Life Cycle Assessment Framework for Embodied Environmental Impacts of Building Construction Systems

Abstract

1. Introduction

2. Preliminary Research Analysis

- (a)

- The framework is developed according to principles stated in international LCA standards.

- (b)

- The functional unit is selected to enable comparisons with other LCA results.

- (c)

- The building life span and service life are selected based on structural design codes.

- (d)

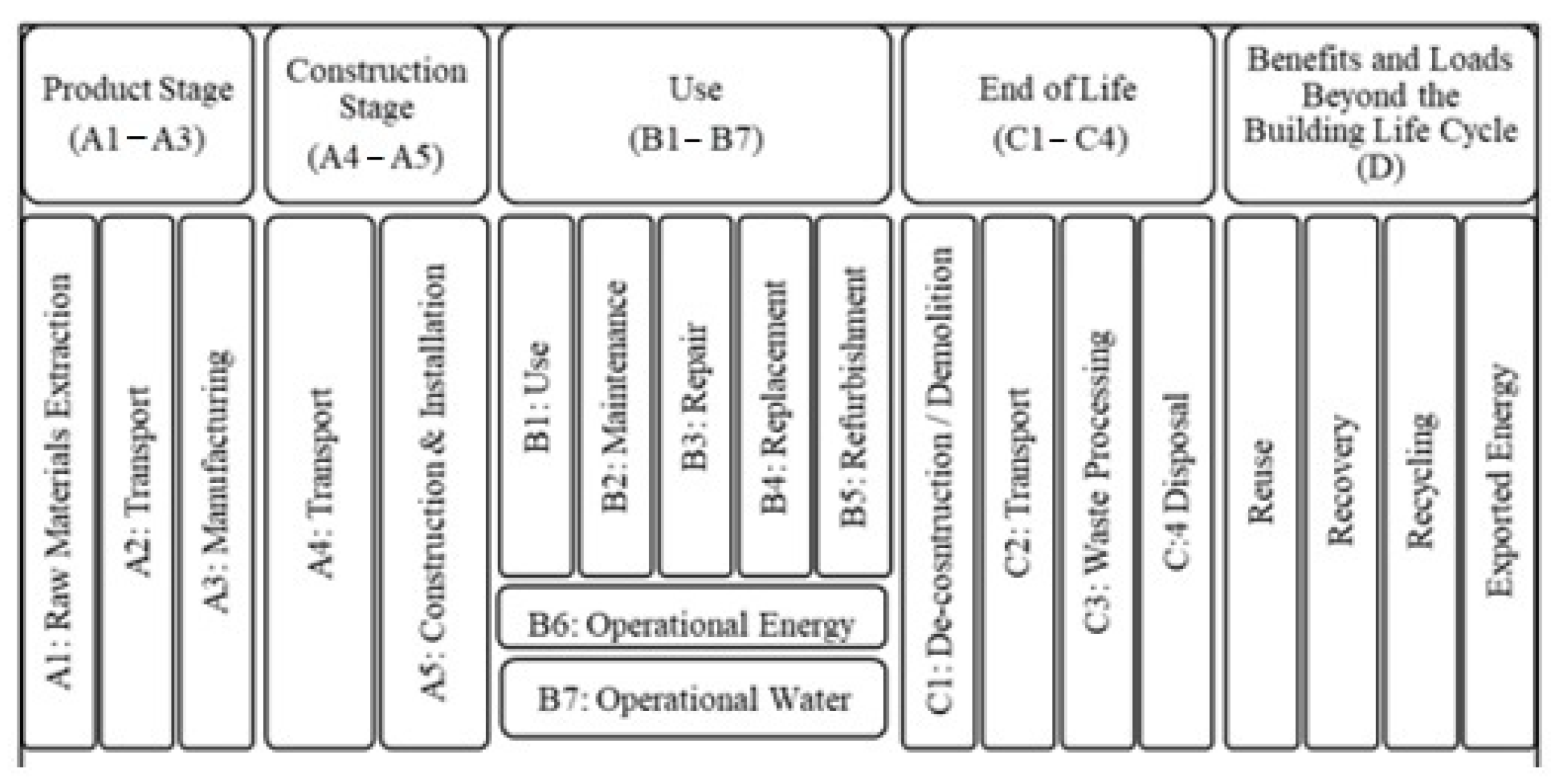

- The system boundaries are defined relative to the life cycle stages.

