1. Background

The building construction industry (including commercial, residential, and industrial buildings) accounts for 5% of global energy use and 10% of global GHG emissions [

1]. A primary source of these emissions is the manufacture of building construction materials such as steel, cement, and glass. To significantly reduce the GHG emissions associated with manufacture of these materials, step-change reductions are needed in the embodied energy and carbon. As aggressive building energy codes push new construction towards net-zero-energy and net-zero-carbon operations, corresponding efforts to reduce embodied energy and carbon from building construction materials must be pursued to achieve building sector decarbonization goals. For example, Chastes et al. reviewed 90 case studies and found that embodied carbon accounted for 26–57% and 74–100% of the total life cycle carbon emissions of low-energy and near zero-energy buildings, respectively [

2].

In the past couple of decades, progressive building energy codes as well as the underlying research on reducing the operational energy and its related greenhouse gas emissions have stimulated changes of practice in building design and operation. Significant progress has been made in reducing the operational energy of a building during its use phase, largely the result of energy codes. In general, we have a clear understanding of operational carbon emissions and a solid knowledgebase of carbon reduction strategies for reducing building energy use.

In contrast, strategies to reduce embodied carbon in the remaining life-cycle stages of a building are less defined and studied. The World Green Building Council defines the embodied carbon of a building as the carbon emissions associated with the materials and construction processes throughout the whole life cycle of a building [

3]. The selection of building materials and systems is largely unregulated, as long as minimum health, safety, and performance standards are met. One challenge is that upstream energy use and carbon emissions resulting from the production of building materials and equipment are more difficult to measure and track than operational energy use and emissions. Relying on the self-assessment and reporting by the manufacturers of building products alone cannot provide an accurate assessment of the embodied carbon of a building. Assessing the embodied carbon of a building has remained challenging for building design teams because a building consists of hundreds or thousands of materials and components, which require specific expertise, training, and ready-to-use tools. Building design teams often do not process such broad expertise or tools. For instance, a 100% recycled-steel beam, produced using renewable energy, may have significantly lower levels of embodied carbon compared to a virgin-steel beam produced using a coal-fired furnace even though their structural performance is the same [

1]. The location of steel manufacture not only determines the type of energy source from the local grid, but also plays an important role in the amount of carbon derived from transporting products to the construction site. Furthermore, the complexity of global manufacturing and supply chains makes it even more difficult to measure carbon emissions from material extraction to product assembly.

A major barrier to incorporating embodied-carbon related policies, standards, and regulations into practice lies in the complexity of embodied carbon counting, which requires standardized methodologies at the national level, robust analyses based on adequate data, and thorough evaluations of the readiness and maturity of the required techniques, technologies, and materials. To the knowledge of the authors, there is no comprehensive review on embodied carbon research and practice in the United States. To respond to such an important need, this literature review aims to provide a comprehensive look into the landscape of embodied carbon research and practice in the United States. It reviews the existing state-of-the-art methods, databases, and tools to assess embodied carbon. We identified the knowledge gaps at multiple levels across building materials, components, and whole building designs. This study provides a basis for the governments, academia, industry, and other institutes to collaboratively fill in these gaps and develop standards and codes to decarbonize buildings and their interface with other sectors.

2. Background of the Development of the Concept of the Embodied Carbon

2.1. Life Cycle Assessment

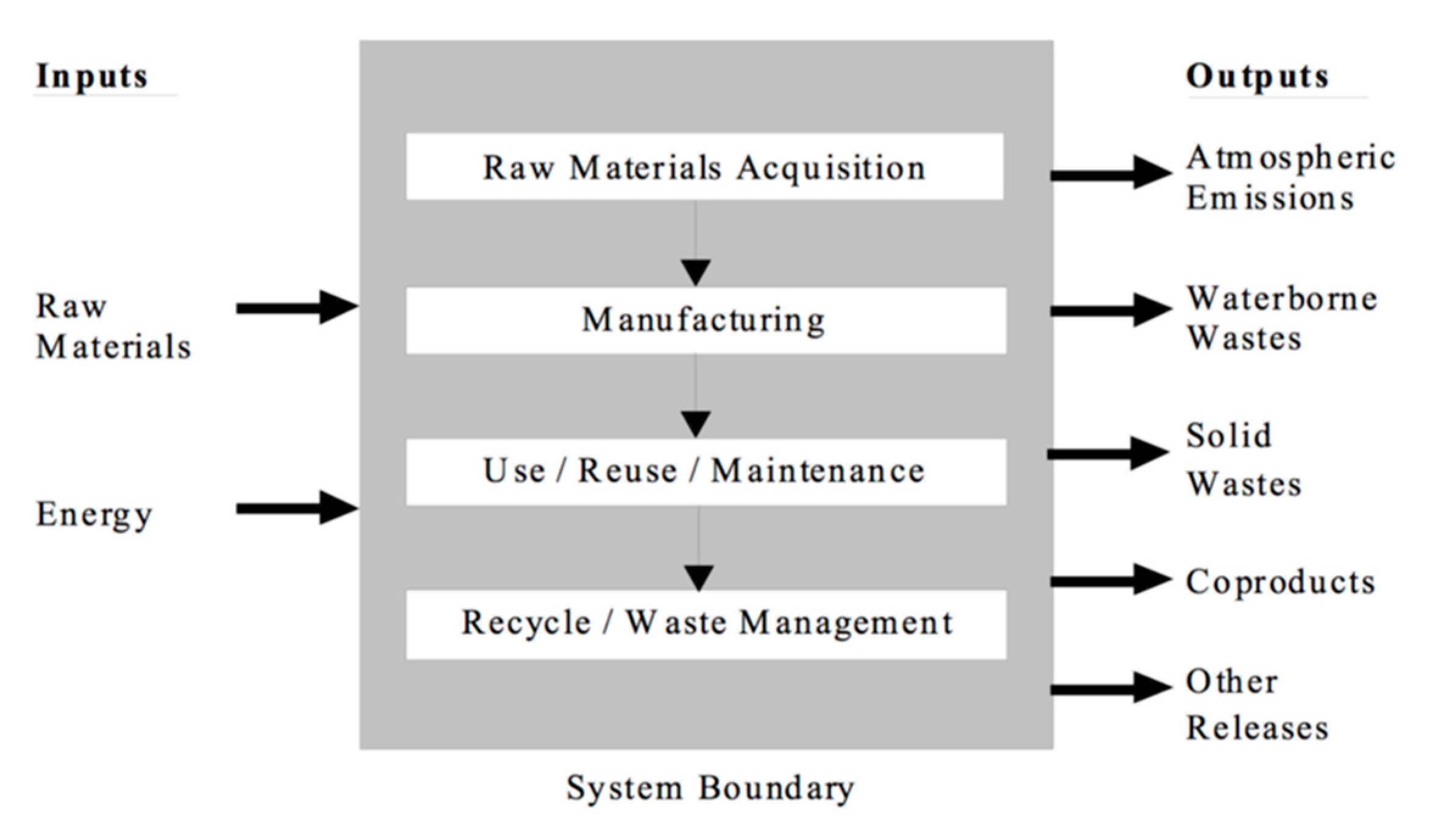

The development of embodied carbon is intertwined with the development of life cycle assessment (LCA) methodologies for materials and buildings, since embodied carbon is a part of the whole life cycle carbon associated with a building project. An LCA is a method to assess the environmental impacts of a product or service throughout its entire life cycle [

4]. Each LCA is composed of four stages: goal and scope definition (in this stage, the intent of LCA is defined), inventory analysis, impact assessment, and result interpretation. The LCA method was standardized in the 1990s by the international standardization organization (ISO) in ISO 14040 and 14044; the most used version is from 2006, which is still updated and extended regularly [

5].

