Experimental Performance of an Advanced Air-Type Photovoltaic/Thermal (PVT) Collector with Direct Expansion Air Handling Unit (AHU)

Abstract

1. Introduction

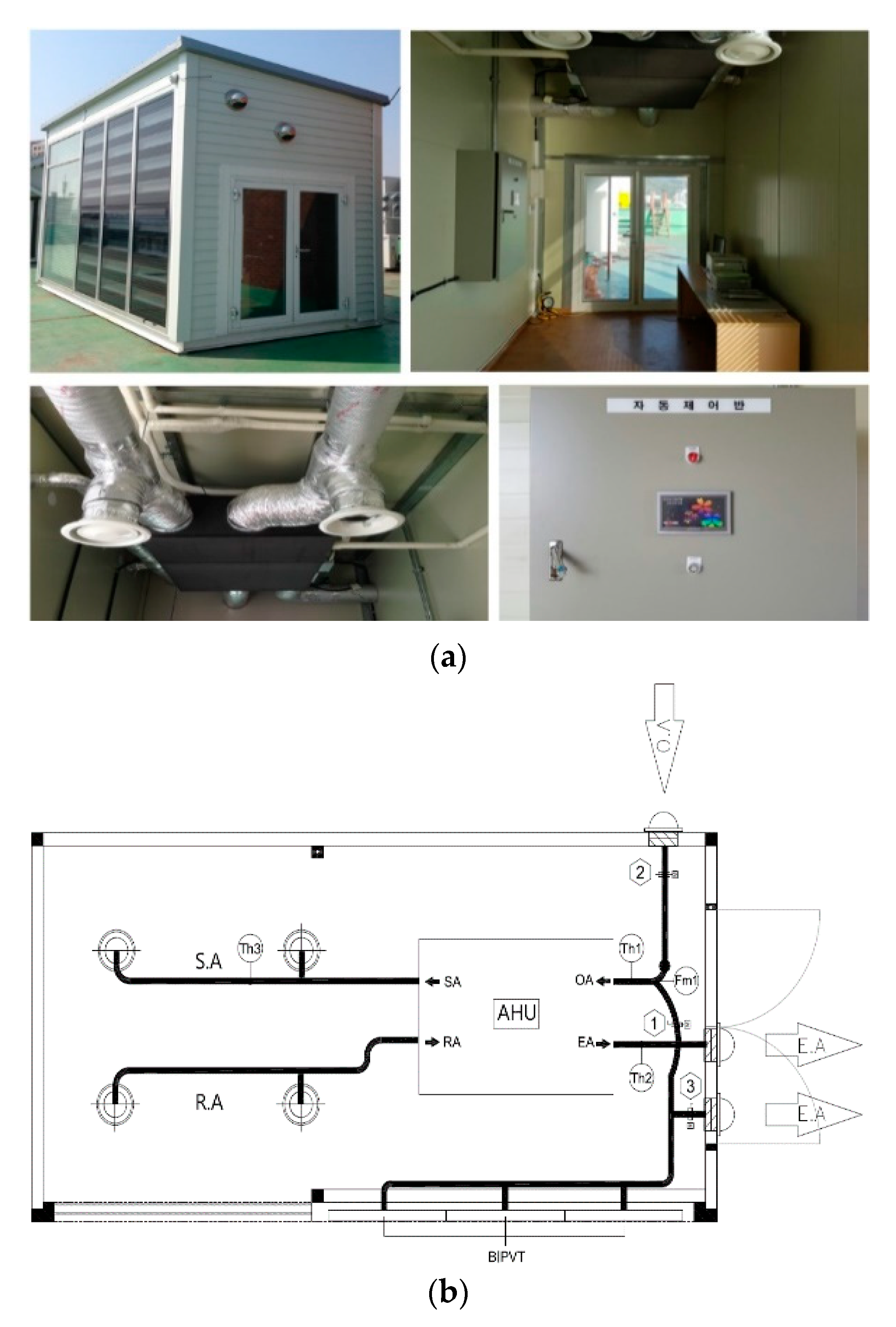

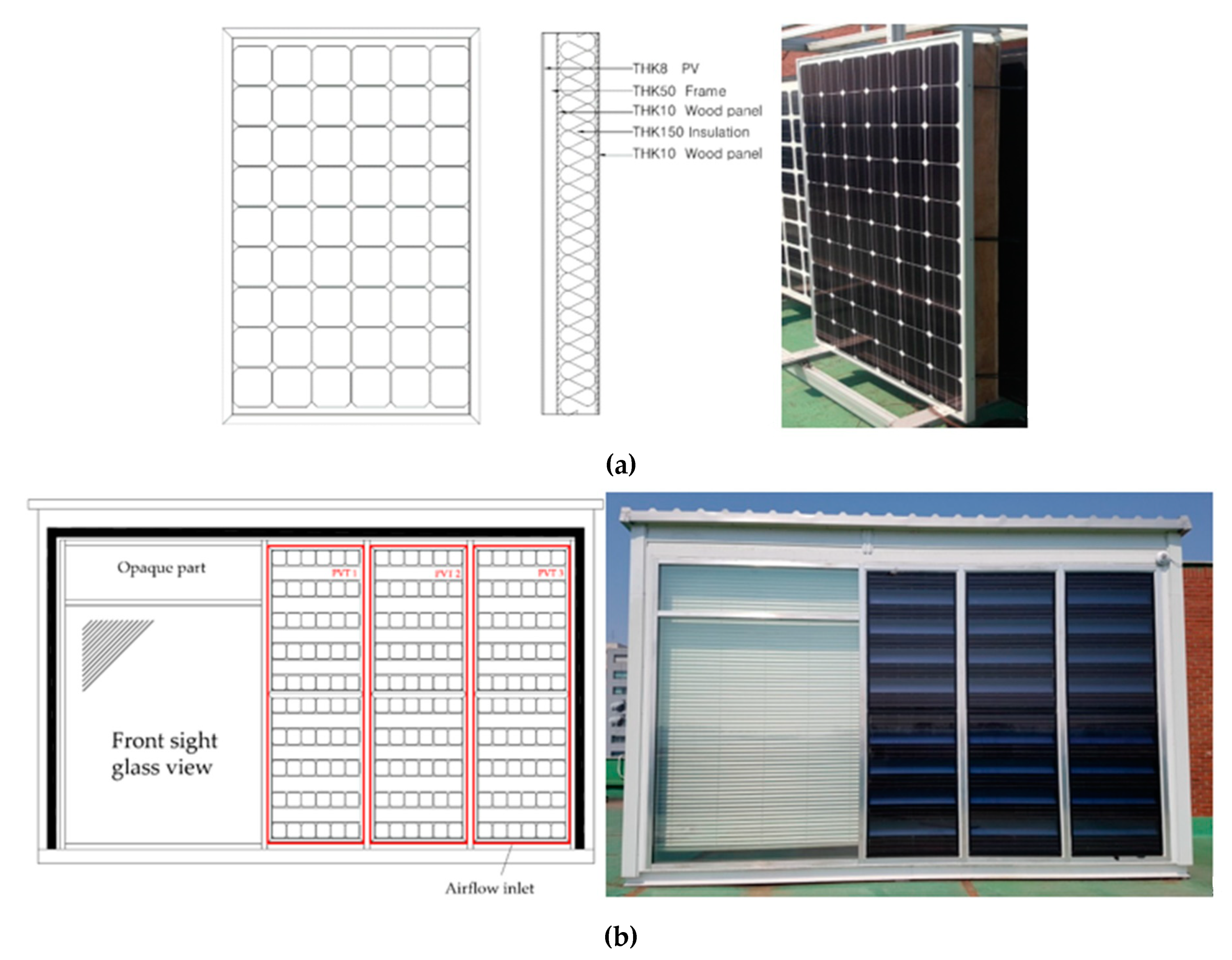

2. Experimental House of the AHU System with BIPVT Collector

