Fique as a Sustainable Material and Thermal Insulation for Buildings: Study of Its Decomposition and Thermal Conductivity

Abstract

:1. Introduction

2. Methodology

2.1. Measurement of Thermal Conductivity

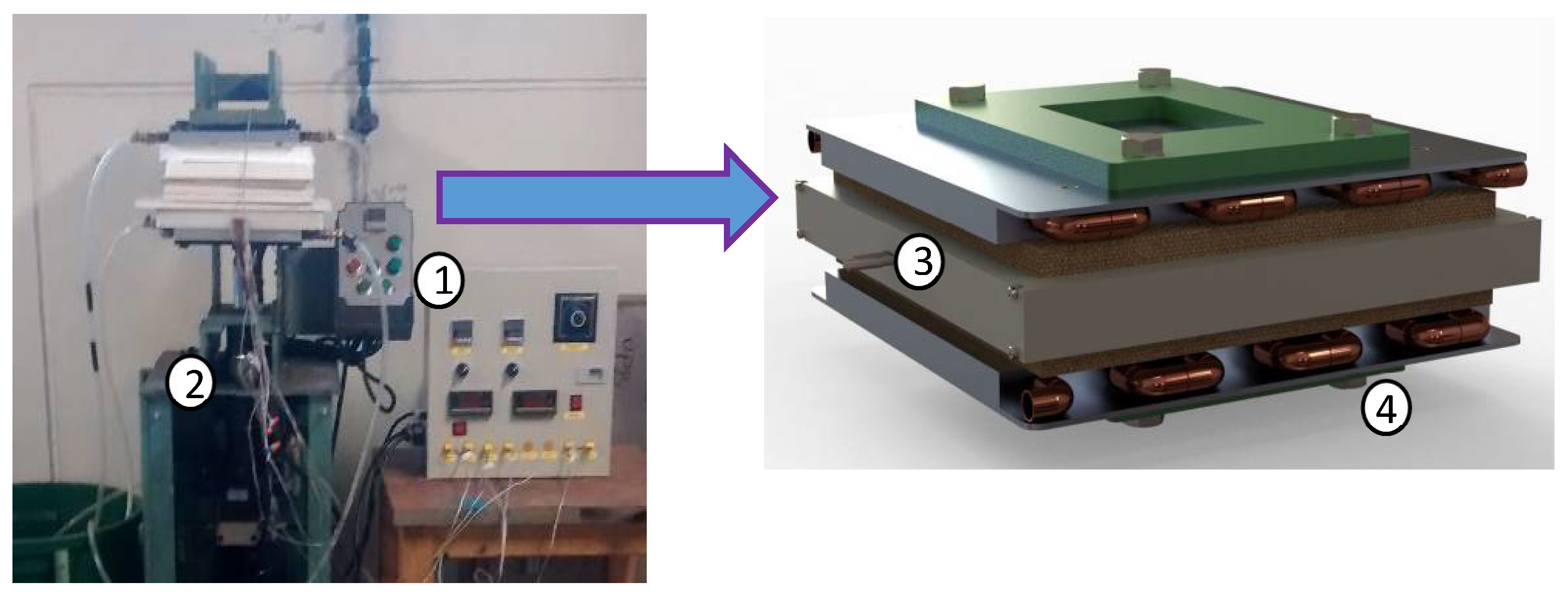

2.1.1. Measurement and Control System

2.1.2. Support System

2.1.3. Heating System (Guarded-Hot-Plate)

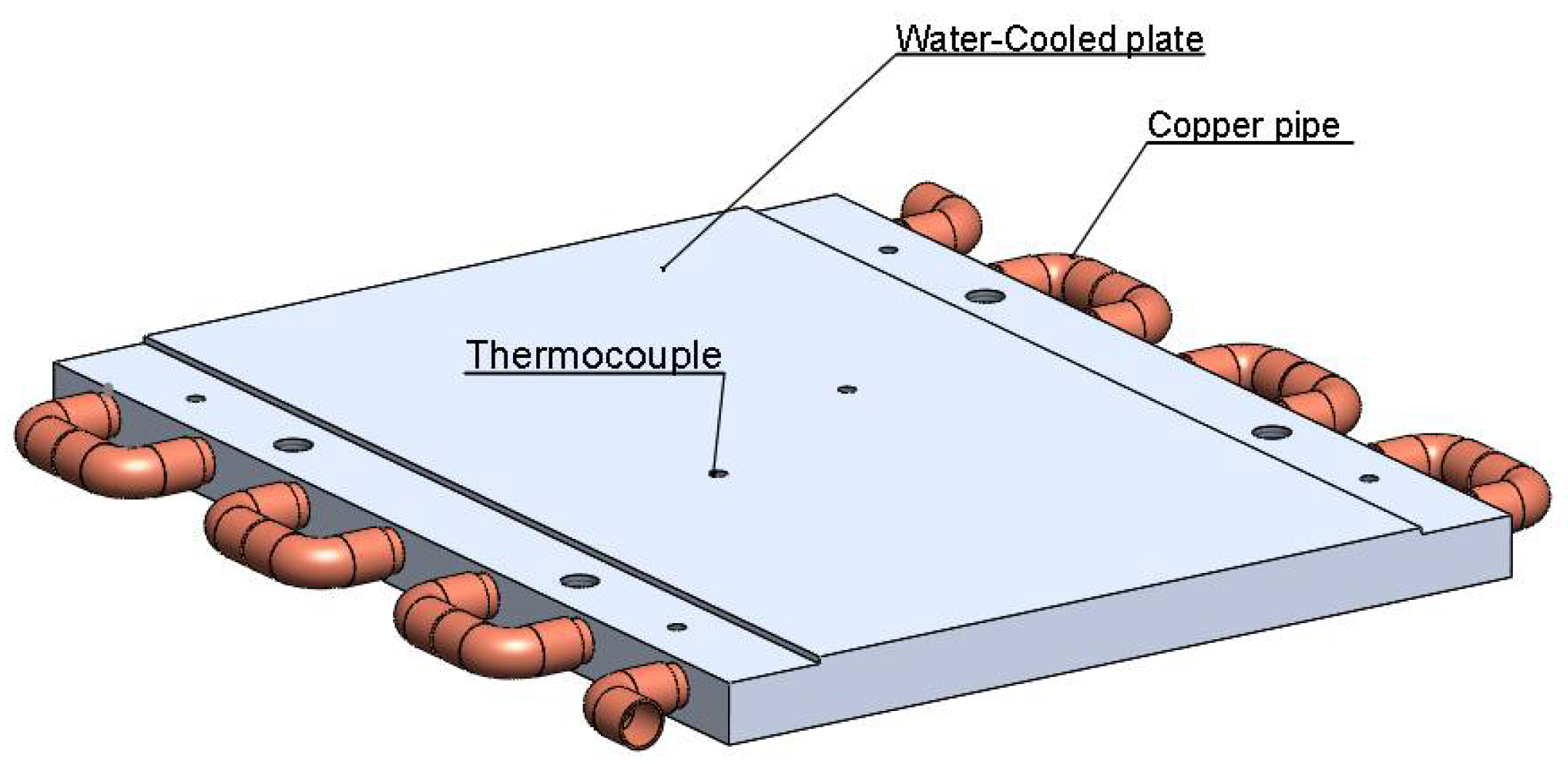

2.1.4. Cooling System

2.2. Kinetic Modelling

3. Results and Discussion

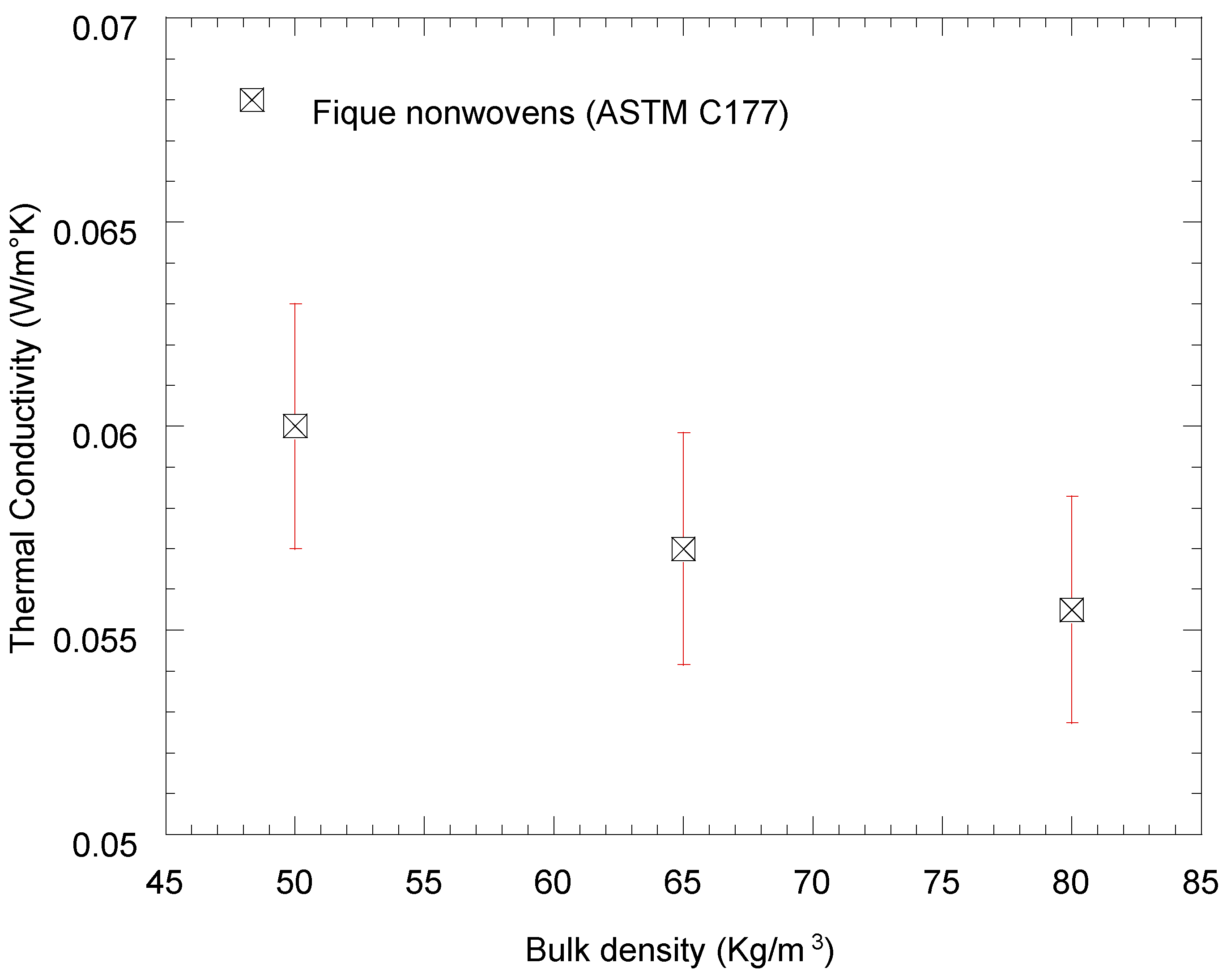

3.1. Thermal Conduction

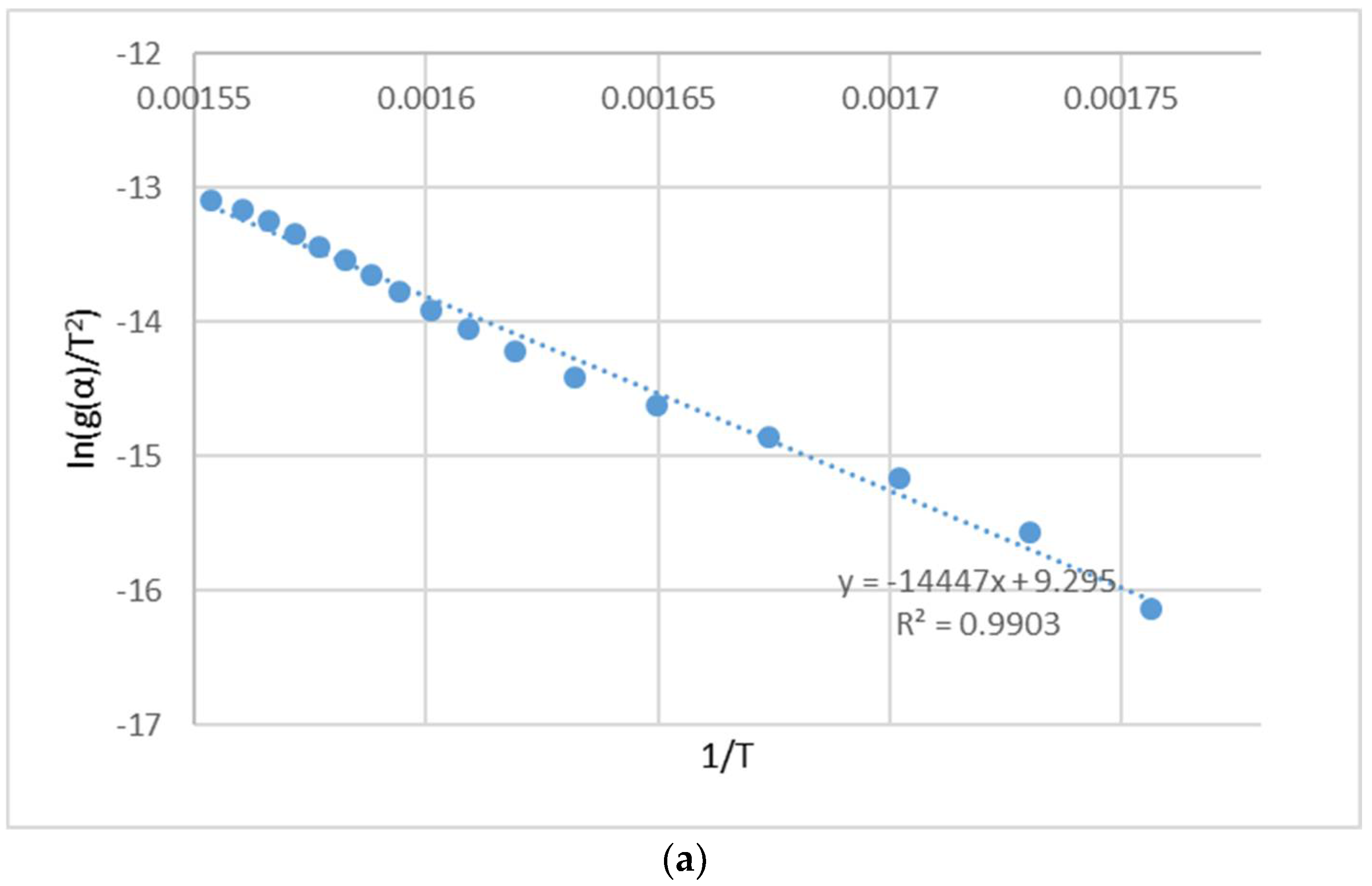

3.2. Thermal Decomposition

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ortiz, A.C.; Peña, J.Z. Implicaciones Históricas y Biológicas del Cambio Climático. NOVA 2010, 8. Available online: http://unicolmayor.edu.co/publicaciones/index.php/nova/article/view/154 (accessed on 8 October 2015).