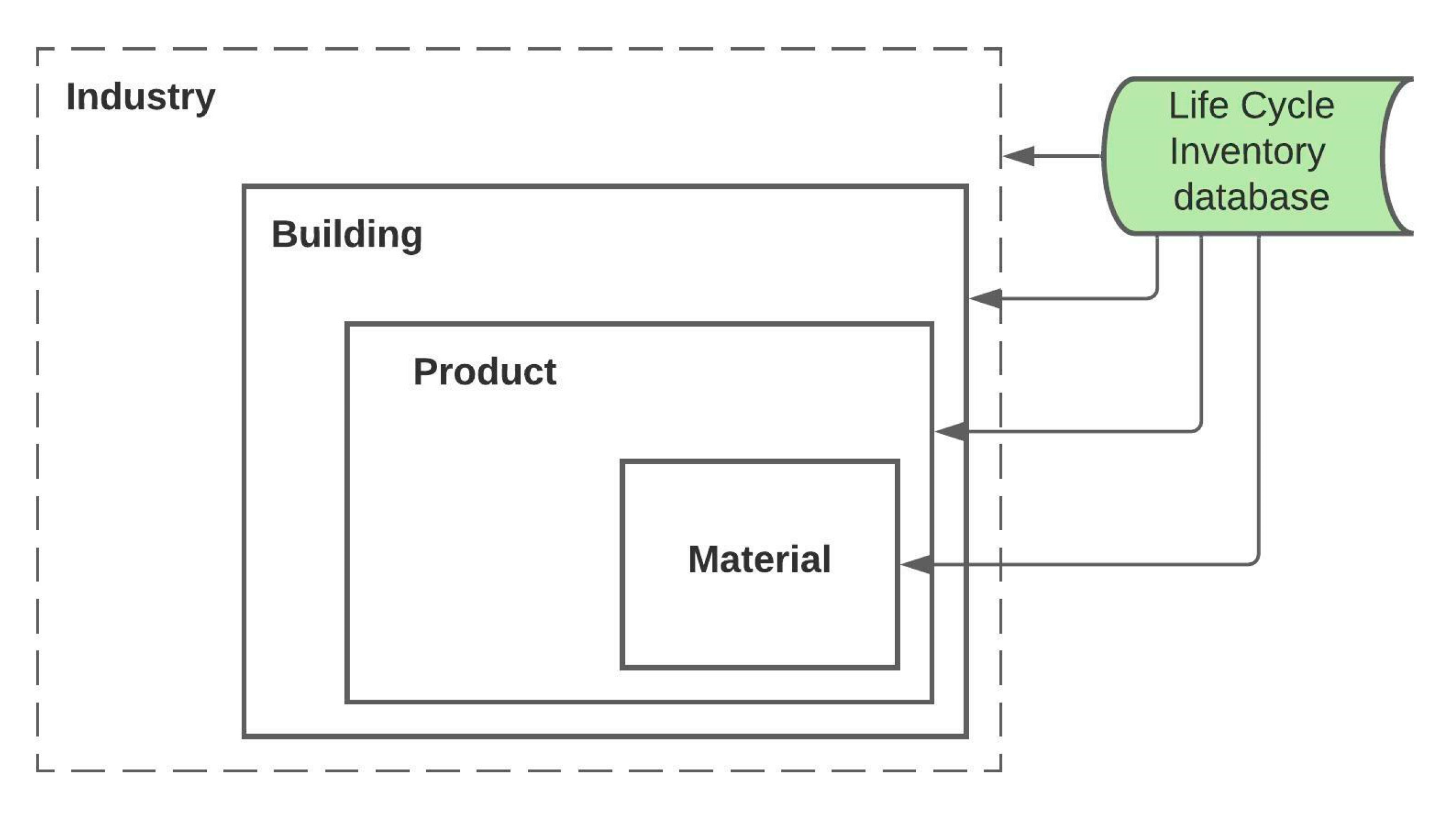

Embodied carbon quantification is one of many results from an LCA. When an LCA is applied in the building and construction sector, four different levels of assessments (depending on the chosen scopes, system boundaries, and functional units) may be conducted at building material level, building product level (including building components, systems, and assemblies), whole building level, or industry level (see

Figure 1); however, all four often use the same databases of inputs. Defining different system design parameters will result in different findings, hence, these choices should be discussed, compared, and determined at the beginning of a project, so the project team is in agreement over the goal and design of the LCA. The most commonly conducted LCAs are at the material and the whole building levels.

2.2. Life-Cycle Embodied Carbon

The term embodied carbon is sometimes used without a clear definition, which may result in incomplete calculations or incorrect comparisons.