3. Experimental Setup

3.1. Comparison of BIPVT and BIPV System

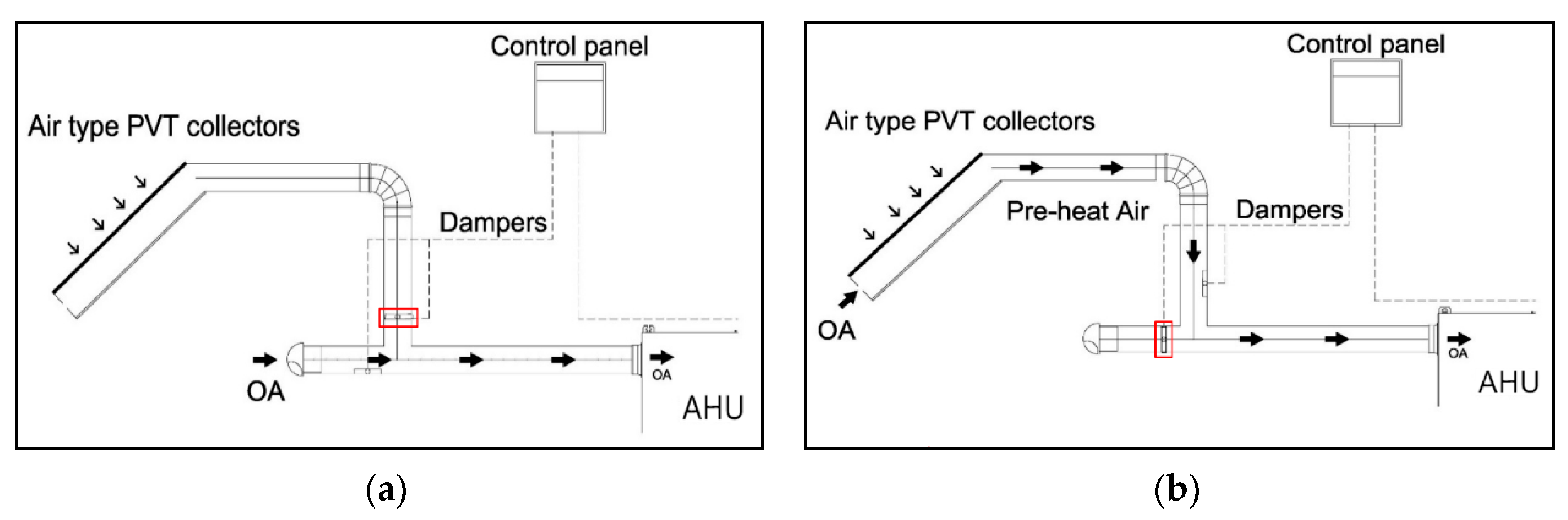

3.2. AHU System with BIPVT Collectors

4. Results and Discussions

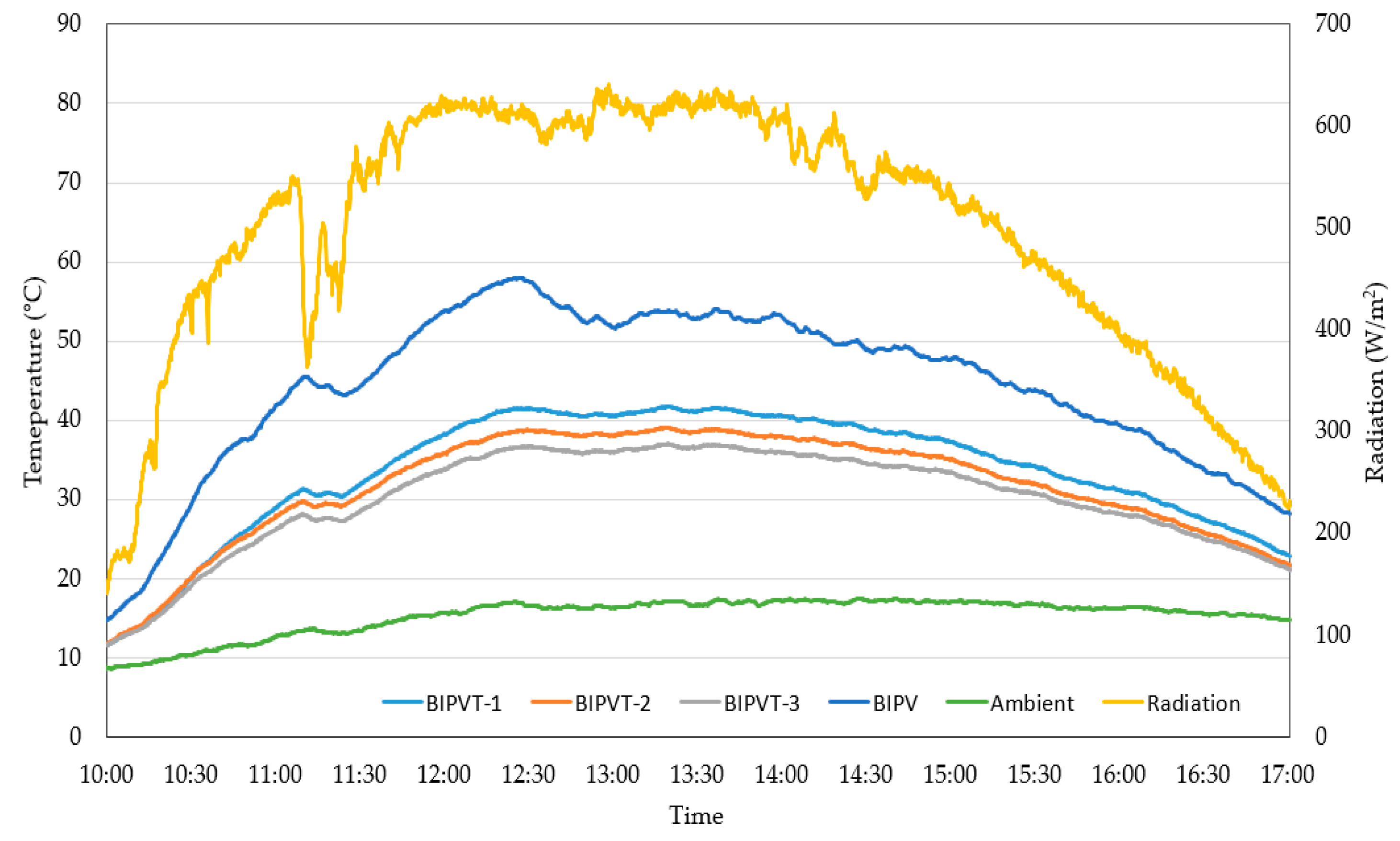

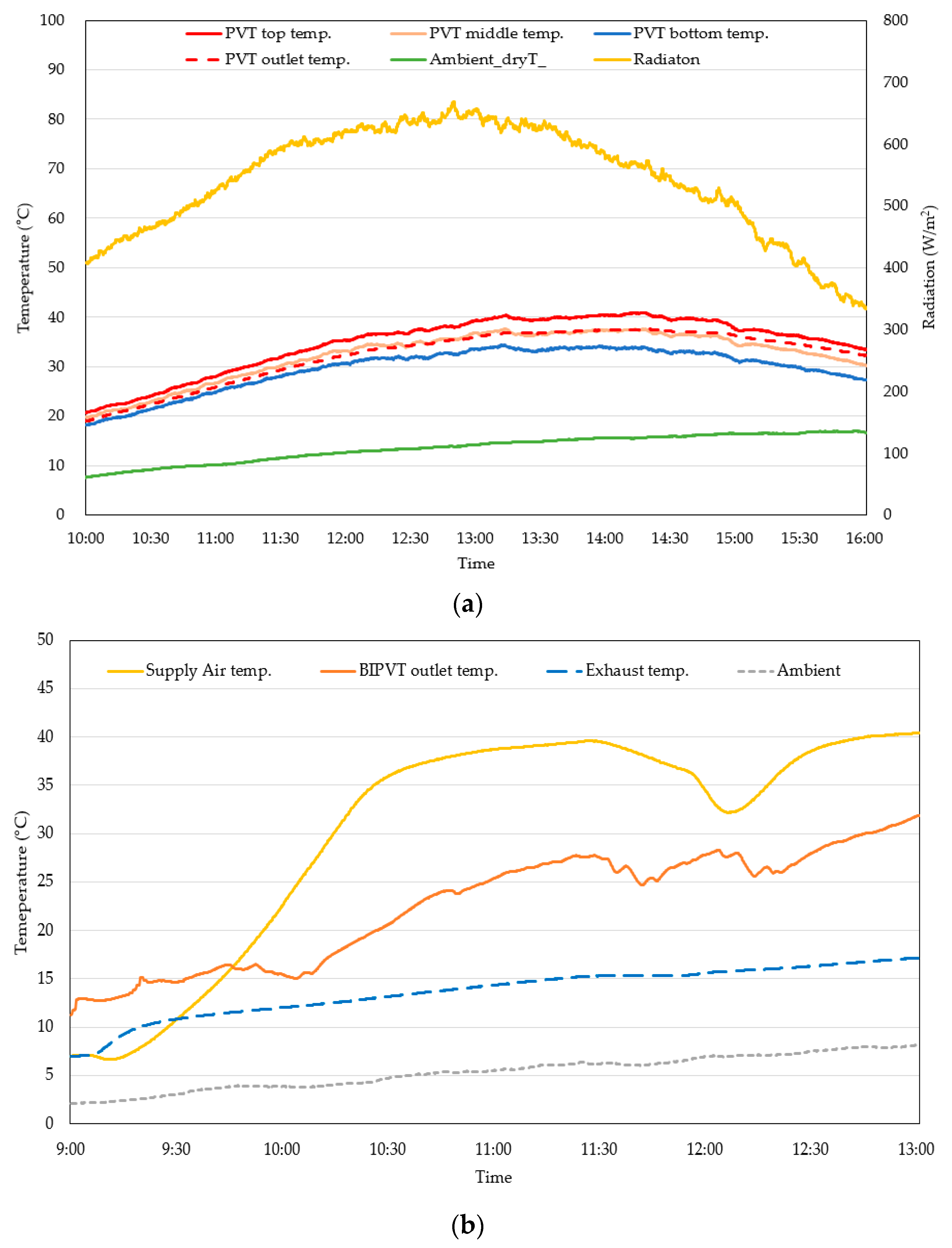

4.1. Comparison of Performance with the BIPVT and BIPV Systems

4.2. AHU System with BIPVT Collector

5. Conclusions

- (1)

- The air-type BIPVT collector can prevent the degradation of PV power generation that is often caused by increasing PV temperature. During experimental tests, the BIPVT collector produced electrical energy of about 200 W when the solar radiation was more than 800 W/m2, which was 30 W more than the total electrical energy produced by the BIPV system. Moreover, the BIPVT collector was kept at a lower PV temperature than the BIPV, where the maximum difference of PV module temperature was about 22 °C.

- (2)

- Air-type BIPVT collectors were found to maintain electrical efficiency even when solar radiation increased. During midday when solar radiation was the highest, PV electrical efficiency of the BIPV decreased up to 12% due to an increased PV module temperature. However, the electrical efficiency of BIPVT was steady at 14%.

