An Overview on Solid Waste Generation and Management: Current Status in Chile

Abstract

:1. Introduction

2. Generation, Management and Disposal of Solid Wastes: A global Overview

2.1. Municipal Solid Waste (MSW)

2.1.1. Sources and Composition

2.1.2. Factors Influencing MSW Generation

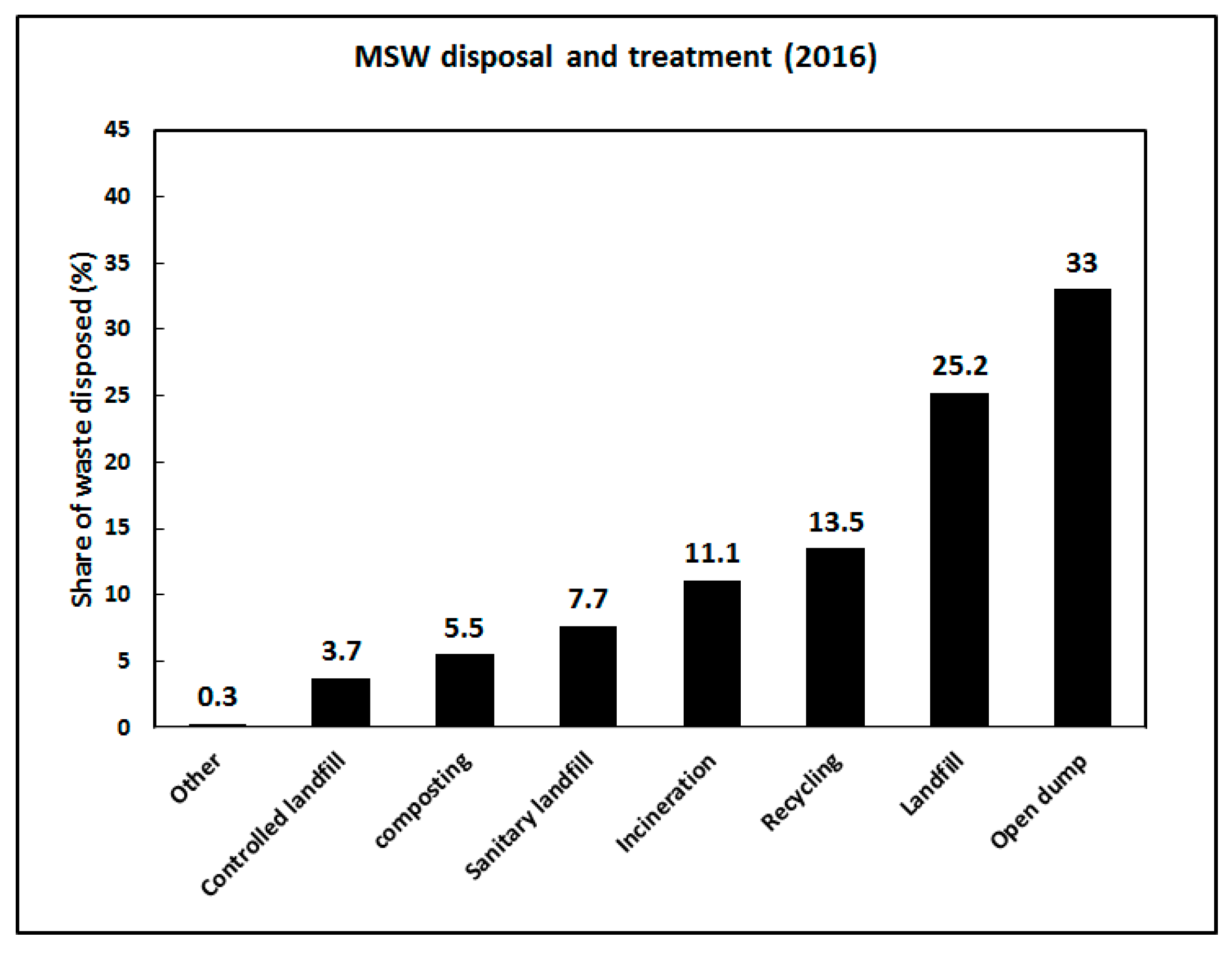

2.1.3. Waste Collection and Disposal

2.2. Industrial Waste

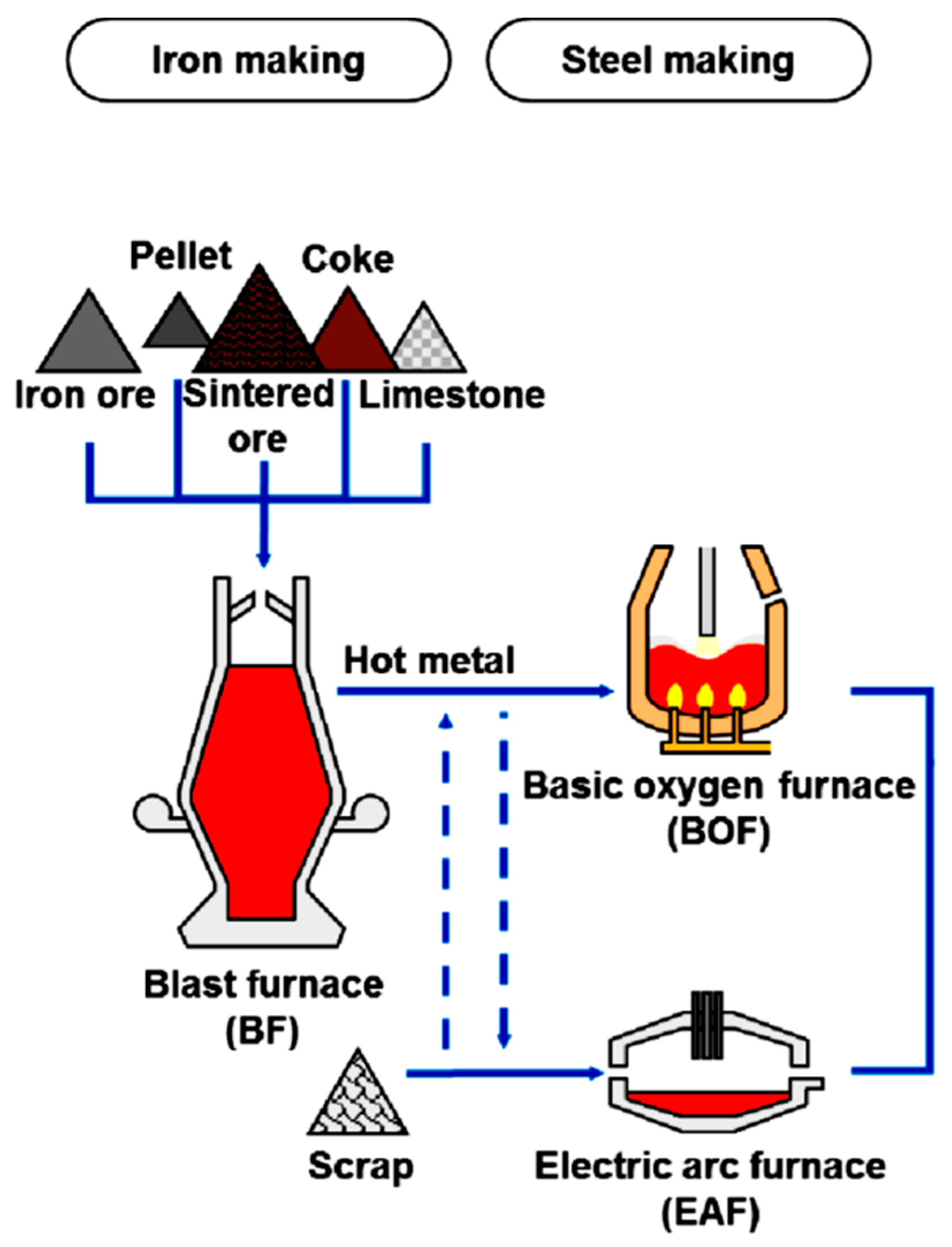

2.2.1. Iron and Steelmaking Sector

2.2.2. Aluminium Sector

3. Waste Management in Chile: Current Status

3.1. Waste Management: Legislations and Regulations

3.2. Waste Management Initiatives

3.3. Municipal and Industrial Wastes

3.4. Copper Mining Waste

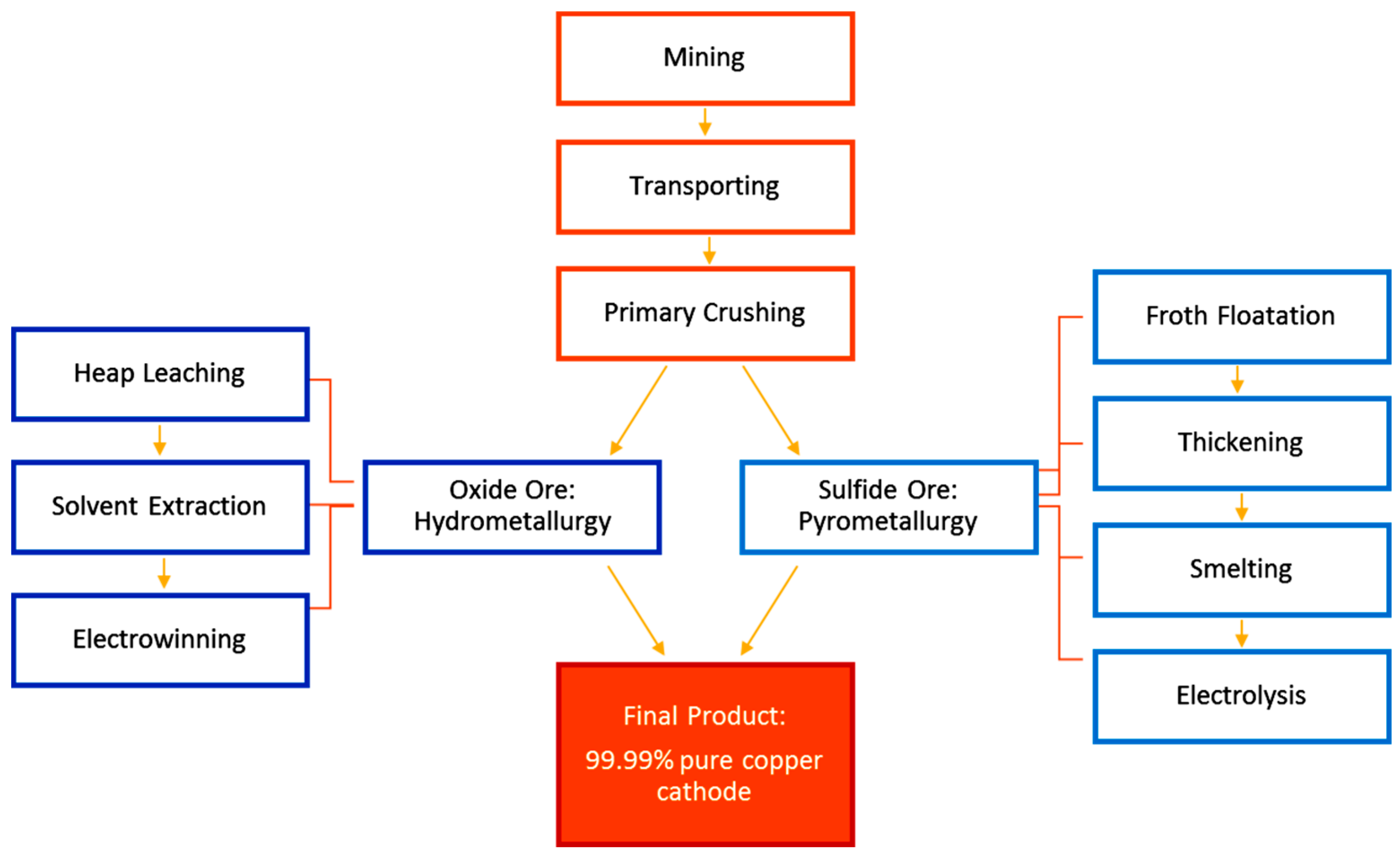

3.4.1. General Information