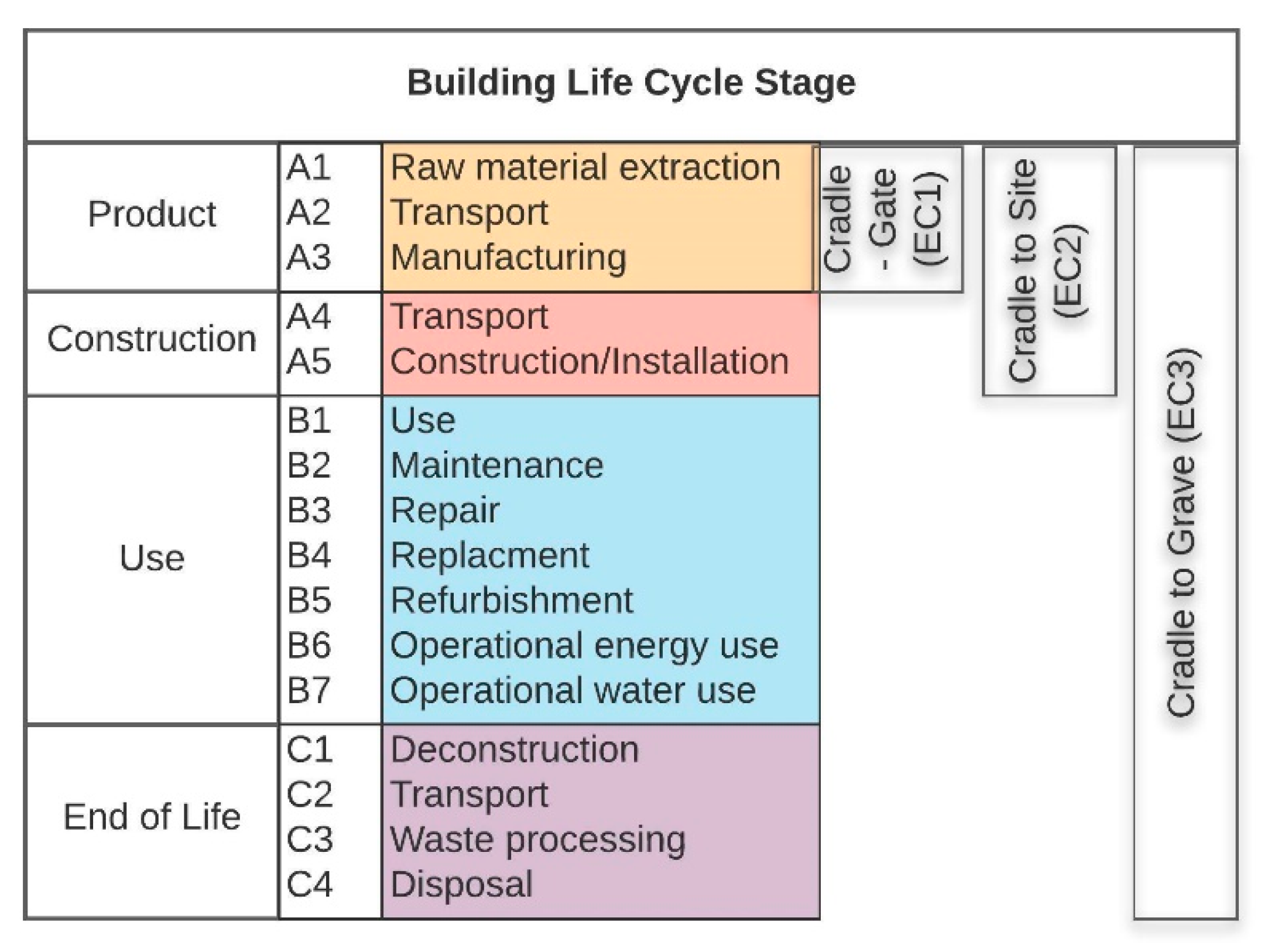

Figure 2 illustrates the different types of embodied carbon that are often referred to and discussed in the building sector as well as their relation to the entire life cycle of a building. Definition of the goal and scope, the life cycle inventory analysis, and the interpretation are based on the ISO 14044 standard [

6]. This study focuses on the “cradle to grave” scope for LCAs (A through C). As shown in

Figure 2, stage A encompasses the product and construction phases and includes A1 through A5. Sub-stages A1 through A3 are commonly included in the “cradle to gate” scope (or upfront carbon) and sub-stages A1 through A4 are typically included in the “cradle to site” scope by researchers and practitioners, which will lead to different results of the overall embodied carbon assessment for the same building due to differing system boundaries. For reference, we designate the “cradle to gate” scope as embodied carbon one (EC1), “cradle to site” as embodied carbon two (EC2), and “cradle to grave” as embodied carbon three (EC3).

The carbon emissions of any building include two broad categories: life-cycle embodied carbon and operational carbon. Life-cycle embodied carbon is the “cradle to grave” carbon associated with constructing and maintaining a building during all phases of production, onsite construction, building in operation (except utilities in B6), and final demolition and disposal. Operational carbon (B6) is composed of the carbon emissions generated from the use of energy to condition and power a building.

Life-cycle embodied carbon consists of three primary categories: initial embodied carbon, recurring embodied carbon, and end-of-life embodied carbon. Initial embodied carbon (IEC) is the carbon emitted on-site and off-site for building activities, such as construction, on-site prefabrication, transportation, and other related activities (e.g., site preparation). IEC spans life cycle stages A1-A5. IEC accounts for a significant portion of the total life-cycle embodied carbon and can be reduced by decreasing the area of the building, using fewer energy-intensive materials, and optimizing other design strategies (e.g., use of lightweight systems instead of heavy structure systems). Recurring embodied carbon (REC) is the carbon emitted during the use stage and is associated with the repair, replacement, refurbishment, and maintenance of the building. REC spans life cycle stages B1-B5. End-of life embodied carbon (EEC) is the carbon emitted during the demolition, deconstruction, transport of deconstructed building assemblies, waste processing, and material disposal. EEC is often neglected in tracking and counting mechanisms currently. IEC and EEC occur once over the lifetime of a building, while REC is influenced and modified by multiple factors (i.e., climatic condition of building site, use condition, maintenance frequency).

The life-cycle embodied carbon (LCEC) can be calculated using Equation (1) below:

where LCEC

b is the “cradle to grave” life-cycle embodied carbon of a building (kgCO

2eq/m

2), IEC

b (kgCO

2eq/m

2) is the initial embodied carbon, and

(kgCO

2eq/m

2) is the recurring carbon of a building product or material (maintenance and repair).

is the building type factor; certain building types need more frequent maintenance and repair than others, such as those with swimming pools.

is the location (climatic) condition. EEC

b (kgCO

2eq/m

2) is the end-of-life embodied carbon.

3. Literature Scan Methodology

We conducted an initial literature search and review using the keywords “Embodied carbon”, “Embodied GHGs”, and “Embodied CO

