Properties of Steel Fiber-Reinforced Alkali-Activated Slag Concrete Made with Recycled Concrete Aggregates and Dune Sand

Abstract

:1. Introduction

2. Materials and Methods

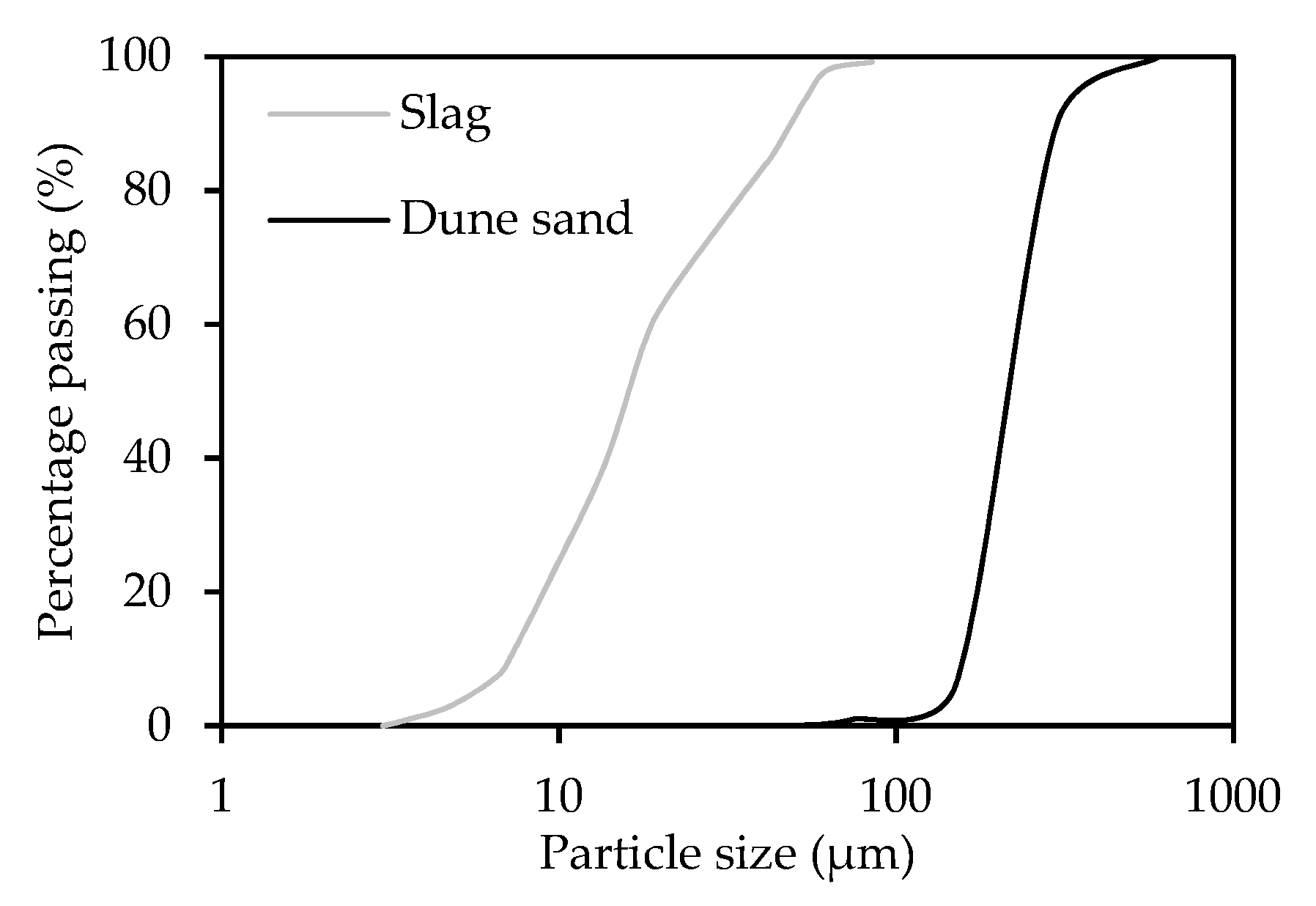

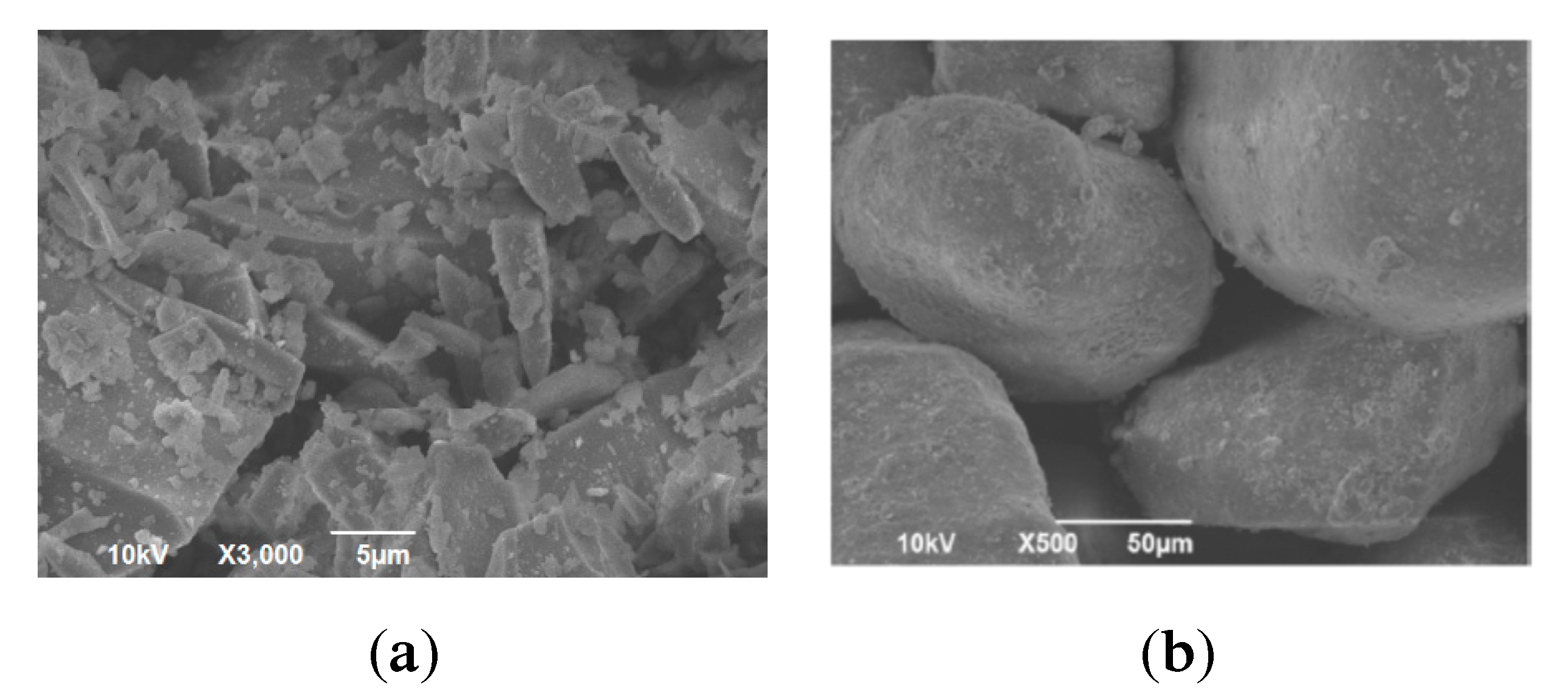

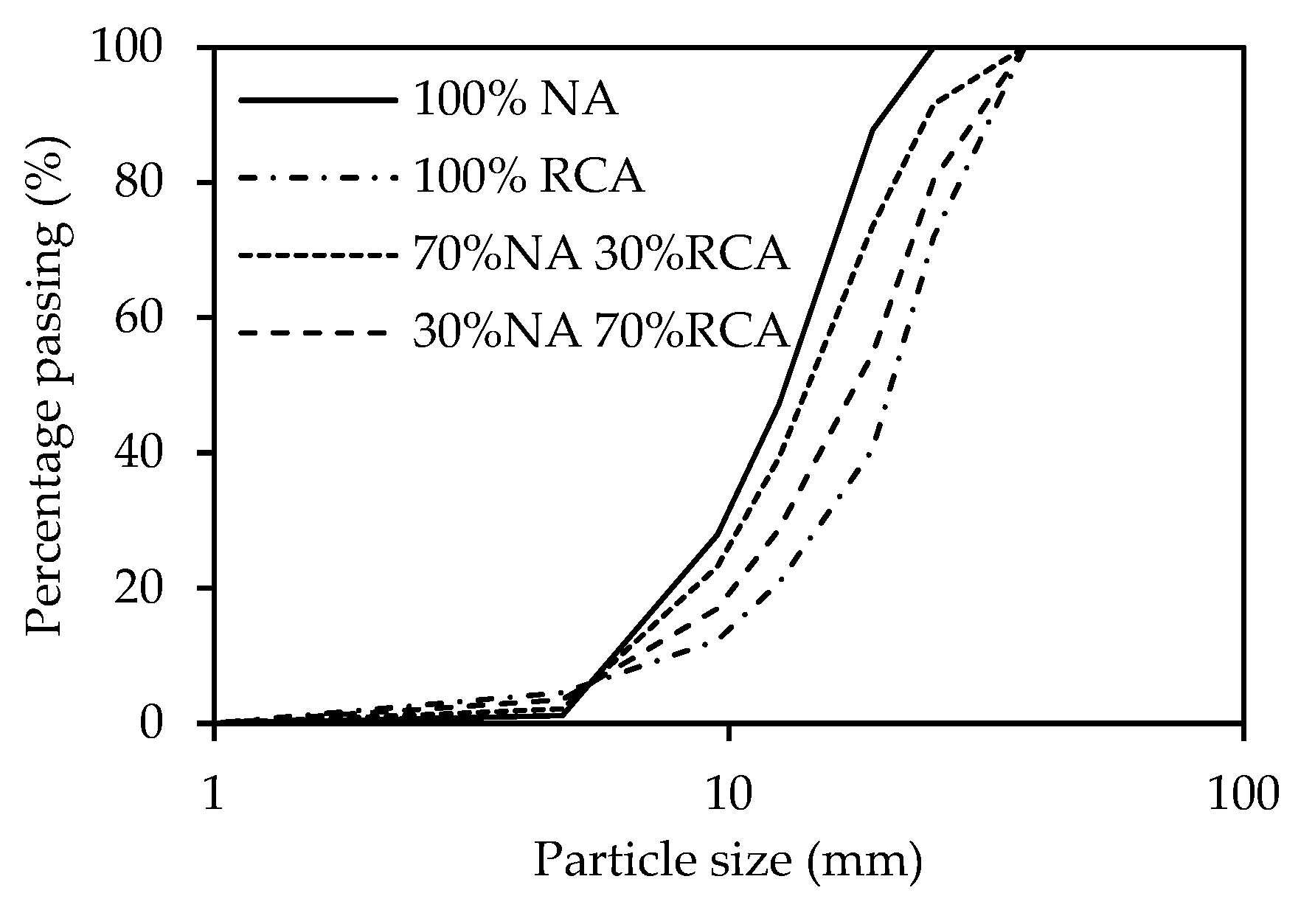

2.1. Materials

