Abstract

Municipal solid waste (MSW) processing is still problematic in Indonesia. From the hierarchy of waste management, it is clear that energy recovery from waste could be an option after prevention and the 5R (rethink, refuse, reduce, reuse, recycle) processes. The Presidential Regulation No 35/2018 mandated the acceleration of waste-to-energy (WtE) plant adoption in Indonesia. The present study aimed to demonstrate a techno-economic evaluation of a commercial WtE plant in Indonesia by processing 1000 tons of waste/day to produce ca. 19.7 MW of electricity. The WtE electricity price is set at USD 13.35 cent/kWh, which is already higher than the average household price at USD 9.76 cent/kWh. The capital investment is estimated at USD 102.2 million. The annual operational cost is estimated at USD 12.1 million and the annual revenue at USD 41.6 million. At this value, the internal rate of return (IRR) for the WtE plant is 25.32% with a payout time (PoT) of 3.47 years. In addition, this study also takes into account electricity price sales, tipping fee, and pretreatment cost of waste. The result of a sensitivity analysis showed that the electricity price was the most sensitive factor. This study reveals that it is important to maintain a regulated electricity price to ensure the sustainability of the WtE plant in Indonesia.

1. Introduction

Municipal solid waste management (MSWM) is gaining higher public concern due to a rapid increase in urban population. According to the hierarchy of waste management, MSWM should be started with the highest priority by preventing the generation of waste, followed by rethink, refuse, reduce, reuse, and recycle (5R) programs [1]. The following preferred stage is energy recovery using waste-to-energy technology. The last option in the waste hierarchy is direct waste disposal in a landfill [2].

Through the Waste Wise Cities program, UN-Habitat has also addressed the 12 key principles for handling MSW [1]. These principles extended the scope of waste hierarchy by involving stakeholders as well as aligning the MSWM to achieve SDGs. Despite numerous initiatives led by the UN to tackle MSWM problems, the implementation of MSWM in many parts of the world is still problematic, especially in developing countries with limited access to investment and social problems. Hence, it is always interesting to investigate the MSWM approaches in various developing countries as a part of their effort to reach SDGs.

The challenge of MSWM in developing countries is typically characterized by problems related to unsorted waste at source, limited access to a waste collection network, excessive use of landfills, uncontrolled release of leachate, and gas emission from landfills [3]. Due to limited and higher prices for landfills, as well as increased social pressure, the use of landfills is becoming less attractive. This is also accompanied by a growing sense of urgency to apply a higher waste hierarchy such as WtE. WtE technology is often viewed as an attractive option as it eliminates waste and also facilitates energy recovery. Furthermore, WtE also plays a role in reducing global warming emissions as compared with traditional landfills [4]. It is also important to note that the implementation of WtE does not hinder reuse and recycle activities [5]. As a result, numerous studies on WtE application in developing countries have been reported in the present literature such as India [6] and Pakistan [7].

The implementation of WtE in developing countries faces numerous challenges and obstacles from social and economic aspects. There are also several additional factors that have to be considered such as identification of waste characteristics and volume, appropriate tariff system regulations, adequate human resources, ability to cover huge investments and operational costs, as well as appropriate regulatory support from the government [8]. Despite the large investment for WtE, it is also important to note that WtE is not a silver bullet for solving MSW problems and it should be combined with reliable 5R programs.

2. Current Status of Waste to Energy (WtE) in Indonesia

Indonesia is one of the most populous developing countries, with more than 270 million people in 2020 [9]. Almost half of the population live in urban areas, which results in high municipal waste production. However, municipal waste management is still problematic in many parts of Indonesia due to the overcapacity of existing landfills. On average, 81% of households still directly disposed of their waste without sorting or reutilization, eventually ending up in landfills [10].

Since landfills still play a major role for MSWM in Indonesia, the current practice contradicts the principle of waste management. Since 2008, the government of Indonesia has initiated a series of actions to reduce the use of landfills. It was started by a Legislative Act no. 18, in 2008, which obligates the central and municipal governments to suppress the growth of waste generated by the adoption of 5R initiatives [11,12]. Moreover, the act also encourages waste management to use eco-friendly products and environmentally friendly technology. Furthermore, in 2012, the central government produced an executive order that considers waste as an alternative resource to be further reprocessed directly or indirectly [13].

Waste recycling and reuse practices in Indonesia are still progressing slowly due to social and technical challenges. However, several initiatives such as the creation of “waste banks”, have been implemented in several areas in Indonesia, for example, in Surabaya [14]. This initiative is often managed by a local community in Indonesia. Waste banks encourage people to sort their waste and incentivize selling the waste to waste banks. Nonetheless, there are also limitations associated with the current practice of waste banks in Indonesia. Many waste banks have not been managed properly with a lack of funding and facilities making it difficult to process the collected waste efficiently. Furthermore, a large part of society still does not appreciate the presence of these ‘facilities’, thereby reducing the incoming waste to waste banks [15].