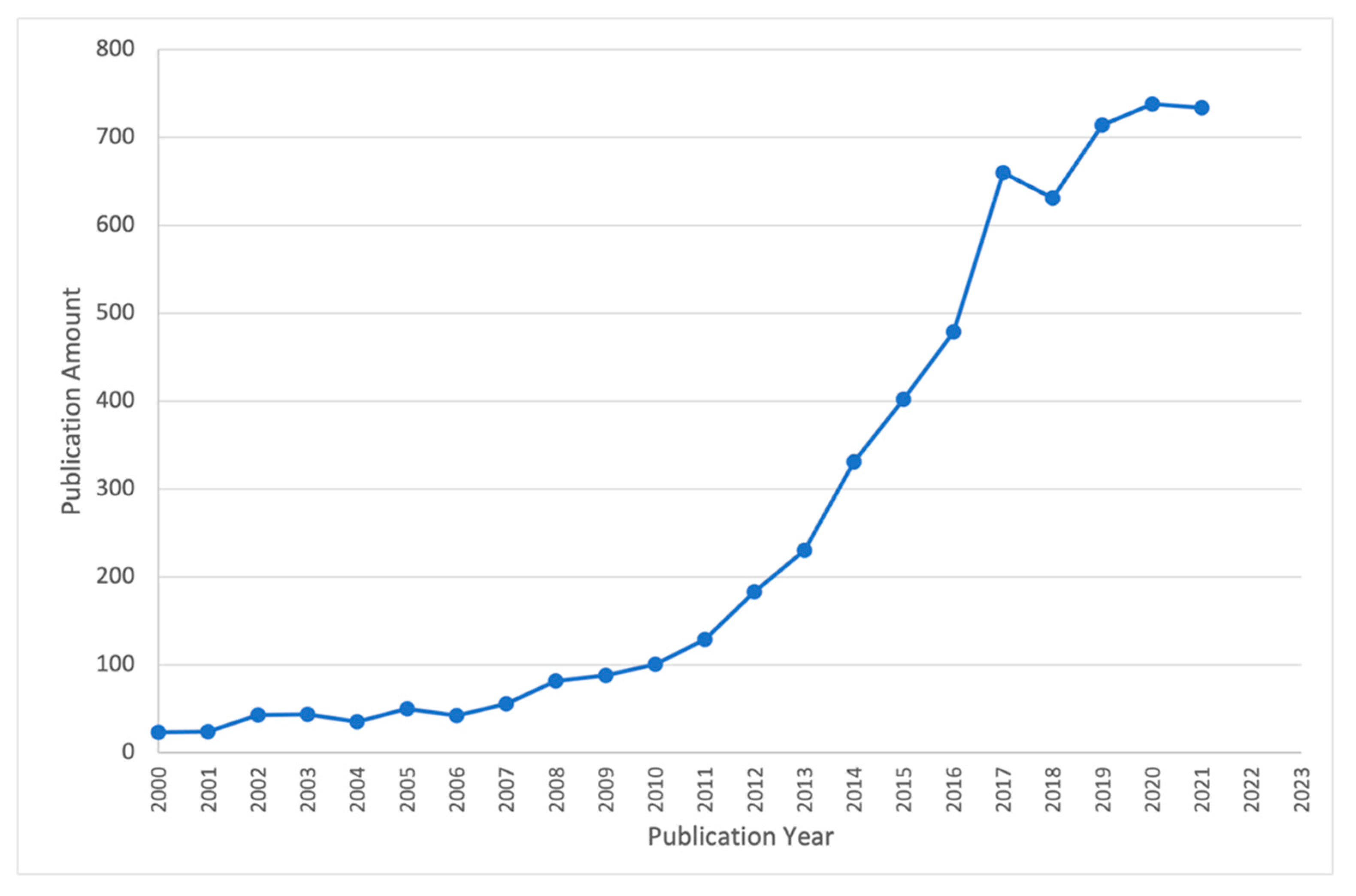

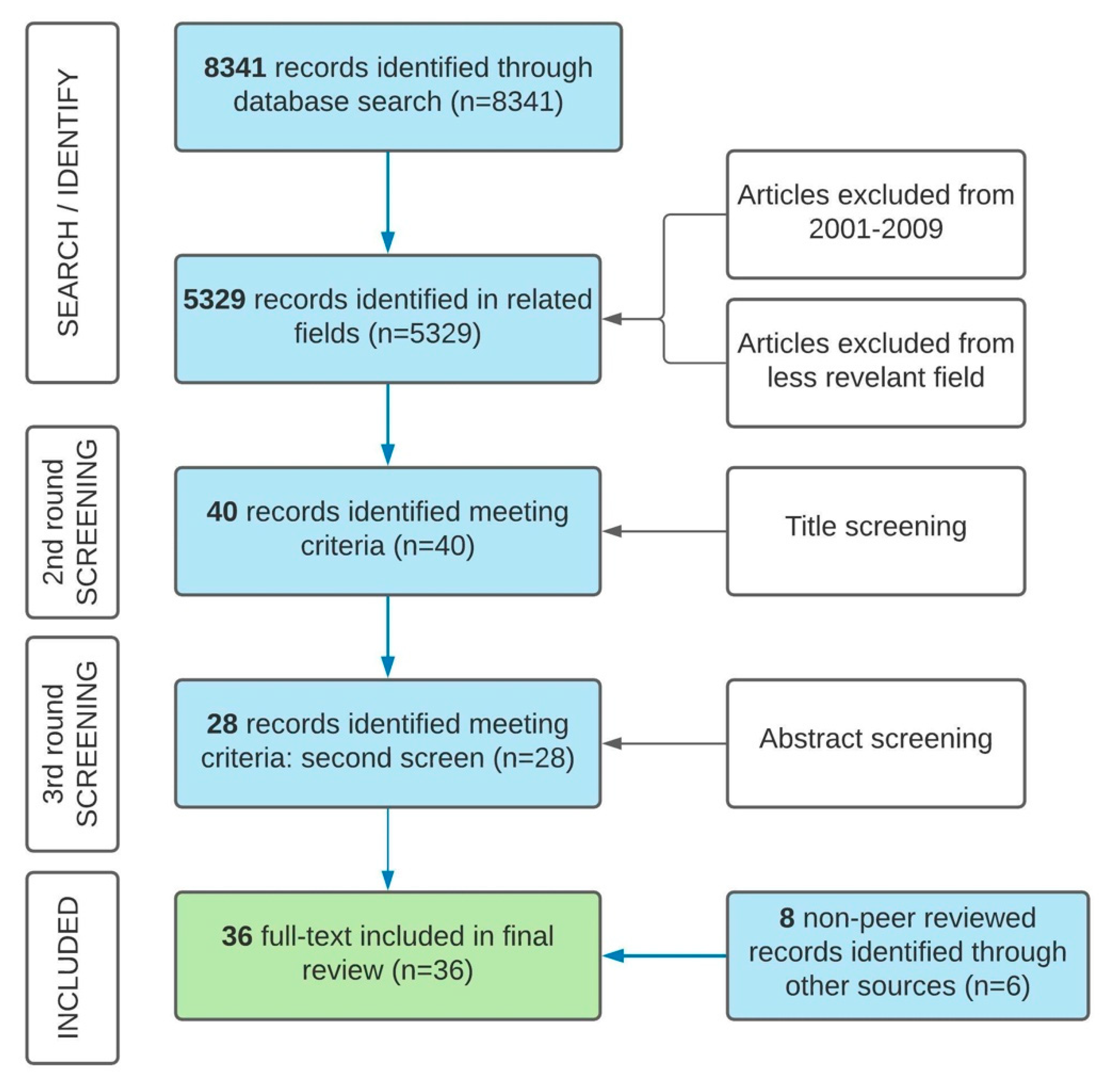

2” through the ScienceDirect website. The search yielded 8341 relevant books, journals and papers published between 2010–2021 that matched our initial search criteria. As illustrated in

Figure 3, the interest in embodied carbon in the building industry has grown exponentially since 2010. We decided to focus on the literature in the past ten years, from 2010–2021, and excluded publications from less related fields—Chemical Engineering (273); Earth and Planetary Science (259), Agricultural and Biological Science (504), Social Science (1196); Economics, Econometrics, and Finance (455); and Business, Management, and Accounting (448). Additionally, articles from encyclopedias, short communications, conference abstracts, discussions, mini reviews, and other uncategorized types were also excluded. Thus, we narrowed our search results to 5329 relevant papers in the more directly related fields of Energy, Environmental Science, Engineering, and Materials Science.

