Abstract

The food industry is responsible for supplying the food demand of the ever-increasing global population. The food chain is one of the major contributors to greenhouse gas (GHG) emissions, and global food waste accounts for one-third of produced food. A solution to this problem is preserving crops, vegetables, and fruits with the help of an ancient method of sun drying. For drying agricultural and marine products, several types of dryers are also being developed. However, they require a large amount of energy supplied conventionally from pollutant energy sources. The environmental concerns and depletion risks of fossil fuels persuade researchers and developers to seek alternative solutions. To perform drying applications, sustainable solar power may be effective because it is highly accessible in most regions of the world. Greenhouse dryers (GHDs) are simple facilities that can provide large capacities for drying agricultural products. This study reviews the integration of GHDs with different solar technologies, including photovoltaic (PV), photovoltaic-thermal (PVT), and solar thermal collectors. Additionally, the integration of solar-assisted greenhouse dryers (SGHDs) with heat pumps and thermal energy storage (TES) units, as well as their hybrid configuration considering integration with other renewable energy sources, is investigated to improve their thermal performance. In this regard, this review presents and discusses the most recent advances in this field. Additionally, the economic analysis of SGHDs is presented as a key factor to make these sustainable facilities commercially available.

1. Introduction

The world’s population is growing steadily and is projected to reach up to approximately 8.6 billion by 2030, 10.1 billion by 2050, and 12.7 billion by 2100. Therefore, an increase in food production is inevitable to satisfy the basic needs of livelihood [1,2,3]. Along with the increase in productivity, the reduction in food grain wastage, post-harvest losses, and losses incurred at various stages of the food supply chain will play a major role in dealing with food insecurity. According to a report released by the Food and Agriculture Organization (FAO) in 2020, about one-third of the produced food (almost 1.3 billion tonnes) is lost every year [4,5]. In developing countries, about 30–40% of total food production is lost mostly at post-harvest and processing levels, while in developed countries the same value is lost at retail and consumer levels [6,7,8]. Post-harvest losses are significantly restricted via the drying of raw food crops. Preservation of agricultural products for a long time entails reducing their moisture content in a way to keep their essential nutrients [9,10].

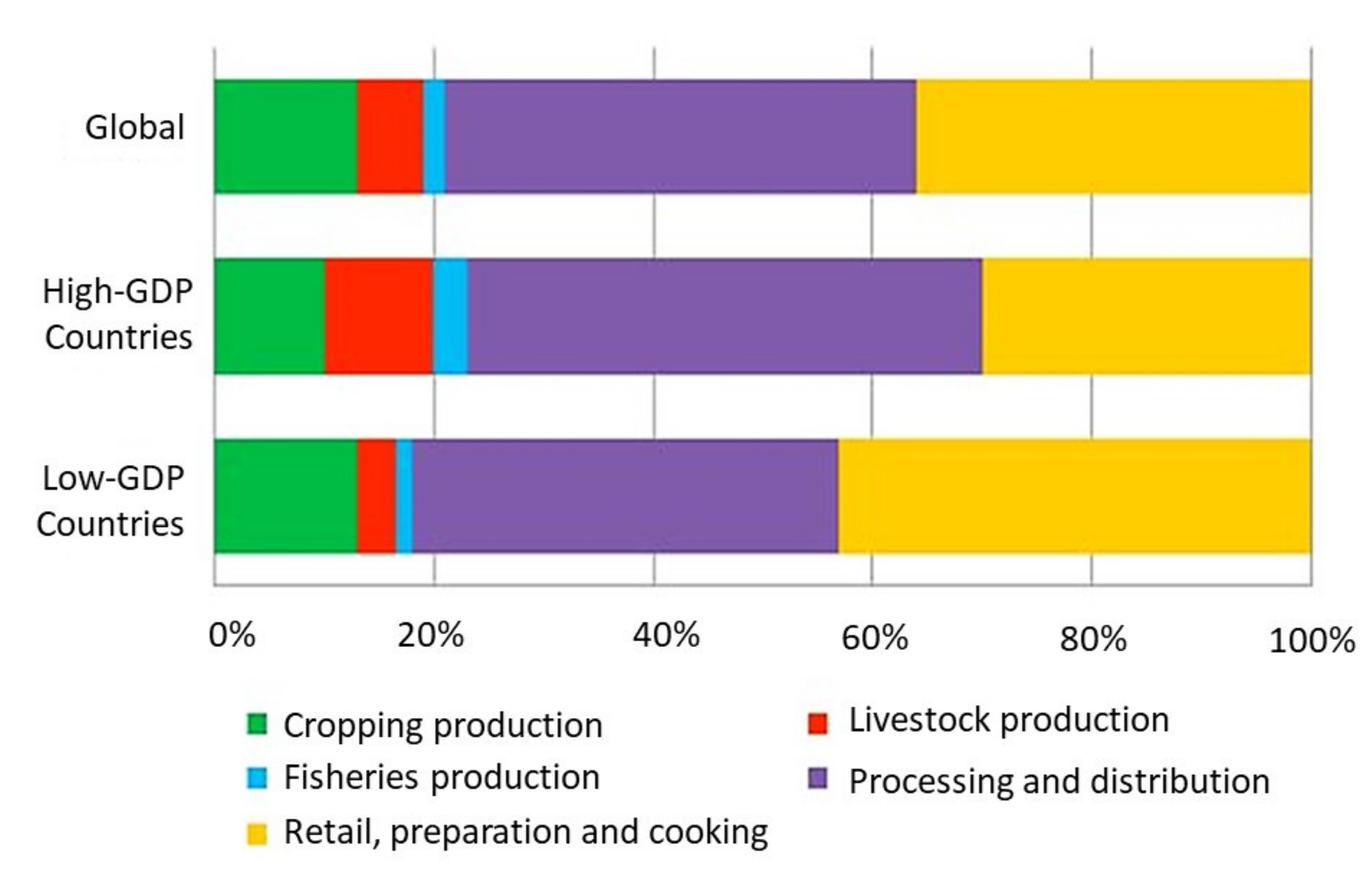

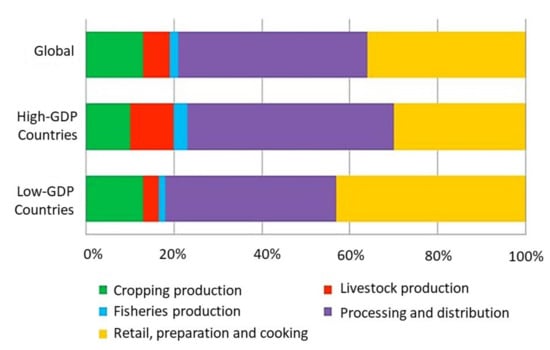

Agricultural crop drying is an energy-intensive process in which both heat and mass transfer occur. From primitive times, “sun drying” has been a common traditional practice to preserve cultivated crops. However, to satisfy the ever-increasing population’s food demand, an increase in the use of conventional energy sources at different stages of the food supply chain is inevitable [11,12]. It has also been reported that the global energy demand will increase about 40–50% by 2030 to meet the global food demand [13,14]. An indicative diagram in Figure 1 shows the scenario of energy utilization at different stages of the food supply chain. The figure reveals that energy utilization at the stage of post-harvest food processing comprises a significant percentage share of the total energy utilization in the whole food supply chain [8,15].

Figure 1.

Utilization of energy at different stages of the whole food supply chain, adapted with permission from [16].

Among several existing procedures, open-air sun drying is widely used due to its low cost but encompasses the major drawback of losing considerable thermal energy, resulting in poor utilization of heat during the process. Consequently, the drying process gets affected, causing the production rate to be lowered, which results in a long drying period [17,18]. Other than the lower thermal efficiency of this process, some other factors affect the sun drying’s productivity, such as climatic conditions, rain, wind, birds, pests, and rodents. Additionally, there is a large possibility of food contamination and food-linked diseases because of fungus growth in dried food crops due to uncontrolled external parameters [19]. In this regard, modern and advanced drying systems that are newly conceptualized and proposed can overcome the aforesaid problems of the drying systems. These advanced dryers help to enhance the overall energy efficiency of the systems, quality of the dried food, drying period, and hygiene of the food corps [20,21]. Out of various types of globally developed dryers, greenhouse dryers (GHDs) are easy to install and have higher load capacities [22]. With the growing concern on the depletion of fossil fuels, environmental pollutions, and global warming, the use of renewable energy sources (RESs) to power agricultural operations and the food supply chain processes is in the limelight [23,24]. The use of renewable energies in agriculture and food production systems will release the burden on the environment. In this context, solar drying as a renewable-based post-harvest food processing method can reduce the use of conventional fossil fuels and considerably mitigate adverse impacts caused by greenhouse gas (GHG) emissions from this sector [12,25].

Among various solutions, solar greenhouse dryers (SGHDs) [26,27,28,29] and hybrid solar drying systems [30,31] are the most widely suggested remedies found in the literature. It is a well-known fact that solar energy is the primary RES while the other forms of renewable energies are indirect conversions of solar energy. Thus, solar energy-based advanced agricultural crop drying systems and their various aspects need extensive discussion to develop a sustainable food supply chain mitigating food insecurity in economic and environment-friendly ways. Therefore, the drying systems require a careful and proper design and analysis before installation to achieve the anticipated productivity and efficiency. For this, various parameters such as drying kinetics, effective energy interactions and utilization, and different techniques for energy loss reduction need appropriate consideration.

In the current literature, there are several separate works on the food crop drying using solar energy illustrating the modeling methods [32,33,34], different system configurations [35,36,37], economic and environmental characteristics [23,38], etc. Therefore, it is acknowledged that an investigation on crop drying methodologies has been carried out by various researchers from the viewpoints of different energy sources for crop drying, system configurations, and performance optimizations, both numerically and experimentally. However, to the best of the authors’ knowledge, there is very little availability of work summarizing the up-to-date research and development of SGHDs for agricultural food crops considering their energy, economic, and performance enhancement perspectives. Such an investigation could act as a “one-stop-shop” to assist the research and development of SGHDs. The main focus of this paper will be on presenting a comprehensive overview of recent technological developments of SGHDs and their current and future perspectives concerning technology, performance, and the economy. The present study reports an overall framework as follows: the solar drying technologies for agricultural products elaborated in Section 2; recent advancements in SGHDs and possible techniques to enhance their performance are represented in Section 3; Section 4 discusses the associated economic sustainability of the most recent studies on SGHDs; and conclusions and prospects of these sustainable drying facilities are discussed in Section 5.

2. Solar-Assisted Dryers for Agricultural and Marine Products

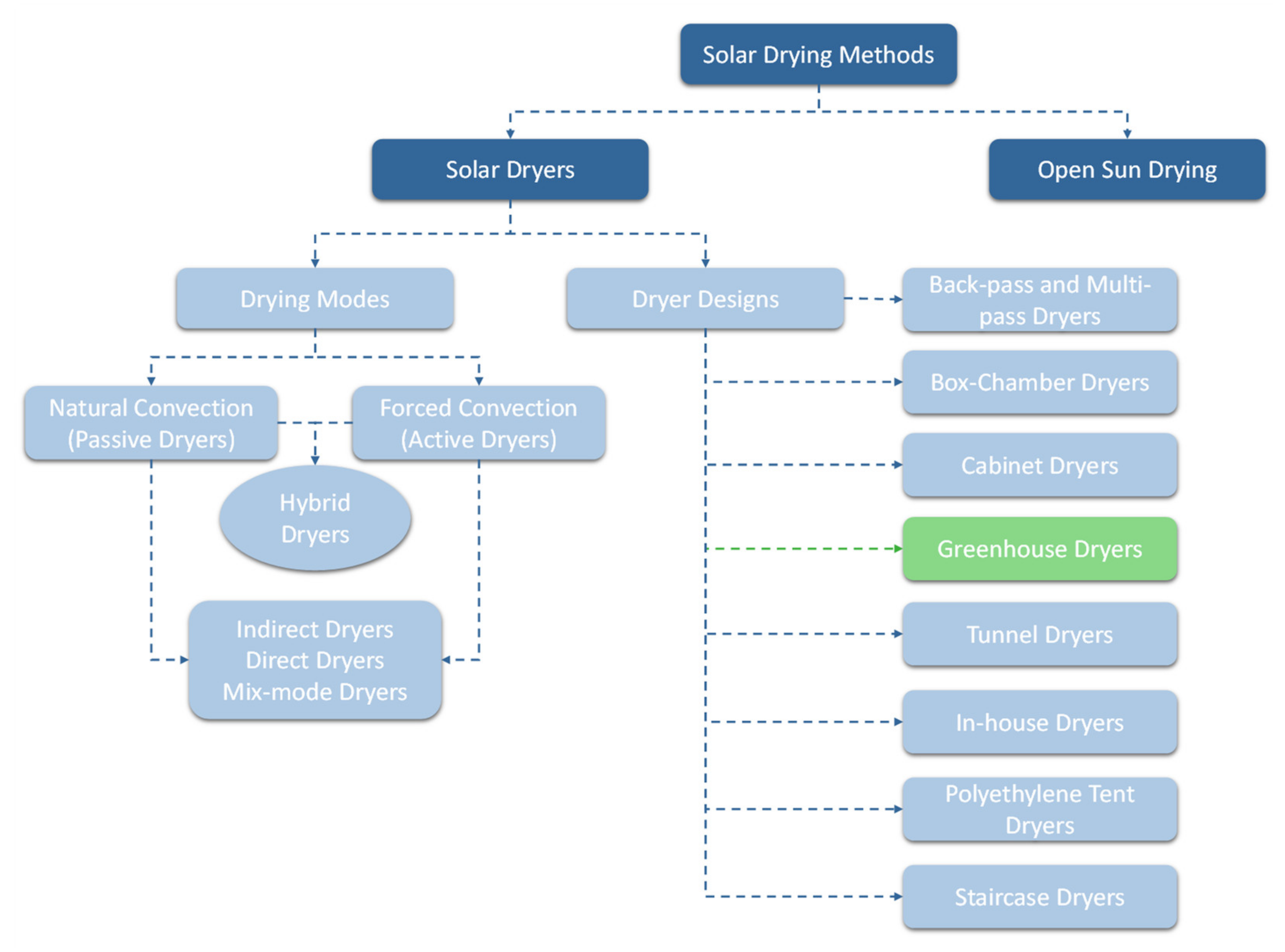

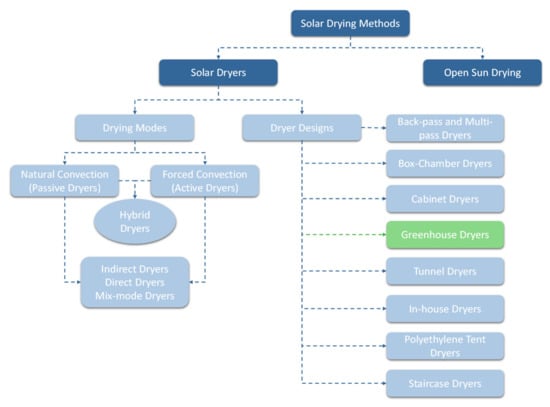

In recent decades, several types of solar dryers have been developed to decrease post-harvest losses and improve the quality of agricultural products. The utilization of solar energy for drying agricultural and marine items is the most appealing and economical solution [39]. Solar drying under controlled conditions of temperature and moisture removing rate confirms perfect drying and the required quality of the final product. However, only a few designs of solar dryers are deployed on scales other than demo projects or used at the industrial level [19,40]. The classification of solar dryers for agricultural and marine products is mainly performed according to the size of the dryer, design of the system, and solar energy consumption mode. Figure 2 depicts passive, active, and hybrid solar-powered dryers considering techniques for air circulation (natural or forced) and methods of heat transfer (direct or indirect).

Figure 2.

Categorization of solar-powered dryers, adapted from refs. [19,40,41].

