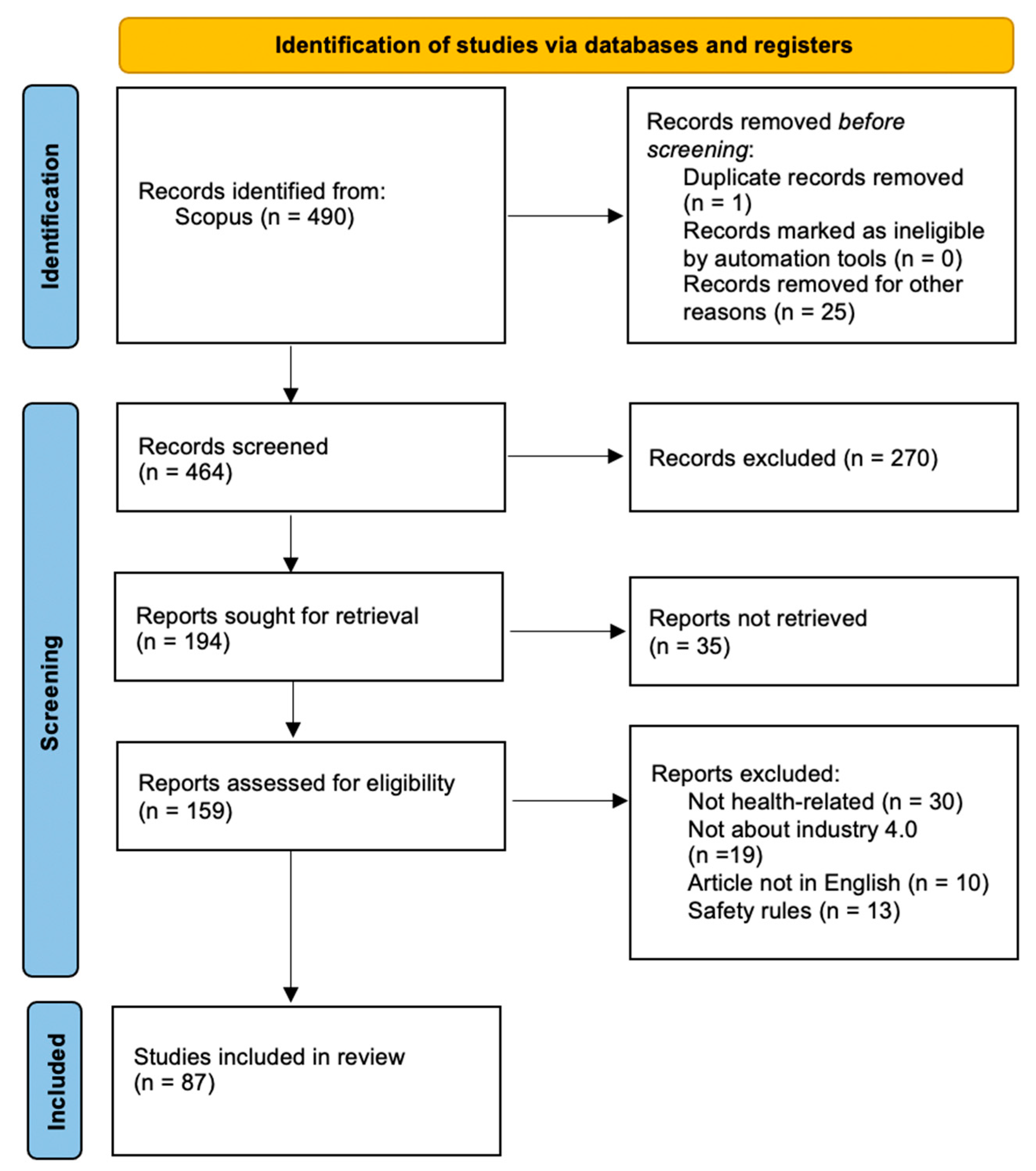

2. Material and Methods

2.1. Data Sources and Search Strategies

2.2. Eligibility Criteria

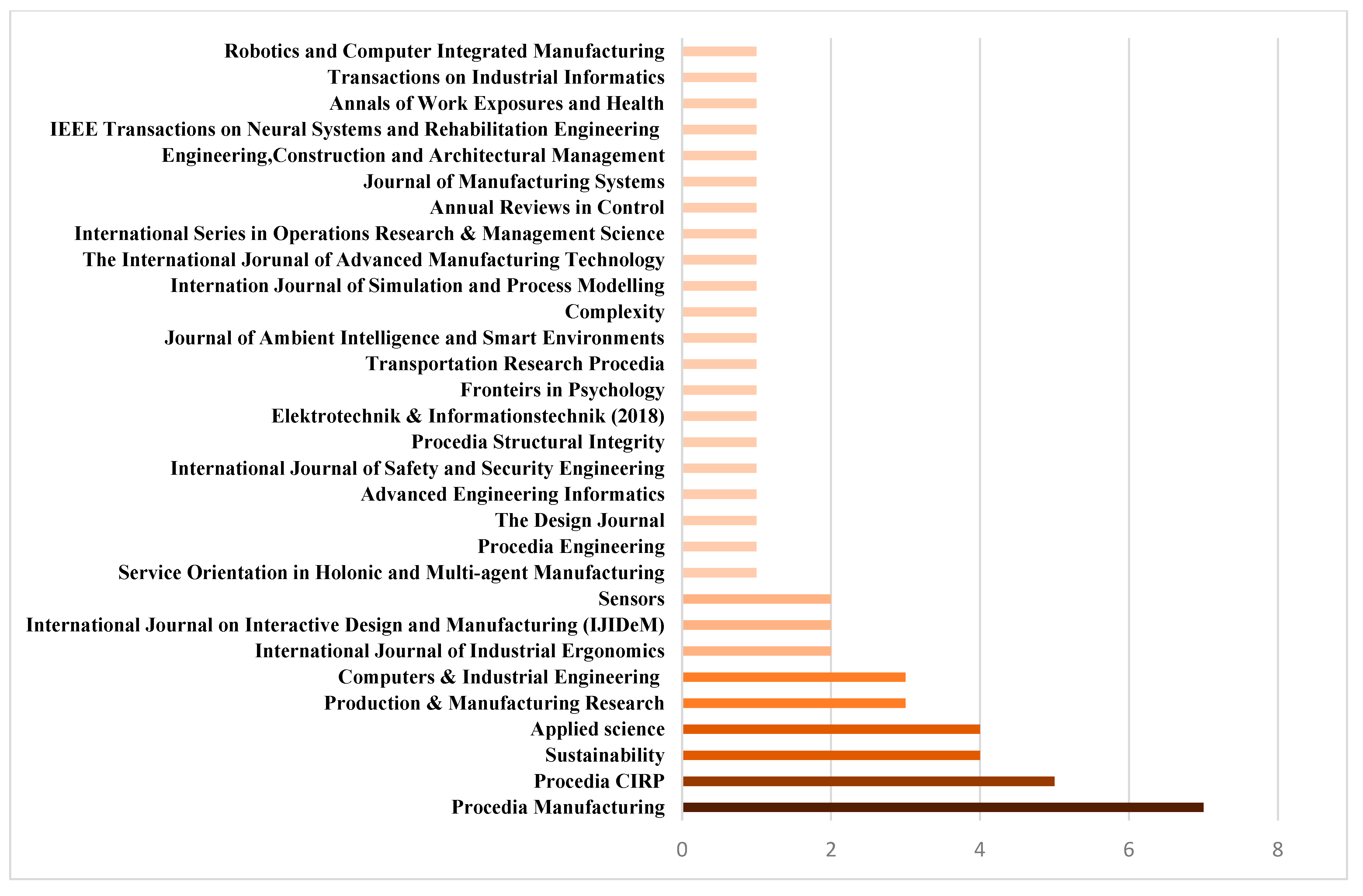

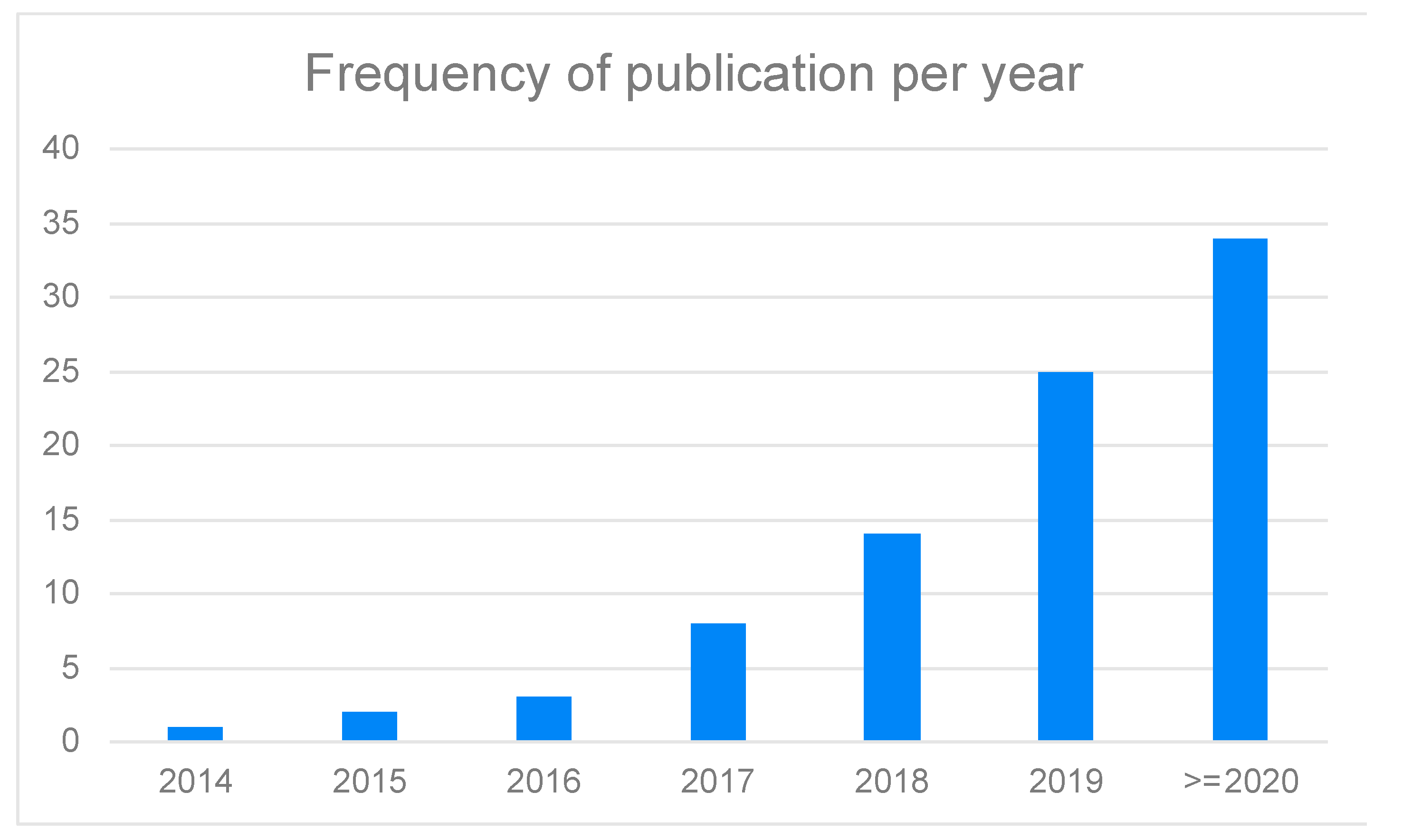

2.3. Details of Included Studies

3. Results

3.1. Short-Term Fatigue

3.1.1. Short-Term Fatigue Measurement

3.1.2. Reduction of Fatigue

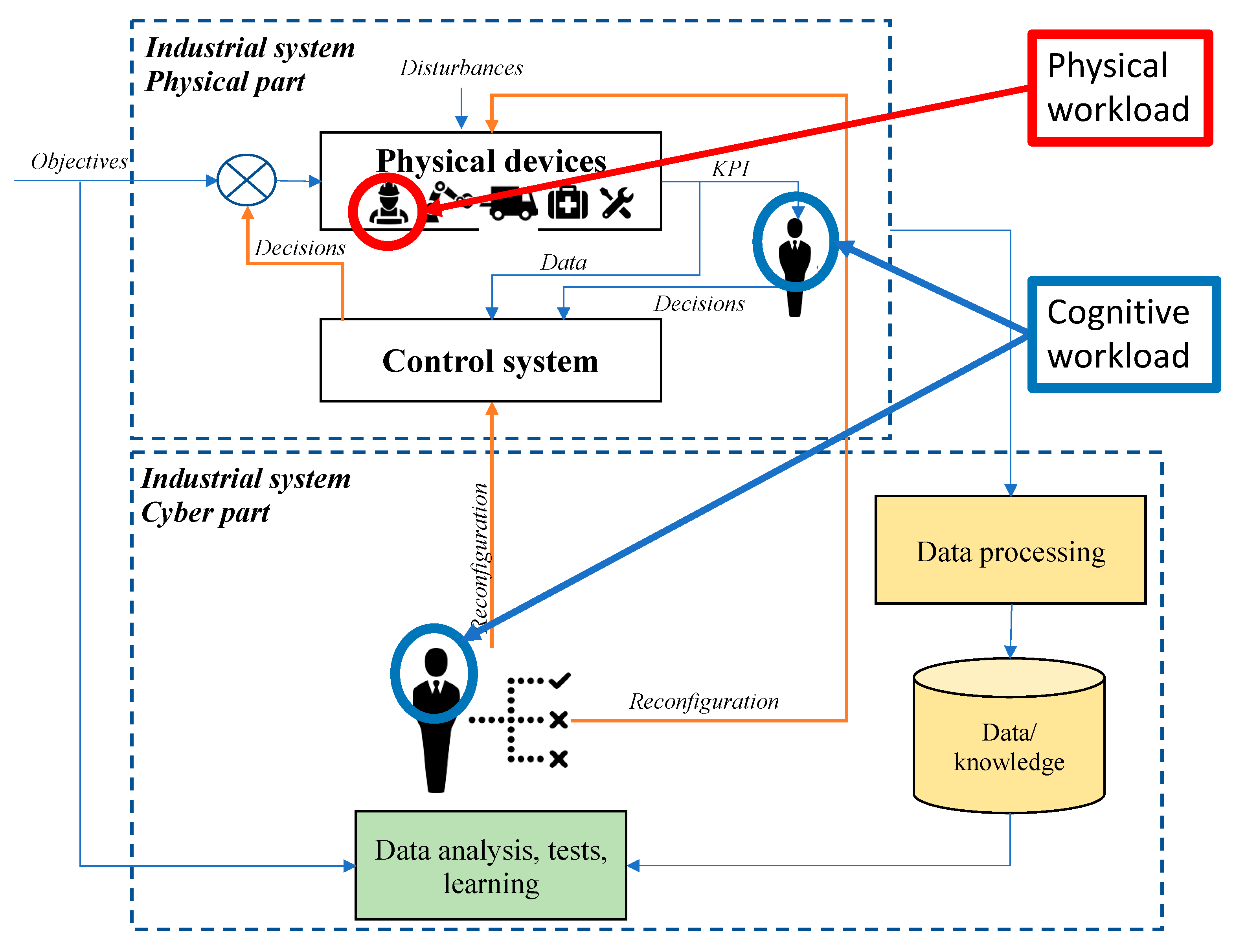

3.1.3. Integration of Human Short-Term Fatigue into an Industrial Decision System

3.2. Long-Term Physical Strain

3.2.1. Long-Term Physical Strain Risks Measurement

3.2.2. Reduction of Long-Term Physical Risks

3.2.3. Integration of Long-Term Physical Risks in Decision System

3.3. Psychosocial Risks

3.3.1. Psychosocial Parameters Measurement

3.3.2. Integration of Psychosocial Risks in the Decision System

3.4. Synthesis on Health-Related Parameters Measurement in the Literature

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nayyar, A.; Kumar, A. (Eds.) A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development; Advances in Science, Technology & Innovation; Springer International Publishing: Cham, Germany, 2020; ISBN 978-3-030-14543-9. [Google Scholar]

- Sgarbossa, F.; Grosse, E.H.; Neumann, W.P.; Battini, D.; Glock, C.H. Human factors in production and logistics systems of the future. Annu. Rev. Control 2020, 49, 295–305. [Google Scholar] [CrossRef]

