The Combined Effect of Alcohols and Calophyllum inophyllum Biodiesel Using Response Surface Methodology Optimization

Abstract

:1. Introduction

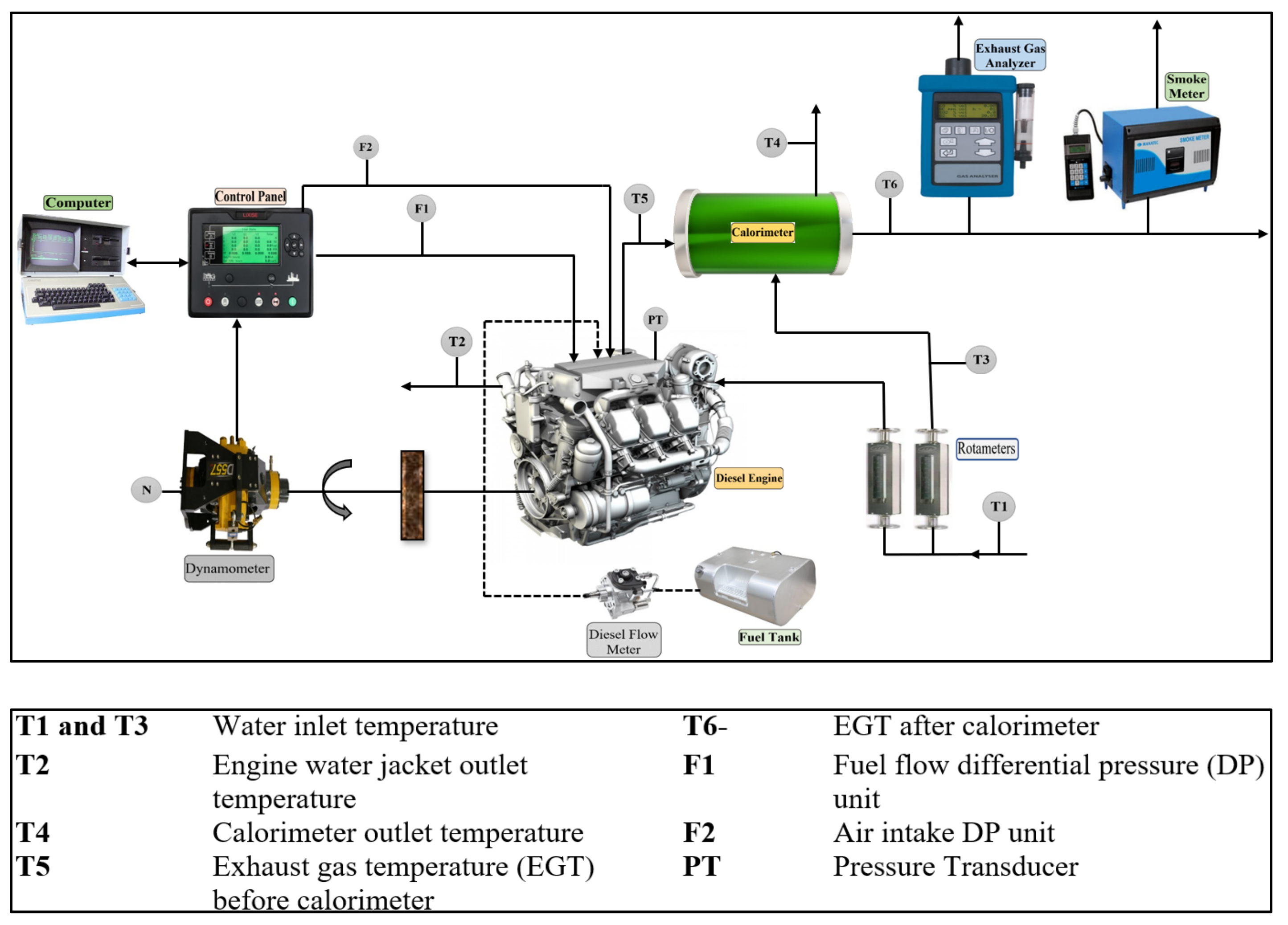

2. Materials and Methods

2.1. Chemical Properties of Calophyllum inophyllum

2.2. N-octanol