2.1. Open Sun Drying

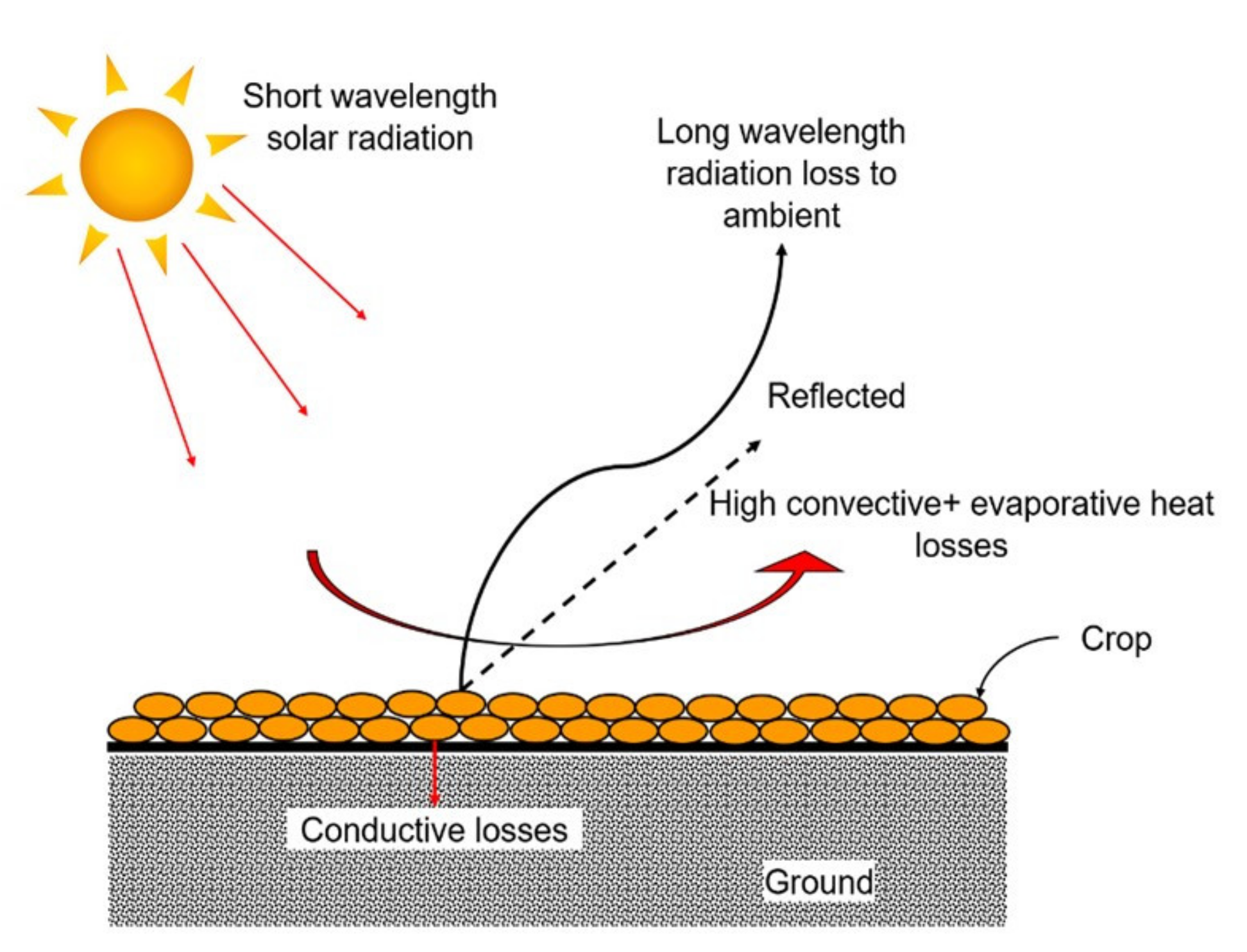

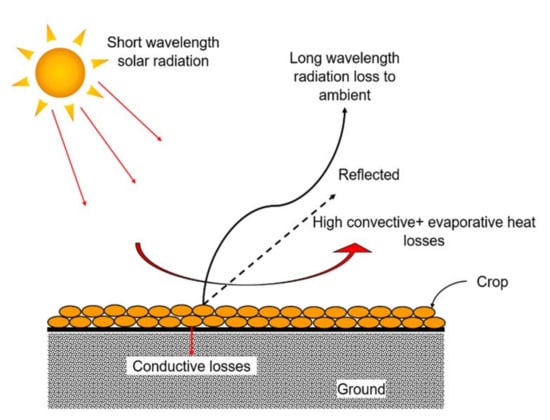

Figure 3 illustrates the functioning of the open-sun-drying method in which solar radiation is directly incident the surface of the crop. A portion of the received solar radiation is absorbed by the drying product depending upon the surface structure and color of the crop, while the remaining part is reflected in the environment. The solar radiation is absorbed and converted into heat and causes the temperature of the crop to increase. Further, due to the elevated temperature of the crop, longwave radiation is lost from the crop surface to the ambient, while the longwave convective heat loss occurs due to natural convection and blowing wind via moist air over the crop surface. The evaporation of moisture from the crop results in evaporative losses. Drying of the products depends on some external parameters, including the intensity of solar radiation, ambient temperature, wind velocity, and relative humidity, as well as internal parameters like rate of moisture transfer within and to the surface of the product by the diffusion process that depends on the type of the drying product [42].

Figure 3.

Basics of the open-sun-drying method, adapted with permission from [19].

In the open-sun-drying process, substantial losses occur because of numerous factors including birds, rodents, insects, and micro-organisms, while unpredicted storms or rain worsen the condition. Further, excess/insufficient drying; impurities due to external contaminants such as dirt, dust, insects, and micro-organisms; and color fading by ultra-violet (UV) radiation are characteristics of open-sun-drying [40]. Additionally, open-sun-drying is a sluggish process that can lead to significantly huge losses. Products dried under open-sun-drying usually fail to meet international standard quality [43].

2.2. Passive Solar Dryers

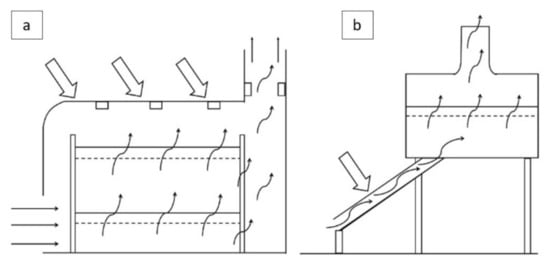

Direct passive solar dryers with natural convection have simple and low-cost construction. The drying chamber of a passive solar dryer typically contains a thermally insulated box of a transparent sheet made of glass/polyethylene/polycarbonate with inlet and outlet openings [28,44,45,46]. The air heated by received solar radiation flows across the crops either by buoyancy forces or pressure gradients, or a combination of both [47,48,49,50,51,52]. Throughout drying, a part of solar radiation reflects the ambient while the remaining is transferred to the cabinet and absorbed by the drying product. The typical drying efficiency of a passive solar dryer has been reported as 20 to 40%, depending on the type of the drying product, airflow rate, and location [44]. The efficiency of a dryer is defined as the ratio of the energy utilized for heating the sample from moisture evaporation to the total consumed energy.

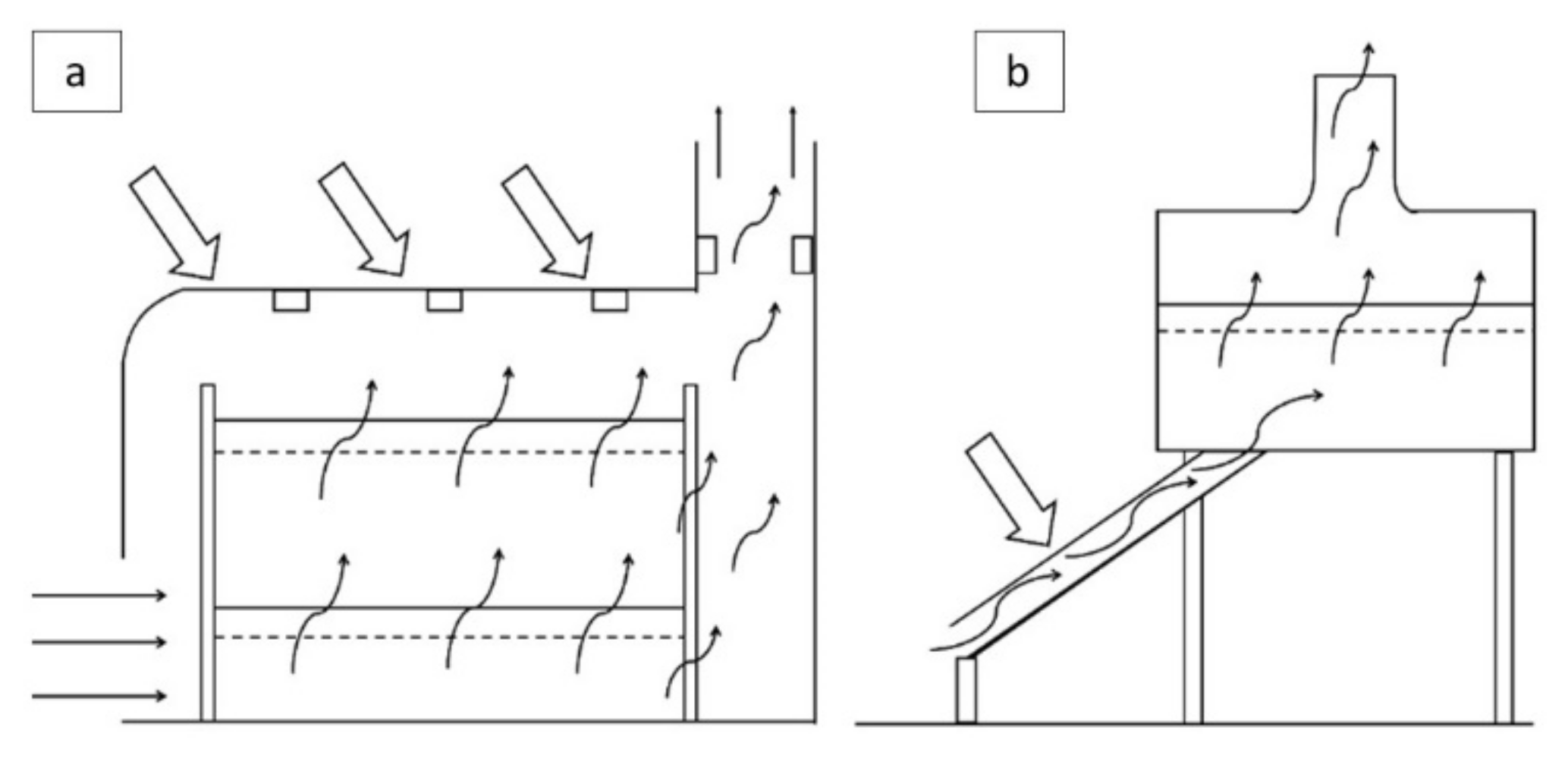

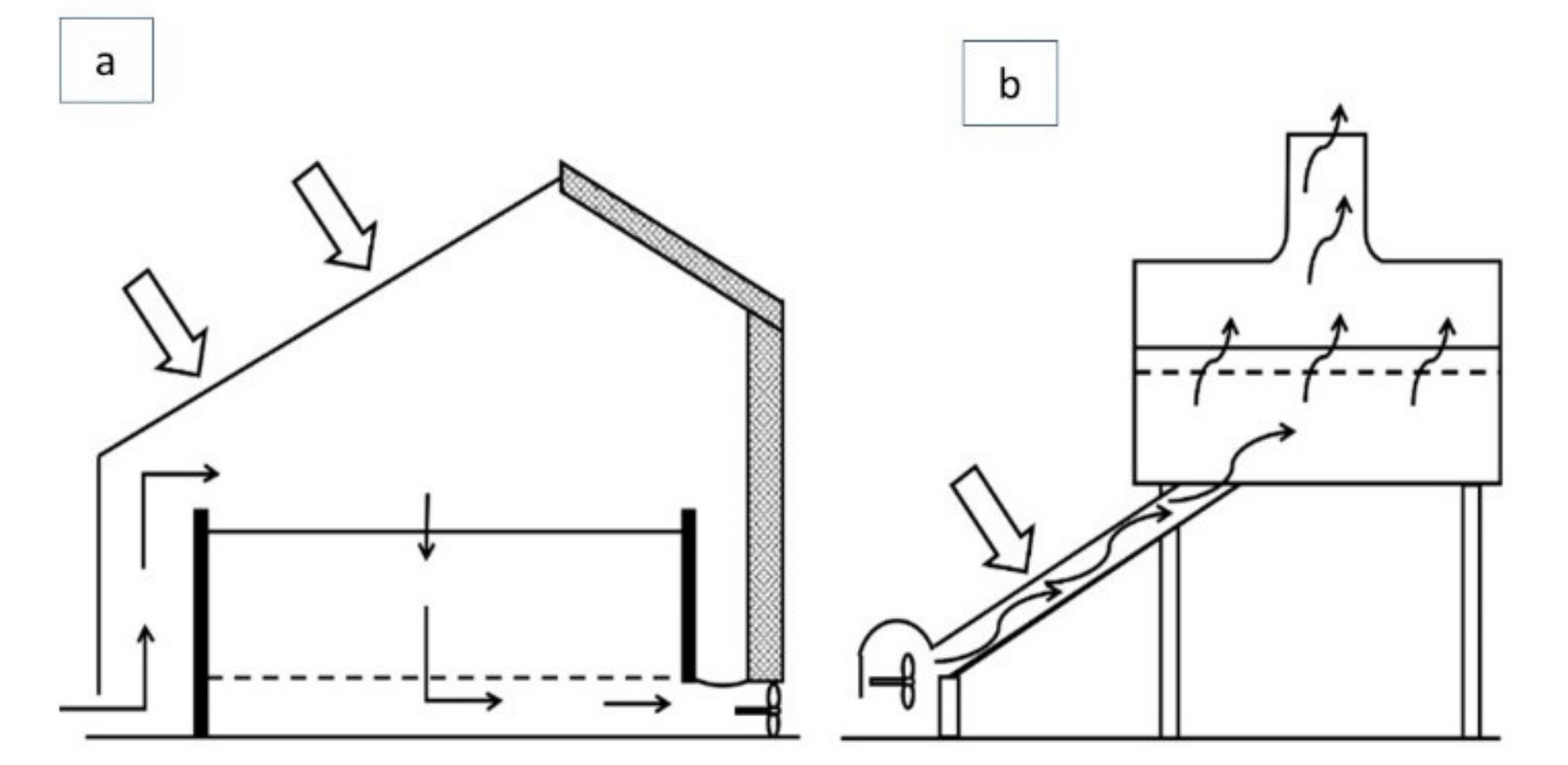

The indirect passive solar dryer with forced convection comprises a drying chamber and a solar air collector. A low-pressure solar air collector is used to heat the air that enters the drying chamber and passes over the drying tray via an air duct. Air vents or a chimney at the top of the drying chamber expel the moist air out [53,54]. The average drying efficiency of indirect passive solar dryers ranging from 13 to 25%, which is smaller than direct solar dryers [44]. However, it is stated that, unlike a direct passive dryer, this approach faces the issue of cracking and facilitates the protection of vitamins and color since drying products are not exposed directly to solar radiation [47,50]. Figure 4 represents passive direct and indirect solar dryers. The passive dryers are recommended for operation in small batches for fruits and vegetable drying [55].

Figure 4.

Schematic of passive solar dryers, adapted with permission from [56]; (a) direct type; and (b) indirect type.

2.3. Active Solar Dryers

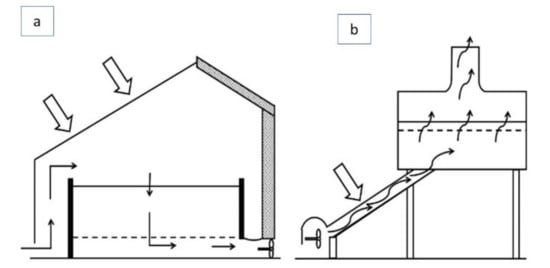

Active solar dryers consist of an air circulation system to circulate the heated air in the drying unit or flow from the solar air heater to the drying unit (Figure 5). An external arrangement is made for circulating the air in the drying chamber. Fans or blowers run by electricity produced with the help of a photovoltaic (PV) panel or grid circulate the air for drying [50]. An exhaust fan is used for moving the air, and these types of solar dryers can be used in large-scale commercial drying operations. These dryers have been introduced to be more appropriate to dry crops with high moisture content such as kiwi, papaya, cabbage, and cauliflower than passive solar dryers [55,57,58]. The active dryer needs more capital cost than a passive dryer, and its operating and maintenance costs are also higher to attain high product quality as well as drying efficiency, where optimum air mass flow rate and temperature are required for regulation [57].

Figure 5.

Schematic of active; (a) direct-type solar dryer, and (b) indirect-type solar dryer, adapted with permission from [56].

