A Factorial Ecological-Extended Physical Input-Output Model for Identifying Optimal Urban Solid Waste Path in Fujian Province, China

Abstract

:1. Introduction

1.1. Importance and Motivation

1.2. Literature Review

1.3. Contribution and Novelty

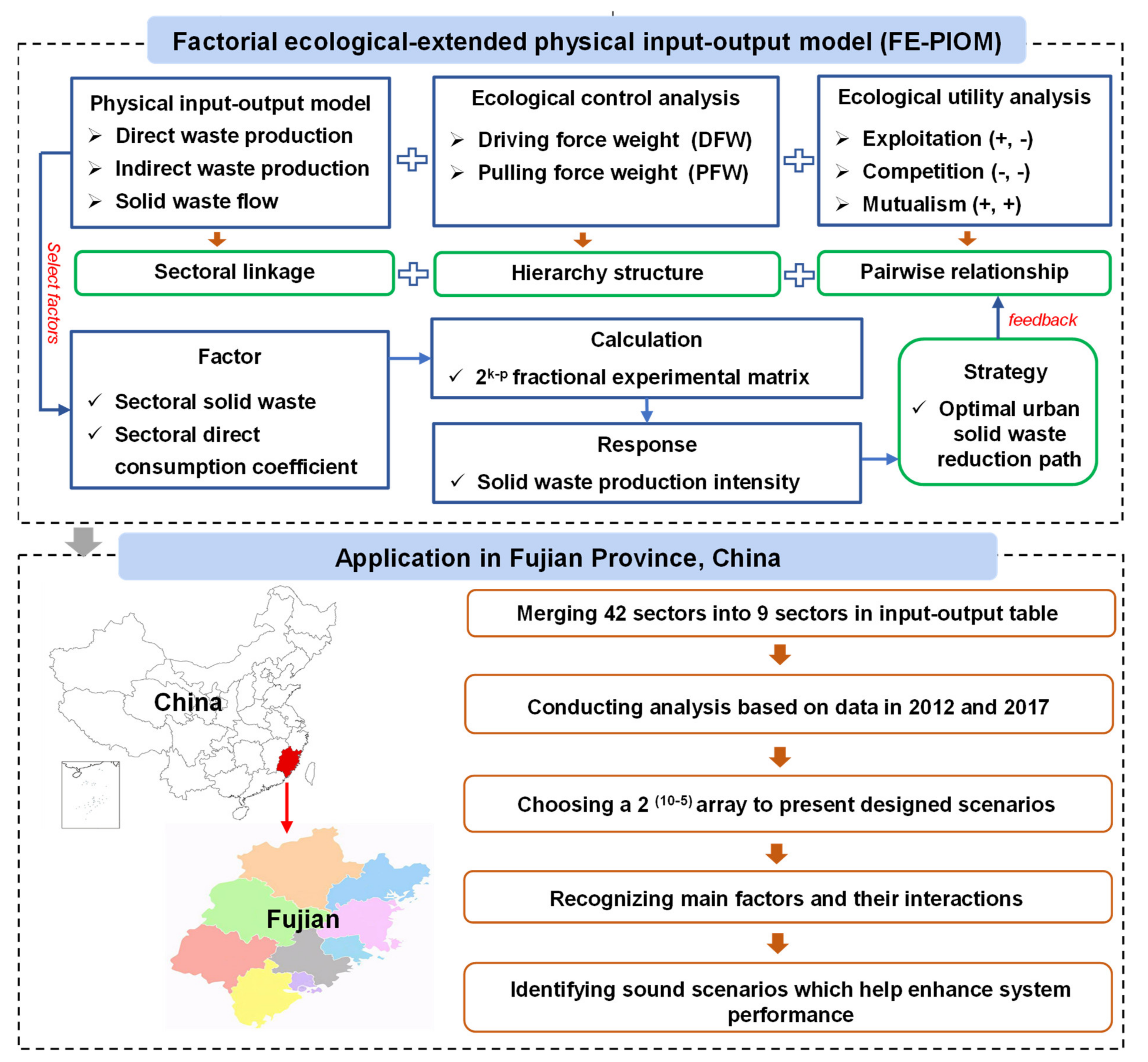

2. Materials and Methods

2.1. Physical Input-Output Model

2.2. Ecological Network Analysis

