Life Cycle Environmental Assessment of Light Steel Framed Buildings with Cement-Based Walls and Floors

Abstract

1. Introduction

- Base line LCA, when LCA is used to assess an individual product or project with the goal of identifying areas of potential improvement in their environmental performance,

- Comparative LCA, when LCA is used to compare environmental impacts of several alternatives that perform the same function in order to select the alternative with the lowest environmental impact.

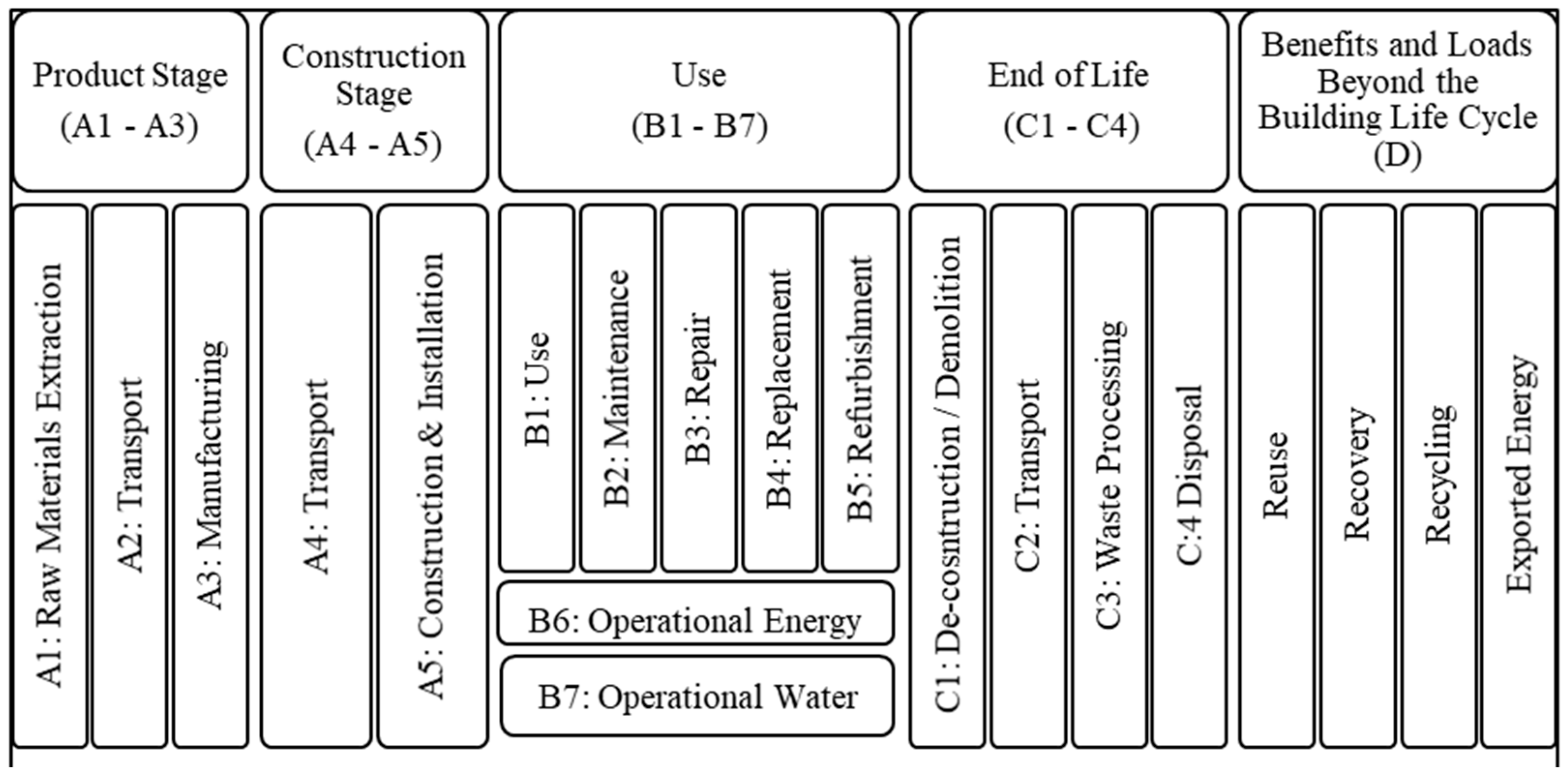

2. LCA Methodology

- Product stage (Modules A1 to A3): includes the production of building materials from raw material supply until the gate of the factory.

- Construction stage (Modules A4 and A5): includes transportation of building materials to the construction site and the construction process.

- Use stage (Modules B1 to B7): includes all data related to use, repair, replacement, refurbishment, and operation use of energy and water.

- End-of-life stage (Modules C1 to C4): includes data related to the building demolition/dismantling.

- An additional module D which allocates the net benefits due to possible reuse or recycling of materials beyond building life cycle (BBL).

2.1. Goal and Scope

2.2. Life Cycle Inventory (LCI)

- In the production and construction phases, this involves raw material extraction, processing, manufacturing, and transportation to the site and building construction.

- In the use phase, it involves the operating energy consumption associated with the building use, repair, and maintenance. The design life is usually assumed in the range of 40 to 60 years [35]. The present study is based on a design life of 50 years as suggested by the European design code EN 1990 [36].

- In the end-of-life phase, it involves building demolition, recycling, and possible re-use. Different building components have different end of life scenarios according to their reuse/recycle potentials. These scenarios vary from complete demolition to reuse/resale of part or all the building.

- Develop 3D structural models for the building.

- Utilize the structural analysis/design tool linked to the BIM software to perform the structural design considering the appropriate geometric, loading, material, and design code requirements.

- Utilize the BIM 5D tool link to calculate the required material quantities.

2.3. Life Cycle Assessment

- (a)

- Selection of impact categories: EN 15,978 recommends 25 indicators for LCA. Due to the complex nature of the many elements within the built environment, the impacts occurring throughout a building’s life cycle cover a broad range of potential impact categories. Most of these are attributable to the manufacture and eventual disposal of materials, but also relate to the resources consumed during operation (such as energy and water. This complexity is one reason why building LCAs are often simplified by using a more streamlined LCA approach [8]. A streamlined LCA that chooses to assess only one environmental parameter may involve the consideration of only one or two different impact categories. Due to their relative importance, the most common indicators used in practice are the global warming potential (GWP) measured in weight of the equivalent emission of CO2 and the amount of primary energy (PE) consumption.