3. Methodology of LCA Framework

3.1. Goal and Scope of LCA

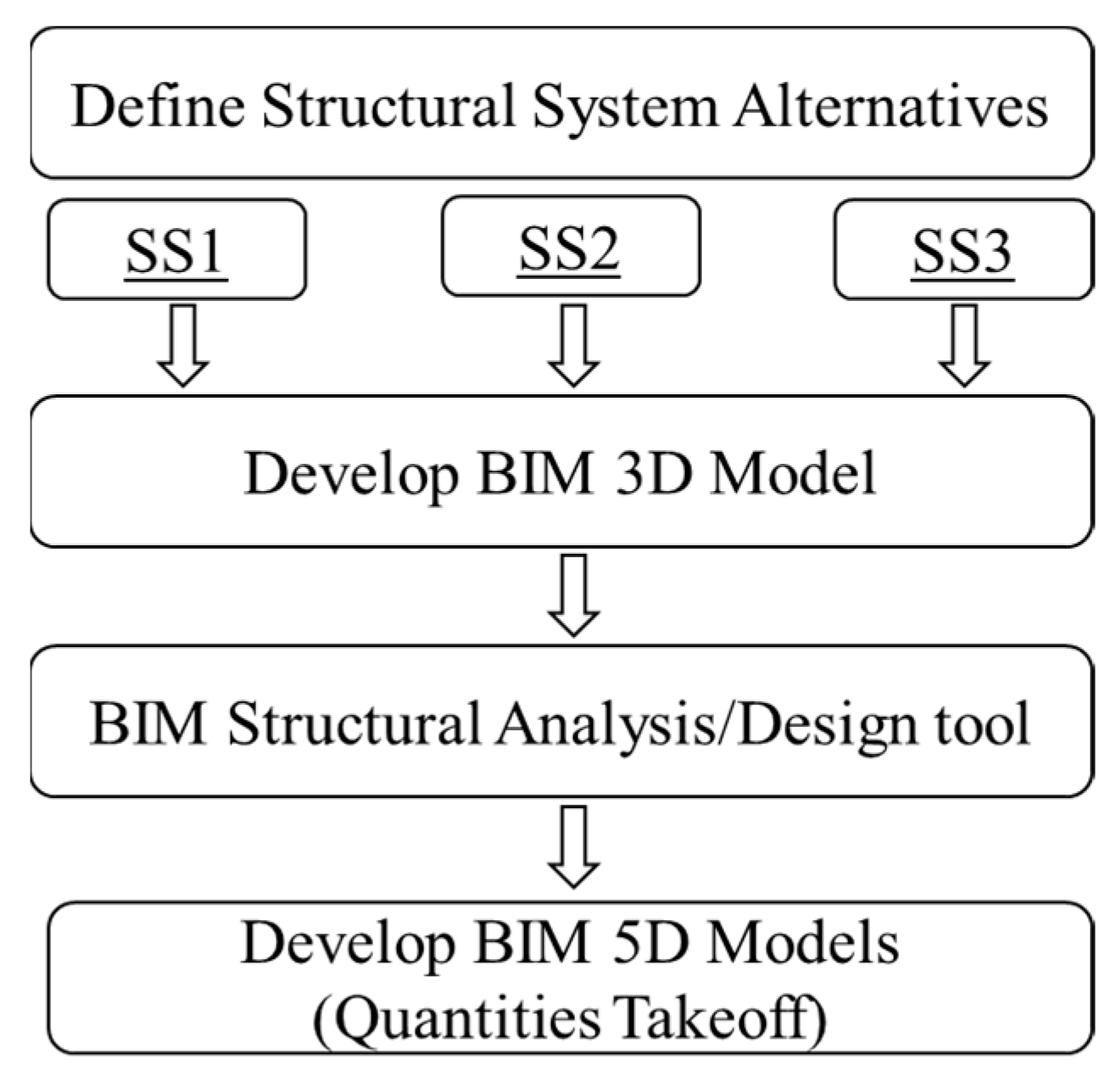

3.2. Life Cycle Inventory

- Develop 3D structural models for the construction of system alternatives.

- Perform the structural analysis/design of the design alternatives using available tools linked to the BIM software.

- Utilize the BIM 5D tool link to calculate the required material quantities for each design alternative.

- Calculate the embodied energy and embodied GHG emissions for each design alternative using the relevant life cycle inventory data.

- (i)

- Generic LCI data in which the environmental data used in LCAs are based on typical material production data and construction procedures that are specific to the region where the building is to be constructed. Changes in any of these items can considerably influence the results of the assessment. The generic data available in LCI databases cannot be assumed to hold in other geographic regions where manufacturing and construction procedures may vary significantly. Generic LCI databases are usually developed by LCA consultancy companies, by academic institutions, or by industrial organizations (e.g., Worldsteel database of steel products [31]).

- (ii)

- Specific LCI data which are provided by manufactures and producers in the form Environmental Product Declarations (EPDs). An EPD is an independently validated certificate that contains clear and comparable data about the life-cycle environmental impact of products. EPDs are constructed and registered according to ISO 14025 [32] in the framework of a program, such as the International EPD System [33]. All EPDs registered in the International EPD System are publicly available and free to download from their website. The construction industry has widely adopted EPDs as a method of reporting and sharing environmental data.

