1. Introduction

Concrete is one of the most popular construction materials in the world due to its strength and durability. However, despite its benefits, concrete production is also responsible for 8% of the global CO

2 emissions [

1]. A literal way to offset this is to grow plants on concrete to facilitate CO

2 uptake [

2,

3,

4,

5]. Designing a concrete material that can be host to small plant species and micro-organisms without any superficial layer refers to the process of bio-receptivity. In 1995, Guillitte was the first person to define and recognize bio-receptivity, stating that ‘The aptitude of a material (or any other inanimate object) to be colonized by one or several groups of living organisms without necessarily undergoing any biodeterioration [

5]’.

Bio-receptive concrete material can be a solution to create a more sustainable version of this popular construction material for the future of net-zero buildings. As defined by Guillitte in 1995, bio-receptive concretes can be colonized by micro-organisms, macro-organisms and plants [

5]. The green layer can protect the exposed material from harsh weather, and provide thermal and sound insulation [

4]. By using the photosynthesis process, these small non-vascular plants can take in up to 3.9 billion metric tons of carbon per year [

6]. The presence and the movement of water through the plant body contribute to cooling down the surrounding air by evapotranspiration [

7], thus reducing the cooling load on the building. The structure of these plants is such that they are able to trap dust and other impurities, cleaning up the air to breathe [

8]. Best of all, bio-receptive facades, being a result of the material property of the main building fabric, are viewed as self-sustaining systems (autonomous). This facade system requires no external irrigation or maintenance facilities, unlike the typical green wall systems.

When provided with the appropriate combination of material, environmental and plant properties, bio-receptive facades can prove to be an economically feasible greening medium. Material property is the most important factor to create a bio-receptive concrete facade. To achieve bio-receptivity, high surface roughness with high porosity and a neutral pH level is desired [

2]. Physical properties like roughness and porosity are often valued over the chemical composition of the material, being the contributing factors for the presence of water on and within the surface [

9,

10]. Surface roughness can be defined as the topographic profile of the surface [

11]. This degree of roughness helps to create a microclimate on the surface, by trapping in moisture from rain, dew and the accumulation of dust, and by providing the necessary shading from a harsh environment [

12]. The amount of water that can be absorbed and retained in a material is determined by the level of porosity of the material [

13]. As defined by Tran and Hoang [

11], ‘Porosity is the ratio of open pore volume to the total volume of materials.’ A network of interconnected pores allows the permeability of water through the material, providing the moisture for survival of the micro-organisms. These physical properties together with a low pH around 8–10 have been reported to create the suitable chemical composition to make the material bio-receptive [

5]. The pH value determines the alkalinity of the material, and binding materials like fly ash, slag or silica fumes have less hydroxyl ions, which help to create a neutral base to promote the plant growth [

14].

Despite the reported benefits of a bio-receptive facade, it is often viewed as a deteriorating factor in building envelopes (

Figure 1). In the public eye, the lack of order and shabby growth conditions of moss or lichens creates an impression of a dirty and damaged surface [

12]. In recent times researchers have been trying different ways to redefine bio-receptivity and promote its benefits. Some of the notable works are the research work in University College London, UCL Bartlett, in 2016, where Professor Cruz and Beckett tested digitally fabricated (glass fiber-reinforced concrete) GRC limestone concrete panels transplanted with moss to create growable concrete blocks [

2]. Another early exploration in this field was by Ottelé et al. in 2010, where the geometry of the top layer of the concrete panel was used to foster plant growth on its surface. His experiment also showed a clear dependency of plant growth on the material property [

4]. Lastly, Huang et al. tested the role of different micro-grooves for the formation and growth of microalgae biofilm [

15]. In line with the cited research experiences, this research is a further exploration into the relevance of geometrical articulation of a surface on its potential for bio-receptivity. Here, the problem has been addressed to stimulate bio-receptivity through solutions based on real time practical experimentations.

The main objective of this research was to explore the impact of geometry on the ordered growth of mosses, in order to highlight its benefits and promote (mass) the use of these bio-receptive concrete facade panels. Geometry has been used to facilitate the ordered and systematic growth of mosses on concrete facade panels, resulting in an aesthetically pleasing and functional surface layer. The research followed a top-down approach where, first, designs were developed based on the literature and field surveys, and these were then validated through practical experimentations and simulations, finally providing a general design guideline for the use of geometry as a design variable in the development of bio-receptive facade panels.

