Blockchain-Based Traceability for Anti-Counterfeit in Cross-Border E-Commerce Transactions

Abstract

:1. Introduction

2. Theoretical Background

2.1. Counterfeiting from the Perspective of Green SCM

2.1.1. Green Supply Chain Management

2.1.2. Counterfeiting Issues

2.2. Key Features and Applications of Blockchain for Supply Chain

3. A Systemic Methodology for Anti-Counterfeiting in E-Commerce Environment

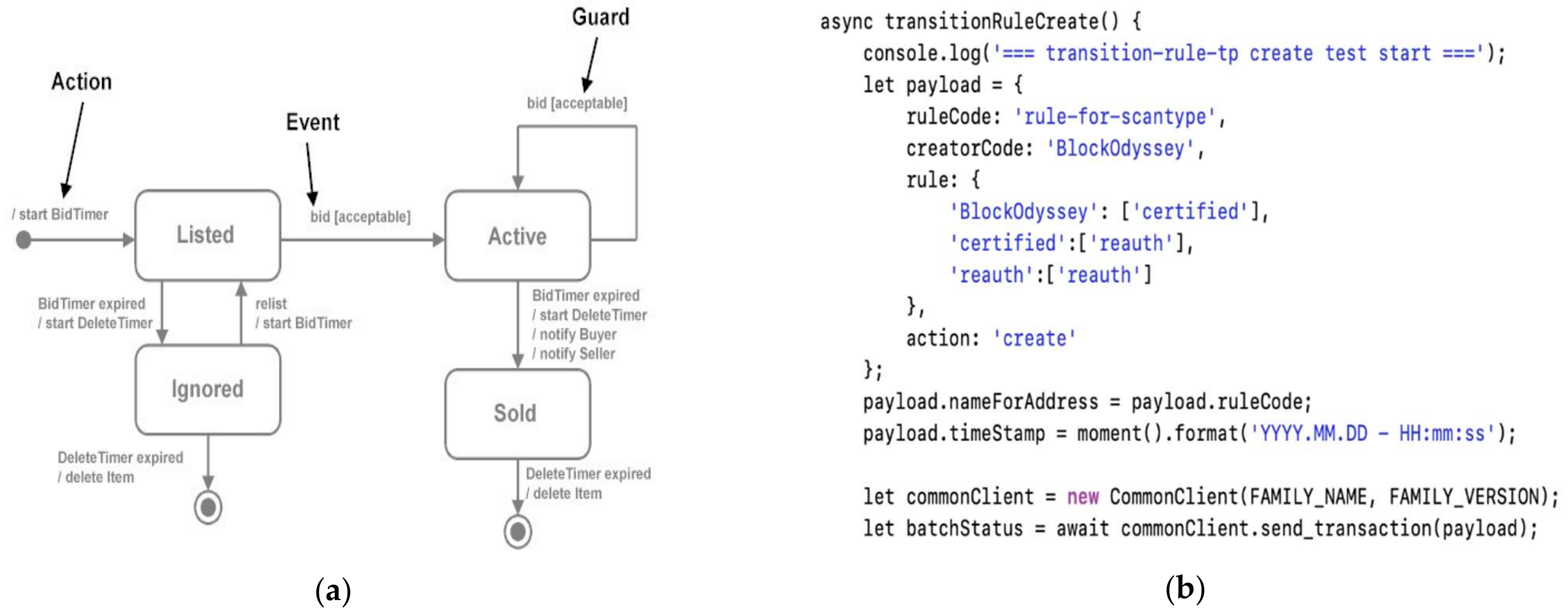

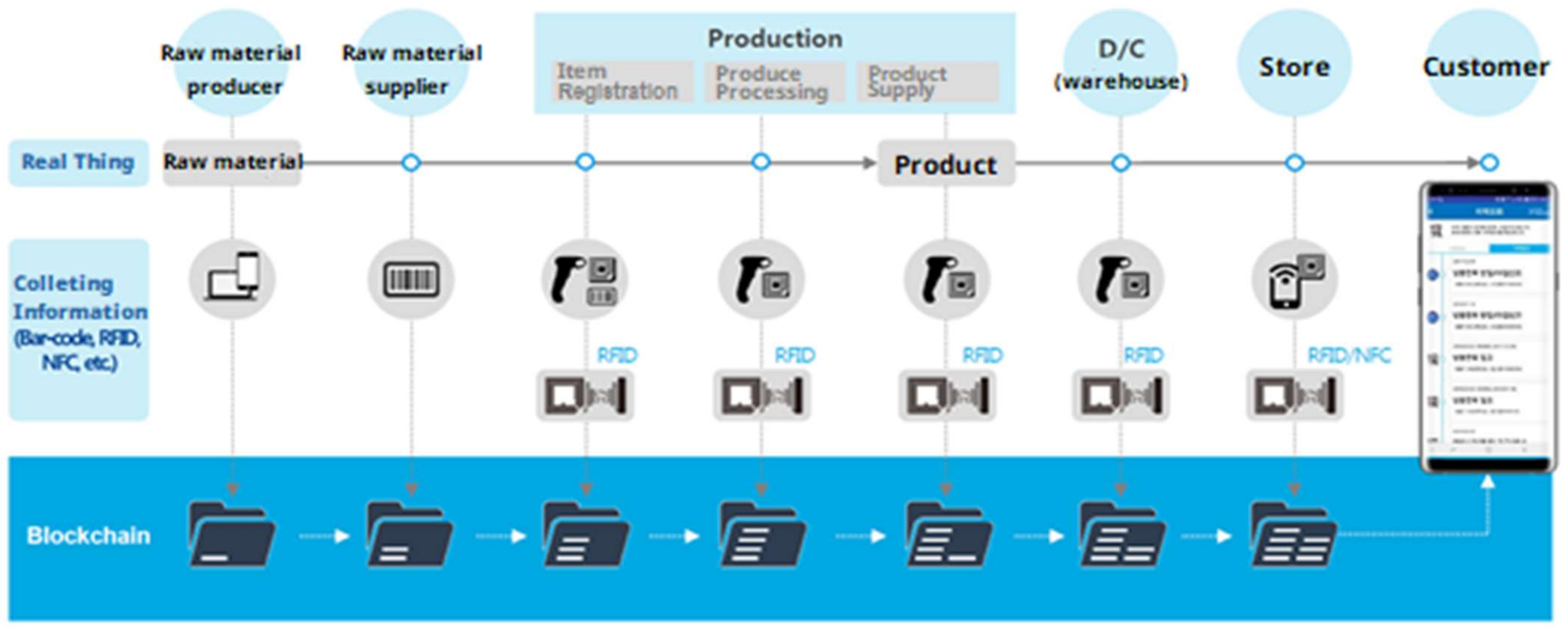

3.1. System Configuration

3.2. Pseudo Data Test

- Product Name: A ginseng health drink

- Sharing information: Cultivation place, processing and production, distribution, certificates, warehousing, etc.