2.3. N-butanol

2.4. Uncertainty Analysis+

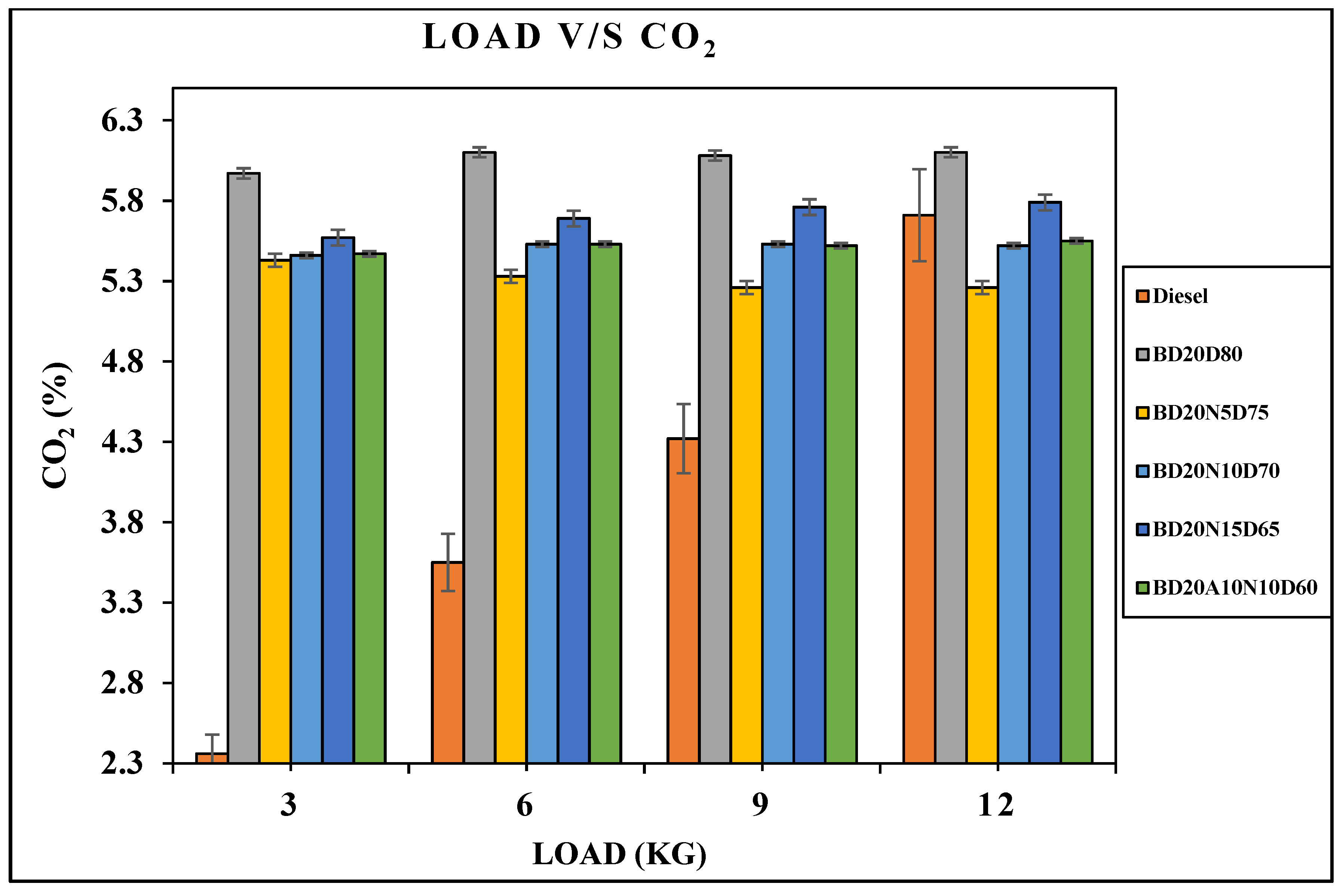

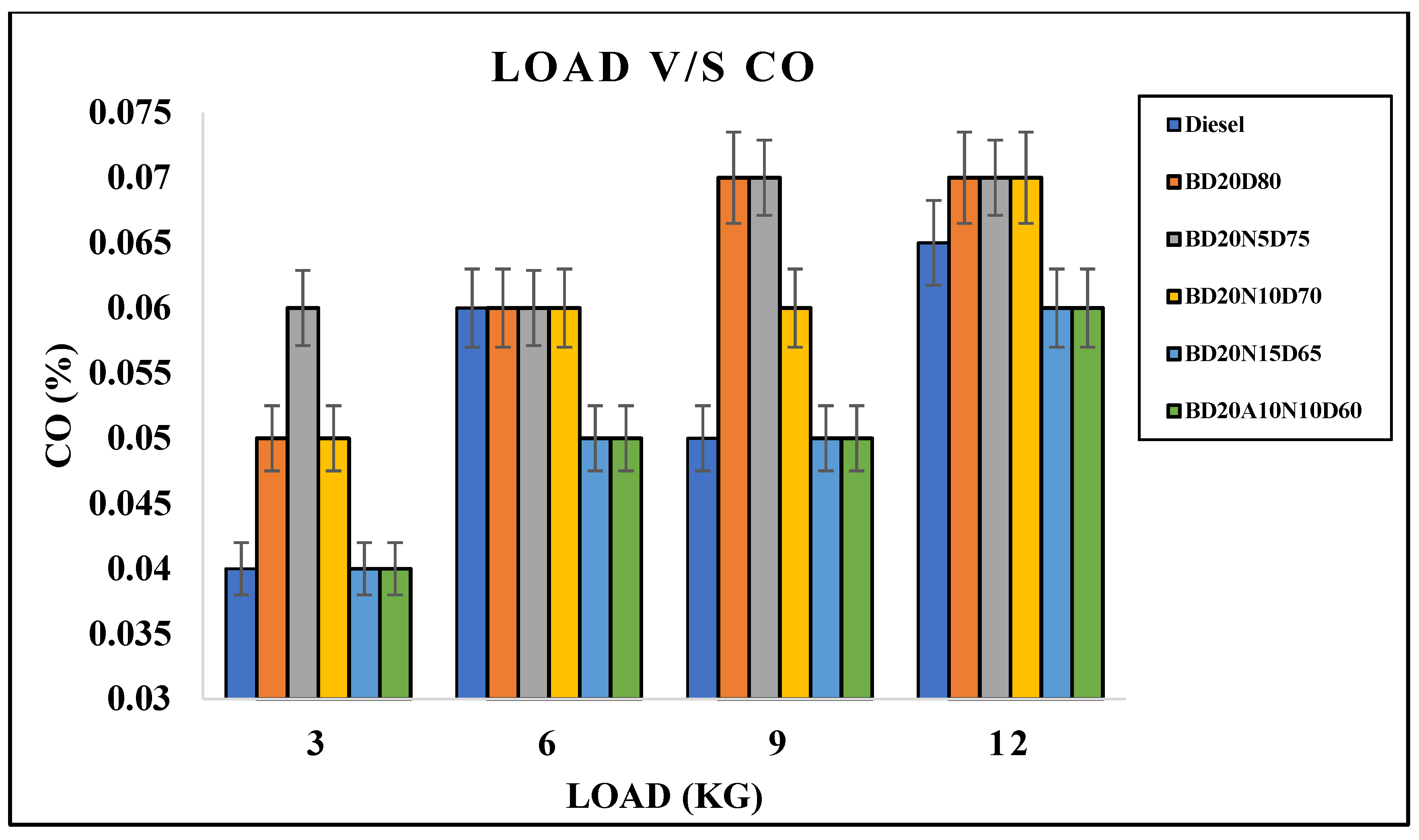

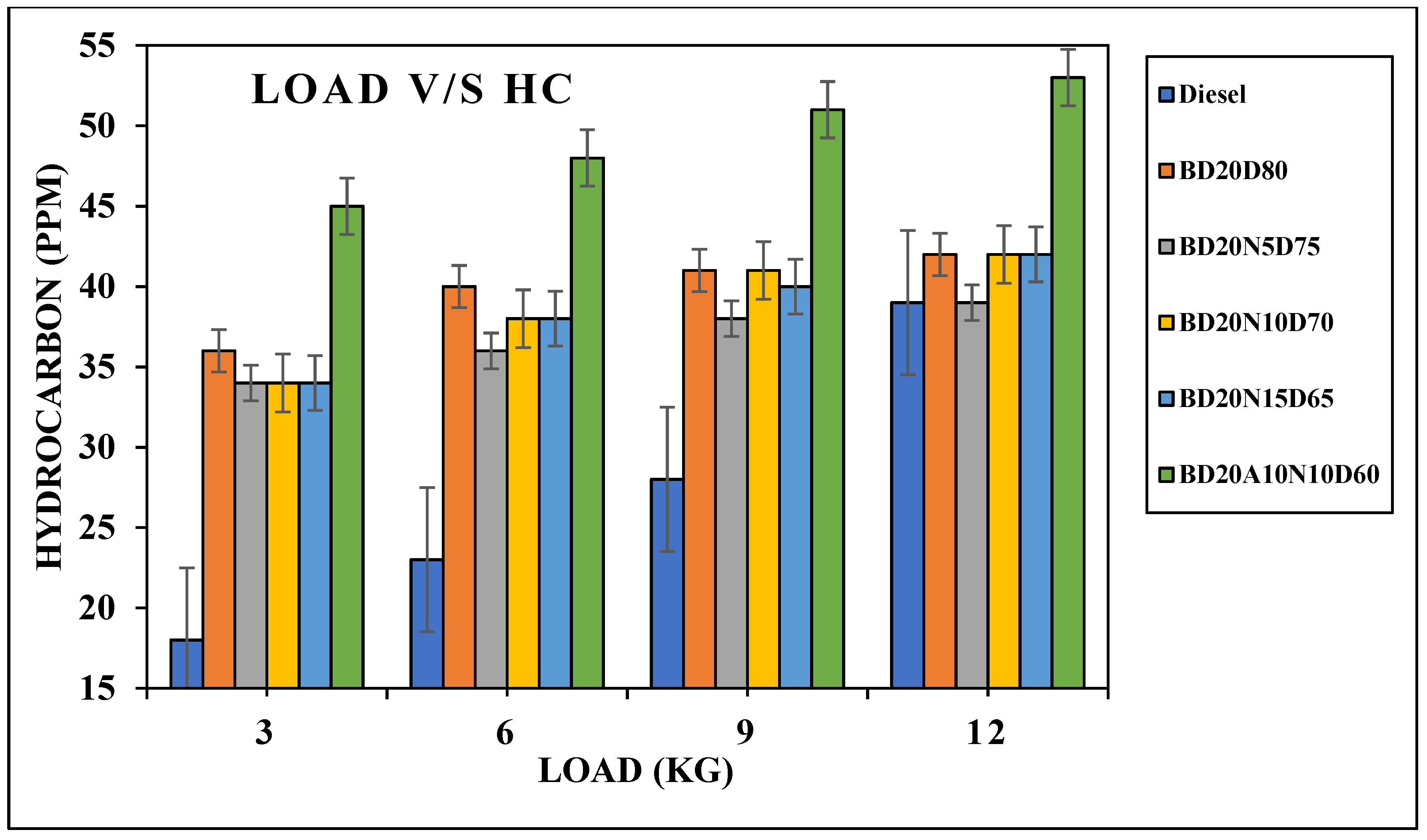

3. Results

3.1. Performance Test Results for Diesel & Different Biodiesel Blends

- s = series number