- Battini, D.; Delorme, X.; Dolgui, A.; Sgarbossa, F. Assembly line balancing with ergonomics paradigms: Two alternative methods. IFAC Pap. 2015, 48, 586–591. [Google Scholar] [CrossRef]

- Koukoulaki, T. The impact of lean production on musculoskeletal and psychosocial risks: An examination of sociotechnical trends over 20 years. Appl. Ergon. 2014, 45, 198–212. [Google Scholar] [CrossRef] [PubMed]

- Costa, D.; Pires, F.; Rodrigues, N.; Barbosa, J.; Igrejas, G.; Leitao, P. Empowering Humans in a Cyber-Physical Production System: Human-in-the-loop Perspective. In Proceedings of the 2019 IEEE International Conference on Industrial Cyber Physical Systems (ICPS), Taipei, Taiwan, 6–9 May 2019; pp. 139–144. [Google Scholar]

- Putnik, G.D.; Ferreira, L.; Lopes, N.; Putnik, Z. What is a Cyber-Physical System: Definitions and models spectrum. FME Trans. 2019, 47, 663–674. [Google Scholar] [CrossRef]

- Kadir, B.A.; Broberg, O.; Conceição, C.S. da Current research and future perspectives on human factors and ergonomics in Industry 4.0. Comput. Ind. Eng. 2019, 137, 106004. [Google Scholar] [CrossRef]