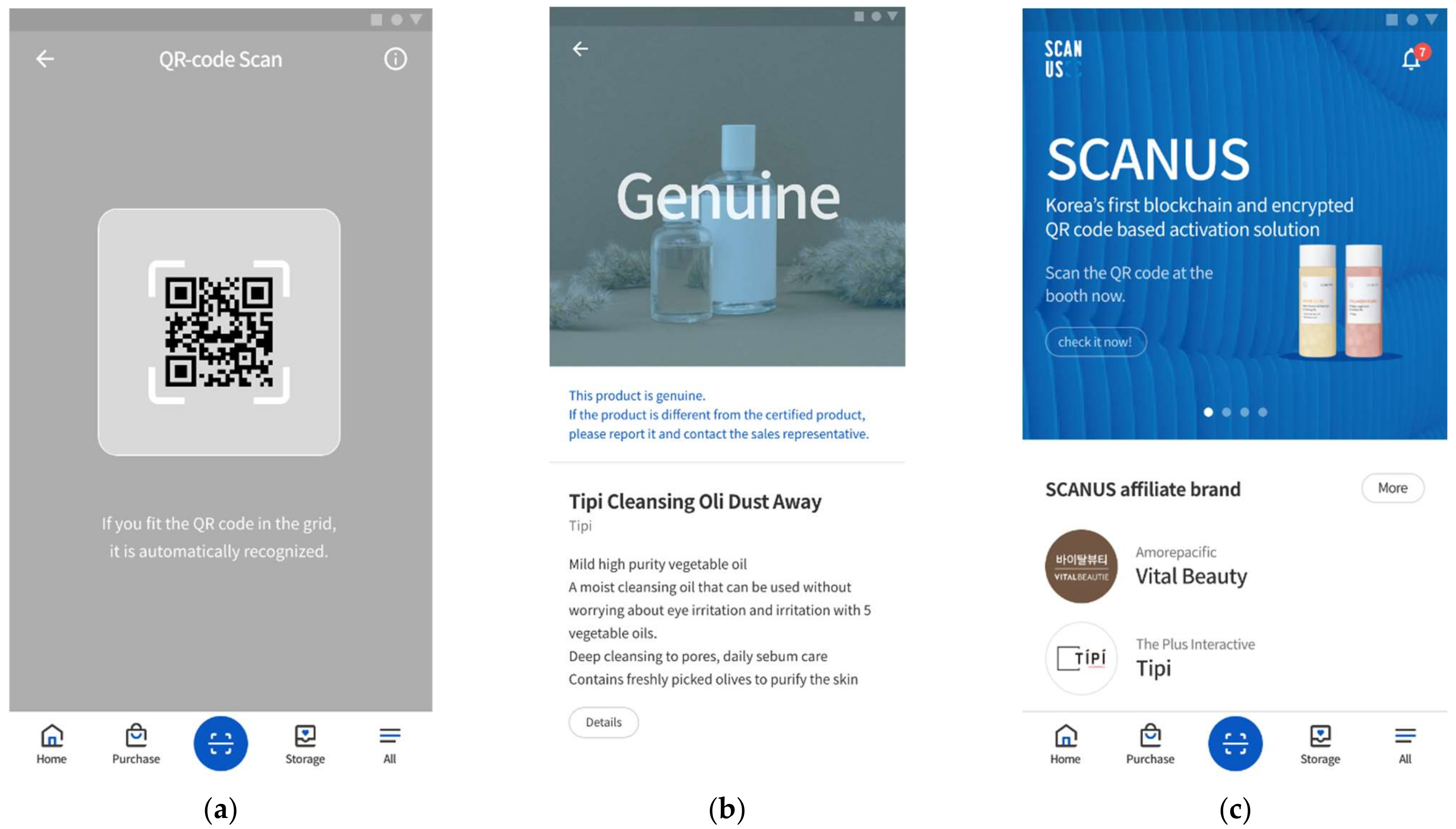

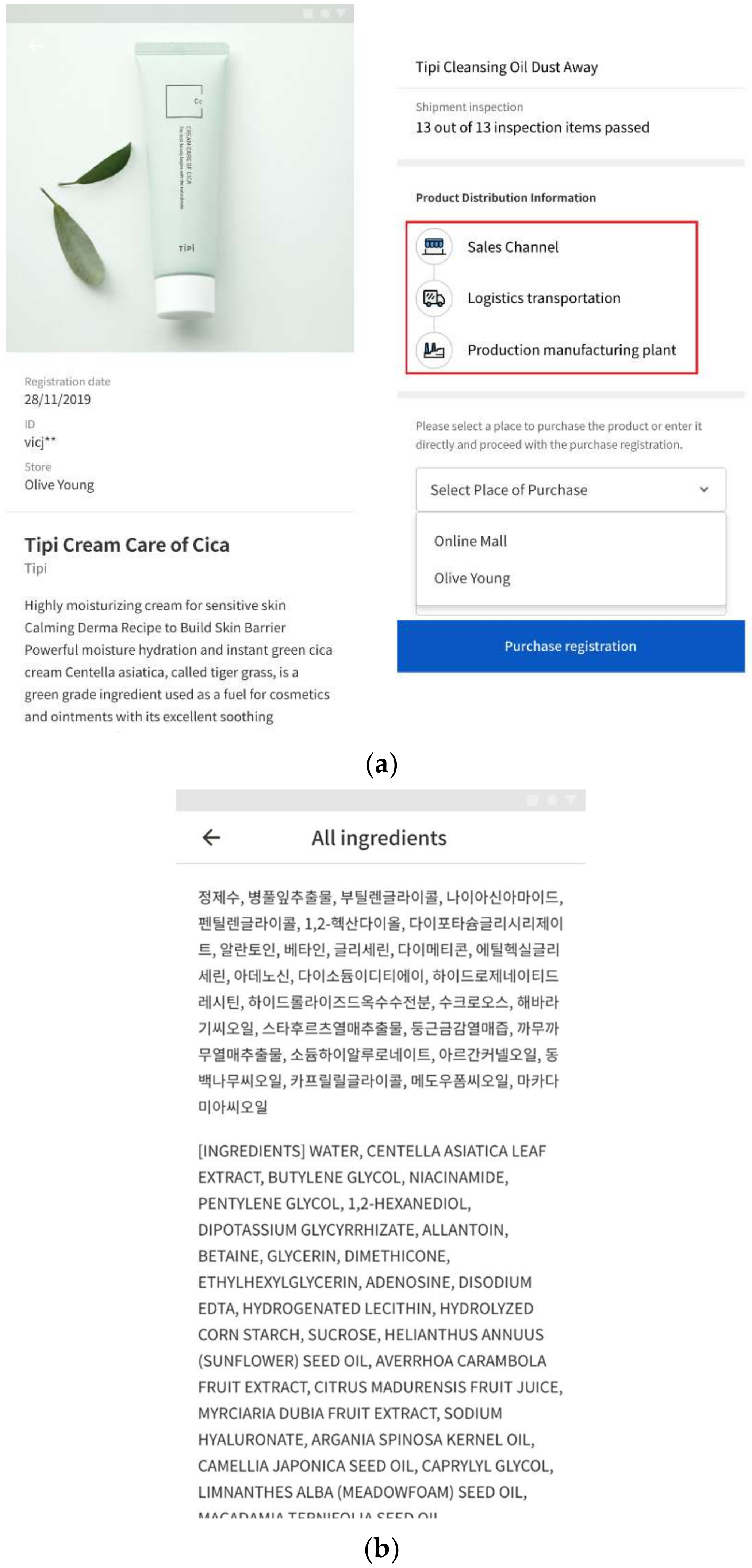

3.3. Real Business Data Test

4. Implications and Limitations

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yoo, M.; Won, Y. A Study on the Transparent Price Tracing System in Supply Chain Management Based on Blockchain. Sustainability 2018, 10, 4037. [Google Scholar] [CrossRef] [Green Version]

- Martinsen, U.; Björklund, M. Matches and Gaps in the Green Logistics Market. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 562–583. [Google Scholar] [CrossRef] [Green Version]

- Lambert, D.M.; Cooper, M.C. Issues in Supply Chain Management. Ind. Mark. Manag. 2000, 29, 65–83. [Google Scholar] [CrossRef]

- Qu, T.; Yang, H.D.; Huang, G.Q.; Zhang, Y.F.; Luo, H.; Qin, W. A Case of Implementing RFID-Based Real-Time Shop-Floor Material Management for Household Electrical Appliance Manufacturers. J. Intell. Manuf. 2012, 23, 2343–2356. [Google Scholar] [CrossRef] [Green Version]

- Tan, B.Q.; Wang, F.; Liu, J.; Kang, K.; Costa, F. A Blockchain-Based Framework for Green Logistics in Supply Chains. Sustainability 2020, 12, 4656. [Google Scholar] [CrossRef]

- Zheng, X.; Zhu, S.; Lin, Z. Capturing the Essence of Word-of-Mouth for Social Commerce: Assessing the Quality of Online e-Commerce Reviews by a Semi-Supervised Approach. Decis. Support Syst. 2013, 56, 211–222. [Google Scholar] [CrossRef]