- i = number in series s

- m = points y in the chart

- n = point number in each series

- yis = numbers value of series ‘s’ and the ith point

- ny = Actual number of data values in all series

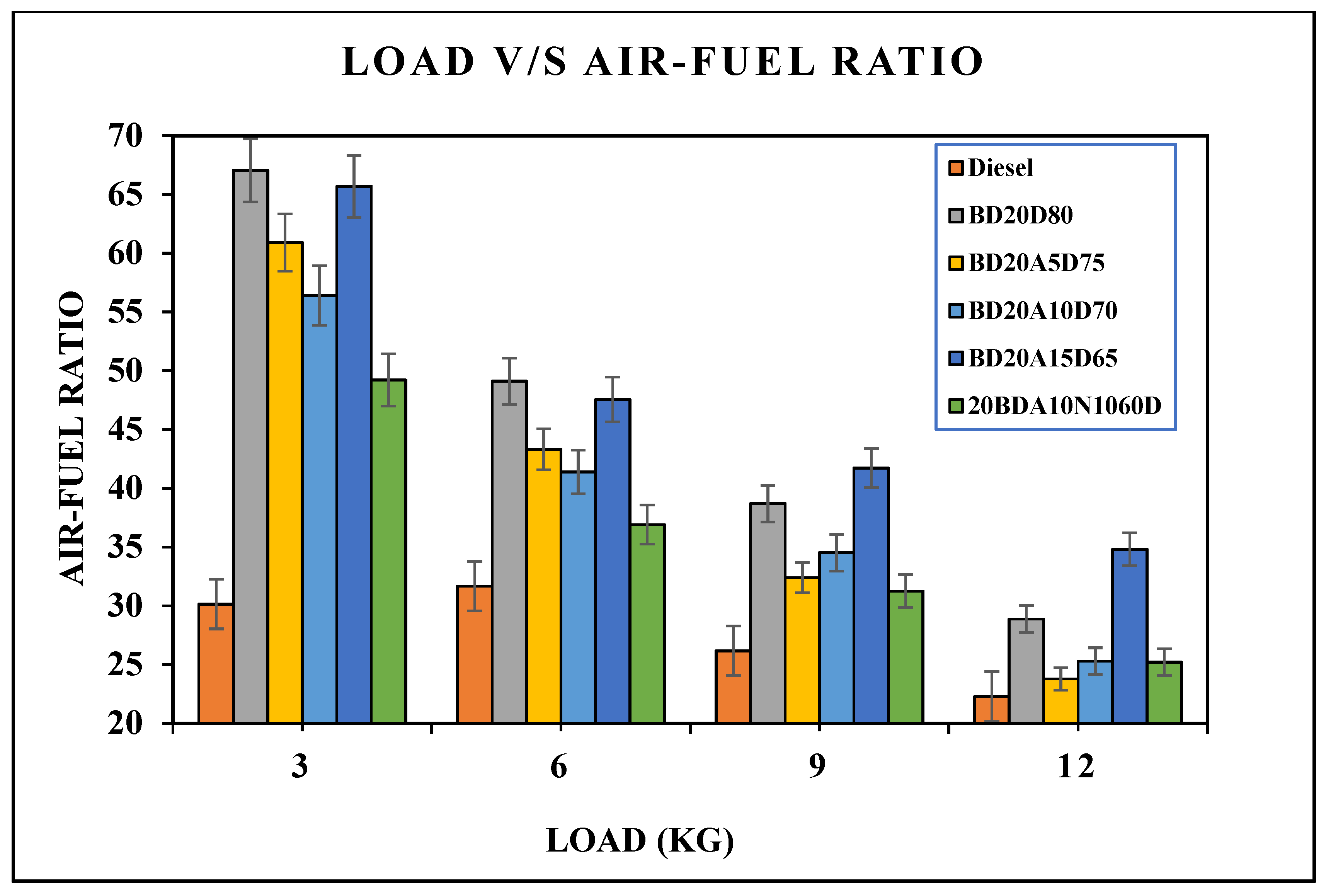

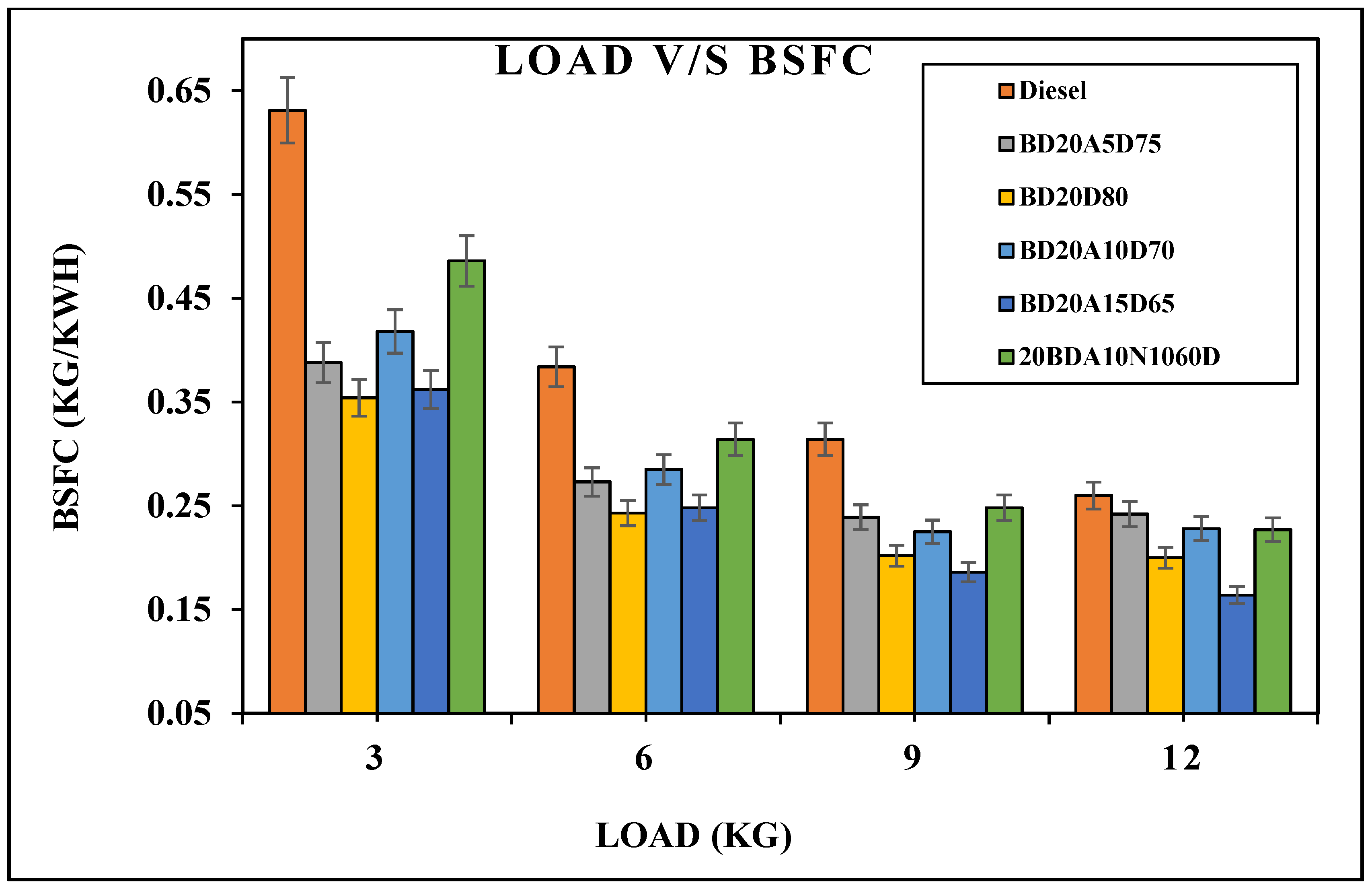