2.3. Fractional Factorial Analysis

3. Case Study

3.1. Study Area

3.2. Data Collection and Analysis

4. Results and Discussion

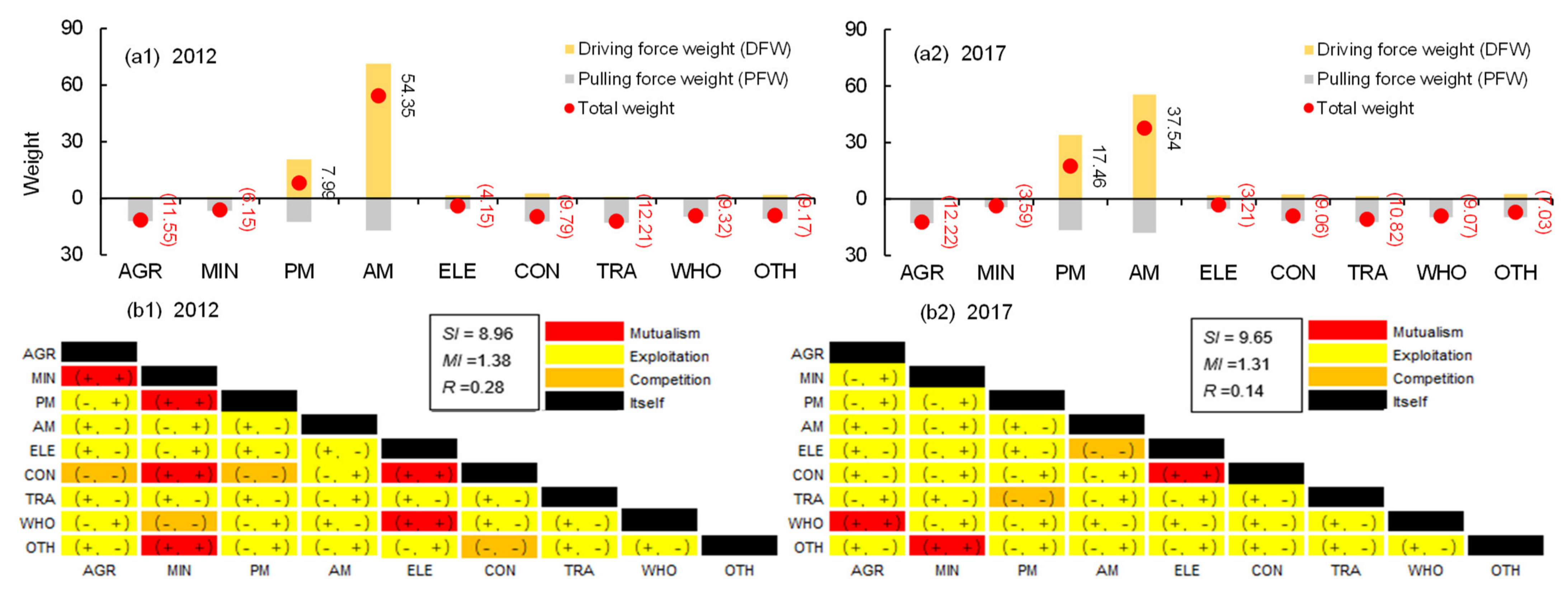

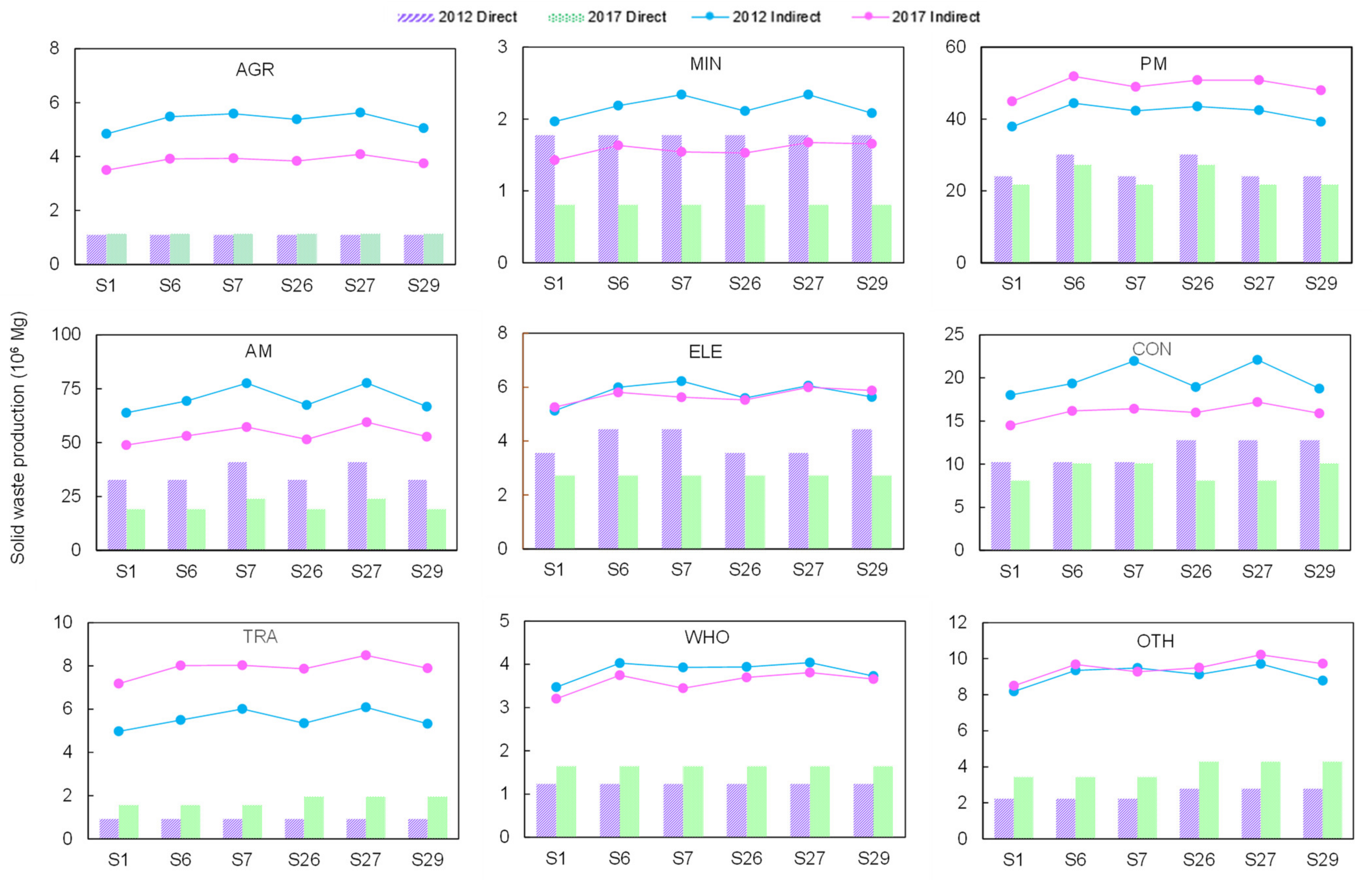

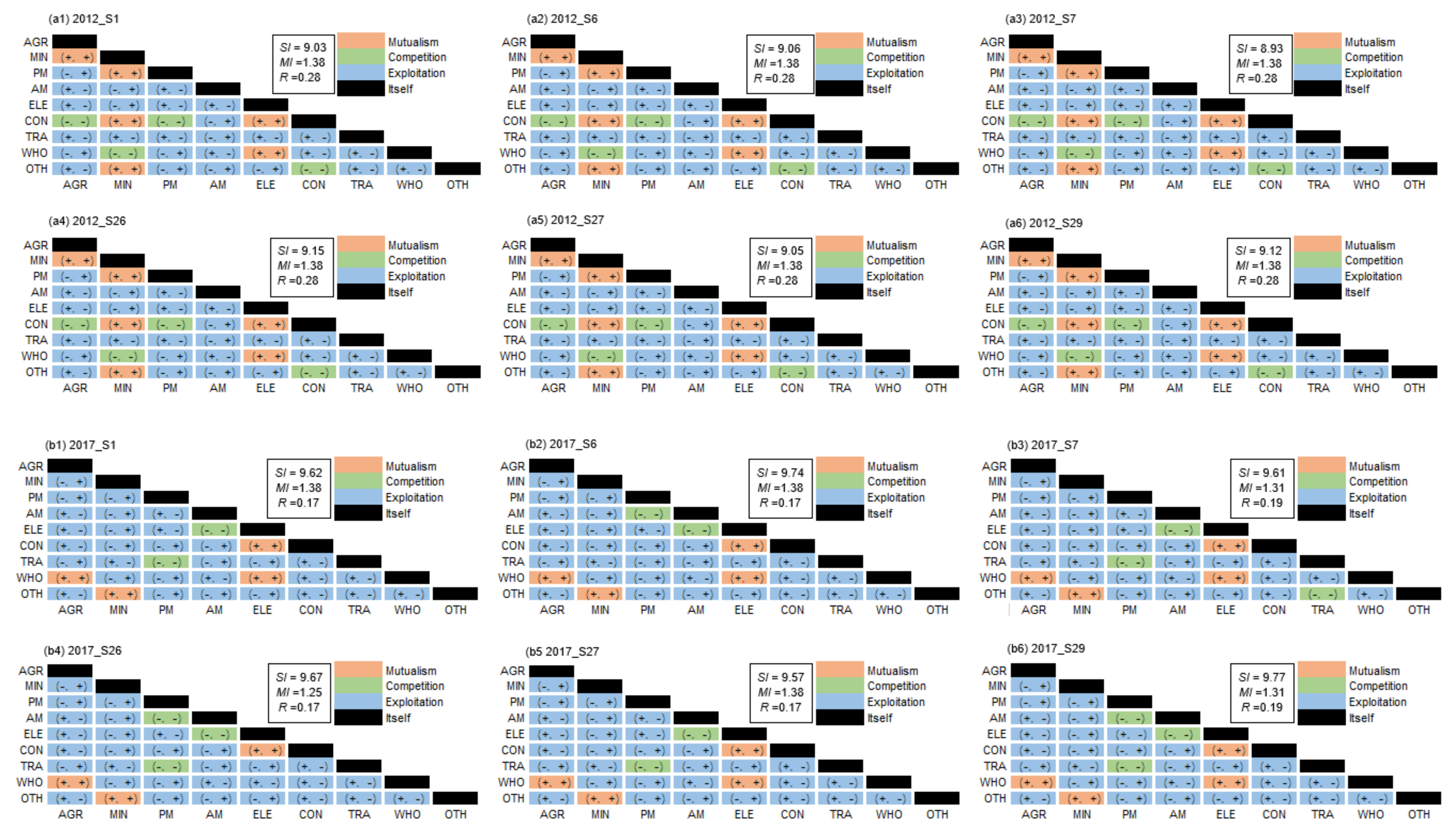

4.1. Status in 2012 and 2017

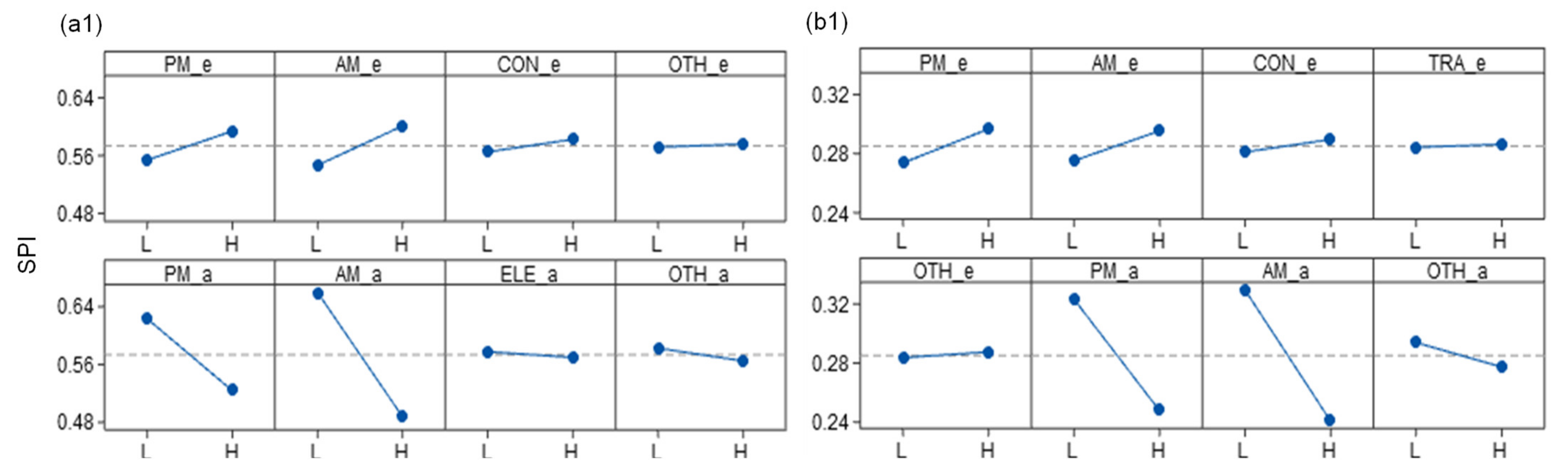

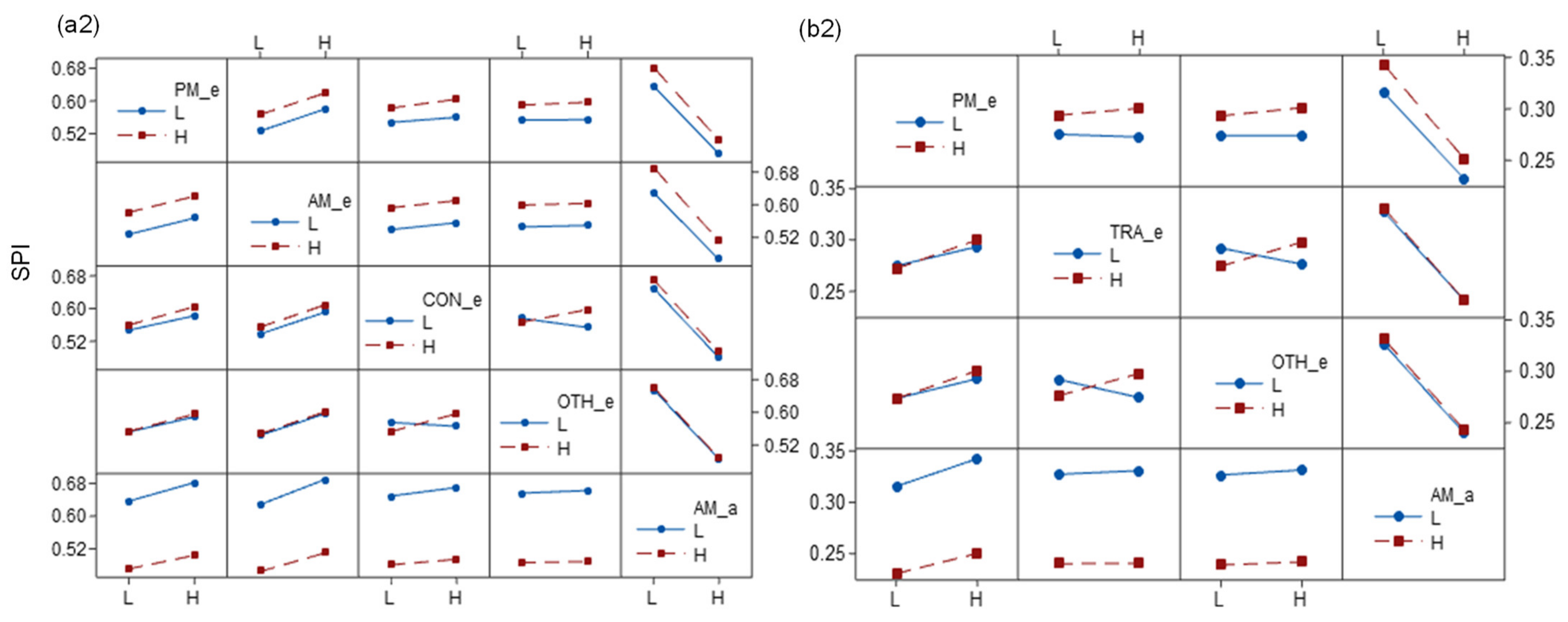

4.2. Identification of Key Factors

4.3. Adjustment of USWS

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Category | Description | References |

|---|---|---|

| Physical input-output model | Investigate the impacts of four categories of solid waste recycling on urban solid waste metabolism to support sustainable development. | Liang and Zhang |

| Estimate the regional energy and environmental benefits of solid waste utili-zation for energy recovery. | Wang et al. | |

| Rank economic sectors based on solid waste productions and pointed out potential areas to pursue innovations in material use. | Meyer et al. | |

| Quantify different types of solid waste production recycling over the period 2005–2017 in China. | Huang et al. | |

