Assessment of a Municipal Solid Waste Incinerator Bottom Ash as a Candidate Pozzolanic Material: Comparison of Test Methods

Abstract

:1. Introduction

2. Materials and Methods

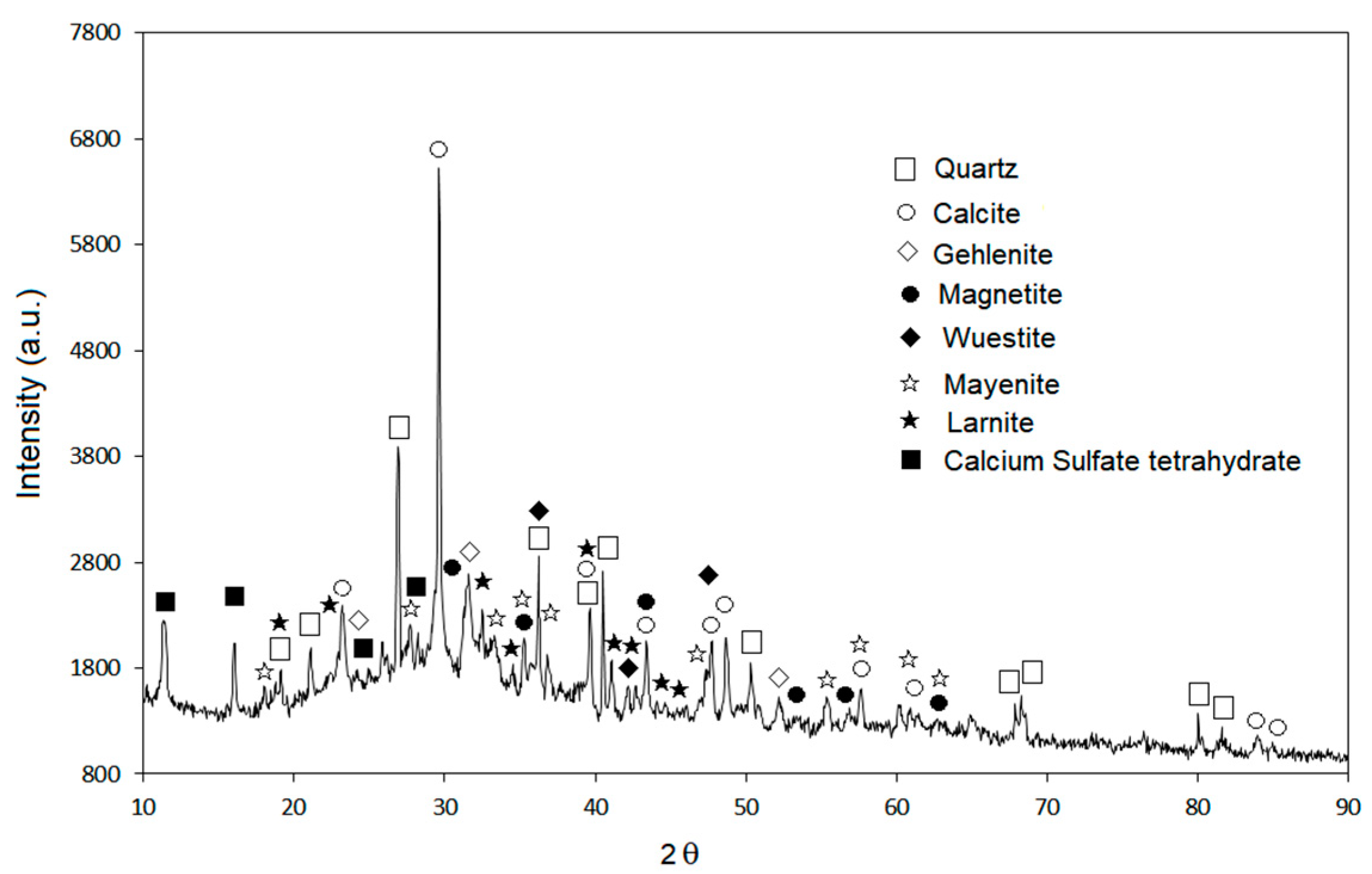

2.1. Raw Waste Material: Characterization

2.2. Methods

2.2.1. Mortar Specimens—Mechanical Tests

2.2.2. SAI index

2.2.3. Efficiency k-Factor

2.2.4. Conductivity Test

2.2.5. Frattini Test

2.2.6. Cement Paste Specimens—Setting Times and Mechanical Properties