- Bernard, B.P.; Putz-Anderson, V. Musculoskeletal disorders and workplace factors. In A Critical Review of Epidemiologic Evidence for Work-Related Musculoskeletal Disorders of the Neck, Upper Extremity, and Low Back; U.S. Department of Health and Human Services: Cincinatti, OH, USA, 1997. [Google Scholar]

- Widanarko, B.; Legg, S.; Stevenson, M.; Devereux, J.; Eng, A.; Mannetje, A.T.; Cheng, S.; Douwes, J.; Ellison-Loschmann, L.; McLean, D.; et al. Prevalence of musculoskeletal symptoms in relation to gender, age, and occupational/industrial group. Int. J. Ind. Ergon. 2011, 41, 561–572. [Google Scholar] [CrossRef]

- Fan, Z.J.; Silverstein, B.A.; Bao, S.; Bonauto, D.K.; Howard, N.L.; Spielholz, P.O.; Smith, C.K.; Polissar, N.L.; Viikari-Juntura, E. Quantitative exposure-response relations between physical workload and prevalence of lateral epicondylitis in a working population. Am. J. Ind. Med. 2009, 52, 479–490. [Google Scholar] [CrossRef]

- Edwards, D.J.; Rillie, I.; Chileshe, N.; Lai, J.; Hosseini, M.R.; Thwala, W.D. A field survey of hand–arm vibration exposure in the UK utilities sector. Eng. Constr. Archit. Manag. 2020, 27, 2179–2198. [Google Scholar] [CrossRef]

- González-Muñoz, E.L.; Chaurand, R.Á. Analysis of the Role of Job Stress in the Presence of Musculoskeletal Symptoms, Related with Ergonomic Factors. Procedia Manuf. 2015, 3, 4964–4970. [Google Scholar] [CrossRef]