- (b)

- Assignment of LCI results (classification): which involves assigning the emissions, wastes and resources used to the chosen impact categories.

- (c)

- Modeling category indicators (characterization).

2.4. Sensitivity Analysis

3. Application

3.1. Building Description

- CFS system has a much shorter erection time due to off-site construction so that it shall has the least effect on the on-going activities on the university campus

- Cold formed steel wall panels acting as bearing walls. Each panel is composed of CFS C-channel with dimensions 140 × 70 × 20 × 1.6 and spaced at 600 mm center to center. The panels are covered with 12 mm ferrocement boards mm from both sides.

- Cold formed steel floor panels acting as floor beams. Each panel is composed of CFS C-joists with dimensions 250 × 70 × 200 × 3 mm and spaced at 600 mm center to center.

- Flooring slab composed of 50 mm light reinforced concrete slab cast on metal deck.

- Reinforced concrete strip footing foundations under all bearing walls.

3.2. Bill of Material

3.3. LCA Using Athena Impact Estimator

- Resource extraction (correspond to stages A1 and A2 in EN15978).

- Product manufacturing (correspond to stage A3 in EN15978).

- Construction of the building (correspond to stages A4 and A5 in EN15978). This stage covers the environmental impacts associated with:

- (i)

- Transportation of building material to construction site. The environmental impacts depend on the transportation trucks and the transportation distances.

- (ii)

- Construction Processes. Environmental impacts occur at site from the use of different construction equipment.

- Building occupancy and maintenance (correspond to stages B1 to B6 in EN15978). Environmental data related to stages B1 to B5 should be based on the expected maintenance and repair scenarios considering the assumed design life of each building. Building materials related to the structural components of the building do not usually need to be repaired or replaced over the design life of the building. On the other hand, environmental impacts related to stage B6 are calculated using an energy analysis software.

- Building demolition/deconstruction/materials at end-of-life disposition (disposal or transfer for recycling or reuse) (corresponds to stages C1 to C4 in EN15978). Detailed information on these processes do not usually exist at the design stage. Building elements have several end-of-life treatments depending on the possibilities of recycling or reuse of the building material and the construction system used. Steel members in CFS construction systems have very high potential for reuse/recycle while as other members made of concrete are mostly landfilled. Average estimates of environmental impacts related to this stage are used by The Athena software based on the analysis of demolition data of similar buildings.

- Beyond Building life impacts related to possible material recycling or reuse (correspond to Module D in EN 15978). Recycled steel is mostly reused in steel making plants to produce new steel.

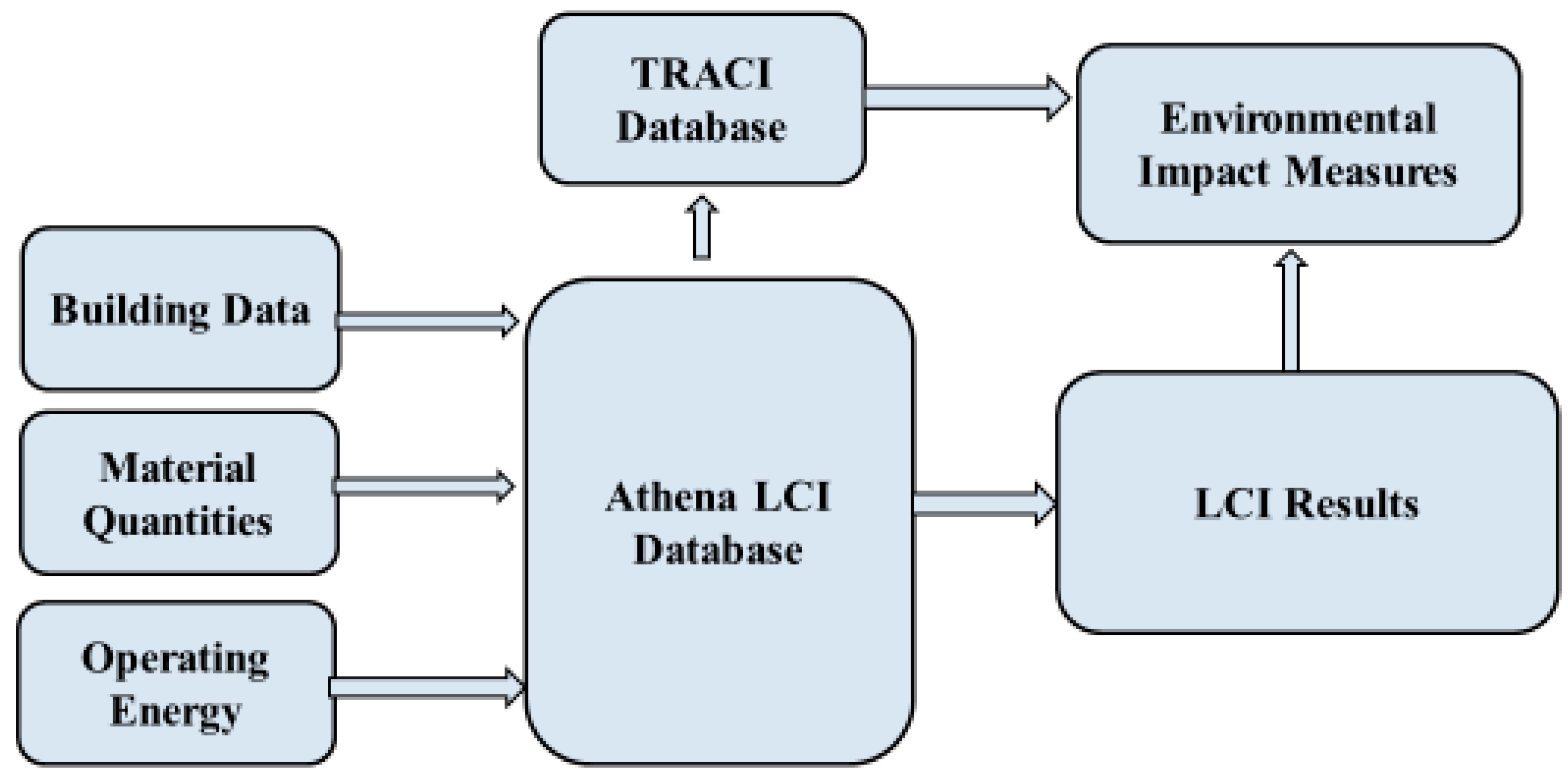

- Scenario databases to quantify all life cycle material and energy use.