3. Results and Discussion

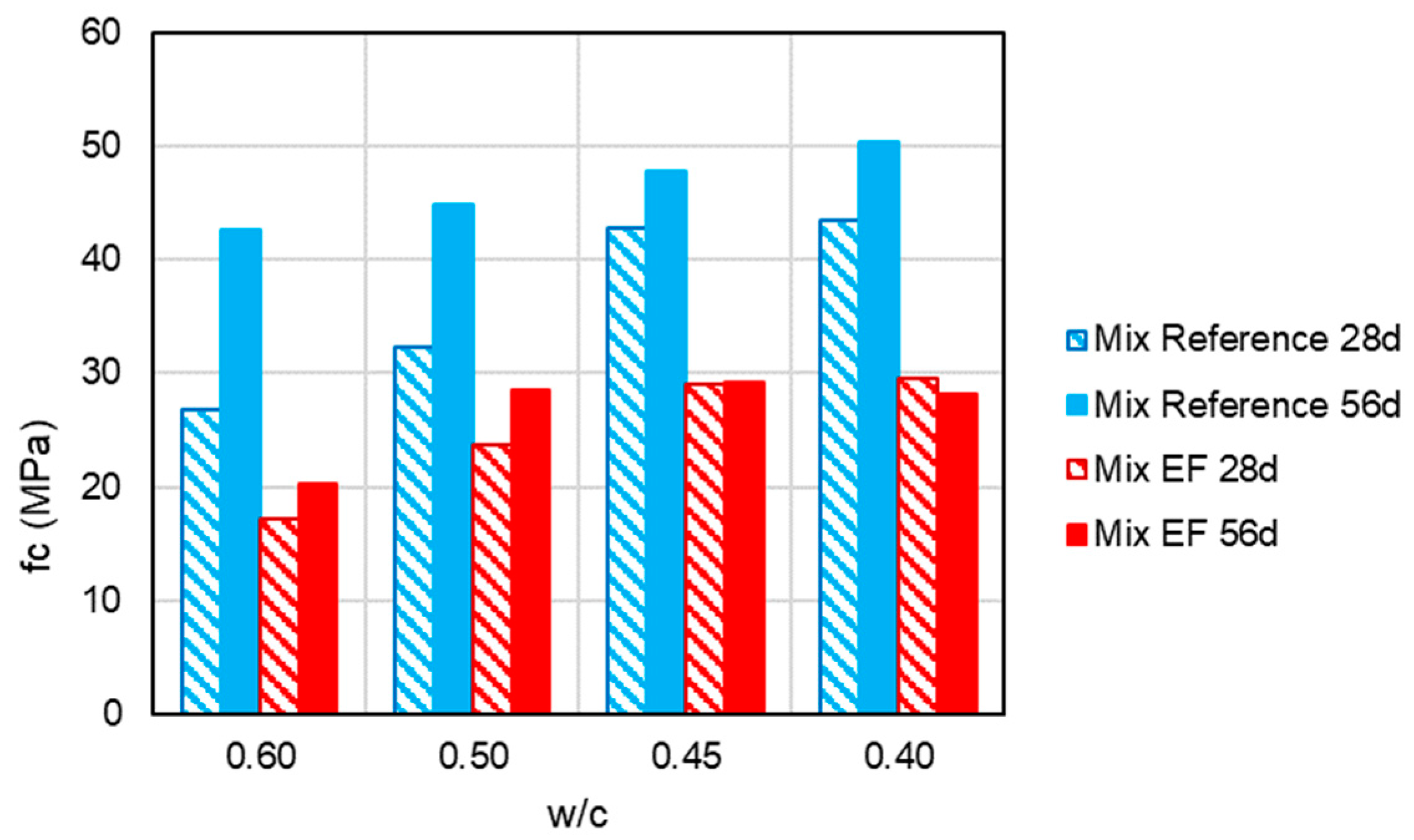

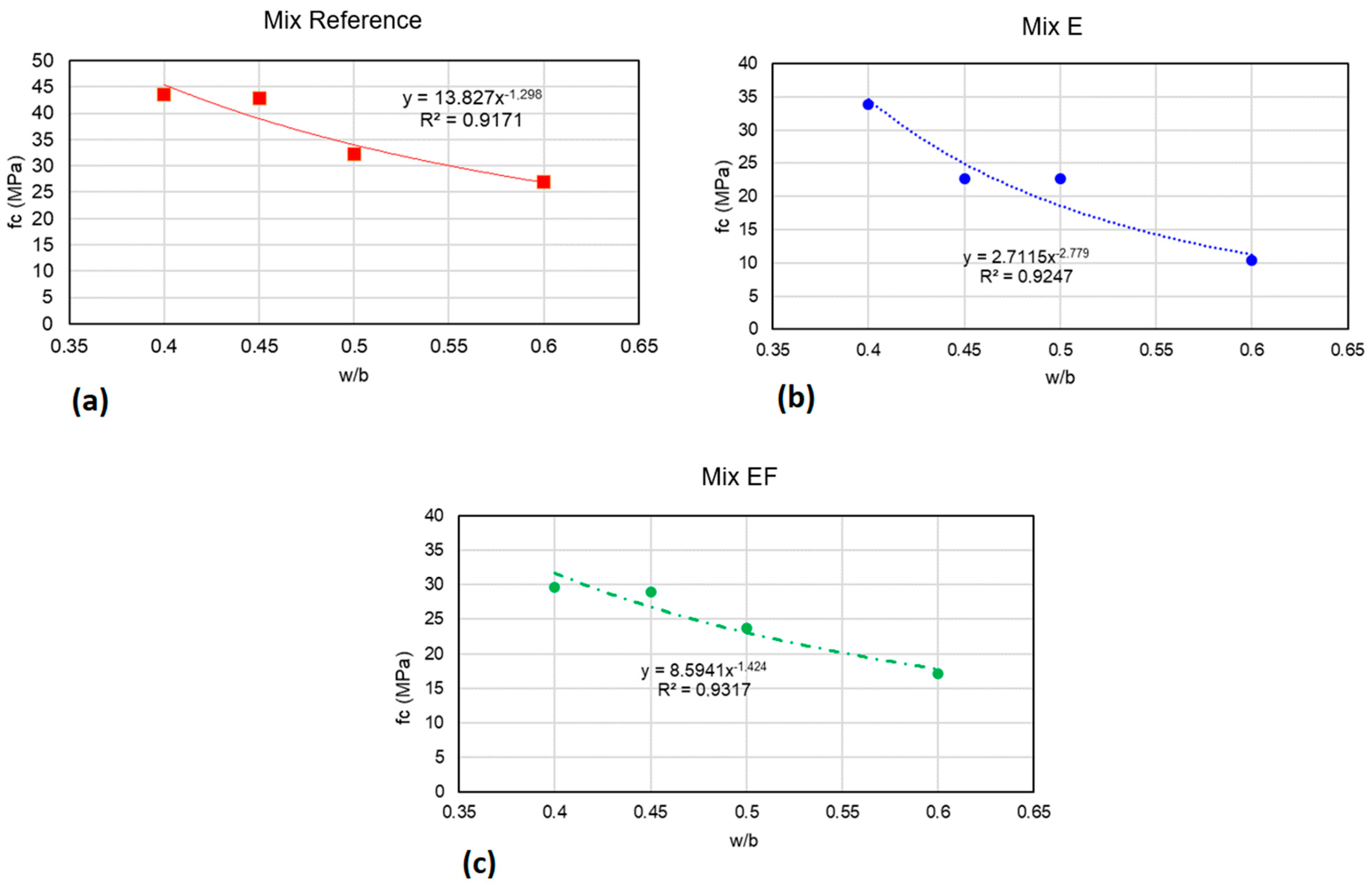

3.1. SCM-Mortars and SAI Values

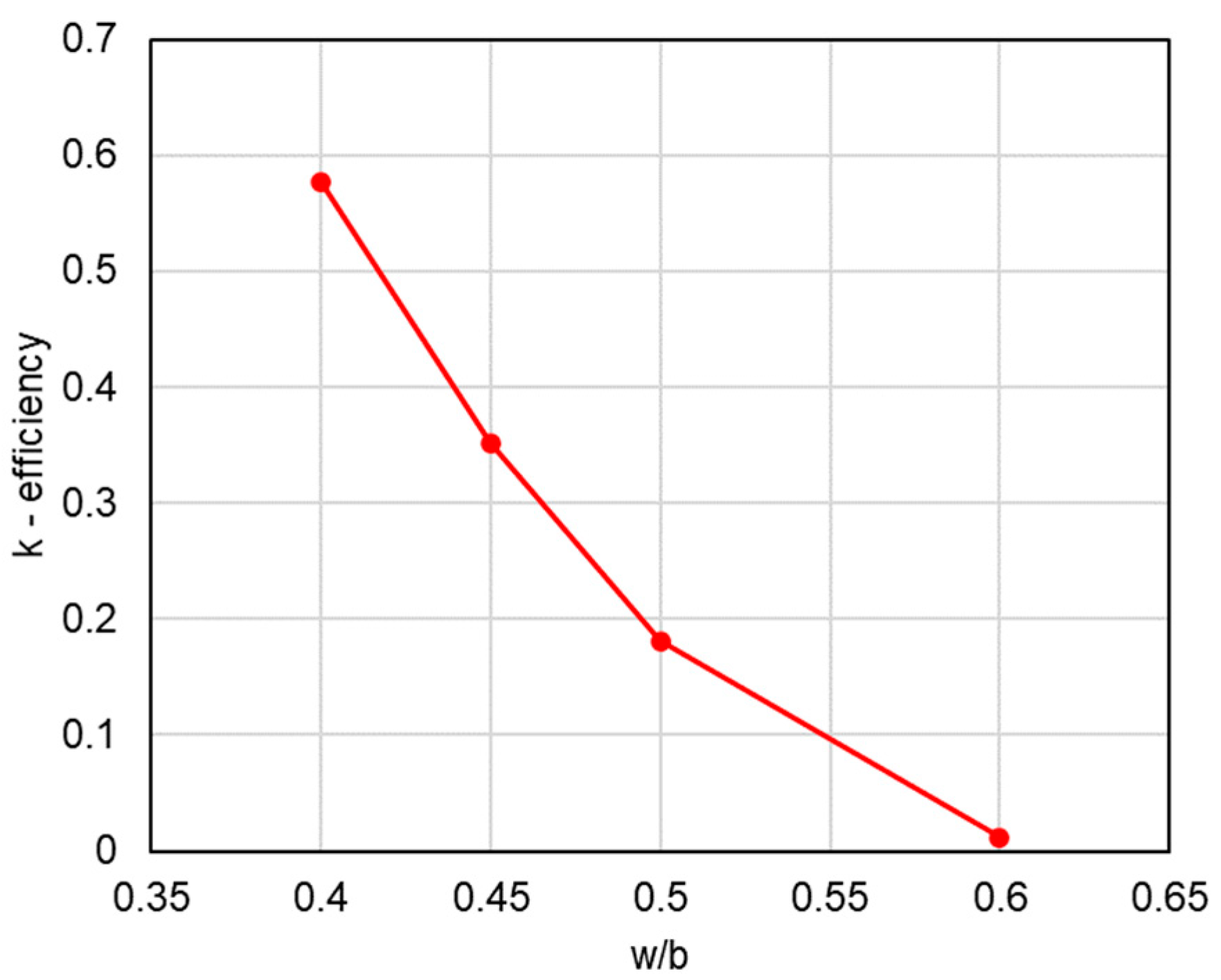

3.2. k-Value of MSWI BA Mortars

3.3. Conductivity Test

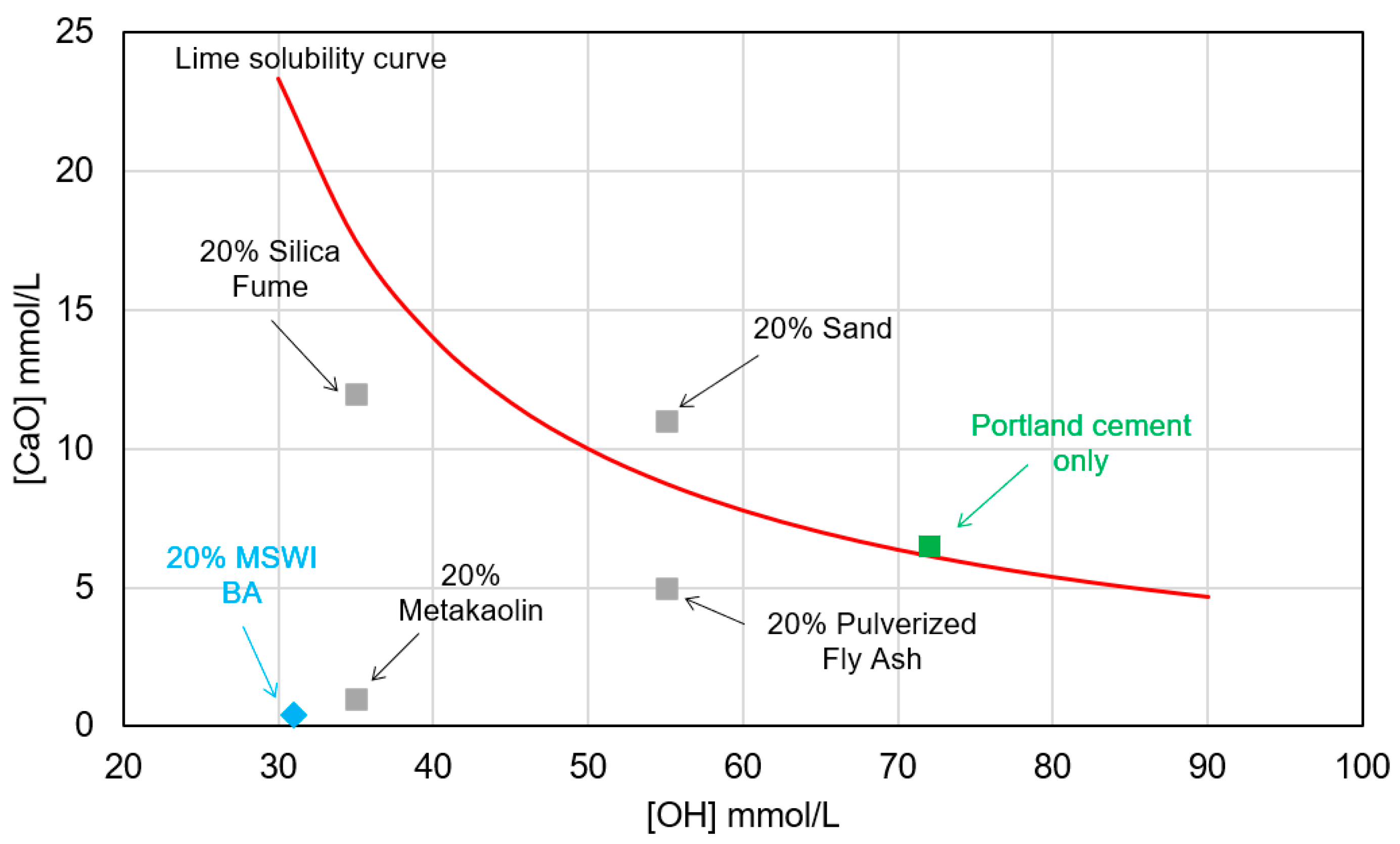

3.4. Frattini Test

3.5. Setting Times and Mechanical Properties of Cement Pastes

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ASTM C125-20. Standard Terminology Relating to Concrete and Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2020.

- Uzal, B.; Turanli, L.; Mehta, P.K. High-volume natural pozzolan concrete for structural applications. ACI Mater. J. 2007, 104, 535. [Google Scholar]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Influence of pozzolan from various by-product materials on mechanical properties of high-strength concrete. Constr. Build. Mater. 2007, 21, 1589–1598. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Alqedra, M.A.; Mo, K.H.; Sumesh, M. Evaluation of industrial by-products as sustainable pozzolanic materials in recycled aggregate concrete. Sustainability 2017, 9, 767. [Google Scholar] [CrossRef] [Green Version]

- Siddique, R.; Khan, M.I. Supplementary Cementing Materials; Springer Science Business Media: Berlin, Germany, 2011. [Google Scholar]

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and carbon emissions. Mater. Struct. 2014, 47, 1055–1065. [Google Scholar] [CrossRef]

