Experimental Study on the Effect of Fulvic Acid in Waste Slurry on Flocculation and Zeta Potential

Abstract

:1. Introduction

2. Materials and Methods

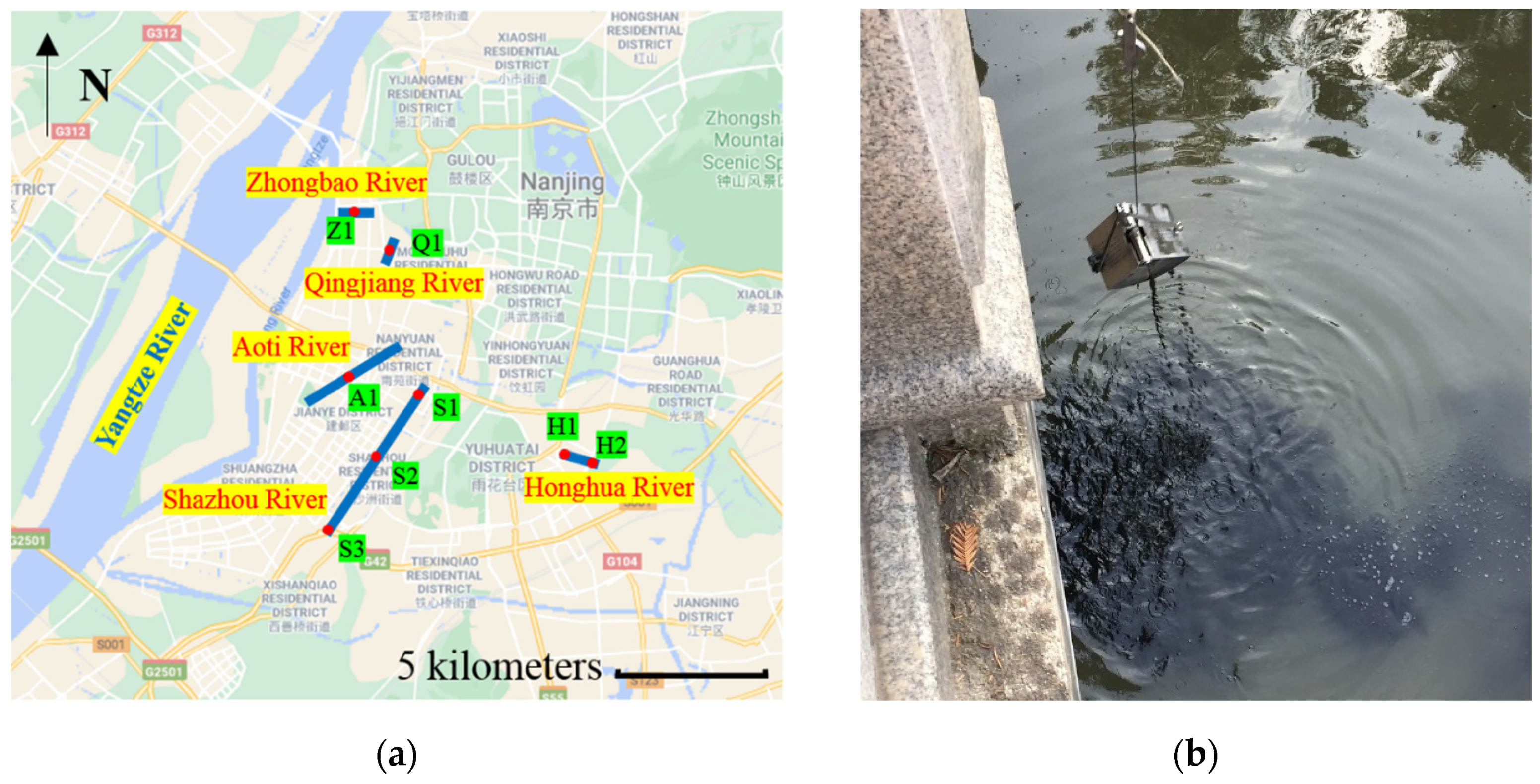

2.1. Waste Slurry

2.2. Fulvic Acid

2.3. Flocculant

2.4. Experiment on the Effect of the FA Content on Flocculation and Separation

2.5. Flocculation and Separation Tests of Waste-Dredged Slurry

3. Results

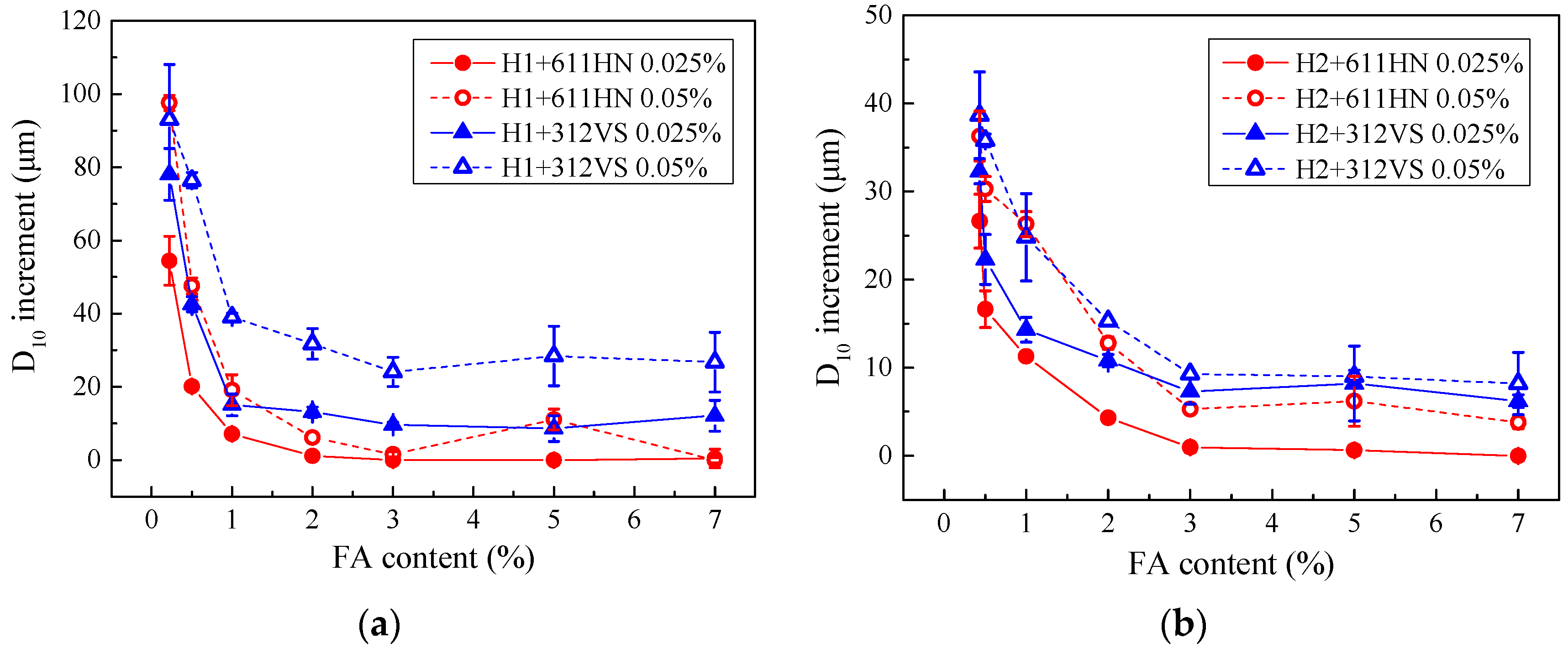