- The Athena LCI Database to calculate a life cycle inventory.

- The TRACI methodology to perform life cycle impact assessment.

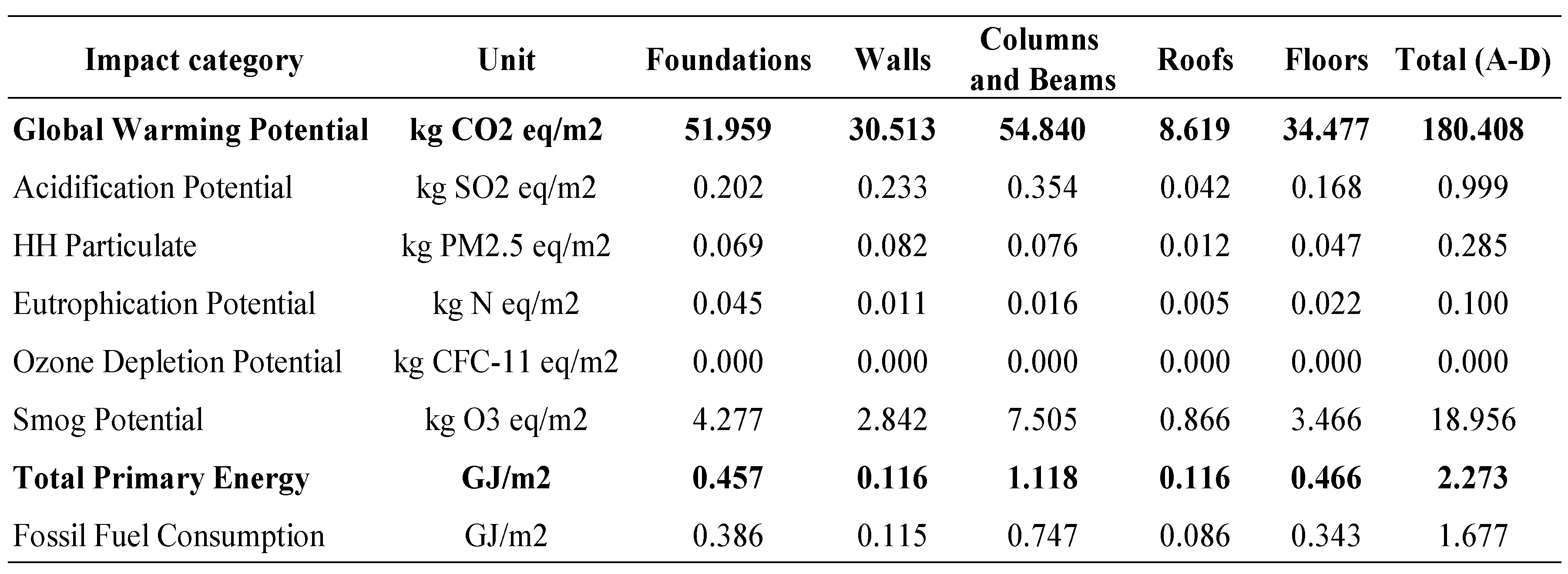

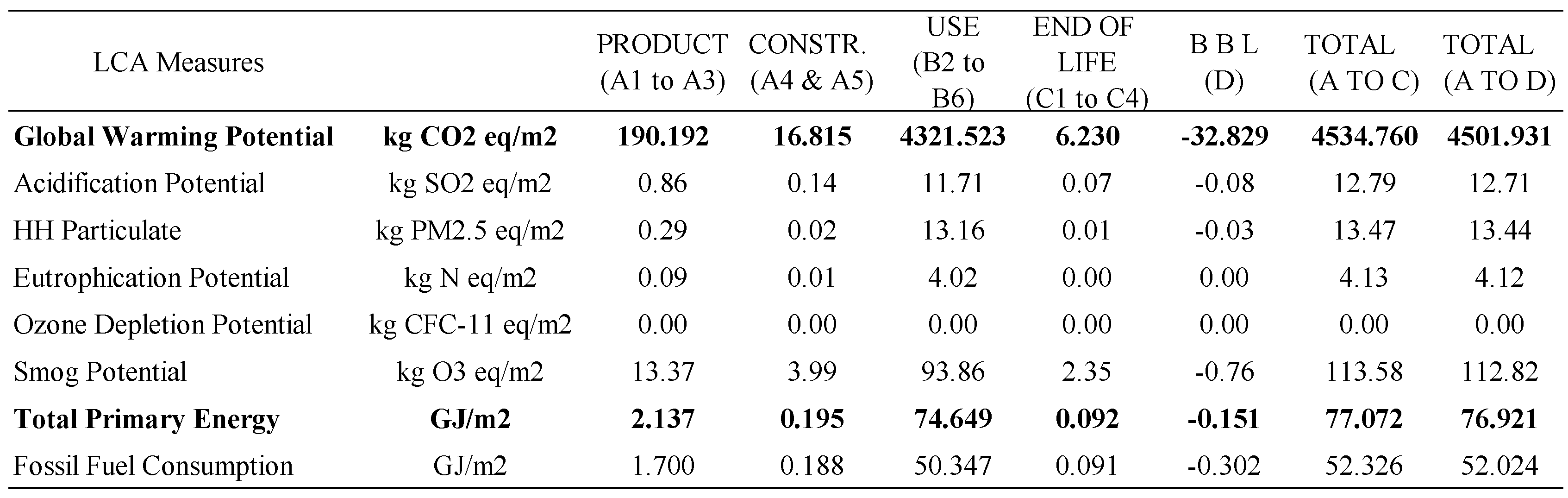