2.4. Hybrid Solar Dryers

In a hybrid solar dryer, the agricultural products are dried under direct solar radiation and/or backup energy or stored heat when sunlight is not available. These types of dryers are utilized in single and mixed modes of drying. The hybrid dryer could decrease microbial infestation in drying products [58,59,60]. Lamrani and Draoui [61] presented a simulation study on wood drying via a hybrid solar electrical dryer integrated with thermal energy storage (TES) system. The application of the TES ensures that uninterrupted wood drying and temperature of the drying chamber are greater than that of the ambient air by about 4–20 °C during the night. Mohammed et al. [62] conducted an economic analysis and evaluated the drying performance of novel hybrid active and passive-mode solar dryers for drying fruits in East Africa. A passive hybrid improved solar dryer (ISD) and improved PV-assisted hot air dryer using an active hybrid solar dryer ‘Solar Photovoltaic and Electric (SPE)’ were built as low-cost methods to dry fruits in Uganda. The results indicated that ISD and SPE dryers perform better than the open-sun-drying method. Additionally, the economic analysis indicates that drying costs were found to be low for the products dried using the ISD than SPE dryer. Comparably, the pay-back period (PP) for the SPE was 2.4 times longer than that of the ISD dryer. Hybrid solar dryers have been utilized for a variety of crops such as mushrooms [63], pineapples [64], and cashew nuts [65]. These kinds of dryers are appropriate for the fast drying of crops to provide high product quality.

3. Solar-Assisted Greenhouse Dryers (SGHDs)

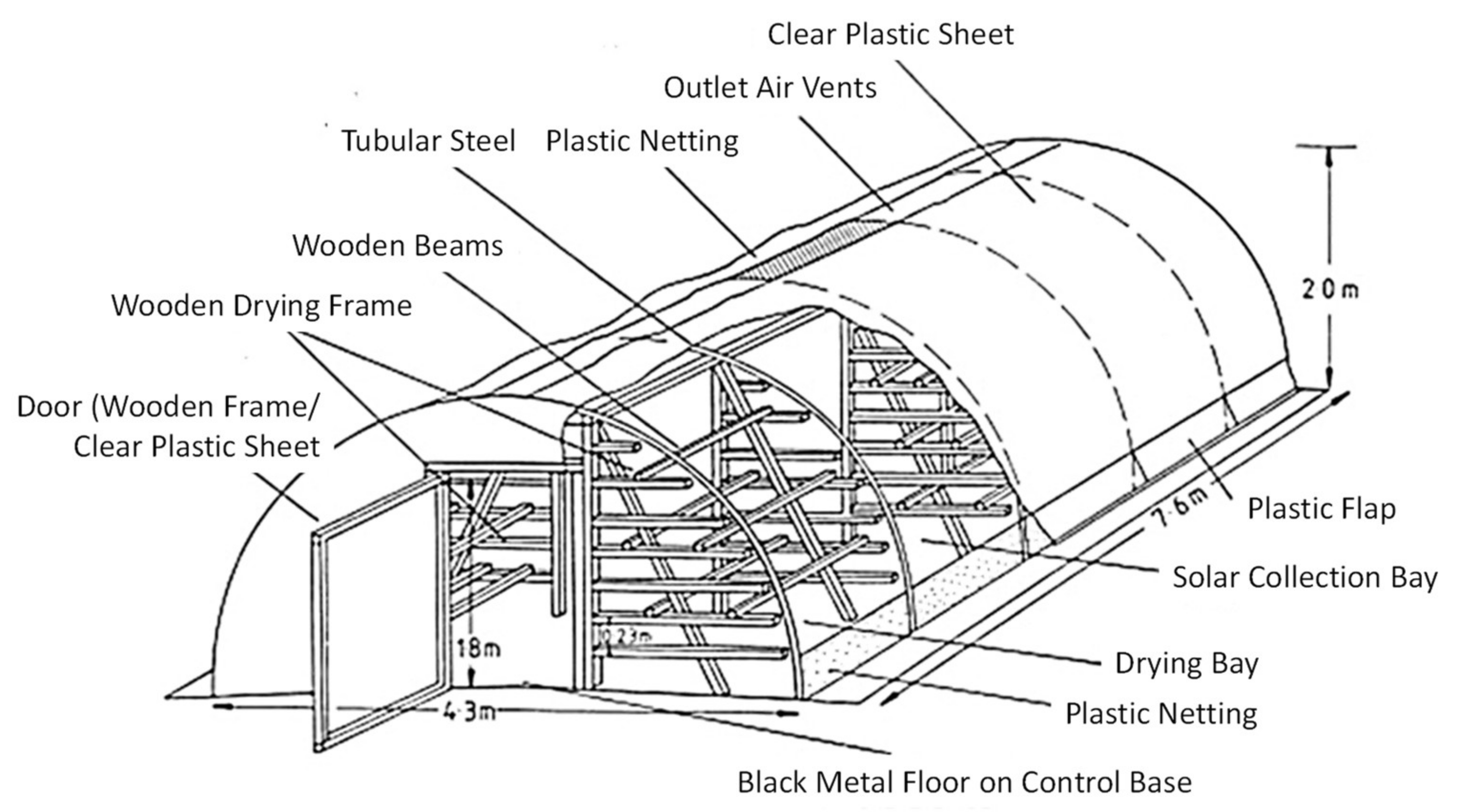

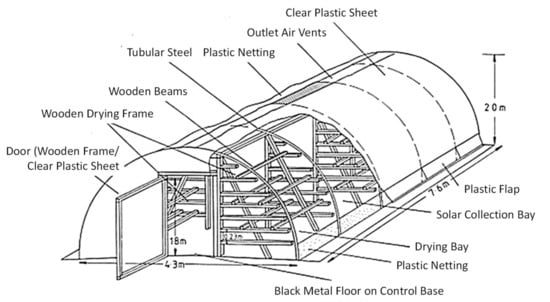

SGHDs involving heat transfer through natural convection are called passive dryers, whereas SGHDs involving heat transfer through forced convection are called active dryers. To naturally circulate the air inside, the passive type of SGHDs is generally designed with a ventilator or chimney. On the other hand, the inside air is forced by an exhaust fan to come out of the passive types of SGHDs. A greenhouse is employed very often for cultivating crops. In these structures, the desired microclimate is provided by supplying the required heating, cooling/ventilation, and carbon dioxide (CO2), allocating almost 65–85% to provide heating and cooling demands [66]. According to the literature, the annual energy demand for greenhouse production is about 220–320 MJ/m2 of the greenhouse area, mainly in the countries of Italy, Greece, and Southern France, with the value of 3600 MJ/m2 in Germany, Poland, and the Netherlands [67]. However, greenhouses can also be applied to dry agricultural food crops as low-cost facilities with a simple design. GHDs can also be applied for soil solarization, poultry, space heating, and aquaculture [68]. A schematic of a typical GHD is shown in Figure 6.

Figure 6.

Schematic view of a typical GHD with natural circulation, adapted with permission from [69].

Several studies have been conducted by researchers to improve the performance of GHDs. Some of these advancements are their integration with PV modules [26,50,52,70,71,72,73,74]; application of an opaque north wall to hamper heat loss from the dryer to ambient [75,76,77,78,79]; integration of thermal storage materials i.e., sand, phase change materials (PCMs), rock-bed and black colored concrete floor [80,81,82,83]; integration of solar air heaters for faster drying [27,84]; and adding a supplementary area for drying area augmentation [85]. In this section, we discuss the most common technologies that are integrated with GHDs to improve their thermal efficiency, decrease the drying time, and increase the quality of the final product.

3.1. Passive Solar Greenhouse Dryers

A novel greenhouse consists of two heating rooms and a drying compartment was conceptualized by Tanwanichkul et al. [86]. The greenhouse was placed in an east-west direction, facing south to maximize the obtained solar radiation energy. In this design, two north walls along with the whole drying chamber were made of concrete slabs colored in black to decrease the heat loss. Additionally, some rubber sheets hung inside the drying chambers to exchange heat with the drying air inside. The results revealed that the use of rubber sheets decreases the moisture content from 36.4% to 2.8% in less than two days. They also reported that dried products have better quality compared to traditional drying methods. In another study by Boonyasri et al. [87], the semi-cylindrical roof of a GHD was covered with polycarbonate sheets to dry pork. In this design, the roof was made of polycarbonate sheets because of high transmittance in the short wavelength, low thermal conductivity due to the air channels in the sheets, low density, and high flexibility. They reported the maximum and daily drying performance of the GHD as 55.7% and 42.8%, respectively.

Prakash et al. [82] assessed the annual performance of a modified GHD using TES on the ground under active and passive modes of operation. The TES was applied on the barren floor, and the floor was covered with a black polyvinyl chloride (PVC) sheet and a black coating floor. The experimental evaluation results under no-load conditions indicated a higher conductivity for the floor covered with a black PVC sheet compared to other floors. Considering both active and passive modes, the GHD under the active mode yielded better efficiency, especially for the vegetables containing high moisture, including tomato and capsicum. Pochont et al. [88] conducted a performance assessment of red chili drying in a passive GHD and reported that this type of dryer is more efficient than open-sun-drying and produces dried crops with higher quality. The experimental results demonstrated that the amount of moisture in the food crop has dropped down from 80% to 18.67% in 12 h under the passive mode of operation.

In another study by Ahmad and Prakash [89], a GHD integrated with a sensible TES on the bed of the drying chamber, operating under natural convection, was developed to dry tomato flakes. The heat transfer process was evaluated for different floors, including the gravel bed, the ground bed, the concrete bed, and the black-painted gravel bed. The results revealed a maximum heat gain of 53% for the GHD with the black-painted gravel bed, while this value was obtained as 33%, 49%, and 29% for the concrete bed, gravel bed, and ground bed, respectively. Additionally, the average drying efficiency of the GHD was reported as 23.49%.

Bouraoui and Ben Nejma [90] evaluated the effects of different geometries of the greenhouse and different atmospheric weather conditions on the performances of a SGHD utilized for drying olive mill wastewater through simulation modeling in COMSOL Multiphysics® software interface. The results showed that at the optimum operating condition the conceptualized SGHD performs better in terms of both energy and economy compared to the open-sun-drying process. In a study by Jagadeesh et al. [91], among six proposed shapes for GHDs with the same capacity of 30 ft3, an ideal shape was selected under no-load conditions. In this case, various shapes of Parabola, Quonset, Modified Quonset, Pyramid, Igloo, and tropical were investigated as shown in Figure 7. They reported the maximum inside temperature of 72 °C occurs in the Quonset with the capability of generating 64% higher temperature in comparison with the ambient, while Igloo could generate 53% higher temperature than the ambient both in summer days. Quonset could generate 7% higher temperature values in comparison with tropical shape in summer and 5% higher values in winter.

Figure 7.

Photo of different shapes of passive SGHDs proposed in ref. [91] (adapted with permission).

3.2. Performance Enhancement Techniques Employed in Solar Greenhouse Dryers

According to the literature, the thermal performance of passive SGHDs is rather low, and therefore, to increase efficiency, solar collecting and storage units are usually integrated. In this case, solar collecting units, including PV modules, photovoltaic-thermal (PVT) modules, and solar thermal collectors along with TES units, can be employed. When separate collecting systems are employed, the configuration of SGHDs is active. As a whole, passive SGHDs have priority in some cases because of being simpler and having lower costs in comparison with active SGHDs. In this section, the most recent advances in performance enhancement techniques employed in SGHDs are presented and their benefits and potential barriers are comprehensively discussed.

