Effect of Green Construction on a Building’s Carbon Emission and Its Price at Materialization

Abstract

1. Introduction

2. Calculation of Carbon Emissions at the Materialization Stage

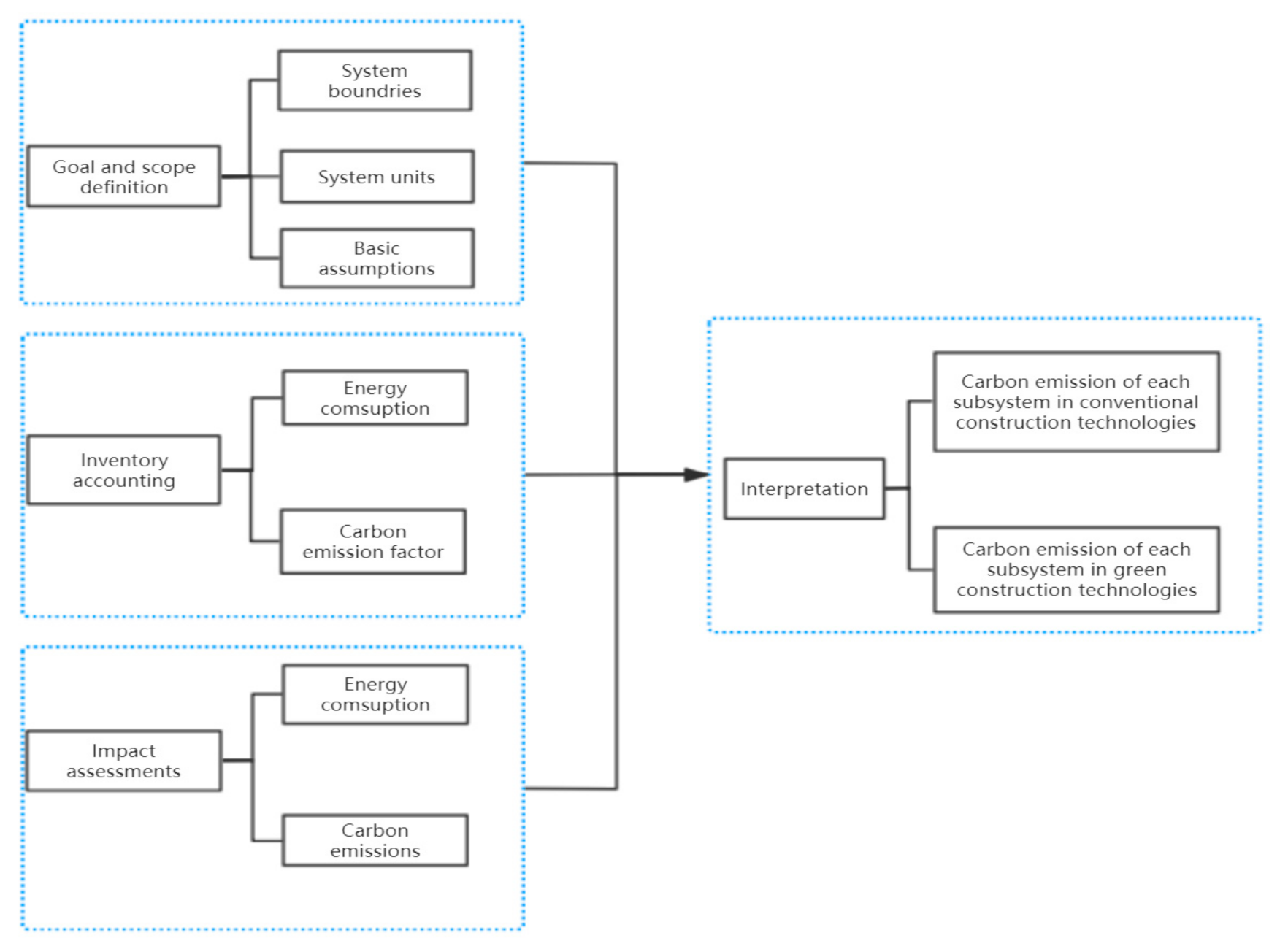

2.1. Framework for Estimating Carbon Emissions

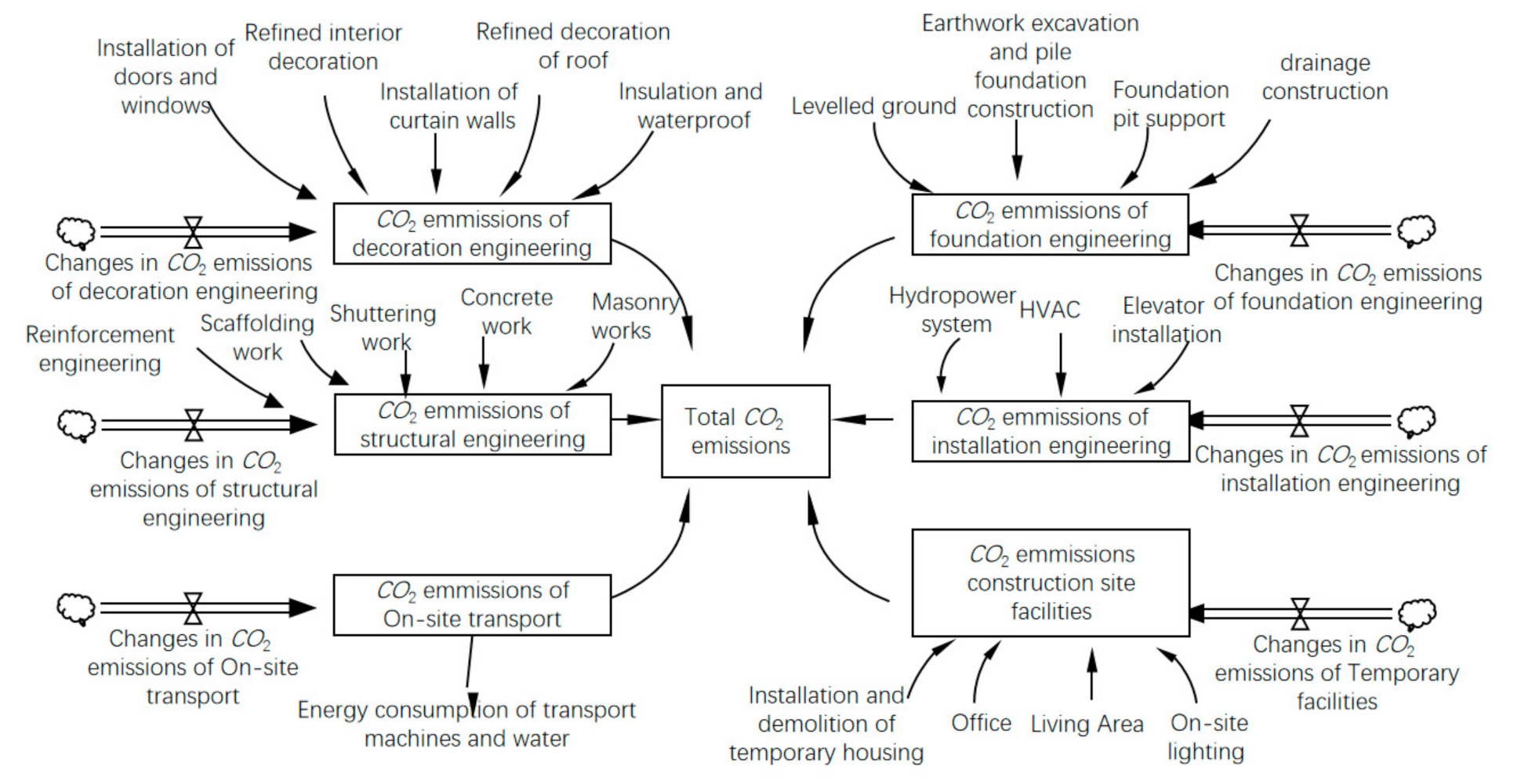

2.2. Modeling CO2 Emission in Each Subsystem

2.3. Calculation of Carbon Emission at the Materialisation Stage

3. Overview: A Case Study

4. Discussion

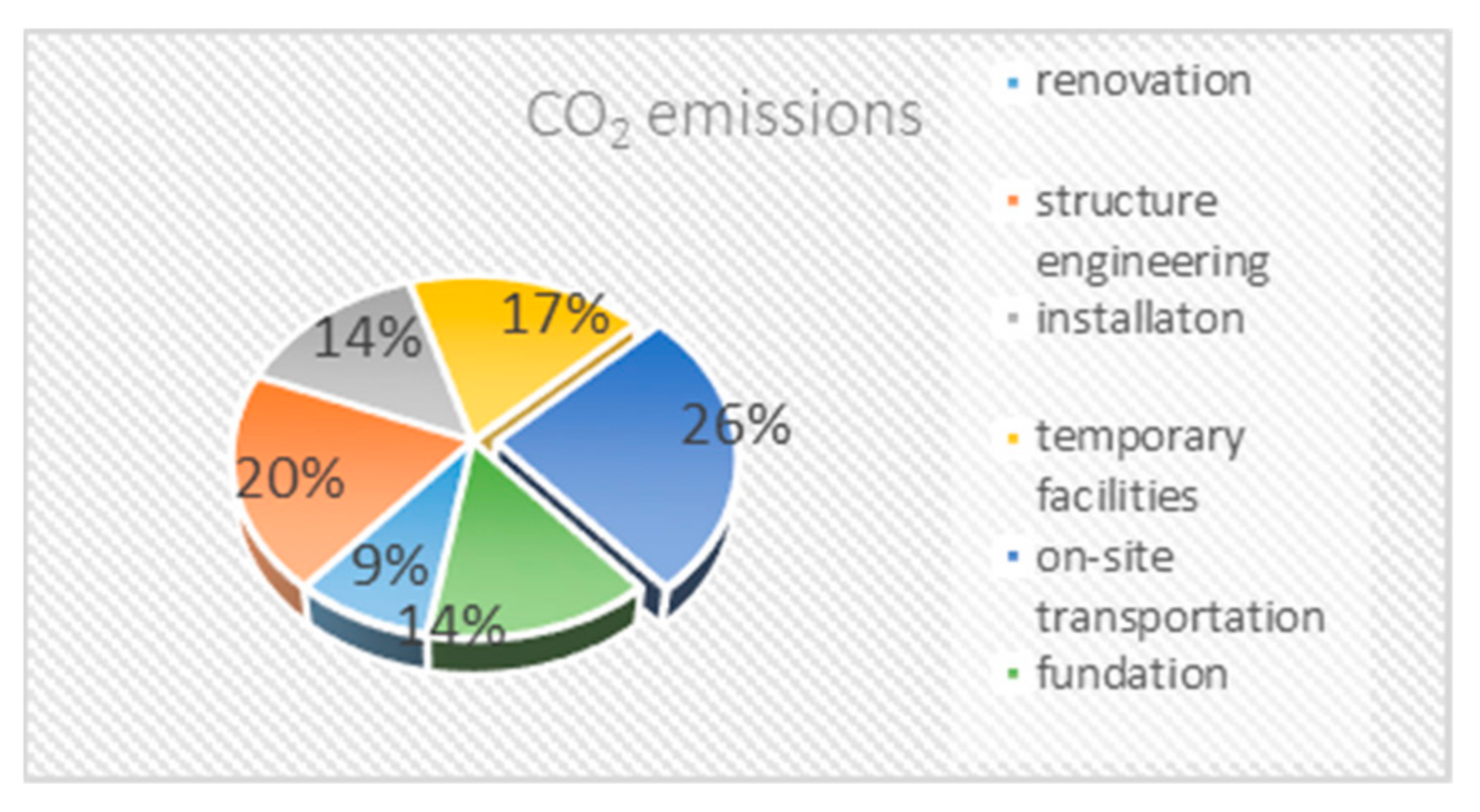

4.1. Carbon Emissions during Construction

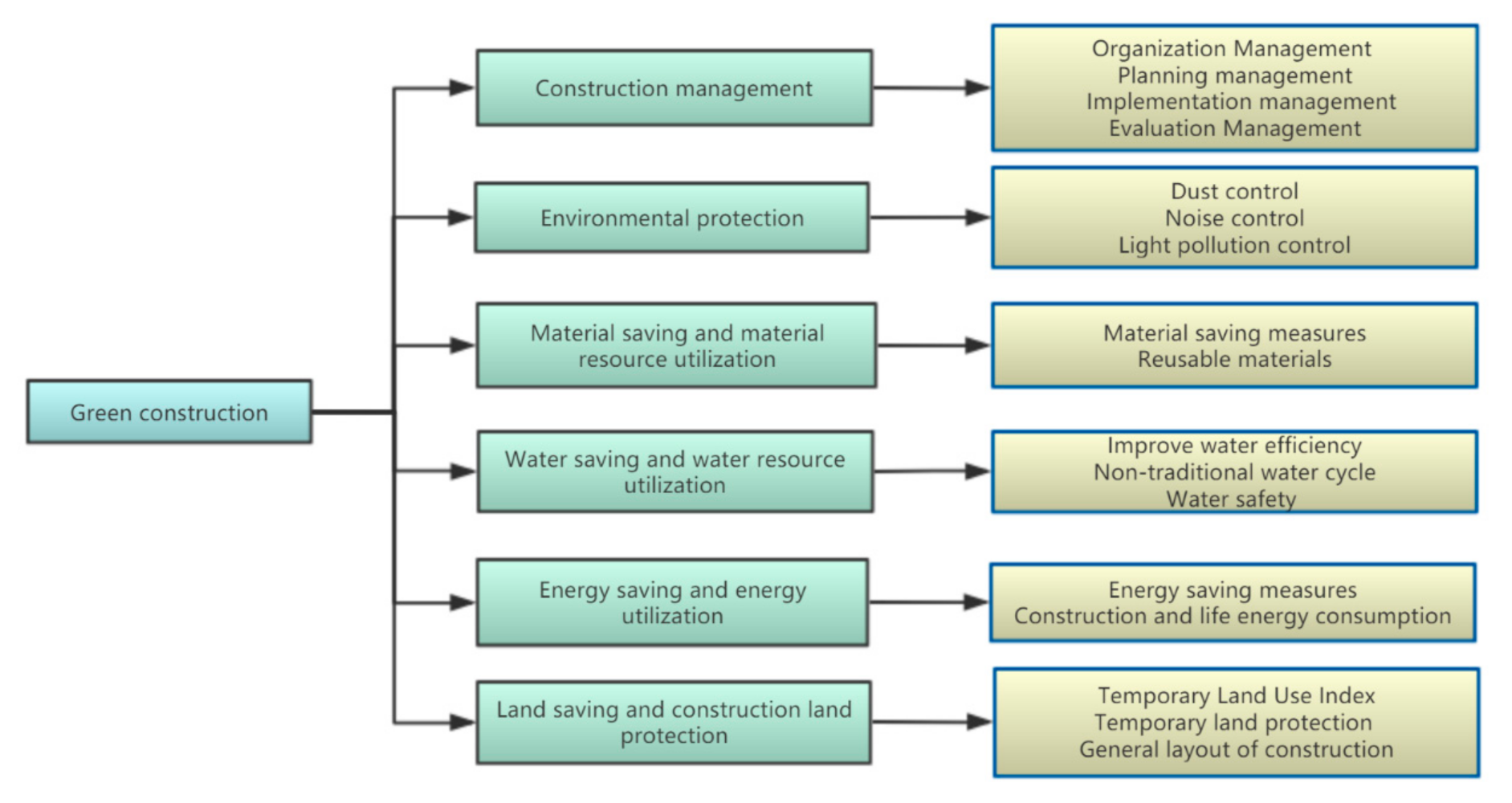

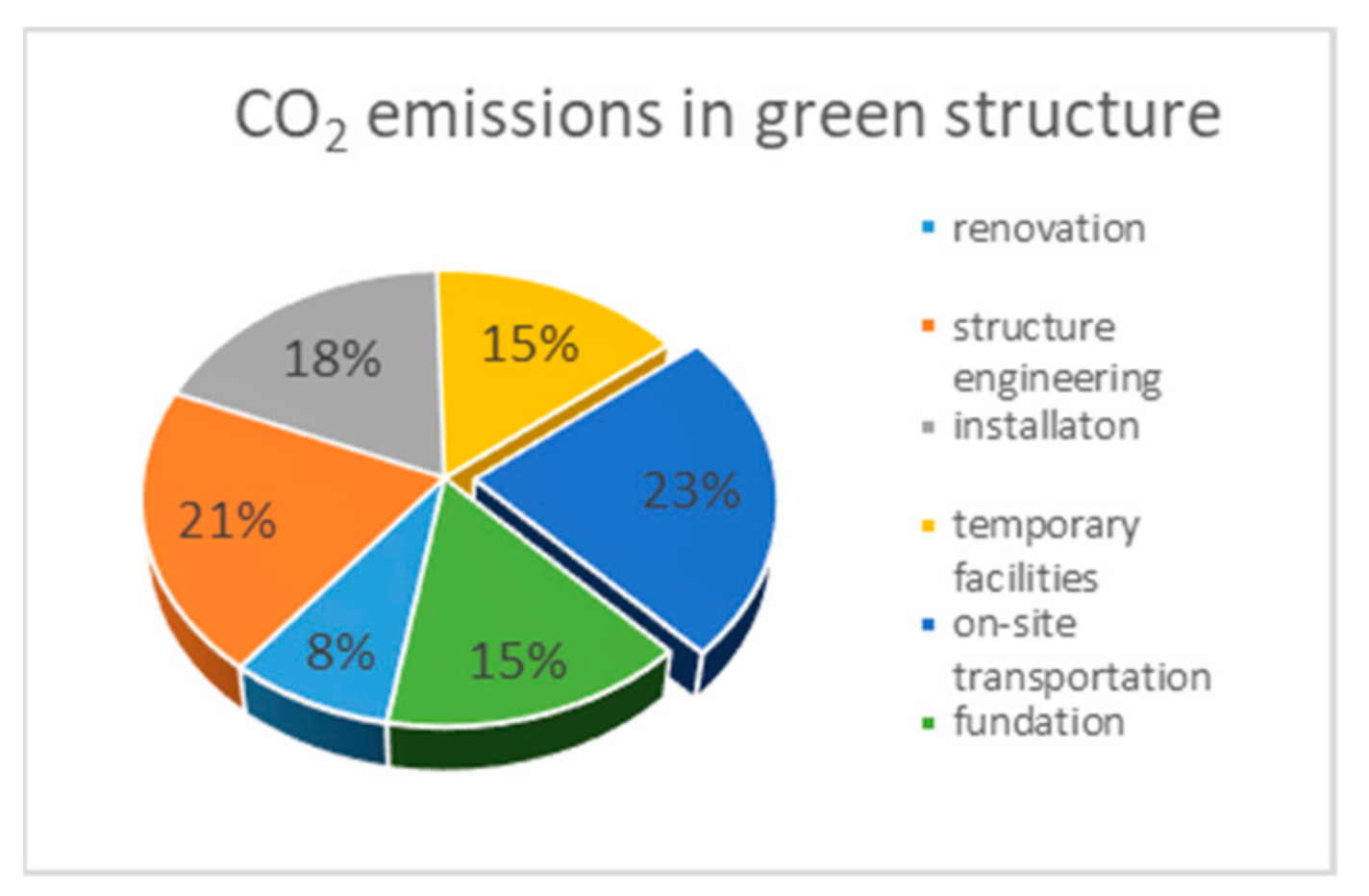

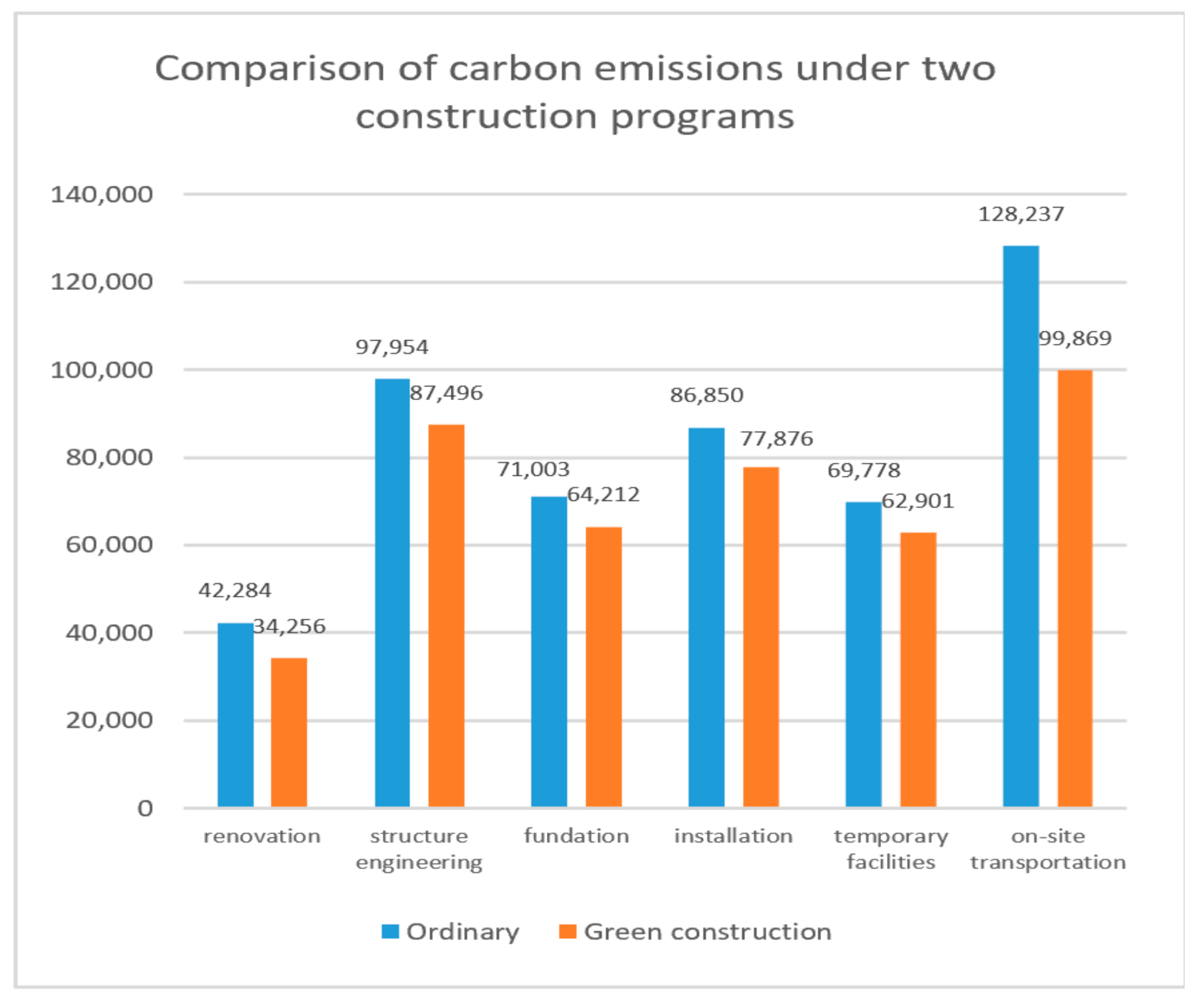

4.2. Effect of Green Construction on Building’s Carbon Emission