3.1.1. N-octanol Blends

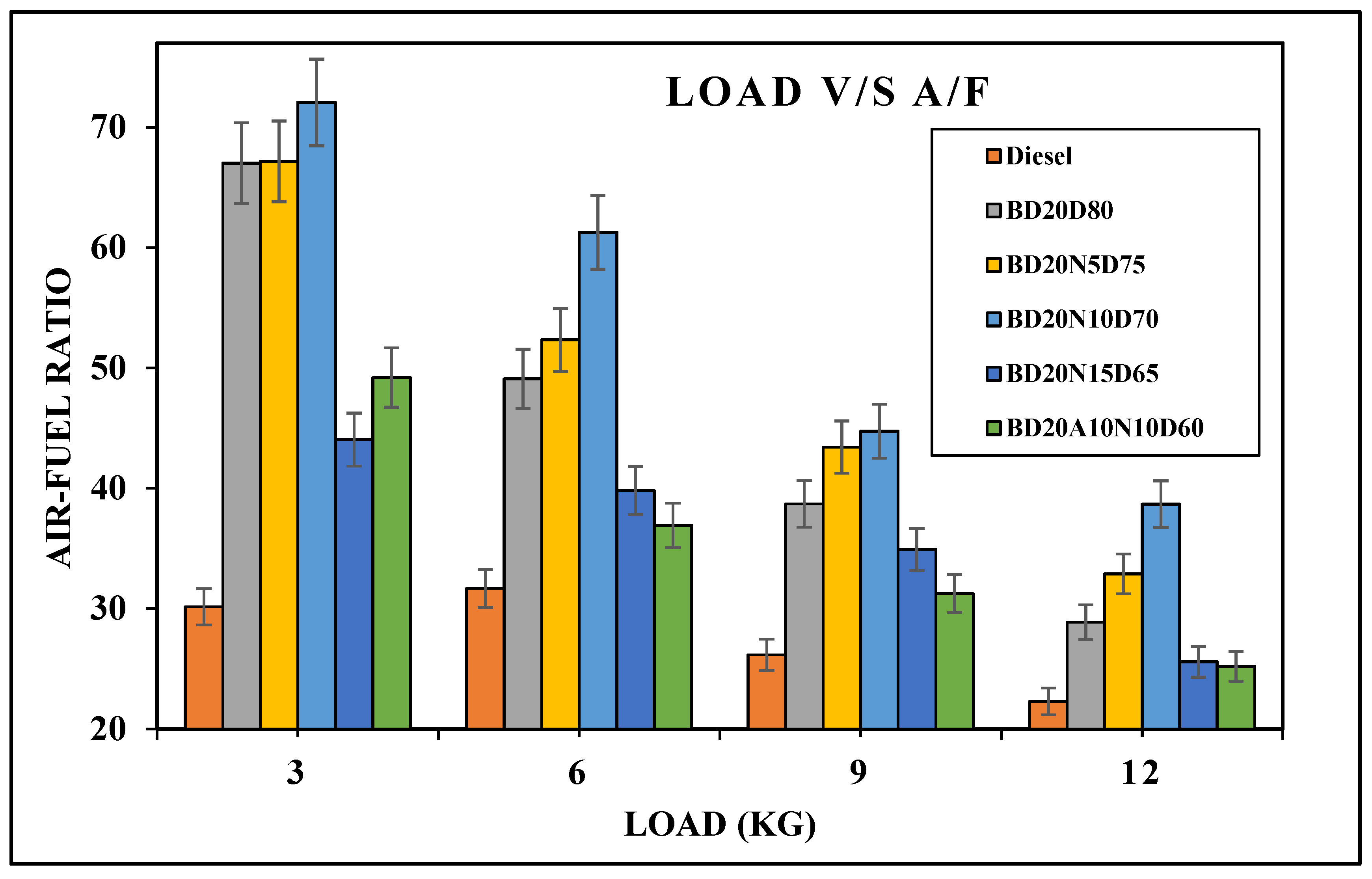

3.1.2. N-butanol Blends

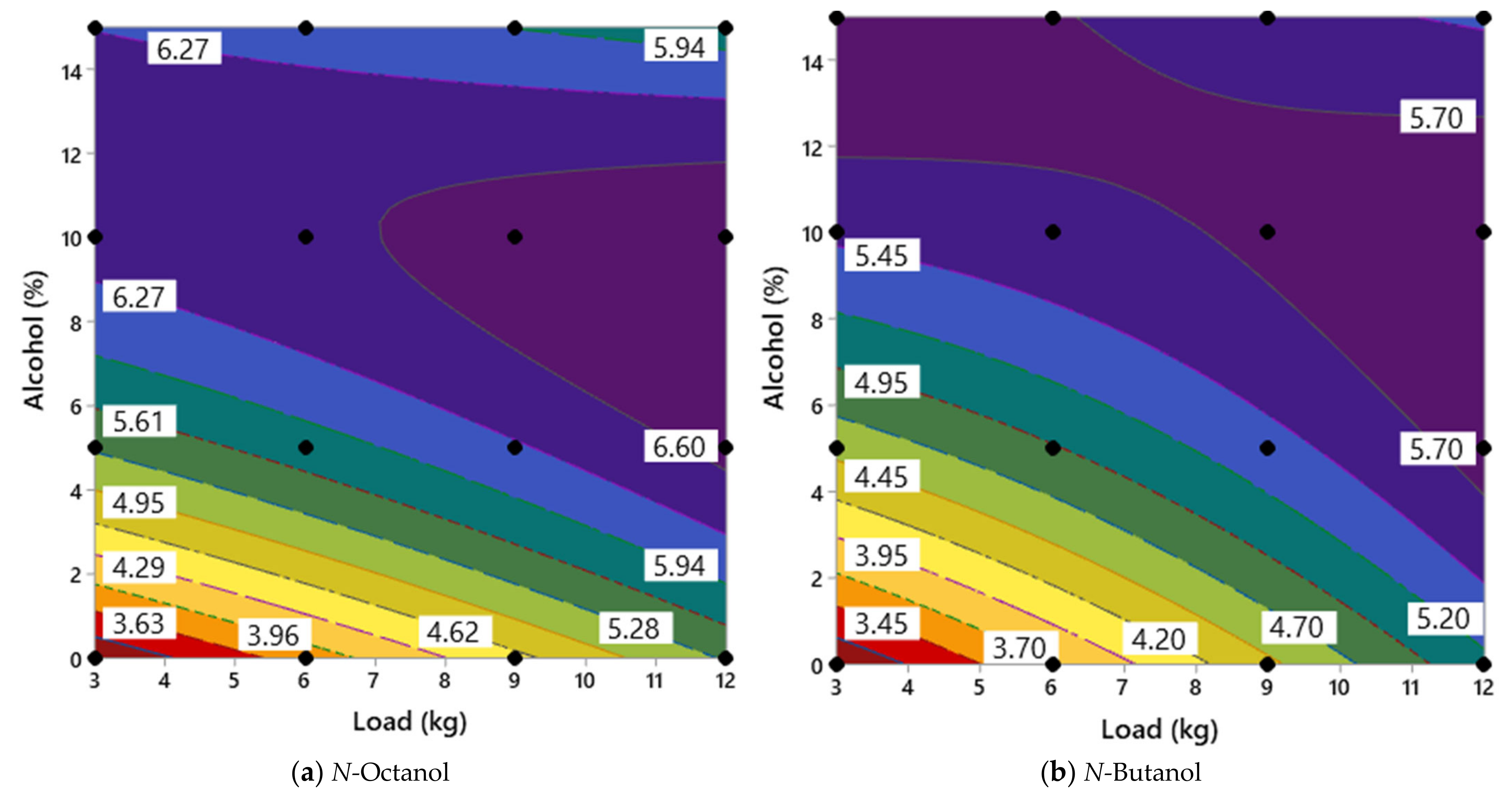

4. Response Surface Methodology (RSM) Optimization Method

- = intercept

- = linear regression coefficient of ith factor (linear)