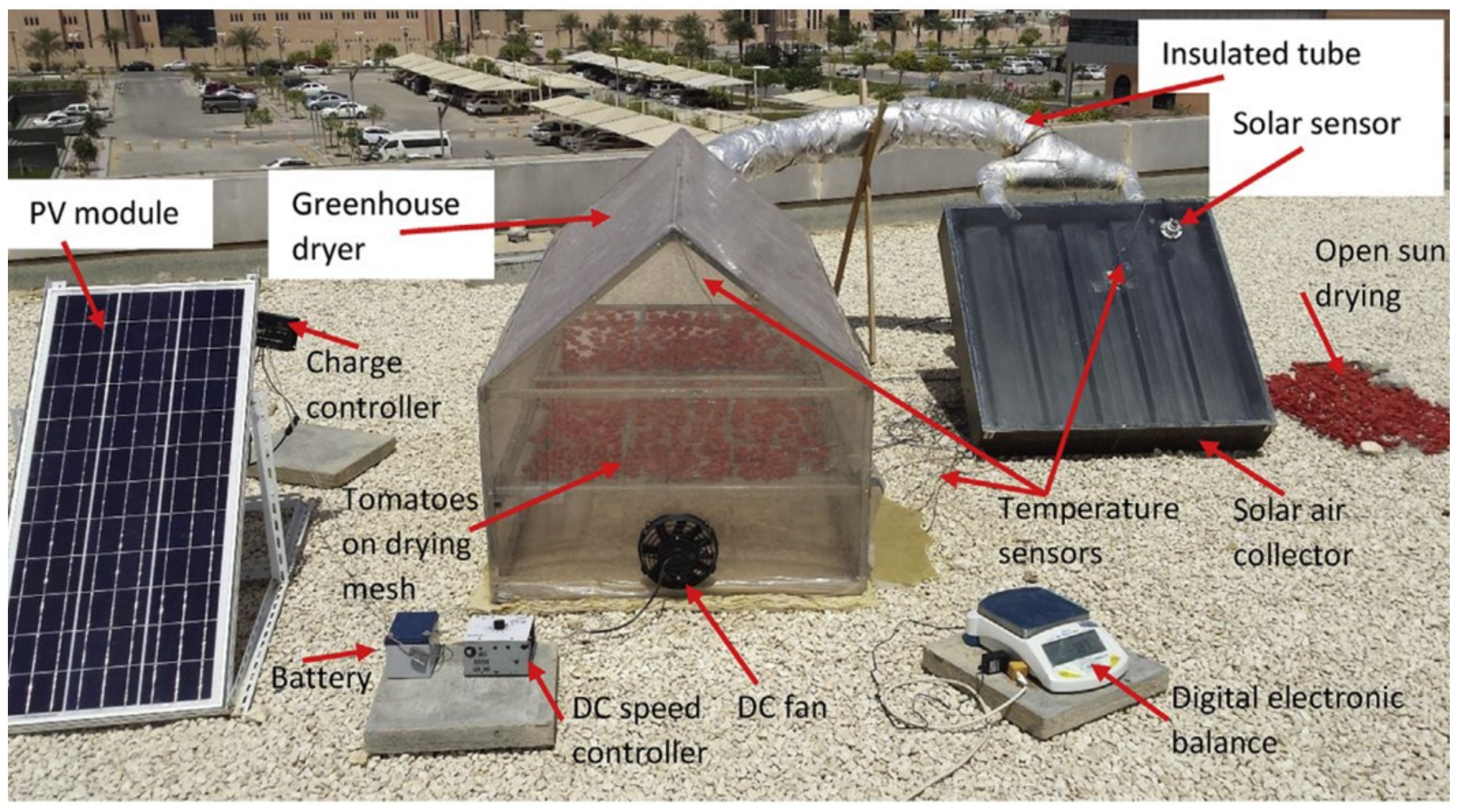

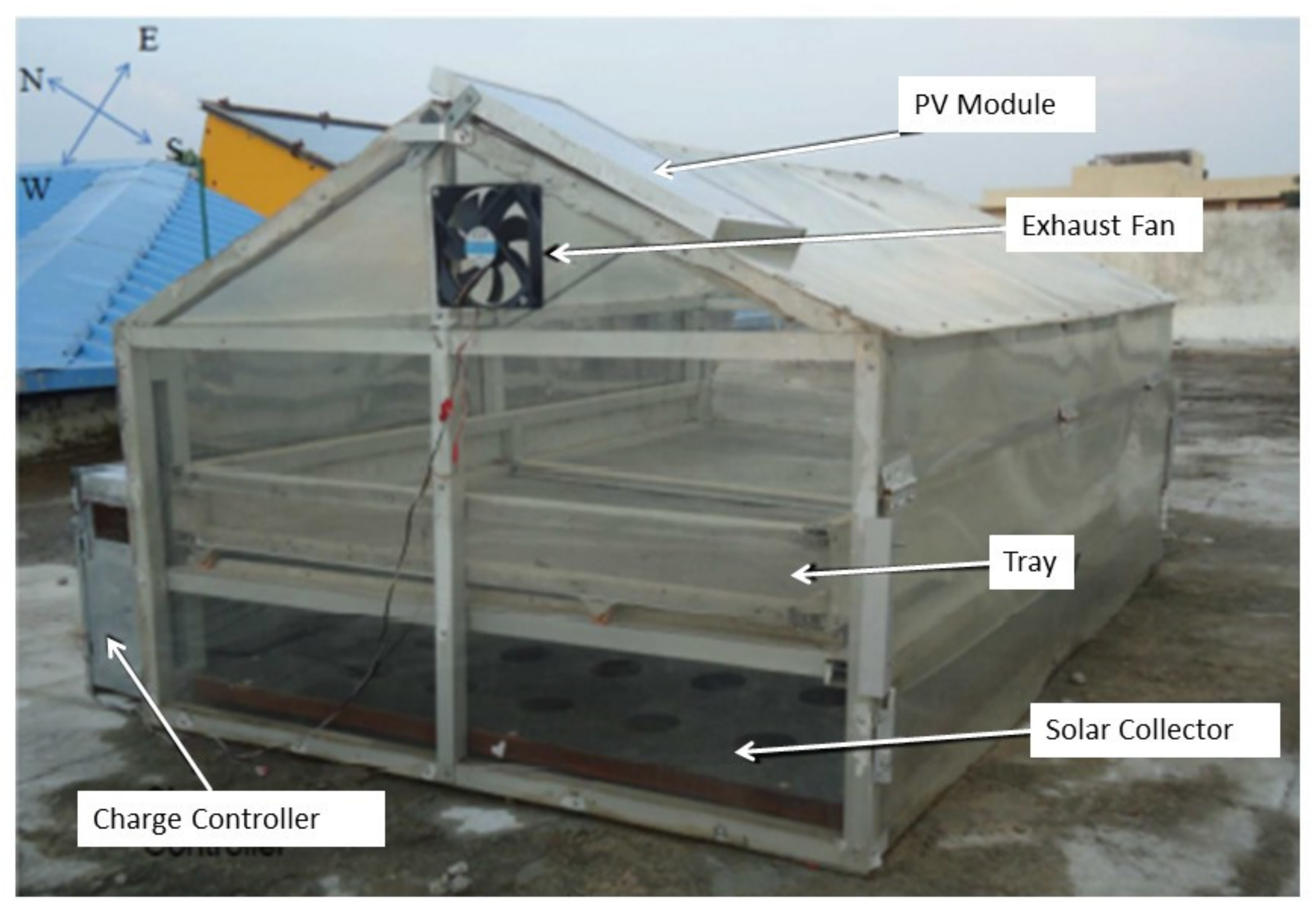

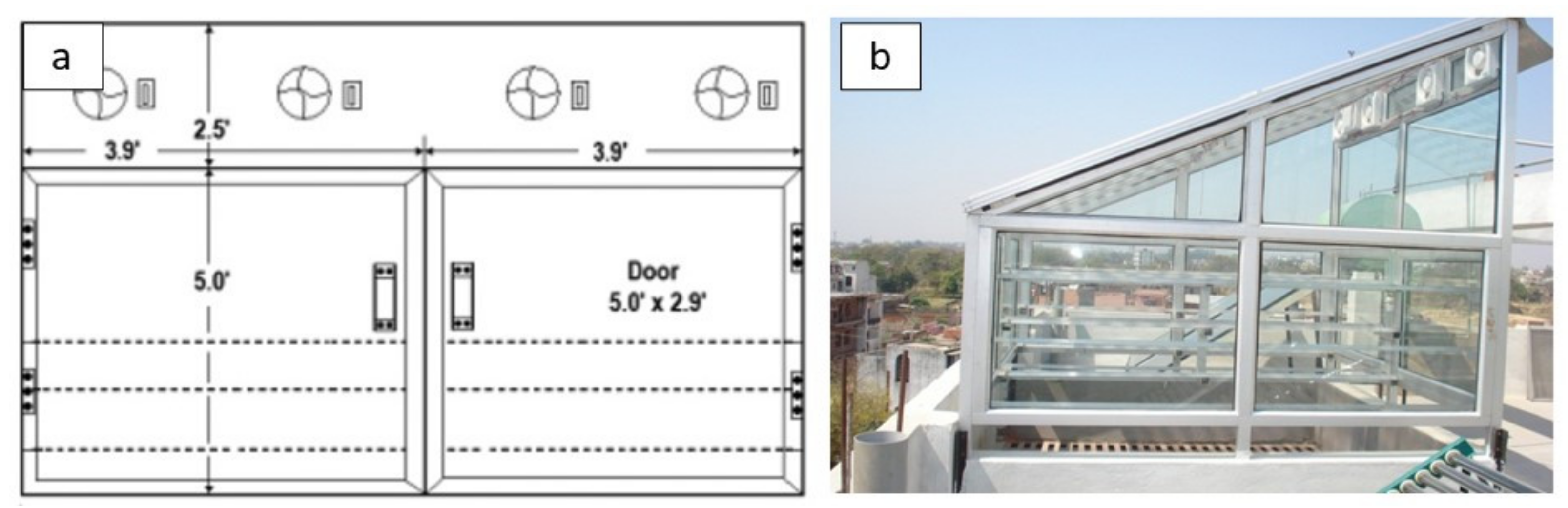

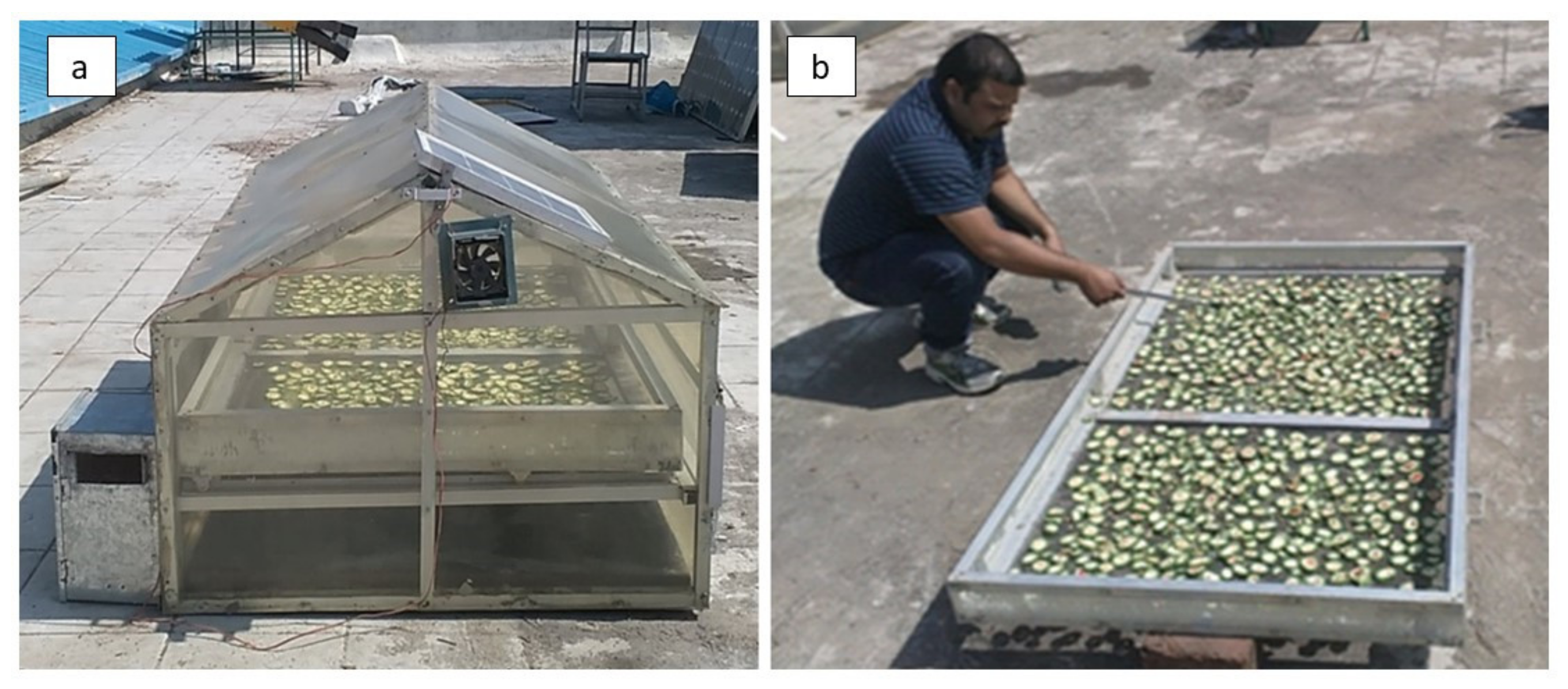

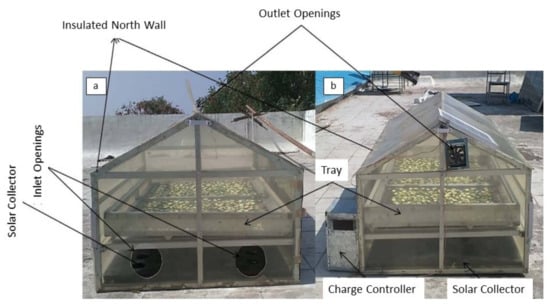

3.2.1. GHDs Integrated with PV Modules

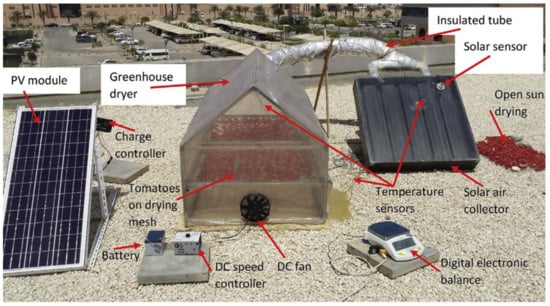

Several researchers have studied GHDs and their integration with PV modules to supply the electricity demand and thereby reduce the CO2 emissions produced by conventional fossil fuels as a source of power. In locations where there is not enough availability of land, PV modules can be integrated with GHDs by their installation on roofs or walls. Azam et al. [92] developed a stand-alone GHD integrated with a solar flat-plate collector (FPC) with air as the working fluid and a solar PV system to dry tomatoes (Figure 8). In this study, the energy efficiency of the conceptualized solar hybrid drying system was estimated when it was operating under forced convection mixed-mode. It was found that with the increase in the gap between the input and output energies, the efficiency of the GHD decreased. The PV system’s best efficiency was reported when the tomato slices were treated by an osmosis process resulting in a drying time of 28 h. It was also reported that the useful heat gain ranges between 6.45% and 26.62% of the available insolation over the dryer. According to the experimental results, the average overall efficiency of the SGHD was reported between 6.14% and 17.96%.

Figure 8.

Photo of the experimental setup of the PV-powered GHD developed in ref. [92] for drying tomatoes (adapted with permission).

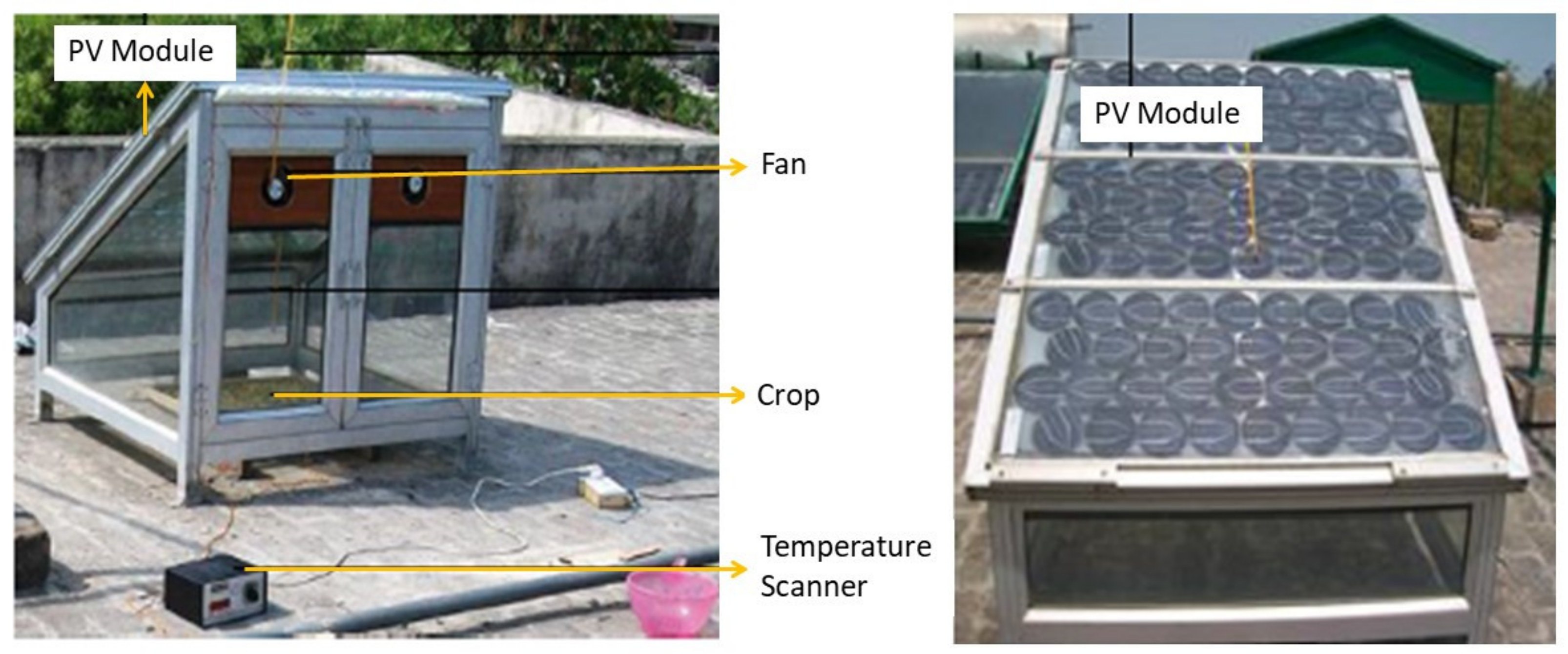

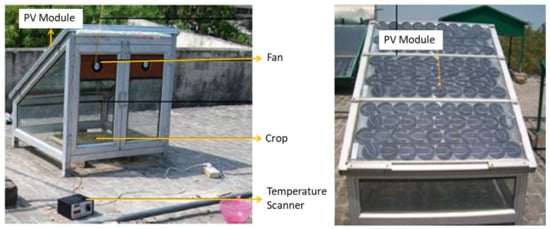

Saini et al. [38] integrated a GHD with different types of PV modules under forced operation mode (Figure 9). In this study, the temperature values of the crop, the greenhouse, and PV cells were calculated with experimental validation using MATLAB 2013a. From the results, the maximum payback time and overall thermal energy were calculated as 1.13 years and 1838.16 kWh, respectively, for crystalline silicon (c-Si) technology, while the minimum associated values were obtained as 0.39 years and 1527.86 kWh for copper indium gallium selenide (CIGS) PV technology. They asserted that covering the roof of the GHD with PV modules can both save power and enhance the quality of the dried product because of the shading effect created by the modules, avoiding the crop decolorating.

Figure 9.

PV modules integrated with the GHD developed in ref. [38] (adapted with permission).