3.4.2. Typical Mining Wastes

3.4.3. Waste Disposal and Environmental Initiatives

3.5. Other Solid Wastes—Electronic Waste, Plastics

4. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Global Waste Generation—Statistics & Facts. Available online: https://www.statista.com/topics/4983/waste-generation-worldwide/ (accessed on 28 August 2021).

- What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. Chapter 2. Available online: https://datatopics.worldbank.org/what-awaste/trends_in_solid_waste_management.html (accessed on 28 August 2021).

- What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. Available online: https://openknowledge.worldbank.org/handle/10986/30317 (accessed on 30 August 2021).

- What a Waste Global Database. Available online: https://datacatalog.worldbank.org/dataset/what-waste-global-database (accessed on 30 August 2021).

- Center for Sustainable Systems, University of Michigan. 2021. “Municipal Solid Waste Factsheet”. Pub. No. CSS04-15. Available online: https://css.umich.edu/factsheets/municipal-solid-waste-factsheet (accessed on 20 August 2021).

- Bidlingmaier, W.; Sidaine, J.M.; Papadimitriou, E.K. Separate collection and biological waste treatment in the European Community. Rev. Environ. Sci. Bio/Technol. 2004, 3, 307–320. [Google Scholar] [CrossRef]

- What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. Available online: https://www.worldbank.org/en/news/infographic/2018/09/20/what-a-waste-20-a-global-snapshot-of-solid-waste-management-to-2050 (accessed on 20 August 2021).