The slow progress in the 5R has encouraged the Government of Indonesia to implement large-scale WtE technology as part of MSWM. The application of WtE technologies is considered to be feasible for tropical MSW, even without any additional fuel [16]. The 2008 Regulation No. 18 was followed by a newer Presidential Regulation No. 18/2016, which aimed to accelerate the construction of Pembangkit Listrik Tenaga Sampah (PLTSa) or waste-to-energy plants in seven cities. According to this regulation, the minimum size of the WtE plant was capped at a minimum of 1000 tons of waste per day [17]. However, this regulation did not provide any additional support for private or state-owned enterprises other than a statement that assigned the Perusahaan Listrik Negara (PLN) or State Electricity Company to buy the electricity generated from waste. The lack of incentives was further proven by the slow development of the new WtE plants in Indonesia (only one pilot plant was completed from 2016 to 2019). The slow progress of WtE plant adoption in Indonesia is often associated with the lack of government guarantees in tipping fees and electricity prices.

Subsequently, the government renewed the Presidential Regulation No. 18/2016 by releasing a newer President Regulation No. 35/2018. The new regulation encouraged the development of WtE plants in 12 cities by providing more detailed incentives to operation a WtE plant. The regulation mandated the central government to provide an incentive (known as tipping fee) to the local government as high as USD 33.78 (equivalent to Indonesian Rupiah (IDR) of 500,000) for each ton of waste processed in the WtE plant. Furthermore, the new regulation also stated a distinctive tariff for each kWh of electricity sold from the WtE plant to PLN, which was around USD 13.35 cent/kWh for a plant under 20 MW and USD 14.54 cent/kWh for a plant above 20 MW with a correction factor.

However, since the enforcement of President Regulation No. 35/2018, only one pilot plant out of 12 WtE plants has been operating since 2018, known as PLTSa Merah Putih in Bantar Gebang, Jakarta. Recently, in May 2021, a WtE plant in Benowo, East Java Province, started to operate by processing 1000 tons of waste/day with an electricity capacity production of 11 MW as the first large-scale WtE plant in Indonesia [18].

Despite a series of government regulations to support the development and operation of WtE plants in Indonesia, the construction of WtE plants in Indonesia is still considered to be slow. One of the most critical factors influencing the establishment of WtE plants is the debate over electricity price, which is higher than that of conventional coal-based electricity. For illustration, the Komisi Pemberantasan Korupsi (KPK) or Corruption Eradication Commission, estimated that the purchase of electricity produced from a WtE plant would increase PLN’s operating costs up to IDR 3.6 trillion per year due to a higher purchased electricity price [19,20]. As a result, an increase in operational costs would put more pressure on PLN and increase the nation’s expenditure, as PLN is a state-owned enterprise.

The present study aimed to investigate the techno-economic evaluation of a commercial WtE plant in Indonesia. Here, the effect of President Regulation No. 35/2018 on our techno-economic evaluation was also examined. Fixed capital and operating costs were both considered. At the same time, income from sold electricity, tipping fees, and recyclable waste were also taken into account. To justify the economic attractiveness of the project, the internal rate of return (IRR) and payout time (PoT) as economic feasibility parameters were introduced. Furthermore, sensitivity analyses were also performed to obtain the influence of critical factors on the IRR and PoT parameters.

3. Methodology

3.1. Estimation of Capital Investment

A capital investment estimation was made based on documents published by United Nations. It has been determined that in developing countries, a 150,000 ton per year WtE plant would typically cost around USD 35.2 million and this value was used in the present study [21]. For comparison, the World Bank has estimated that a typical WtE plant costs around USD 190/annual ton of waste incinerated [22]. From this estimation by the World Bank, a WtE plant at the same capacity (150,000 ton/year) would cost around USD 33.5 million. Afterwards, the initial capital investment was determined by using the standard six-tenths rule [23,24].

3.2. Economic Feasibility Study Parameters

Techno-economic usually resulted in a few economic parameters such as net present value (NPV), return on investment (RoI), payout time (PoT), and internal rate of return (IRR). These parameters are widely accepted and have been implemented in many WtE techno-economic studies [25,26,27,28,29]. However, the NPV only indicates the absolute value of a project which greatly differs at different scales. The second parameter, RoI, indicates the ratio of annual profit to capital investment. This value also varies considerably between the scales of assessed projects, and thus is difficult to compare. Therefore, to assess the feasibility of this project, the IRR and PoT were used.

The IRR (Equation (1)) demonstrates the rate of return of a specific investment, whereas PoT (Equation (2)) expresses the time needed to recover the initial investment [30]. These two parameters have been widely accepted in many techno-economic works in the literature such as a feasibility study on heat exchanger replacement [31], a feasibility study on a WtE industry in China [29], and a feasibility study on gasification and anaerobic digestion WtE plants in Saudi Arabia [27]. Additionally, the IRR and PoT are two of the most easy-to-compare parameters available. They can give value to investment interest and the time span needed to recoup the capital cost. They can be represented as follows:

where stands for initial investment which comprises the total investment made, is the net cash flow which comprises the difference between operating incomes and operating expenses, and is the number of years. The income and expenditures highly rely on season, regulation, and operating conditions. However, to simplify, these values were assumed to be constant over the lifetime of the WtE plant.

4. Results and Discussion

4.1. Estimation of WtE Plant Capacity

In general, a WtE plant uses a direct incinerator, air gasifier, or plasma gasifier to generate energy in the form of heat or volatiles. The scale of electricity generated is strongly correlated to the calorific value of waste. It has been suggested that a WtE plant should be supplied with feed that contains no less than 6 MJ/kg calorific value [21]. Subsequently, the calorific value of MSW was assumed to be 6.5 MJ/kg. The calorific value is not directly related to the actual energy generated due to heat loss. Typically, the conversion of heat to electricity varies around 35%, which was taken as an assumption in this study.

