A Study into the Availability, Costs and GHG Reduction in Drop-In Biofuels for Shipping under Different Regimes between 2020 and 2050

Abstract

:1. Introduction

2. Materials and Methods

- Model the marine biofuel supply chain;

- Determine the availability of feedstocks;

- Determine the future demand for marine biofuel;

- Determine the required model parameters;

- Perform a scenario analysis.

2.1. Mathematical Model Formulation

2.1.1. Economic Objective

2.1.2. Environmental Objective

2.1.3. Constraints

2.2. Supply and Demand Scenarios

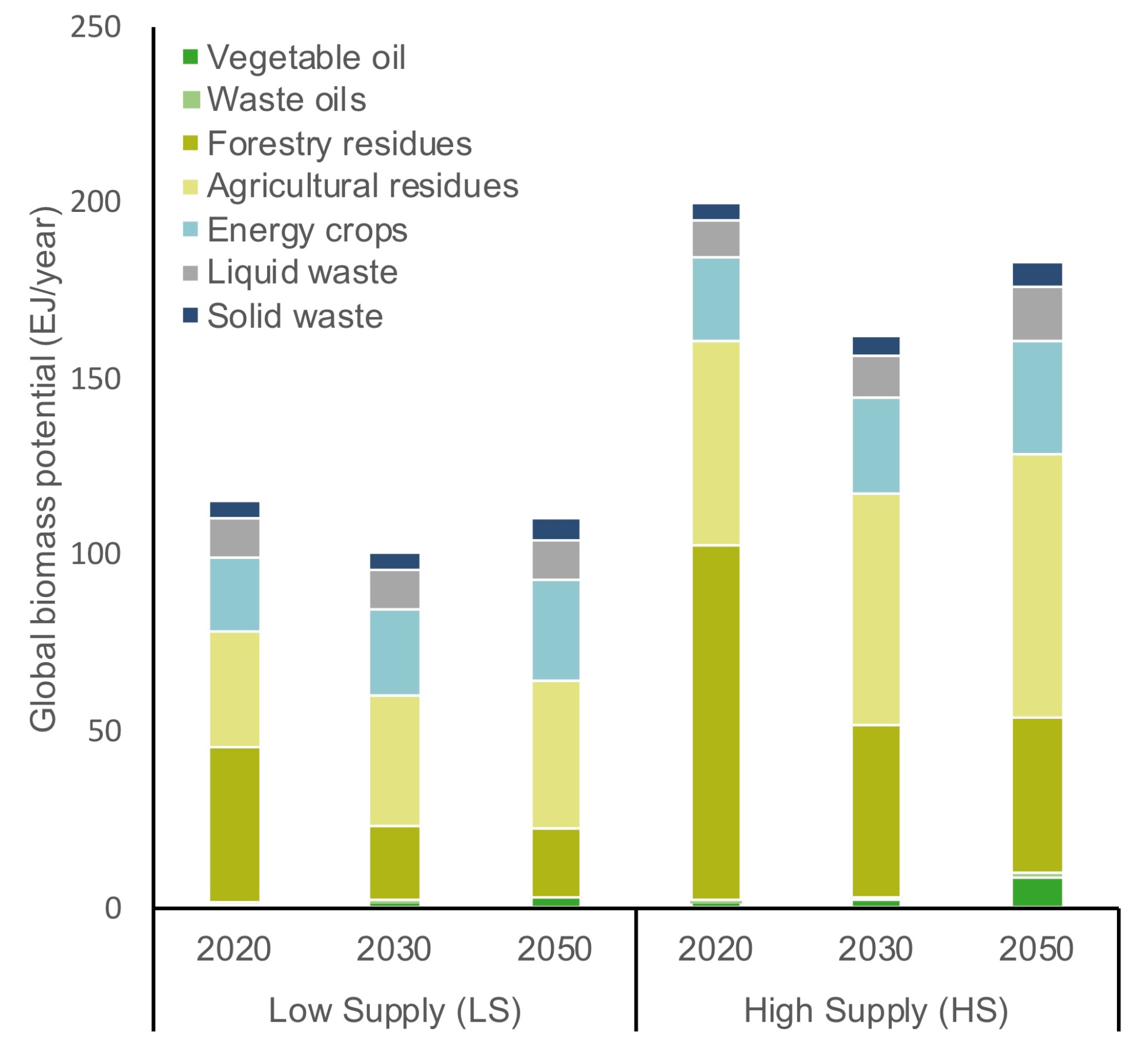

2.2.1. Biomass Supply Scenarios

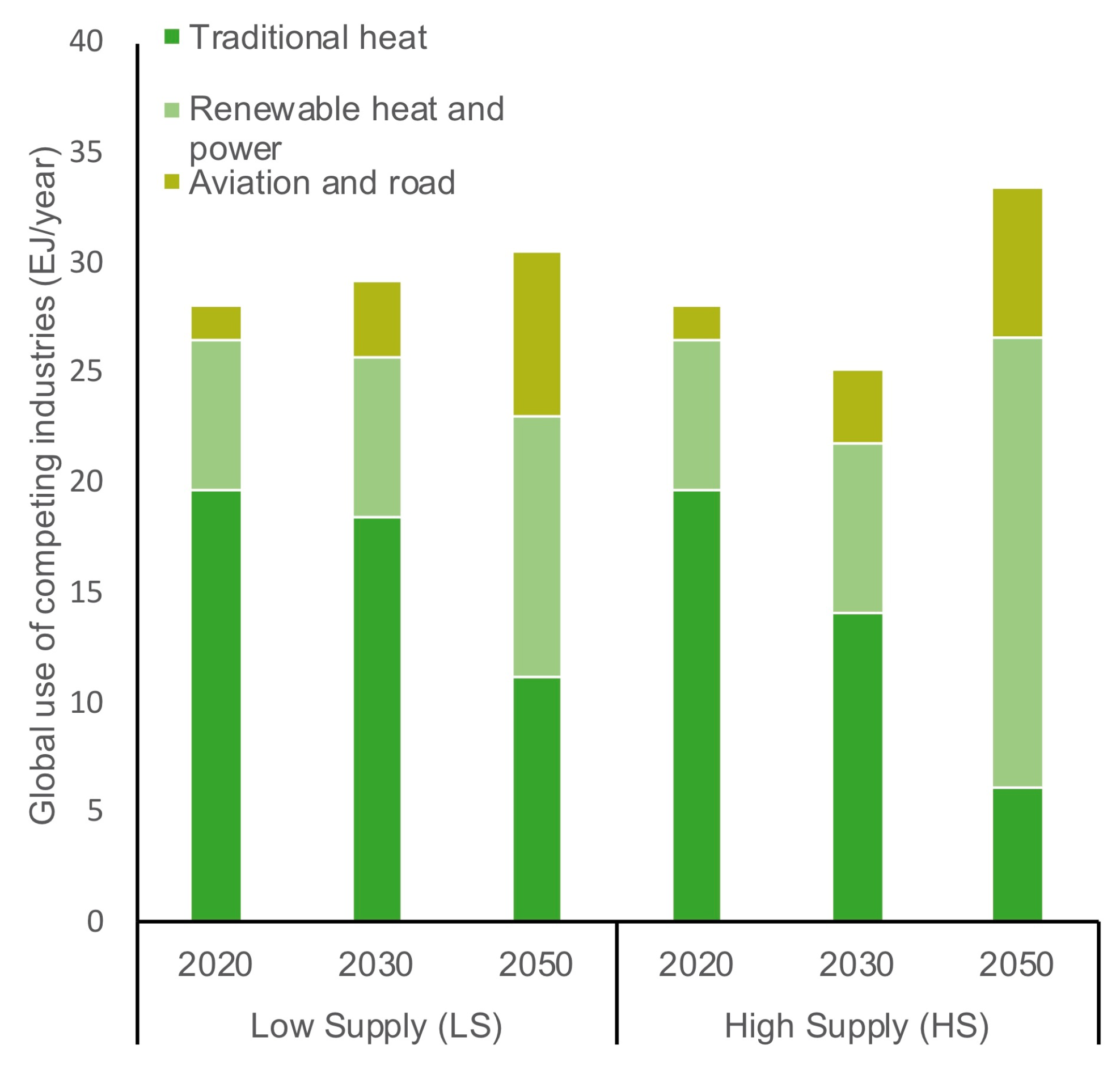

2.2.2. Biofuel Demand Scenarios

2.3. Model Parameters

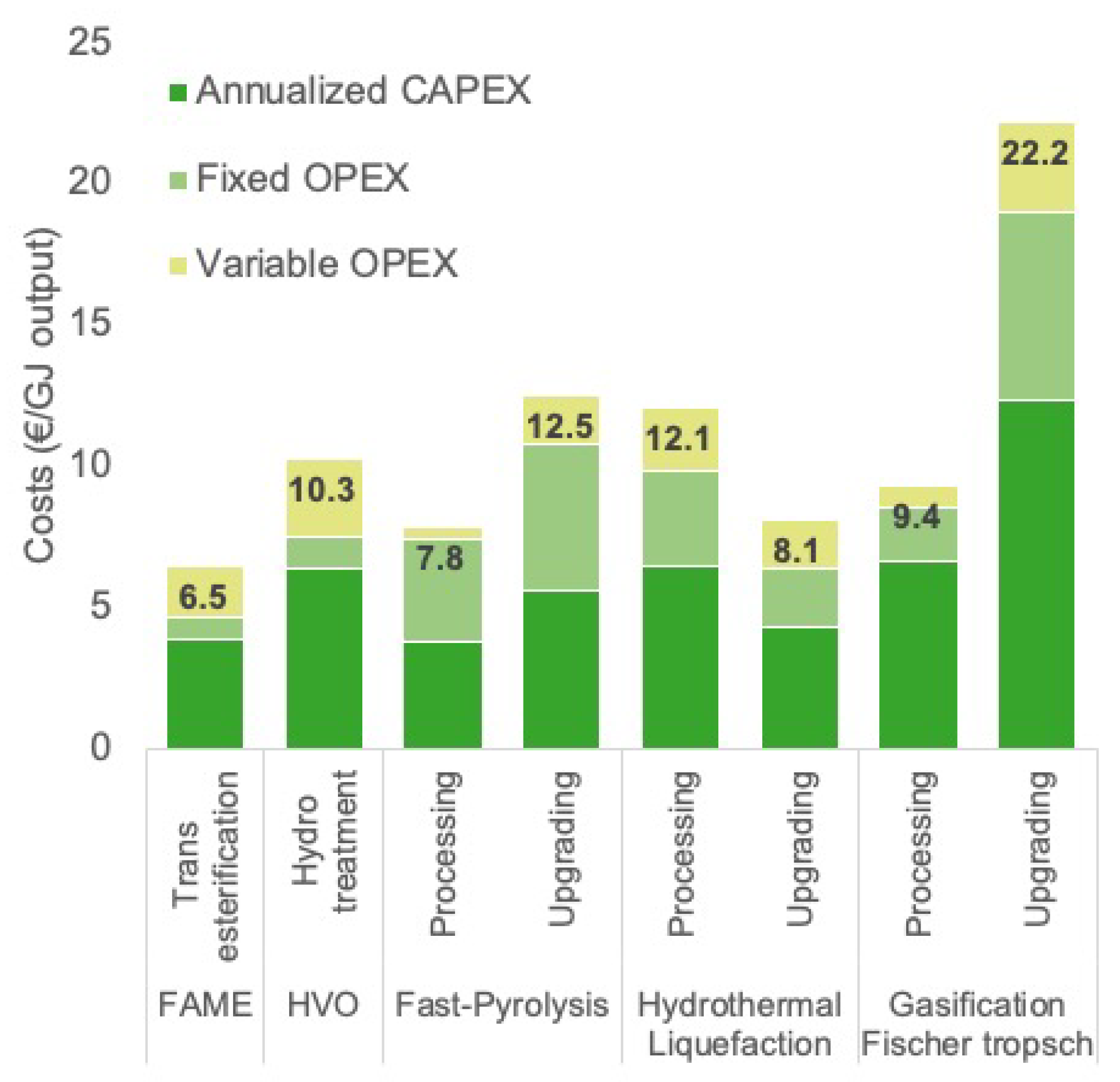

2.3.1. Economic Parameters

2.3.2. Environmental Parameters

2.3.3. Technological Parameters

3. Results

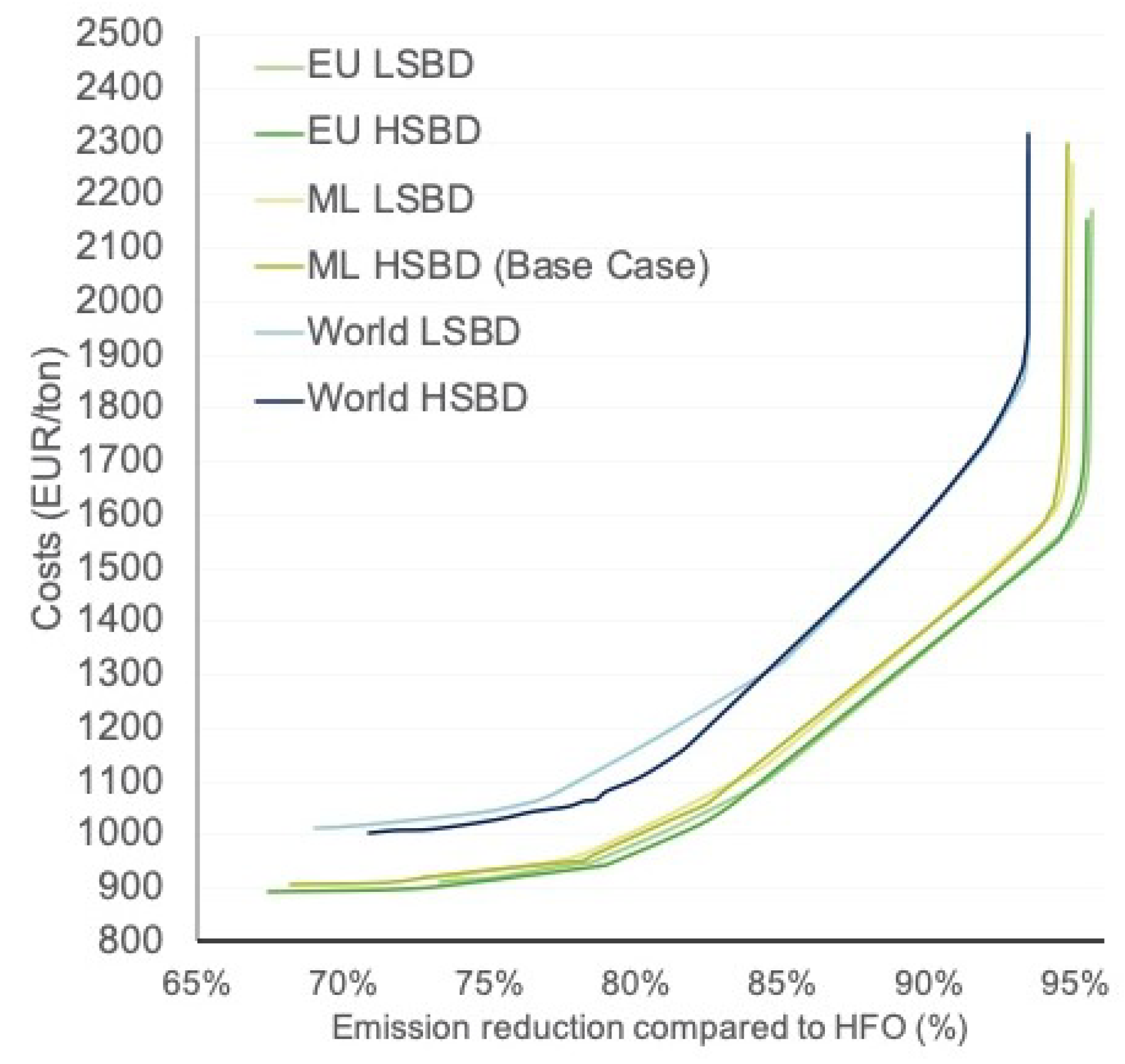

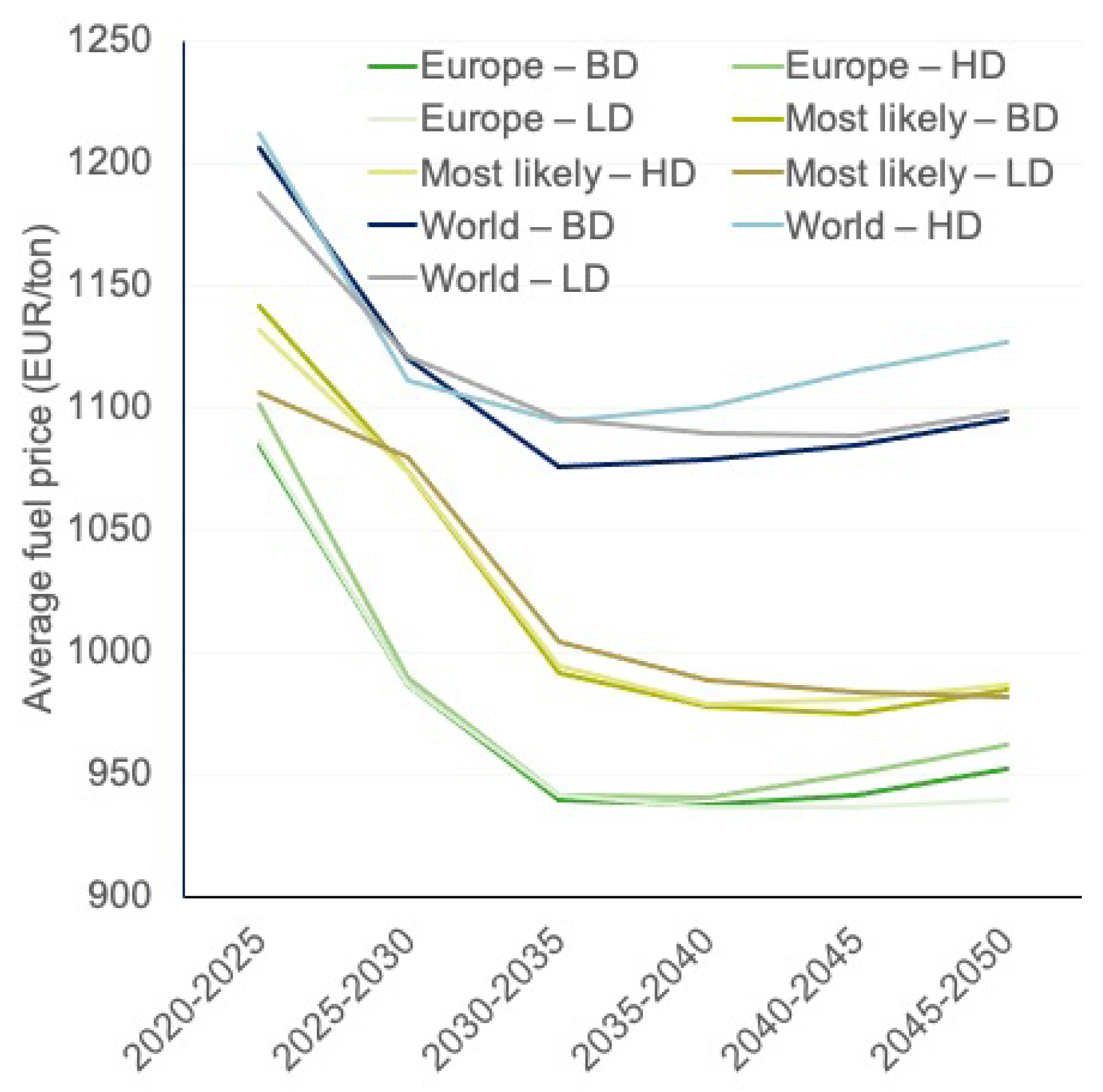

3.1. Costs Versus Emissions

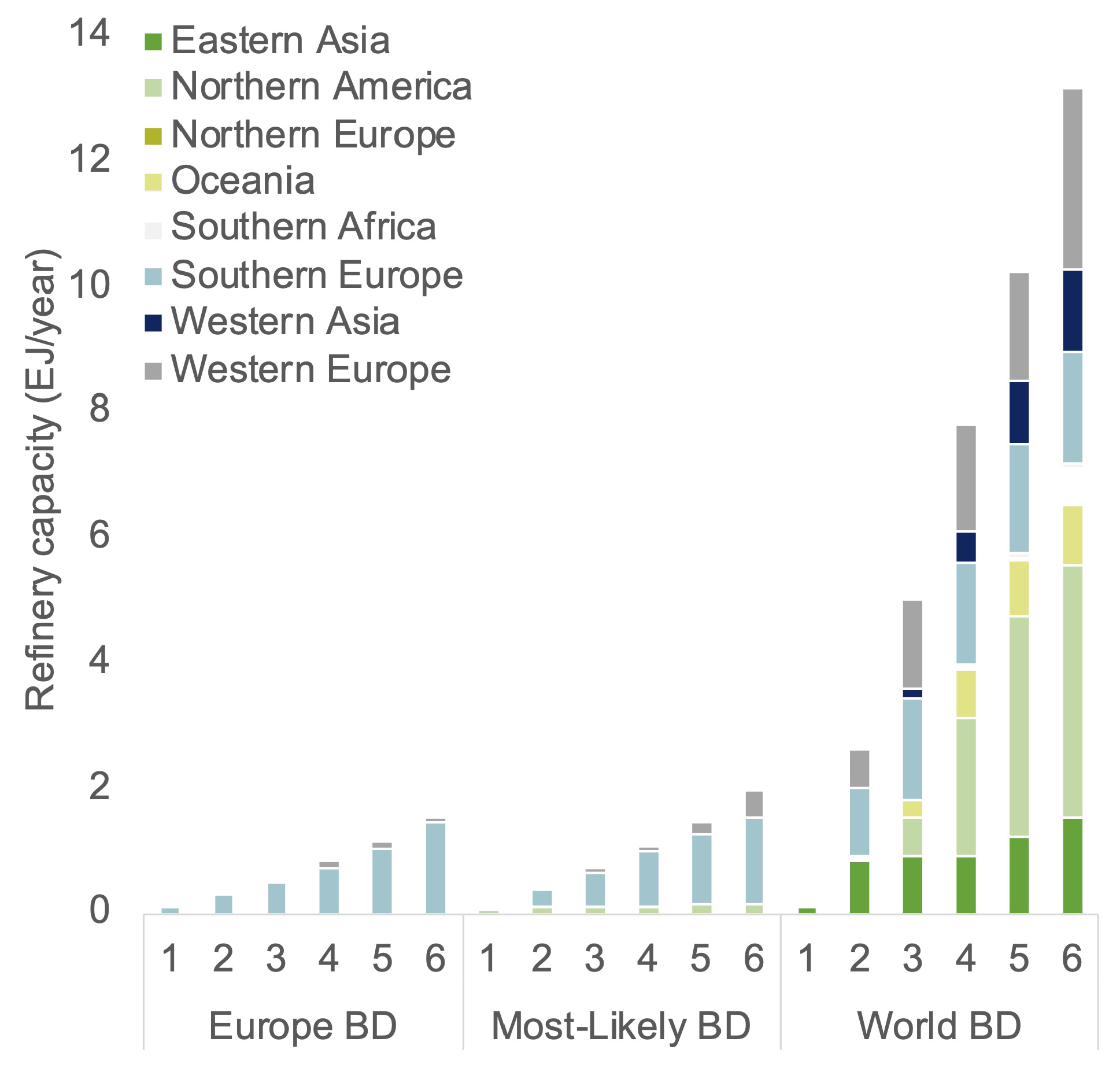