2. Strategy and Methods

To achieve the research goals, the methodology followed here was a top-down approach. The approach was divided into two main stages. The first stage involved the formulation of the design scenarios, where designs were developed based on literature research and field surveys. The second stage was the experimental setup, where the designs were validated through experimentation to create a set of design guidelines that can enhance the bio-receptive quality of concrete panels. In the first stage, the boundary conditions were set for the concrete mixture according to the research results from the doctoral dissertation of Manso [

3], used to fabricate the designed panels. In the second stage the moss-growing experiment was carried out within a controlled environment in a greenhouse, assuming an ideal growth condition (temperature 20–24 °C, RH 75–85%), while the water retention experiment was setup in a laboratory replicating the effect of rainfall onto the surface of the concrete panels. Due to time restraints, carrying out the experiments in outdoor conditions was not within the scope of this research.

2.1. Definition of the Design Scenarios

In this section, the first stage of the top-down approach has been discussed, where following the design of the research strategy, prototype designs were developed. The research began with a thorough literature review on the plant biology of mosses, material properties of concrete, environmental properties, influence of geometry on bio-receptivity and field surveys.

The literature review and practical insight from the field survey provided an outline to design several geometrical options to facilitate engineered moss growth on concrete. According to the studies, mosses are non-vascular plants, with no root system, which take in water through capillary action. Mosses require water to carry out the fertilization process and wind for spore dispersal [

8]. Being poikilohydric, mosses that are found in exposed surfaces often grow in tufts or cushion form to minimize water loss [

16]. Mosses, being small plant species, need to have a microclimate on and above the surface. The micro-climate can help to maintain the required moisture level, a cooler temperature and a low wind speed. The role of geometry is vital to create the desired micro-climate conditions for this plant growth.

An engineered growth refers to employing surface geometry to create a self-sustaining system for the growth of mosses in desired areas and in a desired coverage. The presence of water is essential for the growth and development of bio-colonization [

17]. The surface roughness, being the most crucial physical characteristic of the material, should be able to retain water from the rain, dew and other natural phenomena on its surface [

12,

17,

18]. The surface morphology can also help to create areas of shading to protect plants from direct sunlight and provide buffers to high wind speed causing detachment and also gather nutrients onto its surface.