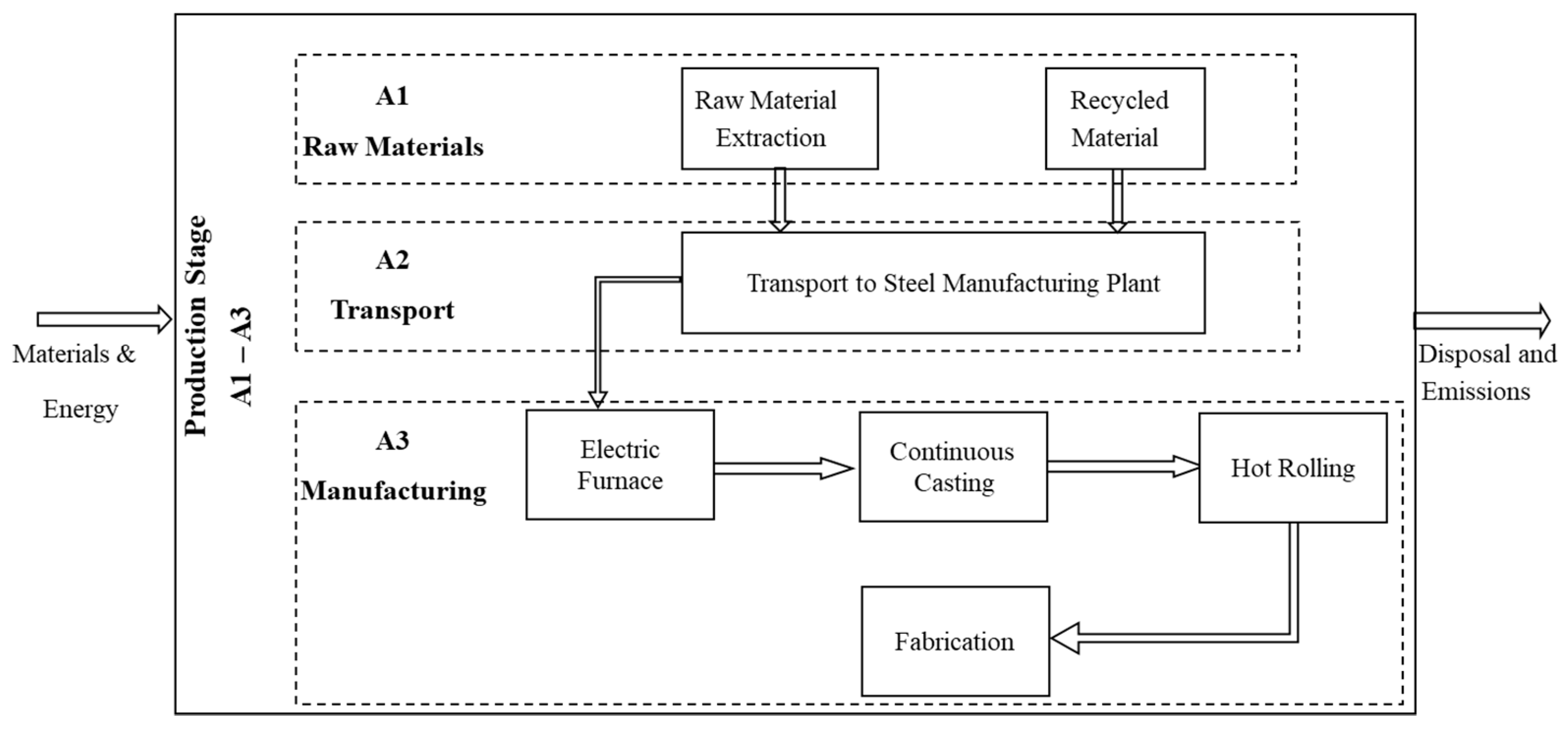

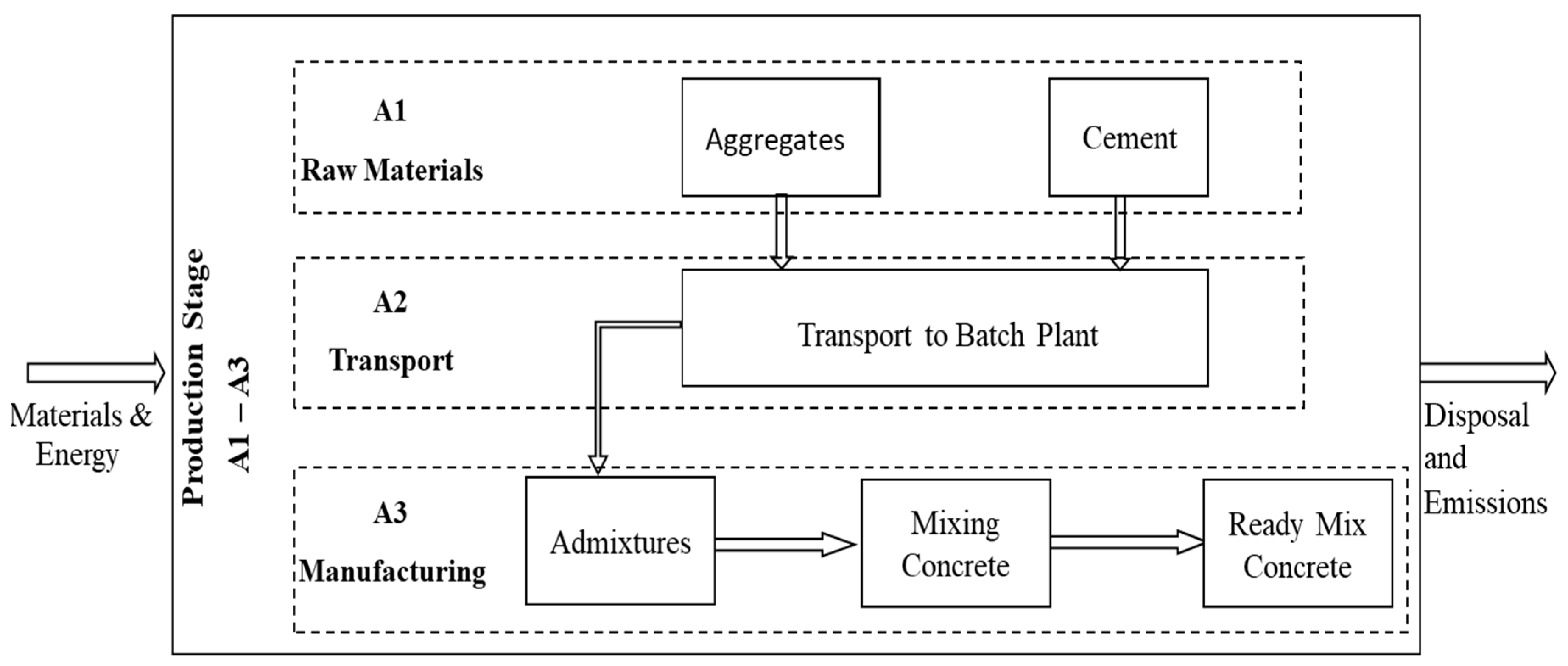

- In the material production stage (Modules A1 to A3): Verified EPDs having similar production conditions to Egypt were used to calculate embodied energy and GHG emissions.

- In the construction stage (Modules A4 and A5) and end-of-life stage (Modules C1 to C4): embodied energy and GHG emissions were calculated based on the design of relevant construction operations.

3.3. Life Cycle Impact Assessment

- Use of non-renewable primary energy resources expressed in Mega Joules (MJ), net calorific value.

- GWP expressed in carbon dioxide equivalent expressed in kg CO2eq using the characterization factors recommended by the IPCC [8].