- Patel, V.; Meka, S. Forecasting of Municipal Solid Waste Generation for Medium Scale Towns Located in the State of Gujarat, India. Int. J. Innov. Rese. Sci. Engg. Tech. 2013, 2, 4707–4716. [Google Scholar]

- EPA. Adjusting waste generation. In Appendix H: Methodology to Calculate Waste Generation Based on Previous Year; United State Environmental Protection Agency: Washington, DC, USA, 1997; p. 5. [Google Scholar]

- Rachdawong, P.; Khaodhiar, S.; Sangiampaisalsuk, N. Analysis of solid waste generation-Characteristics in Bangkok, Thailand. J. Environ. Res. 2000, 22, 80–92. [Google Scholar]

- Sukholthaman, P.; Chanvarasuth, P.; Sharp, A. Analysis of waste generation variables and people’s attitudes towards waste management system: A case of Bangkok, Thailand. J. Mater. Cycles Waste Manag. 2017, 19, 645–656. [Google Scholar] [CrossRef]

- Liu, J.; Li, Q.; Gu, W.; Wang, C. Generation of Municipal Solid Waste in China: Evidences from Provincial Data. Int. J. Environ. Res. Public Health 2019, 16, 1717. [Google Scholar] [CrossRef] [Green Version]

- Masebinu, S.O.; Akinlabi, E.T.; Muzenda, E.; Aboyade, A.O.; Mbohwa, C.; Manyuchi, M.M.; Naidoo, P. A Review on Factors affecting Municipal Solid Waste Generation. In Proceedings of the 2nd International Engineering Conference (IEC 2017) Federal University of Technology, Minna, Nigeria, 17–19 October 2017. [Google Scholar]

- Wang, A.; Zhang, L.; Shi, Y.; Rozelle, S.; Osborn, A.; Yang, M. Rural Solid Waste Management in China: Status, Problems and Challenges. Sustainability 2017, 9, 506. [Google Scholar] [CrossRef] [Green Version]

- Zeng, C.; Niu, D.; Zhao, Y. A comprehensive overview of rural solid waste management in China. Front. Environ. Sci. Eng. 2015, 9, 949–961. [Google Scholar] [CrossRef]

- Municipal Solid Waste in the U.S.—Statistics & Facts. Available online: https://www.statista.com/topics/2707/municipal-solid-waste-in-the-united-states/ (accessed on 23 August 2021).

- Distribution of Municipal Solid Waste Treatment and Disposal Worldwide in 2016, by Method. Available online: https://www.statista.com/statistics/916682/global-municipal-solid-waste-treatment-by-method/ (accessed on 22 August 2021).

- EPA Victoria. Industrial Waste Resource Guidelines. Solid Industrial Waste Hazard Categorisation and Management. Available online: https://www.epa.vic.gov.au/about-epa/publications/iwrg631 (accessed on 23 August 2021).

- Maczulak, A.E. Pollution: Treating Environmental Toxins; Infobase Publishing: New York, NY, USA, 2010; p. 120. ISBN 9781438126333. [Google Scholar]

- United States Environmental Protection Agency EPA. Facts and Figures about Materials, Waste and Recycling. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials (accessed on 21 August 2021).

- The Role of Steel Manufacturing in the Global Economy. 2019. Available online: https://www.worldsteel.org/en/dam/2520Summary.pdf (accessed on 10 August 2021).

- Steel Industry Co-Products. Available online: https://www.worldsteel.org/publications/position-papers/co-product-position-paper.html (accessed on 21 August 2021).

- Solid Waste Management in a Steel Plant. Available online: https://www.ispatguru.com/solid-waste-management-in-a-steel-plant/ (accessed on 23 August 2021).

- U.S. Department of Transportation. User Guidelines for Waste and Byproduct Materials in Pavement Construction. Available online: https://www.fhwa.dot.gov/publications/research/infrastructure/structures/97148/ssa1.cfm (accessed on 23 August 2021).

- Kongkarat, S.; Khanna, R.; Koshy, P.; O’Kane, P.; Sahajwalla, V. Use of waste Bakelite as a raw material resource for recarburization in steelmaking processes. Steel Res. Int. 2011, 82, 1228–1239. [Google Scholar] [CrossRef]

- The Management of Steel Industry By-Products and Waste ed; International Iron and Steel Institute: Brussels, Belgium, 1987.

- Rahman, M.; Khanna, R.; Sahajwalla, V.; O’Kane, P. The influence of ash impurities on interfacial reactions between carbonaceous materials and EAF slag at 1550 C. ISIJ Int. 2009, 49, 329–336. [Google Scholar] [CrossRef] [Green Version]

- Aluminium—The Second Most Used Metal in the World. Available online: https://etem.com/blog/aluminium-the-second-most-used-metal-in-the-world (accessed on 3 September 2021).

- Countries with the Largest Smelter Production of Aluminium from 2016 to 2020. Available online: https://www.statista.com/statistics/264624/global-production-of-aluminum-by-country/ (accessed on 3 September 2021).