- Nikolakis, W.; John, L.; Krishnan, H. How Blockchain Can Shape Sustainable Global Value Chains: An Evidence, Verifiability, and Enforceability (EVE) Framework. Sustainability 2018, 10, 3926. [Google Scholar] [CrossRef] [Green Version]

- Caldarelli, G.; Rossignoli, C.; Zardini, A. Overcoming the Blockchain Oracle Problem in the Traceability of Non-Fungible Products. Sustainability 2020, 12, 2391. [Google Scholar] [CrossRef] [Green Version]

- Prashar, D.; Jha, N.; Jha, S.; Lee, Y.; Joshi, G.P. Blockchain-Based Traceability and Visibility for Agricultural Products: A Decentralized Way of Ensuring Food Safety in India. Sustainability 2020, 12, 3497. [Google Scholar] [CrossRef] [Green Version]

- Chang, S.E.; Luo, H.L.; Chen, Y. Blockchain-Enabled Trade Finance Innovation: A Potential Paradigm Shift on Using Letter of Credit. Sustainability 2019, 12, 188. [Google Scholar] [CrossRef] [Green Version]

- Iansiti, M.; Lakhani, K.R. The Truth About Blockchain. Harv. Bus. Rev. 2017, 95, 119–127. [Google Scholar]

- Peter, H. Lewis Attention Shoppers: Internet Is Open. Available online: https://www.nytimes.com/1994/08/12/business/attention-shoppers-internet-is-open.html (accessed on 12 June 2020).

- Babenko, V.; Kulczyk, Z.; Perevosova, I.; Syniavska, O.; Davydova, O. Factors of the Development of International E-Commerce under the Conditions of Globalization. SHS Web Conf. 2019, 65, 04016. [Google Scholar] [CrossRef] [Green Version]

- Retail E-Commerce Sales Worldwide from 2014 to 2023. Available online: https://www.statista.com/statistics/379046/worldwide-retail-e-commerce-sales/ (accessed on 5 January 2021).

- China Ecommerce 2020. Available online: https://www.emarketer.com/content/china-ecommerce-2020 (accessed on 5 January 2021).

- Ding, F.; Huo, J.; Campos, J.K. The Development of Cross Border E-Commerce. In Proceedings of the International Conference on Transformations and Innovations in Management, Shanghai, China, 9–10 September 2017; Atlantis Press: Shanghai, China. [Google Scholar]

- Chen, L. Developing Asia in the Era of Cross-Border E-Commerce. Available online: https://www.eria.org/ERIA-DP-2017-11.pdf (accessed on 5 January 2021).

- Gomez-Herrera, E.; Martens, B.; Turlea, G. The Drivers and Impediments for Cross-Border e-Commerce in the EU. Inf. Econ. Policy 2014, 28, 83–96. [Google Scholar] [CrossRef] [Green Version]

- Wang, J. Opportunities and Challenges of International E-Commerce in the Pilot Areas of China. Int. J. Mark. Stud. 2014, 6, 141. [Google Scholar] [CrossRef] [Green Version]

- SCMP Supply Chain Management Definitions and Glossary. Available online: https://cscmp.org/CSCMP/Educate/SCM_Definitions_and_Glossary_of_Terms.aspx (accessed on 5 January 2021).

- Webster, F.E. The Changing Role of Marketing in the Corporation. J. Mark. 1992, 56, 1–17. [Google Scholar] [CrossRef]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance Measurement for Green Supply Chain Management. Benchmarking Int. J. 2005, 12, 330–353. [Google Scholar] [CrossRef] [Green Version]

- Lim, S.-J.; Phillips, J. Embedding CSR Values: The Global Footwear Industry’s Evolving Governance Structure. J. Bus. Ethics 2008, 81, 143–156. [Google Scholar] [CrossRef]