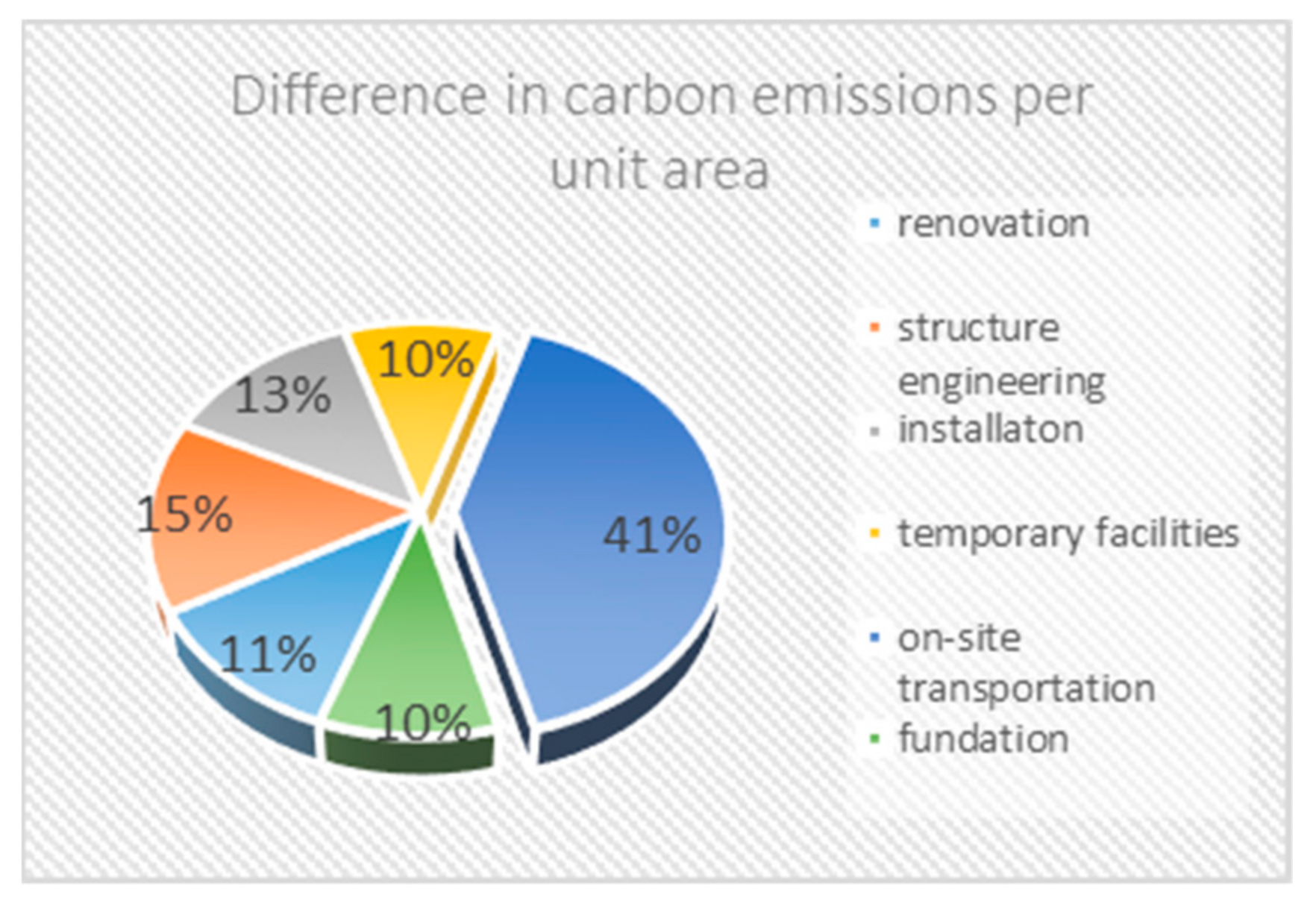

4.3. Analysis of Carbon Emission Differences under Different Construction Programs

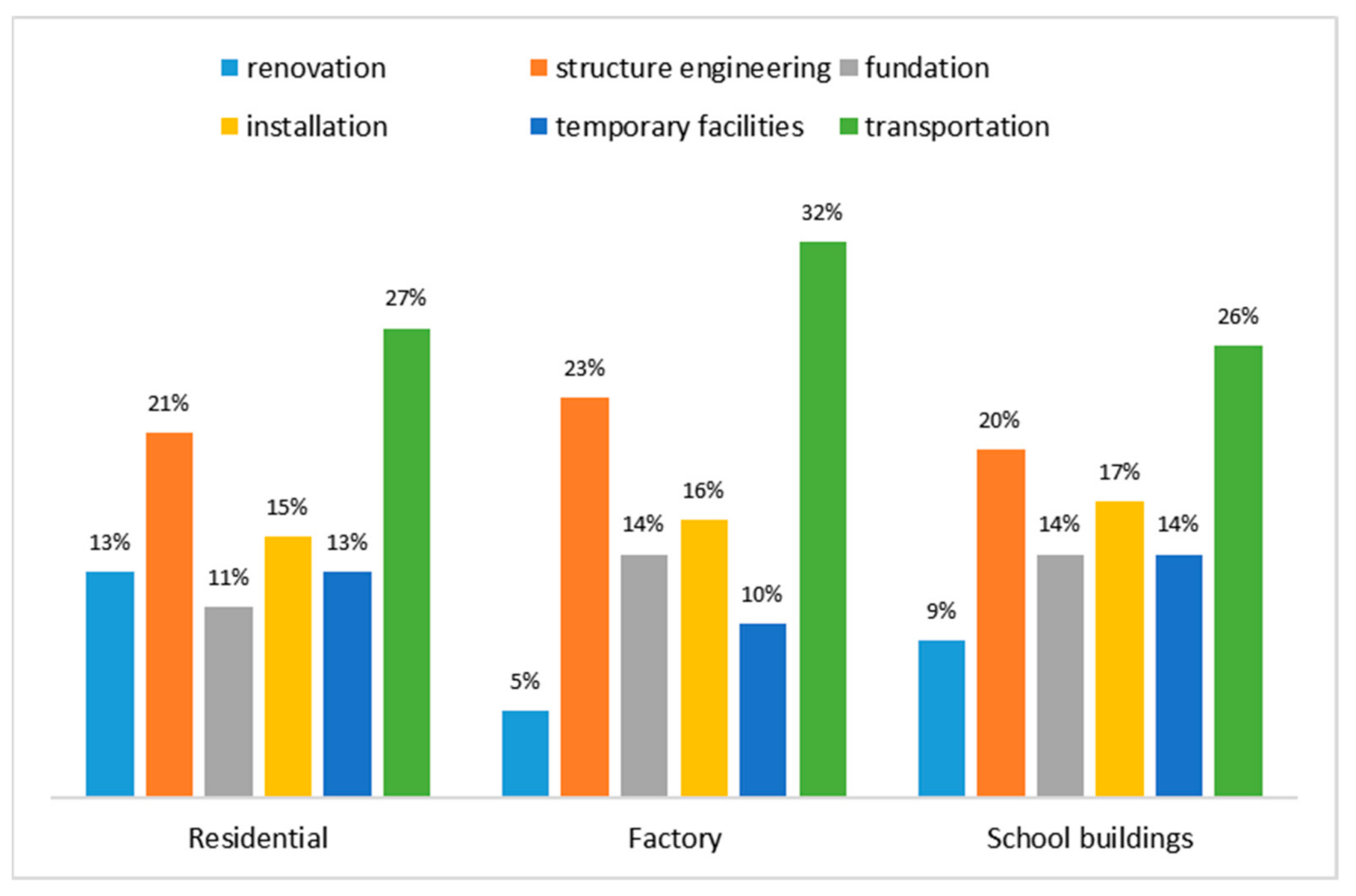

4.4. Effect of Transportation Engineering Based on Different Buildings on Carbon Emissions

5. Discussion and Conclusions

5.1. Effect of Green Construction Based on Subsystems on Carbon Trading Prices

5.2. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- UNFCCC. Adoption of the Paris Agreement; United Nations Office at Geneva: Geneva, Switzerland, 2015. [Google Scholar]

- Working Group I. The IPCC 6th Assessment Report; 1-4 IPCC: Stockholm, Sweeden, 2018. [Google Scholar]