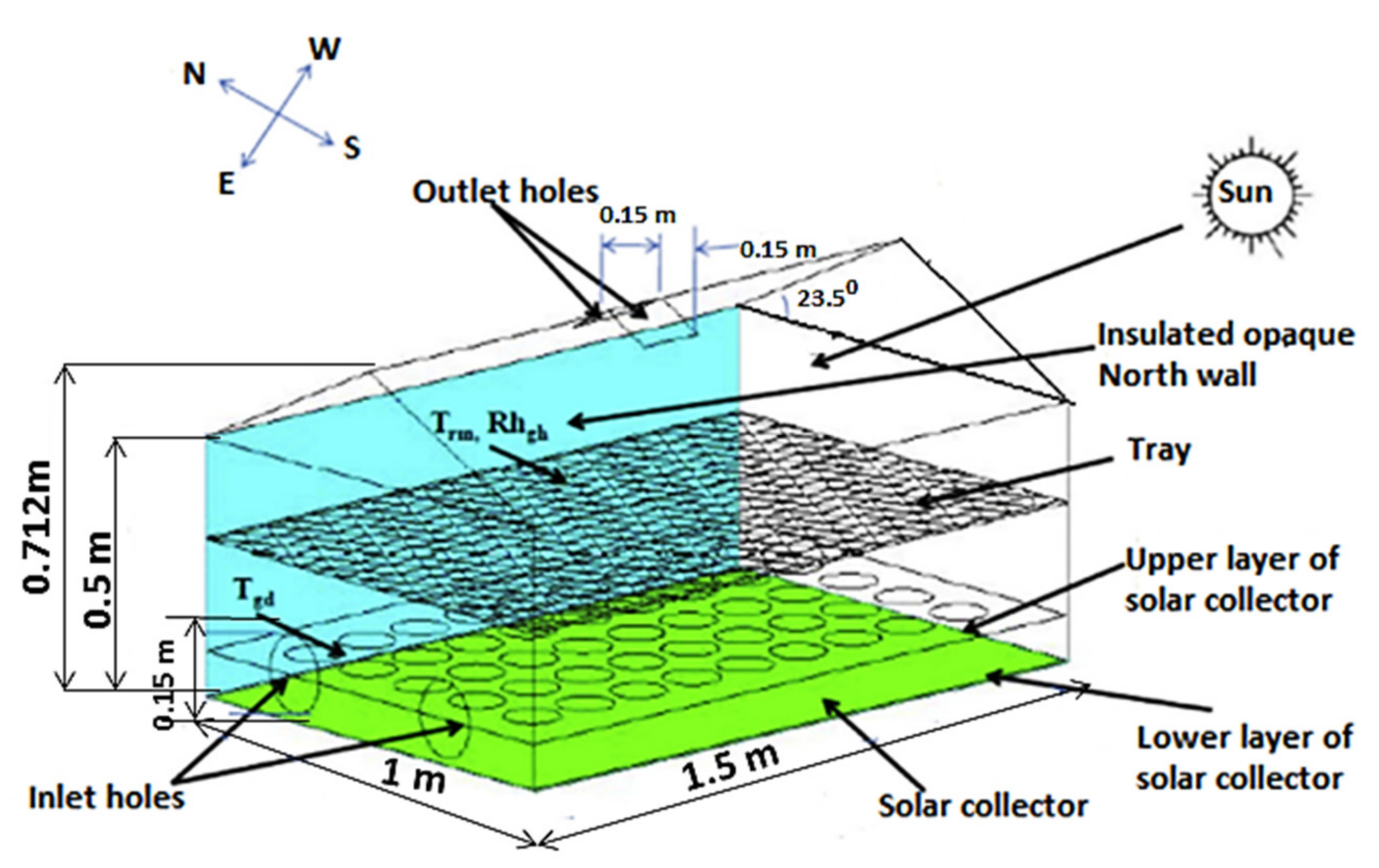

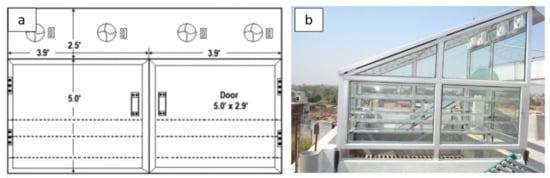

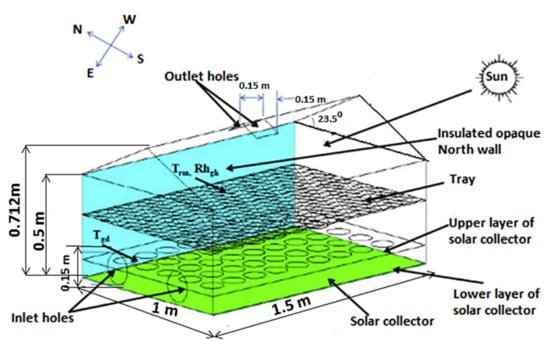

Chauhan et al. [93] designed a GHD with a unique solar collector composed of two layers of different materials integrated with a PV module. The dryer was tested under the forced convection mode and no-load condition with and without the solar collector. They reported the convective heat transfer coefficient of the GHD using the solar collector as 150%, which was higher than the case without the collector. In this study, the exergy, energy, and electric efficiency were also analyzed for the exhaust fan of the installed PV system. They reported that the fabricated GHD with the solar collector has the best performance in the temperature range of 40–70 °C for crop drying (Figure 10).

Figure 10.

Experimental setup of the GHD developed in ref. [94] with an embedded solar collector (adapted with permission).

In a study by Margarita et al. [94], the drying process of moringa leaves was evaluated using different drying systems, including a GHD integrated with solar PV modules, direct open-sun-drying, and an electric oven under the climate condition of Campeche, México. The best performance for the drying process inside the GHD was achieved by providing a dried air temperature of 59 °C, resulting in a drying time of 4 h with a drop in moisture percentage of the leaves from 82.29% to 4.09%. A longer drying process was obtained under open-sun-drying, causing the production of the dried materials with lower quality. Nimnuan and Nabnean [95] experimentally evaluated the performance of a SGHD during the drying process of cassumunar ginger under the climate conditions of Sa Kaeo province, Thailand. The structure of the GHD was composed of a parabolic-shaped roof with a cover of polycarbonate plates and a concrete floor (9 × 12.4 m2). In the proposed design, nine DC fans powered by three 50 W PV modules were installed to ventilate the dryer as shown in Figure 11. According to the results, the drying air temperature varied from 30 °C to 55 °C, while the drying time was 1 day to reach the moisture content of the cassumunar ginger from an initial value of 90% (w.b.) to 10% (w.b.). They claimed that the developed SGHD results in a considerable reduction in the drying time with a saving value up to 67% compared with the open-sun-drying. In another study by Vengsungnle et al. [96], the energy analysis of a PV-ventilated mixed-mode SGHD with automatic closed-loop control for drying of Ganoderma was investigated and the obtained results were compared with the open-sun-drying process. The results indicated a considerable effect of the ventilated frequency and drying temperature on the evaporating moisture of the Ganoderma. As the literature survey shows, the PV modules are mainly used in GHDs to drive the exhaust fan and make the whole drying process more sustainable. However, in most of the studies, the drying process in PV-powered GHDs has shown more profitability by providing higher drying air temperatures and therefore lower drying time that produces a dried product with higher quality.

Figure 11.

Energy transfer mechanisms that occur in a polycarbonate cover PV-powered GHD, adapted with permission from [95].