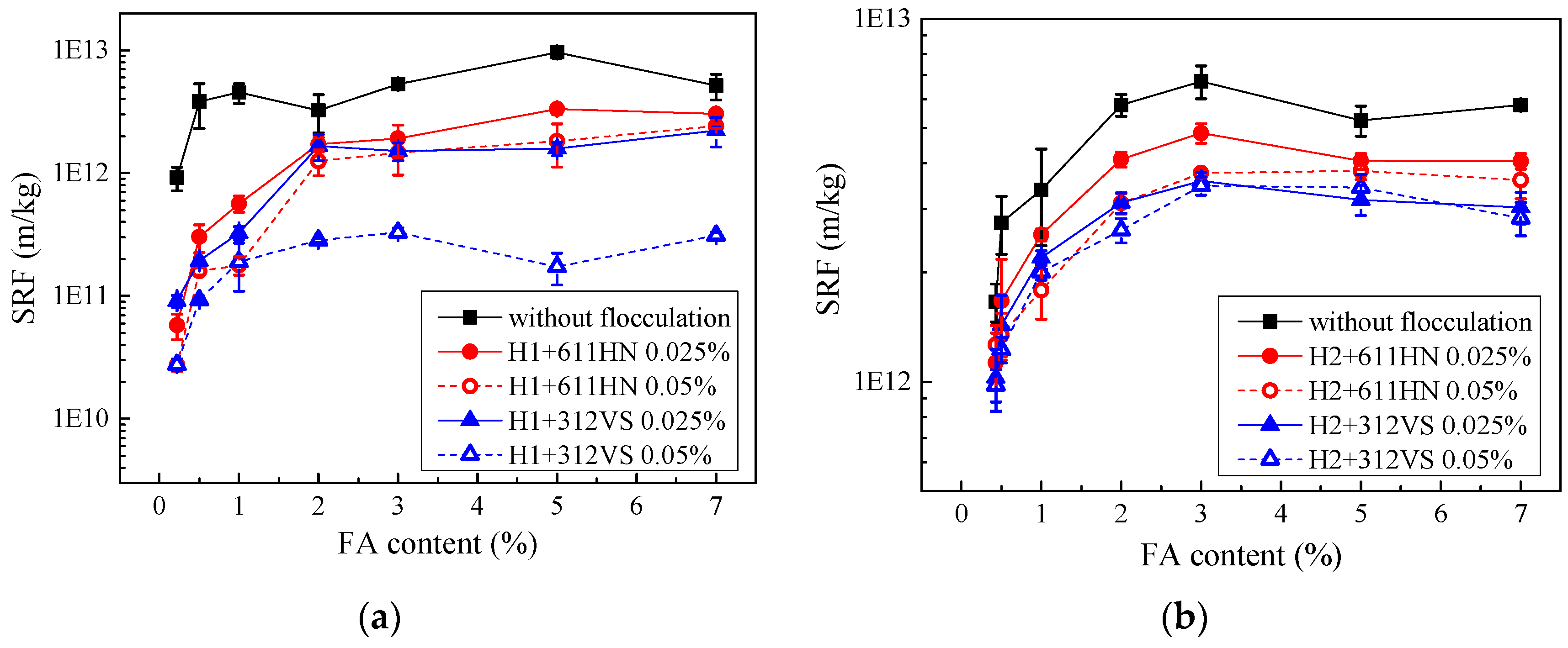

3.1. The Effect of the FA Content on Flocculation and Filtration

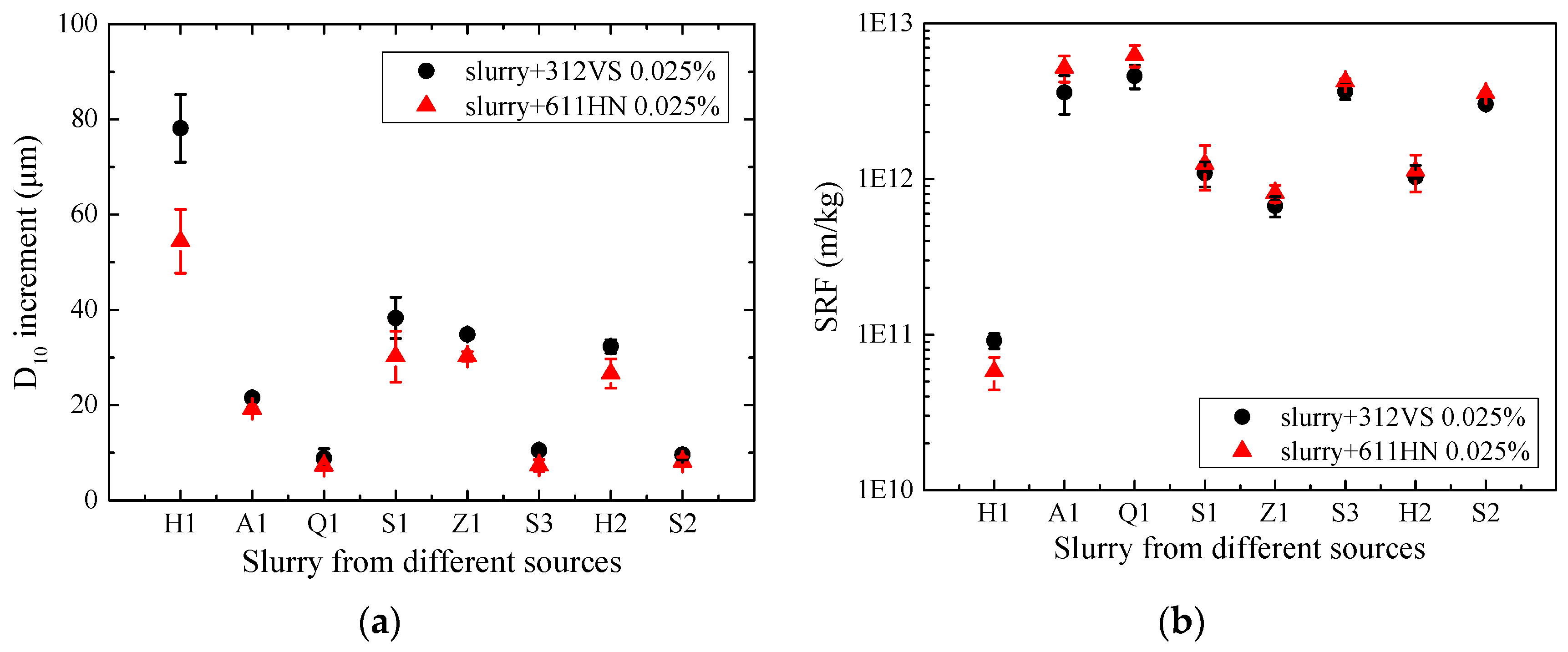

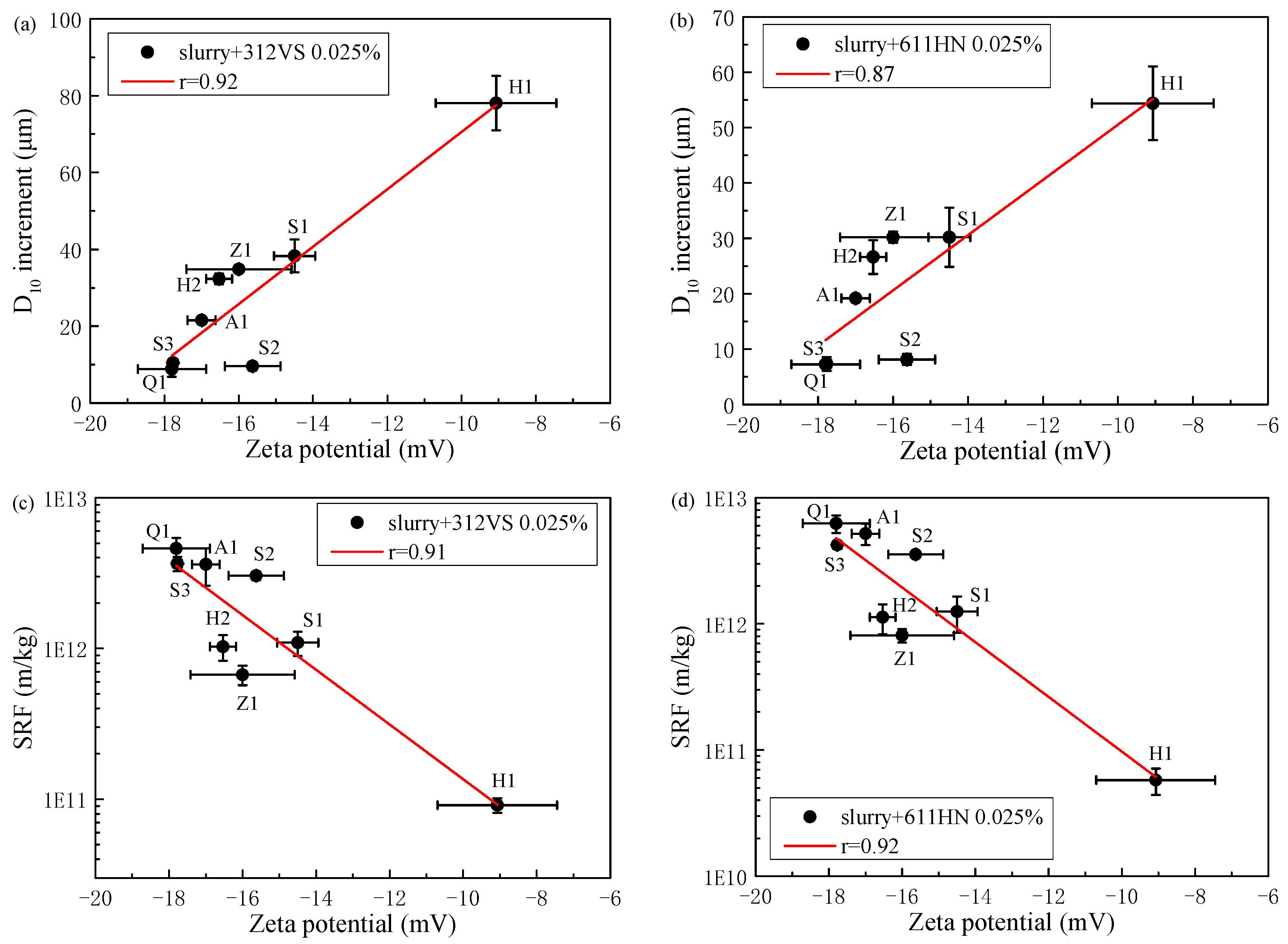

3.2. Flocculation and Separation Results of the Eight Dredged Slurry Samples

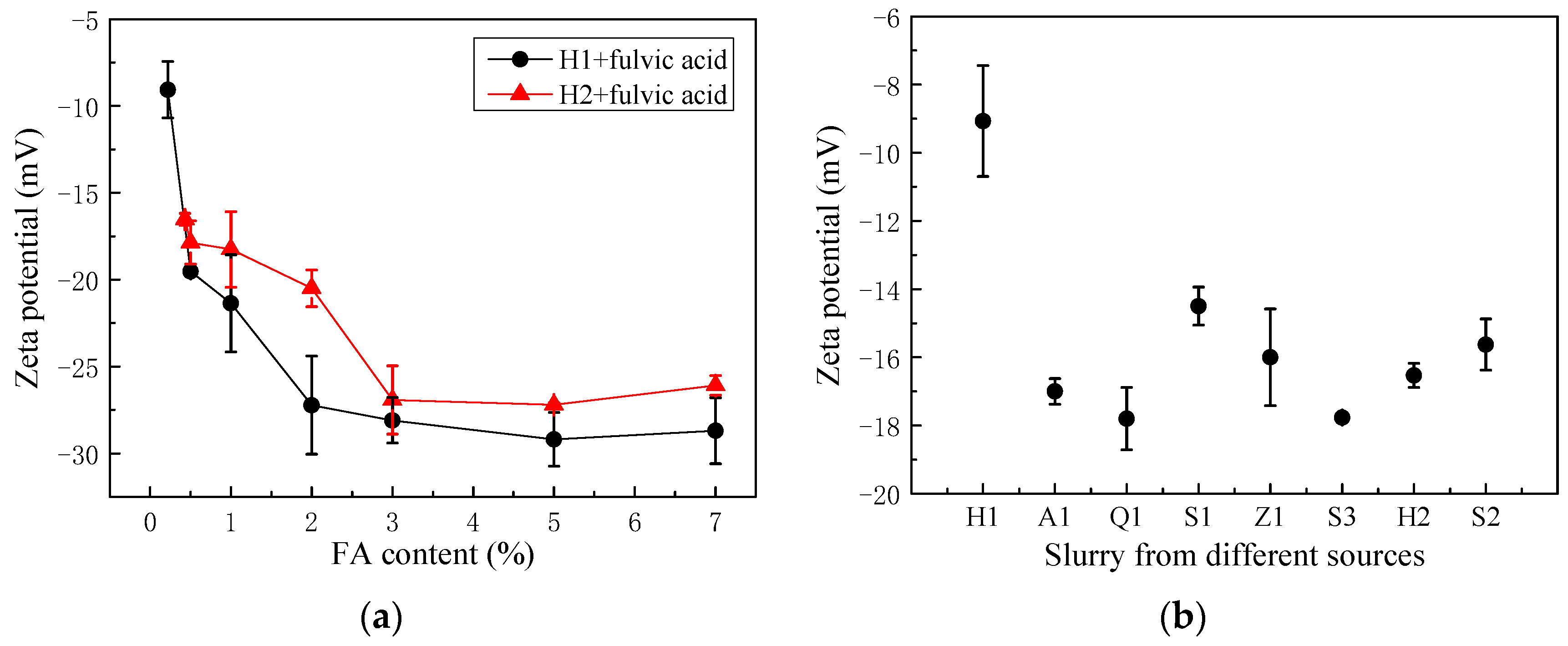

3.3. Zeta Potential Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, C. Properties of fired