3.2. Technology and Feedstock Deployment

3.3. Trade Flows

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| S | Set of supply nodes. |

| R | Set of candidate refinery nodes. |

| D | Set of demand nodes. |

| H | Set of regions. |

| B | Set of biomass feedstocks. |

| J | Set of intermediate products. |

| G | Set of end products. |

| P | Set of plant sizes. |

| I | Set of supply steps. |

| T | Set of time periods. |

| Used amount of biomass of supply step at supply node to produce intermediate product during time period (PJ). | |

| Flow of intermediate between supply node and refinery node during time period (PJ). | |

| Flow of biofuel between refinery node and demand node during time period (PJ). | |

| Variable that indicates if a refinery of size producing biofuel at refinery node is built during time period . | |

| Unit costs of biomass at supply node during time period (mln €/PJ). | |

| Unit costs of producing intermediate from biomass at supply node during time period (mln €/PJ). | |

| Unit costs for inland transport of biomass to supply node during time period (mln €/kton). | |

| Variable costs related to running a refinery producing biofuel at refinery node during time period (mln €/PJ). | |

| Annualized fixed costs of running a refinery of size producing fuel at refinery node in time period (mln €/5 years). | |

| Unit overseas transport costs between supply node and refinery node (mln €/kton). | |

| Emissions related to cultivation of feedstock (kton CO-eq/PJ). | |

| Emissions related to the conversion of biomass to intermediate (kton CO-eq/PJ). | |

| Emissions related to the inland transport at supply node in supply step (kton CO-eq/kton). | |

| Emissions related to the upgrading to biofuel (kton CO-eq/PJ). | |

| Emissions related to the sea transport in between nodes (kton CO-eq/kton). | |

| Lower heating value of biomass type (MJ/kg). | |

| Lower heating value of intermediate product (MJ/kg). | |

| Lower heating value of biofuel (MJ/kg). | |

| Biofuel demand at demand location during time period (PJ). | |