- = quadratic regression coefficients of ith factor (one-way)

- = interaction of ith and jth factors (two-way)

- = interaction of ith, jth and kth factors (three-way)

- dependent variable

+ 0.1281 Alcohol (%)∗Alcohol (%) − 0.0865 Load (kg)∗Alcohol (%)

− 0.000137 Alcohol (%)∗Alcohol (%) + 0.000010 Load (kg)∗Alcohol (%)

− 0.000213 Alcohol (%)∗Alcohol (%) + 0.000003 Load (kg)∗Alcohol (%)

− 0.02452 Alcohol (%)∗Alcohol (%) − 0.02071 Load (kg)∗Alcohol (%)

− 0.01142 Alcohol (%)∗Alcohol (%) – 0.01967 Load (kg)∗Alcohol (%)

+ 0.0675 Alcohol (%)∗Alcohol (%) − 0.0980 Load (kg)∗Alcohol (%)

− 0.1000 Alcohol (%)∗Alcohol (%) – 0.0773 Load (kg)∗Alcohol (%)

5. Conclusions

- BD20A10N10D60 showed the highest BTE and lowest CO emission among the blends of N-octanol. BD20N10D70 was found to have the highest calorific value and lowest BSFC among the blends. BD20N5D75 showed the lowest HC emission among the blends of N-butanol. BD20A5D75 and BD20A10D70 showed the lowest HC emissions among the blends of octanol. BD20A10N10D60 showed the highest BTE and lowest CO emission among the blends of N-butanol. BD20N5D75 showed the lowest HC emission among the blends of N-butanol.

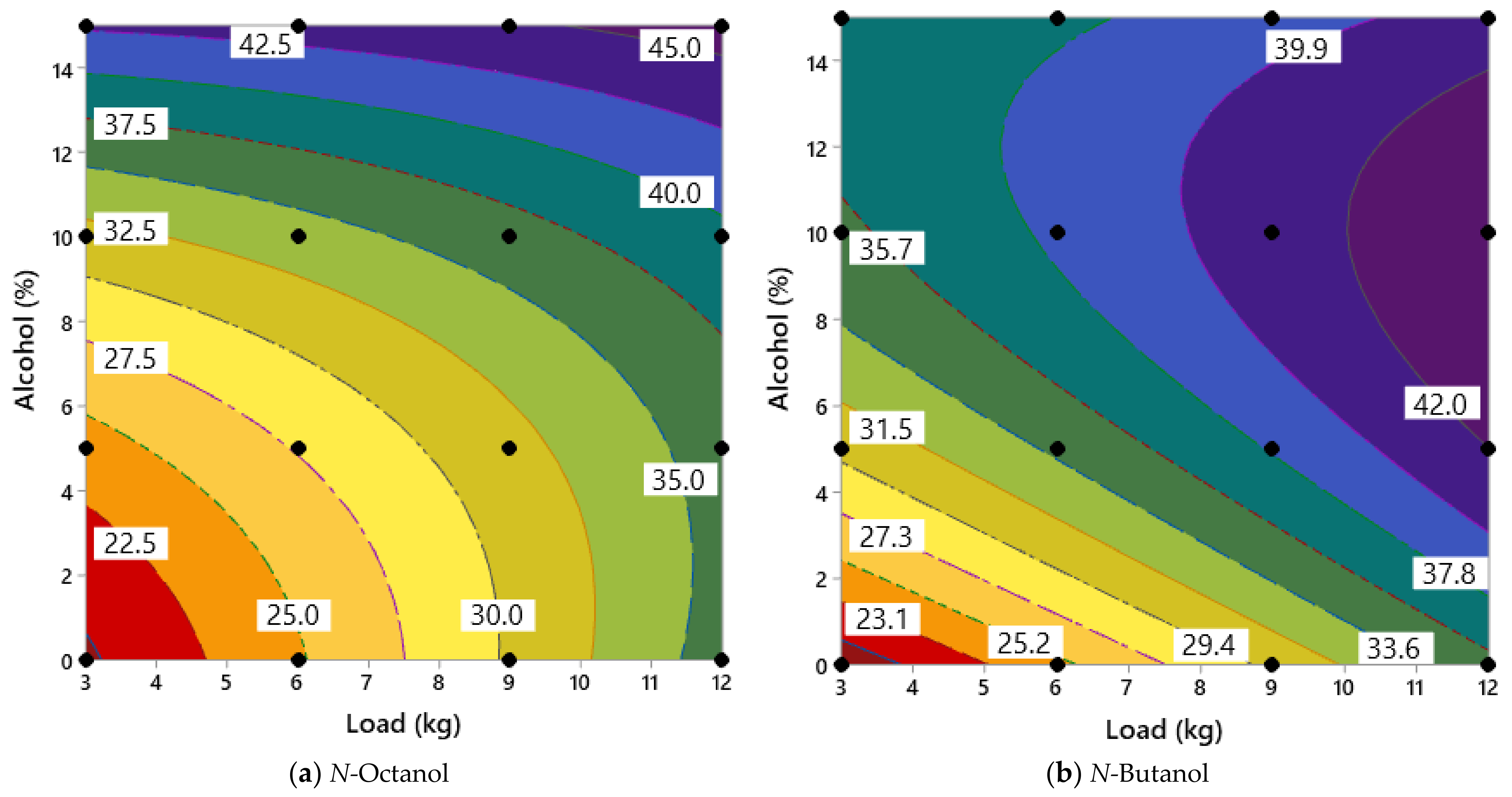

- A hybrid blend of octanol and N-butanol that is BD20A10N10D60 is the optimum blend among the blends of N-octanol and N-butanol. From RSM optimization method, it is observed that when alcohol is not added, the BTE increases consistently with load and it reaches the maximum at full load. At 15% alcohol, the increase in BTE with load is much lesser. Hence, the optimized value is obtained at no alcohol and maximum load.

- The role of N-octanol and N-butanol additives in the performance and emission of the engine is significant. With the increase of load, the emission increased and further deteriorated with the rise in the percentage of N-octanol. However, the use of N-butanol additive reduces the emissions at full loads.

- The mathematical models from RSM are perfectly fitted with the experimental readings with more than 92% accuracy, which indicates their perfect fitting for optimization.

- The ANOVA of the parameter interactions indicates that the alcohol percentage in the blend also significantly influences engine performance and emission profile.