Subsequently, we reviewed the titles of the 5329 articles in a second selection round, further eliminating irrelevant topics and resulting in a smaller subset of 40 articles. Most of the eliminated articles focused on specific technical developments and did not offer new knowledge for developing embodied carbon standards, methodologies, databases, or tools. One such example is a paper entitled “Comprehensive investigation of embodied carbon emissions, costs, design parameters, and serviceability in optimum green construction of two-way slabs in buildings”. While the title of the article appeared applicable, the body of the article was irrelevant to our objectives. We also excluded articles that presented case studies outside of the United States and Canada because the life-cycle assessment of embodied carbon is sensitive to and influenced by its geographic system boundary. We will further discuss system boundary selections later in this paper.

The third-round of the literature selection process involved reading the abstracts of the 40 articles to determine whether the publication provided information on one or more of the following aspects: embodied carbon data, calculation tools, or embodied carbon code requirements and regulations. In the end, we identified 28 papers for in-depth review and analysis.

During our literature review, we focused on three essential components of embodied carbon, which are necessary for any LCA project assessing embodied carbon. They are the calculation method, the database of embodied carbon, and a calculator (tool) that converts material qualities and properties to embodied carbon (measured in kgCO

2eq/m

2). The majority of the research papers were focused on methods, tools, and case studies, with very few on data collection and database development. To fill this gap, we scanned publications from industry practitioners, not-for-profit organizations, and federal agencies through an open internet search, using key words such as “embodied carbon data,” and/or “embodied energy data,” in combination with “building,” and/or “construction”. We also investigated published documents on life-cycle inventory (LCI) data from the US and Canada, since LCI data serve as the primary inputs for conducting the inventory analysis in LCA. High-quality data that are consistent, accurate, and relevant allow for robust and meaningful results [

8]. Our search resulted in 8 more publications from the US Department of Energy, the American Institute of Architects, and industry and academic collaborative entities (e.g., the Carbon Leadership Forum). The literature scan methodology is shown in

Figure 4. In total, we reviewed 36 articles in extensive details to identify the current state of the knowledge of existing methods, databases, and tools on embodied carbon in buildings. In addition, the knowledge gaps were analyzed and quantified by summarizing the topics found in each article. Findings are presented in the following sections.

4. Review of Existing Methods, Data, and Tools

4.1. Standards and Methods

4.1.1. Standards for an LCA

The quantification of embodied carbon is intertwined with the development of an LCA. There are two gold standards for an LCA—ISO 14040 environmental management life-cycle assessment principles and framework [

9], and ISO 14044 environmental management life-cycle assessment requirements and guidelines [

10], which serve as internationally binding standards for conducting LCAs. All LCAs should comply with these standards, following the guidelines and steps laid out in them. The two standards combined cover both LCA and LCI studies, with LCI studies closely tied to embodied carbon assessment. However, these two standards do not describe LCA evaluation techniques in detail, nor do they specify calculation methodologies for the individual phases of the LCA. This gap was intentionally left to give LCA researchers and practitioners the space to further develop methodologies that fit their particular context, which in turn has led to the development of a variety of LCA methods and tools.

Overall, there are three commonly used, recognized, and agreed upon LCA methods, which we will describe in the following sections.

4.1.2. Economic Input–Output Method

The economic Input–Output (I–O) method is a widely adopted strategy for an LCA. It was developed by economist Wassily Leontief in the 1930s for the United States economy, and earned him the Nobel Prize in Economics in 1973. This method includes an economic input–output table and a set of equations to use in a model [

11]. The model represents the various inputs required to produce a unit of output in each economic sector based on surveyed census data of purchases and sales in the sector (e.g., single family home sector). By assembling a table describing all the major economic sectors, Leontief was able to trace all the economic purchases needed to produce outputs in each sector from the very beginning when raw materials are extracted. The I–O model was popular in the mid-20th century for high-level economic planning purposes, and later on when it was adopted as an LCA method. As illustrated in

Figure 5, by appending data on energy, environmental, and other flows to the Input–Output table, non-economic impacts, such as carbon emissions, can be predicted.

The I–O method has a complete system boundary [

12]. As illustrated in

Figure 5, the system boundary shows which processes are in the calculation and which are not; therefore, the I–O method can potentially overcome the major drawback of the process analysis method (discussed in the next section). However, this method has some limitations as well. The I–O analysis is generally viewed as a “black box” providing users with little understanding of the values being assumed in the model for each process [

13]. In addition, even though the I–O method may produce a relatively accurate assessment of the overall embodied carbon, a perfect I–O model may not result in valid results for a particular material or product because it is based on many inherent assumptions that were originally developed for national economic assessment [

14,

15]. For this reason, the I–O method should be used as a screening tool or a scoping tool to evaluate the alternatives when detailed data are missing from the process-based method [

15]. This screening tool can be used to make high-level selections and provide information to decision makers to make educated decisions.

Figure 5.

Overview of the Input–Output method (Source: EPA 1993) [

16].

Figure 5.

Overview of the Input–Output method (Source: EPA 1993) [

16].

4.1.3. Process Method

Compared to the I–O method, which is a top-down approach, the process-based method is a bottom-up approach. Data are derived from the knowledge of industrial processes within the life cycle of a product (a product can be a building component, e.g., windows, or a building material, e.g., cement), and the logistic flows connecting them [

17]. However, this method may result in the most incomplete outcomes because of the complexity of the upstream requirements for goods and services [

17]. The magnitude of this knowledge gap varies with the type of product or process being assessed, and the granularity of the study as well as the inaccuracy of the assessment may be as high as 50% or greater than the actual results [

18]. In comparison, the I–O method would include the diesel refinery process and more [

19]. The Process LCA method tends towards establishing tight system boundaries, which limits the scope of the project and, thus, the time and effort needed to collect information on the inputs and outputs. While this is useful in developing a manageable LCA project, defining such narrow boundaries for the analysis automatically limits the results and creates an underestimation of the life cycle impacts. Furthermore, the other main issue with process-based LCA methods concerns circularity effects. Since several precursor products are used in the manufacture of a final product, an LCA of all contributing materials and processes is required before completing the LCA of any material or process [

20].

4.1.4. Hybrid Method

An emerging method is a hybrid of the two methods above, which has been a main development area in LCA methodology in the past decade. The hybrid methods attempt to combine the advantages of both methods and minimize their limitations. Generally speaking, a hybrid method can be I–O based or process-based and they combine the process data and the I–O data in different ways [

21]. Researchers have proposed promising hybrid methods that are specifically tailored towards the building and construction industry. A literature review of hybrid life cycle inventory methods found 97 peer-reviewed publications referencing the use of a hybrid LCI between 2010 and 2015 [

22]. Mostly recently, Yu proposed a hybrid method focused on embodied emissions in the built environment, which can potentially be used as a value engineering tool [

23]. Overall, there is no adequate consensus on how to develop a hybrid method, or how to compare a hybrid method with the previous two methods. Therefore, it is fairly unclear why and how a hybrid method can and should be applied.