| Ecological network analysis | Analyze the directions, locations, and drivers of carbon flows resulting from global trade. | Zhang et al. |

| Evaluate water-related impacts of energy-related decisions. | Wang et al. | |

| Estimate the metabolic status of energy system in China. | Wang | |

| Investigate integral carbon emissions at city scale. | Zhang et al. | |

| Fractional factorial analysis | Experimental designs for detecting response sensitivity in environmental fields. | Jiang et al. |

| Gerrewey et al. | ||

| Li et al. |

Appendix B

| Scenario | PM_e | AM_e | ELE_e (in 2012) | CON_e (in 2012) | OTH_e | PM_a | AM_a | ELE_a (in 2012) | CON_a (in 2012) | OTH_a |

|---|---|---|---|---|---|---|---|---|---|---|

| CON_e (in 2017) | TRA_e (in 2017) | CON_a (in 2017) | TRA_a (in 2017) | |||||||

| 1 | L | L | L | L | L | H | H | H | H | H |

| 2 | H | L | L | L | L | L | L | L | L | H |

| 3 | L | H | L | L | L | L | L | L | H | L |

| 4 | H | H | L | L | L | H | H | H | L | L |

| 5 | L | L | H | L | L | L | L | H | L | L |

| 6 | H | L | H | L | L | H | H | L | H | L |

| 7 | L | H | H | L | L | H | H | L | L | H |

| 8 | H | H | H | L | L | L | L | H | H | H |

| 9 | L | L | L | H | L | L | H | L | L | L |

| 10 | H | L | L | H | L | H | L | H | H | L |

| 11 | L | H | L | H | L | H | L | H | L | H |

| 12 | H | H | L | H | L | L | H | L | H | H |

| 13 | L | L | H | H | L | H | L | L | H | H |

| 14 | H | L | H | H | L | L | H | H | L | H |

| 15 | L | H | H | H | L | L | H | H | H | L |

| 16 | H | H | H | H | L | H | L | L | L | L |

| 17 | L | L | L | L | H | H | L | L | L | L |

| 18 | H | L | L | L | H | L | H | H | H | L |

| 19 | L | H | L | L | H | L | H | H | L | H |

| 20 | H | H | L | L | H | H | L | L | H | H |

| 21 | L | L | H | L | H | L | H | L | H | H |

| 22 | H | L | H | L | H | H | L | H | L | H |

| 23 | L | H | H | L | H | H | L | H | H | L |

| 24 | H | H | H | L | H | L | H | L | L | L |

| 25 | L | L | L | H | H | L | L | H | H | H |

| 26 | H | L | L | H | H | H | H | L | L | H |

| 27 | L | H | L | H | H | H | H | L | H | L |

| 28 | H | H | L | H | H | L | L | H | L | L |

| 29 | L | L | H | H | H | H | H | H | L | L |

| 30 | H | L | H | H | H | L | L | L | H | L |

| 31 | L | H | H | H | H | L | L | L | L | H |

| 32 | H | H | H | H | H | H | H | H | H | H |

References

- Batista, M.; Caiado, R.G.G.; Quelhas, O.L.G.; Lima, G.B.A.; Filho, W.L.; Yparraguirre, I.T.R. A framework for sustainable and integrated municipal solid waste management: Barriers and critical factors to developing countries. J. Clean. Prod. 2021, 312, 127516. [Google Scholar] [CrossRef]

- Karagoz, S.; Deveci, M.; Simic, A.; Aydin, N.; Bolukbas, U. A novel intuitionistic fuzzy MCDM-based CODAS approach for locating an authorized dismantling center: A case study of Istanbul. Waste Manag. Res. 2020, 1–13. [Google Scholar] [CrossRef]

- China Statistical Yearbook; National Bureau of Statistics Press: Beijing, China, 2020. (In Chinese)

- Simic, V.; Karagoz, S.; Deveci, M.; Aydin, N. Picture fuzzy extension of the CODAS method for multi-criteria vehicle shredding facility location. Expert Syst. Appl. 2021, 175, 114644. [Google Scholar] [CrossRef]

- Danilina, V.; Grigoriev, A. Information provision in environmental policy design. J. Environ. Inform. 2020, 36, 1–10. [Google Scholar] [CrossRef]

- Xu, X.; Huang, G.; Liu, L.; He, C. A factorial environment-oriented input-output model for diagnosing urban air pollution. J. Clean. Prod. 2019, 237, 117731. [Google Scholar] [CrossRef]

- Xing, L.; Dong, X.; Guan, J.; Qiao, X. Betweenness centrality for similarity weight network and its application to measuring industrial sectors’ pivotability on the global value chain. Phys. A Stat. Mech. Appl. 2018, 516, 19–36. [Google Scholar] [CrossRef]

- Liang, S.; Qu, S.; Xu, M. Betweenness-based method to identify critical transmission sectors for supply chain environmental pressure mitigation. Environ. Sci. Technol. 2016, 50, 1330–1337. [Google Scholar] [CrossRef]

- Leontief, W. Input-Output Economics; Oxford University Press: Oxford, UK, 1986. [Google Scholar]

- Towa, E.; Zeller, V.; Achten, W.M.J. Input-output models and waste management analysis: A critical review. J. Clean. Prod. 2020, 249, 119359. [Google Scholar] [CrossRef]

- Liang, S.; Zhang, T.Z. Comparing urban solid waste recycling from the viewpoint of urban metabolism based on physical input–output model: A case of Suzhou in China. Waste Manag. 2012, 32, 220–225. [Google Scholar] [CrossRef]