In this study, a WtE plant with a capacity of 1000 tons of pretreated waste per day or around 20% more than the average municipal waste in Indonesia [32] was examined. Furthermore, from 1000 tons per day of feed, 75% of it was fed to the incinerator. At the same time, the remaining (25%) feed was processed as a recyclable waste that could be sold to a third party. Hence, the plant could handle 750 tons of waste per day and generate 19.7 MW capacity or equivalent to ca. 474 MWh electricity per day.

Using Equation (3), the initial investment to build this plant at the intended capacity of 1000 tons of waste per day is estimated at around USD 60 million. However, this value does not include the cost to purchase the land and the maintenance of the land. Therefore, this value was assumed to be around 70% of the purchased equipment cost or around USD 42.1 million. Thus, these values were summed and regarded as the fixed capital, valued at USD 102,230,073.31.

4.2. Estimation of Operating Expenses

To maintain the production of electricity from waste incineration, a few expenses should be considered. Operational expenses usually include pretreatment costs, salaries for 80 employees, and other ordinary chemical plant expenses such as maintenance costs, taxes, and asset depreciation. The pretreatment cost is intended to pay for the sorting process of waste and the drying process. This cost is due to the nature of MSW in Indonesia which usually has high water content and mixed type of waste. Here, the pretreatment cost was set at USD 6.76 per ton of waste, and this value could vary regionally, depending on waste condition and composition.

As seen in Table 1, pretreatment cost accounts for more than 20% of total operational cost. This ratio highlights the importance of the sorting process in the source of waste, especially to separate the organic from the inorganic waste.

Table 1.

Annual operating expenses of a 1000-ton-per-day WtE plant in Indonesia.

4.3. Operating Incomes

Incomes from the operation of the WtE plant in this study come from three primary sources: electricity sales, government tipping fees, and the sale of recyclable waste, which were assumed to account for 25% of total waste. The electricity sales and government tipping fees are based on President Regulation No. 35/2018 [33]. In addition, the sale of recyclable waste was estimated to be USD 0.02 per kg of recyclable waste sold.

As seen in Table 2, electricity sales account for more than half of the income in the WtE plant, followed by tipping fees at ca. 30%, and recyclable waste sales at ca. 15%. Hence, it shows that the price of electricity is critical, and assumed to remain the same as the committed price from the government. Furthermore, the current tipping fee at USD 33.78/ton of waste also played an essential role in recouping the investment and operational costs. Thus, it is crucial to assess the sensitivity of economic parameters to the tipping fees and electricity prices, as provided later in Section 4.5.

Table 2.

Operating incomes of a 1,000-ton-per-day WtE plant in Indonesia.