2.2. Mixture Proportioning

2.3. Sample Preparation

2.4. Experimental Methods

3. Results and Discussion

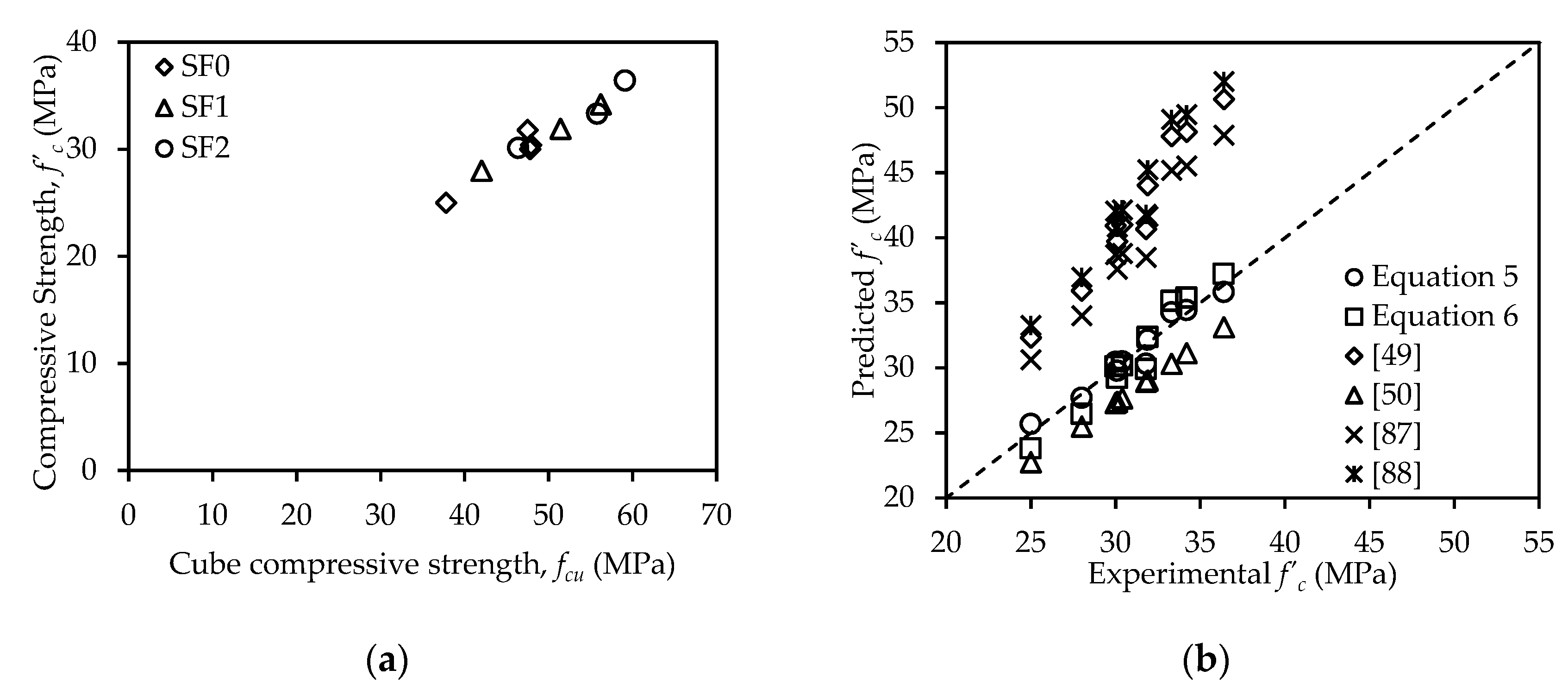

3.1. Compressive Strength

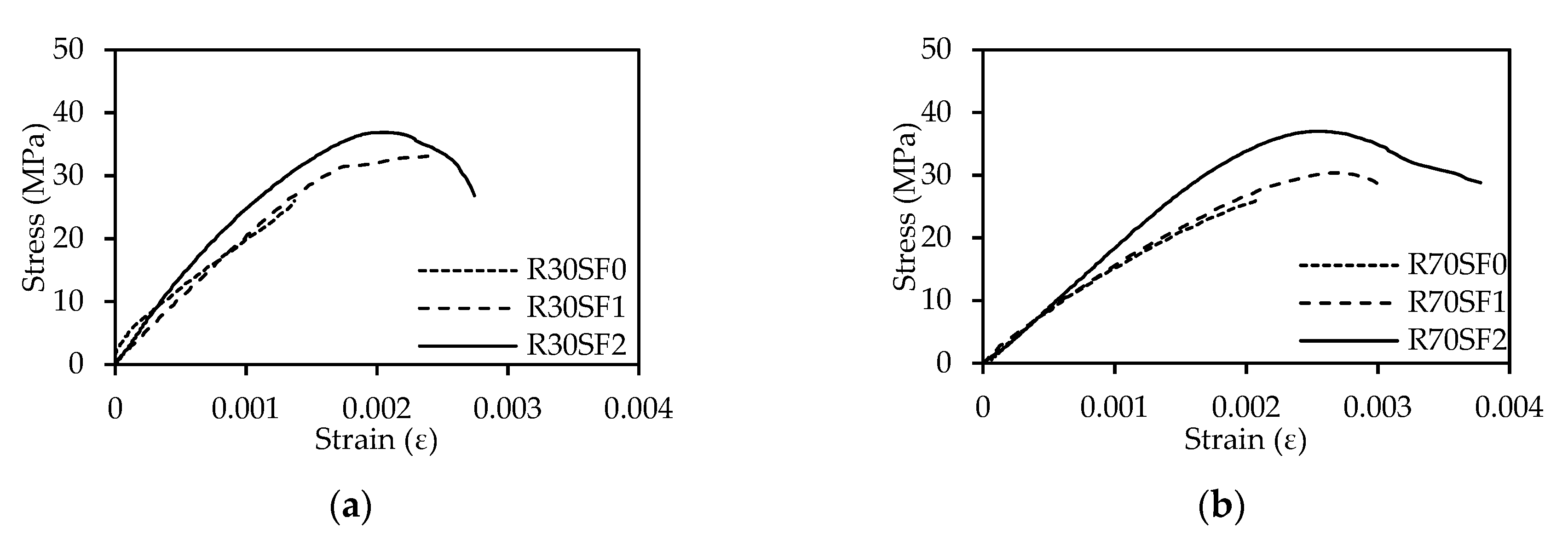

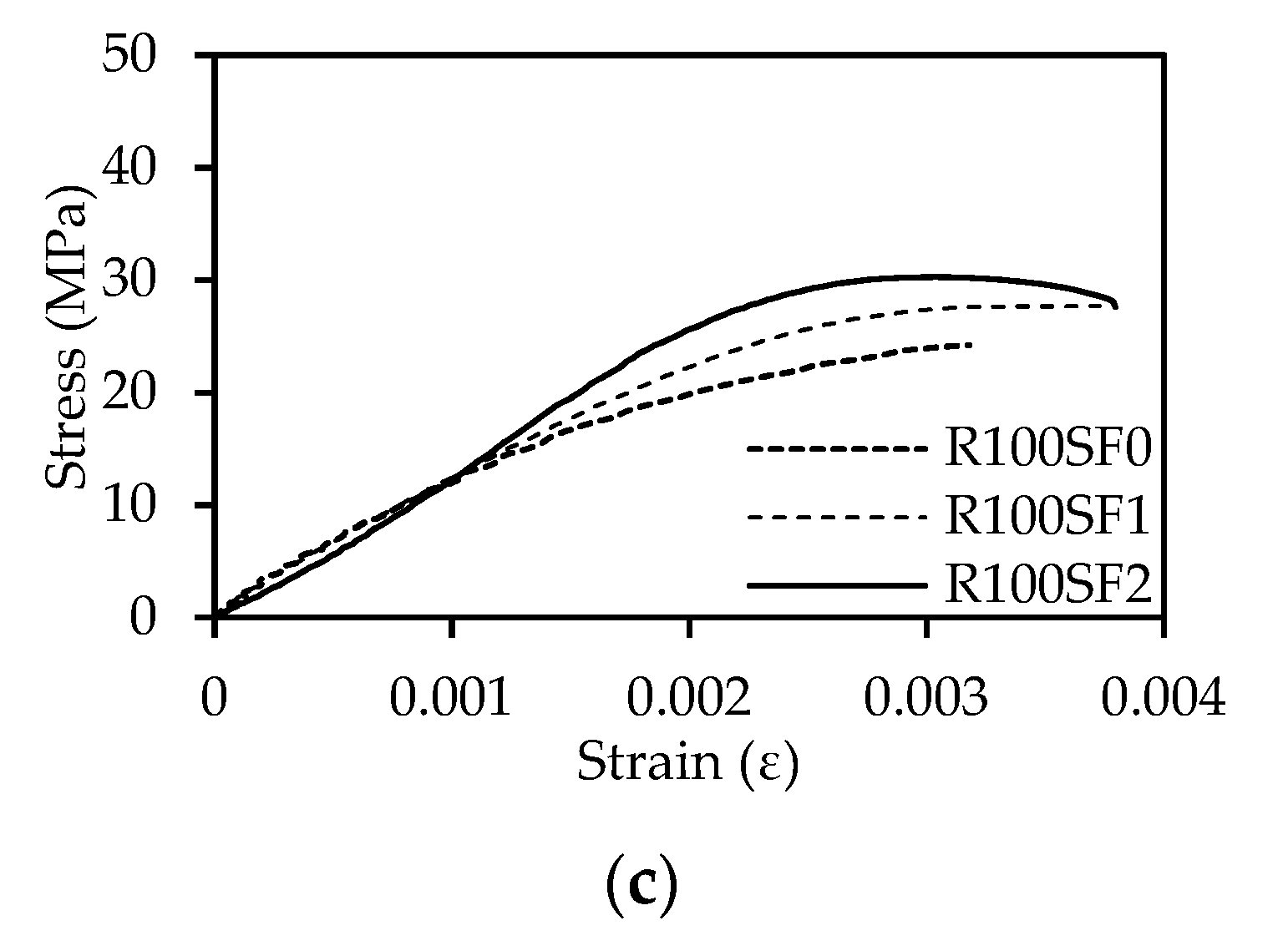

3.2. Compressive Stress-Strain Response