- (3)

- Through tests in the experimental building, it was found that the connection of the BIPVT collector with the AHU system can save energy for heating. In the heating period, BIPVT collectors can supply preheated air to the AHU unit, and the AHU system can save energy to heat the cold outdoor air. The temperature of the preheated air from the BIPVT collector was 32 °C, which was 15 °C higher than the outdoor air.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sathe, T.M.; Dhoble, A.S. A review on recent advancements in photovoltaic thermal techniques. Renew. Sustain. Energy Rev. 2017, 76, 645–672. [Google Scholar] [CrossRef]

- Kazem, H.A. Evaluation and analysis of water-based photovoltaic/thermal (PV/T) system. Case Stud. Therm. Eng. 2019, 13, 100401. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Vicidomini, M. Design, simulation and experimental investigation of a solar system based on PV panels and PVT collectors. Energies 2016, 9, 497. [Google Scholar] [CrossRef]

- Kazem, H.A.; Al-Waeli, A.H.; Chaichan, M.T.; Al-Waeli, K.H.; Al-Aasam, A.B.; Sopian, K. Evaluation and comparison of different flow configurations PVT systems in Oman: A numerical and experimental investigation. Sol. Energy 2020, 208, 58–88. [Google Scholar] [CrossRef]

- Bakari, R. Heat transfer optimization in air flat plate solar collectors integrated with baffles. J. Power Energy Eng. 2018, 6, 70–84. [Google Scholar] [CrossRef]

- Hegazy, A.A. Comparative study of the performances of four photovoltaic/thermal solar air collectors. Energy Convers. Manag. 2000, 41, 861–881. [Google Scholar] [CrossRef]

- Pottler, K.; Sippel, C.M.; Beck, A.; Fricke, J. Optimized finned absorber geometries for solar air heating collectors. Sol. Energy 1999, 67, 35–52. [Google Scholar] [CrossRef]

- Riffat, S.B.; Cuce, E. A review on hybrid photovoltaic/thermal collectors and systems. Int. J. Low-Carbon Technol. 2011, 6, 212–241. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Kaushik, S.C.; Tyagi, S.K. Advancement in solar photovoltaic/thermal (PV/T) hybrid collector technology. Renew. Sustain. Energy Rev. 2012, 16, 1383–1398. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Safaei, M.R.; Leon, A.S.; Tlili, I.; Khan, I.; Tian, Z.; Goodarzil, M.; Arjomandi, M. Experimental investigation on thermal performance of a PV/T-PCM (Photovoltaic/Thermal) system cooling with a PCM and nanofluid. Energies 2019, 12, 2572. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Goodarzi, M.; Tlili, I.; Alkanhal, T.A.; Arjomandi, M. Thermodynamic potential of a high-concentration hybrid photovoltaic/thermal plant for co-production of steam and electricity. J. Therm. Anal. Calorim. 2020, 1–10. [Google Scholar] [CrossRef]

- Boutina, L.A.; Khelifa, A.; Touafek, K.; Lebbi, M.; Baissi, M.T. Improvement of PVT air-cooling by the integration of a chimney tower (CT/PVT). Appl. Therm. Eng. 2018, 129, 1181–1188. [Google Scholar] [CrossRef]

- Tiwari, S.; Agrawal, S.; Tiwari, G.N. PVT air collector integrated greenhouse dryers. Renew. Sustain. Energy Rev. 2018, 90, 142–159. [Google Scholar] [CrossRef]

- Fan, W.; Kokogiannakis, G.; Ma, Z. Optimisation of life cycle performance of a double-pass photovoltaic thermal-solar air heater with heat pipes. Renew. Energy 2019, 138, 90–105. [Google Scholar] [CrossRef]