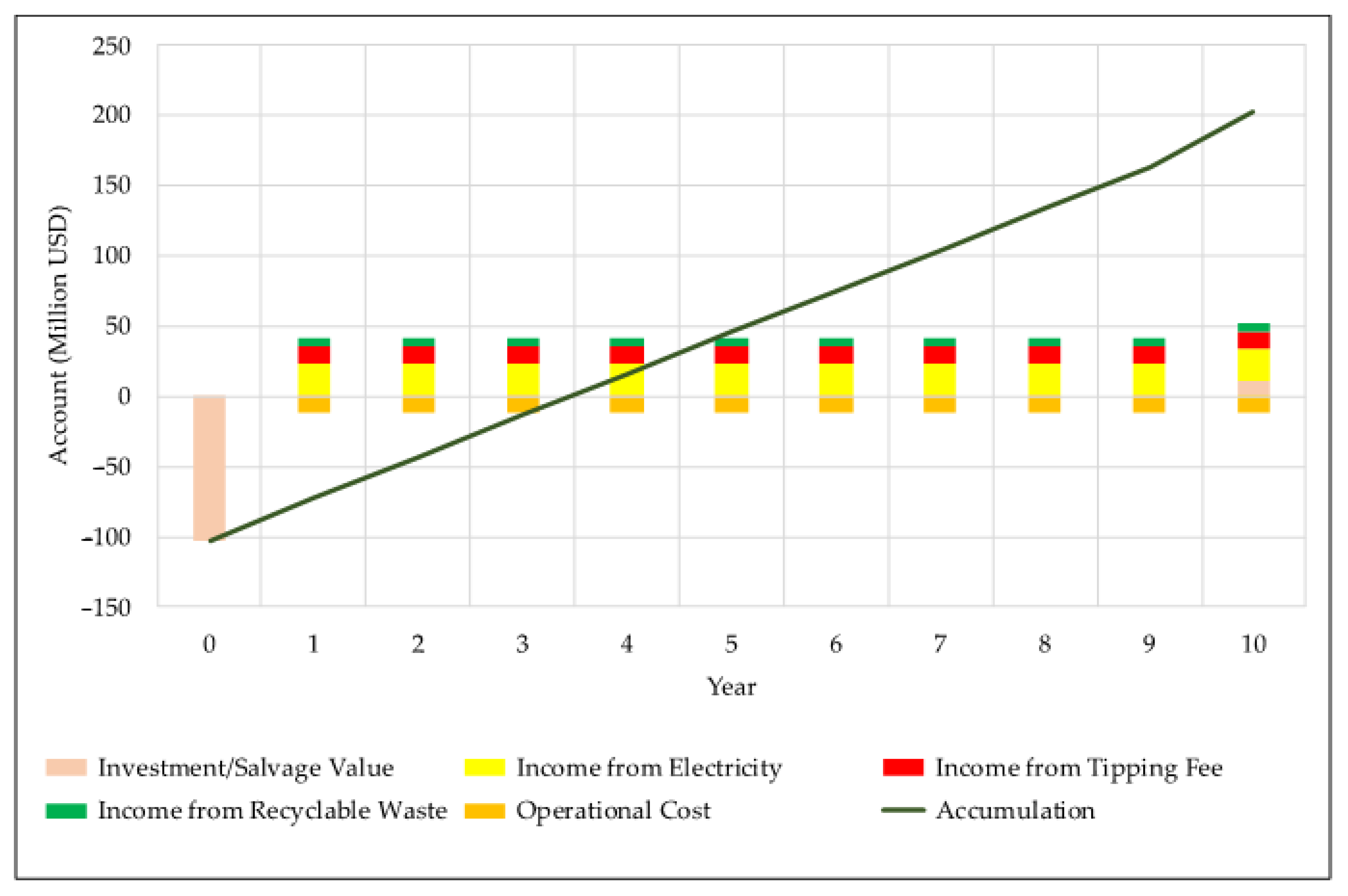

4.4. Economic Evaluation for the Base Case

The feasibility study conducted accounts for ten years of operating to obtain IRR and PoT values comparable to other projects. Additionally, the plant is assumed to have salvage value, valued at 10% of the initial capital investment cost after 25 years of operation (plant lifetime). From the cashflow analysis of a 1000-ton-per-day WtE Plant in Indonesia, which produces about 470 MWh of electricity per day (Figure 1), the plant will reach the economical even point or payout time at 3.44 years after the inception. At the same time, the IRR of the plant reaches 25.59%.

Figure 1.

Feasibility study cash flow of a 1000-ton-per-day WtE plant in Indonesia.

The comparison of the present results to other studies is presented in Table 3. The value of the PoT and IRR found in this study is quite attractive and indicates a more favorable environment for WtE plant operation in Indonesia than in other countries. However, other studies do not necessarily include a substantial amount of tipping fees or special prices on electricity sold as promised by the government.

Table 3.

Comparison of WtE plant economic feasibility studies.

In addition, it is also interesting to note that the WtE electricity price that has been used in the present study was USD 13.35 cent/kWh, which is higher than the average electricity price of a typical household in Indonesia, which is around USD 9.76 cent/kWh. As a result, this may cause a substantial deficit to PLN. In addition, the tipping fees provided by the municipal government may not reach USD 33.78 per ton of waste. In East Java, the tipping fees are set at USD 10.14 per ton of waste, which largely impacts the WtE plant’s profitability [34].