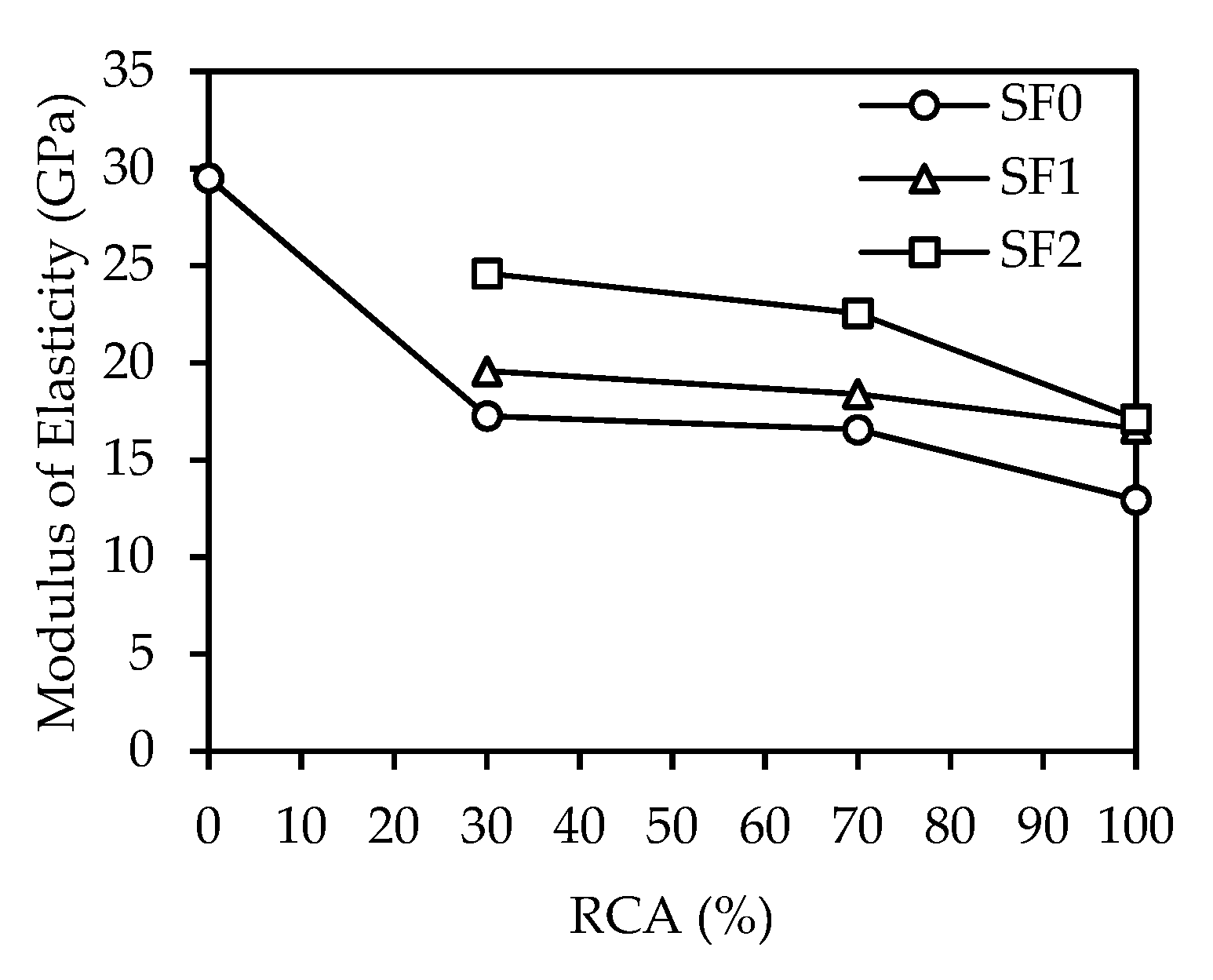

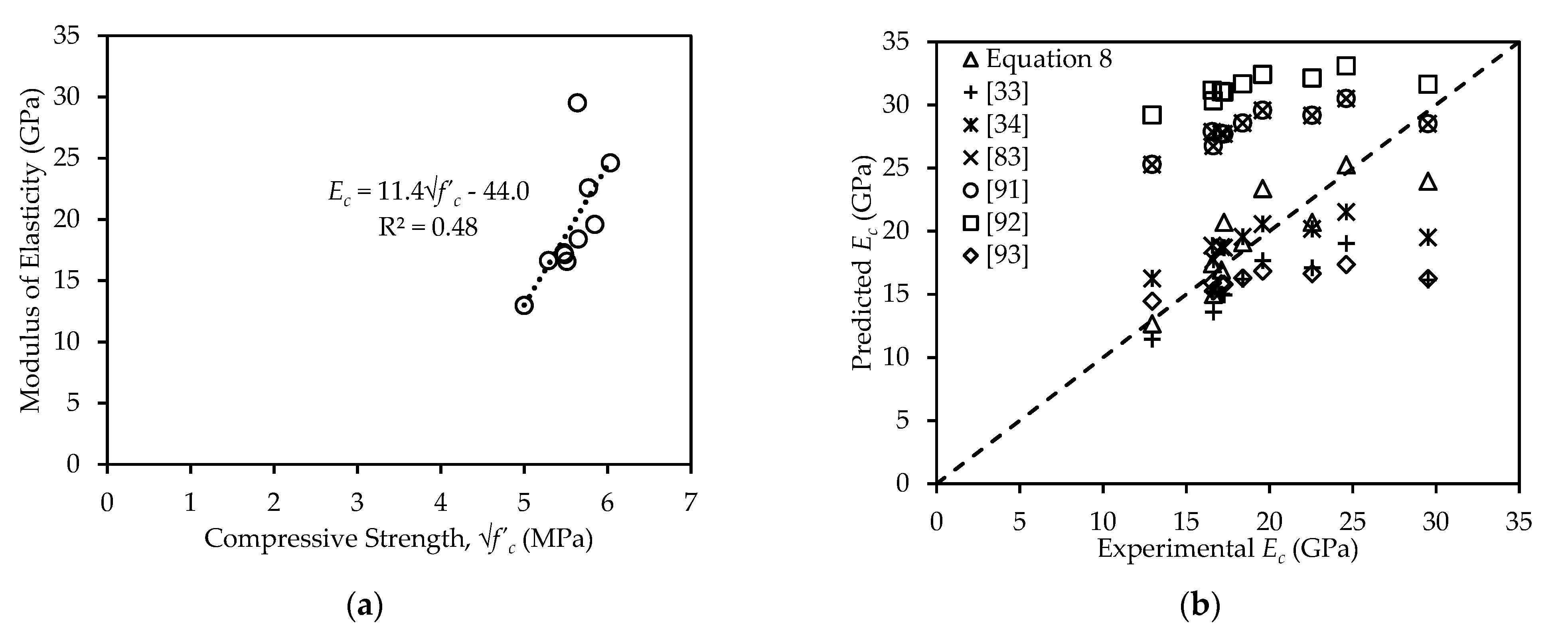

3.3. Modulus of Elasticity

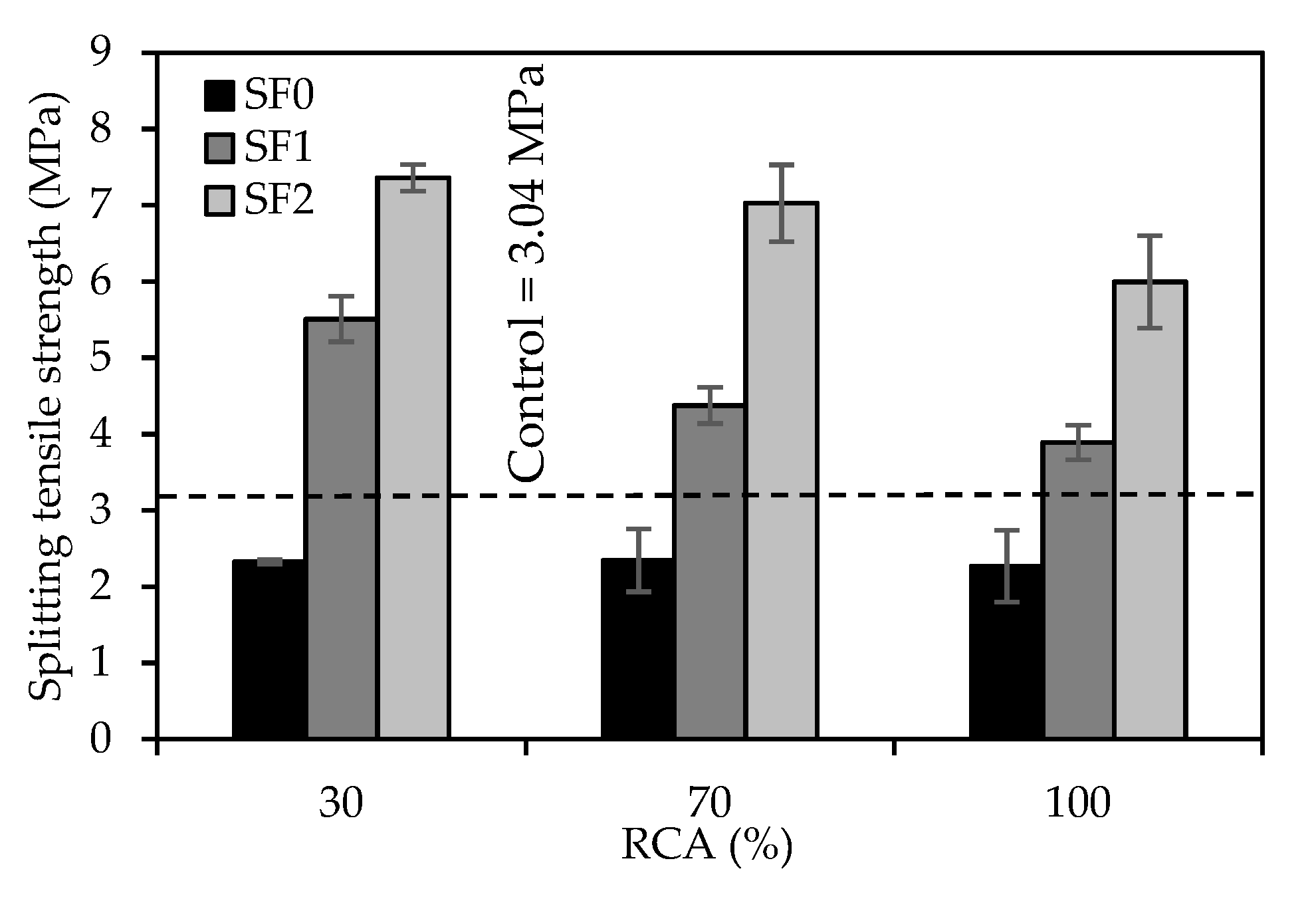

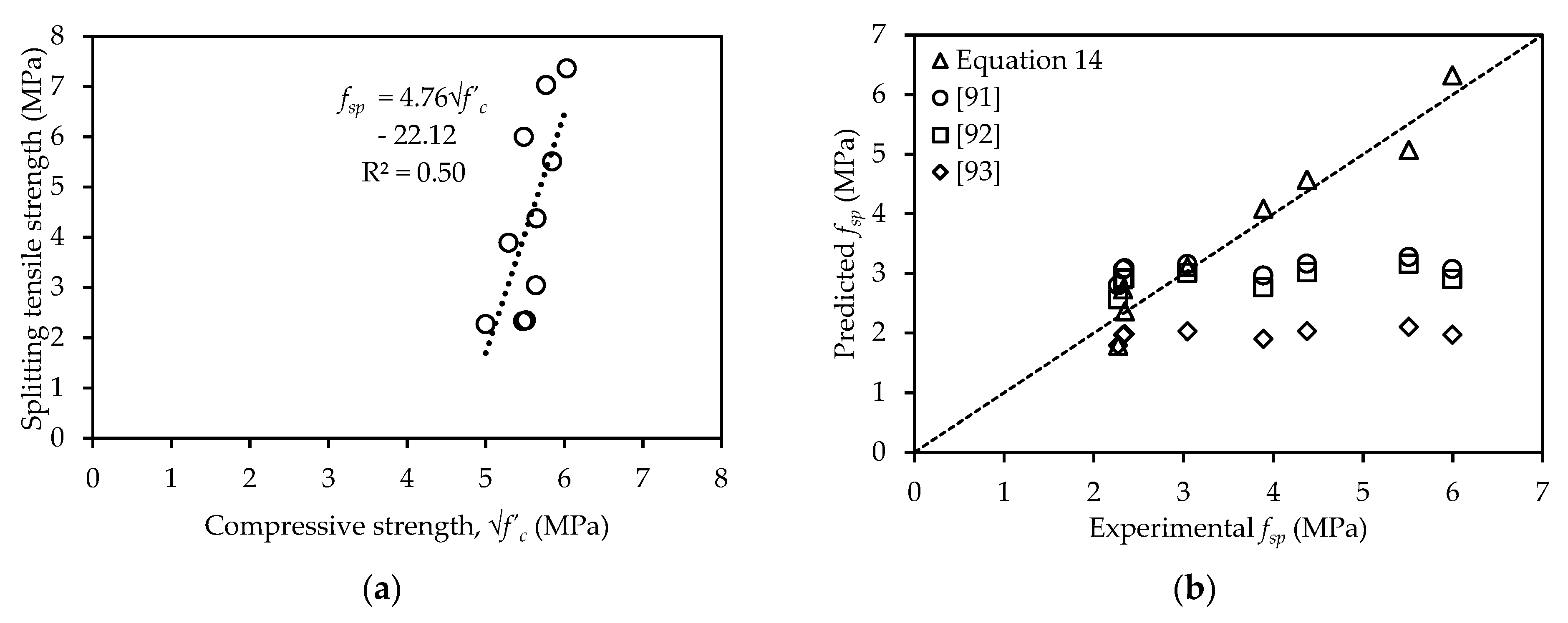

3.4. Splitting Tensile Strength

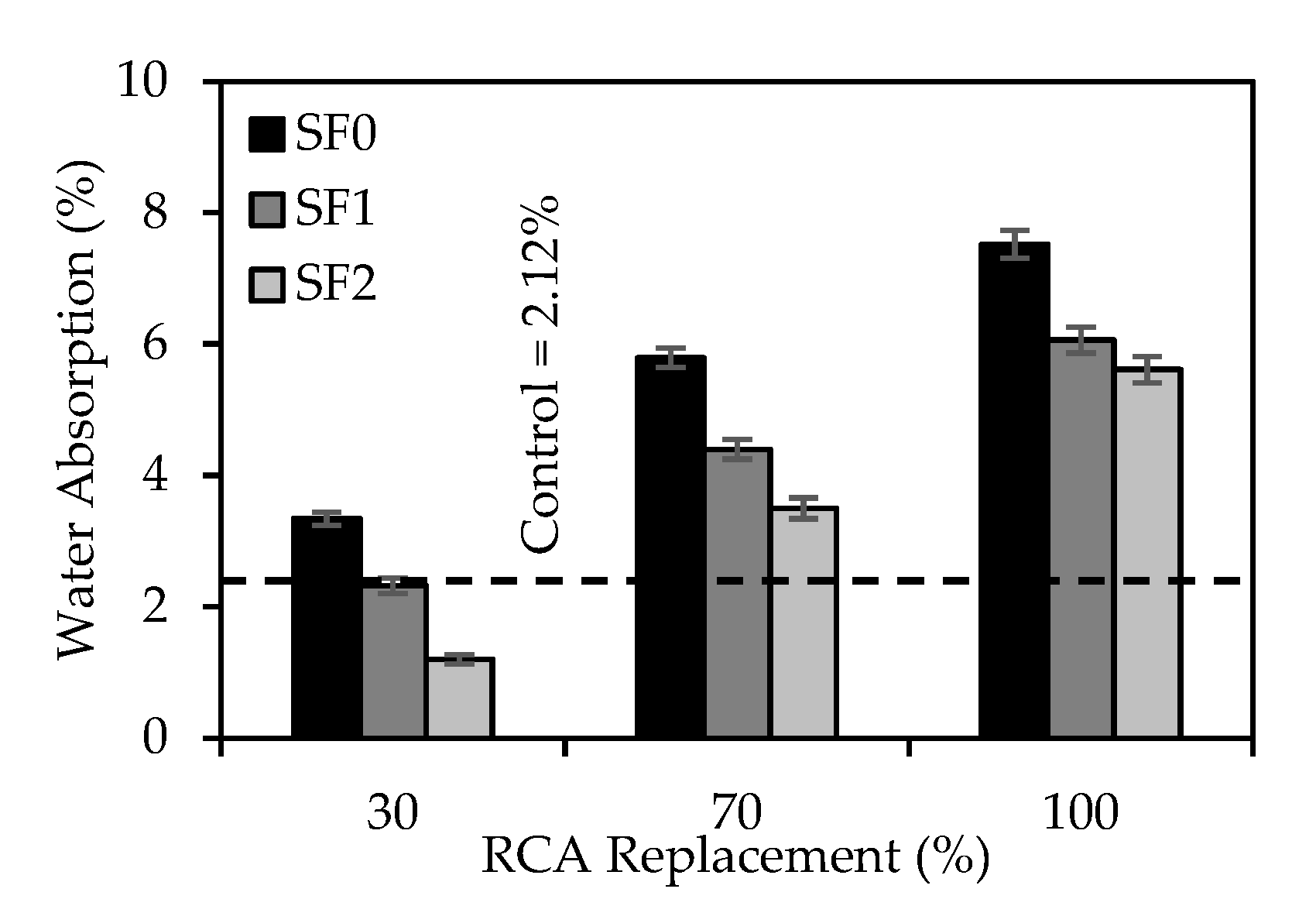

3.5. Water Absorption

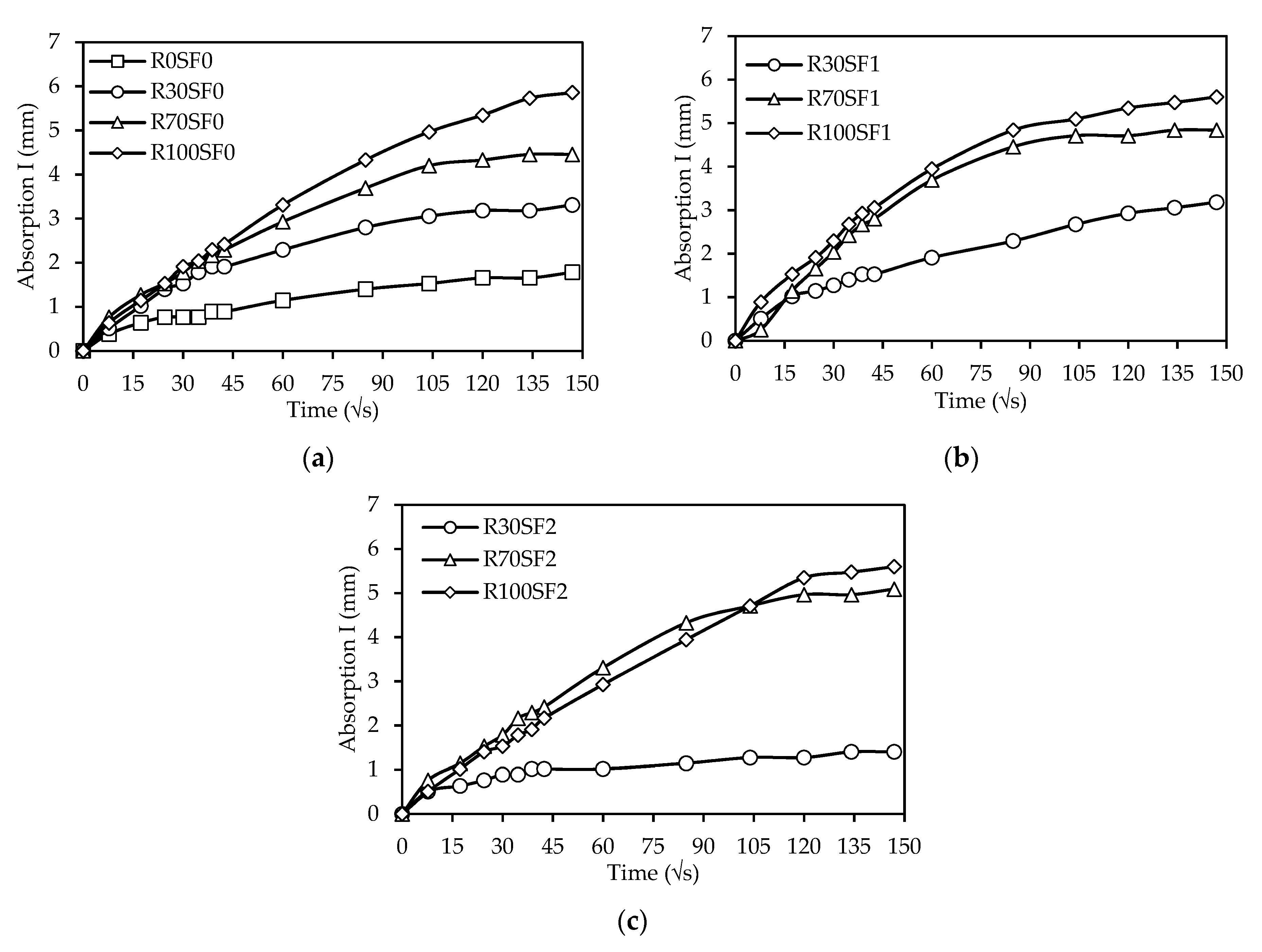