4. LCA Results

5. Discussion of Results

5.1. Embodied Versus Operational Environmental Impacts

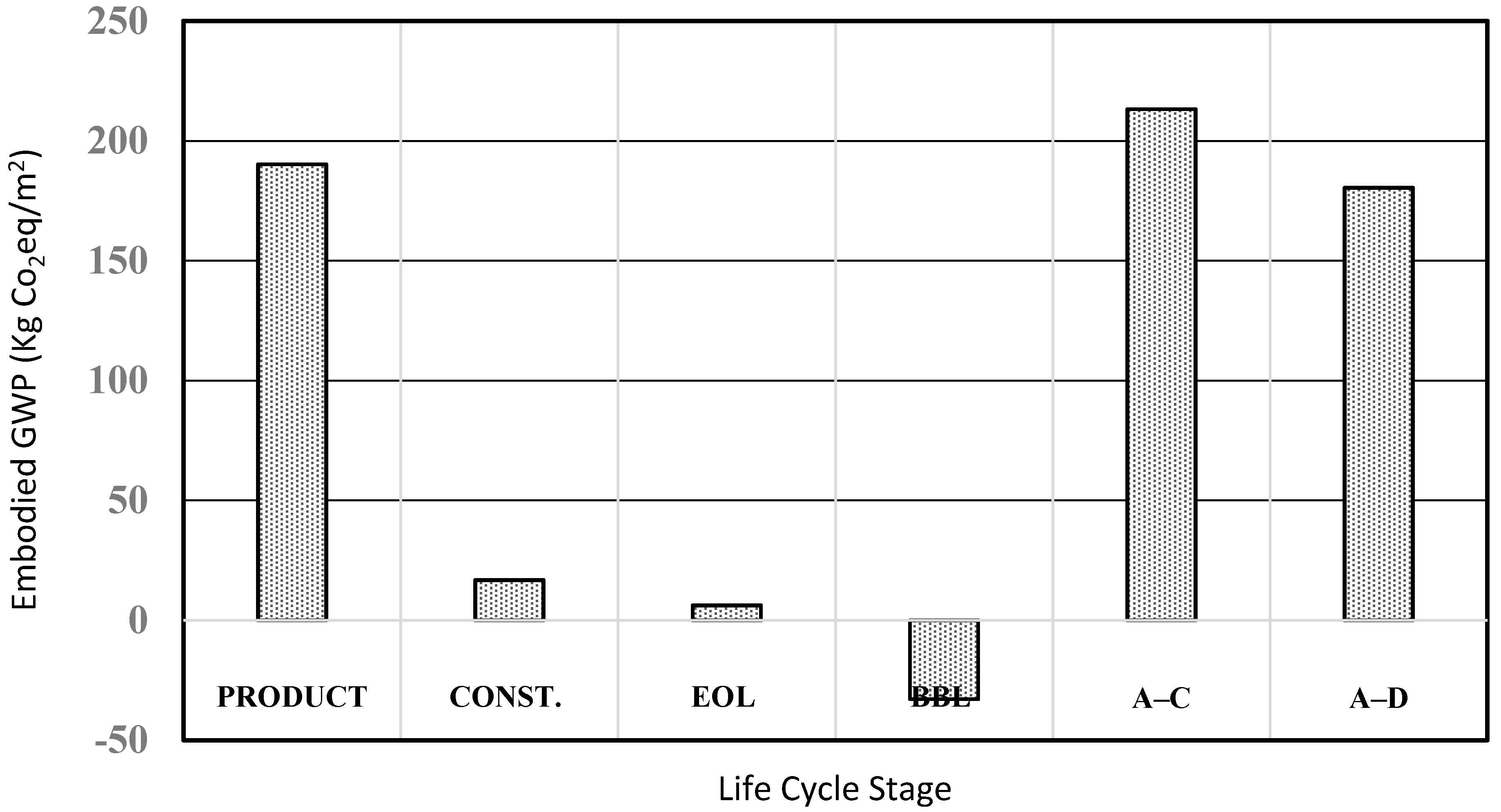

5.2. Life cycle Global Warming Potential