- The RSM analysis provided the optimal thermal efficiency value and emissions at higher loads and moderate percentage of alcohol.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Akram, N.; Montazer, E.; Kazi, S.; Soudagar, M.E.M.; Raju V., D.; Ahmed, W.; Zubir, M.N.M.; Afzal, A.; Muhammad, M.R.; Ali, H.M.; et al. Experimental investigations of the performance of a flat-plate solar collector using carbon and metal oxides based nanofluids. Energy 2021, 227, 120452. [Google Scholar] [CrossRef]

- Sateesh, K.A.; Yaliwal, V.S.; Soudagar, M.E.M.; Banapurmath, N.R.; Fayaz, H.; Safaei, M.R.; Elfasakhany, A.; El-Seesy, A.I. Utilization of biodiesel/Al2O3 nanoparticles for combustion behavior enhancement of a diesel engine operated on dual fuel mode. J. Therm. Anal. Calorim. 2021. [Google Scholar] [CrossRef]

- Fayaz, H.; Mujtaba, M.; Soudagar, M.E.M.; Razzaq, L.; Nawaz, S.; Nawaz, M.A.; Farooq, M.; Afzal, A.; Ahmed, W.; Khan, T.Y.; et al. Collective effect of ternary nano fuel blends on the diesel engine performance and emissions characteristics. Fuel 2021, 293, 120420. [Google Scholar] [CrossRef]

- Mujtaba, M.; Cho, H.M.; Masjuki, H.; Kalam, M.; Farooq, M.; Soudagar, M.E.M.; Gul, M.; Afzal, A.; Ahmed, W.; Raza, A.; et al. Effect of primary and secondary alcohols as oxygenated additives on the performance and emission characteristics of diesel engine. Energy Rep. 2021, 7, 1116–1124. [Google Scholar] [CrossRef]

- Razzaq, L.; Farooq, M.; Mujtaba, M.; Sher, F.; Farhan, M.; Hassan, M.; Soudagar, M.; Atabani, A.; Kalam, M.; Imran, M. Modeling viscosity and density of ethanol-diesel-biodiesel ternary blends for sustainable environment. Sustainability 2020, 12, 5186. [Google Scholar] [CrossRef]

- Khan, H.M.; Iqbal, T.; Yasin, S.; Irfan, M.; Kazmi, M.; Fayaz, H.; Mujtaba, M.; Ali, C.H.; Kalam, M.; Soudagar, M.E.M. Production and utilization aspects of waste cooking oil based biodiesel in Pakistan. Alex. Eng. J. 2021, 60, 5831–5849. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Afzal, A.; Safaei, M.R.; Manokar, A.M.; El-Seesy, A.I.; Mujtaba, M.A.; Samuel, O.D.; Badruddin, I.A.; Ahmed, W.; Shahapurkar, K.; et al. Correction to: Investigation on the effect of cottonseed oil blended with different percentages of octanol and suspended MWCNT nanoparticles on diesel engine characteristics. J. Therm. Anal. Calorim. 2020, 1–18. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Mujtaba, M.A.; Safaei, M.R.; Afzal, A.; Ahmed, W.; Banapurmath, N.R.; Hossain, N.; Bashir, S.; Badruddin, I.A.; Goodarzi, M.; et al. Effect of Sr@ ZnO nanoparticles and Ricinus communis biodiesel-diesel fuel blends on modified CRDI diesel engine characteristics. Energy 2020, 215, 119094. [Google Scholar] [CrossRef]

- Hossain, N.; Mahlia, T.M.I.; Miskat, M.I.; Chowdhury, T.; Barua, P.; Chowdhury, H.; Nizamuddin, S.; Ahmad, N.B.; Zaharin, N.A.B.; Mazari, S.A.; et al. Bioethanol production from forest residues and life cycle cost analysis of bioethanol-gasoline blend on transportation sector. J. Environ. Chem. Eng. 2021, 9, 105542. [Google Scholar] [CrossRef]

- Wategave, S.; Banapurmath, N.; Sawant, M.; Soudagar, M.E.M.; Mujtaba, M.; Afzal, A.; Basha, J.S.; Alazwari, M.A.; Safaei, M.R.; Elfasakhany, A. Clean combustion and emissions strategy using reactivity controlled compression ignition (RCCI) mode engine powered with CNG-Karanja biodiesel. J. Taiwan Inst. Chem. Eng. 2021. [Google Scholar] [CrossRef]

- Venkanna, B.; Reddy, C.V.; Wadawadagi, S.B. Performance, emission and combustion characteristics of direct injection diesel engine running on rice bran oil/diesel fuel blend. Diesel Engine 2009, 14, 15. [Google Scholar]

- Belagur, V.K.; Venkataramana, R. Injection timing impact on Calophyllum inophyllum linn oil (Honne Oil)/diesel fuelled diesel engine. Int. Energy J. 2011, 11, 3. [Google Scholar]

- Nanthagopal, K.; Ashok, B.; Saravanan, B.; Pathy, M.R.; Sahil, G.; Ramesh, A.; Nabi, N.; Rasul, M.G. Study on decanol and Calophyllum inophyllum biodiesel as ternary blends in CI engine. Fuel 2019, 239, 862–873. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Darla, S.; Chyuan, O.H.; Ramesh, A.; Jacob, A.; Sahil, G.; Thiyagarajan, S.; Geo, V.E. Comparative assessment of hexanol and decanol as oxygenated additives with Calophyllum inophyllum biodiesel. Energy 2019, 173, 494–510. [Google Scholar] [CrossRef]

- Nanthagopal, K.; Ashok, B.; Saravanan, B.; Korah, S.M.; Chandra, S. Effect of next generation higher alcohols and Calophyllum inophyllum methyl ester blends in diesel engine. J. Clean. Prod. 2018, 180, 50–63. [Google Scholar] [CrossRef]

- Tamilvanan, A.; Balamurugan, K.; Ashok, B.; Selvakumar, P.; Dhamotharan, S.; Bharathiraja, M.; Karthickeyan, V. Effect of diethyl ether and ethanol as an oxygenated additive on Calophyllum inophyllum biodiesel in CI engine. Environ. Sci. Pollut. Res. 2020, 1–19. [Google Scholar] [CrossRef]

- Tiwari, P.K.; Raj, S.; Kumar, S.; Singh, P.; Swaraj, R.; Sarkar, S.; Nayak, S.K.; Mishra, P.C. Influence of Calophyllum inophyllum and Jojoba oil methyl ester blended with n-pentanol additive upon overall performance, combustion and emission characteristics of a TDI engine operated in natural aspirated mode. Fuel 2021, 288, 119576. [Google Scholar] [CrossRef]

- Wang, S.; Viswanathan, K.; Esakkimuthu, S.; Azad, K. Experimental investigation of high alcohol low viscous renewable fuel in DI diesel engine. Environ. Sci. Pollut. Res. 2021, 28, 12026–12040. [Google Scholar] [CrossRef] [PubMed]

- Yesilyurt, M.K.; Aydin, M.; Yilbasi, Z.; Arslan, M. Investigation on the structural effects of the addition of alcohols having various chain lengths into the vegetable oil-biodiesel-diesel fuel blends: An attempt for improving the performance, combustion, and exhaust emission characteristics of a compression ignition engine. Fuel 2020, 269, 117455. [Google Scholar]

- Rangabashiam, D.; Munuswamy, D.B.; Balasubramanian, S.D.; Christopher, D. Performance, emission, and combustion analysis on diesel engine fueled with blends of neem biodiesel/diesel/additives. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 1–11. [Google Scholar] [CrossRef]

- Yesilyurt, M.K. A detailed investigation on the performance, combustion, and exhaust emission characteristics of a diesel engine running on the blend of diesel fuel, biodiesel and 1-heptanol (C7 alcohol) as a next-generation higher alcohol. Fuel 2020, 275, 117893. [Google Scholar] [CrossRef]

- Bawane, R.K.; Muthuraja, A.; Shelke, G.N.; Gangele, A. Impact analysis of Calophyllum inophyllum oil biodiesel on performance and emission characteristic of diesel engine under variation in compression ratio, engine load, and blend proportion. Int. J. Ambient. Energy 2020, 1–12. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, M.; Badruddin, I.A.; Banapurmath, N.; Khan, T.Y.; Bashir, M.N.; Akram, N.; Farade, R.; Afzal, A. The effects of graphene oxide nanoparticle additive stably dispersed in dairy scum oil biodiesel-diesel fuel blend on CI engine: Performance, emission and combustion characteristics. Fuel 2019, 257, 116015. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Cho, H.M.; Masjuki, H.H.; Kalam, M.A.; Farooq, M.; Soudagar, M.E.M.; Gul, M.; Ahmed, W.; Afzal, A.; Bashir, S.; et al. Effect of alcoholic and nano-particles additives on tribological properties of diesel–palm–sesame–biodiesel blends. Energy Rep. 2020, 7, 1162–1171. [Google Scholar] [CrossRef]