3.6. Capillary Sorptivity

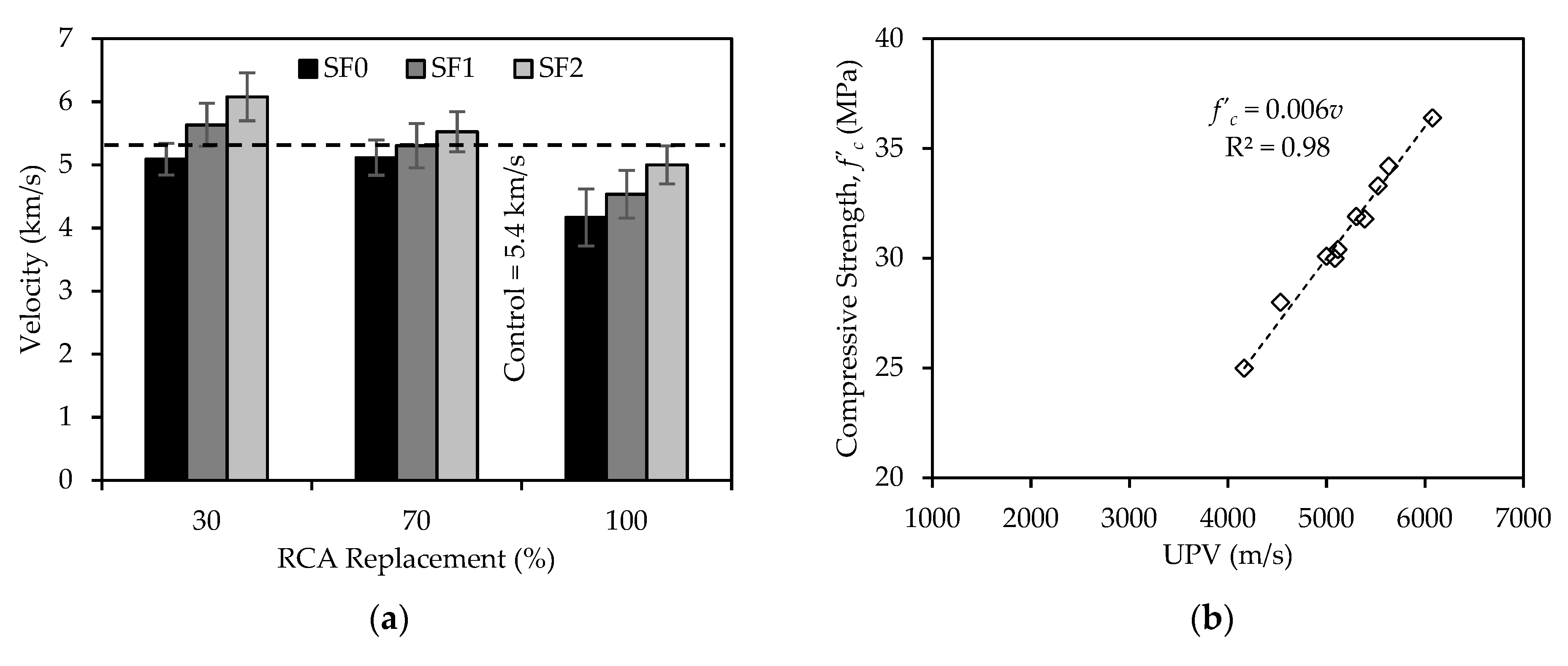

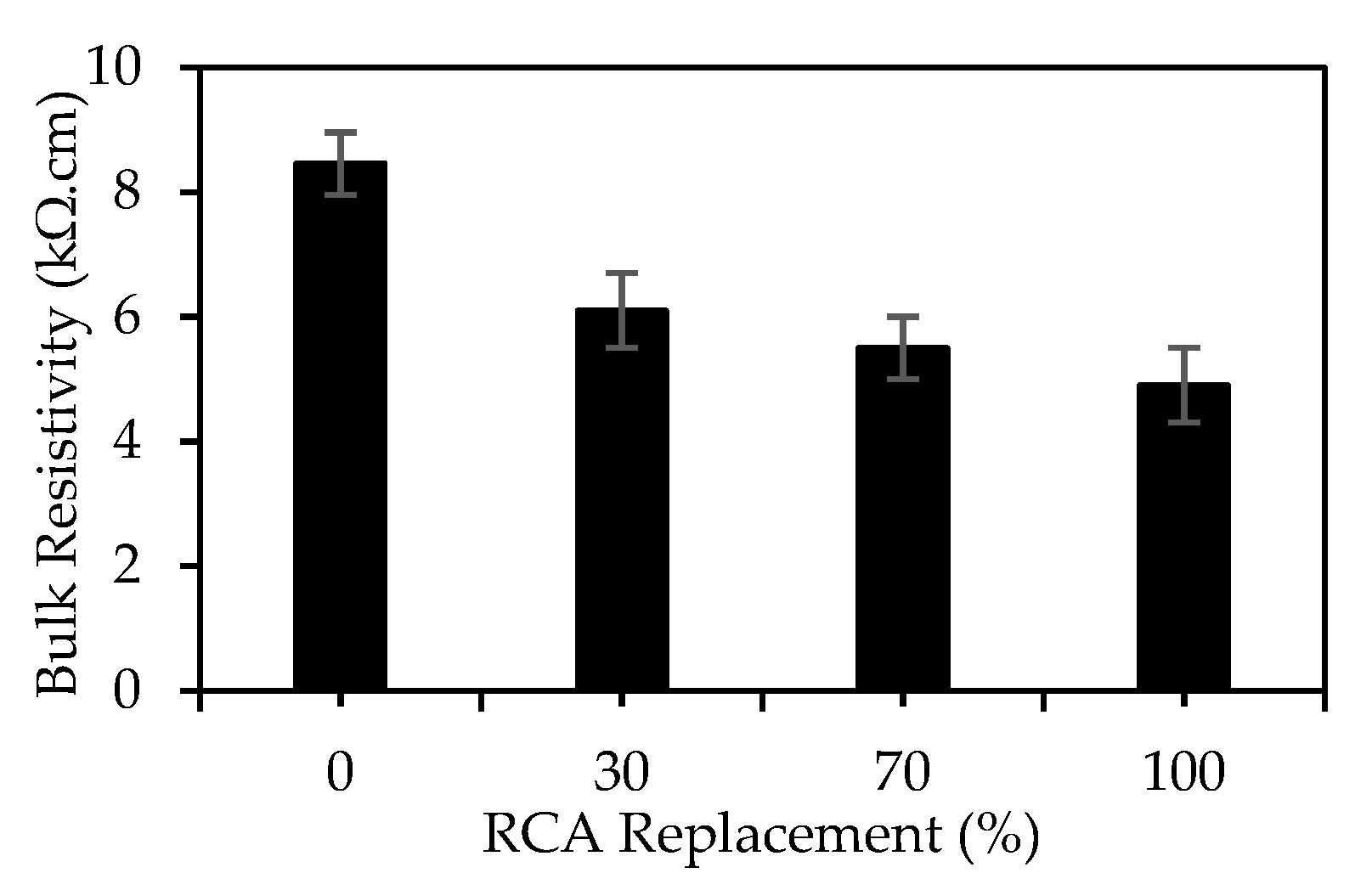

3.7. Ultrasonic Pulse Velocity and Bulk Resistivity

3.8. Abrasion Resistance

4. Conclusions

- The compressive strength development profile of the control mix showed that 81 and 98% of the 28-day cube compressive strength were attained within 1 and 7 days. Upon RCA replacement, the 1-, 7-, and 28-day cube compressive strengths were reduced by up to 44, 23, and 20%, respectively. However, this adverse effect of RCA replacement could be countered by steel fiber inclusion, with a more significant impact noted at 1 day.