- Dobrowolska, M.; Ślazyk-Sobol, M.; Flakus, M.; Deja, A. Climate and Ties in Workplace versus Sense of Danger and Stress, Based on Empirical Research in the Aviation Industry. Sustainability 2020, 12, 5302. [Google Scholar] [CrossRef]

- Hartvigsen, J.; Lings, S.; Leboeuf-Yde, C.; Bakketeig, L. Psychosocial factors at work in relation to low back pain and consequences of low back pain; a systematic, critical review of prospective cohort studies. Occup. Environ. Med. 2004, 61, e2. [Google Scholar]

- Gualtieri, L.; Rauch, E.; Vidoni, R. Emerging research fields in safety and ergonomics in industrial collaborative robotics: A systematic literature review. Robot. Comput. Integr. Manuf. 2021, 67, 101998. [Google Scholar] [CrossRef]

- Schulte, P.A.; Streit, J.M.K.; Sheriff, F.; Delclos, G.; Felknor, S.A.; Tamers, S.L.; Fendinger, S.; Grosch, J.; Sala, R. Potential Scenarios and Hazards in the Work of the Future: A Systematic Review of the Peer-Reviewed and Gray Literatures. Ann. Work Expo. Health 2020, 64, 786–816. [Google Scholar] [CrossRef]

- Mahmoudabadi, M.Z. Shared Representation of Work-Related Musculoskeletal Risk Factors and Comparison of Assessment Methods: An Experimental Study in the Truck Manufacturing Industry. Ph.D. Thesis, Universite d’Angers, Angers, France, 2015. [Google Scholar]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Pistolesi, F.; Lazzerini, B. Assessing the Risk of Low Back Pain and Injury via Inertial and Barometric Sensors. IEEE Trans. Ind. Inform. 2020, 16, 7199–7208. [Google Scholar] [CrossRef]

- Ranavolo, A.; Ajoudani, A.; Cherubini, A.; Bianchi, M.; Fritzsche, L.; Iavicoli, S.; Sartori, M.; Silvetti, A.; Vanderborght, B.; Varrecchia, T.; et al. The Sensor-Based Biomechanical Risk Assessment at the Base of the Need for Revising of Standards for Human Ergonomics. Sensors 2020, 20, 5750. [Google Scholar] [CrossRef]

- Conforti, I.; Mileti, I.; Panariello, D.; Caporaso, T.; Grazioso, S.; Del Prete, Z.; Lanzotti, A.; Di Gironimo, G.; Palermo, E. Validation of a novel wearable solution for measuring L5/S1 load during manual material handling tasks. In Proceedings of the 2020 IEEE International Workshop on Metrology for Industry 4.0 & IoT, Rome, Italy, 3–5 June 2020; pp. 501–506. [Google Scholar]

- Ali, S.E.; Khan, A.N.; Zia, S.; Mukhtar, M. Human Activity Recognition System using Smart Phone based Accelerometer and Machine Learning. In Proceedings of the 2020 IEEE International Conference on Industry 4.0, Artificial Intelligence, and Communications Technology (IAICT), Bali, Indonesia, 7–8 July 2020; pp. 69–74. [Google Scholar]

- Maczewska, A.; Polak-Sopinska, A.; Wisniewski, Z. Computer-Aided Occupational Risk Assessment of Physical Workload in the Logistics 4.0. In Advances in Human Factors, Business Management and Leadership; Kantola, J.I., Nazir, S., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Germany, 2020; Volume 961, pp. 378–390. ISBN 978-3-030-20153-1. [Google Scholar]

- Battini, D.; Finco, S.; Sgarbossa, F. Human-Oriented Assembly Line Balancing and Sequencing Model in the Industry 4.0 Era. In Scheduling in Industry 4.0 and Cloud Manufacturing; Sokolov, B., Ivanov, D., Dolgui, A., Eds.; International Series in Operations Research & Management Science; Springer International Publishing: Cham, Germany, 2020; Volume 289, pp. 141–165. ISBN 978-3-030-43176-1. [Google Scholar]

- Madonna, M.; Monica, L.; Anastasi, S.; Di Nardo, M. Evolution of Cognitive Demand in the Human–Machine Interaction Integrated with Industry 4.0 Technologies. Wit Trans. Built Environ 2019, 189, 13–19. [Google Scholar]

- Widodo, L.; Daywin, F.J.; Nadya, M. Ergonomic risk and work load analysis on material handling of PT. XYZ. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 528, p. 012030. [Google Scholar]

- Pradani, W.R.; Rahayu, M.; Martini, S.; Kurniawan, M.I. Design of Wood Pellets Carrier using Ergonomic Function Deployment (EFD) Approach to Increase Productivity of Work: A Research at PTPN VIII Ciater. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 528, p. 012011. [Google Scholar]

- Longo, F.; Nicoletti, L.; Padovano, A. Modeling workers’ behavior: A human factors taxonomy and a fuzzy analysis in the case of industrial accidents. Int. J. Ind. Ergon. 2019, 69, 29–47. [Google Scholar] [CrossRef]

- Horváthová, B.; Dulina, Ľ.; Čechová, I.; Gašo, M.; Bigošová, E. Data collection for ergonomic evaluation at logistics workplaces using sensor system. Transp. Res. Procedia 2019, 40, 1067–1072. [Google Scholar] [CrossRef]

- Ansari, F.; Hold, P.; Sihn, W. Human-Centered Cyber Physical Production System: How Does Industry 4.0 impact on Decision-Making Tasks? In Proceedings of the 2018 IEEE Technology and Engineering Management Conference (TEMSCON), Evanston, IL, USA, 28 June–1 July 2018; pp. 1–6. [Google Scholar]

- Stern, H.; Becker, T. Influence of work design elements on work performance and work perception—An experimental investigation. Procedia CIRP 2018, 72, 1233–1238. [Google Scholar] [CrossRef]

- Paviglianiti, A.; Pasero, E. VITAL-ECG: A de-bias algorithm embedded in a gender-immune device. In Proceedings of the 2020 IEEE International Workshop on Metrology for Industry 4.0 & IoT, Rome, Italy, 3–5 June 2020; pp. 314–318. [Google Scholar]

- Conforti, I.; Mileti, I.; Del Prete, Z.; Palermo, E. Assessing ergonomics and biomechanical risk in manual handling of loads through a wearable system. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0&IoT), Naples, Italy, 4–6 June 2019; pp. 388–393. [Google Scholar]