bricks incorporating TFT-LCD waste glass powder with reservoir sediments. Sustainability 2018, 10, 2503. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Yan, C.; Xu, B.; Ruan, X.; Wei, Z. The use of urban river sediments as a primary raw material in the production of highly insulating brick. Ceram. Int. 2014, 40, 8833–8840. [Google Scholar] [CrossRef]

- Wang, L.; Shao, Y.; Zhao, Z.; Chen, S.; Shao, X. Optimized utilization studies of dredging sediment for making water treatment ceramsite based on an extreme vertex design. J. Water Process Eng. 2020, 38, 101603. [Google Scholar] [CrossRef]

- Min, F.; Wang, X.; Li, M.; Ni, Y.; Zhang, J. Preparation of High-Porosity and High-Strength Ceramisites from Municipal Sludge Using Starch and CaCO3 as a Combined Pore-Forming Agent. J. Mater. Civil Eng. 2021, 33, 4020502. [Google Scholar] [CrossRef]

- Park, J.; Son, Y.; Noh, S.; Bong, T. The suitability evaluation of dredged soil from reservoirs as embankment material. J. Environ. Manag. 2016, 183, 443–452. [Google Scholar] [CrossRef] [PubMed]

- Koś, K.; Gruchot, A.; Zawisza, E. Bottom Sediments from a Dam Reservoir as a Core in Embankments—Filtration and Stability: A Case Study. Sustainability 2021, 13, 1221. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, L.; Haque, M.; Chen, B.; Ren, Z.; Cao, X.; Shen, Z. Sustainable conversion of contaminated dredged river sediment into eco-friendly foamed concrete. J. Clean. Prod. 2020, 252, 119799. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, R.; Cai, Y.; Fu, H.; Li, X.; Hu, X. Vacuum preloading and electro-osmosis consolidation of dredged slurry pre-treated with flocculants. Eng. Geol. 2018, 246, 123–130. [Google Scholar] [CrossRef]