- Maloni, M.J.; Brown, M.E. Corporate Social Responsibility in the Supply Chain: An Application in the Food Industry. J. Bus. Ethics 2006, 68, 35–52. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Qianli, D. Impact of Green Supply Chain Management Practices on Firms’ Performance: An Empirical Study from the Perspective of Pakistan. Environ. Sci. Pollut. Res. 2017, 24, 16829–16844. [Google Scholar] [CrossRef] [PubMed]

- King, A.A.; Lenox, M.J. Lean and green? An empirical examination of the relationship between lean production and environmental performance. Prod. Oper. Manag. 2001, 10, 244–256. [Google Scholar] [CrossRef]

- Sarkis, J.; Rasheed, A. Greening the Manufacturing Function. Bus. Horiz. 1995, 38, 17–27. [Google Scholar] [CrossRef]

- Allenby, B. Supporting Environmental Quality: Developing an Infrastructure for Design. Environ. Qual. Manag. 1993, 2, 303–308. [Google Scholar] [CrossRef]

- Klassen, R.D.; McLaughlin, C.P. The Impact of Environmental Management on Firm Performance. Manag. Sci. 1996, 42, 1199–1214. [Google Scholar] [CrossRef]

- Yu, Z.; Golpîra, H.; Khan, S.A.R. The Impact of GSCM on Manufacturing Enterprise’s Performance. J. Adv. Manuf. Syst. 2018, 17, 445–459. [Google Scholar] [CrossRef]

- Handfield, R.; Walton, S.V.; Sroufe, R.; Melnyk, S.A. Applying Environmental Criteria to Supplier Assessment: A Study in the Application of the Analytical Hierarchy Process. Eur. J. Oper. Res. 2002, 141, 70–87. [Google Scholar] [CrossRef]

- Kumar, A.; Jain, V.; Kumar, S. A Comprehensive Environment Friendly Approach for Supplier Selection. Omega 2014, 42, 109–123. [Google Scholar] [CrossRef]

- Theyel, G. Customer and Supplier Relations for Environmental Performance. In Greening the Supply Chain; Springer: London, UK, 2006; pp. 139–149. [Google Scholar]

- Smith, K.T. An Examination of Marketing Techniques that Influence Millennials’ Perceptions of Whether a Product is Environmentally Friendly. J. Strateg. Mark. 2010, 18, 437–450. [Google Scholar] [CrossRef]

- Mamic, I. Managing Global Supply Chain: The Sports Footwear, Apparel and Retail Sectors. J. Bus. Ethics 2005, 59, 81–100. [Google Scholar] [CrossRef]

- Min, H.; Galle, W.P. Green Purchasing Strategies: Trends and Implications. Int. J. Purch. Mater. Manag. 1997, 33, 10–17. [Google Scholar] [CrossRef]

- Choi, D.; Hwang, T. The Impact of Green Supply Chain Management Practices on Firm Performance: The Role of Collaborative Capability. Oper. Manag. Res. 2015, 8, 69–83. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do Green Supply Chains Lead to Competitiveness and Economic Performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Green Gold: How Sustainability Became Big Businessforconsumer Brands 2020. Available online: https://www.ft.com/content/ce523ca1-c8c2-43e7-86ad-ffa5d6605d2c (accessed on 14 January 2021).

- Srivastava, S.K. Green Supply-Chain Management: A State-of-the-Art Literature Review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Rivoli, P. Labor Standards in the Global Economy: Issues for Investors. J. Bus. Ethics 2003, 43, 223–232. [Google Scholar] [CrossRef]

- Gleim, M.R.; Smith, J.S.; Andrews, D.; Cronin, J.J. Against the Green: A Multi-Method Examination of the Barriers to Green Consumption. J. Retail. 2013, 89, 44–61. [Google Scholar] [CrossRef]

- CNBC DISRUPTOR 50 Coupang, a SoftBank-Backed Start-Up, is Crushing Amazon to Become South Korea’s Biggest Online Retailer 2020. Available online: https://www.cnbc.com/2020/06/16/coupang-crushed-amazon-to-become-south-koreas-biggest-online-retailer.html (accessed on 14 January 2021).