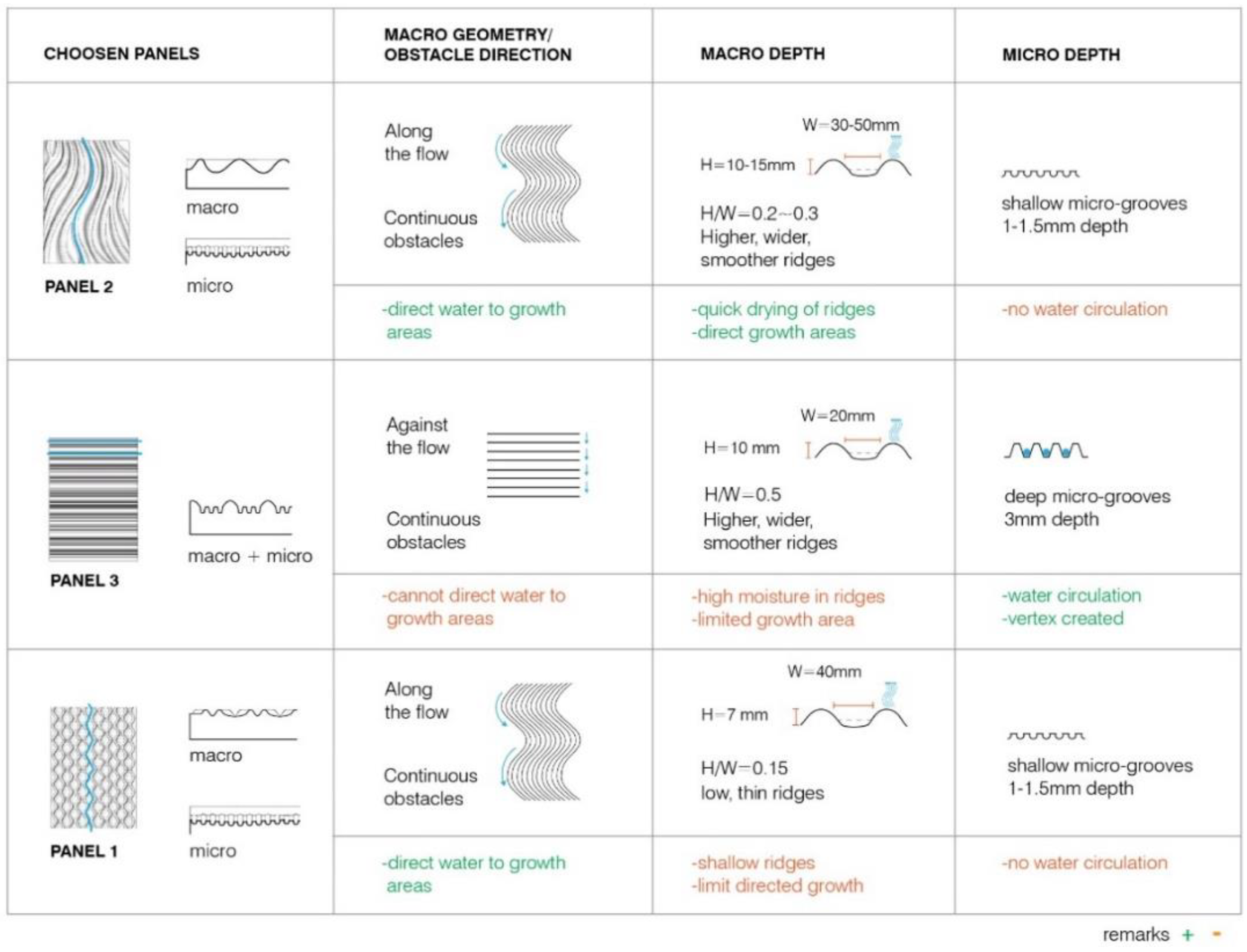

Based on this parameter, four distinct geometric panels were designed, catering to the environmental factors for a self-sustaining system (

Figure 2). The geometric features of each designed panel were classified into two geometry levels, macro- and micro-level geometry. A combination of both these geometric levels helped to create a micro-climate within its surface by influencing the water flow path of the panels and direct growth in desired areas. The micro-geometric features, called micro-grooves, were used where moss coverage was desired, creating slow water movement into water catchment areas and anchorage facilities. The macro-geometric features created the overall surface undulations, which helped to distinguish between the growth and no-growth areas. Two extra panels, a plain concrete panel and a naturally rough concrete panel with exposed sand and gravel layers, were also created for a more vivid comparative analysis between the ordered and random surface geometries (

Figure 2).

To maintain an aesthetically pleasing look to the designed geometric panels, the geometric compositions investigated in this research were inspired by patterns found in nature depicting different functional qualities. The patterns were further translated into surface geometry on the four panels through a method of repetition called rhythm, creating a sense of harmony and order that is aesthetically pleasing to the human eye (

Figure 3) [

19]. Panel 1 has been designed in an alternating rhythm method, Panel 2 in a flowing rhythm, Panel 3 in a regular rhythm and Panel 4 followed a random rhythm.

To achieve bio-receptivity, the concrete needs high surface roughness with high porosity and a neutral pH level [

2]. To further proceed with a foolproof concrete mixture with bio-receptive properties, the recipe was adapted from the doctoral dissertation of Manso. Factors like the type of binder to be used, the aggregate sizes, the water/cement ratio and the amount of cement paste determined the material composition for bio-receptivity [

3].

Table 1 shows the material content for 1

of concrete. For detailed calculation, refer to

Appendix A (

Figure A1).

The prototype making process was carried out as following. The negatives of the four prototype designs were fabricated through CNC milling on hard foam material. The foam molds were next brushed with a sealing agent, silicone, to reduce their adhesion quality to concrete and ensure easy demolding (

Figure 4a). Finally, after 24 h. of hardening, the molds were filled with the prescribed concrete mixture (

Figure 4b). The mixture was left to set uncovered in the molds for 48 h without any curing to achieve the highest possible porous quality of the concrete panels. In total, 12 concrete panels in the size 350 × 250 × 40 mm were made. For each tile, 3.25 L of the mixture were cast into the molds. Among the two sets of the concrete panels cast, one set was used for the macro-level water-related laboratory testing and the other set for the controlled moss growth experiment.

2.2. Experimental Setup

2.2.1. Water Retention Experiment

As already found, water is essential for the growth and survival of mosses. The designed geometric patterns on the concrete panels have been used to influence the water flow movement on and within its surface. To test and validate this hypothesis, the following water retention testing was carried out in a laboratory setup. The goal of this experiment was to measure how much the weight of each of the panels changed due to their water absorption and retention capacities, which were solely influenced by the surface geometry of each panel irrespective of their material composition.