- Anda, R.; Fu, H.; Wang, J.; Lei, H.; Hu, X.; Ye, Q.; Cai, Y.; Xie, Z. Effects of pressurizing timing on air booster vacuum consolidation of dredged slurry. Geotext. Geomembr. 2020, 48, 491–503. [Google Scholar] [CrossRef]

- Wu, S.; Zhu, W.; Chen, Y.; Liu, J.; Shu, S. Pore characteristics of cake and its effect on cake filtration. Sep. Sci. Technol. 2021, 56, 789–799. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, W.; Gao, H.; Wang, D. Comprehensive assessment of flocculation conditioning of dredged sediment using organic polymers: Dredged sediment dewaterability and release of pollutants. Sci. Total Environ. 2020, 739, 139884. [Google Scholar] [CrossRef]

- Liu, F.; Wu, W.; Fu, H.; Wang, J.; Hai, J.; Cai, Y.; Hu, X.; Yuan, W.; Lou, X. Application of flocculation combined with vacuum preloading to reduce river-dredged sludge. Mar. Georesour. Geotec. 2020, 38, 164–173. [Google Scholar] [CrossRef]

- Cui, Y.; Zhu, W.; Wu, S.; Liu, J.; Hou, H.; Lin, N. The role of lime in dredged mud dewatered by a plate and frame filter press and potential substitutes. Environ. Sci. Pollut. Res. 2021, 28, 17331–17342. [Google Scholar] [CrossRef] [PubMed]

- Ertel, J.; Hedges, J. Sources of sedimentary humic substances: Vascular plant debris. Geochim. Cosmochim. Acta 1985, 49, 2097–2107. [Google Scholar] [CrossRef]

- Stevenson, F. Humus Chemistry: Genesis, Composition, Reactions; John Wiley & Sons: Hoboken, NJ, USA, 1994. [Google Scholar]

- Hu, C.; Liu, H.; Qu, J.; Wang, D.; Ru, J. Coagulation behavior of aluminum salts in eutrophic water: Significance of Al13 species and pH control. Environ. Sci. Technol. 2006, 40, 325–331. [Google Scholar] [CrossRef]

- Zhang, H.; Lin, H.; Li, Q.; Cheng, C.; Shen, H.; Zhang, Z.; Zhang, Z.; Wang, H. Removal of refractory organics in wastewater by coagulation/flocculation with green chlorine-free coagulants. Sci. Total Environ. 2021, 787, 147654. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Yu, W.; Liang, L.; Wang, T. Effect of natural organic matter on coagulation efficiency and characterization of the flocs formed. Environ. Sci. 2013, 34, 4290–4294. [Google Scholar]

- Sillanpää, M.; Ncibi, M.C.; Matilainen, A.; Vepsäläinen, M. Removal of natural organic matter in drinking water treatment by coagulation: A comprehensive review. Chemosphere 2018, 190, 54–71. [Google Scholar] [CrossRef]

- Ministry of Agriculture of the People’s Republic of China Determination of Humus Content in Soil; China Agriculture Press: Beijing, China, 2010; Available online: http://www.doc88.com/p-1621945745549.html (accessed on 11 June 2021).

- Wu, H.; Liu, Z.; Yang, H.; Li, A. Evaluation of chain architectures and charge properties of various starch-based flocculants for flocculation of humic acid from water. Water Res. 2016, 96, 126–135. [Google Scholar] [CrossRef]

- Chen, F.; Liu, W.; Pan, Z.; Wang, Y.; Guo, X.; Sun, S.; Jia, R. Characteristics and mechanism of chitosan in flocculation for water coagulation in the Yellow River diversion reservoir. J. Water Process Eng. 2020, 34, 101191. [Google Scholar] [CrossRef]

- McLaughlin, R.; Bartholomew, N. Soil Factors Influencing Suspended Sediment Flocculation by Polyacrylamide. Soil Sci. Soc. Am. J. 2007, 71, 537–544. [Google Scholar] [CrossRef]

- Yan, X.; Zhang, X. Interactive effects of clay and polyacrylamide properties on flocculation of pure and subsoil clays. Soil Res. 2014, 52, 727–737. [Google Scholar] [CrossRef]