- Zhang, R.; Zheng, S.; Ma, S.; Zhang, Y. Recovery of alumina and alkali in Bayer red mud by the formation of andradite-grossular hydrogarnet in hydrothermal process. J. Hazard. Mater. 2011, 189, 827–835. [Google Scholar] [CrossRef]

- Khanna, R.; Konyukhov, Y.V.; Ikram-ul-haq, M.; Burmistov, I.; Cayumil, R.; Belov, V.A.; Rogachev, S.O.; Leybo, D.V.; Mukherjee, P.S. An innovative route for valorising iron and aluminium oxide rich industrial wastes: Recovery of multiple metals. J. Environ. Manag. 2021, 295, 113035. [Google Scholar] [CrossRef]

- Patel, S.; Pal, B.K. Current Status of an Industrial Waste: Red Mud an Overview. IJLTEMAS 2015, 7, 1–16. [Google Scholar]

- Yolandi, S.; Oberholster, S.P.; Somerset, V. A decision-support framework for industrial waste management in the iron and steel industry: A case study in Southern Africa. Case Stud. Chem. Environ. Eng. 2021, 3, 100097. [Google Scholar]

- Khairul, M.A.; Zanganeh, J.; Moghtaderi, B. The composition, recycling and utilisation of Bayer red mud. Resour. Conserv. Recyc. 2019, 141, 483–498. [Google Scholar] [CrossRef]

- Totten, G.E.; MacKenzie, D.S. Handbook of Aluminium: Volume 2: Alloy Production and Materials Manufacturing; Marcel Dekker, Inc.: New York, NY, USA, 2003; Volume 2, ISBN 0-8247-0896-2. [Google Scholar]

- The Aluminium Association: Primary Production. Available online: https://www.aluminum.org/industries/production/primary-production (accessed on 7 July 2021).

- OECD Global Forum on Environment. Focusing on Sustainable Materials Management. Materials case study 2: Aluminium. Available online: https://www.oecd.org/env/waste/46194971.pdf (accessed on 23 August 2021).

- United States Environmental Protection Agency EPA. Bauxite and Alumina Production Wastes. Available online: https://www.epa.gov/radiation/tenorm-bauxite-and-alumina-production-wastes (accessed on 7 July 2021).

- The Aluminium Association: Recycling. Available online: https://www.aluminum.org/industries/production/recycling (accessed on 7 July 2021).

- Liu, Y.; Lin, C.; Wu, Y. Characterization of red mud derived from a combined Bayer process and bauxite calcination method. J. Hazard. Mater. 2007, 146, 255–261. [Google Scholar] [CrossRef]

- Mayes, W.M.; Jarvis, A.P.; Burke, I.T.; Walton, M.; Feigl, V.R.; Klebercz, O.; Gruiz, K. Dispersal and attenuation of trace contaminants downstream of the Ajka bauxite residue (red mud) depository failure. Hungary. Environ. Sci. Technol. 2011, 45, 5147–5155. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, P. Method of De-Alkalizing Red Mud and Recovering Aluminium and Iron. Available online: https://patents.google.com/patent/CN103031443A/en (accessed on 7 July 2021).

- Kumar, R.A.S.; Premchand, J.P. Utilization of Iron Values of Red Mud for Metallurgical Applications. Environ. Waste Manag. 1998, 108–119. [Google Scholar] [CrossRef]

- Gronostajski, J.; Marciniak, H.; Matuszak, A. New methods of aluminium and aluminium-alloy chips recycling. J. Mater. Process. Technol. 2000, 106, 34–37. [Google Scholar] [CrossRef]

- The SPL Waste Management Challenge in Primary Aluminum. Available online: https://www.lightmetalage.com/news/industry-news/smelting/the-spl-waste-management-challenge-in-primary-aluminum/ (accessed on 7 July 2021).

- Ministerio del Medio Ambiente. Informe del Estado del Medio Ambiente (IEMA) 2020, Chapter 10, p. 2. “Residuos”—SINIA. Available online: https://sinia.mma.gob.cl/index.php/resiudos/ (accessed on 29 August 2021).

- Ulloa, G.; Cayumil, R.; Sánchez, M. Urban Mining in Chile: State of the art. In Proceedings of the Fourth Symposium of Urban Mining and Circular Economy, Bergamo, Italy, 21–22 May 2018. [Google Scholar]

- Basel Convention. On the Control of Transboundary Movements of Hazardous Wastes and Their Disposal; Basel Convention: Geneva, Switzerland, 2014. [Google Scholar]

- United Nations Environment Program. Stockholm Convention on Persistent Organic Pollutants. United Nations, Geneva. Nations, Geneva. 2019. Available online: https://www.unep.org/annualreport/2019/index.php (accessed on 30 August 2021).