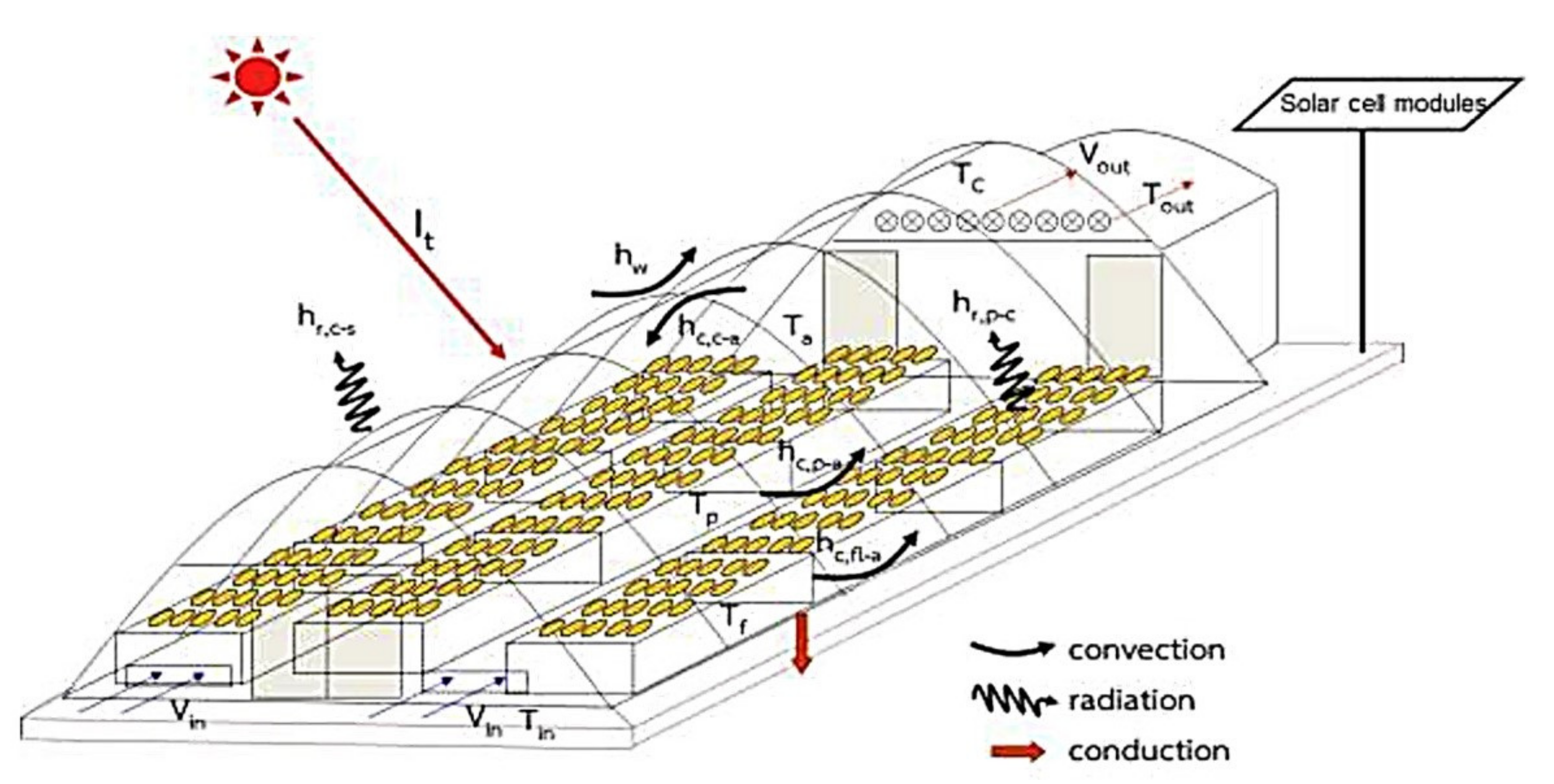

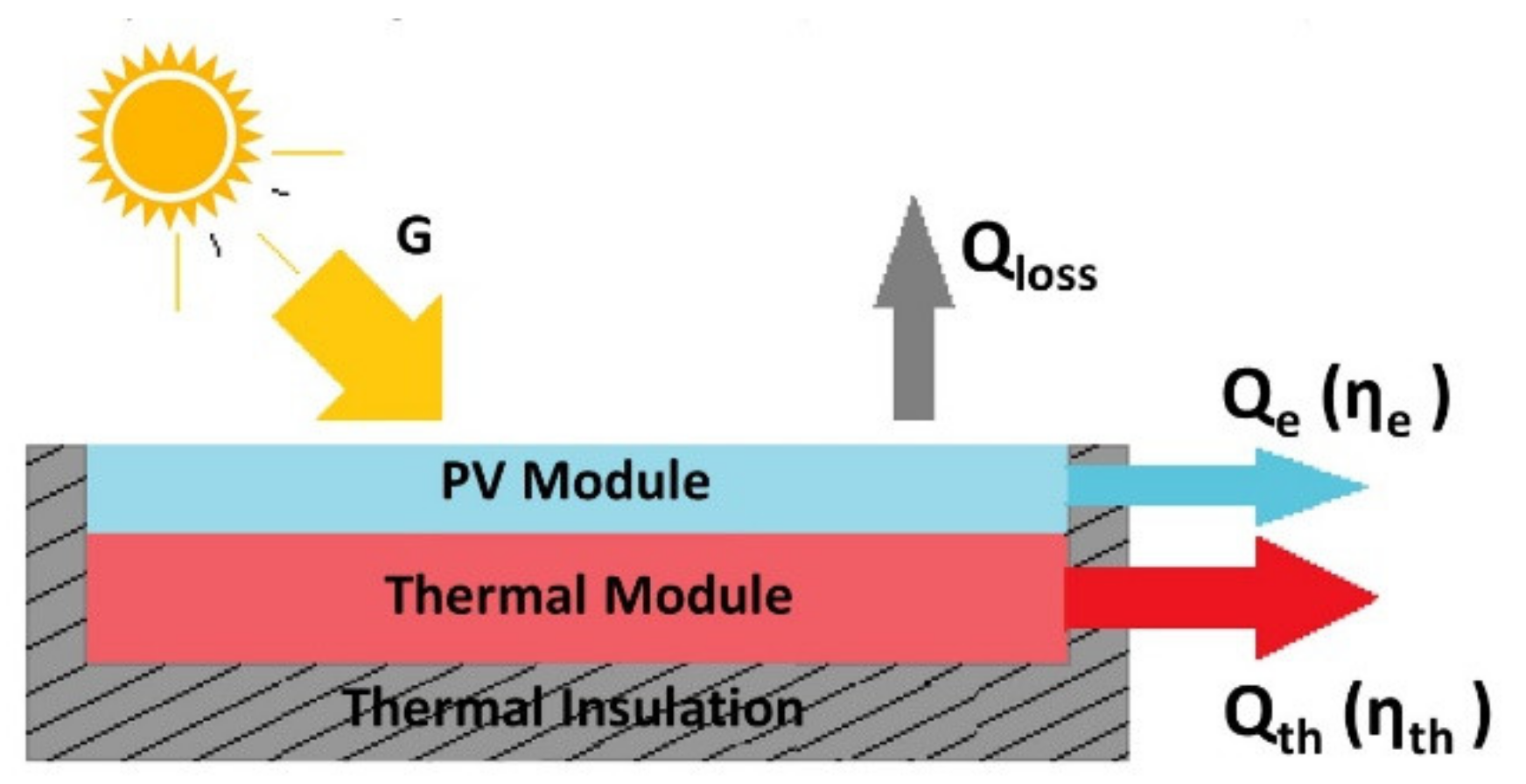

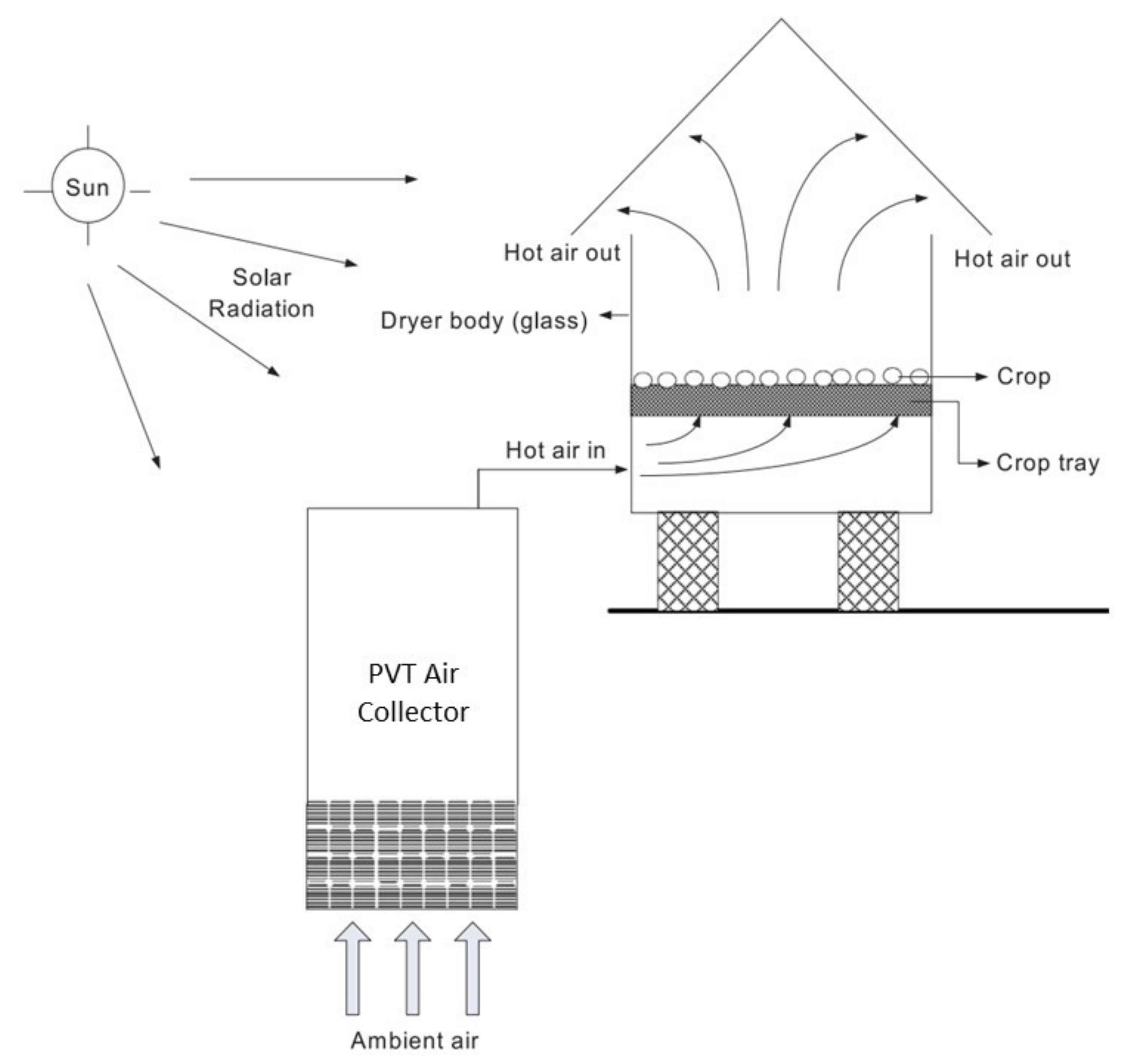

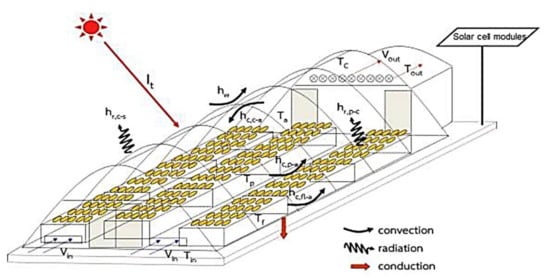

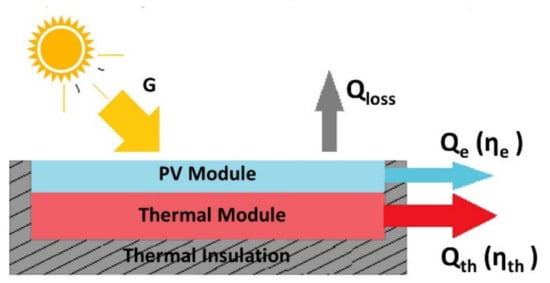

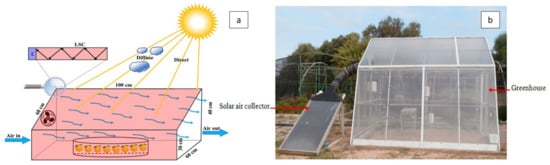

3.2.2. GHDs Integrated with PVT Modules

A PVT module is a combination of a PV module and a thermal collector that simultaneously generates electricity and thermal power. In PV modules, the electric performance experiences a linear decrease along with the conversion, but the output power of solar cells increases when the generated heat is extracted by using a thermal collector in the form of PVT modules [97]. As shown in Figure 12, a portion of incident solar radiation on the PV module at the intensity of G (W/m2) is converted to heat, Qth (W/m2), while the remaining portion empowers the PV module, Qe (W/m2), with a given electric efficiency of ηe and thermal efficiency of ηth. Thermal insulation is also used to reduce the sides and back heat losses and therefore make the system more efficient.

Figure 12.

Representation of the energy flows in a typical PVT module, adapted with permission from [99].

The integration of PVT modules with GHDs can decrease fossil fuel consumption and bring more sustainability. Nayak et al. [98] developed a hybrid PVT UV-stabilized polyethylene GHD that could reduce initial costs. By comparing the dried samples with fresh ones, it was found that not only nutritional value and the original color of the product are retained but also the moisture content is properly reduced, resulting in a dried product with a longer shelf life.

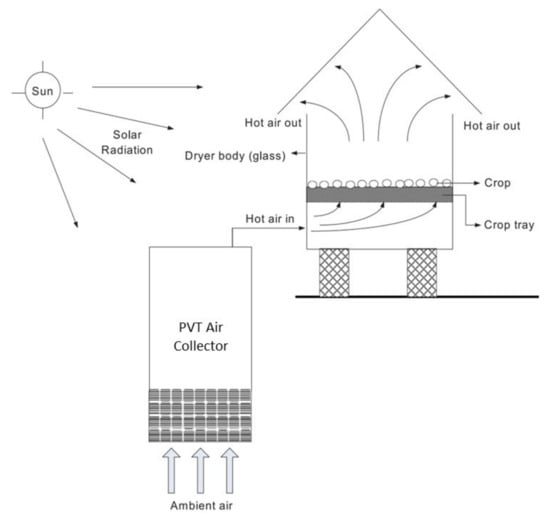

Tiwari et al. [100] investigated the thermal behavior of a developed PVT-GHD (Figure 13). They reported that there is a greater possibility of controlling the PVT air collector’s temperature compared to the open-air sun drying system. They also asserted that by modifying the ongoing air flow rate and the number of PV modules placed on the air collector, drying of different products in the dryer is possible. They also claimed that for the crops containing a comparatively higher percentage of moisture, the SGHD under forced convection is preferred, while for the crops containing a comparatively lower percentage of moisture, natural convection mode is a better option.

Figure 13.

Schematic view of a mix-mode GHD integrated with a PVT module, adapted with permission from [100].

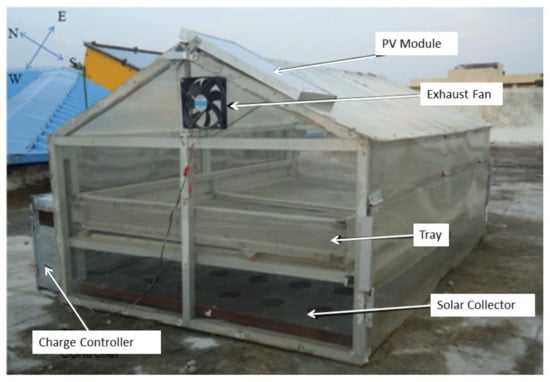

In another study, Tiwari et al. [50] developed a PVT-GHD and evaluated its performance under the mixed mode of operation. They used MATLAB software to model the system and to calculate temperature values of the crop, greenhouse, and solar cells, where the experimental data were used to validate the calculated data. The results indicated a negligible discoloration of the dried product with overall higher quality. From the results, theoretical values of overall thermal energy and exergy were calculated as 1.92 kWh and 2.03 kWh, respectively, while the experimental values were obtained as 0.532 kWh and 0.535 kWh. They reported that an increase in the temperature of PV cells during the experiments causes an immediate decrease in thermal efficiency. In a study by Shyam et al. [101], a single-slope roof-type PVT-GHD was designed, and its performance was evaluated by a thermal model validated by experimental data (Figure 14). They reported that working with three fans is an optimal option under no-load conditions. From the results, the daily overall thermal energy was calculated as 20.5 kWh, which was higher than values obtained in cases operating with one, two, and four fans.

Figure 14.

(a) Schematic front view, and (b) photo of the east view of the PVT-GHD, adapted with permission from [101].

Considering the most recent works investigated the GHDs integrated with PVT modules, higher thermal performance values have been reported by researchers. However, decreasing the electric efficiency of integrated PV modules due to the increase in their temperature during the drying process is an undesirable effect that can be mitigated by providing higher airflow rates. Involving variable drying airflow rates, the GHD will become applicable to dry different materials.

3.2.3. GHDs Integrated with Solar Thermal Collectors

In a study by Chauhan and Kumar [102], a GHD with an insulated north wall working in the passive mode was designed, constructed, and analyzed under no-load conditions. In this study, convective heat transfer and diffusivity coefficients, ‘heat loss factor’, ‘heat utilization factor’, and ‘coefficient of performance’ (COP) were evaluated for two distinct cases as Case-I and Case-II, which are the GHD with and without solar air heater. The schematic view of the GHD with the solar thermal collector is shown in Figure 15. The results indicated the maximum value of the COP for Case-I and Case-II as 0.9 and 0.86 with the highest heat utilization factors of 0.68 and 0.61, respectively. Additionally, during the first day of evaluation, the maximum temperature deviation of 30 °C between the inner and outer atmosphere of the GHD was recorded.

Figure 15.

Schematic of the GHD with insulated north wall and a solar collector embedded on the floor, adapted from [102].

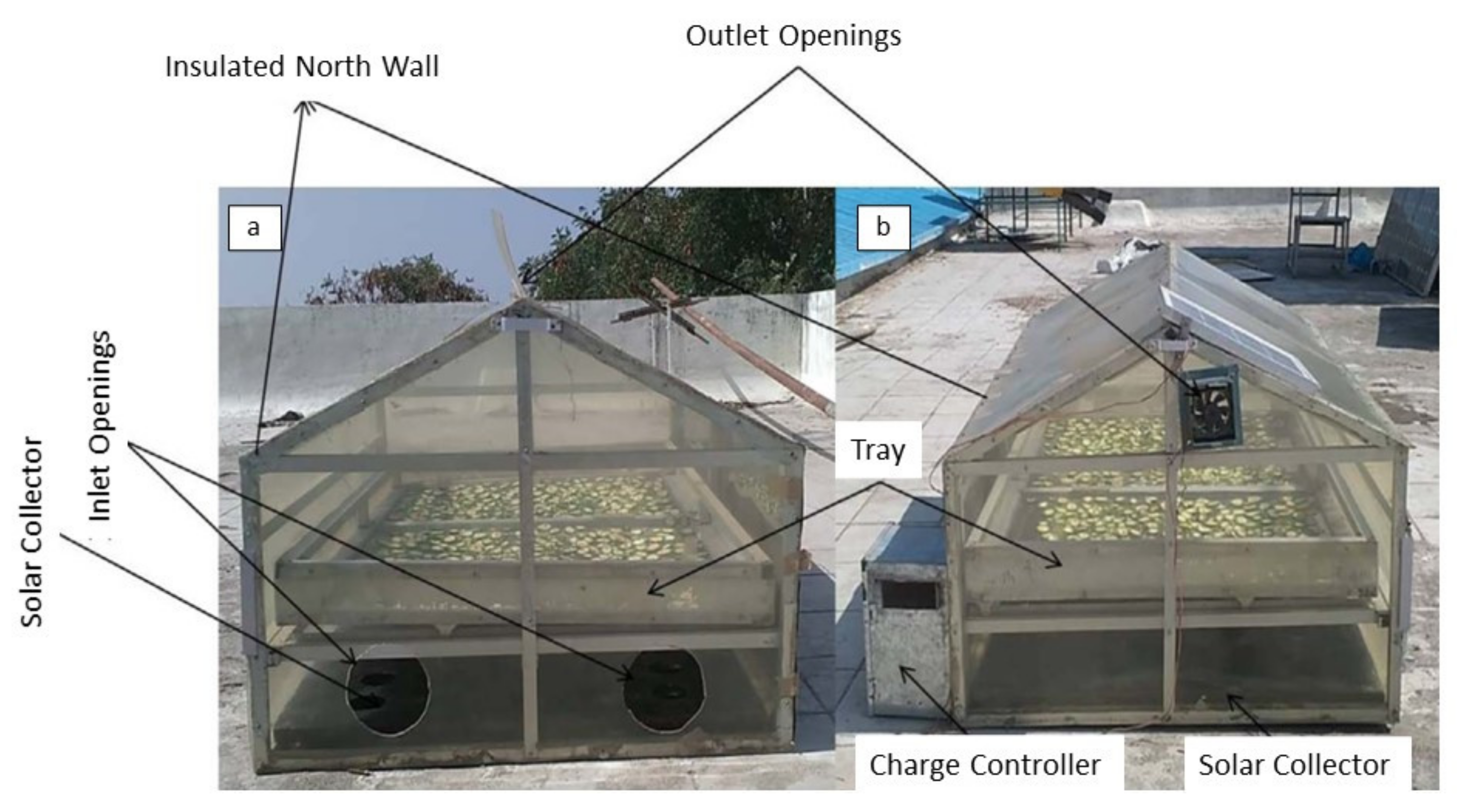

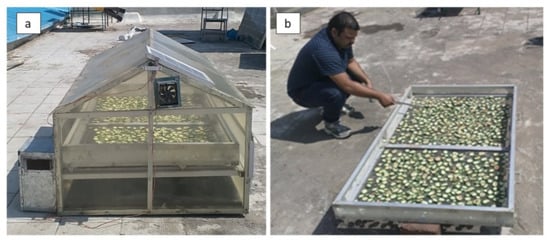

In another study by Chauhan et al. [103], a SGHD composed of an opaque and insulated north wall with an embedded solar air heating collector at the bottom was studied for drying of bitter gourd flake as shown in Figure 16. In this study, thermal models were developed for the theoretical performance investigation of drying through natural and forced convection. Along with this, experimental tests were carried out for drying in the open sun, both in the natural and forced convection modes. The theoretical and experimental results were observed to be in good harmony. A root mean square deviation (RMSD) between 3.25 and 5.82% for the temperature of the food crop (bitter gourd flakes) and the inside air was also observed, whereas a deviation of 2.83–5.26% was recorded for the moisture evaporation rate. The coefficient of correlation values between 0.98 and 0.99 under natural mode and 0.99 to 1 under the forced mode were also reported. The experimental results indicated that the final moisture ratio of 0.12 can be achieved within 15 h for drying via the forced convection process, whereas it takes 16 h to achieve the final moisture ratio of 0.14 during drying via the natural convection process. Furthermore, it was shown that it takes 21 h to yield the final moisture ratio of 0.25 for drying in the open sun. For drying the bitter gourd flakes, net CO2 mitigations of 33.04 and 36.34 tons under natural and forced modes were reported, respectively.

Figure 16.

Photo of the experimental setup of the GHD with an embedded solar collector [103] (adapted with permission); (a) natural mode, (b) forced mode.

Tuncer et al. [104] designed and developed a ‘quadruple-pass solar air collector’ (QPSAC), which was integrated with a pilot-scale GHD. The thermal performance of the fabricated SGHD was experimentally and numerically analyzed during the drying of red pepper and kiwi fruit (Figure 17). Experimental results demonstrated that the average thermal performance of the conceptualized model varies from 71.63% to 80.66% and the maximum value of the thermal performance of the collector is 90.30% at an airflow rate of 0.01 kg/s. Furthermore, they reported that the integration of the GHD with the solar collector substantially shortens the drying time. The results explored that because of the abundant residence time of flowing air, higher thermal energy can be obtained with the triple-pass and quadruple-pass arrangements compared to the single-pass or double-pass arrangements for a fixed value of solar collector area.

Figure 17.

Experimental setup of the QPSAC integrated with a GHD, adapted with permission from [104].

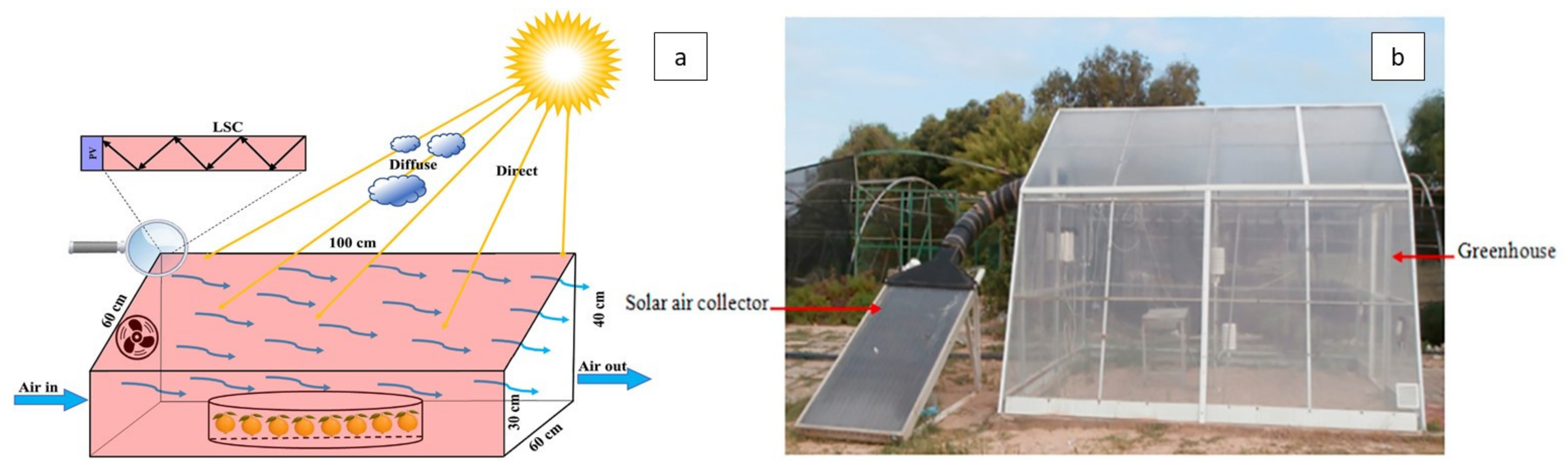

In an effort by El-Bashir and Al-Jaghwani [105], luminescent solar concentrator (LSC) dryers were studied. In this regard, a novel active GHD using LSC technology was developed as depicted in Figure 18a and its performance was experimentally evaluated under the climate conditions of Riyadh city, Saudi Arabia during summer. In this regard, the drying process of five kinds of fruits, including banana, mango, lemon, fig, and tomato, was evaluated and final moisture contents were calculated. The results showed that the dried fruits have higher quality and experience lower drying time than the case of drying in the open sun. It was also reported that in rural areas and places where there is no access to the grid, a LSC dryer would be an appropriate option. A SGHD with forced convection was designed by Khadraoui et al. [106] for drying red pepper, and its performance was evaluated under climate conditions of North of Tunisia. A solar FPC having a length of 2 m, a width of 1 m, and a volume of 0.28 m3 was considered to heat the air inside. Moreover, an east-west-oriented chapel-shaped greenhouse with a floor area of 14.8 m2 as a drying chamber was considered (Figure 18b). The results revealed a reduction of the drying time by 7 h compared to the case of drying in the open sun. Moreover, the maximum and minimum efficiencies of the solar thermal collector were reported as 88% and 30%, respectively.