- Xie, R.; Zhao, G.; Zhu, B.; Lai, M. Regional Transfer of Haze Pollutants Embodied in China’s Foreign Trade and Factors Affecting it: A GERIO-based Empirical Analysis. Emerg. Mark. Financ. Trade 2016, 52, 1335–1347. [Google Scholar] [CrossRef]

- Ma, X.M.; Cai, Y. Report on China’s Low-Carbon Finance Development; Peking University Press: Beijing, China, 2014; pp. 6–11. (In Chinese)

- Jin, F.J.; Ma, L.; Xu, D. Environmental stress and optimized path of industrial development in the Yellow River Basin. Res. Sci. 2020, 42, 127–136. [Google Scholar] [CrossRef]

- Tong, Y.; Yin, Y.; Qian, L.; An, J.L. Analysis of the Characteristics of Hazy Phenomena in Nanjing Area. China Environ. Sci. 2011, 27, 584–588. [Google Scholar]

- Zhou, S.; Ding, Y.; Wang, Z.P.; Dong, J.L.; She, A.M.; Wei, Y.Q.; Li, R.G. Weathering of roofing insulation materials under multi-field coupling conditions. Materials 2019, 12, 3348. [Google Scholar] [CrossRef] [PubMed]

- Huo, T.; Ren, H.; Zhang, X.; Cai, W.; Feng, W.; Zhou, N.; Wang, X. China’s energy consumption in the building sector: A Statistical Yearbook-Energy Balance Sheet based splitting method. J. Clean. Prod. 2018, 185, 665–679. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Wu, X. A Building Environmental Impact Assessment System Based on LCA. Urban Environ. Urban Ecol. 2004, 9, 27–29. (In Chinese) [Google Scholar]

- Zhang, D.Y.; Zhang, L.X. Research Progress on Carbon Source Emission Estimation Methods. Inn. Mong. For. Sci. 2005, 1, 20–23. (In Chinese) [Google Scholar]