- IPCC—Intergovernmental Panel on Climate Change. Cambio Climático 2014—Impactos, Adaptación y Vulnerabilidad. Available online: http://www.ipcc.ch/home_languages_main_spanish.shtml (accessed on 24 October 2016).

- Liu, L.; Li, H.; Lazzaretto, A.; Manente, G.; Tong, C.; Liu, Q.; Li, N. The development history and prospects of biomass-based insulation materials for buildings. Renew. Sustain. Energy Rev. 2017, 69, 912–932. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP)—SBCI. Available online: http://www.unep.org/sbci/AboutSBCI/Background.asp (accessed on 19 October 2016).

- Buildings Energy Data Book. Available online: http://buildingsdatabook.eren.doe.gov/ChapterIntro1.aspx (accessed on 19 October 2016).

- Buildings—Energy—European Commission. Energy. Available online: http://ec.europa.eu/energy/en/topics/energy-efficiency/buildings (accessed on 19 October 2016).

- De Boeck, L.; Verbeke, S.; Audenaert, A.; De Mesmaeker, L. Improving the energy performance of residential buildings: A literature review. Renew. Sustain. Energy Rev. 2015, 52, 960–975. [Google Scholar] [CrossRef]

- Carpio, C.; Coviello, M. Eficiencia Energética en América Latina y el Caribe: Avances y Desafíos del último Quinquenio. Available online: http://www.cepal.org/es/publicaciones/4106-eficiencia-energetica-america-latina-caribe-avances-desafios-ultimo-quinquenio (accessed on 19 October 2016).

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Tangjuank, S. Thermal insulation and physical properties of particleboards from pineapple leaves. Int. J. Phys. Sci. 2011, 6, 4528–4532. [Google Scholar]

- Papadopoulos, A. State of the art in thermal insulation materials and aims for future developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Demirhan, C. Mechanical, thermal and acoustical characterizations of an insulation composite made of bio-based materials. Sustain. Cities Soc. 2016, 20, 17–26. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; De Baynast, H.; Lebert, A.; Sun, S.; Lopez-Mingo, C.J.S.; Leclaire, P.; Michaud, P. Mechanical, thermal and acoustical characterizations of an insulating bio-based composite made from sunflower stalks particles and chitosan. Ind. Crop. Prod. 2014, 58, 244–250. [Google Scholar] [CrossRef] [Green Version]

- Mounika, M.; Ramaniah, K.; Prasad, A.R.R.; Rao, K.M.; Reddy, K. Thermal conductivity characterization of bamboo fiber reinforced polyester composite. J. Mater. Environ. Sci. 2012, 3, 1109–1116. [Google Scholar]

- Binici, H.; Eken, M.; Dolaz, M.; Aksogan, O.; Kara, M. An environmentally friendly thermal insulation material from sunflower stalk, textile waste and stubble fibres. Constr. Build. Mater. 2014, 51, 24–33. [Google Scholar] [CrossRef]