4. LCA of Embodied Energy and GHG Emissions

4.1. LCA in Modules A1 to A3 (Material Production Stage)

4.1.1. Steel Production

4.1.2. Concrete Production

4.2. LCA in Modules A4 and A5 (Construction Stage)

4.2.1. Transportation to Construction Site (Module A4)

4.2.2. Construction Process (Module A5)

4.3. LCA in Modules B1 to B5 (Use Stage)

4.4. LCA in Modules C1 to C4 (End-of-Life Stage)

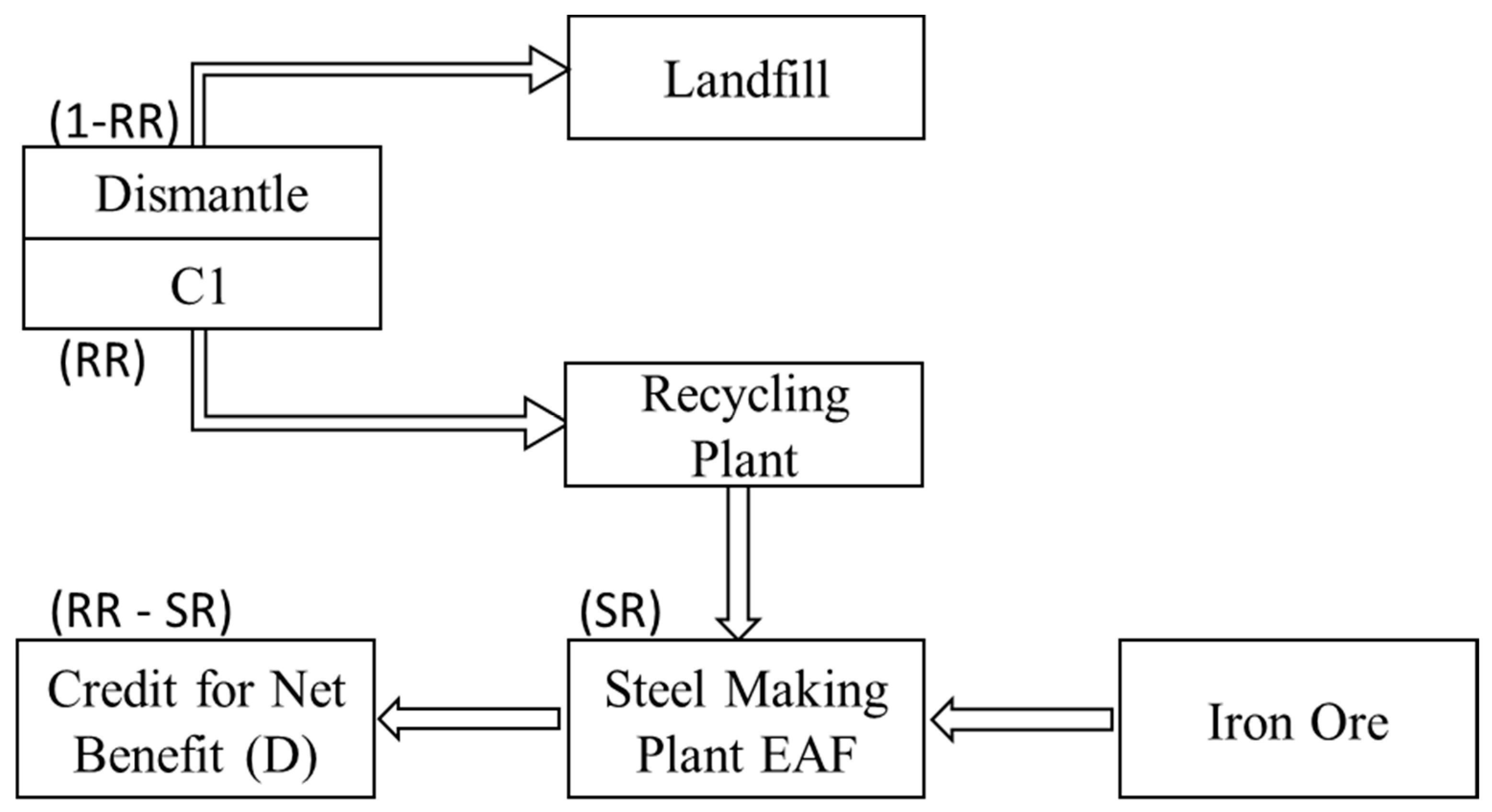

4.5. LCA in Module D (Beyond System Boundary)

4.6. Sustainability Assessment

4.6.1. Materials and Resources: Building Life Cycle Impact Reduction

4.6.2. Materials and Resources: Construction and Demolition Waste Management

5. Case Study: Application

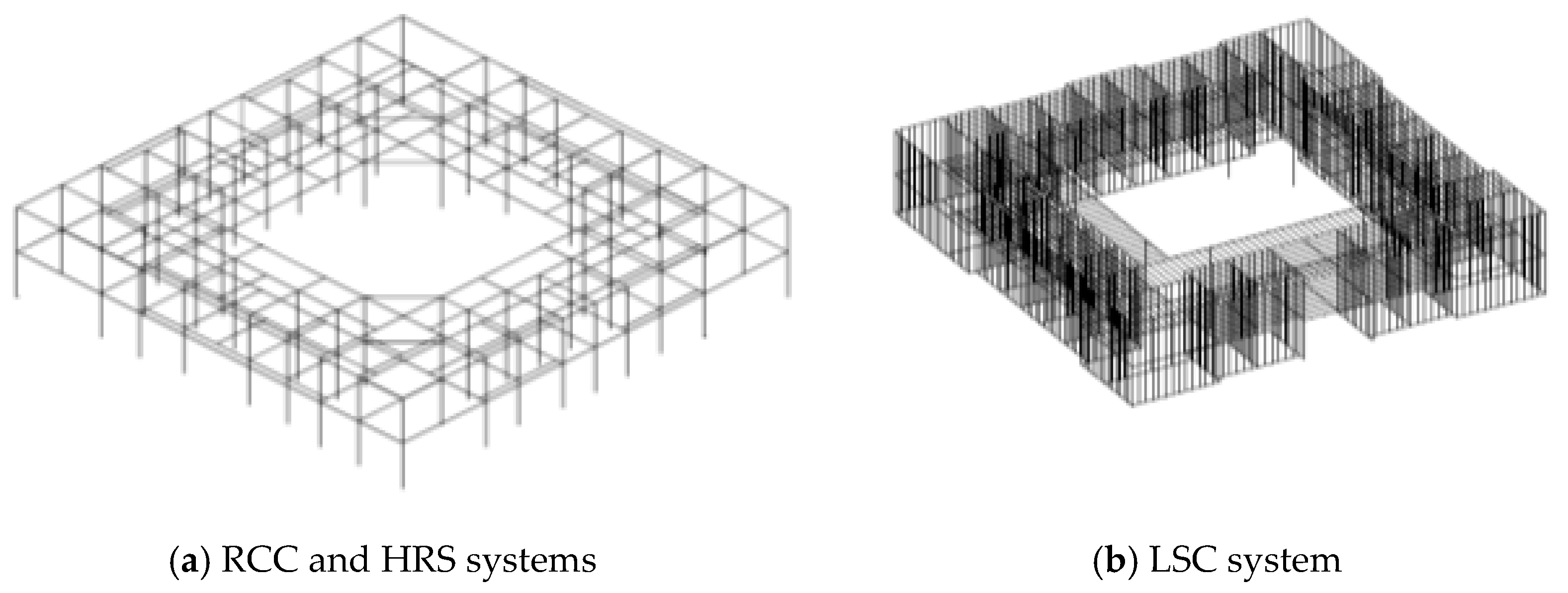