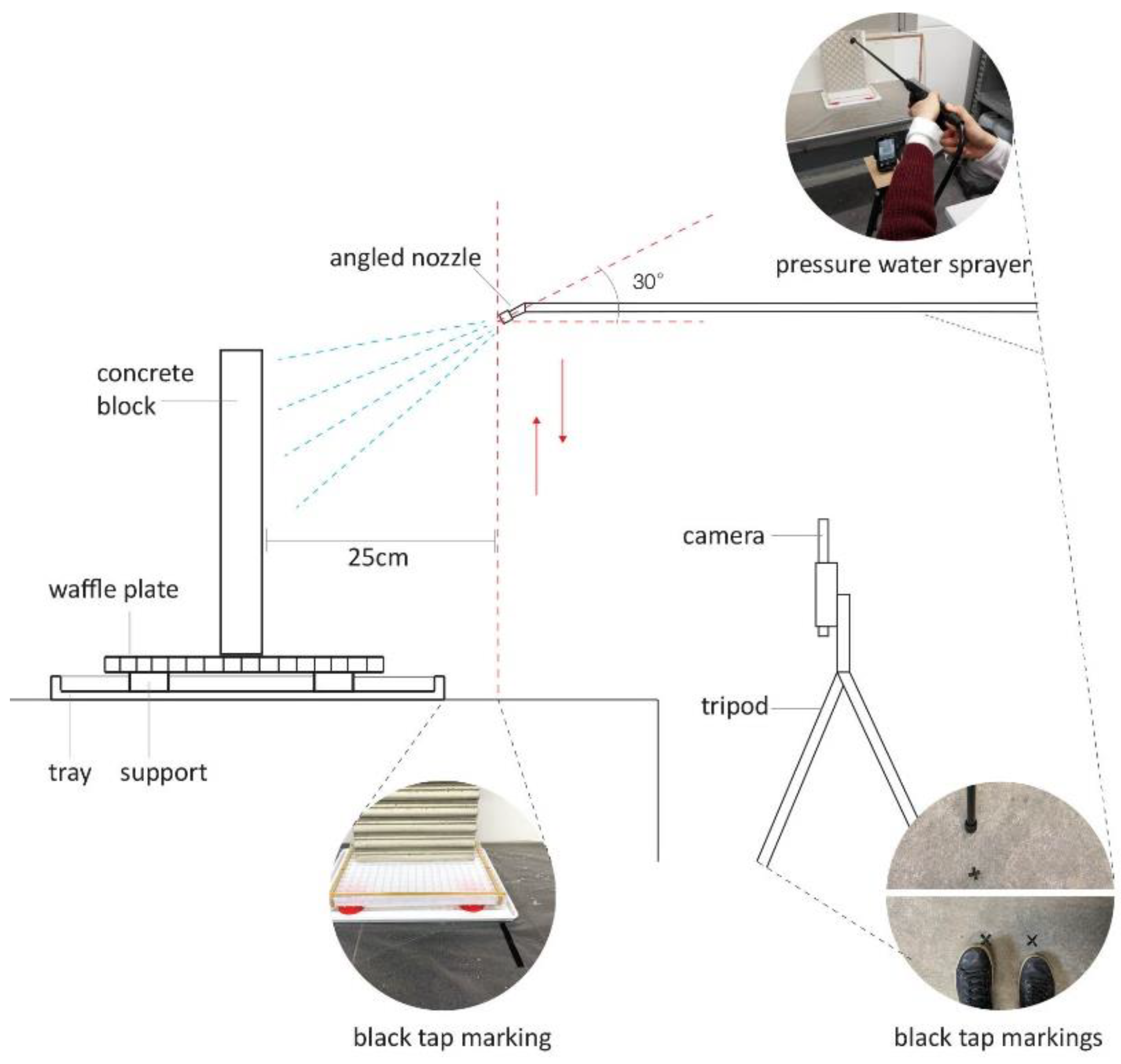

The experiment began with the laboratory setup as shown in

Figure 5, the panel was placed over a waffle grill to allow the sprayed water to drain out into the tray below. Next, a camera was set from a suitable distance to record the water movement on the surface. For better visibility, water soluble beetroot juice was diluted with water for spraying. A pressure water sprayer with a 30° nozzle angle was filled with the red-color water and positioned at a fixed distance of 25 cm from the concrete block. Black tap markings were used to demark the standing position for spraying, the distance of the spray nozzle from the block and the position of the tripod for the camera. The room temperature was measured to be 22 °C and RH 55% for the record.