- Cheriaf, M.; Rocha, J.C.; Pera, J. Pozzolanic properties of pulverized coal combustion bottom ash. Cem. Concr. Res. 1999, 29, 1387–1391. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rattanasak, U.; Jaturapitakkul, C. Utilization of fly ash blends from pulverized coal and fluidized bed combustions in geopolymeric materials. Cem. Concr. Compos. 2011, 33, 55–60. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.M.; Kwon, S.J.; Myung, N.V.; Singh, J.K.; Lee, H.S.; Mandal, S. Evaluation of strength development in concrete with ground granulated blast furnace slag using apparent activation energy. Materials 2020, 13, 442. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, Z.; Khayat, K.H.; Shi, C. Changes in rheology and mechanical properties of ultra-high performance concrete with silica fume content. Cem. Concr. Res. 2019, 123, 105786. [Google Scholar] [CrossRef]

- Pellegrino, C.; Faleschini, F.; Meyer, C. Recycled materials in concrete. In Developments in the Formulation and Reinforcement of Concrete; Woodhead Publishing: Sawston, UK, 2019; pp. 19–54. [Google Scholar]

- Silva, K.D.C.; Silva, G.C.; Natalli, J.F.; Mendes, J.C.; Silva, G.J.B.; Peixoto, R.A.F. Rock wool waste as supplementary cementitious material for portland cement-based composites. ACI Mater. J. 2018, 115, 653–661. [Google Scholar] [CrossRef]

- Da Silva Magalhães, M.; Faleschini, F.; Pellegrino, C.; Brunelli, K. Cementing efficiency of electric arc furnace dust in mortars. Constr. Build. Mater. 2017, 157, 141–150. [Google Scholar] [CrossRef]

- Parron-Rubio, M.E.; Perez-Garcia, F.; Gonzalez-Herrera, A.; Oliveira, M.J.; Rubio-Cintas, M.D. Slag substitution as a cementing material in concrete: Mechanical, physical and environmental properties. Materials 2019, 12, 2845. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Papayianni, I.; Anastasiou, E. Effect of granulometry on cementitious properties of ladle furnace slag. Cem. Concr. Compos. 2012, 34, 400–407. [Google Scholar] [CrossRef]

- Manso, J.M.; Rodriguez, Á.; Aragón, Á.; Gonzalez, J.J. The durability of masonry mortars made with ladle furnace slag. Constr. Build. Mater. 2011, 25, 3508–3519. [Google Scholar] [CrossRef]

- Anastasiou, E.K. Effect of high calcium fly ash, ladle furnace slag, and limestone filler on packing density, consistency, and strength of cement pastes. Materials 2021, 14, 301. [Google Scholar] [CrossRef] [PubMed]

- Santamaria, A.; Ortega-Lopez, V.; Skaf, M.; García, V.; Gaitero, J.J.; San-José, J.T.; González, J.J. Ladle furnace slag as cement replacement in mortar mixes. In Proceedings of the Fifth International Conference on Sustainable Construction Materials and Technologies, Kingston University, London, UK, 14–17 July 2019; pp. 14–17. [Google Scholar]

- Bignozzi, M.C.; Saccani, A.; Barbieri, L.; Lancellotti, I. Glass waste as supplementary cementing materials: The effects of glass chemical composition. Cem. Concr. Compos. 2015, 55, 45–52. [Google Scholar] [CrossRef]

- Faleschini, F.; Zanini, M.A.; Brunelli, K.; Pellegrino, C. Valorization of co-combustion fly ash in concrete production. Mater. Des. 2015, 85, 687–694. [Google Scholar] [CrossRef]

- Tang, P.; Chen, W.; Xuan, D.; Zuo, Y.; Poon, C.S. Investigation of cementitious properties of different constituents in municipal solid waste incineration bottom ash as supplementary cementitious materials. J. Clean. Prod. 2020, 258, 120675. [Google Scholar] [CrossRef]

- Ribeiro, D.V.; Morelli, M.R. Effect of calcination temperature on the pozzolanic activity of Brazilian sugar cane bagasse ash (SCBA). Mater. Res. 2014, 17, 974–981. [Google Scholar] [CrossRef] [Green Version]

- Antiohos, S.K.; Papadakis, V.G.; Tsimas, S. Rice husk ash (RHA) effectiveness in cement and concrete as a function of reactive silica and fineness. Cem. Concr. Res. 2014, 61, 20–27. [Google Scholar] [CrossRef]

- Cosentino, I.; Restuccia, L.; Ferro, G.A.; Tulliani, J.M. Type of materials, pyrolysis conditions, carbon content and size dimensions: The parameters that influence the mechanical properties of biochar cement-based composites. Theor. Appl. Fract. Mech. 2019, 103, 102261. [Google Scholar] [CrossRef]

- Chimenos, J.M.; Fernandez, A.I.; Nadal, R.; Espiell, F. Short-term natural weathering of MSWI bottom ash. J. Hazard. Mater. 2000, 79, 287–299. [Google Scholar] [CrossRef]

- Pivato, A.; Pasetto, M.; Faleschini, F.; Beggio, G.; Hennebert, P. Research to industry and industry to research. Detritus 2019, 8, I–III. [Google Scholar]

- British Standards Institution. EN 450-1:2012. Fly Ash for Concrete. Definition, Specifications and Conformity Criteria; CEN: Brussels, Belgium, 2012. [Google Scholar]

- ASTM C618. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Papadakis, V.G.; Tsimas, S. Supplementary cementing materials in concrete: Part I: Efficiency and design. Cem. Concr. Res. 2002, 32, 1525–1532. [Google Scholar] [CrossRef]

- British Standards Institution. EN 196-5:2011. Methods of Testing Cement. Pozzolanicity Test for Pozzolanic Cement; CEN: Brussels, Belgium, 2011. [Google Scholar]