- Gaur, V.; Gaiha, A. Havard Business Review; Harvard Business Publishing, Brighton, Massachusetts, USA. May 2020. Available online: https://hbr.org/2020/05/building-a-transparent-supply-chain (accessed on 14 January 2021).

- Lee, D. Thousands of Fraudsters are Selling via Shopify, Analysis Finds 2020. Available online: https://www.ft.com/content/0280592d-0adf-4dcb-a831-4f8a85f414bc (accessed on 14 January 2021).

- Kouhizadeh, M.; Sarkis, J. Blockchain Practices, Potentials, and Perspectives in Greening Supply Chains. Sustainability 2018, 10, 3652. [Google Scholar] [CrossRef] [Green Version]

- Bumblauskas, D.; Mann, A.; Dugan, B.; Rittmer, J. A Blockchain use Case in Food Distribution: Do You Know Where Your Food has been? Int. J. Inf. Manag. 2020, 52, 102008. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Choosing the Right Approach to Green Your Supply Chains. Mod. Supply Chain Res. Appl. 2019, 1, 54–67. [Google Scholar] [CrossRef]

- Haq, I.; Muselemu, O. Blockchain Technology in Pharmaceutical Industry to Prevent Counterfeit Drugs. Int. J. Comput. Appl. 2018, 180, 8–12. [Google Scholar] [CrossRef]

- Hastig, G.M.; Sodhi, M.S. Blockchain for Supply Chain Traceability: Business Requirements and Critical Success Factors. Prod. Oper. Manag. 2020, 29, 935–954. [Google Scholar] [CrossRef]

- Mettler, M. Blockchain Technology in Healthcare: The Revolution Starts Here. In Proceedings of the 2016 IEEE 18th International Conference on e-Health Networking, Applications and Services (Healthcom), Munich, Germany, 14–16 September 2016; IEEE: Munich, Germany; pp. 1–3. [Google Scholar]

- Olk, P.; West, J. The Relationship of Industry Structure to Open Innovation: Cooperative Value Creation in Pharmaceutical Consortia. RD Manag. 2020, 50, 116–135. [Google Scholar] [CrossRef]

- Kennedy, Z.C.; Stephenson, D.E.; Christ, J.F.; Pope, T.R.; Arey, B.W.; Barrett, C.A.; Warner, M.G. Enhanced Anti-Counterfeiting Measures for Additive Manufacturing: Coupling Lanthanide Nanomaterial Chemical Signatures with Blockchain Technology. J. Mater. Chem. C 2017, 5, 9570–9578. [Google Scholar] [CrossRef]

- Woodside, A.G.; Fine, M.B. Sustainable Fashion Themes in Luxury Brand Storytelling: The Sustainability Fashion Research Grid. J. Glob. Fash. Mark. 2019, 10, 111–128. [Google Scholar] [CrossRef]

- Crosby, M.; Pattanayak, P.; Verma, S.; Kalyanaraman, V. BlockChain Technology: Beyond Bitcoin. Appl. Innov. 2016, 2, 71. [Google Scholar]

- Hsu, C.-S.; Tu, S.-F.; Huang, Z.-J. Design of an E-Voucher System for Supporting Social Welfare using Blockchain Technology. Sustainability 2020, 12, 3362. [Google Scholar] [CrossRef] [Green Version]

- Nam, S. How Much are Insurance Consumers Willing to Pay for Blockchain and Smart Contracts? A Contingent Valuation Study. Sustainability 2018, 10, 4332. [Google Scholar] [CrossRef] [Green Version]

- Frizzo-Barker, J.; Chow-White, P.A.; Adams, P.R.; Mentanko, J.; Ha, D.; Green, S. Blockchain as a Disruptive Technology for Business: A Systematic Review. Int. J. Inf. Manag. 2020, 51, 102029. [Google Scholar] [CrossRef]

- Zheng, Z.; Xie, S.; Dai, H.; Chen, X.; Wang, H. An Overview of Blockchain Technology: Architecture, Consensus, and Future Trends. In Proceedings of the 2017 IEEE International Congress on Big Data (BigData Congress), Honolulu, HI, USA, 25–30 June 2017; IEEE: Honolulu, HI, USA; pp. 557–564. [Google Scholar]