- Grazi, L.; Trigili, E.; Proface, G.; Giovacchini, F.; Crea, S.; Vitiello, N. Design and Experimental Evaluation of a Semi-Passive Upper-Limb Exoskeleton for Workers With Motorized Tuning of Assistance. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 2276–2285. [Google Scholar] [CrossRef] [PubMed]

- Nardo, M.D.; Forino, D.; Murino, T. The evolution of man–machine interaction: The role of human in Industry 4.0 paradigm. Prod. Manuf. Res. 2020, 8, 20–34. [Google Scholar] [CrossRef]

- Weckenborg, C.; Spengler, T.S. Assembly Line Balancing with Collaborative Robots under consideration of Ergonomics: A cost-oriented approach. IFAC Pap. 2019, 52, 1860–1865. [Google Scholar] [CrossRef]

- Becker, T.; Stern, H. Future Trends in Human Work area Design for Cyber-Physical Production Systems. Procedia CIRP 2016, 57, 404–409. [Google Scholar] [CrossRef]

- Aslan, A.I. International European Congress on Social Sciences-IV. 13. Available online: https://www.researchgate.net/publication/336699164_The_Role_of_Industry_40_in_Occupational_Health_and_Safety (accessed on 6 May 2021).

- Antao, L.; Pinto, R.; Reis, J.; Goncalves, G.; Pereira, F.L. Cooperative Human-Machine Interaction in Industrial Environments. In Proceedings of the 2018 13th APCA International Conference on Control and Soft Computing (CONTROLO), Ponta Delgada, Portugal, 4–6 June 2018; pp. 430–435. [Google Scholar]

- Mattsson, S. Forming a cognitive automation strategy for Operator 4.0 in complex assembly. Comput. Ind. Eng. 2020, 139, 105360. [Google Scholar] [CrossRef]

- Simões, B. Cross reality to enhance worker cognition in industrial assembly operations. Int. J. Adv. Manuf. Technol. 2019, 105, 3965–3978. [Google Scholar] [CrossRef]

- Merkel, L.; Berger, C.; Schultz, C.; Braunreuther, S.; Reinhart, G. Application-specific design of assistance systems for manual work in production. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 10–13 December 2017; pp. 1189–1193. [Google Scholar]

- Meißner, D.W.I.J.; Schmatz, M.S.F.; Beuß, D.I.F.; Sender, D.W.I.J.; Flügge, I.W.; Gorr, D.K.F.E. Smart Human-Robot-Collaboration in Mechanical Joining Processes. Procedia Manuf. 2018, 24, 264–270. [Google Scholar] [CrossRef]

- Paredes-Astudillo, Y.A.; Moreno, D.; Vargas, A.-M.; Angel, M.-A.; Perez, S.; Jimenez, J.-F.; Saavedra-Robinson, L.A.; Trentesaux, D. Human Fatigue Aware Cyber-Physical Production System. In Proceedings of the 2020 IEEE International Conference on Human-Machine Systems (ICHMS), Rome, Italy, 7–9 September 2020; pp. 1–6. [Google Scholar]

- Suarez-Fernandez de Miranda, S.; Aguayo-González, F.; Salguero-Gómez, J.; Ávila-Gutiérrez, M.J. Life cycle engineering 4.0: A proposal to conceive manufacturing systems for industry 4.0 centred on the human factor (DfHFinI4. 0). Appl. Sci. 2020, 10, 4442. [Google Scholar] [CrossRef]

- Cimini, C.; Pirola, F.; Pinto, R.; Cavalieri, S. A human-in-the-loop manufacturing control architecture for the next generation of production systems. J. Manuf. Syst. 2020, 54, 258–271. [Google Scholar] [CrossRef]

- Stern, H.; Becker, T. Concept and Evaluation of a Method for the Integration of Human Factors into Human-Oriented Work Design in Cyber-Physical Production Systems. Sustainability 2019, 11, 4508. [Google Scholar] [CrossRef]

- Brauner, P.; Ziefle, M. Why consider the human-in-the-loop in automated cyber-physical production systems? Two cases from cross-company cooperation. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; pp. 861–866. [Google Scholar]

- Lamon, E.; Peternel, L.; Ajoudani, A. Towards a Prolonged Productivity in Industry 4.0: A Framework for Fatigue Minimisation in Robot-Robot Co-Manipulation. In Proceedings of the 2018 IEEE-RAS 18th International Conference on Humanoid Robots (Humanoids), Beijing, China, 6–9 November 2018; pp. 1–6. [Google Scholar]

- Stern, H.; Becker, T. Development of a Model for the Integration of Human Factors in Cyber-physical Production Systems. Procedia Manuf. 2017, 9, 151–158. [Google Scholar] [CrossRef]

- Fantini, P.; Tavola, G.; Taisch, M.; Barbosa, J.; Leitao, P.; Liu, Y.; Sayed, M.S.; Lohse, N. Exploring the integration of the human as a flexibility factor in CPS enabled manufacturing environments: Methodology and results. In Proceedings of the IECON 2016 42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 5711–5716. [Google Scholar]

- Gaham, M.; Bouzouia, B.; Achour, N. Human-in-the-Loop Cyber-Physical Production Systems Control (HiLCP2sC): A Multi-objective Interactive Framework Proposal. In Service Orientation in Holonic and Multi-Agent Manufacturing; Borangiu, T., Thomas, A., Trentesaux, D., Eds.; Studies in Computational Intelligence; Springer International Publishing: Cham, Germany, 2015; Volume 594, pp. 315–325. ISBN 978-3-319-15158-8. [Google Scholar]

- Reis, J.; Pinto, R.; Goncalves, G. Human-centered application using cyber-physical production system. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 8634–8639. [Google Scholar]

- Siafara, L.C.; Kholerdi, H.; Bratukhin, A.; Taherinejad, N.; Jantsch, A. SAMBA—An architecture for adaptive cognitive control of distributed Cyber-Physical Production Systems based on its self-awareness. Elektrotechnik Und Inf. 2018, 135, 270–277. [Google Scholar] [CrossRef]

- Vernim, S.; Walzel, H.; Knoll, A.; Reinhart, G. Towards capability-based worker modelling in a smart factory. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 10–13 December 2017; pp. 1576–1580. [Google Scholar]

- Menolotto, M.; Komaris, D.-S.; Tedesco, S.; O’Flynn, B.; Walsh, M. Motion Capture Technology in Industrial Applications: A Systematic Review. Sensors 2020, 20, 5687. [Google Scholar] [CrossRef]