- The effect of RCA replacement and steel fiber addition on the 28-day cylinder compressive strength (f’c) is similar to that of the cube strength (fcu). The confinement effect of cubes under compressive loads was unaffected by RCA replacement. As such, f’c and fcu of alkali-activated slag concrete were related using two linear regression models to predict one property from the other with reasonably to high accuracy (R2 = 0.85 and 0.95). These relationships offer a more accurate approach in comparison with other models proposed in past literature.

- Plain alkali-activated slag concrete mixes achieved the design cylinder compressive strength of 30 MPa with 30 and 70% RCA replacement. The plain concrete mix made with 100% RCA replacement could not achieve design strength.

- An alkali-activated slag concrete mix could be produced with 100% RCA in combination with 2% steel fibers, by volume, while sustaining insignificant loss (<6%) in the 28-day cube and cylinder compressive strengths. Based on a comparison with data published in the literature, alkali-activated slag was found to be a more suitable binder than OPC in concrete made with more than 30% RCA.

- The replacement of NA by RCA decreased the peak stress and increased the corresponding peak strain of alkali-activated slag concrete. Steel fiber addition increased the peak stress and further increased the peak strain. This is indicative of enhanced deformability and energy absorption capacity.

- The slope of the compression stress-strain curves characterized the modulus of elasticity. The values of Ec decreased by up to 56% with 100% RCA replacement. The incorporation of steel fibers could enhance Ec by up to 43%. Yet, none of the mixes incorporating RCA and steel fibers could attain Ec of the control mix, highlighting a more pronounced impact of RCA replacement than steel fiber addition.

- The splitting tensile strength of alkali-activated slag concrete decreased with RCA replacement. Yet, every 1% steel fiber added led to, on average, a 97% increase in fsp compared to plain counterparts, thus reversing the negative effect of RCA on fsp. Also, RCA replacement and steel fiber addition had a more pronounced impact on fsp than f’c. All RCA-based mixes could be produced with equivalent or superior fsp to that of the NA-based control when at least 1% steel fiber, by volume, was added.

- Two linear regression models were developed to estimate the Ec and fsp. The prediction accuracy improved upon the inclusion of RCA replacement percentage and steel fiber volume fraction in the models. Codified equations could not provide accurate estimations of Ec and fsp.

- The water absorption and sorptivity increased by up to 255 and 356%, respectively, upon replacing NA with RCA. Yet, it could be decreased by up to 65 and 16%, correspondingly, when steel fibers were added to the mixes. RCA replacement decreased the mechanical properties due to more pore space, i.e., higher water absorption and sorptivity, while steel fiber inclusion densified the binding matrix, i.e., less pore space, and improved the concrete’s resistance to water permeation and transport, thereby enhancing its mechanical properties.

- The bulk resistivity and ultrasonic pulse velocity decreased by up to 42 and 23%, respectively, when NA was replaced by 100% RCA. Yet the plain mixes with 30 and 70% RCA were reported to have excellent concrete quality, while those made with 100% RCA were classified to have good concrete quality. The incorporation of steel fiber increased the UPV, resulting in excellent concrete quality for all RCA-based mixes. A linear regression model was proposed to predict UPV from f’c with high accuracy (R2 = 0.98).

- Abrasion mass loss increased with RCA replacement. The addition of steel fibers improved the resistance, i.e., reduced the mass loss, by up to 74%. Mixes incorporating 2% steel fiber, by volume, regardless of RCA replacement, had comparable abrasion resistance to that of the NA-based control mix.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stoner, J.; Wankel, C. Global Sustainability Initiatives: New Models and New Approaches; Information Age Publishing: Charlotte, NC, USA, 2008; p. 248. [Google Scholar]

- Environmental Resources Limited. Demolition Waste; Construction Press Limited: Lancaster, UK, 1980. [Google Scholar]

- Gálvez-Martos, J.-L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef] [Green Version]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Kong, D.; Lei, T.; Ma, C.; Jiang, J. Effect and mechanism of surface-coating pozzolanic materials around aggregate on properties and ITZ microstructure of recycled aggregate concrete. Constr. Build. Mater. 2010, 24, 701–708. [Google Scholar] [CrossRef]

- Muduli, R.; Mukharjee, B.B. Effect of incorporation of metakaolin and recycled coarse aggregate on properties of concrete. J. Clean. Prod. 2019, 209, 398–414. [Google Scholar] [CrossRef]

- Bostanci, S.C.; Limbachiya, M.; Kew, H. Use of recycled aggregates for low carbon and cost effective concrete construction. J. Clean. Prod. 2018, 189, 176–196. [Google Scholar] [CrossRef] [Green Version]

- Azúa, G.; González, M.; Arroyo, P.; Kurama, Y. Recycled coarse aggregates from precast plant and building demolitions: Environmental and economic modeling through stochastic simulations. J. Clean. Prod. 2019, 210, 1425–1434. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, C.; Ding, T.; Akbarnezhad, A. A recycled aggregate concrete high-rise building: Structural performance and embodied carbon footprint. J. Clean. Prod. 2018, 199, 868–881. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, C.; Li, Y.; Pan, X.; Poon, C.S.; Xie, Z. Performance Enhancement of Recycled Concrete Aggregates through Carbonation. J. Mater. Civ. Eng. 2015, 27. [Google Scholar] [CrossRef]

- Ikea, T.; Yamane, S.; Sakamoto, A. Strength of concrete containing recycled aggregate concrete. In Proceedings of the 2nd RILEM Symposium on Demolition and Reuse of Waste, Bagneux, France, 12–15 April 1988. [Google Scholar]

- Hansen, T.C.; Boegh, E. Elasticity and drying shrinkage concrete of recycled-aggregate. ACI J. 1985, 82, 648–652. [Google Scholar]

- Akbarnezhad, A.; Ong, K.C.G.; Zhang, M.H.; Tam, C.T.; Foo, T.W.J. Microwaveassisted beneficiation of recycled concrete aggregates. Constr. Build. Mater. 2011, 25, 3469–3479. [Google Scholar] [CrossRef]

- Guo, Z.; Jiang, T.; Zhang, J.; Kong, X.; Chen, C.; Lehman, D.E. Mechanical and durability properties of sustainable self-compacting concrete with recycled concrete aggregate and fly ash, slag and silica fume. Constr. Build. Mater. 2020, 231, 117115. [Google Scholar] [CrossRef]

- Davidovits, J. High-Alkali Cements for 21st Century Concretes. Spec. Publ. 1994, 144, 383–398. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Herzog, H.; Eliasson, B.; Kaarstad, O. Capturing greenhouse gases. Sci. Am. 2000, 282. [Google Scholar] [CrossRef]

- Earth System Research Laboratory. Trends in atmospheric carbon dioxide. Available online: https://gml.noaa.gov/ccgg/trends/ (accessed on 10 July 2020).

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A. Composition and microstructure of alkali activated fly ash binder: Effect of the activator. Cem. Concr. Res. 2005, 35, 1984–1992. [Google Scholar] [CrossRef]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. On The development of fly ash-based geopolymer concrete. ACI Mater. J. 2004, 101, 467–472. [Google Scholar]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Bellum, R.R.; Muniraj, K.; Madduru, S.R.C. Investigation on modulus of elasticity of fly ash-ground granulated blast furnace slag blended geopolymer concrete. Mater. Today Proc. 2020, 27, 718–723. [Google Scholar] [CrossRef]

- Ismail, N.; El-Hassan, H. Development and characterization of fly ash/slag-blended geopolymer mortar and lightweight concrete. J. Mater. Civ. Eng. 2018, 30, 04018029. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B Eng. 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; Wang, C.; Zhao, J.; Liu, F.; Fang, C. Study on the optimum initial curing condition for fly ash and GGBS based geopolymer recycled aggregate concrete. Constr. Build. Mater. 2020, 247, 118540. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Properties of metakaolin-high calcium fly ash geopolymer concrete containing recycled aggregate from crushed concrete specimens. Constr. Build. Mater. 2018, 161, 365–373. [Google Scholar] [CrossRef]

- Al-Majidi, M.H.; Lampropoulos, A.; Cundy, A.; Meikle, S. Development of geopolymer mortar under ambient temperature for in situ applications. Constr. Build. Mater. 2016, 120, 198–211. [Google Scholar] [CrossRef] [Green Version]

- Chi, M. Effects of dosage of alkali-activated solution and curing conditions on the properties and durability of alkali-activated slag concrete. Constr. Build. Mater. 2012, 35, 240–245. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications; Institut Géopolymère: Saint-Quentin, France, 2008. [Google Scholar]

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- El-Hassan, H.; Shehab, E.; Al-Sallamin, A. Effect of curing regime on the performance and microstructure characteristics of alkali-activated slag-fly ash blended concrete. J. Sustain. Cem. Mater. 2021, 1–29. [Google Scholar] [CrossRef]

- El-Hassan, H.; Shehab, E.; Al-Sallamin, A. Influence of different curing regimes on the performance and microstructure of alkali-activated slag concrete. J. Mater. Civ. Eng. 2018, 30, 04018230. [Google Scholar] [CrossRef]