4.2. Data and Databases

4.2.1. Data Sources

There are different types of LCA data, which affects how embodied carbon is derived, estimated, and assessed. The LCA data results from the method used for assessment, therefore, the data, the methodology, and their application should be linked. Standards for assessing LCI data follow the ISO standards mentioned above. Assessing data quality requirements is one of the steps under scope definition during the first stage of any LCA as stipulated in the ISO standards. Data may come from a primary or secondary source.

A primary source of data comes directly from an entity that collects the data and/or analyzes it to evaluate the environmental performance or impact of a product or service. The product can be materials (e.g., cement, steel) or their aggregations and assemblies (e.g., concrete ready-mix, steel “I” beams). A primary data source is generally a definitive and more reliable source of information because of its traceability. A primary source is the first choice if it is available. A known example of a primary data source is an EPD (i.e., Environmental Product Declaration), which also allows the use of secondary data sources.

An EPD (mostly referred to Type III EPD in the context of building embodied carbon) is an independently verified and registered document that communicates transparent and comparable information about the life-cycle environmental impact of products [

24]. The international EPD system has its roots in the Nordic European Union (EU) nations, where the first and leading global EPD program was developed and operated in accordance with the ISO 14025, TS/14027, 14040 standards. For the building and construction sector, manufacturer EPDs also comply with the ISO 21930 and EN 15804 standards [

25].

An alternative to the primary data source is a secondary data source. Broadly defined, secondary data comes from citing a primary LCI database or a literature source (i.e., results in the published literature). However, such data sources may use information in ways that are inconsistent with the intent of the primary source and introduce potential biases. Hence, they are less reliable, but sometimes they are the only data source available free of charge. One example is the Bath Inventory of Carbon and Energy (ICE) database created by the University of Bath, which consists of over 400 datasets, whose main data sources include published academic research, industry statistics, government publications, and references from other primary LCI databases [

25]. The advantages of using secondary data sources include flexibility and the existence of multi-level data, which allows data to be collected and presented at the material level, product level, and/or building level.

4.2.2. Current Databases

OpenLCA Nexus [

26] is by far the most comprehensive website that provides information on LCI datasets globally. It was created in 2012 for OpenLCA, which is an open-source LCA software. OpenLCA Nexus includes 25 datasets, mainly developed for European countries. Using the Nexus website, users can search for individual datasets, based on customized search criteria such as country, price, sector, etc. Some of the datasets include LCI data of United States (US) origin.

In order to create a reliable and relatively accurate embodied carbon assessment, LCI databases need to be regionally sensitive, taking into consideration local manufacturing technology, fuel sources, transportation, and recycled content differences for products produced in various regions. For example, Emami et al. used regional databases (that represent the studied location) from Simapro and GaBI to study two residential buildings in Finland. For the whole building assessment, the resulting discrepancy is estimated to be around 15%, which subsequently leads to different design solutions/directions for the studied cases [

27]. Another research effort compared the life-cycle impact of passive house-compliant small residential buildings in Italy using the AH-LCA evaluation tool v1.6 and EPDs. This led to differences/discrepancies in all LCA environmental impact categories up to 10% for Global Warming Potential, 20% for Acidification Potential and Eutrophication Potential, and 40–50% for Renewable Primary Energy [

28]. In both cases, the discrepancy cannot be simply attributed to specific product data in the databases. The data sources are unknown or unspecified in the studies. Due to the imprecision of LCI, these “huge” differences are not uncommon in LCAs. Differences of this magnitude have the potential to mislead design choices and project investments if embodied carbon were to be introduced to building standards or codes. A national protocol to guide database development, application, and result verification and comparison is critical but currently missing.

In this study, we focus on databases that are relevant to the US and Canada.

Table 1 lists nine commonly used and known databases, including regional data samples from the US and Canada. Overall, comprehensive embodied carbon data exist to evaluate all life-cycle stages of buildings in the US and are available to users. Four out of the nine reviewed databases use primary data sources. Seven are free for users or tool developers. Some databases, such as ecoinvent, are very comprehensive, containing data on hundreds if not thousands of unique processes.

Data standardization and transparency need to be improved. Not all databases are regularly maintained, nor do they consistently include documentation about their data sources and methodologies. Not all databases make data sources and collecting processes visible and transparent to general users. This information is often embedded in some reference reports, which can take significant effort for users to discover. For example, with respect to the transparency of the data used in the Building for Environment and Sustainability (BEES) database, NIST noted:

“Reliable, transparent U.S. LCI data are, at present, only available from commercial tools. BEES does not publish fully transparent data because none are publicly available and NIST does not intend to compete with private sector tools by placing these data in the public domain”.

4.3. Tools

In this section, we review tools that are available and more popular among building practitioners in the US.

Table 2 compares six tools with respect to their provider, method, and the databases used, as well as the type of embodied carbon (EC) assessment that can be performed. The table also provides information on the cost and format of each tool. Each tool is discussed in detail in subsequent sections. Athena and Tally provide whole building assessments and are mostly used by building designers and professional consultants. The other tools provide assessments at the material and/or the product level. GaBi and SimaPro are the most well known LCA tools, with the latter being mostly used for research purpose in academia, but neither is US-focused. BEES is the only tool that uses the Economic I–O method and provides both LCA and LCI assessments.

Transparency and quality assurance of the tools need to be improved. Overall, there is no standard testing procedure to compare or evaluate the results from the tool. For example, ASHRAE Standard 140 (Standard Method of Test for Building Energy Simulation Computer Programs) creates standardized and citable test procedures for validating, diagnosing, and improving the generation of building energy modeling software [

34]. This is critical to increase confidence in the use of building energy modeling. An equivalent standard does not exist for embodied carbon tools. Moreover, the result accuracy from a tool is partially determined by its underlying database, which could be developed by another entity. For example, SimaPro v.8 notes that the extensive ecoinvent background reports can be accessed via the SimaPro help menu or the ecoinvent website [

35].

4.3.1. Athena

The North American governments began to develop LCI data in the 1990s, as part of their effort to develop an LCA [

36]. The data for the building industry has been the pilot data developed in Canada by Environment and Climate Change Canada in 1991. In the mid-1990s, the Canadian “Athena Project” made these data available in spreadsheets, and in 2002 the data were converted and integrated into an LCA tool, now called the Athena Impact Estimator for Buildings (IE for Buildings) [

37]. Later, the Athena Sustainable Materials Institute (ASMI) was established as a non-profit research collaborative that continues to upgrade, manage, and develop a suite of tools and LCI data. Athena is free for users. It uses the GaBi database, which is built from the ground up using actual mill or engineering process models and is not reliant on trade or government data sources [

38]. So far, IE for Buildings is still one of the most suitable calculation tools for researchers and practitioners to assess the embodied carbon of whole buildings in the US, because their data is North America-based.