- Li, B.; Li, Y.X.; Wu, B.; Fu, F.F. Research on Carbon Emission Measurement Model of Construction. J. Inf. Technol. Civ. Eng. 2011, 2, 5–10. (In Chinese) [Google Scholar]

- Yu, P.; Chen, X.Q.; Ma, L.Y. Review on Studies of Life Cycle Carbon Emission from Residential Buildings. Build. Sci. 2011, 27, 9–12. (In Chinese) [Google Scholar]

- Zhang, Z.H.; Shang, C.J.; Qian, K. Evaluation of Carbon Emission in Building’s Life Cycle. Constr. Econ. 2010, 2, 44–46. (In Chinese) [Google Scholar]

- Ximenes, F.A.; Grant, T. Quantifying the Greenhouse Benefits of the Use of Wood Products in Two Popular House Designs in Sydney, Australia. Int. J. Life Cycle Assess. 2013, 18, 891–908. [Google Scholar] [CrossRef]

- Wang, J.J.; Zhao, W.; Wang, S.L. Study on Calculation Methods of Carbon Emissions of Buildings during the Construction. Build. Sci. 2014, 2, 8–12. (In Chinese) [Google Scholar]

- Zhang, X.; Shen, L.; Zhang, L. Life Cycle Assessment of the Air Emissions during Building Construction Process: A Case Study in Hong Kong. Renew. Sustain. Energy Rev. 2013, 17, 160–169. [Google Scholar] [CrossRef]

- Gong, X.Z.; Nie, Z.R.; Wang, Z.H.; Cui, S.; Gao, F.; Zuo, T. Life Cycle Energy Consumption and Carbon Dioxide Emission of Residential Building Designs in Beijing: A Comparative Study. J. Ind. Ecol. 2012, 16, 576–587. [Google Scholar] [CrossRef]

- Available online: www.tanpaifang.com (accessed on 8 January 2021).