- Wang, H.N.; Wang, X.E.; Song, J.N.; Wang, S.; Liu, X.Y. Uncovering regional energy and environmental benefits of urban waste utilization: A physical input-output analysis for a city case. J. Clean. Prod. 2018, 189, 922–932. [Google Scholar] [CrossRef]

- Meyera, D.E.; Li, M.; Ingwersen, W.W. Analyzing economy-scale solid waste generation using the United States environmentally-extended input-output model. Resour. Conserv. Recycl. 2020, 157, 104795. [Google Scholar] [CrossRef]

- Huang, Q.; Chen, G.W.; Wang, Y.F.; Xu, L.X.; Chen, W.Q. Identifying the socioeconomic drivers of solid waste recycling in China for the period 2005–2017. Sci. Total Environ. 2020, 725, 138137. [Google Scholar] [CrossRef]

- Balogun, A.; Quan, S.; Pradhan, B.; Dano, U.; Yekeen, S. An improved flood susceptibility model for assessing the correlation of flood hazard and property prices using geospatial technology and fuzzy-ANP. J. Environ. Inform. 2021, 37, 1–10. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.G.; Hubacek, K.; Tian, X.; Lu, Z.M. Analysis of CO2 transfer processes involved in global trade based on ecological network analysis. Appl. Energy 2019, 233–234, 576–583. [Google Scholar] [CrossRef]

- Wang, S.; Fath, B.; Chen, B. Energy-water nexus under energy mix scenarios using input-output and ecological network analyses. Appl. Energy 2019, 232–234, 827–839. [Google Scholar] [CrossRef]

- Wang, R. Ecological network analysis of China’s energy-related input from the supply side. J. Clean. Prod. 2020, 272, 122796. [Google Scholar] [CrossRef]

- Zheng, H.M.; Li, A.M.; Meng, F.X.; Liu, G.Y.; Hu, Y.C.; Zhang, Y.; Casazza, M. Ecological network analysis of carbon emissions from four Chinese metropoles in multiscale economies. J. Clean. Prod. 2021, 279, 123226. [Google Scholar] [CrossRef]

- Montoya, A.C.V.; Mazareli, R.C.S.; Delforno, T.P.; Centurion, V.B.; Oliveira, V.M.; Silva, E.L.; Varesche, M.B.A. Optimization of key factors affecting hydrogen production from coffee waste using factorial design and metagenomic analysis of the microbial community. Int. J. Hydrog. Energy 2020, 45, 4205–4222. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, T.T.; Shi, Y.Z.; Wendroth, O.; Liu, B.Y. Comparing the performance of an autoregressive state-space approach to the linear regression and artificial neural network for streamflow estimation. J. Environ. Inform. 2021, 37, 1–10. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.P.; Huang, G.H.; Fu, H.Y.; Zhang, J.L.; Cheng, G.H. Identification of water quality management policy of watershed system with multiple uncertain interactions using a multi-level-factorial risk-inference-based possibilistic-probabilistic programming approach. Environ. Sci. Pollut. Res. 2017, 24, 14980–15000. [Google Scholar] [CrossRef]

- Lagrandeur, J.; Croquer, S.; Poncet, S.; Sorin, M. A 2D numerical benchmark of an air Ranque-Hilsch vortex tube based on a fractional factorial design. Int. Commun. Heat Mass Transf. 2021, 125, 105310. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, Y.; Banks, C.; Heaven, S.; Longhurst, P. Investigation of the impact of trace elements on anaerobic volatile fatty acid degradation using a fractional factorial experimental design. Water Res. 2017, 125, 458–465. [Google Scholar] [CrossRef] [Green Version]

- Gerrewey, T.V.; Ameloot, N.; Navarrete, O.; Vandecruys, M.; Perneel, M.; Boon, N.; Geelen, D. Microbial activity in peat-reduced plant growing media: Identifying influential growing medium constituents and physicochemical properties using fractional factorial design of experiments. J. Clean. Prod. 2020, 256, 120303. [Google Scholar] [CrossRef]

- Li, S.; Zhao, T.Y.; Chu, C.Q.; Wang, J.Q.; Alam, M.S.; Tong, T. Lateral cyclic response sensitivity of rectangular bridge piers confined with UHPFRC tube using fractional factorial design. Eng. Struct. 2021, 235, 111883. [Google Scholar] [CrossRef]

- Almazán-Gómez, M.A.; Duarte, R.; Langarita, R.; Sánchez-Chóliz, J. Effects of water re-allocation in the Ebro river basin: A multiregional input-output and geographical analysis. J. Environ. Manag. 2019, 241, 645–657. [Google Scholar] [CrossRef]

- Shafiei, M.; Moosavirad, S.H.; Azimifard, A.; Biglari, S. Water consumption assessment in Asian chemical industries supply chains based on input-output analysis and one-way analysis of variance. Environ. Sci. Pollut. Res. 2020, 27, 12242–12255. [Google Scholar] [CrossRef]

- Chen, B.; Yang, Q.; Zhou, S.L.; Li, J.S.; Chen, G.Q. Urban Economy’s Carbon flow through external trade: Spatial-temporal evolution for macao. Energy Policy 2017, 110, 69–78. [Google Scholar] [CrossRef]