- CONAMA. Plan Nacional de Implementación para la Gestión de los Contaminantes Orgánicos Persistentes (COPs) en Chile. 2005, 1–67. Available online: https://www.informea.org/en/plan-nacional-de-implementaci%C3%B3n-para-la-gesti%C3%B3n-de-los-contaminantes-org%C3%A1nicos-persistentes-cops-en (accessed on 29 August 2021).

- MERCOSUR: A Status Report and Prospects for Canada-Mercosur Relations. Available online: https://www.sice.oas.org/TPD/CAN_MER/Studies/MercosurFocal_e.pdf (accessed on 21 August 2021).

- Ministerio del Medio Ambiente. Santiago Recicla. Available online: http://centralenergia.cl/uploads/2011/09/Bases_generales_del_medio_ambiente_LEY-19300.pdf (accessed on 20 August 2021).

- Available online: https://www.informea.org/en/framework-law-waste-management-law-no-20920-2016 (accessed on 10 August 2021).

- Available online: https://eticayseguridad.uc.cl/documentos/comite-seguridad/normativa-seguridad/127-dcto-148-residuos-peligrosos/file.html (accessed on 21 August 2021).

- Ministerio del Medio Ambiente. Santiago Recicla. Available online: http://www.santiagorecicla.cl/ (accessed on 30 May 2021).

- Glavič, P.; Lukman, R. Review of sustainability terms and their definitions. J. Cleaner Product. 2007, 15, 1875–1885. [Google Scholar] [CrossRef]

- Ministerio del Medio Ambiente. Economía Circular. Available online: https://mma.gob.cl/economia-circular/ (accessed on 1 September 2021).

- Average per Capita Generation of Municipal Solid Waste Worldwide in 2016, by Region. Available online: https://www.statista.com/statistics/916618/global-per-capita-generation-of-municipal-solid-waste-by-region/ (accessed on 1 September 2021).

- Blazquez, C.; Paredes-Belmar, G. Network design of a household waste collection system: A case study of the commune of Renca in Santiago, Chile. Waste Manag. 2020, 116, 179–189. [Google Scholar] [CrossRef]

- Pontificia Universidad Católica. Estudio Caracterización de Residuos Sólidos Domiciliarios en la Region Metropolitana; UCV: Valparaíso, Chile, 2006. [Google Scholar]

- Chile and Canada Partner to Reduce Emissions from the Waste Management Sector. Available online: https://www.ccacoalition.org/en/news/chile-and-canada-partner-reduce-emissions-waste-management-sector (accessed on 23 August 2021).

- Chile–Developing a Legal Framework for EPR in Chile. Available online: https://prevent-waste.net/wp-content/uploads/2020/09/Chile.pdf (accessed on 28 August 2021).

- Rojas, A.; Yabar, H.; Mizunoya, T.; Higano, Y. The Potential Benefits of Introducing Informal Recyclers and Organic Waste Recovery to a Current Waste Management System: The Case Study of Santiago de Chile. Resources 2018, 7, 18. [Google Scholar] [CrossRef] [Green Version]

- AVINA. Politicas Publicas Para la Inclusion de los Recicladores de Base al Sistema de Gestion de Residuos Municipales en Chile; AVINA: Santiago, Chile, 2013. (In Galician) [Google Scholar]

- Hutchison, I.P.G.; Ellison, R.D. Mine Waste Management: A Resource for Mining Industry Professionals, Regulators and Consulting Engineers. United States, 1992. Available online: https://www.osti.gov/biblio/6715101-mine-waste-management-resource-mining-industry-professionals-regulators-consulting-engineers (accessed on 10 August 2021).

- Ministerio de Energía. Energías Renovables. Available online: http://www.energia.gob.cl/energias-renovables (accessed on 31 May 2021).

- Sociedad Nacional de Minería. Fundamentos y Desafíos para el Desarrollo Minero. 2017. Available online: https://www.sonami.cl/v2/centro-de-documentacion/publicaciones-tecnicas/ (accessed on 31 May 2021).

- SERNAGEOMIN, n.d. Cierre de Faenas Mineras. Available online: https://www.sernageomin.cl/cierre-de-faenas-mineras/ (accessed on 31 May 2021).

- Ministerio Del Medio Ambiente, 2018c. Norma de Emisión Para Fundiciones de Cobre y Fuentes Emisoras de Arsénico. Available online: https://www.leychile.cl/Navegar?idNorma=1057059 (accessed on 11 August 2021).

- Fundación Chile. Desde el Cobre a la Innovación. Roadmap Tecnológico 2015–2035. Available online: http://programaaltaley.cl/wp-content/uploads/2016/04/Roadmap-Tecnologico-Alta-ley.pdf (accessed on 12 August 2021).