| Capacity of a refinery of size producing fuel (PJ). | |

| Availability of feedstock at supply node during time period (PJ). | |

| Conversion yield from intermediate product to biofuel . | |

| Conversion yield from biomass to intermediate . | |

| Lower boundary for biomass type in supply step at supply node . | |

| Upper boundary for biomass type in supply step at supply node . | |

| Ratio between density of biomass type and the maximum freight density. | |

| C | Total system costs over the entire studied period. |

| Costs related to the intermediate bio-energy carrier during . | |

| Cost of biomass during . | |

| Costs of processing the intermediate bio-energy carrier to a biofuel . | |

| Costs related to the inland transport of the intermediate bio-energy carrier during . | |

| Costs related to the upgrading process during . | |

| Variable costs related to the upgrading process during . | |

| Fixed costs related to the upgrading process during . | |

| Costs related to sea transport during . | |

| Costs related to sea transport of the intermediate product during . | |

| Costs related to sea transport of the biofuel during . | |

| E | Total system emissions over the entire studied period. |

| Emissions related to the intermediate product during . | |

| Emissions related to cultivation and harvesting of biomass during . | |

| Emissions related to the processing phase during . | |

| Emissions related to the inland transport of biomass during . | |

| Emissions related to the upgrading phase during . | |

| Emissions related to sea transport during . | |

| Emissions related to the sea transport of the intermediate products during . | |

| Emissions related to the sea transport of the biofuel products during . |

References

- Tyrovola, T.; Dodos, G.; Kalligeros, S.; Zannikos, F. The introduction of biofuels in marine sector. J. Environ. Sci. Eng. A 2017, 6, 415–421. [Google Scholar] [CrossRef]

- EU. Reducing Emissions from the Shipping Sector. Available online: https://ec.europa.eu/clima/policies/transport/shipping_en (accessed on 11 March 2021).