- ASTM C311/C311M-18. Standard Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland-Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Luxan, M.D.; Madruga, F.; Saavedra, J. Rapid evaluation of pozzolanic activity of natural products by conductivity measurement. Cem. Concr. Res. 1989, 19, 63–68. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Antiohos, S.; Tsimas, S. Supplementary cementing materials in concrete: Part II: A fundamental estimation of the efficiency factor. Cem. Concr. Res. 2002, 32, 1533–1538. [Google Scholar] [CrossRef]

- Donatello, S.; Tyrer, M.; Cheeseman, C.R. Comparison of test methods to assess pozzolanic activity. Cem. Concr. Compos. 2010, 32, 121–127. [Google Scholar] [CrossRef] [Green Version]

- Bumanis, G.; Vitola, L.; Stipniece, L.; Locs, J.; Korjakins, A.; Bajare, D. Evaluation of Industrial by-products as pozzolans: A road map for use in concrete production. Case Stud. Constr. Mater. 2020, 13, e00424. [Google Scholar] [CrossRef]

- Thorstensen, R.T.; Fidjestol, P. Inconsistencies in the pozzolanic strength activity index (SAI) for silica fume according to EN and ASTM. Mater. Struct. 2015, 48, 3979–3990. [Google Scholar] [CrossRef] [Green Version]

- Inkaew, K.; Saffarzadeh, A.; Shimaoka, T. Modeling the formation of the quench product in municipal solid waste incineration (MSWI) bottom ash. Waste Manag. 2016, 52, 159–168. [Google Scholar] [CrossRef]

- Schollbach, K.; Alam, Q.; Caprai, V.; Florea, M.V.A.; Van der Laan, S.R.; Van Hoek, C.J.G.; Brouwers, H.J.H. Combined characterization of the MSWI bottom ash. In Proceedings of the Thirty-Eighth International Conference on Cement Microscopy, Lyon, France, 17–21 April 2016; pp. 74–84. [Google Scholar]

- Zhang, T.; Zhao, Z. Optimal use of MSWI bottom ash in concrete. Int. J. Concr. Struct. Mater. 2014, 8, 173–182. [Google Scholar] [CrossRef] [Green Version]

- Caprai, V.; Gauvin, F.; Schollbach, K.; Brouwers, H.J.H. MSWI bottom ash as binder replacement in wood cement composites. Constr. Build. Mater. 2019, 196, 672–680. [Google Scholar] [CrossRef]

- Pivato, A. Analysis of chemical and ecotoxicological data from leaching tests of inert wastes performed for the assessment of end of waste status. In Proceedings of the SIDISA 2021—XI International Symposium on Environmental Engineering, Turin, Italy, 29 June–2 July 2021. [Google Scholar]

- Lancellotti, I.; Ponzoni, C.; Bignozzi, M.C.; Barbieri, L.; Leonelli, C. Incinerator bottom ash and ladle slag for geopolymers preparation. Waste Biomass Valorization 2014, 5, 393–401. [Google Scholar] [CrossRef]

- Tang, P.; Florea, M.V.A.; Spiesz, P.; Brouwers, H.J.H. Application of thermally activated municipal solid waste incineration (MSWI) bottom ash fines as binder substitute. Cem. Concr. Compos. 2016, 70, 194–205. [Google Scholar] [CrossRef]

- Qiao, X.C.; Tyrer, M.; Poon, C.S.; Cheeseman, C.R. Novel cementitious materials produced from incinerator bottom ash. Resour. Conserv. Recycl. 2008, 52, 496–510. [Google Scholar] [CrossRef]

- Mazouzi, W.; Kacimi, L.; Cyr, M.; Clastres, P. Properties of low temperature belite cements made from aluminosilicate wastes by hydrothermal method. Cem. Concr. Compos. 2014, 53, 170–177. [Google Scholar] [CrossRef]

- He, Z.; Li, Y. The influence of mayenite employed as a functional component on hydration properties of ordinary Portland cement. Materials 2018, 11, 1958. [Google Scholar] [CrossRef] [Green Version]

- Adesanya, E.; Sreenivasan, H.; Kantola, A.M.; Telkki, V.V.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Ladle slag cement—Characterization of hydration and conversion. Constr. Build. Mater. 2018, 193, 128–134. [Google Scholar] [CrossRef]

- Babu, K.G.; Rao, G.S.N. Efficiency of fly ash in concrete with age. Cem. Concr. Res. 1996, 26, 465–474. [Google Scholar] [CrossRef]

- Schiessl, P.; Hardtl, R. Efficiency of Fly Ash in Concrete Evaluation of Ibac Test Results. In Technical Report of Institut für Bauforschung; RWTH Aachen University: Aachen, Germany, 1991. [Google Scholar]

- Baki, V.A.; Nayır, S.; Erdoğdu, Ş.; Ustabaş, İ. Determination of the pozzolanic activities of trachyte and rhyolite and comparison of the test methods implemented. Int. J. Civil. Eng. 2020, 18, 1053–1066. [Google Scholar] [CrossRef]

- Hashemi, S.S.G.; Mahmud, H.B.; Djobo, J.N.Y.; Tan, C.G.; Ang, B.C.; Ranjbar, N. Microstructural characterization and mechanical properties of bottom ash mortar. J. Clean. Prod. 2018, 170, 797–804. [Google Scholar] [CrossRef]