The ridge part of the designed panel surfaces was sand polished to smoothen it for efficient redirection of water from ridges towards the alcove. Next, the panels were oven dried for a period of 6 h at 45 °C. The oven drying was only done once at the beginning of the experiment to ensure complete drying of the panels. The experiment was carried out in the following steps:

Step 1: The weight before spraying was recorded.

Step 2: The panels were calibrated vertically according to the setup described in the previous section.

Step 3: The colored water measuring 150 mL was sprayed for a duration of 30 s, in an up and down motion of the sprayer to allow even wetting of the panel.

Step 4: After a period of 2 min, the amount of water drained out into the tray was measured and the readings for temperature, surface relative humidity and weight of the panels were recorded.

Step 5: The temperature, humidity and weight readings were recorded twice more, after 10 min and 20 min from the spraying time (

Figure 6a–c).

The procedure was repeated for day 3 and day 7 to test the water retention ability of the panels over a period of 7 days. The whole laboratory setup and experiment procedure was repeated a second time to check for any discrepancies in the two sets. In the results section, all the data from the experiment have been thoroughly documented and analyzed to further deduce the findings.

2.2.2. Moss-Growing Experiment

The second set of the freshly cast panels were used for the moss-growing experiment. The experiment was carried out in the greenhouse of the TU Delft botanical garden. The experiment was dated between the end of February to mid-May, after a trial phase for the first three weeks of February.

The saxicolous moss fragments with rip spores were collected from the botanical garden stone surfaces. The slurry was prepared, according to the findings of our literature review. Buttermilk and moss fragments in a (1:1) ratio were blended for 24 h before application. The buttermilk helped to create an acidic base for the mixture. The panels were prepared by polishing the ridges with sandpaper for a smoother finish where no moss growth is desired and then thoroughly cleaned with water and vinegar to remove any surface contaminants. The prepared slurry was painted in desired areas using a paint brush.

Based on the findings of the trial period, the panels recoated with moss slurry were placed in the warmer tropical greenhouse. The experiment was carried out in a span of 12 weeks. It was done in two phases, where during first 6 weeks, the panels were placed in horizontal position, and for the last 6 weeks, in an upright position (

Figure 7). The temperature ranging between 20–24 °C and RH 75–85% was maintained within the greenhouse and rainwater was sprayed onto the panels twice or thrice daily for around 30 s each time depending on the weather conditions. During the dark cycle of the day, the panels were kept uncovered due to the high humidity (RH 60%+) inside the greenhouse.

5. Conclusions

This research is a testimony that bio-receptive material can be geometrically articulated to engineer a self-sustaining process and manipulate the organic growth of mosses in an ordered system that is not only functionally viable but also aesthetically pleasing, to further change the perception of people towards bio-receptivity. The building material chosen to be investigated was concrete, due to its inherent bio-receptive quality and the capacity to reduce its carbon footprint with a more sustainable and greener version. The research followed a top-down approach where, firstly, designs were developed based on a literature review and field surveys, then the fabricated panels were validated through practical experimentations and finally, a general design guideline was provided.

The presence of water is vital for the growth and development of mosses on stony surfaces. Through the experimentations, the surface roughness or topography was found to be the most crucial feature to create the desired micro-climate for the bio-receptive characteristics of the concrete panels. For vertical application of the panels, the geometric features, like the deep micro-grooves, can create greater water catchment areas on the surface in combination with continuous ‘along-the-flow’ macro geometries, which can help to direct the flow path, creating a clear distinction between growth and no-growth areas. For the efficient functioning of these geometric features, the initial maturing of the mosses should be allowed in a horizontal position before its vertical application. In support to these geometric features, the material properties of concrete are also equally important as they influence the water absorption capacity of the concrete. The absorption quality of the surface was enhanced by using blast furnace slag cement and a high-water cement ratio of 0.60 in combination with a lack of curing during the hardening process. Using these guidelines, countless options of surface morphology can be used to create a self-sustaining bio-receptive concrete facade panel.

The results of this research work clearly coincide with some of the previous research works where the role of surface roughness or topography in bio-receptivity were established, namely the work of Ottelé et al. and Huang et al. [

15]. In the former, the geometry of the top layer of the concrete panel showed an innovative way to foster plant growth on its surface, providing a multifunctional characteristic to a regular construction material. The experiment also provided a clear relationship between the properties of the material and the growth of vegetation on the surface [

4]. In the latter, the role of grooves was shown to have a significant effect on the concentration of microbial attachment on the substrate, which is a great analogy to the role of micro-grooves in this research [

15].