- Pinto, J.; Paiva, A.; Varum, H.; Costa, A.; Cruz, D.; Pereira, S.; Fernandes, L.; Tavares, P.; Agarwal, J. Corn’s cob as a potential ecological thermal insulation material. Energy Build. 2011, 43, 1985–1990. [Google Scholar] [CrossRef]

- Wei, K.; Lv, C.; Chen, M.; Zhou, X.; Dai, Z.; Shen, D. Development and performance evaluation of a new thermal insulation material from rice straw using high frequency hot-pressing. Energy Build. 2015, 87, 116–122. [Google Scholar] [CrossRef]

- Hurtado, P.L.; Rouilly, A.; Vandenbossche, V.; Raynaud, C. A review on the properties of cellulose fibre insulation. Build. Environ. 2016, 96, 170–177. [Google Scholar] [CrossRef] [Green Version]

- Madurwar, M.V.; Ralegaonkar, R.V.; Mandavgane, S.A. Application of agro-waste for sustainable construction materials: A review. Constr. Build. Mater. 2013, 38, 872–878. [Google Scholar] [CrossRef]

- Ingrao, C.; Giudice, A.L.; Bacenetti, J.; Tricase, C.; Dotelli, G.; Fiala, M.; Siracusa, V.; Mbohwa, C. Energy and environmental assessment of industrial hemp for building applications: A review. Renew. Sustain. Energy Rev. 2015, 51, 29–42. [Google Scholar] [CrossRef]

- Kymäläinen, H.-R.; Sjöberg, A.-M. Flax and hemp fibres as raw materials for thermal insulations. Build. Environ. 2008, 43, 1261–1269. [Google Scholar] [CrossRef]

- Guzmán, R.E.; Gómez, S.; Amelines, O.; Aparicio, G.M. Superficial modification by alkalization of cellulose Fibres obtained from Fique leaf. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bristol, UK, 9–13 July 2018; Volume 437, p. 012015. [Google Scholar] [CrossRef]

- An, L.; Wang, J.; Petit, D.; Armstrong, J.N.; Li, C.; Hu, Y.; Huang, Y.; Shao, Z.; Ren, S. A scalable crosslinked fiberglass-aerogel thermal insulation composite. Appl. Mater. Today 2020, 21, 100843. [Google Scholar] [CrossRef]

- Dou, L.; Zhang, X.; Cheng, X.; Ma, Z.; Wang, X.; Si, Y.; Yu, J.; Ding, B. Hierarchical Cellular Structured Ceramic Nanofibrous Aerogels with Temperature-Invariant Superelasticity for Thermal Insulation. ACS Appl. Mater. Interfaces 2019, 11, 29056–29064. [Google Scholar] [CrossRef]

- Vergara, M.C.A.; Gómez, M.P.C.; Restrepo, M.C.R.; Henao, J.M.; Soto, M.A.P.; Rojo, P.F.G.; Herazo, C.I.C.; Gallego, R.Z. Novel Biobased Textile Fiber from Colombian Agro-Industrial Waste Fiber. Molecules 2018, 23, 2640. [Google Scholar] [CrossRef] [Green Version]

- Monteiro, S.; De Assis, F.S.; Ferreira, C.L.; Simonassi, N.T.; Weber, R.P.; Oliveira, M.S.; Colorado, H.A.; Pereira, A.C. Fique Fabric: A Promising Reinforcement for Polymer Composites. Polymers 2018, 10, 246. [Google Scholar] [CrossRef] [Green Version]

- Fokaides, P.; Apanaviciene, R.; Černeckiene, J.; Jurelionis, A.; Klumbyte, E.; Kriauciunaite-Neklejonoviene, V.; Pupeikis, D.; Rekus, D.; Sadauskiene, J.; Seduikyte, L.; et al. Research Challenges and Advancements in the Field of Sustainable Energy Technologies in the Built Environment. Sustainability 2020, 12, 8417. [Google Scholar] [CrossRef]

- Mansor, M.R.; Salit, M.S.; Zainudin, E.S.; Aziz, N.A.; Ariff, H. Life Cycle Assessment of Natural Fiber Polymer Composites. In Agricultural Biomass Based Potential Materials; Springer: Berlin/Heidelberg, Germany, 2015; pp. 121–141. [Google Scholar]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Muñoz, D.M.; Cifuentes, G.C. El fique como aislante térmico. Biotecnol. Sect. Agropecu. Agroind. 2007, 5, 9–16. [Google Scholar]

- Onésippe, C.; Toro, F.; Bilba, K.; Delvasto, S.; Arsène, M.-A. Influence of Fibers Weight Fraction and Nature of Fibers on Thermal and Mechanical Properties of Vegetable Fibers/Cement Composites. In Proceedings of the 11th Conference on Durability of Building Materials and Components (11DBMC), Istanbul, Turkey, 11–14 May 2008; Available online: https://hal.univ-antilles.fr/hal-01693195/document (accessed on 18 June 2018.).