- McGill, R.; Remley, W.; Winther, K. Alternative Fuels for Marine Applications; A Report from the IEA Advanced Motor Fuels Implementing Agreement; Publications Office of the European Union: Luxembourg, 2013; Volume 54. [Google Scholar]

- Moirangthem, K.; Baxter, D. Alternative Fuels for Marine and Inland Waterways; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- Czermanski, E.; Cirella, G.; Oniszczuk-Jastrzabek, A.; Pawlowska, B.; Notteboom, T. An Energy Consumption Approach to Estimate Air Emission Reductions in Container Shipping. Energies 2021, 14, 278. [Google Scholar] [CrossRef]

- Van Vliet, O.P.; Faaij, A.P.; Turkenburg, W.C. Fischer–Tropsch diesel production in a well-to-wheel perspective: A carbon, energy flow and cost analysis. Energy Convers. Manag. 2009, 50, 855–876. [Google Scholar] [CrossRef]

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-art technologies, measures, and potential for reducing GHG emissions from shipping—A review. Transp. Res. Part D Transp. Environ. 2017, 52, 408–421. [Google Scholar] [CrossRef]

- Sustainable Shipping Initiative. The Role of Sustainable Biofuels in the Decarbonisation of Shipping; Technical Report; Sustainable Shipping Initiative, SSI: London, UK, 2019. [Google Scholar]

- De Jong, S.; van Stralen, J.; Londo, M.; Hoefnagels, R.; Faaij, A.; Junginger, M. Renewable jet fuel supply scenarios in the European Union in 2021–2030 in the context of proposed biofuel policy and competing biomass demand. GCB Bioenergy 2018, 10, 661–682. [Google Scholar] [CrossRef]

- Forsberg, G. Biomass energy transport: Analysis of bioenergy transport chains using life cycle inventory method. Biomass Bioenergy 2000, 19, 17–30. [Google Scholar] [CrossRef]

- Mankowska, M.; Plucinski, M.; Kotowska, I. Biomass Sea-Based Supply Chains and the Secondary Ports in the Era of Decarbonization. Energies 2021, 14, 1796. [Google Scholar] [CrossRef]

- Lin, T.; Rodríguez, L.F.; Shastri, Y.N.; Hansen, A.C.; Ting, K.C. GIS-enabled biomass-ethanol supply chain optimization: Model development and Miscanthus application. Biofuels Bioprod. Biorefining 2013, 7, 314–333. [Google Scholar] [CrossRef]

- Giarola, S.; Zamboni, A.; Bezzo, F. Spatially explicit multi-objective optimisation for design and planning of hybrid first and second generation biorefineries. Comput. Chem. Eng. 2011, 35, 1782–1797. [Google Scholar] [CrossRef]

- Smith, T.W.P.; Jalkanen, J.P.; Anderson, B.A.; Corbett, J.J.; Faber, J.; Hanayama, S.; O’Keeffe, E.; Parker, S.; Johansson, L.; Aldous, L.; et al. Third IMO Greenhouse Gas Study 2014; International Maritime Organization (IMO): London, UK, 2014; p. 327. [Google Scholar] [CrossRef] [Green Version]

- Nakada, S.; Saygin, D.; Gielen, D. Global Bioenergy Supply and Demand Projections; A Working Paper for REmap 2030; IRENA: Tokyo, Japan, 2014. [Google Scholar]

- Leguijt, C. Bio-Scope. 2020. Available online: https://ce.nl/wp-content/uploads/2021/03/CE_Delft_190186_Bio-Scope_Def.pdf (accessed on 20 August 2021).

- Daioglou, V.; Doelman, J.C.; Wicke, B.; Faaij, A.; van Vuuren, D.P. Integrated assessment of biomass supply and demand in climate change mitigation scenarios. Glob. Environ. Chang. 2019, 54, 88–101. [Google Scholar] [CrossRef] [Green Version]

- Smeets, E.M.; Faaij, A.P.; Lewandowski, I.M.; Turkenburg, W.C. A bottom-up assessment and review of global bio-energy potentials to 2050. Prog. Energy Combust. Sci. 2007, 33, 56–106. [Google Scholar] [CrossRef] [Green Version]

- Gregg, J.S.; Smith, S.J. Global and regional potential for bioenergy from agricultural and forestry residue biomass. Mitig. Adapt. Strateg. Glob. Chang. 2010, 15, 241–262. [Google Scholar] [CrossRef]

- Hoogwijk, M.; Graus, W. Global Potential of Renewable Energy Sources: A Literature Assessment; Background Report Prepared by Order of REN21; Ecofys: Utrecht, The Netherlands, 2008. [Google Scholar]

- Aronietis, R.; Sys, C.; van Hassel, E.; Vanelslander, T. Forecasting port-level demand for LNG as a ship fuel: The case of the port of Antwerp. J. Shipp. Trade 2016, 1, 2. [Google Scholar] [CrossRef] [Green Version]

- Hsieh, C.; Felby, C. Biofuels for the Marine Shipping Sector; IEA Bioenergy: Paris, France, 2017. [Google Scholar]

- De Wit, M.; Faaij, A. European biomass resource potential and costs. Biomass Bioenergy 2010, 34, 188–202. [Google Scholar] [CrossRef]

- De Wit, M.; Faaij, A. Biomass Resources Potential and Related Costs; Refuel Work Package 3; Copernicus Institute: Utrecht, The Netherlands, 2008. [Google Scholar]

- Allen, J.; Browne, M.; Hunter, A.; Boyd, J.; Palmer, H. Logistics management and costs of biomass fuel supply. Int. J. Phys. Distrib. Logist. Manag. 1998, 28, 463–477. [Google Scholar] [CrossRef]

- Ericsson, K.; Rosenqvist, H.; Nilsson, L.J. Energy crop production costs in the EU. Biomass Bioenergy 2009, 33, 1577–1586. [Google Scholar] [CrossRef] [Green Version]

- Alves, C.M.; Valk, M.; De Jong, S.; Bonomi, A.; van der Wielen, L.A.; Mussatto, S.I. Techno-economic assessment of biorefinery technologies for aviation biofuels supply chains in Brazil. Biofuels Bioprod. Biorefining 2017, 11, 67–91. [Google Scholar] [CrossRef]