4.3.2. Gabi

GaBi (which stands for “Ganzheitliche Bilanz” meaning Holistic Balance in German) was developed by PE Product Engineering GmBH and IKP in Germany. It has been used in over 19 countries [

38]. It was created in the mid 1990s, and has been widely used in many industries, especially in Germany. GaBi allows users to customize the database as well as impact assessment methods and inputs; it also offers the most instinctive graphic interface [

32]. Like SimaPro (detailed in a following section), GaBi is not US-focused. In addition, it is highly focused on the automotive and electronics industries [

38]. Since Gabi was one of the earliest LCI databases developed globally and did contain some data for building and construction materials, it had been used as a primary database and tool by LCA researchers for buildings until the databases that are more focused on the building sector were developed.

4.3.3. Tally

Kieran Timberlake, an architectural firm and Sphera (formerly thinkstep), began to develop a plug-in tool called Tally in 2008, which can extract data from Autodesk Revit models to calculate the embodied emissions of a whole building [

39,

40]. It aims to leverage Revit (the most popular tool for developing building design and construction documents) to provide users with life-cycle impact information for building materials and building assemblies throughout the design process [

41]. Since Tally is a plug-in tool, it provides a familiar interface for designers to use in their early design stage. Tally also uses the GaBi database. So far, it is the only application used in the United States to be fully integrated into Revit as a plug-in tool. Oneclick LCA, developed in Finland, is another software tool that has a plug-in function in Autodesk; however, its database is European-focused [

42].

4.3.4. SimaPro

SimaPro is produced by Pre Sustainability consultants in Netherland, and it was created in the mid-1990s as well. Like Gabi, it is one of the most well known LCA tools. It is used in over 80 countries now. Unlike Gabi, Simapro is used primarily for research purposes in academia and by experienced LCA consultants. Compared to Gabi, it is more sophisticated with many optional add-ons that make it very versatile [

43]. SimaPro allows users to customize the database as well as impact assessment methods and inputs. Simapro data include ecoinvent and the Japanese database. For the US database, it uses the LCI database of NREL.

4.3.5. BEES (NIST)

The BEES (Building for Environmental and Economic Sustainability) tool was developed by the National Institute of Standards and Technology (NIST) in the United States. Its environmental performance of building products follows ISO 14040 standards, and its economic performance measure uses ASTM E917–17e1 or “Standard Practice for Measuring Life-Cycle Costs of Buildings and Building Systems”, which covers the costs of initial investment, replacement, operation, maintenance and repair, and disposal [

44]. Environmental and economic performance are combined into an overall performance measure using the ASTM standard for Multi-Attribute Decision Analysis. For the entire BEES analysis, building products are defined and classified according to the ASTM standard classification for building elements known as UNIFORMAT II [

45]. The advantage of BEES is that it integrates an LCA and LCCA together, while providing the environmental impact assessment and life-cycle cost simultaneously for building products and assemblies. However, unlike Athena and Tally, BEES does not allow the same flexibility to customize building products, and it also does not provide whole building assessment.

4.3.6. Embodied Carbon Calculator for Construction (EC3)

EC3 is both a tool and database developed by the Carbon Leadership Forum along with Skanska and C-Change Lab [

46]. EC3 is an open-access tool that allows benchmarking, assessment, and reductions in embodied carbon; it is focused on the upfront supply chain emissions of construction materials. The EC3 tool utilizes building material quantities from construction estimates and/or BIM models and a database of digital, third party-verified Environmental Product Declarations (EPDs) [

46]. The EC3 database is created with digitized version of EPDs. Compared to other tools, EC3 has a limited temporal boundary (A1–A3) (refer to

Figure 2), but higher-level precision and accuracy in estimation (non-generic data). EC3 is particularly focused on the range of impacts that exist within a given product type (e.g., rebar or mineral wool) due to differences in manufacturing practices, supply chains, fuel mixes, etc. By having EPDs grouped and sorted with equivalent units, it facilitates appropriate comparison of like products.

5. Discussion and Conclusions

5.1. Current Knowledge about Embodied Carbon in the Building Industry

To gain a holistic view of the current knowledge infrastructure for embodied carbon research and practice, we examine the three EC assessment components (method, data, tool) at three different levels (material, product, and building). The product level includes the building components (e.g., windows, doors) and building assemblies (e.g., exterior walls, floors). Some articles covered more than one topic (or component); others included studies across multiple levels. In summary, the building level has the least knowledge developed. Of the information we discovered in our literature review, only about 5% was related to embodied carbon data, 10% to methodology, and 10% to tools at the whole building level. Hence, embodied carbon at the whole building level needs the most development and investment. We acknowledge that our review is mainly focused on peer-reviewed publications. More reports, case studies, and best practice guides on the whole build level exist in the building design community. Some are discussed in this study, but many are not included in our review due to the challenge of evaluating and verifying their contents. This is the limitation of this study; however, we believe that a review of the peer-review publications provides a good overview of the knowledge landscape in the space of embodied carbon in the built environment and identifies the critical gaps to guide our next steps.

5.2. Gaps in Database Development across All Levels

We identified four primary issues pertaining to database quality and the data collection process. The first issue relates to data availability for the use stages (B) and the end-of-life stages (C), since they are both highly dependent on the assumptions of the assessor about how a building may be used and maintained [

47]. Predictions of repair and replacement are particularly challenging and can be very subjective. Within a building, each building component has its individual lifespan. For example, roofing materials and window units have different lifespans and repair cycles, where each timespan depends not only on the product quality but also on the use conditions. Such information can only be obtained at the local level, which becomes a bottleneck for data collection partially due to the lack of awareness, knowledge, skills, and tools to include the total cost of ownership and the associated embodied carbons in building design and development. Building energy standards provide operational assumptions when calculating the whole building operational energy use, but similar assumptions do not exist for product life cycles. This may introduce potential bias by favoring products that have lower upfront embodied carbon (in stages A) but a short life span (in stages B). The lack of information on product durability may also introduce conflicts between resilience and embodied carbon. Both are critical components that must be addressed to combat climate change.

The second issue lies within the pre-use stages (A). There are limited published data for the A4 (transport to site) and A5 (construction and installation) stages in comparison to that for the A1–A3 stages. More standards have been developed and knowledge been gathered for products from sub-stages A1 to A3, which are associated with raw material extraction, transport, and manufacturing. Research into reducing the A1–A3 sub-stage-related carbon emissions has stimulated practice and policy changes in the building industry. One example is the EPDs and product category rules (PCRs). A growing number of local, state, and federal procurement policies require EPDs for reporting the embodied carbon of eligible products [

48]. However, the A4 and A5 stages are critical components of building construction and should not be neglected. Otherwise, another potential bias would favor low-carbon materials or products that are heavy, shipped over a long distance, or require energy-intensive equipment or processes to assemble onsite. For example, wood is a low-carbon construction material, however, its embodied carbon (in A4) may significantly increases as tree logs are shipped from their origin to a second location for primary processing (e.g., producing timbers of specific size and dimensions), to a third location for secondary processing (e.g., making more specific building products), and to a warehouse of a distributor, before reaching the construction site.