- He, C.Y.; Huang, G.H.; Liu, L.R.; Xu, X.L.; Li, Y.P. Evolution of virtual water metabolic network in developing regions: A case study of Guangdong province. Ecol. Indic. 2020, 108, 105750. [Google Scholar] [CrossRef]

- Zhai, M.Y.; Huang, G.H.; Liu, L.R.; Su, S. Dynamic input-output analysis for energy metabolism system in the Province of Guangdong, China. J. Clean. Prod. 2018, 196, 747–762. [Google Scholar] [CrossRef]

- Owen, A.; Scott, K.; Barrett, J. Identifying critical supply chains and final products: An input-output approach to exploring the energy-water-food nexus. Appl. Energy 2018, 210, 632–642. [Google Scholar] [CrossRef]

- Fath, B.D.; Patten, B.C. Review of the foundations of network environ analysis. Ecosystems 1999, 2, 167–179. [Google Scholar] [CrossRef]

- Xia, C.Y.; Chen, B. Urban land-carbon nexus based on ecological network analysis. Appl. Energy 2020, 276, 115465. [Google Scholar] [CrossRef]

- Fang, D.L.; Chen, B. Ecological network analysis for a virtual water network. Environ. Sci. Technol. 2015, 49, 6722–6730. [Google Scholar] [CrossRef] [PubMed]

- Norouzi-Ghazbi, S.; Akbarzadeh, A.; Akbarzadeh-T, M.R. Application of Taguchi design in system identification: A simple, generally applicable and powerful method. Measurement 2020, 151, 106879. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 1976. [Google Scholar]

- Statistical Yearbook of Fujian Province; Fujian Provincial Bureau of Statistics: Fuzhou, China, 2013. (In Chinese). Available online: https://www.chinayearbooks.com/fujian-statistical-yearbook.html (accessed on 2 June 2021).

- Statistical Yearbook of Fujian Province; Fujian Provincial Bureau of Statistics: Fuzhou, China, 2018. (In Chinese). Available online: https://www.chinayearbooks.com/fujian-statistical-yearbook-2018.html (accessed on 2 June 2021).

| No. | Abbreviation | Sector |

|---|---|---|

| 1 | AGR | Agriculture, Forestry, Animal Husbandry and Fishery |

| 2 | MIN | Mining Industry |

| 3 | PM | Food, Wine, Drink, Tea Manufacturing and Tobacco Processing |

| Textile Garments Products | ||

| Timber Processing | ||

| Paper Products | ||

| 4 | AM | Petroleum Processing, Coking and Nuclear Fuel Processing |

| Chemical Products | ||

| Nonmetal Minerals Products | ||

| Smelting and Pressing of Metals | ||

| Metal Products | ||

| General and Special Equipment | ||

| Transportation Equipment | ||

| Electric Equipment and Machinery | ||

| Computer, Communication and Other Electronic Equipment | ||

| Instruments and Meters Machinery | ||

| Others Manufacturing | ||

| 5 | ELE | Production and Supply of Electricity, Gas and Water |

| 6 | CON | Construction |

| 7 | TRA | Transportation, Storage and Postal Services |

| 8 | WHO | Wholesale, Retail and Accommodation |

| 9 | OTH | Other Social Services |

| Input | Intermediate Demand | Final Demand | Import | Import from Other Provinces | Total Output | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Output | AGR | MIN | PM | AM | ELE | CON | TRA | WHO | OTH | |||||

| In 2012 | ||||||||||||||

| Intermediate input | AGR | 3731 | 9 | 21,560 | 1276 | 1 | 770 | 83 | 3232 | 325 | 18,403 | 244 | 2590 | 46,555 |

| MIN | 56 | 2253 | 772 | 19,410 | 4658 | 630 | 18 | 0 | 2 | 1311 | 4501 | 12,849 | 11,758 | |

| PM | 5793 | 189 | 80,049 | 7430 | 125 | 1237 | 486 | 3952 | 6523 | 110,528 | 12,345 | 4611 | 199,356 | |

| AM | 5387 | 2055 | 19,024 | 135,624 | 1677 | 42,888 | 8856 | 1359 | 7270 | 119,423 | 36,241 | 36,670 | 270,652 | |

| ELE | 570 | 653 | 4219 | 10,304 | 6444 | 692 | 1520 | 590 | 1844 | 3267 | 678 | 0 | 29,425 | |

| CON | 447 | 22 | 227 | 303 | 109 | 1237 | 615 | 14 | 467 | 117,306 | 36,221 | 0 | 84,652 | |

| TRA | 580 | 1040 | 5814 | 14,375 | 4348 | 6273 | 580 | 566 | 2232 | 12,003 | 8528 | 0 | 39,283 | |

| WHO | 717 | 324 | 6373 | 8237 | 1951 | 2413 | 1144 | 1647 | 7987 | 24,287 | 2348 | 0 | 52,733 | |

| OTH | 1770 | 817 | 5344 | 9181 | 2765 | 3031 | 9106 | 10,170 | 20,175 | 74,040 | 17,740 | 17 | 118,642 | |

| Added value | 177,671 | 27,503 | 4397 | 55,975 | 64,512 | 7346 | 25,480 | 16,874 | 31,080 | 71,817 | 0 | 0 | 0 | |

| In 2017 | ||||||||||||||

| Intermediate input | AGR | 5635 | 6 | 34,154 | 1820 | 0 | 160 | 4866 | 692 | 786 | 27,473 | 9784 | 4707 | 61,102 |