5.1. Description of Building

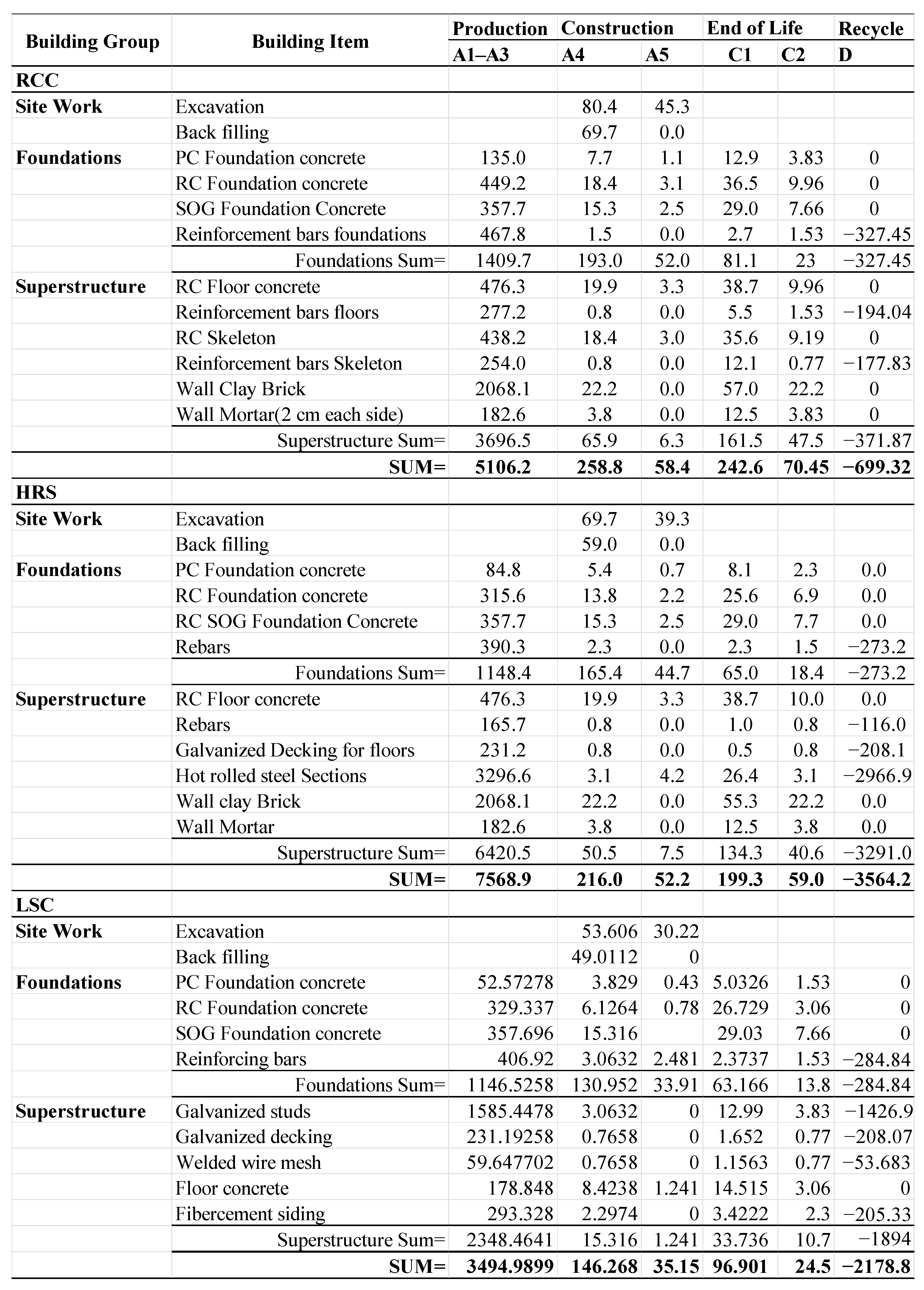

5.2. Quantities of Building Materials

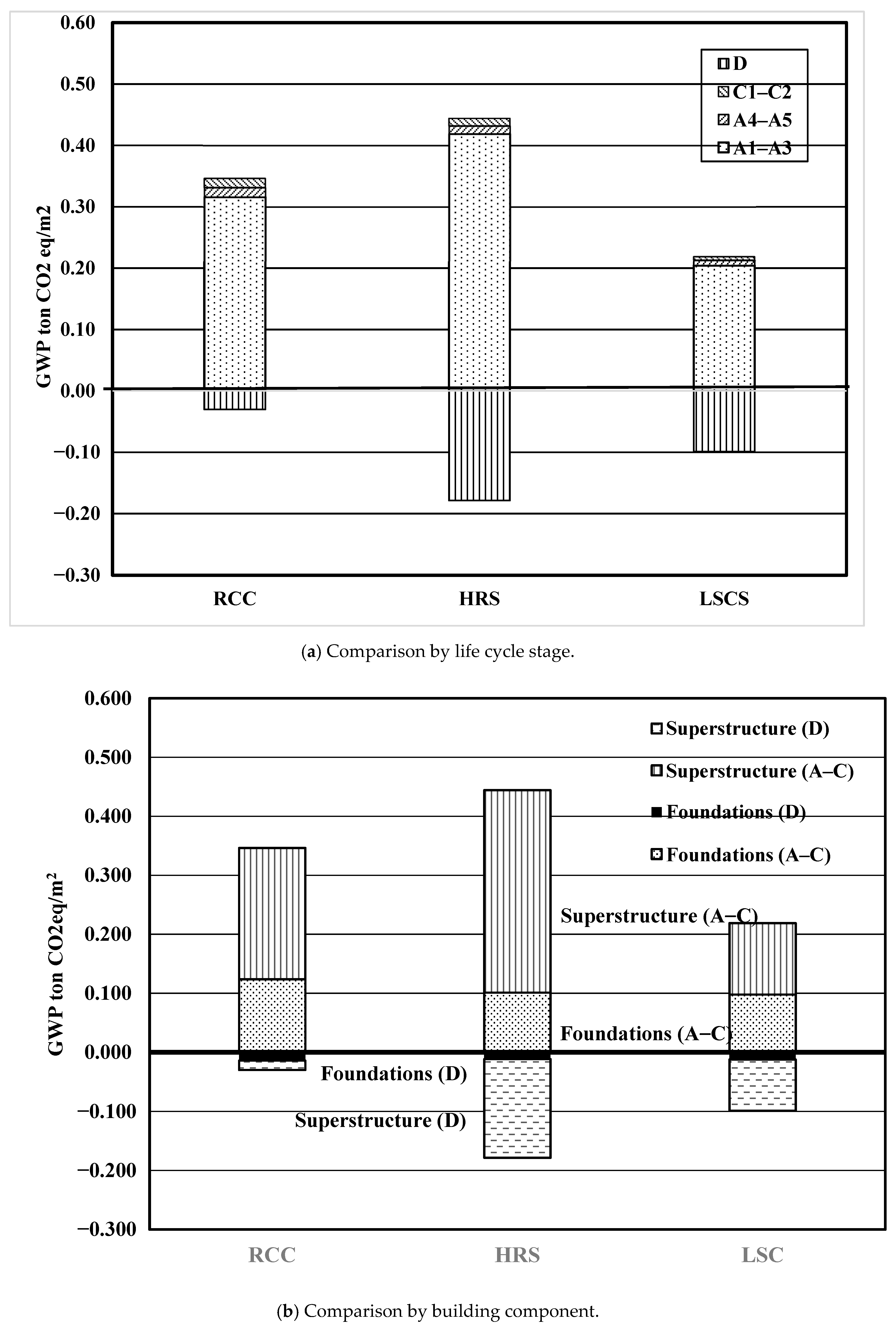

5.3. Life Cycle Impact Assessment

5.3.1. Life Cycle Embodied Energy

5.3.2. Life Cycle Embodied GHG Emissions

6. Discussion of Results

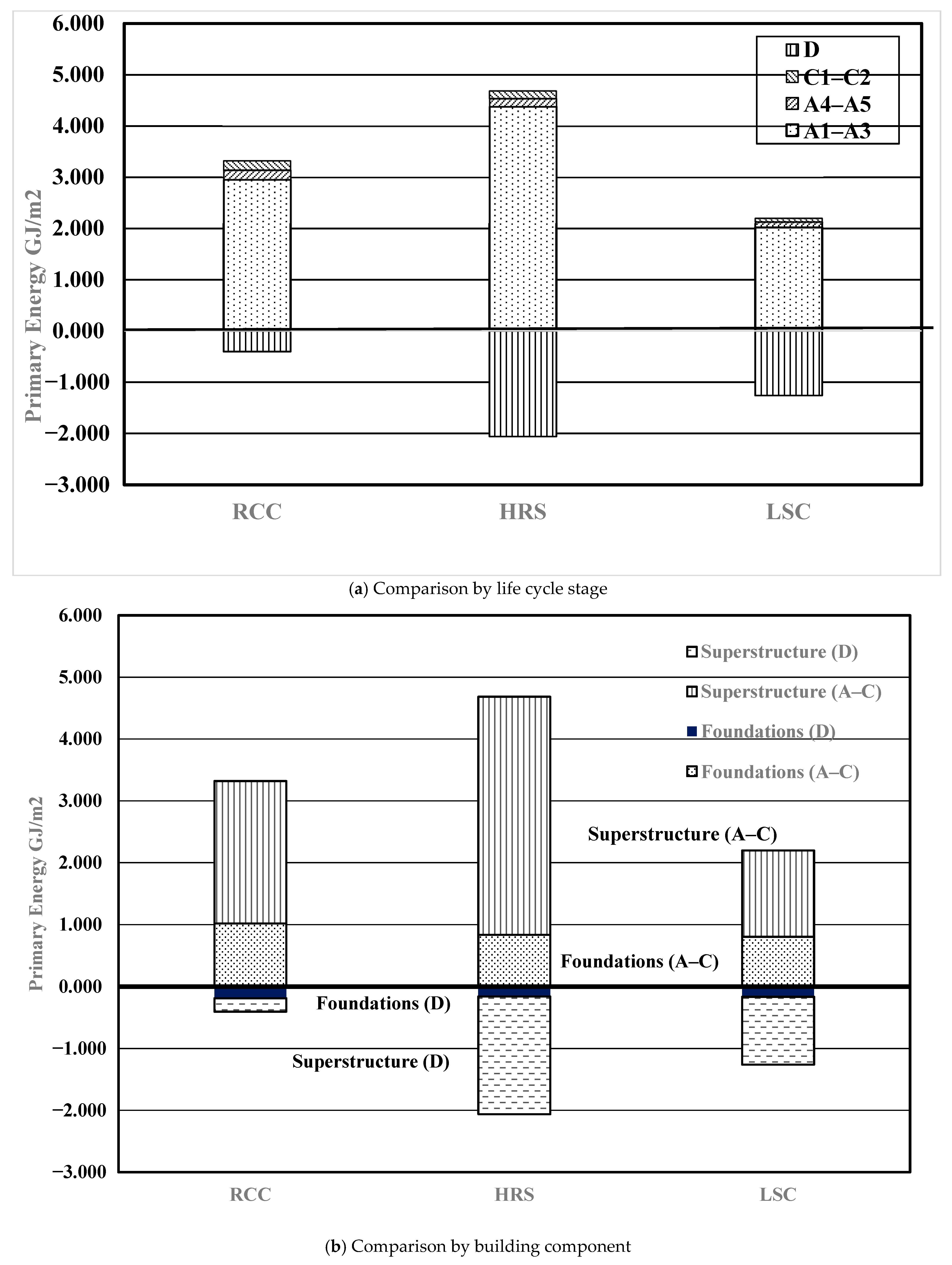

6.1. Life Cycle Embodied Energy

- (a)

- Comparison with benchmark results:The life cycle embodied energy (Modules A to C) is equal to 3.32 GJ/m2 for the RCC system, 4.684 for the HRS system, and 2.198 GJ/m2 for the LSC system. Typical benchmark results are 5–11.6 GJ/m2 reported by [41] based on analyzing 80 buildings all over the world and 9 GJ/m2 reported by Gervasio et al. [42] based on analyzing 76 buildings in Europe.