- Mine Waste Management: A Resource for Mining Industry Professionals, Regulators and Consulting Engineers. Available online: https://www.nsenergybusiness.com/news/top-five-copper-mining-countries/ (accessed on 6 July 2021).

- Copper Mining and Processing: Processing Copper Ores. Available online: https://superfund.arizona.edu/resources/learning-modules-english/copper-mining-and-processing/processing-copper-oreshttps://www.mwen.info/docs/imwa_1999/IMWA1999_Wiertz_403.pdf (accessed on 6 July 2021).

- Schlesinger, M.; King, M.; Sole, K.; Davenport, W. Extractive Metallurgy of Copper (Fifth). Sociedad Nacional de Minería, 2017. Fundamentos y desafíos para el desarrollo minero. Available online: https://www.elsevier.com/books/extractive-metallurgy-of-copper/schlesinger/978-0-08-096789-9 (accessed on 6 July 2021).

- Roadmap Tecnológico de la Minería. Available online: https://corporacionaltaley.cl/?page_id=952&lang=en (accessed on 6 July 2021).

- SERNAGEOMIN, 2018. Preguntas Frecuentes sobre Relaves. Available online: https://www.sernageomin.cl/preguntas-frecuentes-sobre-relaves/ (accessed on 6 July 2021).

- Moskalyk, R.R.; Alfantazi, A. Review of copper pyrometallurgical practice: Today and tomorrow. Miner. Eng. 2003, 17, 893–919. [Google Scholar] [CrossRef]

- Minería Chilena, 2009. Relaves Espesados a la Vanguardia. Available online: https://www.mch.cl/reportajes/relaves-espesados-a-la-vanguardia/ (accessed on 6 July 2021).

- El Ovallino. Tecnosuelos: La Alternativa que Busca “Reverdecer” los Relaves Mineros. 2019. Available online: http://www.elovallino.cl/economia/tecnosuelos-alternativa-que-busca-reverdecer-relaves-mineros (accessed on 6 July 2021).

- Zongjie, L.; Junrui, C.; Zengguang, X.; Yuan, Q.; Jing, C. A Comprehensive Review on Reasons for Tailings Dam Failures Based on Case History. Adv. Civil Eng. 2019, 2019, 4159306. [Google Scholar]

- Palacios, J.; Sánchez, M. Wastes as resources: Update on recovery of valuable metals from copper slags. Miner. Process. Extract. Metall. 2011, 120, 218–223. [Google Scholar] [CrossRef]

- Sánchez, M.; Sudbury, M. Reutilisation of primary metallurgical wastes: Copper slag as a source of copper, molybdenum and iron–brief review of test work and the proposed way forward. In Proceedings of the Third International Slag Valorisation Symposium, Leuven, Belgium, 19–20 March 2013. [Google Scholar]

- Forti, V.; Baldé, C.P.; Kuehr, R.; Bel, G. The Global E-waste Monitor 2020: Quantities, flows and the circular economy potential. United Nations University (UNU)/United Nations Institute for Training and Research (UNITAR)—Co-Hosted SCYCLE Programme, International Telecommunication Union (ITU) & International Solid Waste Association (ISWA), Bonn/Geneva/Rotterdam. Available online: http://ewastemonitor.info/ (accessed on 10 September 2021).

- Magalini, F.; Khetriwal, D.S.; Huisman, J.; Nanorom, I.C. Electronic Waste (E-Waste) Impacts and Mitigation Options in the Off-grid Renewable Energy Sector. 2016. Available online: https://assets.publishing.service.gov.uk/media/58482b3eed915d0b12000059/EoD_Report__20160825_E-Waste_Study_Final-31.08.16.pdf (accessed on 10 September 2021).

- Solving the E-Waste Problem. Available online: https://www.step-initiative.org/ (accessed on 10 September 2021).

- Tsydenova, O.; Bengtsson, M. Chemical hazards associated with treatment of waste electrical and electronic equipment. Waste Manag. 2011, 31, 45–58. [Google Scholar] [CrossRef]

- Cayumil, R.; Khanna, R.; Ikram-Ul-Haq, M.; Rajarao, R.; Hill, A.; Sahajwalla, V. Generation of copper rich metallic phases from waste printed circuit boards. Waste Manag. 2014, 34, 1783–1792. [Google Scholar] [CrossRef]

- Cayumil, R.; Khanna, R.; Rajarao, R.; Mukherjee, P.S.; Sahajwalla, V. Concentration of precious metals during their recovery from electronic waste. Waste Manag. 2016, 57, 121–130. [Google Scholar] [CrossRef]