One potential cause of the lack of data for the A4 and A5 sub-stages may be that those data are highly context- and project-dependent [

49]. After products are shipped away from their original manufacture, it is difficult or sometimes impractical for the manufacturer to track how and where the products are shipped to and where they are used in the final destination. For instance, a stone product wholesale distributor may import products from different countries and store them in warehouses across the United States. Those products would then be shipped to different project sites within or outside of the country. Therefore, the embodied carbon in the A4 and A5 sub-stages is out of reach of the manufacturer and is often neglected in tracking. Such tracking and reporting responsibilities should be shared by manufacturers, distributors, and project developers. Guidelines or standards should be developed to guide data collection and tracking in these stages.

The third issue concerns missing guidelines for supply chain-specific and facility-specific data collection and reporting. In the existing and proposed legislations on embodied carbon, all EPDs are required to be third-party verified. Half of these legislations require product-specific EPDs (a specific product and manufacturer across multiple facilities), the other half require either supply chain-specific EPD (using supply chain-specific data for key processes) or facility-specific EPDs (attributing to a single manufacture and manufacturing facility) [

50]. Supply-chain and facility-specific EPDs aim to incentivize individual manufacturers to better distinguish their low-carbon products. However, PCRs only provide guidelines for calculating industry-average and product-specific EPDs. To improve data accuracy for comparison, the Carbon Leadership Forum (CLF) suggested that EPDs and PCRs should be improved by including supply chain-specific upstream data for processes with large impacts (e.g., production of cement for concrete (A1), manufacturing of mineral wool board (A3)) and developing corresponding guidelines [

51].

The fourth issue revolves around the lack of consensus on how to integrate the benefits and loads of reuse, recycling, and recovery potentials (Stage D) into the whole life-cycle assessments. So far, the majority of the embodied carbon assessment tools and databases focus on the life-cycle stages A through C. Stage D is a particularly important stage, which could provide incentives to promote recycled and reused products and materials. There are very few studies that include stage D, due to the lack of data. As such, it is a huge missed opportunity. A new building that is 30 percent more efficient than average may take at least 10 years, and up to 80 years, to offset the emissions generated from the construction process [

52]. Although building codes and standards traditionally do not address the end-of-life building activities, guidelines are needed to calculate the avoided carbon emissions from reused building components, structures, or even whole buildings (e.g., adaptive reuse).

5.3. The Lack of Quantitative Research on Embodied Carbon at the Building Level

Currently, very few activities are focused on collecting data on embodied carbon or embodied energy at the whole building level. Unlike operational energy, which has abundant data collected from a variety of building types, embodied energy or carbon has few benchmarking references for comparison and target setting. For example, the US EPA ENERGY STAR program publishes the technical reference for US Energy Use Intensity (measured by Btu/sf

2) by Property Type annually. This helps a design team compare its building energy use with similar properties across the nation [

53]. However, a consensus does not exist on how to baseline or benchmark the embodied carbon of a building today.

The most comprehensive assessment of embodied energy in buildings was published in 1979, in a publication entitled “Energy Use for Building Construction” [

54], commissioned by the Advisory Council on Historic Preservation. It aimed to assess the benefits of restoring and rehabilitating existing buildings, hence, it proposed methods to measure the energy needed to produce, replace, repair, and demolish the building materials. The assessments of building materials were then aggregated to calculate the embodied energy of the whole building [

55]. Embodied energy can be used as a proxy for embodied carbon, although the latter includes carbon emissions from non-energy sources. The Advisory Council assessment included three separate embodied energy categories corresponding to different life cycle stages: embodied energy (A1-B5), demolition energy (C1-C4), and operational energy (B6).

The Advisory Council-sponsored research project was a collaboration between the University of Illinois at Urbana-Champaign and Richard Stein Associates, Architects, of New York City. To date, this pioneering effort remains the most thorough evaluation of the embodied energy assessment at the whole building level by different building type, which has ever been produced in the US. The building materials in the report were based on construction industry data from 1967. Obviously, since then, there have been significant changes in building products, technologies, and manufacturing processes. Steel beams, for example, are now made with continuous casting, avoiding the billet reheating of earlier times. Thus, the base numbers for embodied energy from the 1976 report are likely to be outdated, so revision and updates are required.

6. Conclusions

In summary, embodied carbon data exist to evaluate all life-cycle stages of buildings in the United States; however, data development is mainly focused on the A1–A3 stages, so more efforts are needed to collect data on the B and C life-cycle stages. In addition, not all databases are regularly maintained, nor do they make documentation of their data sources and methodologies easily available for end users. A robust database is the backbone of reliable LCA analyses. Data collection and reporting guidelines are needed for supply chain-specific and facility-specific data as well as for transport and construction data. Guidelines for data standardization and transparency are also needed.

A significant effort has been focused on tool development. Most LCA tools are focused on product or material levels and are not specifically designed for buildings. Whole building-level LCA tools that can be embedded in building design software will greatly help design teams incorporate an LCA into their design process [

55]. As more LCA tools are developed to facilitate designs, guidelines are needed to standardize the procedures for validating and developing embodied carbon software. This is critical to increase confidence in the use of embodied carbon tools [

56].

The largest knowledge gap exists at the whole building level. No consensus exists on how to baseline or benchmark the embodied carbon of a building due to the lack of building-level data. Research is needed to create a quantitative benchmark dataset. Methodologies on how to baseline building embodied carbon emissions should be developed. Incremental carbon reduction targets should be determined. The developed methodologies and guidelines should cover the whole life-cycle stage beyond initial building construction. Trade-offs between operational carbon, material/product durability, and embodied carbon should be addressed. Material and product durability is not only relevant to embodied carbon, but also important to resilience planning, which is another critical approach to combat climate change.

Tools, as well as LCA methods and standards (global scale, ISO), have been established to assess embodied carbon in the built environment. The past five years (from 2021) have seen embodied carbon and LCA become a standard feature of commercial and governmental green building systems, particularly in Europe. While this field has developed relatively recently, best practices have already started to emerge and can be adopted in the United States to expedite the promotion of reduction of embodied carbon from buildings. Falling behind the EU, the United States has no industry-agreed guidelines on the complete life-cycle assessment at the whole building level. Moreover, the development of the US LCI database is not accelerating. Thus, there are two actions the US federal agencies can take immediately: (a) develop US-applicable standards based on ISO standards and (b) fund the collection and organization of LCI data.