- Monsalve, L.V.; Bolañoz, I.H.; Lopez, P.F.; Toro, E.F. Teja tipo sándwich de cemento basados en subproductos industriales para el mejoramiento de la comodidad térmica. Rev. Colomb. Mater. 2014, 5, 332–337. [Google Scholar]

- Navacerrada, M.A.; Diaz, C.; Pedrero, A.; Fernández-Morales, P.; Navarro, G.; Cardona, O. Caracterización AcúStica de Muestras de Fique Tejido y no Tejido. Available online: http://www.sea-acustica.es/fileadmin/publicaciones/MAT-0_002.pdf (accessed on 12 May 2021).

- Navacerrada, M.A.; Díaz, C.; Fernández, P. Characterization of a Material Based on Short Natural Fique Fibers. BioResources 2014, 9, 3480–3496. [Google Scholar] [CrossRef] [Green Version]

- Proaño, E.; Bonilla, O.; Aldas, M. Desarrollo de un Material Compuesto de Matriz de Poliuretano Rígido Reforzado con Fibra de Raquis de Palma Africana. Rev. Politécnica 2015, 36, 89. [Google Scholar]

- Navacerrada, M.A.; Díaz, C.; Pedrero, A.; Isaza, M.; Fernández, P.; Álvarez-Lopez, C.; Restrepo-Osorio, A. Caracterización Acústica y Térmica de no Tejidos Basados en Fibras Naturales; European Acoustics Association: Porto, Portugal, 2016. [Google Scholar]

- Gutiérrez Vera, C.K. Estudio del Rendimiento Acústico y Térmico de la Fibra de Cabuya Como Panel para Revestimiento de Paredes; Universidad Laica Vicente Rocafuente: Guayaquil, Ecuador, 2017; Available online: http://repositorio.ulvr.edu.ec/handle/44000/2077 (accessed on 18 June 2018).

- Sánchez, G.F.G.; Lopez, R.E.G.; Restrepo-Osorio, A.; Arroyo, E.H. Fique as thermal insulation morphologic and thermal characterization of fique fibers. Cogent Eng. 2019, 6, 1579427. [Google Scholar] [CrossRef]

- Gomez, T.S.; Navacerrada, M.; Díaz, C.; Fernández-Morales, P. Fique fibres as a sustainable material for thermoacoustic conditioning. Appl. Acoust. 2020, 164, 107240. [Google Scholar] [CrossRef]

- Hadded, A.; Benltoufa, S.; Fayala, F.; Jemni, A. Thermo physical characterisation of recycled textile materials used for building insulating. J. Build. Eng. 2016, 5, 34–40. [Google Scholar] [CrossRef]

- ASTM C177—13 Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/C177-13.htm (accessed on 16 May 2021).

- Sher, F.; Iqbal, S.Z.; Liu, H.; Imran, M.; Snape, C.E. Thermal and kinetic analysis of diverse biomass fuels under different reaction environment: A way forward to renewable energy sources. Energy Convers. Manag. 2020, 203, 112266. [Google Scholar] [CrossRef]

- Slopiecka, K.; Bartocci, P.; Fantozzi, F. Thermogravimetric analysis and kinetic study of poplar wood pyrolysis. Appl. Energy 2012, 97, 491–497. [Google Scholar] [CrossRef]

- Jones, J.; Saddawi, A.; Dooley, B.; Mitchell, E.; Werner, J.; Waldron, D.; Weatherstone, S.; Williams, A. Low temperature ignition of biomass. Fuel Process. Technol. 2015, 134, 372–377. [Google Scholar] [CrossRef] [Green Version]

- Coats, A.W.; Redfern, J.P. Kinetic Parameters from Thermogravimetric Data. Nat. Cell Biol. 1964, 201, 68–69. [Google Scholar] [CrossRef]

- Álvarez, A.; Pizarro, C.; García, R.; Bueno, J.; Lavín, A. Determination of kinetic parameters for biomass combustion. Bioresour. Technol. 2016, 216, 36–43. [Google Scholar] [CrossRef]

- Rueda-Ordóñez, Y.J.; Tannous, K. Isoconversional kinetic study of the thermal decomposition of sugarcane straw for thermal conversion processes. Bioresour. Technol. 2015, 196, 136–144. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Burnham, A.K.; Criado, J.M.; Perez-Maqueda, L.A.; Popescu, C.; Sbirrazzuoli, N. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim. Acta 2005, 520, 1–19. [Google Scholar] [CrossRef]