- (b)

- Comparison by construction system:Compared with the conventional RCC system, the HRS system has 41% more life cycle embodied energy, while the LSC system has 34% less life cycle embodied energy.

- (c)

- Embodied to operational energy:The operational energy over a 50-year design life of the same building was calculated using energy simulation as detailed in Abouhamad and Abu-Hamd [10]. The operational energy was found to be nearly the same for all three building systems at 31.60 GJ/m2. The ratio of embodied energy to operational energy is equal to 10.5% for the RCC system, 14.83% for the HRS system, and 6.96% for the LSC system. Typical benchmark results are 6–20% reported by Chastas et al. [21] based on an analysis of 90 residential buildings.

- (d)

- Added benefits from Module D:The added net benefits from Module D reach 12.2% for the RCC system, 44% for the HRS system, and 57.4% for the LSC system. When each system is credited with these net benefits, the LSC system has the least whole life cycle embodied energy followed by the HRS system and the RCC system. This is attributed to the light-weight design of LSC systems in addition to the benefits given to the system from Module D due to recycling of steel members and reuse of ferrocement wall boards. These results show that material recycling/reuse reduced the embodied energy by 12% for the RCC system, 44% for the HRS system, and 57% for LSC framing.

- (e)

- Comparison by life cycle stage:

- The material production stage (Modules A1 to A3) has the highest contribution to embodied energy as it represents 89% for the RCC system, 93.5% for the HRS system, and 92% for the LSC system.

- The contribution of the construction stage (Modules A4 and A5) is 5.5% for the RCC system, 3.3% for the HRS system, and 4.8% for the LSC system.

- The contribution of the end-of-life stage (Modules C1 and C2) is 5.5% for the RCC system, 3.2% for the HRS system, and 3.2% for the LSC system.

- The contribution of substructure (site work and foundations) to the life cycle embodied energy is 30.7% for the RCC system, 17.8% for the HRS system, and 36.6% for the LSC system.

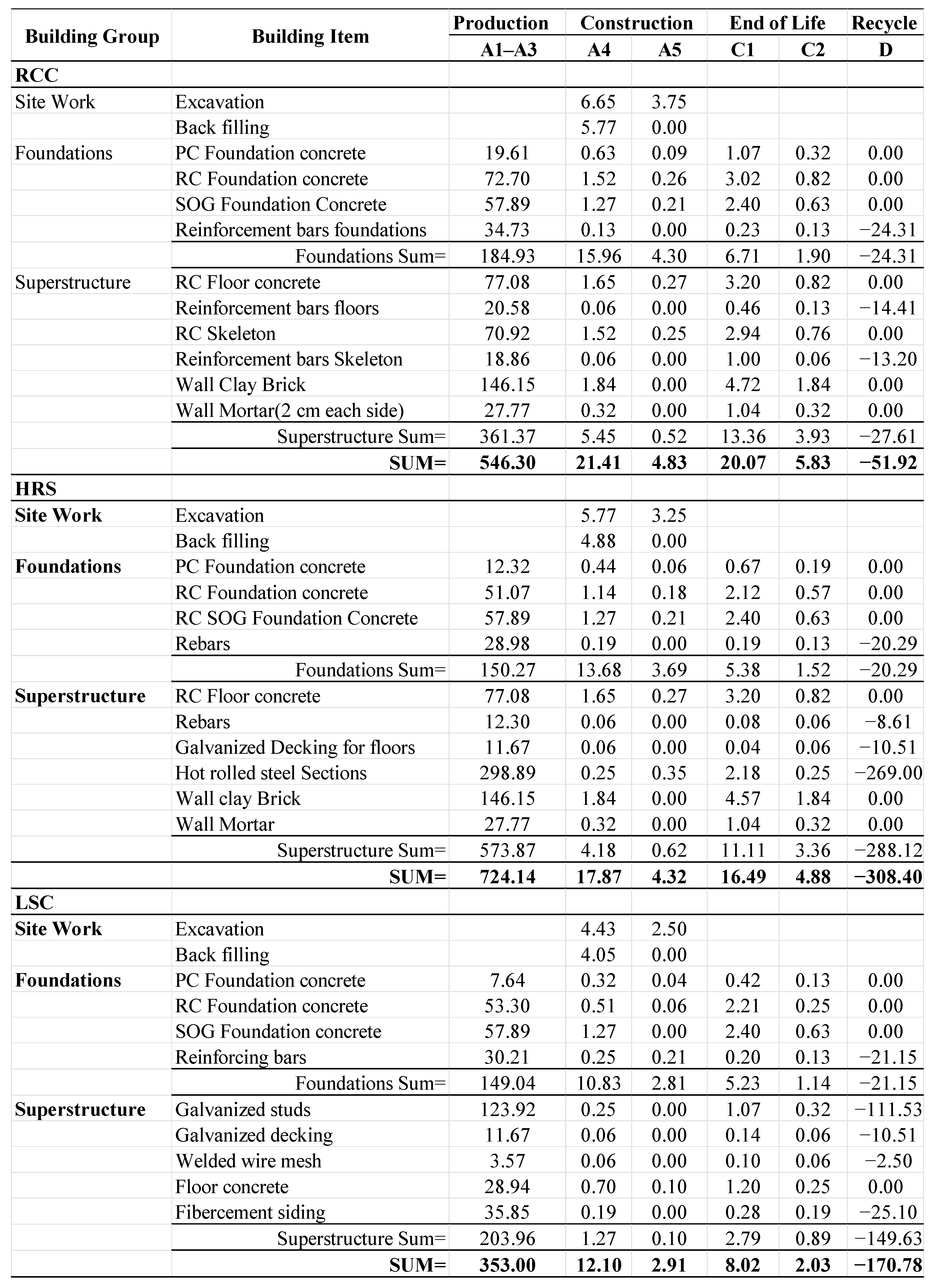

6.2. Life Cycle GHG Emissions

- (a)

- Comparison with available benchmark results:The life cycle GHG emissions (Modules A to C) expressed in ton CO2eq/m2 is equal to 0.346 for the RCC system, 0.444 for the HRS system, and 0.219 for the LSC system. Typical benchmark results are 0.867 t CO2eq/m2 for office buildings and 0.337 t CO2eq/m2 for residential buildings for a 50-year design life reported by Rock et al. [23] based on the analysis of more than 650 life cycle assessment case studies, 0.3–0.9 t CO2eq/m2 reported by the IEA [41] based on analyzing 80 buildings all over the world, and 0.85 t CO2eq/m2 reported by Gervasio et al. [42] based on analyzing 76 buildings in Europe.