- Gao, Y.; Liu, X.J. Identify and the Value of Green Building Carbon Emissions Based on Cost-effectiveness. J. Xi’an Univ. Archit. Technol. 2016, 48, 755–759. [Google Scholar]

- Zhao, R.; Zhou, X.; Min, X.F. Game Theoretical Analysis on Purchase of Carbon labelled Product Based on System Dynamics. J. Syst. Sci. 2021, 29, 111–114. [Google Scholar]

- Haites, E. Carbon Taxes and Greenhouse Gas Emissions Trading Systems: What have we learned? Clim. Policy 2018, 18, 955–966. [Google Scholar] [CrossRef]

- Peuportier, B.; Thiers, S.; Guiavarch, A. Eco-design of buildings using thermal simulation and life cycle assessment. J. Clean. Prod. 2013, 39, 73–78. [Google Scholar] [CrossRef]

- Yang, Z.; Da, Y.; Shan, H.; Guo, S. Modelling of Energy Consumption and Carbon Emission from the Building Construction Sector in China, A Process-based LCA Approach. Energy Policy 2019, 134, 1–9. [Google Scholar]

- Lin, L.; Jiang, Y.; Yan, D.; Peng, C. Analysis of Energy Consumption in Building Construction and CO2 Emission. Energy China 2015, 37, 7–14. [Google Scholar]

- Sartori, I.; Hestnes, A. Energy use in the life cycle of conventional and low energy buildings: A review article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Monahan, J.; Powell, J.C. An Embodied Carbon and Energy Analysis of Modern Methods of Construction in Housing: A Case Study Using a Life Cycle Assessment Framework. Energy Build. 2011, 43, 179–188. [Google Scholar] [CrossRef]

- Säynäjoki, A.; Heinonen, J.; Junnila, S.; Horvath, A. Can life-cycle assessment produce reliable policy guidelines in the building sector? Environ. Res. Lett. 2017, 12, 013001. [Google Scholar] [CrossRef]

- Su, X.; Zhang, X. A Detailed Analysis of the Embodied Energy and Carbon Emissions of Steel-construction Residential Buildings in China. Energy Build. 2016, 119, 323–330. [Google Scholar] [CrossRef]

- Buyle, M.; Braet, J.; Audenaert, A. Life Cycle Assessment in the Construction Sector: A Review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar] [CrossRef]

- China National Institute of Standardization. GB/T 24040-2008; Environmental Management—Life Cycle Assessment—Principles and Framework; Standard Press of China: Beijing, China, 2008. (In Chinese)

- Yildiz, I.; Caliskan, H. Energetic and exergetic carbon dioxide equivalents and prices of the energy sources for buildings in Turkey. Environ. Prog. Sustain. Energy 2018, 37, 912–925. [Google Scholar] [CrossRef]

- De Wolf, C.; Pomponi, F.; Moncaster, A. Measuring embodied carbon dioxide equivalent of buildings: A review and critique of current industry practice. Energy Build. 2017, 140, 68–80. [Google Scholar] [CrossRef]

- Gao, Y.; Li, Z.D.; Zhang, H.; Yu, B.; Wang, J.Y. A carbon emission analysis model for prefabricated construction based on LCA. J. Eng. Manag. 2018, 32, 30–34. (In Chinese) [Google Scholar]

- Ni, J.Q.; Heber, A.J.; Diehl, C.A.; Lim, T.T. Se-structures and environment: Ammonia, hydrogen sulphide and carbon dioxide release from pig manure in under-floor deep pits. J. Agric. Eng. Res. 2000, 77, 53–66. [Google Scholar] [CrossRef]

- Guidelines for Green Construction; Construction Quality 223; Ministry of Construction of the People’s Republic of China: Beijing, China, 2007. (In Chinese)

- Junnila, S.; Horvath, A.; Guggemos, A.A. Life-cycle assessment of office buildings in Europe and the United States. J. Infrastruct. Syst. 2006, 12, 10–17. [Google Scholar] [CrossRef]

- Wang, L. Study on Application of Green Energy-saving Construction Technology in Building Construction. Energy Conserv. Environ. Prot. 2018, 31, 43–44. (In Chinese) [Google Scholar]

- Thormark, C. Environmental Analysis of a Building with Reused Building Materials. Int. J. Low. Energy Sust. Build. 2000, 1, 1–18. [Google Scholar]

- Venkatarama Reddy, B.V.; Jagadish, K.S. Embodied Energy of Common and Alternative Building Materials and Technologies. Energy Build. 2003, 35, 129–137. [Google Scholar] [CrossRef]

- Chen, X.L.; Liu, X.B. Research on Carbon Emission Regulation Policy of Building Sector Based on Carbon Tax /Subsidy: Taking EU’s Building Sector Carbon Emission Policy for Example. Urban Dev. Stud. 2013, 10, 21–27. (In Chinese) [Google Scholar]