- Perez-Maqueda, L.A.; Criado, J.M. The Accuracy of Senum and Yang’s Approximations to the Arrhenius Integral. J. Therm. Anal. Calorim. 2000, 60, 909–915. [Google Scholar] [CrossRef]

- Órfão, J.; Antunes, F.; Figueiredo, J. Pyrolysis kinetics of lignocellulosic materials—Three independent reactions model. Fuel 1999, 78, 349–358. [Google Scholar] [CrossRef]

- Rueda-Ordoñez, Y.J. Thermal Decomposition Analysis of Sugarcane Straw in Inert and Oxidative Atmospheres through Thermoanalytical Methods. Ph.D. Thesis, University of Campinas, Campinas, Brazil, 2016. Available online: http://repositorio.unicamp.br/bitstream/REPOSIP/320795/1/RuedaOrdonez_YesidJavier_D.pdf (accessed on 2 September 2019).

- Du, Z.; Sarofim, A.F.; Longwell, J.P. Activation energy distribution in temperature-programmed desorption: Modeling and application to the soot oxygen system. Energy Fuels 1990, 4, 296–302. [Google Scholar] [CrossRef]

| Authors | Description | Year |

|---|---|---|

| Muñoz y Cifuentes [31] | Study of the thermal life of containers insulated with fique and the thermal conductivity of four commercial presentations of the material (chopped, unchopped, in wadding fabric and chopped in a thermosetting resin matrix). | 2007 |

| Onésippe et al. [32] | Analysis of the mechanical and thermal behavior of a composite material made of cement reinforced with bagasse and fique fibers. | 2008 |

| Monsalve et al. [33] | Study of the mechanical and thermal behavior of a material made up of three layers: two outer layers of composite with cementitious matrix with fique fiber and aluminum oxide powder and an inner layer of recycled newsprint pulp (cellulose). | 2013 |

| Navacerrada et al. [34] | Characterization of samples made of woven and nonwoven fique of different densities and thicknesses, for which sound absorption, air flow resistivity, and thermal conductivity as a function of density were measured. | 2013 |

| Navacerrada et al. [35] | Characterization of samples made up of nonwoven fique samples with a polymeric surface coating. | 2014 |

| Proaño [36] | Development of two types of rigid polyurethane matrix composite materials, one reinforced with cabuya (fique) fibers and the other reinforced with African palm rachis fibers. Tests were carried out on bending, traction, density, combustion speed, and acoustic and thermal properties. | 2015 |

| Navacerrada et al. [37] | Determination of the acoustic and thermal properties of samples made from coconut, coconut/fique, and fique nonwoven fibers, which were produced by two methods: pressing with binder and punching. | 2016 |

| Vera [38] | Study of the acoustic and thermal performance of cabuya fiber as a wall cladding panel. | 2018 |

| García et al. [39] | Morphological study and description of the thermal decomposition process of three types of fique fiber samples: untreated, washed with a commercial softener, and after soaking for 24 h in the same softener. | 2019 |

| Gómez et al. [40] | Morphological and thermo-acoustic characterization of nonwoven fique samples. The sound absorption, resistivity, dynamic stiffness and thermal conductivity of the material were measured. | 2020 |