- (b)

- Comparison by construction system:Compared with the conventional RCC system, the HRS system has 28% more life cycle GHG emissions, while the LSC system has 37% less life cycle GHG emissions.

- (c)

- Added benefits from Module D:The added net benefits from Module D are equal to 8.7% for the RCC system, 40.2% for the HRS system, and 45.2% for the LSC system. When each system is credited with these net benefits, the LSC system has the least whole life cycle GHG emissions followed by the HRS system and RCC system. This is attributed to the light-weight design of LSC systems in addition to the benefits given to the system from Module D due to the recycling of steel members and reuse of ferrocement wall boards. These results show that material recycling/reuse reduced the embodied GHG emissions by 9% for the RCC system, 49% for the HRS system, and 44% for the LSC system.

- (d)

- Comparison by life cycle stage:

- The material production stage (Modules A1 to A3) has the highest contribution to GHG emissions as it represents 91.3% for the RCC system, 94.3% for the HRS system, and 93.4% for the LSC system.

- The contribution of the construction stage (Modules A4 and A5) is 4.4% for the RCC system, 2.9% for the HRS system, and 4.0% for the LSC system.

- The contribution of the end-of-life stage (Modules C1 and C2) is 4.3% for the RCC system, 2.8% for the HRS system, and 2.65% for the LSC system.

- The contribution of substructure (site work and foundations) to the life cycle GHG emissions is 35.7% for the RCC system, 22.7% for the HRS system, and 44.7% for the LSC system.

6.3. Sustainability Assessment

6.3.1. LEED Credit Points from Reduction of Building Life Cycle Impact

6.3.2. LEED Credit Points from Construction and Demolition Waste Management

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- IPCC. Summary for policymakers. In Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways; Masson-Delmotte, P., Zhai, H.O., Pörtner, D., Roberts, J., Skea, P.R., Shukla, A., Pirani, W., Moufouma-Okia, C., Péan, R., Pidcock, S., Eds.; World Meteorological Organization: Geneva, Switzerland, 2018; p. 32. [Google Scholar]

- GABC Global Alliance for Buildings and Construction. International Energy Agency and the United Nations Environment Program: 2019 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; United Nations Environment Program: Nairobi, Kenya, 2019. [Google Scholar]

- EBC Evaluation of Embodied Energy and CO2eq for Building Construction (Annex 57), Energy in Buildings and Communities Program, International Energy Agency. 2016. Available online: http://www.iea-ebc.org/Data/publications/EBC_Annex_57_Results_Overview.pdf (accessed on 6 December 2020).

- CIF Climate Investment Funds: Egypt. 2020. Available online: https://www-cif.climateinvestmentfunds.org/country/egypt (accessed on 6 December 2020).

- CAIT Total GHG Emissions Including Land-Use and Forestry, MENA. World Resources Institute. CAIT Climate Data Explorer. 2018. Available online: http://cait.wri.org (accessed on 18 May 2020).

- United Nations. Report of the Conference of the Parties on its twenty-first session, held in Paris from 30 November to 13 December 2015. In United Nations Framework Convention on Climate Change; Available online: https://unfccc.int/resource/docs/2015/cop21/eng/10.pdf (accessed on 6 December 2020).

- European Commission. Roadmap to a Resource Efficient Europe; Communication from the Commission to the European Parliament, the Council, The European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- IPCC. Special Report Global Warming of 1.5 °C. In Intergovernmental Panel on Climate Change; Masson-Delmotte, V., Zhai, P., Portner, H.O., Eds.; The United Nations: Herndon, VA, USA, 2018. [Google Scholar]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://sustainabledevelopment.un.org/post2015/transformingourworld/publication (accessed on 18 April 2020).

- Abouhamad, M.; Abu-Hamd, M. Framework for construction system selection based on life cycle cost and sustainability assessment. J. Clean. Prod. 2019, 241, 118397. [Google Scholar] [CrossRef]

- Abouhamad, M.; Abu-Hamd, M. Life cycle cost analysis of light steel framed buildings with cement-based walls and floors. In Proceedings of the Canadian Society of Civil Engineers Annual Conference, Montreal, QC, Canada, 12–15 June 2019. paper CON-82. [Google Scholar]

- Abouhamad, M.; Abu-Hamd, M. Life cycle environmental assessment of light steel framed buildings with cement-based walls and floors. Sustainability 2020, 12, 10686. [Google Scholar] [CrossRef]

- EBC Assessing Life Cycle Related Environmental Impacts Caused by Buildings (Annex 72). Energy in Buildings and Communities Program, International Energy Agency. 2020. Available online: http://annex72.iea-ebc.org/ (accessed on 18 April 2020).

- ISO 14040: 2006. Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- ISO 14044: 2006. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- EN 15978:2011. Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method; European Standard: Brussels, Belgium, 2011. [Google Scholar]

- EN 15804:2014. Sustainability of Construction Works—Environmental Product Declarations—Core Rules for Product Category of Construction Products; European Standard: Brussels, Belgium, 2012. [Google Scholar]

- Zeng, R.; Chini, A. A review of research on embodied energy of buildings using bibliometric analysis. Energy Build. 2017, 155, 172–184. [Google Scholar] [CrossRef]

- Dixit, M.K. Life cycle embodied energy analysis of residential buildings: A review of literature to investigate embodied energy parameters. Renew. Sustain. Energy Rev. 2017, 79, 390–413. [Google Scholar] [CrossRef]

- de Wolf, C.; Pomponi, F.; Moncaster, A. Measuring embodied carbon dioxide equivalent of buildings: A review and critique of current industry practice. Energy Build. 2017, 140, 68–80. [Google Scholar] [CrossRef]

- Chastas, P.; Theodosiou, T.; Kontoleon, K.J.; Bikas, D. Normalizing and assessing carbon emissions in the building sector: A review on the embodied CO2 emissions of residential buildings. Build. Environ. 2018, 130, 212–226. [Google Scholar] [CrossRef]

- Fenner, A.E.; Kibert, C.J.; Woo, J.; Morque, S.; Razkenari, M.; Hakim, H.; Lu, X. The carbon footprint of buildings: A review of methodologies and applications. Renew. Sustain. Energy Rev. 2018, 94, 1142–1152. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings—The hidden challenge for effective climate change mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- Birgisdottir, H.; Moncaster, A.; Wiberg, A.H.; Chae, C.; Yokoyama, K.; Balouktsi, M.; Seo, S.; Oka, T.; Lützkendorf, T.; Malmqvist, T. IEA EBC annex 57 ‘evaluation of embodied energy and CO2eq for building construction’. Energy Build. 2017, 154, 72–80. [Google Scholar] [CrossRef]

- Simonen, K.; Rodriguez, B.; McDade, E.; Strain, L. Embodied carbon benchmark study: LCA for low carbon construction. 2017. Available online: http://hdl.handle.net/1773/38017 (accessed on 18 April 2020).