4.5. Simulation Analysis

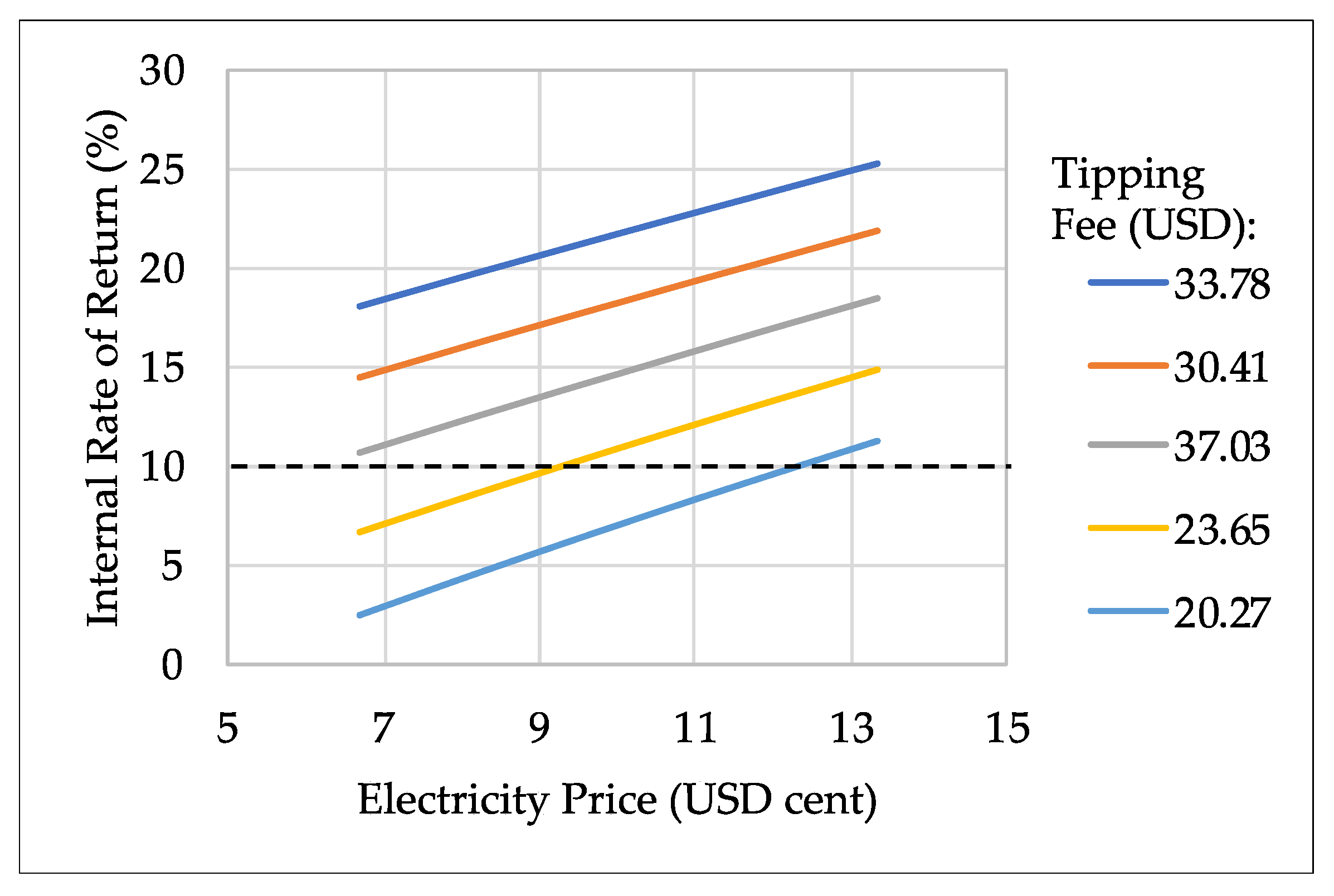

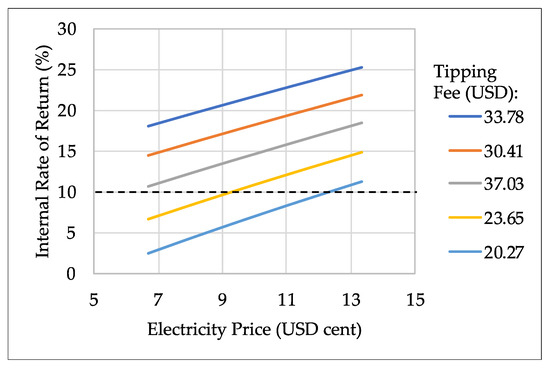

The sensitivity analysis of the economic parameters was conducted by changing the amount of tipping fees and price of electricity to the IRR and PoT values. The tipping fees were supposed to be set at a maximum of USD 33.78 per ton of waste processed. However, tipping fees vary significantly between municipal governments and are often far below the intended values.

As seen in Figure 2, a dividing line has been provided to indicate the zone where the combination of electricity price and tipping fees give an IRR above or below 10%. Thus, for example, tipping fees of USD 20.27/ton and an electricity price around the same as the electricity price of a typical household in Indonesia (USD 0.1001/kWh) give an IRR at 6.94%, which is comparable with the finding by Roswulandari et al. who studied 280 kWh/ton of waste and assumed the purchasing price by PLN to be around USD 0.1686/kWh [34].

Figure 2.

Values of internal rate of return at various tipping fees and electricity price combinations.