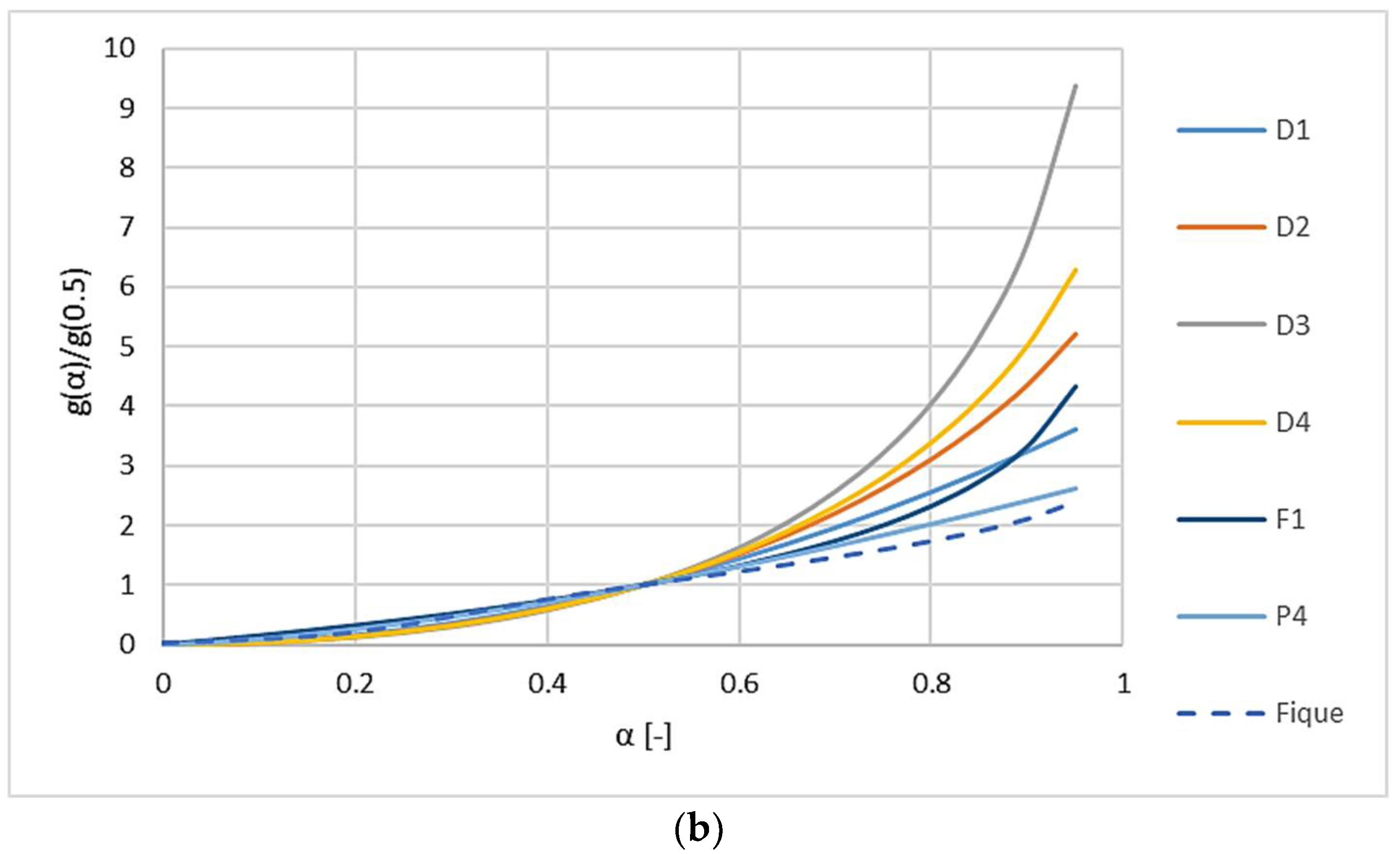

| Reaction Model | Code | f(α) a | g(α) b |

|---|---|---|---|

| Power law | P1 | 4α3/4 | α1/4 |

| Power law | P2 | 3α2/3 | α1/3 |

| Power law | P3 | 2α1/2 | α1/2 |

| Power law | P4 | 2/3α1/2 | α3/2 |

| Phase-boundary controlled reaction (contracting area) | R2 | ||

| Phase-boundary controlled reaction (contracting volume) | R3 | ||

| Avrami Erofe’ev (m = 2) | A2 | ||

| Avrami Erofe’ev (m = 3) | A3 | ||

| Avrami Erofe’ev (m = 4) | A4 | ||

| First-order | F1 | (1 − α) | −ln(1 − α) |

| nth-order | Fn | ||

| One-dimensional diffusion | D1 | ||

| Two-dimensional diffusion | D2 | ||

| Three-dimensional diffusion | D3 | ||

| Ginstling–Brounstein diffusion | D4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García Sánchez, G.F.; Guzmán López, R.E.; Gonzalez-Lezcano, R.A. Fique as a Sustainable Material and Thermal Insulation for Buildings: Study of Its Decomposition and Thermal Conductivity. Sustainability 2021, 13, 7484. https://doi.org/10.3390/su13137484

García Sánchez GF, Guzmán López RE, Gonzalez-Lezcano RA. Fique as a Sustainable Material and Thermal Insulation for Buildings: Study of Its Decomposition and Thermal Conductivity. Sustainability. 2021; 13(13):7484. https://doi.org/10.3390/su13137484

Chicago/Turabian StyleGarcía Sánchez, Gabriel Fernando, Rolando Enrique Guzmán López, and Roberto Alonso Gonzalez-Lezcano. 2021. "Fique as a Sustainable Material and Thermal Insulation for Buildings: Study of Its Decomposition and Thermal Conductivity" Sustainability 13, no. 13: 7484. https://doi.org/10.3390/su13137484

APA StyleGarcía Sánchez, G. F., Guzmán López, R. E., & Gonzalez-Lezcano, R. A. (2021). Fique as a Sustainable Material and Thermal Insulation for Buildings: Study of Its Decomposition and Thermal Conductivity. Sustainability, 13(13), 7484. https://doi.org/10.3390/su13137484