- Gervasio, H.; Dimova, S. Model for Life Cycle Assessment (LCA) of Buildings; EUR 29123 EN; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-79973-0. Available online: Publications.jrc.ec.europa.eu (accessed on 20 April 2020). [CrossRef]

- Rodrigues, V.; Martins, A.A.; Nunes, M.I.; Quintas, A.; Mata, T.M.; Caetano, N.S. LCA of constructing an industrial building: Focus on embodied carbon and energy. Energy Procedia 2018, 153, 420–425. [Google Scholar] [CrossRef]

- Nwodo, M.N.; Anumba, C.J. A review of life cycle assessment of buildings using a systematic approach. Build. Environ. 2019, 162, 106290. [Google Scholar] [CrossRef]

- EN 1990:2002. Eurocode—Basis of Structural Design; European Standard: Brussels, Belgium, 2002. [Google Scholar]

- Abu-Hamd, M.; Atef, D.; Masoud, M. Application of 4D and 5D BIM in cold formed steel residential buildings. In Proceedings of the 5th International Structural Specialty Conference, Canadian Society for Civil Engineering, London, ON, Canada, 8–11 June 2016. STR-862-1-10. [Google Scholar]

- Worldsteel Association. Life Cycle Assessment Methodology Report. 2011. Available online: https://www.worldsteel.org (accessed on 18 April 2020).

- ISO 14025:2006. Environmental Labels and Declarations—Type III Environmental Declarations—Principles and Procedures; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ED. The International EDP System. 2020. Available online: https://www.environdec.com/ (accessed on 18 April 2020).

- ERA. Electricity Production and Consumption Data. 2020. Available online: https://egyptera.org. (accessed on 18 April 2020).

- IPCC. IPCC Guidelines for National Greenhouse Gas Inventories. In Volume 2: Energy. Prepared by the National Greenhouse Gas Inventories Program; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2006. [Google Scholar]

- Dixit, M.K. Life cycle recurrent embodied energy calculation of buildings: A review. J. Clean. Prod. 2019, 209, 731–754. [Google Scholar] [CrossRef]

- SMI. Demolition Energy Analysis of Office Building Systems; Athena Sustainable Materials Institute: Ottawa, ON, Canada, 1997. [Google Scholar]

- EU Directive 2008/98/EC of the European Parliament. Available online: http://ec.europa.eu/environment/circular-economy/index_en.htm (accessed on 18 April 2020).

- U.S. Green Building Counci. LEED v4 for Building Design and Construction; US Green Building Council: Washington, DC, USA, 2019. [Google Scholar]

- STAAD PRO 3D Structural Analysis and Design Software, Bentley. Available online: www.bentley.com. (accessed on 18 April 2020).

- IEA (International Energy Agency). Evaluation of Embodied Energy and CO2 eq. for Building Construction (Annex 57)—Subtask 4: Case Studies and Recommendations for the Reduction of Embodied Energy and Embodied Greenhouse Gas Emissions from Buildings; Institute for Building Environment and Energy Conservation: Tokyo, Japan, 2016. [Google Scholar]

- Gervasio, H.; Dimova, S.; Pinto, A. Benchmarking the life-cycle environmental performance of buildings. Sustainability 2018, 10, 1454. [Google Scholar] [CrossRef]

| Building Material | Unit | Embodied Energy | Embodied GHG Emissions |

|---|---|---|---|

| MJ/Unit | kg CO2-eq | ||

| Concrete Class 20 MPa | m3 | 1755 | 255 |

| Concrete Class 30 MPa | m3 | 2070 | 335 |

| Cement Mortar | m3 | 2240 | 341 |

| Clay Brick | m3 | 4061 | 287 |

| Hot rolled steel sections | ton | 29,890 | 2710 |

| Galvanized studs | ton | 29,170 | 2280 |

| Galvanized decking | ton | 33,448 | 1689 |

| Reinforcing Steel | ton | 12,000 | 891 |

| Welded wire mesh | ton | 12,329 | 737 |

| Equipment | Productivity/Hour | Fuel Consumption | Embodied Energy | Embodied GHG Emissions |

|---|---|---|---|---|

| Liters/Hour | GJ/Hour | kg CO2eq/Hour | ||

| Excavator | 21 m3 | 15 | 0.574 | 47.514 |

| Wheel Loader | 200 m3 | 15 | 0.574 | 47.514 |

| Concrete Mix Truck 10 m3 | 40 m3 | 5 | 0.191 | 15.838 |

| Concrete Pump | 40 m3 | 5 | 0.191 | 15.838 |

| Concrete Vibrator | 40 m3 | 5 | 0.191 | 15.838 |

| Mobile Crane 20 t | 5 t | 5 | 0.191 | 15.838 |

| Building Element | Demolition/Dismantling | % Landfill | % Recycle | % Reuse |

|---|---|---|---|---|

| Concrete elements | Demolition | 100% | 0 | 0 |

| Steel reinforcement | Dismantling | 30% | 70% | 0 |

| Hot rolled steel members | Dismantling | 10% | 90% | 0 |

| Cold formed steel members | Dismantling | 10% | 90% | 0 |

| Brick wall | Demolition | 100% | 0 | 0 |

| Fiber cement wall boards | Dismantling | 30% | 0 | 70% |

| Building Material | UOM | RCC | HRS | LSC |

|---|---|---|---|---|

| Foundation | ||||

| PC foundation concrete | m3 | 76.904 | 48.328 | 29.956 |

| RC foundation concrete | m3 | 217.02 | 152.46 | 159.1 |

| RC slab on grade concrete | m3 | 172.8 | 172.8 | 172.8 |

| Rebar foundation | ton | 38.982 | 32.526 | 33.91 |

| Superstructure | ||||

| RC floor concrete | m3 | 230.1 | 230.1 | 86.4 |

| Rebars floor | ton | 23.1 | 13.806 | --- |

| RC skeleton | m3 | 211.7 | --- | --- |

| Re bars skeleton | ton | 21.17 | --- | --- |

| Welded wire mesh | ton | --- | --- | 4.838 |

| Galvanized decking | ton | --- | 6.912 | 6.912 |

| Hot rolled steel sections | ton | --- | 110.291 | --- |

| Galvanized studs | ton | --- | --- | 54.352 |

| Wall clay brick | m3 | 509.25 | 509.25 | --- |

| Wall mortar | m3 | 81.48 | 81.48 | --- |

| Fibercement siding | m2 | --- | --- | 4074 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abouhamad, M.; Abu-Hamd, M. Life Cycle Assessment Framework for Embodied Environmental Impacts of Building Construction Systems. Sustainability 2021, 13, 461. https://doi.org/10.3390/su13020461

Abouhamad M, Abu-Hamd M. Life Cycle Assessment Framework for Embodied Environmental Impacts of Building Construction Systems. Sustainability. 2021; 13(2):461. https://doi.org/10.3390/su13020461

Chicago/Turabian StyleAbouhamad, Mona, and Metwally Abu-Hamd. 2021. "Life Cycle Assessment Framework for Embodied Environmental Impacts of Building Construction Systems" Sustainability 13, no. 2: 461. https://doi.org/10.3390/su13020461

APA StyleAbouhamad, M., & Abu-Hamd, M. (2021). Life Cycle Assessment Framework for Embodied Environmental Impacts of Building Construction Systems. Sustainability, 13(2), 461. https://doi.org/10.3390/su13020461