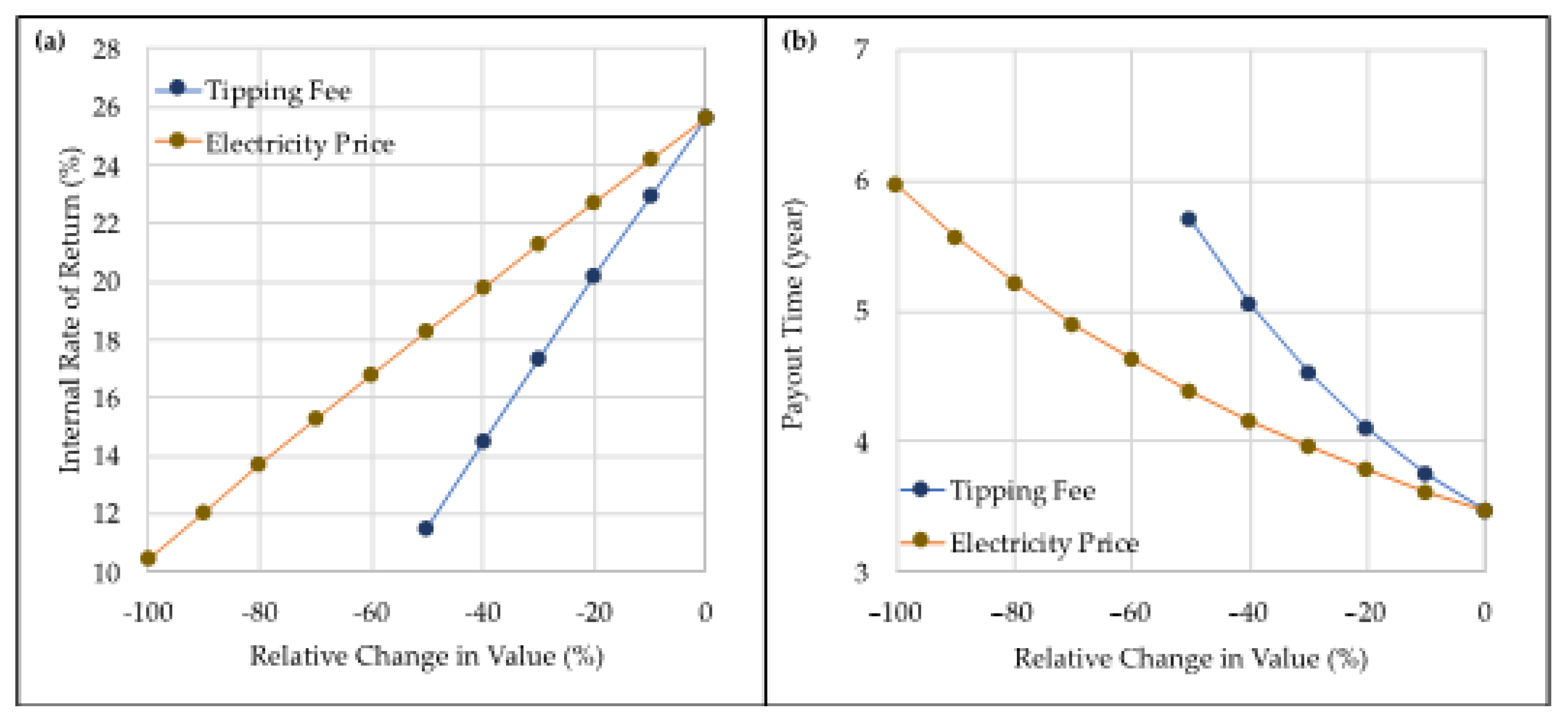

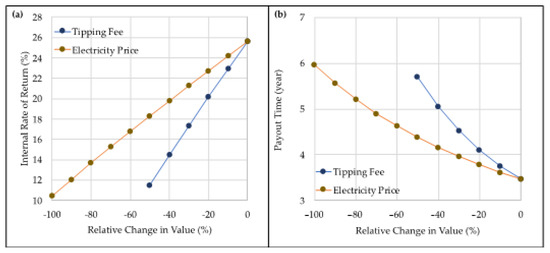

Figure 3 shows the relative change in electricity prices and tipping fees to the IRR and PoT. As the figure suggests, the slope of the electricity price is steeper than the tipping fees. Hence, a change in electricity price give higher sensitivity than that of tipping fees to the IRR and PoT.

Figure 3.

Sensitivity curves: (a) Internal rate of return; (b) payout time, from the change in tipping fees and electricity prices.

Figure 3a also shows an interesting result where the IRR value in the absence of tipping fees (−100% tipping fees or 0 tipping fees) gave an IRR value of 10%. This value of IRR corresponds to the operation scenario based on a very tight budget. A 40% decrease in tipping fees gives an IRR value around 20%. Whereas a WtE plant without a firm electricity price would eventually be forced to shut down as the IRR would reach under 15% after a 40% decrease in electricity prices. Therefore, the government and investors need to devise appropriate policy for electricity supply regulation in Indonesia. Especially in a challenging condition where the exchange rate to USD, crude oil price, inflation, and coal price change significantly [38].

5. Conclusions

Converting waste to energy could be a viable option for Indonesia, which has a significant urban population. Here, the influence of the current Indonesian government regulation (known as Presidential Regulation No. 35/2018) on the feasibility of a WtE plant in Indonesia was investigated. The WtE electricity price was set at USD 13.35 cent/kWh, which was higher than the average current household price at USD 9.76 cent/kWh. For a base case simulation, the economic feasibility of 1000 tons of waste/day to produce ca. 19.7 MW of electricity was assessed. The capital investment was estimated at USD 102.2 million. The annual operational costs were estimated to be USD 12.1 million and the annual revenue was estimated to be USD 41.6 million. At these values, the IRR of the WtE plant is 25.32% with a PoT of 3.47 years. By performing sensitivity analyses of tipping fees and electricity prices to the IRR and PoT, it appears that the electricity price was the most sensitive factor. This study reveals the importance of the government to regulate electricity prices for a WtE plant. The certainty of electricity prices would ensure the sustainability of the WtE plant in Indonesia.

Author Contributions

In this research work, the contributions of each author are as follows: conceptualization by M.M.A. and C.W.P.; methodology by M.M.A., J.K. and C.W.P.; data analyzed by M.M.A. and J.K.; investigation by M.M.A. and J.K.; data curation by J.K.; C.W.P. contributed to provide resources for this study; manuscript writing by M.M.A., J.K. and C.W.P.; review and supervision by M.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The information and database for this research are currently not on a platform or website. They can be provided by the corresponding author.

Acknowledgments

This work is part of a collaboration between the Department of Chemical Engineering, Faculty of Engineering, Universitas Gadjah Mada and Pusat Inovasi Agroteknologi UGM (PIAT UGM; Agro-technology Innovation Center Universitas Gadjah Mada).

Conflicts of Interest

The authors declare no conflict of interest.

References

- UN-Habitat Waste Wise Cities|UN-Habitat. Available online: https://unhabitat.org/waste-wise-cities (accessed on 16 June 2021).