Figure 18.

(a) The prototype of the active LSCD-GHD, adapted with permission from [105], and (b) the GHD integrated with a solar collector, adapted with permission from [106].

Chauhan et al. [107] developed a GHD integrated with a solar collector and an exhaust fan with variable speed to dry bitter gourd flakes as shown in Figure 19. The experiments were conducted under three mass flow rates of drying air as 0.0275, 0.0551, and 0.0826 kg/s to decrease the moisture content of bitter ground flakes from 96.8% to 12.2%. The results indicated that the drying process takes 17 h with an optimum airflow rate of 0.0551 kg/s, while it takes 26 h for the open-sun-drying method. The average efficiency of the GHD was reported as 19.7% when the airflow rate was 0.0551 kg/s. Additionally, the highest hardness of 365 g for the dried bitter gourd flakes was reported at the air mass flow rate of 0.0275 kg/s mainly because of the higher temperature of the inside and the lower rate of air exchange.

Figure 19.

(a) Experimental setup of the GHD integrated with a solar thermal collector, under the forced convection, and (b) open-sun-drying, adapted with permission from [107].

A solar air collector integrated with a chapel-shaped GHD developed for drying grape (sultana) using mixed-mode was experimentally analyzed by Hamdi et al. [28]. From the experimental results, the solar thermal collector’s efficiency was reported between 29.63% and 88.52% during the drying process. The drying air temperature was reported to vary from 28.08 °C to 55.94 °C. Moreover, it took 128 h from the initial wetness of 5.5 g water/g of dry matter to the final dryness of 0.22 g water/g of dry matter. Additionally, the numerical model developed in TRNSYS software was validated, and it was observed that the predicted results match well with the experimental ones. In another study, Azaizia et al. [27] developed a GHD composed of a novel designed greenhouse coupled with a solar FPC to supply heated air for drying red peppers (Figure 20a). From the experimental results, the solar collector’s average thermal efficiency was obtained between 49.54% and 64%. The numerical results obtained from the simulation model based on TRNSYS revealed that an increase in the area of the collector affects the evaporation rate and consequently speeds up the drying process. In a study by Khanlari et al. [108], the thermal performance of a GHD was improved by integration of a simple and low-cost tube-type solar air heater as shown in Figure 20b. The experimental investigation was performed with the air flow rate varying between 0.01 and 0.015 kg/s to assess the thermal performance of the developed SGHD during the drying of apricot samples. The results indicated the average efficiency between 45.6% and 56.8% for the solar air heating collector. Additionally, they reported that the integration of the developed solar air heating collector with the GHD can considerably reduce the drying time.

Figure 20.

(a) Photo of the developed SGHD in ref. [28] (adapted with permission), and (b) tube-type solar air heater integrated with the GHD, adapted with permission from [108].

Integration of GHDs with solar thermal collectors has been reported as the most common integration in the literature in comparison with PV and PVT modules. According to the results reported by researchers, integration of GHDs with solar thermal collectors in all cases can considerably enhance the thermal performance of the greenhouse by providing the desired temperature for the air flowing inside, which has a significant effect on the overall drying process by reducing the drying time and therefore providing a higher quality for the dried product. By designing and fabricating novel solar thermal collectors with low-cost and simple designs, the final cost of the dryer can be considerably decreased.

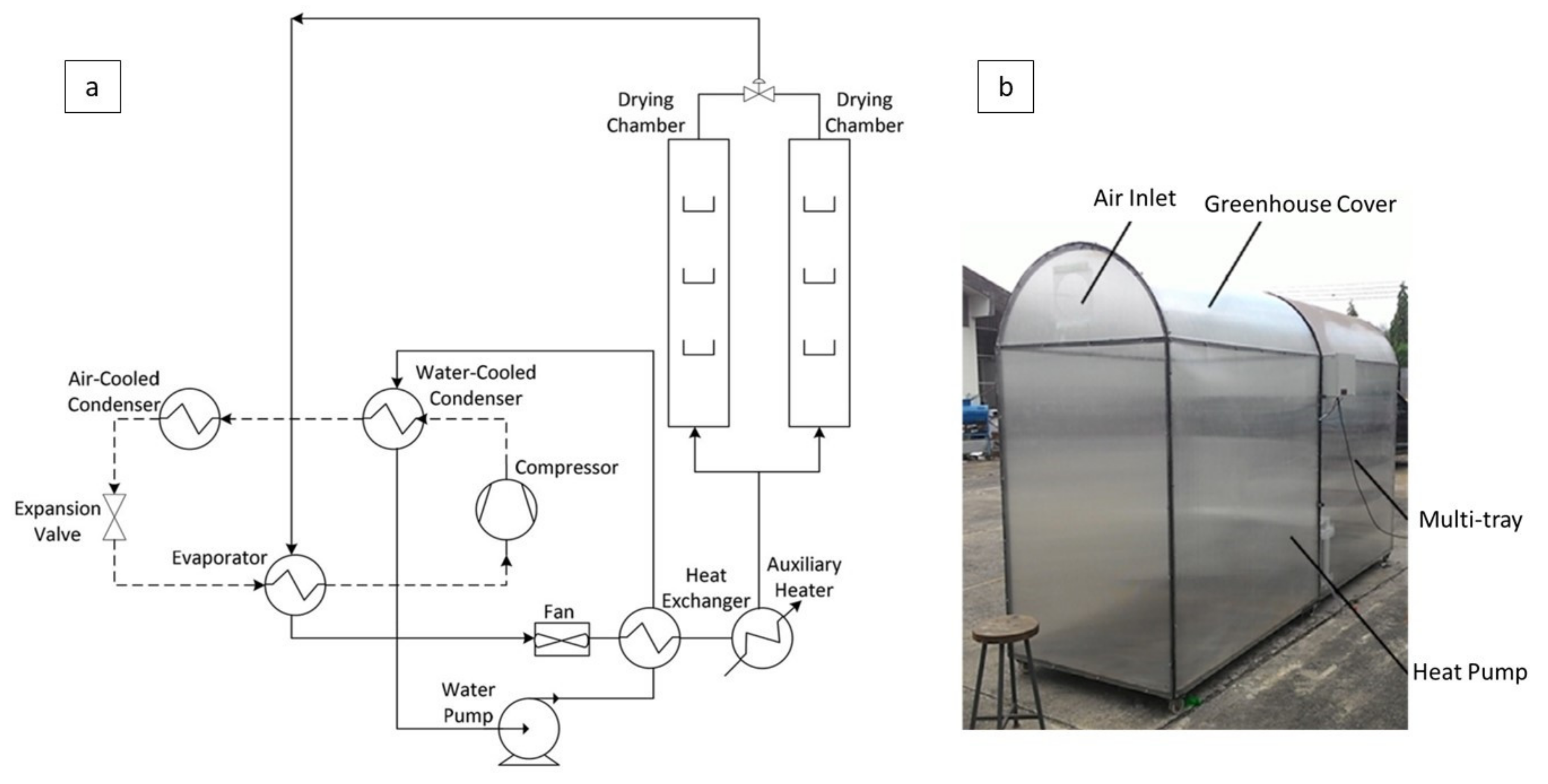

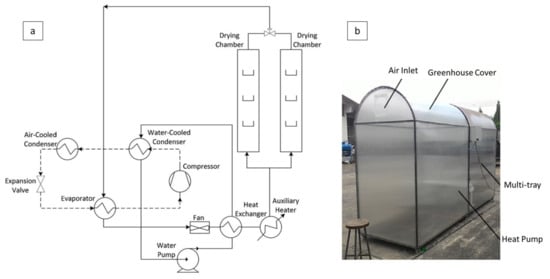

3.2.4. GHDs Integrated with Solar-Assisted Heat Pumps

In recent years, the use of solar-assisted heat pumps has been increasingly investigated in GHDs to increase the quality of dried products. On winter days, when the temperature is not high enough to be used for direct heating, a heat pump can be employed as an energy source [109]. Consuming less energy compared to other drying methods can be mentioned as a notable point for the integration of heat pumps and solar dryers. Solar systems operate periodically, which is a disadvantage for the stand-alone solar facility, while a dryer integrated with both a solar system and a heat pump will ensure significant energy savings [110]. Gan et al. [111] combined a solar-assisted heat pump with a conventional plastic film greenhouse to dry Misai Kucing. The schematic view of the system is shown in Figure 21a. This study aimed to compare the quality of the dried product generated from the SGHD and open-sun-drying. The results indicated the higher drying rates for the samples dried inside the SGHD with a significant color change and loss of two bioactive ingredients for solar-dried products because of the longer drying period. In another study by Naemsai et al. [112], a solar-assisted heat pump dryer (SAHPD) with heat recovery composed of a heat pump, a greenhouse, and some trays was developed to decrease the thermal energy requirement of the drying process of chili peppers (Figure 21b). From the experimental results, it was found that the developed SAHPD can provide higher drying performance over traditional methods. Additionally, the values of drying time, drying efficiency, COP, and specific energy consumption of the system were reported as 24 h, 33.2%, 3.17, and 2.21 kWh/kg, respectively. Around 25% reduction in the drying time was reported because of the integration of the heat recovery system.

Figure 21.

(a) Schematic of the GHD integrated with a solar-assisted heat pump [111]; (b) experimental setup of the SGHD with a heat pump developed in ref. [113] (adapted with permission).

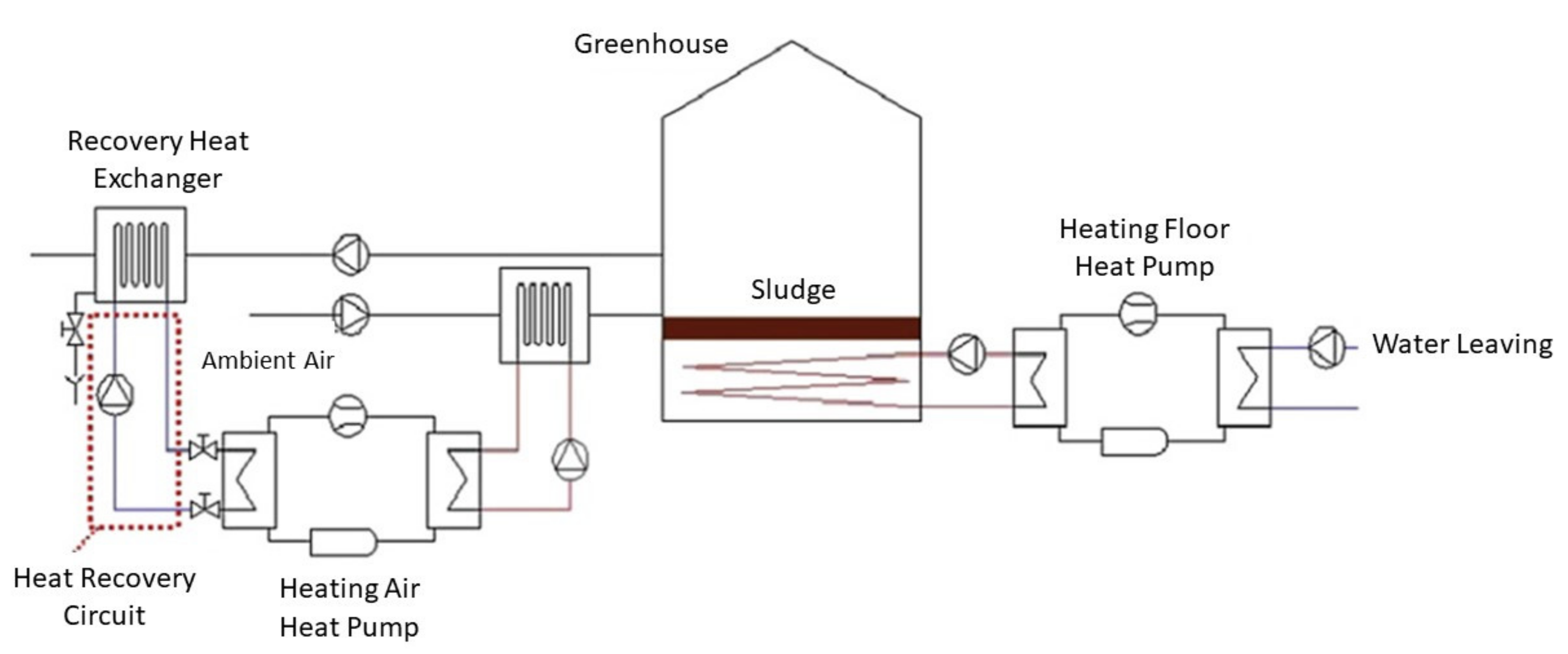

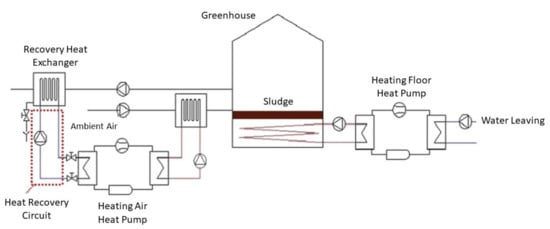

A slipping quasistatic model was build up by Slim et al. [113] to evaluate the heating temperature of the SGHD integrated with a heat pump to optimize the energy consumption of the sludge’s drying process (Figure 22). They reported that climatic parameters, including the available solar radiation and the air temperature, can affect the heat pump’s operating conditions in a way that the COP of 4.9 is obtained in winter while it is increased to 5.2 during mild periods. They claimed that the developed model can be used by designers. An even-span SGHD integrated with a heat pump was developed by Tham et al. [114] for drying Java tea and Sabah snake grass to reduce the humidity of the drying room at night and during rainy days due to a slow rehydration process. The results indicated that using the heat pump can decrease the relative humidity of the drying chamber by 10–15% and keep it at the maximum value of 65% at night and on cloudy days. It was also reported that because of using the heat pump, the drying rate is improved by three to four-fold and the drying time is reduced by 10%.

Figure 22.

Schematic view of the developed SGHD integrated with a heat pump, adapted with permission from [113].

The use of heat pumps in GHDs can increase the temperature of the drying air and consequently shorten the drying time. The only thing that should be considered in these systems is that the performance of heat pumps is decreased on winter days. In some studies, the use of heat recovery units has been suggested that can considerably increase the inside air temperature of the GHD and assist in increasing the thermal performance of the greenhouse and reducing the drying time up to 25%.

3.2.5. SGHDs Integrated with Thermal Energy Storage (TES)

The use of TES units not only plays a crucial role in conserving solar energy and overcoming its intermittency but also causes an improvement in the performance of energy systems. Generally, a difference between the supplied and demanded energy is noticed all the time, and energy storage helps to ease out this energy supply-demand gap [115,116]. Thermal energy in solar greenhouses can be stored using PCMs, which are exclusively more impressive because they can store more heat due to their high energy storage capacity per unit mass [117].