- Yunsheng, Z.; Wei, S.; Zongjin, L.; Xiangming, Z.; Eddie; Chungkong, C. Impact properties of geopolymer based extrudates incorporated with fly ash and PVA short fiber. Constr. Build. Mater. 2008, 22, 370–383. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chareerat, T.; Sirivivatnanon, V. Workability and strength of coarse high calcium fly ash geopolymer. Cem. Concr. Compos. 2007, 29, 224–229. [Google Scholar] [CrossRef]

- Huang, J.; Zou, C.; Sun, D.; Yang, B.; Yan, J. Effect of recycled fine aggregates on alkali-activated slag concrete properties. Structures 2021, 30, 89–99. [Google Scholar] [CrossRef]

- Parthiban, K.; Saravana Raja Mohan, K. Influence of recycled concrete aggregates on the engineering and durability properties of alkali activated slag concrete. Constr. Build. Mater. 2017, 133, 65–72. [Google Scholar] [CrossRef]

- Kathirvel, P.; Kaliyaperumal, S.R.M. Influence of recycled concrete aggregates on the flexural properties of reinforced alkali activated slag concrete. Constr. Build. Mater. 2016, 102, 51–58. [Google Scholar] [CrossRef]

- Akçaözoğlu, S.; Ulu, C. Recycling of waste PET granules as aggregate in alkali-activated blast furnace slag/metakaolin blends. Constr. Build. Mater. 2014, 58, 31–37. [Google Scholar] [CrossRef]

- Shi, X.S.; Collins, F.G.; Zhao, X.L.; Wang, Q.Y. Mechanical properties and microstructure analysis of fly ash geopolymeric recycled concrete. J. Hazard. Mater. 2012, 237–238, 20–29. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Mechanical and durability properties of fly ash geopolymer concrete containing recycled coarse aggregates. Int. J. Sustain. Built Environ. 2016, 5, 277–287. [Google Scholar] [CrossRef] [Green Version]

- Xie, J.; Wang, J.; Zhang, B.; Fang, C.; Li, L. Physicochemical properties of alkali activated GGBS and fly ash geopolymeric recycled concrete. Constr. Build. Mater. 2019, 204, 384–398. [Google Scholar] [CrossRef]

- Hu, Y.; Tang, Z.; Li, W.; Li, Y.; Tam, V.W.Y. Physical-mechanical properties of fly ash/GGBFS geopolymer composites with recycled aggregates. Constr. Build. Mater. 2019, 226, 139–151. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. Influence of double hooked-end steel fibers and slag on mechanical and durability properties of high performance recycled aggregate concrete. Compos. Struct. 2017, 181, 273–284. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A. Influence of glass fibers on mechanical and durability performance of concrete with recycled aggregates. Constr. Build. Mater. 2019, 228, 116783. [Google Scholar] [CrossRef]

- Carneiro, J.A.; Lima, P.R.L.; Leite, M.B.; Toledo Filho, R.D. Compressive stress–strain behavior of steel fiber reinforced-recycled aggregate concrete. Cem. Concr. Compos. 2014, 46, 65–72. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L. Flexural performance and evaluation method of steel fiber reinforced recycled coarse aggregate concrete. Constr. Build. Mater. 2018, 159, 126–136. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L.; Nokken, M. Compressive behavior of steel fiber reinforced recycled coarse aggregate concrete designed with equivalent cubic compressive strength. Constr. Build. Mater. 2017, 141, 235–244. [Google Scholar] [CrossRef] [Green Version]

- Kachouh, N.; El-Hassan, H.; El-Maaddawy, T. Effect of steel fibers on the performance of concrete made with recycled concrete aggregates and dune sand. Constr. Build. Mater. 2019, 213, 348–359. [Google Scholar] [CrossRef]

- Kachouh, N.; El-Hassan, H.; El-Maaddawy, T. Influence of steel fibers on the flexural performance of concrete incorporating recycled concrete aggregates and dune sand. J. Sustain. Cem. Mater. 2020, 10, 1–28. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Nuaklong, P.; Wongsa, A.; Boonserm, K.; Ngohpok, C.; Jongvivatsakul, P.; Sata, V.; Sukontasukkul, P.; Chindaprasirt, P. Enhancement of mechanical properties of fly ash geopolymer containing fine recycled concrete aggregate with micro carbon fiber. J. Build. Eng. 2021, 41, 102403. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, J.P. Concrete Microstructure, Properties and Material; McGraw Hill: New York, NY, USA, 2006. [Google Scholar]

- ACI Committee 201.2. Guide to Durable Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2016; p. 87. [Google Scholar]

- ASTM. Standard Specification for Concrete Aggregates; ASTM C33; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM. Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles machine; ASTM C131; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM. Standard Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate; ASTM C88; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ACI Committee E-701. Aggregates for Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2016; p. 30. [Google Scholar]

- ASTM. Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate; ASTM C29; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM. Standard Test Method for Relative Density (Specific Gravity) And Absorption of Coarse Aggregate; ASTM C127; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM. Standard Test Method for Sieve Analysis of Fine and coarse aggregates; ASTM C136; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- El-Hassan, H.; Ismail, N. Effect of process parameters on the performance of fly ash/GGBS blended geopolymer composites. J. Sustain. Cem. Mater. 2018, 7, 122–140. [Google Scholar] [CrossRef]

- Patankar, S.V.; Ghugal, Y.M.; Jamkar, S.S. Effect of concentration of sodium hydroxide and degree of heat curing on fly ash-based geopolymer mortar. Indian J. Mater. Sci. 2014, 2014, 6. [Google Scholar] [CrossRef]

- Sani, N.A.M.; Man, Z.; Shamsuddin, R.M.; Azizli, K.A.; Shaari, K.Z.K. Determination of excess sodium hydroxide in geopolymer by volumetric analysis. Procedia Eng. 2016, 148, 298–301. [Google Scholar] [CrossRef] [Green Version]

- Hossain, M.S.; Lane, D.S.; Schmidt, B.N. Use of the Micro-Deval Test. for Assessing the Durability of Virginia Aggregates; Virginia Transportation Research Council: Charlottesville, VA, USA, 2007; p. 33. [Google Scholar]

- Montes, C.; Zang, D.; Allouche, E.N. Rheological behavior of fly ash-based geopolymers with the addition of superplasticizers. J. Sustain. Cem. Mater. 2012, 1, 179–185. [Google Scholar] [CrossRef]

- Palacios, M.; Puertas, F. Effect of superplasticizer and shrinkage-reducing admixtures on alkali-activated slag pastes and mortars. Cem. Concr. Res. 2005, 35, 1358–1367. [Google Scholar] [CrossRef]

- Bekaert. Dramix 3D 65/35 Report; Bekaert: Zwevegem, Belgium, 2012; p. 1. [Google Scholar]

- ASTM. Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTM C192; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM C39; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- British Standard BS EN 12390-3:2009. Testing Hardened Concrete-Compressive Strength of Test Specimens; British Standard: London, UK, 2009. [Google Scholar]

- ASTM. Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; ASTM C469; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM C496; ASTM: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete; ASTM C462; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes; ASTM C1585; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM. Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration; ASTM C1202; ASTM: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM. Standard Test Method for Bulk Electrical Resistivity or Bulk Conductivity of Concrete; ASTM C1876; ASTM: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM. Standard Test Method for Pulse Velocity Through Concrete; ASTM C597; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Safiuddin, M.; Scott, B. Abrasion resistance of concrete-design, construction, and case study. Concr. Res. Lett. 2015, 6, 136–148. [Google Scholar]

- Yalcinkaya, C.; Sznajder, J.; Beglarigale, A.; Sancakoglu, O.; Yazici, H. Abrasion resistance of reactive powder concrete: The influence of water-to-cement ratio and steel micro-fibers. Adv. Mater. Lett. 2014, 5, 345–351. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Determining Potential Resistance to Degradation of Pervious Concrete by Impact and Abrasion; ASTM C1747/C1747M–13; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- El-Hassan, H.; Elkholy, S. Performance evaluation and microstructure characterization of steel fiber-reinforced alkali-activated slag concrete incorporating fly ash. J. Mater. Civ. Eng. 2019, 31, 04019223. [Google Scholar] [CrossRef]

- Islam, A.; Alengaram, U.J.; Jumaat, M.Z.; Ghazali, N.B.; Yusoff, S.; Bashar, I.I. Influence of steel fibers on the mechanical properties and impact resistance of lightweight geopolymer concrete. Constr. Build. Mater. 2017, 152, 964–977. [Google Scholar] [CrossRef]

- Temuujin, J.; Williams, R.P.; van Riessen, A. Effect of mechanical activation of fly ash on the properties of geopolymer cured at ambient temperature. J. Mater. Process. Technol. 2009, 209, 5276–5280. [Google Scholar] [CrossRef]

- Elwell, D.J.; Fu, G. Compression Testing of Concrete: Cylinders Versus Cubes. 1995. Available online: https://trid.trb.org/view/496307 (accessed on 10 June 2020).

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Xie, J.-H.; Guo, Y.-C.; Liu, L.-S.; Xie, Z.-H. Compressive and flexural behaviours of a new steel-fibre-reinforced recycled aggregate concrete with crumb rubber. Constr. Build. Mater. 2015, 79, 263–272. [Google Scholar] [CrossRef]

- Mesgari, S.; Akbarnezhad, A.; Xiao, J.Z. Recycled geopolymer aggregates as coarse aggregates for Portland cement concrete and geopolymer concrete: Effects on mechanical properties. Constr. Build. Mater. 2020, 236, 117571. [Google Scholar] [CrossRef]

- ACI Committee 363. State of the Art Report on High-Strength Concrete; American Concrete Institute: Farmington Hills, MI, USA, 1992; Volume 81, pp. 364–411. [Google Scholar] [CrossRef]

- ACI Committee 318. Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Comité Euro-International Du Béton; Federation International de la Precontrainte. CEB-FIP Model Code 1990: Design Code; Thomas Telford, Ltd.: London, UK, 1993.