- Greco, A.; Caterino, M.; Fera, M.; Gerbino, S. Digital Twin for Monitoring Ergonomics during Manufacturing Production. Appl. Sci. 2020, 10, 7758. [Google Scholar] [CrossRef]

- Ojstersek, R.; Buchmeister, B.; Herzog, N.V. Use of Data-Driven Simulation Modeling and Visual Computing Methods for Workplace Evaluation. Appl. Sci. 2020, 10, 7037. [Google Scholar] [CrossRef]

- Bruno, F.; Barbieri, L.; Muzzupappa, M. A Mixed Reality system for the ergonomic assessment of industrial workstations. Int. J. Interact. Des. Manuf. IJIDeM 2020, 14, 805–812. [Google Scholar] [CrossRef]

- Tutak, M.; Brodny, J.; Dobrowolska, M. Assessment of Work Conditions in a Production Enterprise—A Case Study. Sustainability 2020, 12, 5390. [Google Scholar] [CrossRef]

- Bortolini, M.; Faccio, M.; Gamberi, M.; Pilati, F. Motion Analysis System (MAS) for production and ergonomics assessment in the manufacturing processes. Comput. Ind. Eng. 2020, 139, 105485. [Google Scholar] [CrossRef]

- Manghisi, V.M.; Uva, A.E.; Fiorentino, M.; Gattullo, M.; Boccaccio, A.; Evangelista, A. Automatic ergonomic postural risk monitoring on the factory shopfloor—The ergosentinel tool. Procedia Manuf. 2020, 42, 97–103. [Google Scholar] [CrossRef]

- Panariello, D.; Grazioso, S.; Caporaso, T.; Palomba, A.; Di Gironimo, G.; Lanzotti, A. Evaluation of human joint angles in industrial tasks using OpenSim. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0&IoT), Naples, Italy, 4–6 June 2019; pp. 78–83. [Google Scholar]

- Havard, V.; Jeanne, B.; Lacomblez, M.; Baudry, D. Digital twin and virtual reality: A co-simulation environment for design and assessment of industrial workstations. Prod. Manuf. Res. 2019, 7, 472–489. [Google Scholar] [CrossRef]

- Caputo, F.; Greco, A.; Fera, M.; Macchiaroli, R. Workplace design ergonomic validation based on multiple human factors assessment methods and simulation. Prod. Manuf. Res. 2019, 7, 195–222. [Google Scholar] [CrossRef]

- Peruzzini, M.; Pellicciari, M.; Grandi, F.; Andrisano, A.O. Una configuración de realidad virtual multimodal para el diseño centrado en el ser humano de estaciones de trabajo industriales. DYNA 2019, 94, 182–188. [Google Scholar] [CrossRef]

- Caputo, F.; Greco, A.; Fera, M.; Caiazzo, G.; Spada, S. Simulation Techniques for Ergonomic Performance Evaluation of Manual Workplaces During Preliminary Design Phase. In Proceedings of the 20th Congress of the International Ergonomics Association (IEA 2018), Florence, Italy, 26–30 August 2018; Bagnara, S., Tartaglia, R., Albolino, S., Alexander, T., Fujita, Y., Eds.; Springer International Publishing: Cham, Germany, 2019; Volume 822, pp. 170–180, ISBN 978-3-319-96076-0. [Google Scholar]

- Caputo, F.; D’Amato, E.; Greco, A.; Notaro, I.; Spada, S. Human Posture Tracking System for Industrial Process Design and Assessment. In Intelligent Human Systems Integration; Karwowski, W., Ahram, T., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Germany, 2018; Volume 722, pp. 450–455. ISBN 978-3-319-73887-1. [Google Scholar]

- Caputo, F.; Greco, A.; D’Amato, E.; Notaro, I.; Spada, S. On the use of Virtual Reality for a human-centered workplace design. Procedia Struct. Integr. 2018, 8, 297–308. [Google Scholar] [CrossRef]

- Gašová, M.; Gašo, M.; Štefánik, A. Advanced Industrial Tools of Ergonomics Based on Industry 4.0 Concept. Procedia Eng. 2017, 192, 219–224. [Google Scholar] [CrossRef]

- Caporaso, T.; Grazioso, S.; Nardella, S.; Ostuni, B.; Gironimo, G.D.; Lanzotti, A. Biomechanical–based torque reconstruction of the human shoulder joint in industrial tasks. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4. 0&IoT), Naples, Italy, 4–6 June 2019. [Google Scholar]

- Fantini, P.; Pinzone, M.; Taisch, M. Placing the operator at the centre of Industry 4.0 design: Modelling and assessing human activities within cyber-physical systems. Comput. Ind. Eng. 2020, 139, 105058. [Google Scholar] [CrossRef]

- Lanzotti, A.; Carbone, F.; Di Gironimo, G.; Papa, S.; Renno, F.; Tarallo, A.; D’Angelo, R. On the usability of augmented reality devices for interactive risk assessment. Int. J. Saf. Secur. Eng. 2018, 8, 132–138. [Google Scholar] [CrossRef][Green Version]

- Panariello, D.; Grazioso, S.; Caporaso, T.; Di Gironimo, G.; Lanzotti, A. User-centered approach for design and development of industrial workplace. Int. J. Interact. Des. Manuf. IJIDeM 2021, 15, 121–123. [Google Scholar] [CrossRef]

- Papetti, A.; Rossi, M.; Menghi, R.; Germani, M. Human-centered design for improving the workplace in the footwear sector. Procedia CIRP 2020, 91, 295–300. [Google Scholar] [CrossRef]

- Cordella, F.; di Luzio, F.S.; Lauretti, C.; Draicchio, F.; Zollo, L. A biofeedback-based posture correction system for working environments. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0&IoT), Naples, Italy, 4–6 June 2019; pp. 405–409. [Google Scholar]

- Bertram, P.; Motsch, W.; Rübel, P.; Ruskowski, M. Intelligent Material Supply Supporting Assistive Systems for Manual Working Stations. Procedia Manuf. 2019, 38, 983–990. [Google Scholar] [CrossRef]

- Mengoni, M.; Ceccacci, S.; Generosi, A.; Leopardi, A. Spatial Augmented Reality: An application for human work in smart manufacturing environment. Procedia Manuf. 2018, 17, 476–483. [Google Scholar] [CrossRef]

- Laudante, E. Industry 4.0, Innovation and Design. A new approach for ergonomic analysis in manufacturing system. Des. J. 2017, 20, S2724–S2734. [Google Scholar] [CrossRef]

- Laudante, E.; Caputo, F. Design and Digital Manufacturing: An ergonomic approach for Industry 4.0. In Proceedings of the Libro de Actas—Systems & Design: Beyond Processes and Thinking (IFDP-SD2016); Universitat Politècnica València: Valencia, Spain, 2016. [Google Scholar]