- United Nations Environment Programme. Guidelines for National Waste Management Strategies; United Nations Environment Programme: Washington, DC, USA, 2013; ISBN 978-92-807-3333-4. [Google Scholar]

- Dhokhikah, Y.; Trihadiningrum, Y.; Sunaryo, S. Community participation in household solid waste reduction in Surabaya, Indonesia. Resour. Conserv. Recycl. 2015, 102, 153–162. [Google Scholar] [CrossRef]

- Chandel, M.K.; Kwok, G.; Jackson, R.B.; Pratson, L.F. The potential of waste-to-energy in reducing GHG emissions. Carbon Manag. 2012, 3, 133–144. [Google Scholar] [CrossRef] [Green Version]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M. Sustainable waste management: Waste to energy plant as an alternative to landfill. Energy Convers. Manag. 2017, 131, 18–31. [Google Scholar] [CrossRef]

- Ganguly, R.K.; Chakraborty, S.K. Integrated approach in municipal solid waste management in COVID-19 pandemic: Perspectives of a developing country like India in a global scenario. Case Stud. Chem. Environ. Eng. 2021, 3, 100087. [Google Scholar] [CrossRef]

- Korai, M.S.; Mahar, R.B.; Uqaili, M.A. The feasibility of municipal solid waste for energy generation and its existing management practices in Pakistan. Renew. Sustain. Energy Rev. 2017, 72, 338–353. [Google Scholar] [CrossRef]

- Deutsche Gesellschaft Für Internationale Zusammenarbeit (GIZ) GmbH. Waste-to-Energy Options in Municipal Solid Waste Management; Deutsche Gesellschaft Für Internationale Zusammenarbeit (GIZ) GmbH: Eschborn, Germany, 2017. [Google Scholar]

- Badan Pusat Statistik. Potret Sensus Penduduk 2020 Menuju Satu Data Kependudukan Indonesia; Badan Pusat Statistik: Jakarta, Indonesia, 2021.

- Badan Pusat Statistik. Persentase Rumah Tangga Menurut Provinsi dan Perlakuan Memilah Sampah Mudah Membusuk dan Tidak Mudah Membusuk, 2013–2014. Available online: https://www.bps.go.id/statictable/2014/05/02/1360/persentase-rumah-tangga-menurut-provinsi-dan-perlakuan-memilah-sampah-mudah-membusuk-dan-tidak-mudah-membusuk-2013-2014.html (accessed on 28 June 2021).

- Menteri Hukum dan Hak Asasi Manusia Republik Indonesi. Undang-Undang Republik Indonesia Nomor 18 Tahun 2008 Pengelolaan Sampah; Menteri Hukum dan Hak Asasi Manusia Republik Indonesia: Jakarta, Indonesia, 2008.

- Damanhuri, E.; Handoko, W.; Padmi, T. Municipal Solid Waste Management in Indonesia. In Municipal Solid Waste Management in Asia and the Pacific Islands; Springer: Singapore, 2017; pp. 139–156. ISBN 978-981-4451-72-7. [Google Scholar]

- Menteri Hukum dan Hak Asasi Manusia Republik Indonesia. Peraturan Pemerintah Republik Indonesia Nomor 81 Tahun 2012 Pengelolaan Sampah Rumah Tangga dan Sampah Sejenis Sampah Rumah Tangga; Menteri Hukum dan Hak Asasi Manusia Republik Indonesia: Jakarta, Indonesia, 2012.

- Wijayanti, D.R.; Suryani, S. Waste Bank as Community-based Environmental Governance: A Lesson Learned from Surabaya. Procedia Soc. Behav. Sci. 2015, 184, 171–179. [Google Scholar] [CrossRef] [Green Version]

- Alam, A.S.; Irwan, A.L. Haryanto Waste bank governance in local Indonesia: Problems and opportunities. Int. J. Innov. Creat. Chang. 2020, 10, 85–99. [Google Scholar]

- Pasek, A.D.; Gultom, K.W.; Suwono, A. Feasibility of recovering energy from municipal solid waste to generate electricity. J. Eng. Technol. Sci. 2013, 45, 241–256. [Google Scholar] [CrossRef] [Green Version]

- Menteri Hukum dan Hak Asasi Manusia Republik Indonesia. Peraturan Presiden Republik Indonesia Nomor 18 Tahun 2016 Percepatan Pembangunan Pembangkit Listrik Berbasis Sampah di Provinsi DKI Jakarta, Kota Tangerang, Kota Bandung, Kota Semarang, Kota Surakarta, Kota Surabaya, dan Kota Makassar; Menteri Hukum dan Hak Asasi Manusia Republik Indonesia: Jakarta, Indonesia, 2016.

- Office of Assistant to Deputy Cabinet Secretary for State Documents & Translation President Jokowi Inaugurates Benowo Waste-to-Energy Plant. Available online: https://setkab.go.id/en/president-jokowi-inaugurates-benowo-waste-to-energy-plant/ (accessed on 14 June 2021).

- Komisi Pemberantasan Korupsi KPK Bahas Kajian PLTSa dengan Kementerian ESDM. Available online: https://www.kpk.go.id/id/berita/berita-kpk/1522-kpk-bahas-kajian-pltsa-dengan-kementerian-esdm (accessed on 24 May 2021).