- Sata, V.; Tangpagasit, J.; Jaturapitakkul, C.; Chindaprasirt, P. Effect of W/B ratios on pozzolanic reaction of biomass ashes in Portland cement matrix. Cem. Concr. Compos. 2012, 34, 94–100. [Google Scholar] [CrossRef]

- Velázquez, S.; Monzó, J.M.; Borrachero, M.V.; Payá, J. Assessment of the pozzolanic activity of a spent catalyst by conductivity measurement of aqueous suspensions with calcium hydroxide. Materials 2014, 7, 2561–2576. [Google Scholar] [CrossRef] [Green Version]

- Sriwong, C.; Phrompet, C.; Tuichai, W.; Karaphun, A.; Kurosaki, K.; Ruttanapun, C. Synthesis, microstructure, multifunctional properties of mayenite Ca 12 Al 14 O 33 (C12A7) cement and graphene oxide (GO) composites. Sci. Rep. 2020, 10, 1–19. [Google Scholar]

- Qiao, X.C.; Ng, B.R.; Tyrer, M.; Poon, C.S.; Cheeseman, C.R. Production of lightweight concrete using incinerator bottom ash. Constr. Build. Mater. 2008, 22, 473–480. [Google Scholar] [CrossRef]

- Manso, J.M.; Ortega-López, V.; Polanco, J.A.; Setién, J. The use of ladle furnace slag in soil stabilization. Constr. Build. Mater. 2013, 40, 126–134. [Google Scholar] [CrossRef]

- Skaf, M.; Ortega-López, V.; Fuente-Alonso, J.A.; Santamaría, A.; Manso, J.M. Ladle furnace slag in asphalt mixes. Constr. Build. Mater. 2016, 122, 488–495. [Google Scholar] [CrossRef] [Green Version]

- Henríquez, P.A.; Aponte, D.; Ibáñez-Insa, J.; Bizinotto, M.B. Ladle furnace slag as a partial replacement of Portland cement. Constr. Build. Mater. 2021, 289, 123106. [Google Scholar] [CrossRef]

- Adolfsson, D.; Robinson, R.; Engström, F.; Björkman, B. Influence of mineralogy on the hydraulic properties of ladle slag. Cem. Concr. Res. 2011, 41, 865–871. [Google Scholar] [CrossRef]

- Wang, Y.; Ni, W.; Suraneni, P. Use of ladle furnace slag and other industrial by-products to encapsulate chloride in municipal solid waste incineration fly ash. Materials 2019, 12, 925. [Google Scholar] [CrossRef] [Green Version]

- Le Saoût, G.; Lothenbach, B.; Hori, A.; Higuchi, T.; Winnefeld, F. Hydration of Portland cement with additions of calcium sulfoaluminates. Cem. Concr. Res. 2013, 43, 81–94. [Google Scholar] [CrossRef]

| MgO (%) | Al2O3 (%) | SiO2 (%) | P2O5 (%) | SO3 (%) | K2O (%) | CaO (%) | TiO2 (%) | Cr2O3 (%) | MnO (%) | Fe2O3 (%) | CuO (%) | ZnO (%) | PbO (%) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MSWI BA | 8.13 | 12.55 | 21.76 | 2.56 | 4.80 | 0.91 | 36.90 | 1.31 | 0.57 | 0.39 | 8.09 | 0.59 | 1.24 | 0.16 |

| Cement | 2.38 | 4.79 | 19.71 | 0.10 | 2.95 | 1.03 | 65.46 | 0.21 | - | 0.04 | 3.28 | - | - | <0.3 |

| Water | Cement | Water/Binder | Natural Sand | MSWI BA (0–4 mm) | MSWI BA (0–1 mm) | Plasticizer | |