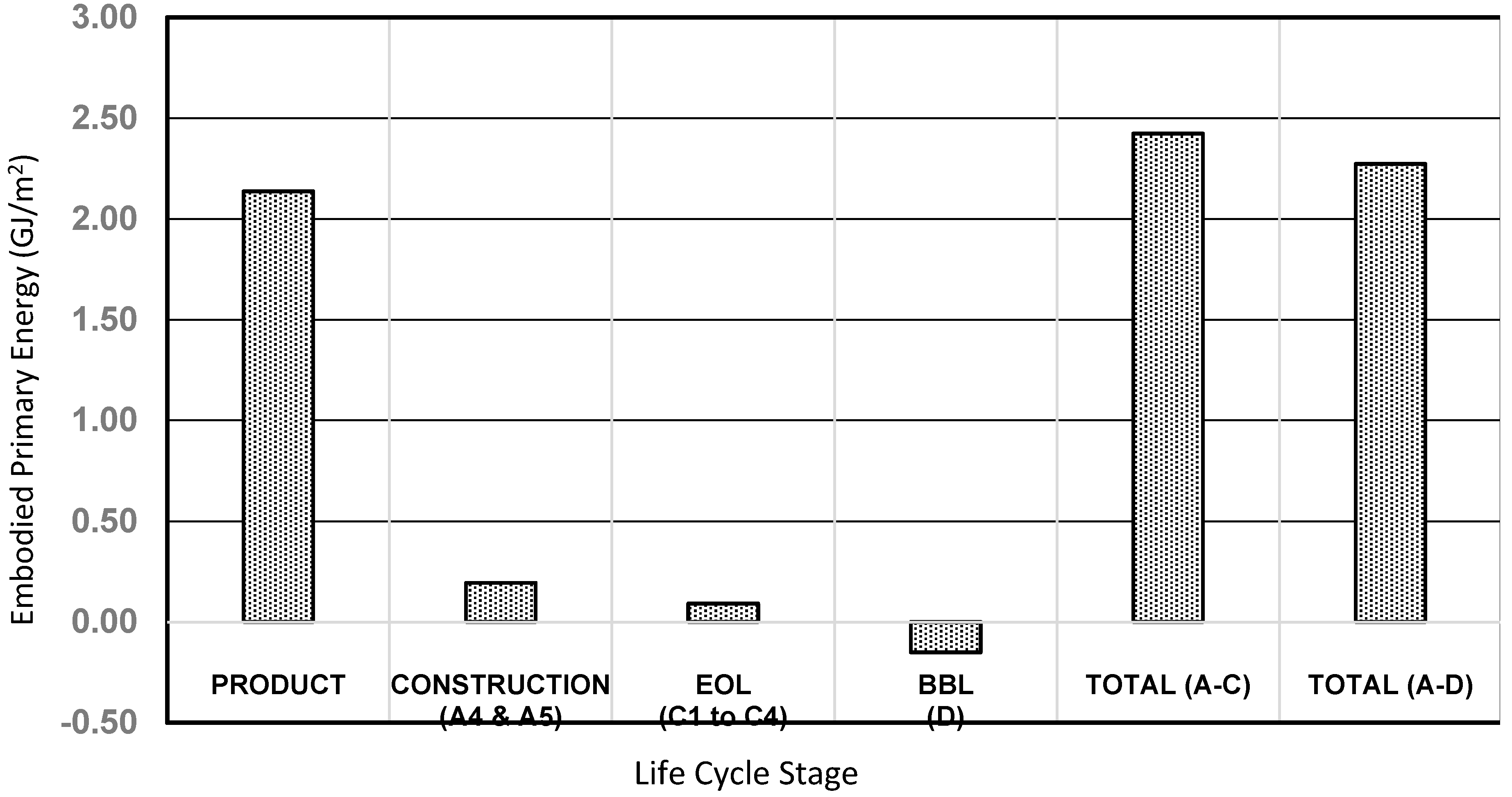

5.3. Life Cycle Primary Energy

6. Conclusions

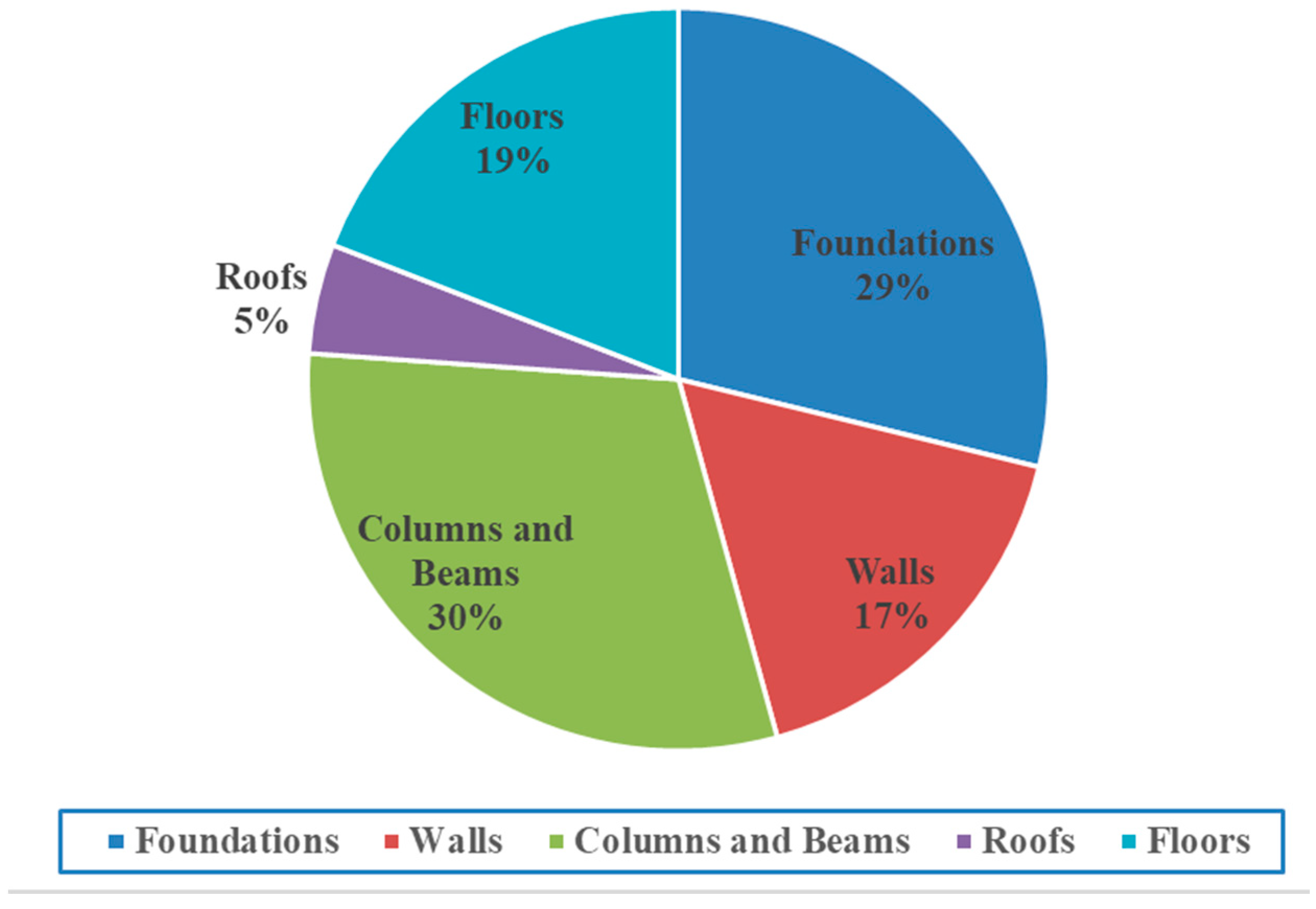

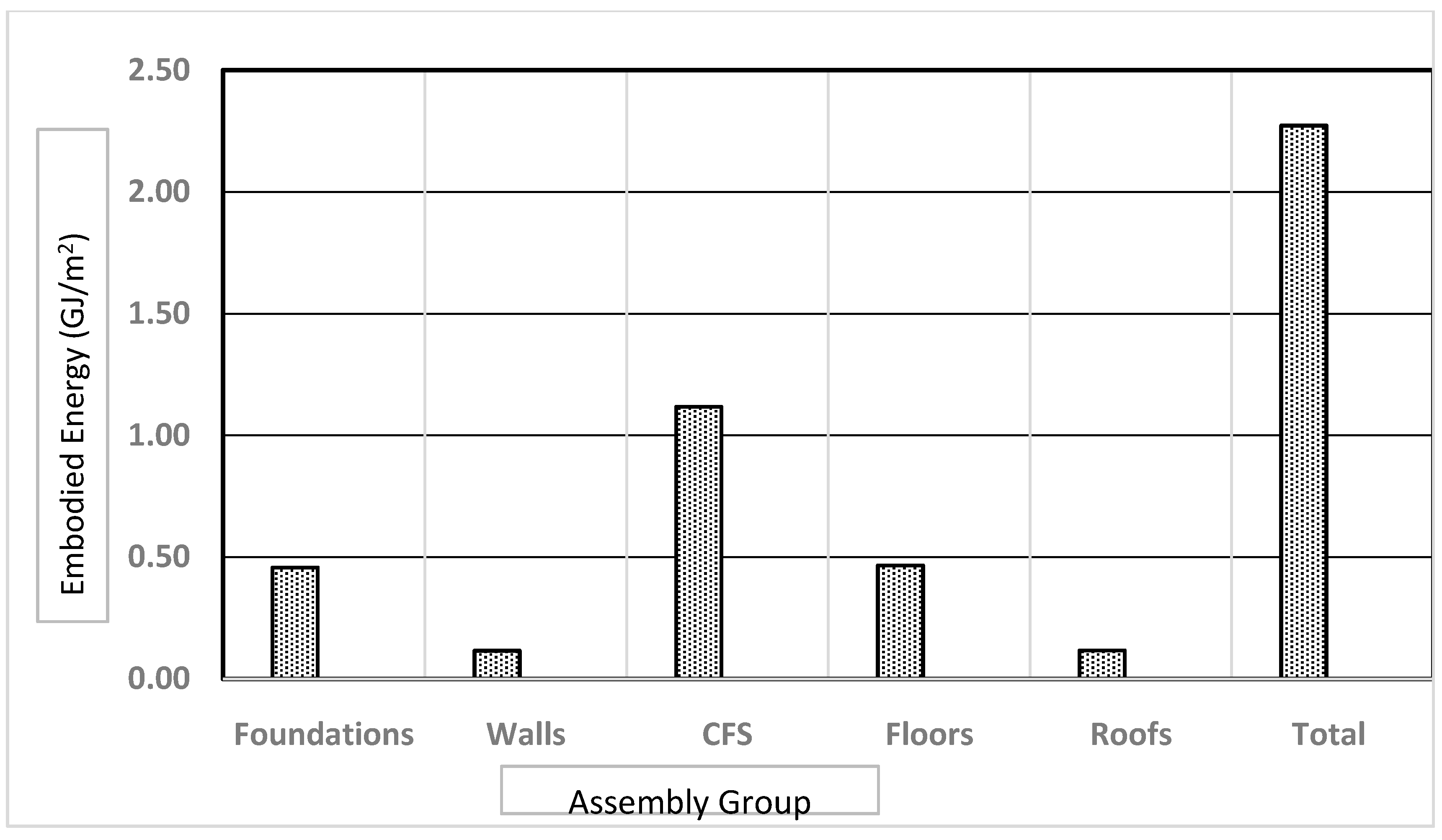

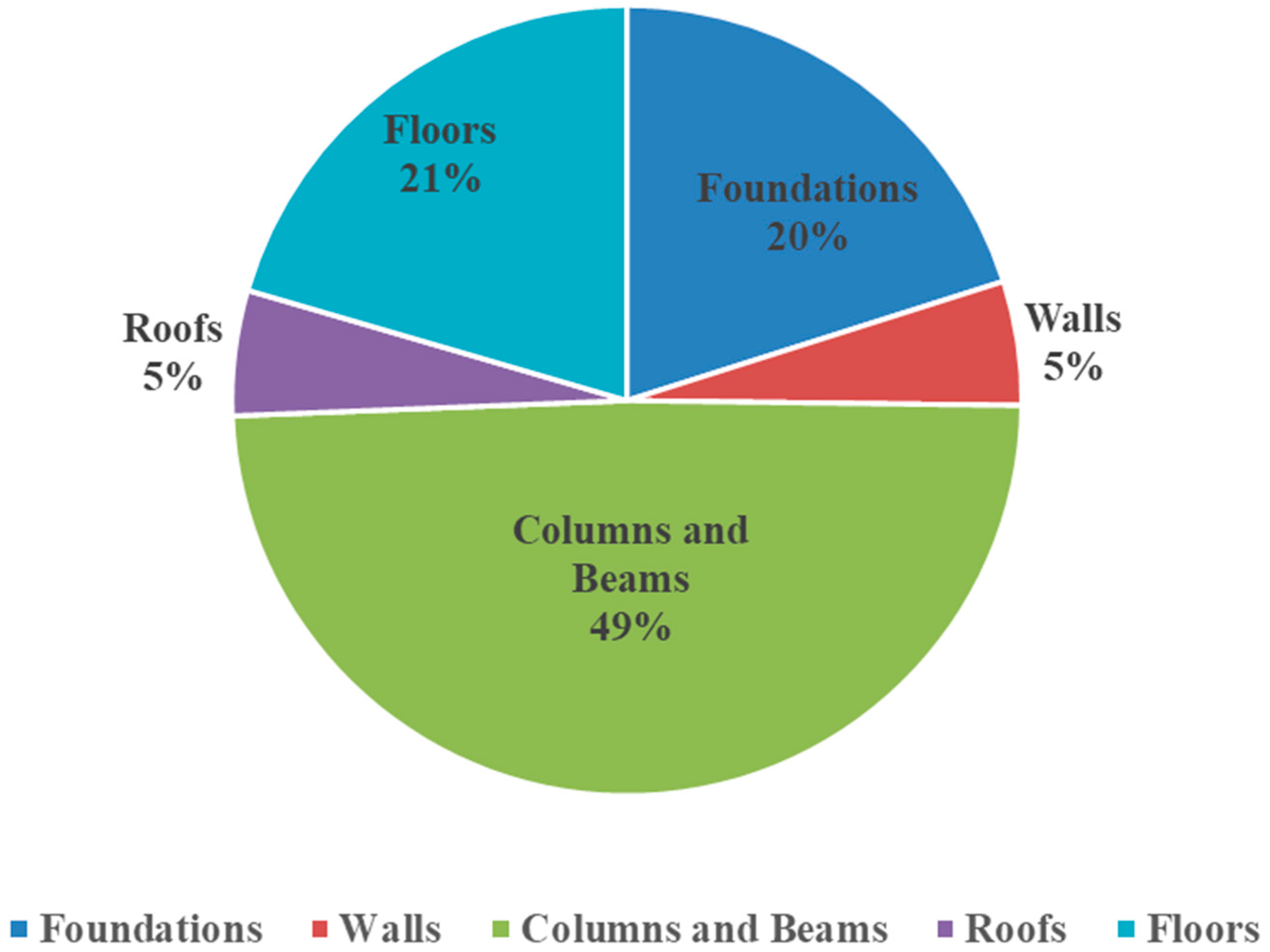

- The building foundations are responsible for 29% of the embodied GWP and 20% of the embodied energy while the CFS skeleton is responsible for 30% of the embodied GWP and 49% of the embodied energy.