- Swanson, R.M.; Platon, A.; Satrio, J.; Brown, R.; Hsu, D.D. Techno-Economic Analysis of Biofuels Production Based on Gasification; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2010. [Google Scholar]

- Rafati, M.; Wang, L.; Dayton, D.C.; Schimmel, K.; Kabadi, V.; Shahbazi, A. Techno-economic analysis of production of Fischer-Tropsch liquids via biomass gasification: The effects of Fischer-Tropsch catalysts and natural gas co-feeding. Energy Convers. Manag. 2017, 133, 153–166. [Google Scholar] [CrossRef] [Green Version]

- Tanzer, S. Plant+ Boom= Boat+ Vroom: A Comparative Technoeconomic and Environmental Assessment of Marine Biofuel Production in Brazil and Scandinavia Using Residual Lignocellulosic Biomass and Thermochemical Conversion Technologies. 2017. Available online: http://resolver.tudelft.nl/uuid:ac21de73-e747-479d-b6e3-5e2b4e7bb88d (accessed on 20 August 2021).

- Cornelio da Silva, C. Techno-Economic and Environmental Analysis of Oil Crop and Forestry Residues based Biorefineries for Biojet Fuel Production in Brazil. 2016. Available online: http://resolver.tudelft.nl/uuid:1dd8082f-f4a5-4df6-88bb-e297ed483b54 (accessed on 20 August 2021).

- Zhu, Y.; Biddy, M.J.; Jones, S.B.; Elliott, D.C.; Schmidt, A.J. Techno-economic analysis of liquid fuel production from woody biomass via hydrothermal liquefaction (HTL) and upgrading. Appl. Energy 2014, 129, 384–394. [Google Scholar] [CrossRef]

- Atsonios, K.; Kougioumtzis, M.A.; Panopoulos, K.D.; Kakaras, E. Alternative thermochemical routes for aviation biofuels via alcohols synthesis: Process modeling, techno-economic assessment and comparison. Appl. Energy 2015, 138, 346–366. [Google Scholar] [CrossRef]

- Sarkar, S.; Kumar, A.; Sultana, A. Biofuels and biochemicals production from forest biomass in Western Canada. Energy 2011, 36, 6251–6262. [Google Scholar] [CrossRef]

- Anex, R.P.; Aden, A.; Kazi, F.K.; Fortman, J.; Swanson, R.M.; Wright, M.M.; Satrio, J.A.; Brown, R.C.; Daugaard, D.E.; Platon, A.; et al. Techno-economic comparison of biomass-to-transportation fuels via pyrolysis, gasification, and biochemical pathways. Fuel 2010, 89, S29–S35. [Google Scholar] [CrossRef]

- AlNouss, A.; McKay, G.; Al-Ansari, T. A comparison of steam and oxygen fed biomass gasification through a techno-economic-environmental study. Energy Convers. Manag. 2020, 208, 112612. [Google Scholar] [CrossRef]

- Tzanetis, K.F.; Posada, J.A.; Ramirez, A. Analysis of biomass hydrothermal liquefaction and biocrude-oil upgrading for renewable jet fuel production: The impact of reaction conditions on production costs and GHG emissions performance. Renew. Energy 2017, 113, 1388–1398. [Google Scholar] [CrossRef]

- Jones, S.B.; Meyer, P.A.; Snowden-Swan, L.J.; Padmaperuma, A.B.; Tan, E.; Dutta, A.; Jacobson, J.; Cafferty, K. Process Design and Economics for the Conversion of Lignocellulosic Biomass to Hydrocarbon Fuels: Fast Pyrolysis and Hydrotreating Bio-Oil Pathway; Technical Report; Pacific Northwest National Lab. (PNNL): Richland, WA, USA, 2013. [Google Scholar]

- Magdeldin, M.; Kohl, T.; Järvinen, M. Techno-economic assessment of the by-products contribution from non-catalytic hydrothermal liquefaction of lignocellulose residues. Energy 2017, 137, 679–695. [Google Scholar] [CrossRef]

- Tews, I.J.; Zhu, Y.; Drennan, C.; Elliott, D.C.; Snowden-Swan, L.J.; Onarheim, K.; Solantausta, Y.; Beckman, D. Biomass Direct Liquefaction Options. TechnoEconomic and Life Cycle Assessment; Technical Report; Pacific Northwest National Lab. (PNNL): Richland, WA, USA, 2014. [Google Scholar]

- Wright, M.M.; Daugaard, D.E.; Satrio, J.A.; Brown, R.C. Techno-economic analysis of biomass fast pyrolysis to transportation fuels. Fuel 2010, 89, S2–S10. [Google Scholar] [CrossRef] [Green Version]

- Meyer, P.A.; Snowden-Swan, L.J.; Rappé, K.G.; Jones, S.B.; Westover, T.L.; Cafferty, K.G. Field-to-fuel performance testing of lignocellulosic feedstocks for fast pyrolysis and upgrading: Techno-economic analysis and greenhouse gas life cycle analysis. Energy Fuels 2016, 30, 9427–9439. [Google Scholar] [CrossRef]

- Brown, T.R.; Thilakaratne, R.; Brown, R.C.; Hu, G. Techno-economic analysis of biomass to transportation fuels and electricity via fast pyrolysis and hydroprocessing. Fuel 2013, 106, 463–469. [Google Scholar] [CrossRef] [Green Version]

- Shemfe, M.B.; Gu, S.; Ranganathan, P. Techno-economic performance analysis of biofuel production and miniature electric power generation from biomass fast pyrolysis and bio-oil upgrading. Fuel 2015, 143, 361–372. [Google Scholar] [CrossRef] [Green Version]