- Kim, J.-H.; Park, S.-H.; Kang, J.-G.; Kim, J.-T. Experimental performance of heating system with building-integrated PVT (BIPVT) collector. Energy Procedia 2014, 48, 1374–1384. [Google Scholar] [CrossRef]

- Abdullah, A.L.; Misha, S.; Tamaldin, N.; Rosli, M.A.M.; Sachit, F.A. Photovoltaic thermal/solar (PVT) collector (PVT) system based on fluid absorber design: A review. J. Adv. Res. Fluid Mech. Therm. Sci. 2018, 48, 196–208. [Google Scholar]

- Singh, H.P.; Jain, A.; Singh, A.; Arora, S. Influence of absorber plate shape factor and mass flow rate on the performance of the PVT system. Appl. Therm. Eng. 2019, 156, 692–701. [Google Scholar] [CrossRef]

- Hu, J.; Sun, X.; Xu, J.; Li, Z. Numerical analysis of mechanical ventilation solar air collector with internal baffles. Energy Build. 2013, 62, 230–238. [Google Scholar] [CrossRef]

- Kim, S.-M.; Kim, J.-H.; Kim, J.-T. Experimental study on the thermal and electrical characteristics of an air-based photovoltaic thermal collector. Energies 2019, 12, 2661. [Google Scholar] [CrossRef]

- International Electrotechnical Commission. Crystalline Silicon Terrestrial Photovoltaic (PV) Module—Design Qualification and Type Approval; IEC: London, UK, 2016. [Google Scholar]

| Specification | BIPVT Module | BIPV Module |

|---|---|---|

| PV cell type | Mono-crystalline silicon | |

| PV module efficiency | 7.6% | 16.2% |

| Maximum power | 123.3 W | 265.08 W |

| Maximum voltage | 15.08 V | 31.01 V |

| Maximum current | 8.18 A | 8.55 A |

| Open circuit voltage (Voc) | 19.05 V | 38.53 V |

| Short circuit current (Isc) | 8.61 A | 9.05 A |

| Collector size | 1584 1031 84.5 mm | 1084 1031 84.35 mm |

| Description | Measurement Range | Accuracy |

|---|---|---|

| Humidity and temperature transmitter | −50 to 100 °C 0 to 100% RH | ±0.8%RH at 23 °C ±0.1 K at 23 °C |

| Pyranometer (nonlinearity) | 0 to 2000 W/m2 | ±1.2% at <1000 W/m2 |

| Thermocouple | −250 to 500 °C | ±0.5 °C |

| Power meter | 15–600 V 0.5–20 A | 0.1% of the reading 0.1% of the range |

| Data logger | −10 V to 10 V, 20 mA | 0.003% DCV |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-H.; Kim, S.-M.; Kim, J.-T. Experimental Performance of an Advanced Air-Type Photovoltaic/Thermal (PVT) Collector with Direct Expansion Air Handling Unit (AHU). Sustainability 2021, 13, 888. https://doi.org/10.3390/su13020888

Kim J-H, Kim S-M, Kim J-T. Experimental Performance of an Advanced Air-Type Photovoltaic/Thermal (PVT) Collector with Direct Expansion Air Handling Unit (AHU). Sustainability. 2021; 13(2):888. https://doi.org/10.3390/su13020888

Chicago/Turabian StyleKim, Jin-Hee, Sang-Myung Kim, and Jun-Tae Kim. 2021. "Experimental Performance of an Advanced Air-Type Photovoltaic/Thermal (PVT) Collector with Direct Expansion Air Handling Unit (AHU)" Sustainability 13, no. 2: 888. https://doi.org/10.3390/su13020888

APA StyleKim, J.-H., Kim, S.-M., & Kim, J.-T. (2021). Experimental Performance of an Advanced Air-Type Photovoltaic/Thermal (PVT) Collector with Direct Expansion Air Handling Unit (AHU). Sustainability, 13(2), 888. https://doi.org/10.3390/su13020888