- The material production stage is responsible for 90% of the embodied GWP and embodied energy. When benefits associated with recycling/reuse are included in the analysis according to Module D of EN 15978, GWP is reduced by 15.4% while the embodied primary energy is reduced by 6.22%.

- CFS framing systems have much lower embodied energy and global warming potential than conventional construction systems.

Author Contributions

Funding

Conflicts of Interest

References

- IPCC. Summary for Policymakers. In Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways; Masson-Delmotte, P., Zhai, H.O., Pörtner, D., Roberts, J., Skea, P.R., Shukla, A., Pirani, W., Moufouma-Okia, C., Péan, R., Pidcock, S., Eds.; World Meteorological Organization: Geneva, Switzerland, 2018; 32p. [Google Scholar]

- GABC Global Alliance for Buildings and Construction. International Energy Agency and the United Nations Environment Program: 2019 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; United Nations Environment Program: Nairobi, Kenya, 2019. [Google Scholar]

- EBC Evaluation of Embodied Energy and CO2eq for Building Construction (Annex 57), Energy in Buildings and Communities Program, International Energy Agency. 2016. Available online: http://www.iea-ebc.org/Data/publications/EBC_Annex_57_Results_Overview.pdf (accessed on 6 December 2020.).

- CIF Climate Investment Funds: Egypt. 2020. Available online: https://www-cif.climateinvestmentfunds.org/country/egypt. (accessed on 6 December 2020).

- CAIT Total GHG Emissions Including Land-Use and Forestry, MENA. World Resources Institute. CAIT Climate Data Explorer. 2018. Available online: http://cait.wri.org (accessed on 18 May 2020).

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. Available online: https://sustainabledevelopment.un.org/post2015/transformingourworld/publication (accessed on 6 December 2020).

- European Comission. Roadmap to a Resource Efficient Europe; Communication from the Commission to the European Parliament, the Council, The European Economic and Social Committee and the Committee of the Regions; European Comission: Brussels, Belgium, 2011. [Google Scholar]

- Crawford, R. Life Cycle Assessment in the Built Environment; Spon Press: London, UK, 2011. [Google Scholar]

- Langer, S.; Bekö, G.; Bloom, E.; Widheden, A.; Ekberg, L. Indoor air quality in passive and conventional new houses in Sweden. Build. Environ. 2015, 93, 92–100. [Google Scholar] [CrossRef]

- Nguyen, B.K.; Altan, H. Tall-Building Projects Sustainability Indicator (TPSI): A New Design and Environmental Assessment Tool for Tall Buildings. Buildings 2012, 2, 43–62. [Google Scholar] [CrossRef]

- AbouHamad, M.; Abu-Hamd, M. Framework for construction system selection based on life cycle cost and sustainability assessment. J. Clean. Prod. 2019, 241, 118397. [Google Scholar] [CrossRef]

- Abouhamd, M.; Abu-Hamd, M. Life Cycle Cost Analysis of Light Steel Framed Buildings with Cement-Base Walls and Floors. In Proceedings of the Canadian Society of Civil Engineers Annual Conference, Montreal, Canada, 12–15 June 2019. paper CON-82. [Google Scholar]

- AISI S100. North American Standard for the Design of Cold-Formed Steel Members; American Iron and Steel Institute: Washington, DC, USA, 2016. [Google Scholar]

- EN 1993.2005. Eurocode-Design of Steel Structures; European Standard: Brussels, Belgium, 2005. [Google Scholar]

- CERM-EX Cold-Formed Steel Structures. Available online: https://www.cerm-ex.com/cold-formed-steel-services (accessed on 9 December 2020).

- ISO 14040: 2006. Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- ISO 14044: 2006. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- Basbagill, J.; Flager, F.; Lepech, M.; Fischer, M. Application of life-cycle assessment to early stage building design for reduced embodied environmental impacts. Build. Environ. 2013, 60, 81–92. [Google Scholar] [CrossRef]

- Anand, C.K.; Amor, B. Recent developments, future challenges, and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Chau, C.; Leung, T.M.; Ng, N. A review on life cycle assessment, life cycle energy assessment and life cycle carbon emissions assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Geng, S.; Wang, Y.; Zuo, J.; Zhou, Z.; Du, H.; Mao, G. Building life cycle assessment research: A review by bibliometric analysis. Renew. Sustain. Energy Rev. 2017, 76, 176–184. [Google Scholar] [CrossRef]

- Nwodo, M.; Anumbab, C. A review of life cycle assessment of buildings using a systematic approach. Build. Environ. 2019, 162, 106290. [Google Scholar] [CrossRef]

- Zeng, R.; Chini, A. A review of research on embodied energy of buildings using bibliometric analysis. Energy Build. 2017, 155, 172–184. [Google Scholar] [CrossRef]

- Dixit, M.K. Life cycle embodied energy analysis of residential buildings: A review of literature to investigate embodied energy parameters. Renew. Sustain. Energy Rev. 2017, 79, 390–413. [Google Scholar] [CrossRef]

- De Wolf, C.; Pomponi, F.; Moncaster, A. Measuring embodied carbon dioxide equivalent of buildings: A review and critique of current industry practice. Energy Build. 2017, 140, 68–80. [Google Scholar] [CrossRef]

- Chastas, P.; Theodosiou, T.; Kontoleon, K.J.; Bikas, D. Normalizing and assessing carbon emissions in the building sector: A review on the embodied CO2 emissions of residential buildings. Build. Environ. 2018, 130, 212–226. [Google Scholar] [CrossRef]