- AS3600. Concrete Structures; Standards Australia: Sydney, Australia, 2009; p. 198. [Google Scholar]

- Bernal, S.; De Gutierrez, R.; Delvasto, S.; Rodriguez, E. Performance of an alkali-activated slag concrete reinforced with steel fibers. Constr. Build. Mater. 2010, 24, 208–214. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Wiley: New York, NY, USA, 1996. [Google Scholar]

- Martys, N.S.; Ferraris, C.F. Capillary transport in mortars and concrete. Cem. Concr. Res. 1997, 27, 747–760. [Google Scholar] [CrossRef]

- Şanal, İ. Performance of macrosynthetic and steel fiber–reinforced concretes emphasizing mineral admixture addition. J. Mater. Civ. Eng. 2018, 30, 04018101. [Google Scholar] [CrossRef]

- Ramadoss, P.; Nagamani, K. Tensile strength and durability characteristics of high-performance fiber reinforced concrete. Arab. J. Sci. Eng. 2008, 41, 307–319. [Google Scholar]

- Tamrakar, N. The Effect of Steel Fibers Type and Content on the Development of Fresh and Hardened Properties and Durability of Self-consolidating Concrete; Ryerson University: Toronto, ON, Canada, 2012. [Google Scholar]

- IS 13311-1. Non-Destructive Testing of Concrete-Part 1: Ultrasonic Pulse Velocity; Bureau of Indian Standards: New Delhi, India, 1992. [Google Scholar]

- Wu, H.; Huang, B.; Shu, X.; Dong, Q. Laboratory evaluation of abrasion resistance of portland cement pervious concrete. J. Mater. Civ. Eng. 2011, 23, 697–702. [Google Scholar] [CrossRef]

| Oxides | Material (%) | |

|---|---|---|

| Slag | Dune Sand | |

| CaO | 42.0 | 14.1 |

| SiO2 | 34.7 | 64.9 |

| Al2O3 | 14.4 | 3.0 |

| MgO | 6.9 | 1.3 |

| Fe2O3 | 0.8 | 0.7 |

| loss on ignition | 1.1 | 0.0 |

| others | 0.2 | 16.0 |

| Physical properties | ||

| Blaine fineness (cm2/g) | 4250 | - |

| specific gravity | 2.70 | 2.77 |

| Property (Unit) | ASTM Test | Dune Sand | NA | RCA |

|---|---|---|---|---|

| dry-rodded density (kg/m3) | C29 [60] | 1663 | 1635 | 1563 |

| absorption (%) | C127 [61] | - | 0.22 | 6.63 |

| Los Angeles abrasion (%) | C131 [57] | - | 16.0 | 32.6 |

| surface area (cm2/g) | C136 [62] | 116.80 | 2.49 | 2.50 |

| soundness (MgSO4, %) | C88 [58] | - | 1.20 | 2.78 |

| specific gravity | C127 [61] | 2.77 | 2.82 | 2.63 |

| fineness modulus | C136 [62] | 1.45 | 6.82 | 7.44 |

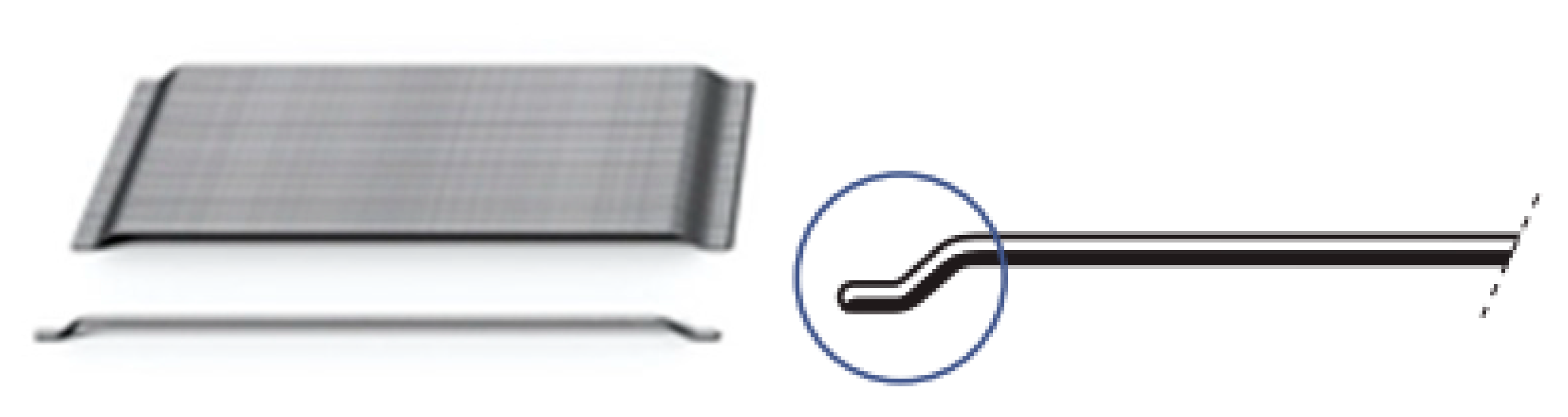

| Material | df (mm) | lf (mm) | Aspect Ratio (lf/df) | Density (g/cm3) | Fiber Network (Fiber/kg) | ft (MPa) | Ef (GPa) |

|---|---|---|---|---|---|---|---|

| steel fiber | 0.55 | 35 | 65 | 7.9 | 14.531 | 1345 | 210 |

| Mix No. | Mix Designation | Mass (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Slag 1 | DS 1 | NA 1 | RCA 1 | SS 1 | SH 1 | SP 1 | SF 1 | ||

| 1 | R0SF0 | 300 | 725 | 1210 | 0 | 99 | 66 | 7.5 | 0 |

| 2 | R30SF0 | 300 | 725 | 847 | 363 | 99 | 66 | 7.5 | 0 |

| 3 | R30SF1 | 300 | 725 | 847 | 363 | 99 | 66 | 7.5 | 78 |

| 4 | R30SF2 | 300 | 725 | 847 | 363 | 99 | 66 | 7.5 | 156 |

| 5 | R70SF0 | 300 | 725 | 363 | 847 | 99 | 66 | 7.5 | 0 |

| 6 | R70SF1 | 300 | 725 | 363 | 847 | 99 | 66 | 7.5 | 78 |

| 7 | R70SF2 | 300 | 725 | 363 | 847 | 99 | 66 | 7.5 | 156 |

| 8 | R100SF0 | 300 | 725 | 0 | 1210 | 99 | 66 | 7.5 | 0 |

| 9 | R100SF1 | 300 | 725 | 0 | 1210 | 99 | 66 | 7.5 | 78 |

| 10 | R100SF2 | 300 | 725 | 0 | 1210 | 99 | 66 | 7.5 | 156 |

| Mix No. | Mix Designation | fcu (MPa) | f’c(MPa) | Increase 1–7 a (%) | Increase 7–28 b (%) | f’c/fcu | ||

|---|---|---|---|---|---|---|---|---|

| 1-Day | 7-Day | 28-Day | ||||||

| 1 | R0SF0 | 38.6 | 46.4 | 47.5 | 31.8 | 20.2 | 2.4 | 0.67 |

| 2 | R30SF0 | 36.9 | 45.6 | 47.8 | 30.0 | 23.6 | 4.8 | 0.63 |

| 3 | R30SF1 | 42.2 | 51.3 | 56.2 | 34.2 | 21.6 | 9.6 | 0.61 |

| 4 | R30SF2 | 43.2 | 51.8 | 59.1 | 36.4 | 19.9 | 14.1 | 0.62 |

| 5 | R70SF0 | 26.4 | 39.1 | 47.9 | 30.4 | 48.1 | 22.5 | 0.63 |

| 6 | R70SF1 | 32.5 | 45.3 | 51.4 | 31.9 | 39.4 | 13.5 | 0.62 |

| 7 | R70SF2 | 37.5 | 51.3 | 55.8 | 33.3 | 36.8 | 8.8 | 0.60 |

| 8 | R100SF0 | 21.8 | 35.6 | 37.8 | 25.0 | 63.3 | 6.2 | 0.66 |

| 9 | R100SF1 | 27.1 | 37.7 | 42.0 | 28.0 | 39.1 | 11.4 | 0.67 |

| 10 | R100SF2 | 28.6 | 39.1 | 46.4 | 30.1 | 36.7 | 18.7 | 0.65 |

| Mix No. | Mix Designation | RCA (%) | Steel Fibers (%) | Sorptivity × 10−2 (mm/√s) |

|---|---|---|---|---|

| 1 | R0F0 | 0 | 0 | 0.86 |

| 2 | R30F0 | 30 | 0 | 1.86 |

| 3 | R30F1 | 30 | 1 | 1.70 |

| 4 | R30F2 | 30 | 2 | 1.56 |

| 5 | R70F0 | 70 | 0 | 3.15 |

| 6 | R70F1 | 70 | 1 | 2.94 |

| 7 | R70F2 | 70 | 2 | 2.85 |

| 8 | R100F0 | 100 | 0 | 4.12 |

| 9 | R100F1 | 100 | 1 | 3.96 |

| 10 | R100F2 | 100 | 2 | 3.75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Hassan, H.; Medljy, J.; El-Maaddawy, T. Properties of Steel Fiber-Reinforced Alkali-Activated Slag Concrete Made with Recycled Concrete Aggregates and Dune Sand. Sustainability 2021, 13, 8017. https://doi.org/10.3390/su13148017

El-Hassan H, Medljy J, El-Maaddawy T. Properties of Steel Fiber-Reinforced Alkali-Activated Slag Concrete Made with Recycled Concrete Aggregates and Dune Sand. Sustainability. 2021; 13(14):8017. https://doi.org/10.3390/su13148017

Chicago/Turabian StyleEl-Hassan, Hilal, Jamal Medljy, and Tamer El-Maaddawy. 2021. "Properties of Steel Fiber-Reinforced Alkali-Activated Slag Concrete Made with Recycled Concrete Aggregates and Dune Sand" Sustainability 13, no. 14: 8017. https://doi.org/10.3390/su13148017

APA StyleEl-Hassan, H., Medljy, J., & El-Maaddawy, T. (2021). Properties of Steel Fiber-Reinforced Alkali-Activated Slag Concrete Made with Recycled Concrete Aggregates and Dune Sand. Sustainability, 13(14), 8017. https://doi.org/10.3390/su13148017