- Ramadhan, A. KPK Temukan Potensi Kerugian Negara dalam Pengelolaan Sampah Menjadi Listrik. Available online: https://nasional.kompas.com/read/2020/03/06/17551071/kpk-temukan-potensi-kerugian-negara-dalam-pengelolaan-sampah-menjadi-listrik (accessed on 24 May 2021).

- United Nations Environment Programme (UNEP). Waste to Energy: Considerations for Informed Decision-Making; United Nations Environment Programme (UNEP): Nairobi, Kenya, 2019. [Google Scholar]

- Kaza, S.; Bhada-Tata, P. Decision Maker’s Guides for Solid Waste Management Technologies; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Tribe, M.A.; Alpine, R.L.W. Scale economies and the “0.6 rule”. Eng. Costs Prod. Econ. 1986, 10, 271–278. [Google Scholar] [CrossRef]

- Dickinson, D.; Balduccio, L.; Buysse, J.; Ronsse, F.; van Huylenbroeck, G.; Prins, W. Cost-benefit analysis of using biochar to improve cereals agriculture. GCB Bioenergy 2015, 7, 850–864. [Google Scholar] [CrossRef]

- Aracil, C.; Haro, P.; Fuentes-Cano, D.; Gómez-Barea, A. Implementation of waste-to-energy options in landfill-dominated countries: Economic evaluation and GHG impact. Waste Manag. 2018, 76, 443–456. [Google Scholar] [CrossRef] [PubMed]

- Mabalane, P.N.; Oboirien, B.O.; Sadiku, E.R.; Masukume, M. A Techno-economic Analysis of Anaerobic Digestion and Gasification Hybrid System: Energy Recovery from Municipal Solid Waste in South Africa. Waste Biomass Valorization 2021, 12, 1167–1184. [Google Scholar] [CrossRef]

- Hadidi, L.A.; Omer, M.M. A financial feasibility model of gasification and anaerobic digestion waste-to-energy (WTE) plants in Saudi Arabia. Waste Manag. 2017, 59, 90–101. [Google Scholar] [CrossRef] [PubMed]

- Sudibyo, H.; Pradana, Y.S.; Budiman, A.; Budhijanto, W. Municipal Solid Waste Management in Indonesia - A Study about Selection of Proper Solid Waste Reduction Method in D.I. Yogyakarta Province. Energy Procedia 2017, 143, 494–499. [Google Scholar] [CrossRef]

- Zhao, X.; Jiang, G.; Li, A.; Wang, L. Economic analysis of waste-to-energy industry in China. Waste Manag. 2016, 48, 604–618. [Google Scholar] [CrossRef] [PubMed]

- Sullivan, W.G.; Wicks, E.M.; Koelling, C.P. Engineering Economy, 16th ed.; Pearson Higher Education, Inc.: Hoboken, NJ, USA, 2015; ISBN 978-0-13-343927-4. [Google Scholar]

- Dewanatan, W.W.; Adiputra, M.K.; Putro, I.K.; Hartanto, S.; Kristanto, J.; Azis, M.M. The influence of carbon tax on the feasibility of industrial project: A case study of heat exchanger replacement at pt kaltim methanol industri, indonesia. ASEAN J. Chem. Eng. 2020, 20, 196–204. [Google Scholar] [CrossRef]

- Badan Pusat Statistik. Statistik Lingkungan Hidup Indonesia 2019; Badan Pusat Statistik: Jakarta, Indonesia, 2019.

- Menteri Hukum dan Hak Asasi Manusia Republik Indonesia. Peraturan Presiden Republik Indonesia Nomor 35 Tahun 2018 Percepatan Pembangunan Instalasi Pengolah Sampah Menjadi Energi Listrik Berbasis Teknologi Ramah Lingkungan; Menteri Hukum dan Hak Asasi Manusia Republik Indonesia: Jakarta, Indonesia, 2018.

- Roswulandari, A.; Daerobi, A.; Gravitiani, E. Waste to Energy (WTE) Putri Cempo as Urban Innovation: A Financial Analysis; Atlantis Press: Paris, France, 2019; Volume 156, pp. 171–174. [Google Scholar]

- Guo, Z. Pre-Feasibility Study of a Waste-to-Energy (WTE) Plant for Baotou City, China. Master’s Thesis, Columbia University, New York, NY, USA, April 2015. [Google Scholar]

- Eke, J.; Onwudili, J.A. Economic evaluation of a hypothetical integrated energy recovery system for trommel fines. Waste Manag. 2021, 124, 213–223. [Google Scholar] [CrossRef]

- Alzate-Arias, S.; Jaramillo-Duque, Á.; Villada, F.; Restrepo-Cuestas, B. Assessment of government incentives for energy fromwaste in Colombia. Sustainability 2018, 10, 1294. [Google Scholar] [CrossRef] [Green Version]

- Menteri Energi dan Sumber Daya Mineral Republik Indonesia. Peraturan Menteri Energi dan Sumber Daya Mineral Republik Indonesia Nomor 3 Tahun 2020 Perubahan Keempat atas Peraturan Menteri Energi dan Sumber Daya Mineral Nomor 28 Tahun 2016 tentang Tarif Tenaga Listrik yang Disediakan oleh PT Perusahaan Listrik Negara (Persero); Menteri Energi dan Sumber Daya Mineral Republik Indonesia: Jakarta, Indonesia, 2020.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).