- Fenner, A.E.; Kibert, C.J.; Woo, J.; Morque, S.; Razkenari, M.; Hakim, H.; Lu, X. The carbon footprint of buildings: A review of methodologies and applications. Renew. Sustain. Energy Rev. 2018, 94, 1142–1152. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings—The hidden challenge for effective climate change mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- Birgisdottir, H.; Moncaster, A.; Wiberg, A.H.; Chae, C.; Yokoyama, K.; Balouktsi, M.; Seo, S.; Oka, T.; Lützkendorf, T.; Malmqvist, T. IEA EBC annex 57 ‘evaluation of embodied energy and CO2eq for building construction’. Energy Build. 2017, 154, 72–80. [Google Scholar] [CrossRef]

- Simonen, K.; Rodriguez, B.; McDade, E.; Strain, L. Embodied Carbon Benchmark Study: LCA for Low Carbon Construction. Available online: http://hdl.handle.net/1773/38017 (accessed on 18 April 2020).

- Gervasio, H.; Dimova, S. Model for Life Cycle Assessment (LCA) of Buildings; EUR 29123 EN; Publications Office of the European Union: Luxembourg, Luxembourg, 2018; ISBN 978-92-79-79973-0. Available online: https://publications.jrc.ec.europa.eu/repository/bitstream/JRC110082/report_d1_online_final.pdf (accessed on 20 December 2020). [CrossRef]

- Rodrigues, V.; Martins, A.A.; Nunes, M.I.; Quintas, A.; Mata, T.M.; Caetano, N.S. LCA of constructing an industrial building: Focus on embodied carbon and energy. Energy Procedia 2018, 153, 420–425. [Google Scholar] [CrossRef]

- EN 15978:2011. Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method; European Standard: Brussels, Belgium, 2011. [Google Scholar]

- EN, 2012. EN 15804:2012. Sustainability of Construction Works—Environmental Product Declarations—Core Rules for Product Category of Construction Products; European Standard: Brussels, Belgium, 2012. [Google Scholar]

- Dixit, M.K. Life cycle recurrent embodied energy calculation of buildings: A review. J. Clean. Prod. 2019, 209, 731–754. [Google Scholar] [CrossRef]

- EN 1990:2002. Eurocode—Basis of Structural Design; European Standard: Brussels, Belgium, 2002. [Google Scholar]

- Abu-Hamd, M.; Atef, D.; Masoud, M. Application of 4D and 5D BIM in Cold Formed Steel Residential Buildings. In Proceedings of the 5th International Structural Specialty Conference, Canadian Society for Civil Engineering, London, ON, Canada, 8–11 June 2016. STR-862-1-10. [Google Scholar]

- eQUEST, 2019, Energy Design Resources. Available online: http://www.doe2.com (accessed on 6 December 2020).

- Ecoinvent. The Swiss Center for Life Cycle Inventory. Available online: https://www.ecoinvent.org (accessed on 6 December 2020).

- Hammond, G.P.; Jones, C.I. Embodied Carbon: The inventory of Carbon and Energy (ICE). In A BSRIA Guide—BG 10/2011; Lowrie, F., Tse, P., Eds.; BSRIA Ltd.: Bracknell, UK, 2011. [Google Scholar]

- TRACI. Tool for the Reduction and Assessment of Chemicals and other Environmental Impacts; US EPA: Washington, DC, USA, 2012. [Google Scholar]

- PRé Consultants. SimaPro|The World’s Leading LCA Software. Available online: https://simapro.com/ (accessed on 6 December 2020).

- Athena Sustainable Materials Institute. Athena Impact Estimator for Buildings. Available online: http://www.athenasmi.org/ (accessed on 6 December 2020).

- Eaton, K.; Amato, A. A comparative life cycle assessment of steel and concrete framed office buildings. J. Constr. Steel Res. 1998, 46, 1–3. [Google Scholar] [CrossRef]

- IEA International Energy Agency. Evaluation of Embodied Energy and CO2 eq. for Building Construction (Annex 57)—Subtask 4: Case Studies and Recommendations for the Reduction of Embodied Energy and Embodied Greenhouse Gas Emissions from Buildings; Institute for Building Environment and Energy Conservation: Tokyo, Japan, 2016. [Google Scholar]

| Material Name | Quantity | UOM |

|---|---|---|

| Plain Concrete Foundation | 30 | m3 |

| Reinforced Concrete Foundation | 66.24 | m3 |

| Slab on Grade Concrete | 38.4 | m3 |

| Reinforcing bars | 10.464 | tons |

| Galvanized studs | 46.08 | tons |

| Galvanized decking | 11.52 | tons |

| Welded wire mesh | 3.84 | tons |

| Floor concrete | 51.2 | m3 |

| Galvanized decking | 2.88 | tons |

| Welded wire mesh | 0.96 | tons |

| Roof concrete | 12.8 | m3 |

| Fibercement siding | 5700 | m2 |

| Global Warming Potential | Primary Energy | |

|---|---|---|

| kg CO2 eq/m2 | GJ/m2 | |

| Embodied | 180.41 | 2.27 |

| Operational | 4321.5 | 74.65 |

| Total | 4501.91 | 76.92 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abouhamad, M.; Abu-Hamd, M. Life Cycle Environmental Assessment of Light Steel Framed Buildings with Cement-Based Walls and Floors. Sustainability 2020, 12, 10686. https://doi.org/10.3390/su122410686

Abouhamad M, Abu-Hamd M. Life Cycle Environmental Assessment of Light Steel Framed Buildings with Cement-Based Walls and Floors. Sustainability. 2020; 12(24):10686. https://doi.org/10.3390/su122410686

Chicago/Turabian StyleAbouhamad, Mona, and Metwally Abu-Hamd. 2020. "Life Cycle Environmental Assessment of Light Steel Framed Buildings with Cement-Based Walls and Floors" Sustainability 12, no. 24: 10686. https://doi.org/10.3390/su122410686

APA StyleAbouhamad, M., & Abu-Hamd, M. (2020). Life Cycle Environmental Assessment of Light Steel Framed Buildings with Cement-Based Walls and Floors. Sustainability, 12(24), 10686. https://doi.org/10.3390/su122410686