- Hu, R.; Chen, L.; Zhu, J.L. Complexity of Airlines’ Dynamic Price Competition with Carbon Emission Trading. J. Transp. Syst. Eng. Inf. Technol. 2018, 18, 6–12. (In Chinese) [Google Scholar]

| Energy | Energy | Carbon Emission Factor | Energy | Energy | Carbon Emission Factor |

|---|---|---|---|---|---|

| Coal | Smokeless coal | 98.3 kg CO2/GJ | Fuel | Motor gasoline | 69.3 kg CO2/GJ |

| Coking coal | 94.6 kg CO2/GJ | Kerosene | 71.5 kg CO2/GJ | ||

| Lignite | 101 kg CO2/GJ | Diesel | 74.1 kg CO2/GJ | ||

| Charcoal | 107 kg CO2/GJ | Fuel oil | 77.4 kg CO2/GJ | ||

| Power | Regional powergrid in North China | 1.246 kg CO2/(kW∙h) | Gas | Natural gas | 56.1 kg CO2/GJ |

| Regional powergrid in Central China | 0.801 kg CO2/(kW∙h) | Coal gas | 44.4 kg CO2/GJ | ||

| Regional powergrid in South China | 0.714 kg CO2/(kW∙h) |

| Project | Content |

|---|---|

| Construction functions | Teaching buildings; residential houses; office buildings; recreation facility |

| Construction characteristics | With large-scale single floor, diversified functional areas and a U-shaped plan |

| Construction area m2 | 8133 |

| Number of floors | 6 |

| Floor height m | 3.9 |

| Construction height m | 25.6 |

| Fire protection | Second class |

| Structure | Frame |

| Primary Classification | Secondary Classification | Carbon Emission Of Each Sub-Item | Total Carbon Emission |

|---|---|---|---|

| Decoration engineering | Installation of doors and windows | 2499 | 42,284 |

| Installation of curtain walls | 2942 | ||

| Refined decoration of roof | 2015 | ||

| Refined interior decoration | 34,617 | ||

| Insulation and waterproof | 211 | ||

| Structural engineering | Reinforcement work | 54,189 | 97,954 |

| Shuttering work | 1367 | ||

| Concrete work | 37,582 | ||

| Masonry work | 4471 | ||

| Scaffolding work | 346 | ||

| On-site transport | Energy consumption of transport machines and water | 128,237 | 128,237 |

| Foundation engineering | Levelled ground | 685 | 71,033 |

| Earthwork excavation and pile foundation construction | 39,373 | ||

| Foundation pit support | 18,623 | ||

| Drainage construction | 12,322 | ||

| Installation engineering | Hydropower system | 53,296 | 86,850 |

| HVAC | 33,423 | ||

| Elevator installation | 131 | ||

| Construction site facilities | Installation and demolition of temporary housing | 5156 | 69,778 |

| Office | 33,630 | ||

| Living area | 27,473 | ||

| On-site lighting | 3519 |

| Primary Classification | Secondary Classification | Carbon Emission of Each Sub-Item | Total Carbon Emission |

|---|---|---|---|

| Decoration engineering | Installation of doors and windows | 2463 | 34,256 |

| Installation of curtain wall | 2673 | ||

| Refined decoration of roof | 198 | ||

| Refined interior decoration | 28,711 | ||

| Insulation and waterproof | 211 | ||

| Structural engineering | Reinforcement work | 49,322 | 87,496 |

| Shuttering work | 1367 | ||

| Concrete work | 32,561 | ||

| Masonry work | 4121 | ||

| Scaffolding work | 125 | ||

| On-site transport | Energy consumption of transport machines and water | 99,869 | 99,869 |

| Foundation engineering | Site levelling | 596 | 64,212 |

| Earthwork excavation and pile foundation construction | 34,512 | ||

| Foundation pit support | 17,863 | ||

| Drainage construction | 11,241 | ||

| Installation engineering | Hydropower system | 46,231 | 77,876 |

| HVAC | 31,521 | ||

| Elevator installation | 124 | ||

| Construction site facilities | Installation and demolition temporary housing | 4213 | 62,901 |

| Office | 31,254 | ||

| Living area | 24,571 | ||

| On-site lighting | 2863 |

| Primary Classification | Carbon Emission Difference | Carbon Emission Difference Per Unit Area |

|---|---|---|

| Decoration engineering | 8028 | 0.987 |

| structural engineering | 10,458 | 1.286 |

| On-site transport | 8974 | 1.103 |

| Foundation engineering | 6877 | 0.846 |

| Installation engineering | 28,368 | 3.488 |

| Construction site facilities | 6791 | 0.835 |

| Primary Classification | Coefficient of Increasing Carbon Price (%) |

|---|---|

| On-site transport | 121.9 |

| Foundation engineering | 94 |

| Decoration engineering | 94.9 |

| Structural engineering | 98.5 |

| Installation engineering | 96.7 |

| Construction site facilities | 94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; Guo, Z.; Ding, Y.; Dong, J.; Le, J.; Fu, J. Effect of Green Construction on a Building’s Carbon Emission and Its Price at Materialization. Sustainability 2021, 13, 642. https://doi.org/10.3390/su13020642

Zhou S, Guo Z, Ding Y, Dong J, Le J, Fu J. Effect of Green Construction on a Building’s Carbon Emission and Its Price at Materialization. Sustainability. 2021; 13(2):642. https://doi.org/10.3390/su13020642

Chicago/Turabian StyleZhou, Shuangxi, Zhenzhen Guo, Yang Ding, Jingliang Dong, Jianming Le, and Jie Fu. 2021. "Effect of Green Construction on a Building’s Carbon Emission and Its Price at Materialization" Sustainability 13, no. 2: 642. https://doi.org/10.3390/su13020642

APA StyleZhou, S., Guo, Z., Ding, Y., Dong, J., Le, J., & Fu, J. (2021). Effect of Green Construction on a Building’s Carbon Emission and Its Price at Materialization. Sustainability, 13(2), 642. https://doi.org/10.3390/su13020642