- Harari, P.; Banapurmath, N.; Yaliwal, V.; Soudagar, M.E.M.; Khan, T.Y.; Mujtaba, M.; Safaei, M.R.; Akram, N.; Goodarzi, M.; Elfasakhany, A.; et al. Experimental investigation on compression ignition engine powered with pentanol and thevetia peruviana methyl ester under reactivity controlled compression ignition mode of operation. Case Stud. Therm. Eng. 2021, 25, 100921. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Banapurmath, N.R.; Afzal, A.; Hossain, N.; Abbas, M.M.; Haniffa, M.A.C.M.; Naik, B.; Ahmed, W.; Nizamuddin, S.; Mubarak, N. Study of diesel engine characteristics by adding nanosized zinc oxide and diethyl ether additives in Mahua biodiesel–diesel fuel blend. Sci. Rep. 2020, 10, 1–17. [Google Scholar] [CrossRef]

- Atabani, A.; César, A.D.S. Calophyllum inophyllum L.—A prospective non-edible biodiesel feedstock. Study of biodiesel production, properties, fatty acid composition, blending and engine performance. Renew. Sustain. Energy Rev. 2014, 37, 644–655. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Afzal, A.; Kareemullah, M. Waste coconut oil methyl ester with and without additives as an alternative fuel in diesel engine at two different injection pressures. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 1–19. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Anand, V.; Aravind, K.; Jeevanantham, A.; Balusamy, S. Effects of n-octanol as a fuel blend with biodiesel on diesel engine characteristics. Fuel 2019, 235, 363–373. [Google Scholar] [CrossRef]

- Devarajan, Y.; Munuswamy, D.B.; Nagappan, B.; Pandian, A.K. Performance, combustion and emission analysis of mustard oil biodiesel and octanol blends in diesel engine. Heat Mass Transf. 2018, 54, 1803–1811. [Google Scholar] [CrossRef]

- Kumar, B.R.; Saravanan, S.; Rana, D.; Anish, V.; Nagendran, A. Effect of a sustainable biofuel–n-octanol–on the combustion, performance and emissions of a DI diesel engine under naturally aspirated and exhaust gas recirculation (EGR) modes. Energy Convers. Manag. 2016, 118, 275–286. [Google Scholar] [CrossRef]

- Mahalingam, A.; Devarajan, Y.; Radhakrishnan, S.; Vellaiyan, S.; Nagappan, B. Emissions analysis on mahua oil biodiesel and higher alcohol blends in diesel engine. Alex. Eng. J. 2018, 57, 2627–2631. [Google Scholar] [CrossRef]

- Kumar, N. Some Studies on use of ternary blends of diesel, biodiesel and n-octanol. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 40, 1721–1728. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, M.; Badruddin, I.A.; Banapurmath, N.; Bin Ali, M.A.; Kamangar, S.; Cho, H.M.; Akram, N. An investigation on the influence of aluminium oxide nano-additive and honge oil methyl ester on engine performance, combustion and emission characteristics. Renew. Energy 2020, 146, 2291–2307. [Google Scholar] [CrossRef]

- Goga, G.; Chauhan, B.S.; Mahla, S.K.; Cho, H.M. Performance and emission characteristics of diesel engine fueled with rice bran biodiesel and n-butanol. Energy Rep. 2019, 5, 78–83. [Google Scholar] [CrossRef]

- Farkade, H.; Pathre, A. Experimental investigation of methanol, ethanol and butanol blends with gasoline on SI engine. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 205–215. [Google Scholar]

- Zheng, Z.; Xia, M.; Liu, H.; Shang, R.; Ma, G.; Yao, M. Experimental study on combustion and emissions of n-butanol/biodiesel under both blended fuel mode and dual fuel RCCI mode. Fuel 2018, 226, 240–251. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Hassan, H.; Ibraheem, L.; He, Z.; Soudagar, M.E.M. Combustion, emission, and phase stability features of a diesel engine fueled by Jatropha/ethanol blends and n-butanol as co-solvent. Int. J. Green Energy 2020, 17, 793–804. [Google Scholar] [CrossRef]

- Khan, H.; Soudagar, M.E.M.; Kumar, R.H.; Safaei, M.R.; Farooq, M.; Khidmatgar, A.; Banapurmath, N.R.; Farade, R.A.; Abbas, M.M.; Afzal, A.; et al. Effect of Nano-Graphene Oxide and n-Butanol Fuel Additives Blended with Diesel—Nigella sativa Biodiesel Fuel Emulsion on Diesel Engine Characteristics. Symmetry 2020, 12, 961. [Google Scholar] [CrossRef]

- Raj, V.M.; Subramanian, T.; Thiyagarajan, S.; Geo, V.E. Effects of minor addition of aliphatic (1-pentanol) and aromatic (benzyl alcohol) alcohols in Simarouba Glauca-diesel blend fuelled CI engine. Fuel 2018, 234, 934–943. [Google Scholar]

- Emiroğlu, A.O.; Şen, M. Combustion, performance and exhaust emission characterizations of a diesel engine operating with a ternary blend (alcohol-biodiesel-diesel fuel). Appl. Therm. Eng. 2018, 133, 371–380. [Google Scholar] [CrossRef]

- Singh, T.S.; Verma, T.N. Impact of tri-fuel on compression ignition engine emissions: Blends of waste frying oil–alcohol–diesel. In Methanol and the Alternate Fuel Economy; Springer: Berlin/Heidelberg, Germany, 2018; pp. 135–156. [Google Scholar]

- Khan, H.; Kareemullah, M.; Ravi, H.C.; Rehman, K.F.; Kumar, R.H.; Afzal, A.; Soudagar, M.E.M.; Fayaz, H. Combined Effect of Synthesized Waste Milk Scum Oil Methyl Ester and Ethanol Fuel Blend on the Diesel Engine Characteristics. J. Inst. Eng. India Ser. C 2020, 101, 947–962. [Google Scholar] [CrossRef]

- Zhu, L.; Cheung, C.S.; Zhang, W.; Huang, Z. Combustion, performance and emission characteristics of a DI diesel engine fueled with ethanol–biodiesel blends. Fuel 2011, 90, 1743–1750. [Google Scholar] [CrossRef]

- Myers, R.H.; Khuri, A.I.; Carter, W.H. Response surface methodology: 1966–l988. Technometrics 1989, 31, 137–157. [Google Scholar] [CrossRef]

| Sl. No. | Engine Specifications |

|---|---|

| 1 | Make: Kirloskar |

| 2 | No. of cylinders: 1 |

| 3 | No. of strokes: 4 |

| 4 | Fuel: Diesel, Biodiesel |

| 5 | Rated power: 5.7 kw at 1500 RPM |

| 6 | Cylinder diameter: 87.5 mm |

| 7 | Stroke length: 110 mm |

| 8 | Compression ratio: 17.5:1 |

| 9 | Air orifice diameter: 20 mm |

| 10 | Cooling type: Water |

| 11 | Volume: 990 cc |

| 12 | Nozzle type/diameter: 3-hole/0.25 mm |

| 13 | Injector pressure: 190 bar |

| 14 | Injection time: 23° before TDC |

| SL | Speed (rpm) | Load (kg) | Torque(N-m) | Brake Power (kW) |

|---|---|---|---|---|

| 1. | 1500 | 3 | 5.4 | 0.9 |

| 2. | 1500 | 6 | 10.9 | 1.8 |

| 3. | 1500 | 9 | 16.3 | 2.6 |

| 4. | 1500 | 12 | 21.8 | 3.4 |

| Properties | Unit | Value |

|---|---|---|

| Flash Point | °C | 210 |

| Fire Point | °C | 220 |

| Density | kg/m3 | 820 |

| Kinematic Viscosity @40 °C | cSt | 3.81 |

| Calorific Value | MJ/Kg | 37.50 |

| Properties | Value |

|---|---|

| Chemical formula | C8H18O |

| Appearance | Colourless liquid |

| Density 15 °C | 830 kg/m3 |

| Viscosity | 7.36 mm2s−1 |

| Molecular Weight | 130.231 g/mol |

| Properties | Value |

|---|---|

| Chemical formula | C4H10O |

| Molar mass | 74.121 g/mole |

| Appearance | Colorless liquid |

| Density 15 °C | 810 kg/m3 |

| Viscosity | 4.1482 mm2s−1 |

| Molecular Weight | 74.12 g/mole |

| Blend | Biodiesel (BD) Content | N-octanol (A) Content | N-butanol (N) Content | Diesel (D) Content |