- Meyer, P.A.; Snowden-Swan, L.J.; Jones, S.B.; Rappé, K.G.; Hartley, D.S. The effect of feedstock composition on fast pyrolysis and upgrading to transportation fuels: Techno-economic analysis and greenhouse gas life cycle analysis. Fuel 2020, 259, 116218. [Google Scholar] [CrossRef]

- Landälv, I.; Waldheim, L.; van den Heuvel, E.; Kalligeros, S. Building up the Future Cost of Biofuel; European Comission, Sub Group on Advanced Biofuels: Brussels, Belgium, 2017. [Google Scholar]

- De Jong, S.; Antonissen, K.; Hoefnagels, R.; Lonza, L.; Wang, M.; Faaij, A.; Junginger, M. Life-cycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol. Biofuels 2017, 10, 64. [Google Scholar] [CrossRef] [Green Version]

- McKinnon, A.; Piecyk, M. Measuring and Managing CO2 Emissions; European Chemical Industry Council: Edinburgh, UK, 2010. [Google Scholar]

- Han, D.; Yang, X.; Li, R.; Wu, Y. Environmental impact comparison of typical and resource-efficient biomass fast pyrolysis systems based on LCA and Aspen Plus simulation. J. Clean. Prod. 2019, 231, 254–267. [Google Scholar] [CrossRef]

- Oasmaa, A.; Kuoppala, E.; Gust, S.; Solantausta, Y. Fast pyrolysis of forestry residue. 1. Effect of extractives on phase separation of pyrolysis liquids. Energy Fuels 2003, 17, 1–12. [Google Scholar] [CrossRef]

- Buah, W.; Cunliffe, A.; Williams, P. Characterization of products from the pyrolysis of municipal solid waste. Process Saf. Environ. Prot. 2007, 85, 450–457. [Google Scholar] [CrossRef]

- Sipra, A.T.; Gao, N.; Sarwar, H. Municipal solid waste (MSW) pyrolysis for bio-fuel production: A review of effects of MSW components and catalysts. Fuel Process. Technol. 2018, 175, 131–147. [Google Scholar] [CrossRef]

- Mullen, C.A.; Boateng, A.A. Chemical composition of bio-oils produced by fast pyrolysis of two energy crops. Energy Fuels 2008, 22, 2104–2109. [Google Scholar] [CrossRef]

- El Takriti, S.; Pavlenko, N.; Searle, S. Mitigating International Aviation Emissions: Risks and Opportunities for Alternative Jet Fuels. 2017. Available online: https://theicct.org/sites/default/files/publications/Aviation-Alt-Jet-Fuels_ICCT_White-Paper_22032017_vF.pdf (accessed on 20 August 2021).

| Feedstock Category | Feedstocks |

|---|---|

| Vegetable oils | Palm, sunflower, soybean and rapeseed |

| Waste oils | UCO and tallow |

| Agricultural residues | Grain residues |

| Forestry residues | Primary: Leftover from logging operations, early thinning or final felling (branches, stumps, tree tops, bark and sawdust, etc.) Secondary: by-products and co-products of industrial wood-processing operation (bark, sawmill slabs, sawdust and wood chips, etc.) |

| Energy crops | Miscanthus, willow and poplar |

| Solid waste | Municipal solid waste |

| Liquid waste | Animal manure and wastewater sludge |

| Geographical Scenario Settings | Supply Scenario Settings | Demand Scenario Settings |

|---|---|---|

| Europe | Low Supply (LS) | Low Demand (LD) |

| European ports comply with the RED II target of 14 % renewable fuel in their transport mix by 2030, reflecting a situation in which shipping is included in this target. Double counting mechanisms are not considered. A linear trend is assumed, reaching up until 2050. | The LS scenario contains a conservative estimation on biomass feedstock availability combined with significant competition from other industries. | The LD scenario uses scenario 11 of the Third GHG Study of the IMO [14]. |

| Most Likely (ML) | High Supply (HS) | Base Demand (BD) |

| Leading countries in sustainability (the USA, The Netherlands, Germany, Canada and the UK) are assumed to follow the RED II targets. | The HS scenario contains a more optimistic view on biomass feedstock availability that would be available for the production of marine biofuels. The road sector is expected to electrify at a fast pace, causing lower competition for certain biomass feedstocks. | The BD scenario uses scenario 8 of the Third GHG Study of the IMO [14]. |

| World | High Demand (HD) | |

| All ports are assumed to achieve the IMO target of 50% GHG reduction by 2050 compared to 2008 levels. | The HD scenario uses scenario 14 of the Third GHG Study of the IMO [14]. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

van der Kroft, D.F.A.; Pruyn, J.F.J. A Study into the Availability, Costs and GHG Reduction in Drop-In Biofuels for Shipping under Different Regimes between 2020 and 2050. Sustainability 2021, 13, 9900. https://doi.org/10.3390/su13179900

van der Kroft DFA, Pruyn JFJ. A Study into the Availability, Costs and GHG Reduction in Drop-In Biofuels for Shipping under Different Regimes between 2020 and 2050. Sustainability. 2021; 13(17):9900. https://doi.org/10.3390/su13179900

Chicago/Turabian Stylevan der Kroft, Douwe F. A., and Jeroen F. J. Pruyn. 2021. "A Study into the Availability, Costs and GHG Reduction in Drop-In Biofuels for Shipping under Different Regimes between 2020 and 2050" Sustainability 13, no. 17: 9900. https://doi.org/10.3390/su13179900

APA Stylevan der Kroft, D. F. A., & Pruyn, J. F. J. (2021). A Study into the Availability, Costs and GHG Reduction in Drop-In Biofuels for Shipping under Different Regimes between 2020 and 2050. Sustainability, 13(17), 9900. https://doi.org/10.3390/su13179900