- Grazi, L.; Chen, B.; Lanotte, F.; Vitiello, N.; Crea, S. Towards methodology and metrics for assessing lumbar exoskeletons in industrial applications. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0&IoT), Naples, Italy, 4–6 June 2018; pp. 400–404. [Google Scholar]

- Mark, B.G.; Rauch, E.; Matt, D.T. Study of the impact of projection-based assistance systems for improving the learning curve in assembly processes. Procedia CIRP 2020, 88, 98–103. [Google Scholar] [CrossRef]

- Klippert, J.; Reuter, M.; Conrad, A.-K.; Wannöffel, M.; Schulte, D.; Wienbruch, T.; Kuhlenkötter, B. Learning factory for decent work—An interdisciplinary workshop on MES for worker representatives. Procedia Manuf. 2020, 45, 55–59. [Google Scholar] [CrossRef]

- Gualtieri, L.; Palomba, I.; Merati, F.A.; Rauch, E.; Vidoni, R. Design of Human-Centered Collaborative Assembly Workstations for the Improvement of Operators’ Physical Ergonomics and Production Efficiency: A Case Study. Sustainability 2020, 12, 3606. [Google Scholar] [CrossRef]

- Peruzzini, M.; Grandi, F.; Pellicciari, M. Exploring the potential of Operator 4.0 interface and monitoring. Comput. Ind. Eng. 2020, 139, 105600. [Google Scholar] [CrossRef]

- Angelopoulou, A.; Mykoniatis, K.; Boyapati, N.R. Industry 4.0: The use of simulation for human reliability assessment. Procedia Manuf. 2020, 42, 296–301. [Google Scholar] [CrossRef]

- Brocal, F.; González, C.; Komljenovic, D.; Katina, P.F.; Sebastián, M.A. Emerging Risk Management in Industry 4.0: An Approach to Improve Organizational and Human Performance in the Complex Systems. Complexity 2019, 2019, 2089763. [Google Scholar] [CrossRef]

- Nicoletti, L.; Padovano, A. Human factors in occupational health and safety 4.0: A cross-sectional correlation study of workload, stress and outcomes of an industrial emergency response. Int. J. Simul. Process Model. 2019, 14, 178. [Google Scholar] [CrossRef]

- Peruzzini, M.; Pellicciari, M. A framework to design a human-centred adaptive manufacturing system for aging workers. Adv. Eng. Inform. 2017, 33, 330–349. [Google Scholar] [CrossRef]

- Kadir, B.A. Human well-being and system performance in the transition to industry 4.0. Int. J. Ind. Ergon. 2020, 76, 102936. [Google Scholar] [CrossRef]

- Mannhardt, F.; Petersen, S.A.; Oliveira, M.F. A trust and privacy framework for smart manufacturing environments. J. Ambient Intell. Smart Environ. 2019, 11, 201–219. [Google Scholar] [CrossRef]

- Mach, S.; Gründling, J.P.; Schmalfuß, F.; Krems, J.F. How to Assess Mental Workload Quick and Easy at Work: A Method Comparison. In Proceedings of the 20th Congress of the International Ergonomics Association (IEA 2018), Florence, Italy, 26–30 August 2018; Bagnara, S., Tartaglia, R., Albolino, S., Alexander, T., Fujita, Y., Eds.; Advances in Intelligent Systems and Computing. Springer International Publishing: Cham, Germany, 2019; Volume 825, pp. 978–984, ISBN 978-3-319-96067-8. [Google Scholar]

- Kaasinen, E.; Aromaa, S.; Heikkilä, P.; Liinasuo, M. Empowering and Engaging Solutions for Operator 4.0—Acceptance and Foreseen Impacts by Factory Workers. In Advances in Production Management Systems. Production Management for the Factory of the Future; Ameri, F., Stecke, K.E., von Cieminski, G., Kiritsis, D., Eds.; IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Germany, 2019; Volume 566, pp. 615–623. ISBN 978-3-030-29999-6. [Google Scholar]

- Jenderny, S.; Foullois, M.; Kato-Beiderwieden, A.-L.; Bansmann, M.; Wöste, L.; Lamß, J.; Maier, G.W.; Röcker, C. Development of an instrument for the assessment of scenarios of work 4.0 based on socio-technical criteria. In Proceedings of the 11th PErvasive Technologies Related to Assistive Environments Conference, Corfu, Greece, 26–29 June 2018; ACM: Corfu, Greece, 2018; pp. 319–326. [Google Scholar]

- Cohen, Y.; Golan, M.; Singer, G.; Faccio, M. Workstation–Operator Interaction in 4.0 Era: WOI 4.0. IFAC Pap. 2018, 51, 399–404. [Google Scholar] [CrossRef]

- Dombrowski, U. Mental Strain as Field of Action in the 4th Industrial Revolution. Procedia CIRP 2014, 6, 100–105. [Google Scholar] [CrossRef]

- Cierniak-Emerych, A.; Golej, R. Changes in safety of Working Conditions as a Result of Introducing 5S Practices. IBIMA Bus. Rev. 2020, 2020, 141027. [Google Scholar] [CrossRef]

- Scafà, M.; Papetti, A.; Brunzini, A.; Germani, M. How to improve worker’s well-being and company performance: A method to identify effective corrective actions. Procedia CIRP 2019, 81, 162–167. [Google Scholar] [CrossRef]

- Ghislieri, C.; Molino, M.; Cortese, C.G. Work and Organizational Psychology Looks at the Fourth Industrial Revolution: How to Support Workers and Organizations? Front. Psychol. 2018, 9, 2365. [Google Scholar] [CrossRef]

- Müller, S.L.; Schröder, S.; Jeschke, S.; Richert, A. Design of a Robotic Workmate. In Digital Human Modeling. Applications in Health, Safety, Ergonomics, and Risk Management: Ergonomics and Design; Duffy, V.G., Ed.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Germany, 2017; Volume 10286, pp. 447–456. ISBN 978-3-319-58462-1. [Google Scholar]

- Pacaux-Lemoine, M.-P.; Berdal, Q.; Enjalbert, S.; Trentesaux, D. Towards human-based industrial cyber-physical systems. In Proceedings of the 2018 IEEE Industrial Cyber-Physical Systems (ICPS), St. Petersburg, Russia, 15–18 May 2018; pp. 615–620. [Google Scholar]