| MIN | 54 | 6112 | 13,257 | 24,993 | 3807 | 4367 | 7 | 0 | 152 | 141 | 24,102 | 16,587 | 12,201 | |

| PM | 7094 | 317 | 174,240 | 17,362 | 144 | 20,976 | 9144 | 8746 | 10,322 | 189,337 | 18,374 | 8410 | 410,896 | |

| AM | 7768 | 534 | 43,473 | 207,395 | 2215 | 30,917 | 13,514 | 732 | 7617 | 157,184 | 78,588 | 31,481 | 361,282 | |

| ELE | 571 | 439 | 4899 | 3574 | 18,867 | 680 | 4220 | 460 | 5870 | 1961 | 0 | 426 | 41,113 | |

| CON | 627 | 25 | 1182 | 982 | 723 | 1331 | 1345 | 153 | 974 | 145,435 | 0 | 352 | 152,426 | |

| TRA | 1183 | 454 | 11,048 | 7535 | 954 | 44,847 | 8090 | 2085 | 7611 | 24,938 | 0 | 4428 | 104,318 | |

| WHO | 798 | 198 | 14,900 | 7825 | 2587 | 2726 | 5977 | 1422 | 8144 | 47,164 | 0 | 3858 | 87,883 | |

| OTH | 1853 | 354 | 10,851 | 8040 | 2559 | 4505 | 14,481 | 23,786 | 56,404 | 118,745 | 32 | 11,611 | 229,935 | |

| Added value | 229,443 | 35,518 | 3762 | 102,892 | 81,757 | 9257 | 41,917 | 42,675 | 49,807 | 132,055 | 0 | 0 | 0 | |

| Sector | Sectoral Direct Solid Waste Production (106 Mg) | Sectoral Indirect Solid Waste Production (106 Mg) | Total Solid Waste Production Coefficient (10−6 Mg/USD) | Final Demand Production (106 Mg) | Export (106 Mg) | Import (106 Mg) | Net Import (106 Mg) |

|---|---|---|---|---|---|---|---|

| In 2012 | |||||||

| AGR | 1.091 | 5.899 | 3.598 | 2.115 | 0.649 | 0.426 | −0.223 |

| MIN | 1.776 | 2.295 | 8.296 | 0.125 | 0.329 | 6.007 | 5.678 |

| PM | 30.105 | 46.337 | 9.188 | 11.898 | 30.484 | 6.502 | −23.982 |

| AM | 40.871 | 76.985 | 10.435 | 20.202 | 31.802 | 31.750 | −0.052 |

| ELE | 4.444 | 5.991 | 8.498 | 1.109 | 0.050 | 0.240 | 0.191 |

| CON | 12.783 | 21.925 | 9.825 | 46.873 | 1.224 | 14.851 | 13.627 |

| TRA | 0.921 | 6.051 | 4.253 | 1.224 | 0.906 | 1.514 | 0.607 |

| WHO | 1.236 | 4.220 | 2.479 | 1.346 | 1.167 | 0.243 | −0.924 |

| OTH | 2.781 | 9.950 | 2.571 | 7.277 | 0.668 | 1.905 | 1.237 |

| In 2017 | |||||||

| AGR | 1.138 | 4.164 | 2.080 | 2.331 | 0.054 | 1.257 | 1.204 |

| MIN | 0.807 | 1.526 | 4.582 | 0.009 | 0.018 | 7.780 | 7.762 |

| PM | 27.185 | 53.466 | 4.703 | 9.887 | 27.277 | 5.257 | −22.019 |

| AM | 23.903 | 58.004 | 5.433 | 20.911 | 14.725 | 24.954 | 10.229 |

| ELE | 2.720 | 5.639 | 4.872 | 0.387 | 0.012 | 0.087 | 0.075 |

| CON | 10.085 | 17.274 | 4.301 | 26.090 | 0.013 | 0.063 | 0.050 |

| TRA | 1.943 | 8.459 | 2.389 | 2.038 | 0.449 | 0.442 | −0.007 |

| WHO | 1.637 | 3.836 | 1.492 | 2.438 | 0.499 | 0.240 | −0.259 |

| OTH | 4.283 | 9.985 | 1.487 | 7.149 | 0.220 | 0.722 | 0.503 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Li, Y.; Huang, G.; Yang, Y.; Wu, X. A Factorial Ecological-Extended Physical Input-Output Model for Identifying Optimal Urban Solid Waste Path in Fujian Province, China. Sustainability 2021, 13, 8341. https://doi.org/10.3390/su13158341

Liu J, Li Y, Huang G, Yang Y, Wu X. A Factorial Ecological-Extended Physical Input-Output Model for Identifying Optimal Urban Solid Waste Path in Fujian Province, China. Sustainability. 2021; 13(15):8341. https://doi.org/10.3390/su13158341

Chicago/Turabian StyleLiu, Jing, Yongping Li, Gordon Huang, Yujin Yang, and Xiaojie Wu. 2021. "A Factorial Ecological-Extended Physical Input-Output Model for Identifying Optimal Urban Solid Waste Path in Fujian Province, China" Sustainability 13, no. 15: 8341. https://doi.org/10.3390/su13158341

APA StyleLiu, J., Li, Y., Huang, G., Yang, Y., & Wu, X. (2021). A Factorial Ecological-Extended Physical Input-Output Model for Identifying Optimal Urban Solid Waste Path in Fujian Province, China. Sustainability, 13(15), 8341. https://doi.org/10.3390/su13158341