- Mamedov, A.; Wagner, L.; Huang, C.; Norton, L.; Levy, G. Polyacrylamide effects on aggregate and structure stability of soils with different clay mineralogy. Soil Sci. Soc. Am. J. 2010, 74, 1720–1732. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Fu, K.; Jiang, L.; Ding, L.; Guan, Q.; Zhang, S.; Zhang, H.; Shi, J.; Fu, X. Flocculation performance of cationic polyacrylamide with high cationic degree in humic acid synthetic water treatment and effect of kaolin particles. Sep. Purif. Technol. 2017, 181, 201–212. [Google Scholar] [CrossRef]

- Petzold, G.; Geissler, U.; Smolka, N.; Schwarz, S. Influence of humic acid on the flocculation of clay. Colloid. Polym. Sci. 2004, 282, 670–676. [Google Scholar]

| Rivers | Length (km) | Latitude and Longitude of Starting Point | Sampling Point |

|---|---|---|---|

| Zhongbao River | 0.72 | E118°43′47″ N32°3′13″ | Z1 |

| Qingjiang River | 0.30 | E118°44′8″ N32°4′13″ | Q1 |

| Aoti River | 3.00 | E118°43′44.7″ N32°1′23.2″ | A1 |

| Honghua River | 0.75 | E118°48′22″ N32°0′20″ | H1, H2 |

| Shazhou River | 5.50 | E118°42′54.1″ N32°58′54.9″ | S1, S2, S3 |

| Sampling Point | FA Content a (%) | HA Content a (%) | Humin Content a (%) | Particle Size (μm) | ||

|---|---|---|---|---|---|---|

| D10 | D50 | D90 | ||||

| Z1 | 0.35 | 0.13 | 1.28 | 5.5 b | 36.3 | 117.6 |

| Q1 | 0.35 | 0.13 | 2.29 | 3.0 | 18.4 | 145.9 |

| A1 | 0.62 | 0.62 | 3.51 | 8.0 | 49.6 | 354.4 |

| H1 | 0.22 | 0.14 | 0.72 | 6.9 | 55.2 | 176.9 |

| H2 | 0.40 | 0.25 | 1.96 | 3.7 | 23.3 | 118.5 |

| S1 | 0.31 | 0.09 | 1.32 | 4.8 | 43.3 | 431.7 |

| S2 | 0.30 | 0.00 | 1.52 | 2.3 | 12.7 | 76.2 |

| S3 | 0.31 | 0.06 | 1.44 | 3.0 | 17.9 | 110.5 |

| Slurry | FA Content (%) | Flocculant | Quantitative Indices |

|---|---|---|---|

| H1 | 0.22, 0.5, 1, 2, 3, 5, 7 | 312VS: 0.025%, 0.05% or 611HN: 0.025%, 0.05% | D10 increment, SRF, zeta potential |

| H2 | 0.40, 0.5, 1, 2, 3, 5, 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Wu, S.; Huang, X. Experimental Study on the Effect of Fulvic Acid in Waste Slurry on Flocculation and Zeta Potential. Sustainability 2021, 13, 7784. https://doi.org/10.3390/su13147784

Yang Y, Wu S, Huang X. Experimental Study on the Effect of Fulvic Acid in Waste Slurry on Flocculation and Zeta Potential. Sustainability. 2021; 13(14):7784. https://doi.org/10.3390/su13147784

Chicago/Turabian StyleYang, Yi, Silin Wu, and Xianwen Huang. 2021. "Experimental Study on the Effect of Fulvic Acid in Waste Slurry on Flocculation and Zeta Potential" Sustainability 13, no. 14: 7784. https://doi.org/10.3390/su13147784

APA StyleYang, Y., Wu, S., & Huang, X. (2021). Experimental Study on the Effect of Fulvic Acid in Waste Slurry on Flocculation and Zeta Potential. Sustainability, 13(14), 7784. https://doi.org/10.3390/su13147784