- Cayumil, R.; Ikram-Ul-Haq, M.; Khanna, R.; Saini, R.; Mukherjee, P.S.; Mishra, B.K.; Sahajwalla, V. High temperature investigations on optimising the recovery of copper from waste printed circuit boards. Waste Manag. 2018, 73, 556–565. [Google Scholar] [CrossRef]

- Ministerio del Medio Ambiente. Chao Bolsas Plásticas. Available online: http://chaobolsasplasticas.cl/ (accessed on 6 July 2021).

| Type of Waste | Generation per Capita (kg/Capita/Day) |

|---|---|

| Industrial waste | 12.73 |

| Agricultural waste | 3.35 |

| Construction and demolition waste | 1.68 |

| Municipal solid waste | 0.74 |

| Hazardous waste | 0.32 |

| Medical waste | 0.25 |

| Electronic waste | 0.02 |

| Waste Sources | Waste Generators | Typical Wastes |

|---|---|---|

| Residential | Single and/or multi-family dwellings, apartment blocks, high-rise buildings. | Food wastes, paper, cardboard, plastics, yard wastes, furniture, glass, metals, bulky items, consumer electronics, whitegoods, batteries and household hazardous wastes |

| Commercial institutes, shopping malls and organizations | Shops, stores, hotels, restaurants, markets, offices, schools, hospitals, government organisations | Paper, cardboard, plastics, food wastes, glass, wood, special wastes, metals, hazardous wastes |

| Municipal services | Street cleaning, landscaping, parks, other recreational areas, beaches, wastewater treatment | General wastes from parks, street sweepings, landscape and tree trimmings, other recreational areas, beaches, sludge. |

| Region | Generation of MSW (2016) (Million Tonnes) | Projection (2050) (Million Tonnes) |

|---|---|---|

| East and Asia Pacific | 468 | 714 |

| Europe and Central Asia | 392 | 490 |

| South Asia | 334 | 661 |

| North America | 289 | 396 |

| Latin America and the Caribbean | 231 | 369 |

| Sub-Saharan Africa | 174 | 516 |

| Middle East and North Africa | 129 | 255 |

| Global Factors | Local Factors |

|---|---|

| Demographics | Population, population density, age, gender, occupation, expenditure on groceries; household count, household density, household type and size, income level, energy consumption. |

| Economics | Gross domestic product, consumer price index, economic growth, employment/unemployment and waste budget. |

| Technology | Manufacturing standards, engineering issues, inefficient equipment and facilities. |

| Legislation & Administration | Policies, laws, enforcement level, management institutions, disposal fees, recycling programmes and amounts recycled |

| Social | Awareness, literacy levels, public cooperation, cultural practices, urbanisation, tourist attractions, political stability. |

| Consumer behaviour | Consumption demand and patterns, cooking activity, lifestyles, disposal patterns. |

| Global Production | #1 | #2 | #3 | #4 | #5 |

|---|---|---|---|---|---|

| China | India | Japan | USA | Russia | |

| 1877.5 | 1064.8 | 100.3 | 83.2 | 72.7 | 71.6 |

| Global Production | #1 | #2 | #3 | #4 | #5 |

|---|---|---|---|---|---|

| China | India | Russia | Canada | U.A.E | |

| 64,000 | 35,800 | 3700 | 3600 | 2900 | 2700 |

| Global Production | #1 | #2 | #3 | #4 | #5 |

|---|---|---|---|---|---|

| Chile | Peru | China | D R Congo | U.S.A | |

| 20 | 5.7 | 2.2 | 1.7 | 1.3 | 1.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cayumil, R.; Khanna, R.; Konyukhov, Y.; Burmistrov, I.; Kargin, J.B.; Mukherjee, P.S. An Overview on Solid Waste Generation and Management: Current Status in Chile. Sustainability 2021, 13, 11644. https://doi.org/10.3390/su132111644

Cayumil R, Khanna R, Konyukhov Y, Burmistrov I, Kargin JB, Mukherjee PS. An Overview on Solid Waste Generation and Management: Current Status in Chile. Sustainability. 2021; 13(21):11644. https://doi.org/10.3390/su132111644

Chicago/Turabian StyleCayumil, Romina, Rita Khanna, Yuri Konyukhov, Igor Burmistrov, Jumat Beisembekovich Kargin, and Partha Sarathy Mukherjee. 2021. "An Overview on Solid Waste Generation and Management: Current Status in Chile" Sustainability 13, no. 21: 11644. https://doi.org/10.3390/su132111644

APA StyleCayumil, R., Khanna, R., Konyukhov, Y., Burmistrov, I., Kargin, J. B., & Mukherjee, P. S. (2021). An Overview on Solid Waste Generation and Management: Current Status in Chile. Sustainability, 13(21), 11644. https://doi.org/10.3390/su132111644