|---|---|---|---|---|---|---|---|

| Mix Ref 1 | 315 | 525 | 0.6 | 1575 | - | - | - |

| Mix E1 | 315 | 420 | 0.6 | 1575 | 105 | - | - |

| Mix EF1 | 315 | 420 | 0.6 | 1575 | - | 105 | - |

| Mix Ref 2 | 266.7 | 533 | 0.5 | 1600 | - | - | 5.33 |

| Mix E2 | 266.7 | 426.7 | 0.5 | 1600 | 106.67 | - | 5.33 |

| Mix EF2 | 266.7 | 426.7 | 0.5 | 1600 | - | 106.67 | 5.33 |

| Mix Ref 3 | 240 | 533 | 0.45 | 1600 | - | 5.33 | |

| Mix E3 | 240 | 426.7 | 0.45 | 1600 | 106.67 | - | 5.33 |

| Mix EF3 | 240 | 426.7 | 0.45 | 1600 | - | 106.67 | 5.33 |

| Mix Ref 4 | 220 | 550 | 0.4 | 1650 | - | - | 5.50 |

| Mix E4 | 220 | 440 | 0.4 | 1650 | 110 | - | 5.50 |

| Mix EF4 | 220 | 440 | 0.4 | 1650 | - | 110 | 5.50 |

| 28 Days | 56 Days | |||||

|---|---|---|---|---|---|---|

| ρ (kg/m3) | fc (MPa) | fcf (MPa) | ρ (kg/m3) | fc (MPa) | fcf (MPa) | |

| Mix Ref 1 (ave.) | 2174 | 26.87 | 5.55 | 2250 | 42.62 | 7.50 |

| (st. dev.) | 9 | 0.91 | 0.23 | 8 | 1.34 | 0.19 |

| Mix E1 (ave.) | 2052 | 10.33 | 3.37 | - | - | - |

| (st. dev.) | 39 | 0.38 | 0.38 | - | - | - |

| Mix EF1 (ave.) | 2046 | 17.12 | 5.55 | 2066 | 20.28 | 5.09 |

| (st. dev.) | 21 | 0.16 | 0.46 | 22 | 0.83 | 0.76 |

| Mix Ref 2 (ave.) | 2195 | 32.29 | 6.78 | 2214 | 44.89 | 8.34 |

| (st. dev.) | 20 | 1.45 | 0.05 | 4 | 0.70 | 0.23 |

| Mix E2 (ave.) | 2049 | 22.74 | 4.71 | - | - | - |

| (st. dev.) | 9 | 0.94 | 0.13 | - | - | - |

| Mix EF2 (ave.) | 2082 | 23.70 | 6.05 | 2137 | 28.48 | 5.71 |

| (st. dev.) | 6 | 0.62 | 0.13 | 5 | 2.56 | 0.27 |

| Mix Ref 3 (ave.) | 2193 | 42.86 | 7.94 | 2285 | 47.78 | 8.65 |

| (st. dev.) | 31 | 0.71 | 0.19 | 26 | 0.64 | 0.35 |

| Mix E3 (ave.) | 1990 | 22.66 | 5.27 | - | - | - |

| (st. dev.) | 24 | 1.14 | 0.21 | - | - | - |

| Mix EF3 (ave.) | 2175 | 29.00 | 6.91 | 2160 | 29.12 | 6.16 |

| (st. dev.) | 28 | 1.72 | 0.24 | 27 | 2.95 | 0.12 |

| Mix Ref 4 (ave.) | 2240 | 43.50 | 7.38 | 2208 | 50.38 | 8.85 |

| (st. dev.) | 30 | 2.45 | 0.70 | 31 | 1.82 | 4.86 |

| Mix E4 (ave.) | 2164 | 33.86 | 6.73 | - | - | - |

| (st. dev.) | 28 | 0.71 | 0.08 | - | - | - |

| Mix EF4 (ave.) | 2133 | 29.58 | 6.81 | 2105 | 28.22 | 5.14 |

| (st. dev.) | 11 | 0.42 | 0.33 | 27 | 0.33 | 0.21 |

| 28 Days | 56 Days | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mix E1 | Mix EF1 | Mix E2 | Mix EF2 | Mix E3 | Mix EF3 | Mix E4 | Mix EF4 | Mix EF1 | Mix EF2 | Mix EF3 | Mix EF4 | |

| SAI,c | 0.38 | 0.63 | 0.70 | 0.73 | 0.53 | 0.68 | 0.78 | 0.68 | 0.48 | 0.63 | 0.61 | 0.56 |

| SAI,f | 0.64 | 1.00 | 0.69 | 0.89 | 0.66 | 0.87 | 0.91 | 0.92 | 0.68 | 0.68 | 0.71 | 0.58 |

| Initial Setting (min) | Final Setting (min) | |

|---|---|---|

| Reference | 205 | 400 |

| MSWI BA 5%w | 245 | 395 |

| MSWI BA 10%w | 285 | 360 |

| MSWI BA 15%w | 255 | 345 |

| MSWI BA 20%w | 205 | 325 |

| MSWI BA 25%w | 135 | 255 |

| MSWI BA 50%w | 65 | 155 |

| Compressive Strength fc (MPa) | |

|---|---|

| Reference | 48.71 ± 0.60 |

| MSWI BA 5%w | 49.21 ± 1.33 |

| MSWI BA 10%w | 49.00 ± 1.61 |

| MSWI BA 15%w | 38.14 ± 0.36 |

| MSWI BA 20%w | 36.08 ± 1.03 |

| MSWI BA 25%w | 34.89 ± 1.05 |

| MSWI BA 50%w | 23.62 ± 1.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faleschini, F.; Toska, K.; Zanini, M.A.; Andreose, F.; Settimi, A.G.; Brunelli, K.; Pellegrino, C. Assessment of a Municipal Solid Waste Incinerator Bottom Ash as a Candidate Pozzolanic Material: Comparison of Test Methods. Sustainability 2021, 13, 8998. https://doi.org/10.3390/su13168998

Faleschini F, Toska K, Zanini MA, Andreose F, Settimi AG, Brunelli K, Pellegrino C. Assessment of a Municipal Solid Waste Incinerator Bottom Ash as a Candidate Pozzolanic Material: Comparison of Test Methods. Sustainability. 2021; 13(16):8998. https://doi.org/10.3390/su13168998

Chicago/Turabian StyleFaleschini, Flora, Klajdi Toska, Mariano Angelo Zanini, Filippo Andreose, Alessio Giorgio Settimi, Katya Brunelli, and Carlo Pellegrino. 2021. "Assessment of a Municipal Solid Waste Incinerator Bottom Ash as a Candidate Pozzolanic Material: Comparison of Test Methods" Sustainability 13, no. 16: 8998. https://doi.org/10.3390/su13168998

APA StyleFaleschini, F., Toska, K., Zanini, M. A., Andreose, F., Settimi, A. G., Brunelli, K., & Pellegrino, C. (2021). Assessment of a Municipal Solid Waste Incinerator Bottom Ash as a Candidate Pozzolanic Material: Comparison of Test Methods. Sustainability, 13(16), 8998. https://doi.org/10.3390/su13168998