- Longo, F.; Padovano, A.; Umbrello, S. Value-Oriented and Ethical Technology Engineering in Industry 5.0: A Human-Centric Perspective for the Design of the Factory of the Future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Pacaux-Lemoine, M.-P. Designing intelligent manufacturing systems through Human-Machine Cooperation principles: A human-centered approach. Ind. Eng. 2017, 111, 581–595. [Google Scholar] [CrossRef]

- Richert, A.; Shehadeh, M.A.; Muller, S.L.; Schroder, S.; Jeschke, S. Socializing with robots: Human-robot interactions within a virtual environment. In Proceedings of the 2016 IEEE Workshop on Advanced Robotics and its Social Impacts (ARSO), Shanghai, China, 8–10 July 2016; pp. 49–54. [Google Scholar]

- Phillips, R.O. A review of definitions of fatigue—And a step towards a whole definition. Transp. Res. Part F Traffic Psychol. Behav. 2015, 29, 48–56. [Google Scholar] [CrossRef]

- Otto, A.; Battaïa, O. Reducing physical ergonomic risks at assembly lines by line balancing and job rotation: A survey. Comput. Ind. Eng. 2017, 111, 467–480. [Google Scholar] [CrossRef]

- Karasek, R.A. Job Demands, Job Decision Latitude, and Mental Strain: Implications for Job Redesign. Adm. Sci. Q. 1979, 24, 285. [Google Scholar] [CrossRef]

- Murcia, N.; Mohafid, A.; Cardin, O. Evaluation Methods of Ergonomics Constraints in Manufacturing Operations for a Sustainable Job Balancing in Industry 4.0. In International Workshop on Service Orientation in Holonic and Multi-Agent Manufacturing; Borangiu, T., Trentesaux, D., Leitão, P., Cardin, O., Lamouri, S., Eds.; Springer International Publishing: Cham, Germany, 2021; pp. 274–285. [Google Scholar]

- Takala, E.-P.; Pehkonen, I.; Forsman, M.; Hansson, G.-Å.; Mathiassen, S.E.; Neumann, W.P.; Sjøgaard, G.; Veiersted, K.B.; Westgaard, R.H.; Winkel, J. Systematic evaluation of observational methods assessing biomechanical exposures at work. Scand. J. Work. Environ. Health 2010, 36, 3–24. [Google Scholar] [CrossRef] [PubMed]

- Chiasson, M.-È.; Imbeau, D.; Aubry, K.; Delisle, A. Comparing the results of eight methods used to evaluate risk factors associated with musculoskeletal disorders. Int. J. Ind. Ergon. 2012, 42, 478–488. [Google Scholar] [CrossRef]

| Industry 4.0/CPPS | Human Factors and Ergonomics |

|---|---|

| Industry 4.0 Industry of the future Cyber-Physical Production System Industrial Cyber-Physical System Smart factory Smart operator | Human factor Ergonomics Well-Being Human-in-the-loop Health monitoring Workplace organization Job design Task design Musculoskeletal disorders Operator fatigue Mental strain |

| Short-term Fatigue | Short-term fatigue measurement | [16,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33] |

| Reduction of fatigue | [7,15,24,34,35,36,37,38,39,40,41,42,43] | |

| Integration of human short-term fatigue in an industrial decision system | [2,44,45,46,47,48,49,50,51,52,53,54,55] | |

| Long-term physical strain | Long-term physical strain risks measurement | [11,16,23,28,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73] |

| Reduction of long-term physical risks | [7,15,27,34,37,38,74,75,76,77,78,79,80,81,82,83] | |

| Integration of long-term physical risks in decision system | [2,45,46,47,50,84,85,86,87,88,89] | |

| Psychosocial constraints | Psychosocial parameters measurement | [16,28,37,39,90,91,92,93,94,95,96] |

| Integration of psychosocial risks in decision system | [2,13,37,45,46,47,50,53,97,98,99,100,101,102,103,104] |

| References | Measurement Methodologies | Health Objectives | |||||

|---|---|---|---|---|---|---|---|

| Observation | Questionnaires | Measurement | Simulation | Short-Term Fatigue | Long-Term Strain | Psychosocial Risks | |

| [19] | X | X | |||||

| [20] | X | X | |||||

| [21] | X | X | |||||

| [22] | X | X | |||||

| [23] | X | X | X | ||||

| [24] | X | X | |||||

| [25] | X | X | |||||

| [26] | X | X | X | ||||

| [28] | X | X | X | X | |||

| [29] | X | X | |||||

| [30] | X | X | X | ||||

| [31] | X | X | |||||

| [32] | X | X | X | ||||

| [33] | X | X | |||||

| [56] | X | X | X | ||||

| [57] | X | X | |||||

| [58] | X | X | |||||

| [56] | X | X | X | ||||

| [59] | X | X | |||||

| [60] | X | X | X | ||||

| [11] | X | X | |||||

| [61] | X | X | |||||

| [62] | X | X | X | ||||

| [63] | X | X | |||||

| [64] | X | X | |||||

| [65] | X | X | |||||

| [66] | X | X | |||||

| [67] | X | X | |||||

| [68] | X | X | |||||

| [69] | X | X | |||||

| [70] | X | X | X | ||||

| [71] | X | X | X | ||||

| [72] | X | X | |||||

| [73] | X | X | X | ||||

| [39] | X | X | |||||

| [90] | X | X | |||||

| [91] | X | X | |||||

| [92] | X | X | |||||

| [93] | X | X | X | ||||

| [94] | X | X | |||||

| [95] | X | X | |||||

| [96] | X | X | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murcia, N.; Cardin, O.; Mohafid, A.; Senkel, M.-P. Health-Related Parameters for Evaluation Methodologies of Human Operators in Industry: A Systematic Literature Review. Sustainability 2021, 13, 13387. https://doi.org/10.3390/su132313387

Murcia N, Cardin O, Mohafid A, Senkel M-P. Health-Related Parameters for Evaluation Methodologies of Human Operators in Industry: A Systematic Literature Review. Sustainability. 2021; 13(23):13387. https://doi.org/10.3390/su132313387

Chicago/Turabian StyleMurcia, Nicolas, Olivier Cardin, Abdelmoula Mohafid, and Marie-Pascale Senkel. 2021. "Health-Related Parameters for Evaluation Methodologies of Human Operators in Industry: A Systematic Literature Review" Sustainability 13, no. 23: 13387. https://doi.org/10.3390/su132313387

APA StyleMurcia, N., Cardin, O., Mohafid, A., & Senkel, M.-P. (2021). Health-Related Parameters for Evaluation Methodologies of Human Operators in Industry: A Systematic Literature Review. Sustainability, 13(23), 13387. https://doi.org/10.3390/su132313387