- Olleros, F.; Zhegu, M. Research Handbook on Digital Transformations; Edward Elgar Publishing: Cheltenham, UK/Northampton, MA, USA, 2016; ISBN 978-1-78471-776-6. [Google Scholar]

- Tapscott, A.; Tapscott, D. How Blockchain is Changing Finance. Harv. Bus. Rev. 2017, 1, 2–5. [Google Scholar]

- Chen, L.; Xu, L.; Shah, N.; Gao, Z.; Lu, Y.; Shi, W. On Security Analysis of Proof-of-Elapsed-Time (PoET). In International Symposium on Stabilization, Safety, and Security of Distributed Systems; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Paliwal, V.; Chandra, S.; Sharma, S. Blockchain Technology for Sustainable Supply Chain Management: A Systematic Literature Review and a Classification Framework. Sustainability 2020, 12, 7638. [Google Scholar] [CrossRef]

- Christidis, K.; Devetsikiotis, M. Blockchains and Smart Contracts for the Internet of Things. IEEE Access 2016, 4, 2292–2303. [Google Scholar] [CrossRef]

- Pournader, M.; Shi, Y.; Seuring, S.; Koh, S.C.L. Blockchain Applications in Supply Chains, Transport and Logistics: A Systematic Review of the Literature. Int. J. Prod. Res. 2020, 58, 2063–2081. [Google Scholar] [CrossRef]

- Sikorski, J.J.; Haughton, J.; Kraft, M. Blockchain Technology in the Chemical Industry: Machine-to-Machine Electricity Market. Appl. Energy 2017, 195, 234–246. [Google Scholar] [CrossRef]

- Cousins, P.D.; Lawson, B.; Petersen, K.J.; Fugate, B. Investigating Green Supply Chain Management Practices and Performance: The Moderating Roles of Supply Chain Ecocentricity and Traceability. Int. J. Oper. Prod. Manag. 2019, 39, 767–786. [Google Scholar] [CrossRef]

- Lee, H.; Yeon, C. Research on How to Prevent Online Counterfeiting with Blockchain-Based Cross Border Data Sharing. In Proceedings of the 2020 International Conference on Information and Communication Technology Convergence (ICTC), Jeju, Korea, 21–23 October 2020; IEEE: Jeju, Korea; pp. 1940–1945. [Google Scholar]

- Liao, K.-C.; Lee, W.-H. A Novel User Authentication Scheme Based on QR-Code. J. Netw. 2010, 5, 937–941. [Google Scholar] [CrossRef]

- Mirabelli, G.; Solina, V. Blockchain and Agricultural Supply Chains Traceability: Research Trends and Future Challenges. Procedia Manuf. 2020, 42, 414–421. [Google Scholar] [CrossRef]

- Tian, F. An Agri-Food Supply Chain Traceability System for China Based on RFID & Blockchain Technology. In Proceedings of the 2016 13th International Conference on Service Systems and Service Management (ICSSSM), Kunming, China, 24–26 June 2016; IEEE: Kunming, China; pp. 1–6. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Yeon, C. Blockchain-Based Traceability for Anti-Counterfeit in Cross-Border E-Commerce Transactions. Sustainability 2021, 13, 11057. https://doi.org/10.3390/su131911057

Lee H, Yeon C. Blockchain-Based Traceability for Anti-Counterfeit in Cross-Border E-Commerce Transactions. Sustainability. 2021; 13(19):11057. https://doi.org/10.3390/su131911057

Chicago/Turabian StyleLee, Heongu, and Changhak Yeon. 2021. "Blockchain-Based Traceability for Anti-Counterfeit in Cross-Border E-Commerce Transactions" Sustainability 13, no. 19: 11057. https://doi.org/10.3390/su131911057

APA StyleLee, H., & Yeon, C. (2021). Blockchain-Based Traceability for Anti-Counterfeit in Cross-Border E-Commerce Transactions. Sustainability, 13(19), 11057. https://doi.org/10.3390/su131911057