|---|---|---|---|---|

| BD20D80 | 20% | Nil | Nil | 80% |

| BD20A5D75 | 20% | 5% | Nil | 75% |

| BD20A10D70 | 20% | 10% | Nil | 70% |

| BD20A15D65 | 20% | 15% | Nil | 65% |

| BD20N5D75 | 20% | Nil | 5% | 75% |

| BD20N10D70 | 20% | Nil | 10% | 70% |

| BD20N15D65 | 20% | Nil | 15% | 65% |

| BD20A10N10D60 | 20% | 10% | 10% | 60% |

| Blends | Calorific Value | Kinematic Viscosity | Flashpoint | Fire Point |

|---|---|---|---|---|

| Unit | KJ/kg | cst | °C | °C |

| Diesel | 43,000 | 3.45 | 52 | 60 |

| BD20+80D | 40,426.63 | 2.93 | 70 | 78 |

| BD20+5N+75D (N-butanol) | 36,227.88 | 3.48 | 86 | 92 |

| BD20+10N+70D (N-butanol) | 34,078.89 | 3.54 | 100 | 110 |

| BD20+15N+65D (N-butanol) | 31,928.96 | 3.59 | 122 | 130 |

| BD20+5A+75D (N-octanol) | 40,035.22 | 3.46 | 66 | 74 |

| BD20+10A+70D (N-octanol) | 36,535.42 | 3.49 | 80 | 88 |

| BD20+15A+65D (Iso-Octanol) | 30,083.66 | 3.54 | 92 | 104 |

| BD20+10A+10N+60D | 25,885.03 | 3.66 | 110 | 120 |

| Parameters | Accuracy (±) | Uncertainty (%) |

|---|---|---|

| BP (kW) | - | ±0.3 |

| BTE (%) | - | ±0.5 |

| BSFC (kg/kWh) | - | ±0.6 |

| CO emission (%) | ±0.01% | ±0.5 |

| NOx emission (ppm) | ±8 ppm | ±0.6 |

| HC emission (ppm) | ±8 ppm | ±0.45 |

| Smoke meter (HSU) | ±1 | ±0.5 |

| Parameters | Alcohol Used | BSFC | BTE | CO2 | CO | HC |

|---|---|---|---|---|---|---|

| Present study | N-octanol | 15.5% decrease | 87.5% decrease | 8% decrease | 15.62% decrease | 20% decrease |

| Raj et al. [40] | Pentanol | 1.8% increase | 1.4% decrease | - | 7.3% decrease | 1.1% decrease |

| Raj et al. [40] | Butanol | 0.9% decrease | 1.4% increase | - | 21.9% decrease | 24% decrease |

| Emiroğlu et al. [41] | Butanol | 5.7% increase | 0.4% decrease | - | 17.6% decrease | 7.1% increase |

| Emiroğlu et al. [41] | Ethanol | 8.5% increase | 0.4% decrease | - | 17.6% decrease | 7.1% increase |

| Emiroğlu et al. [41] | Methanol | 2.8% increase | 0.4% decrease | - | 17.6% decrease | 14.2% increase |

| Singh et al. [42] | Ethanol | 0% | 5.9% decrease | 42.8% decrease | 14.5% increase | |

| Khan et al. [43] | Ethanol | 34% increase | 1.3% increase | - | - | - |

| Zhu et al. [44] | Ethanol | 4.3% increase | 15.4% increase | 1% increase | 2% decrease |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 5 | 1209.48 | 241.897 | 18.68 | 0.000 |

| Linear | 2 | 484.47 | 242.233 | 18.71 | 0.000 |

| Load | 1 | 101.57 | 101.565 | 7.84 | 0.019 |

| Alchohol | 1 | 382.90 | 382.900 | 29.57 | 0.000 |

| Square | 2 | 692.87 | 346.434 | 26.76 | 0.000 |

| Load∗Load | 1 | 2.76 | 2.756 | 0.21 | 0.654 |

| Alchohol∗Alchohol | 1 | 690.11 | 690.113 | 53.30 | 0.000 |

| 2-Way Interaction | 1 | 32.15 | 32.149 | 2.48 | 0.146 |

| Load∗Alchohol | 1 | 32.15 | 32.149 | 2.48 | 0.146 |

| Error | 10 | 129.47 | 12.947 | ||

| Total | 15 | 1338.96 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 5 | 1209.48 | 241.897 | 18.68 | 0.000 |

| Linear | 2 | 484.47 | 242.233 | 18.71 | 0.000 |

| Load (kg) | 1 | 101.57 | 101.565 | 7.84 | 0.019 |

| Alcohol (%) | 1 | 382.90 | 382.900 | 29.57 | 0.000 |

| Square | 2 | 692.87 | 346.434 | 26.76 | 0.000 |

| Load (kg)∗Load (kg) | 1 | 2.76 | 2.756 | 0.21 | 0.654 |

| Alcohol (%)∗Alcohol (%) | 1 | 690.11 | 690.113 | 53.30 | 0.000 |

| 2-Way Interaction | 1 | 32.15 | 32.149 | 2.48 | 0.146 |

| Load (kg)∗Alcohol (%) | 1 | 32.15 | 32.149 | 2.48 | 0.146 |

| Error | 10 | 129.47 | 12.947 | ||

| Total | 15 | 1338.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aneeque, M.; Alshahrani, S.; Kareemullah, M.; Afzal, A.; Saleel, C.A.; Soudagar, M.E.M.; Hossain, N.; Subbiah, R.; Ahmed, M.H. The Combined Effect of Alcohols and Calophyllum inophyllum Biodiesel Using Response Surface Methodology Optimization. Sustainability 2021, 13, 7345. https://doi.org/10.3390/su13137345

Aneeque M, Alshahrani S, Kareemullah M, Afzal A, Saleel CA, Soudagar MEM, Hossain N, Subbiah R, Ahmed MH. The Combined Effect of Alcohols and Calophyllum inophyllum Biodiesel Using Response Surface Methodology Optimization. Sustainability. 2021; 13(13):7345. https://doi.org/10.3390/su13137345

Chicago/Turabian StyleAneeque, Mohammed, Saad Alshahrani, Mohammed Kareemullah, Asif Afzal, C. Ahamed Saleel, Manzoore Elahi M. Soudagar, Nazia Hossain, Ram Subbiah, and Mohamed H. Ahmed. 2021. "The Combined Effect of Alcohols and Calophyllum inophyllum Biodiesel Using Response Surface Methodology Optimization" Sustainability 13, no. 13: 7345. https://doi.org/10.3390/su13137345

APA StyleAneeque, M., Alshahrani, S., Kareemullah, M., Afzal, A., Saleel, C. A., Soudagar, M. E. M., Hossain, N., Subbiah, R., & Ahmed, M. H. (2021). The Combined Effect of Alcohols and Calophyllum inophyllum Biodiesel Using Response Surface Methodology Optimization. Sustainability, 13(13), 7345. https://doi.org/10.3390/su13137345