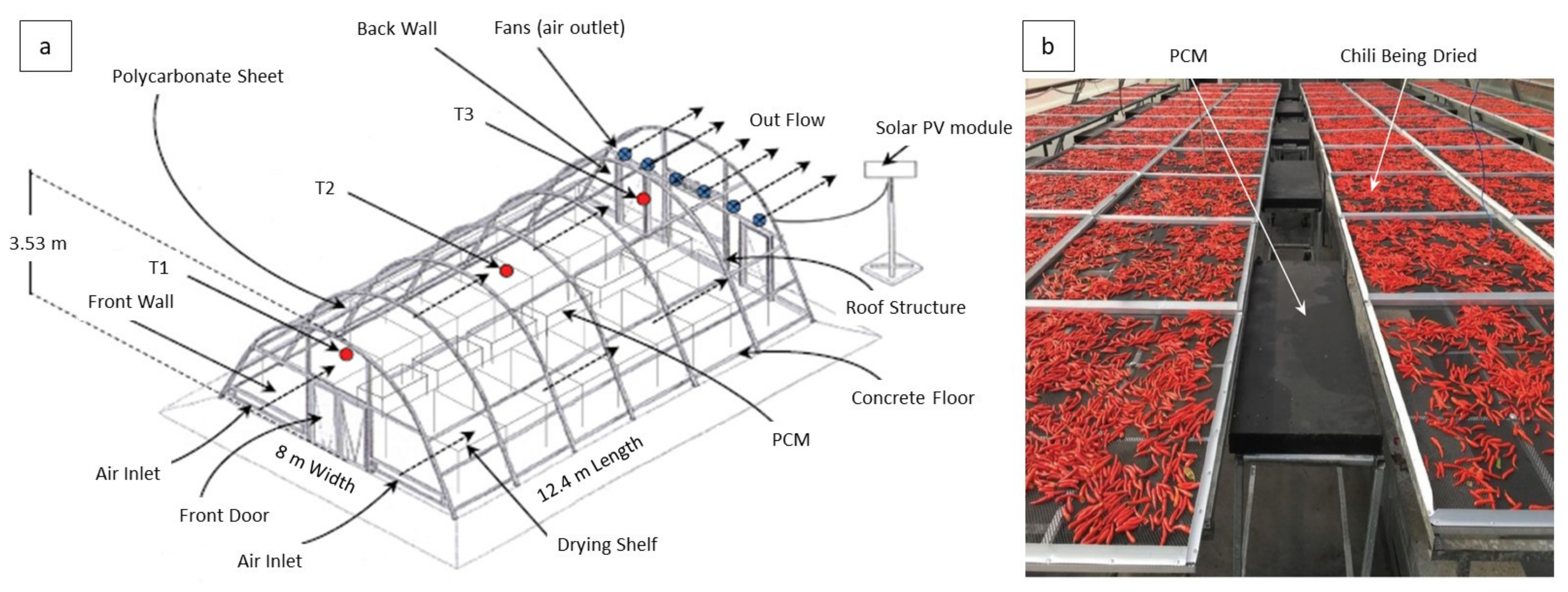

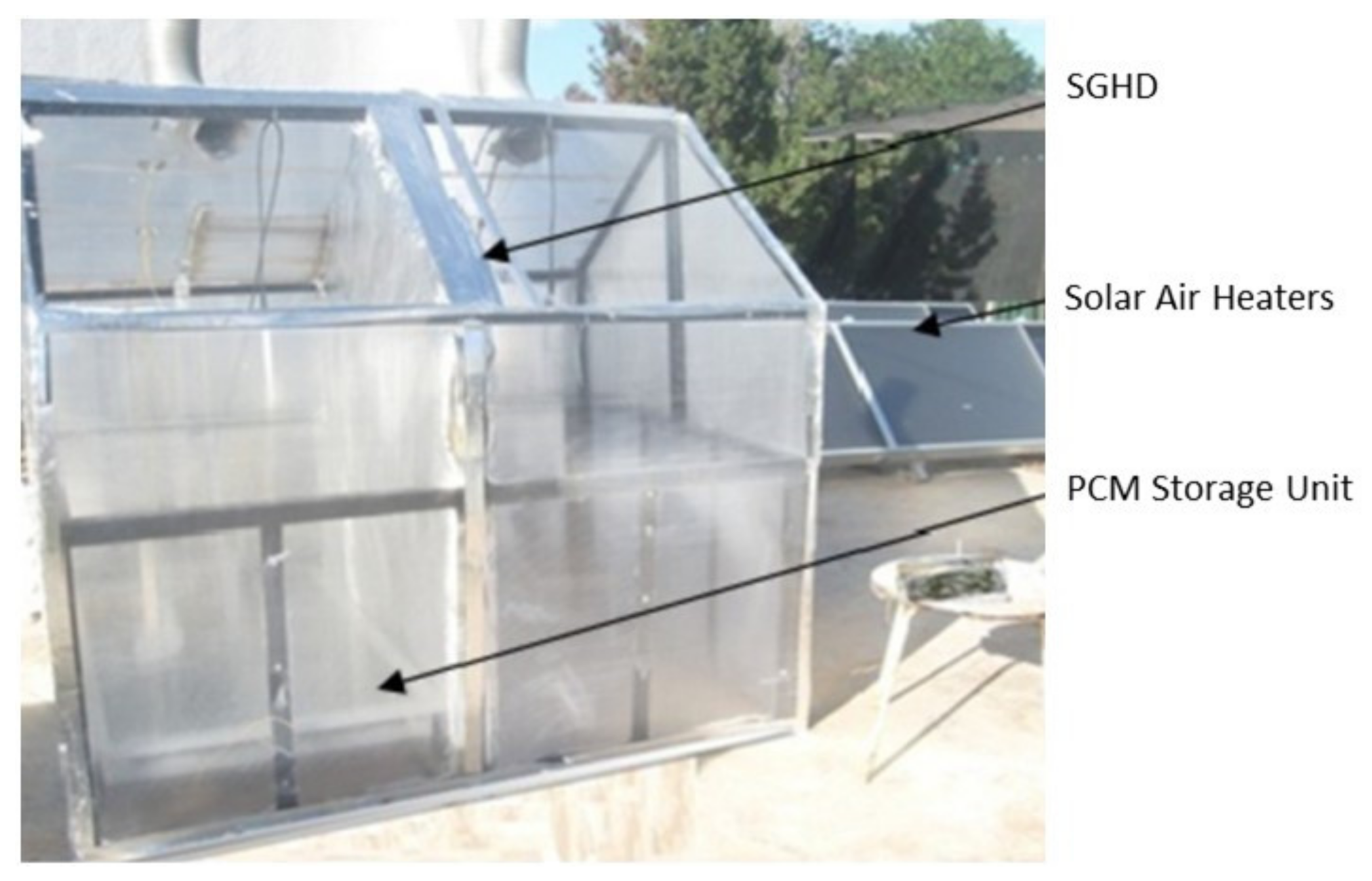

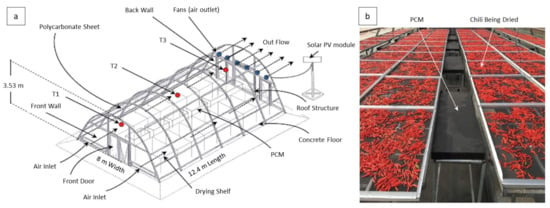

To provide heat requirements of large-scale solar dryers, liquefied petroleum gas (LPG) burners are usually used as auxiliary heaters that can impose additional costs. To solve this problem, PCMs are considered as an appropriate alternative. In this regard, Pankaew et al. [118] investigated the thermal performance of a large-scale SGHD (8 × 12.4 m2) integrated with a PCM as shown in Figure 23 to dry chili under the typical weather of Thailand. The obtained experimental results of the drying process in the SGHD integrated with PCM were compared with those obtained for the same dryer without PCM as well as the open-sun-drying process. The results indicated that 2.5 days is required for drying the chili in the SGHD with PCM, 3.5 days for drying in the SGHD without PCM, and 11 days for drying under the open-sun-drying. During the drying process, the chili’s initial moisture content of 74.7% (w.b.) reached a final value of 10.0% (w.b.). Additionally, the performance of the SGHD with and without the PCM was reported as 13.1% and 11.4%, respectively. In another study conducted by Azaizia et al. [18], a novel mixed-mode SGHD with and without paraffin wax as the PCM was developed and the drying efficiency was evaluated during the drying process of red pepper (Figure 24). During the experiments, it was found that the inside air temperature of the SGHD with PCM is 7.5 °C higher than other dryers during the nocturnal period and the relative humidity is 18.6% lower than the ambient. The moisture content was also reduced to 95% during 30 h, 55 h, and 75 h for drying in the SGHD with PCM, without PCM, and in the open sun, respectively. They concluded that using PCMs in SGHDs to store thermal energy is a promising option to increase drying efficiency.

Figure 23.

(a) Structure of the SGHD integrated with PCM; (b) inside photo of the SGHD with PCM blocks, adapted with permission from [118].

Figure 24.

Experimental setup of the SGHD with PCM developed in ref. [18] (adapted with permission).

Joshua et al. [119] evaluated a mixed-mode SGHD with and without PCM for drying raw bananas with 74% water content and pineapple slices with 87% water content. The results indicated a 75% improvement in drying efficiency for the SGHD with PCM. It was concluded that using PCM integrated with the dryer can both increase the thermal efficiency and eliminate temperature fluctuations during the drying process.

Deeto et al. [120] developed a novel hybrid SGHD for the dehumidification of coffee beans and hot water generation and storage, simultaneously. From the experiments, the flow pattern of circulating water was found to be 0.20 kg/s m2, with a water tank capacity of 60 L and tray products temperature of 45 °C at the 1:1 ratio of the product dehumidification to the solar hot water production. In this design, the thermal energy was stored as hot water to be used during the time without sunlight. During the drying process, it was found that the moisture content of the coffee beans falls from 55% to 12% within 12 h and the effective moisture diffusivity coefficient is 9.754 × 1011 m2/s. Ayyappan et al. [81] evaluated the use of different sensible TES materials, including concrete, sand, and rock-bed, integrated with a SGHD with natural convection during the drying process of coconuts. During all drying processes, the initial moister content of the coconut reached 7% (w.b.) from 52% (w.b.). The results revealed the drying period of 78 h in the dryer with the concrete, 66 h with sand, 53 h with rock-bed, and 174 h in open-sun-drying. Additionally, the dryer efficiency was found to be 9.5% for concrete as the storage medium, 11% for sand as the storage material, and 11.65% for rock-bed as heat storage material. As reported in the literature, both sensible and latent heat storage systems are used in SGHDs to provide a part of the heat requirement. In this case, the use of sensible heat storage is preferred due to the more available materials with lower costs. However, the latent heat storage materials as PCMs can provide higher thermal efficiencies that can significantly decrease the drying time. However, environmental consequences and economic aspects should also be considered. In most studies, the use of PCMs has been introduced by researchers as a promising option to reduce fuel consumption by the use of auxiliary heat suppliers. They can also extend the drying period to the night time.

3.3. Hybrid Solar Greenhouse Dryers

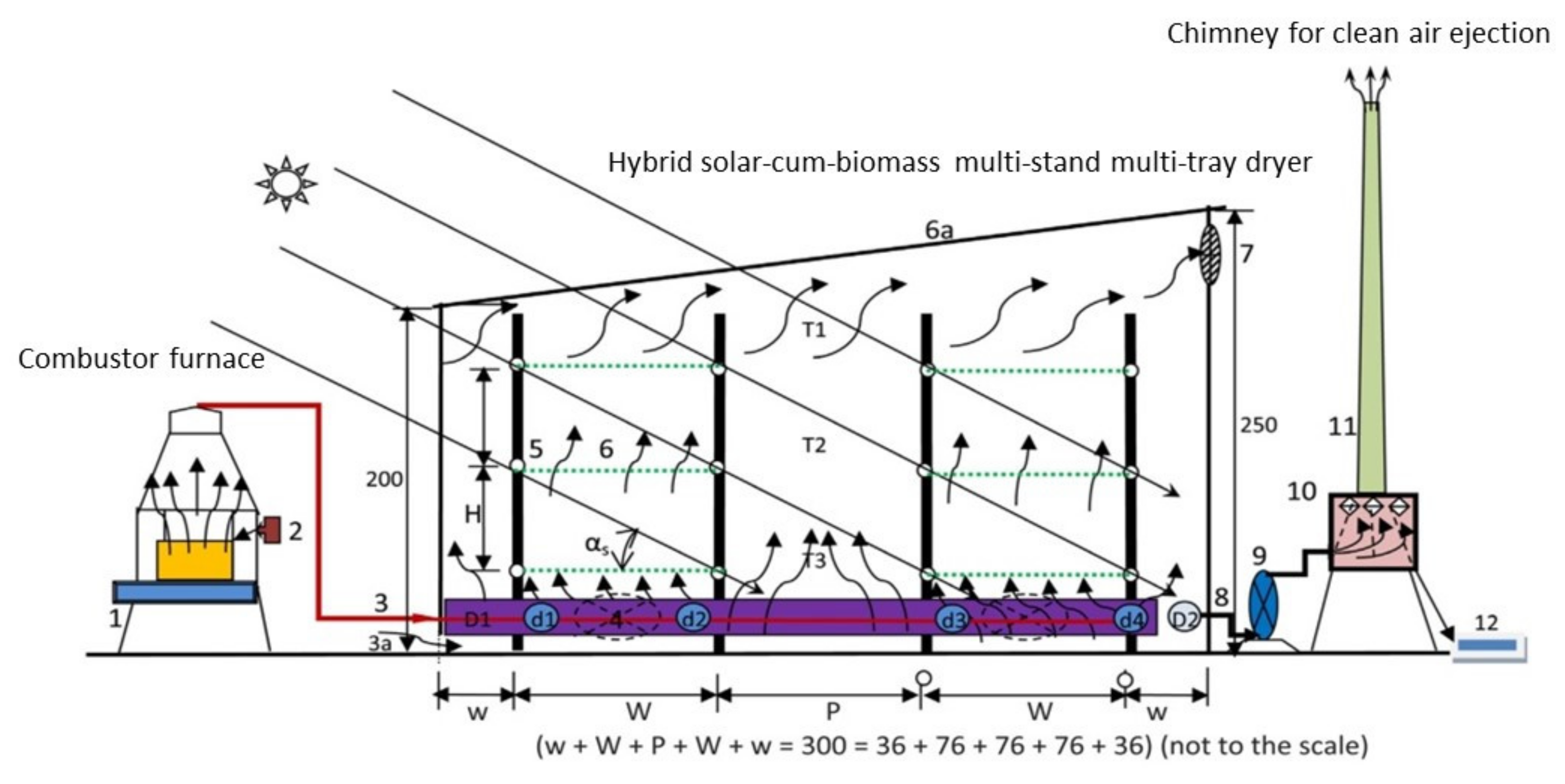

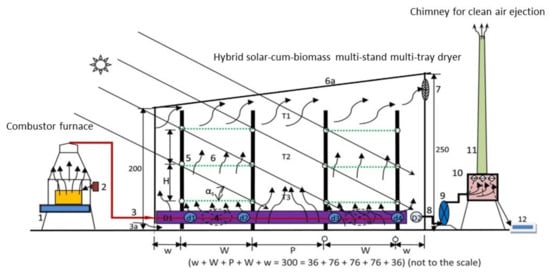

The intermittency of solar energy stops the drying process on cloudy and rainy days and also at night time, which can lead to some major problems in continuous energy supply to the end-users. To overcome this, hybrid renewable power generation systems can be considered as a solution [121,122,123]. Sethi and Dhiman [124] modeled and optimized a solar-cum-biomass hybrid GHD integrated with a flue gas heat transfer pipe network. They presented this dryer for daily steady operation at the drying air temperature of 62 °C using solar and biomass heat. For producing the flue gas with a temperature of 500 °C, a forced draft paddy bale combustor was considered to be integrated with a heat transfer pipe arrangement carrying the flue gas and transferring the heat inside the GHD as shown in Figure 25. From the numerical results, the indoor temperature values were calculated between 26 °C and 38 °C for the heating load of 4–6.5 kW and the ambient air temperature between 10 °C and 18 °C under the climate conditions of Ludhiana, India. Additionally, the required supplement heat was predicted about 26.2 kW when the air temperature reaches −5 °C at night. It was also observed that keeping the indoor air temperature between 60–62 °C requires one to burn 40–80 kg/h paddy straw in the biomass combustor.

Figure 25.

Schematic representation of east-west oriented hybrid greenhouse crop dryer (HGCD), adapted with permission from [125].

A solar–biomass hybrid GHD composed of a drying chamber, drying trays, and biomass unit was studied by Kiburi et al. [125]. In this research, the drying air properties and all other thermal energy performance characteristics were evaluated considering three energy modes of only solar, only biomass, and hybrid solar–biomass. From the experiments, the average energy utilization ratio in the GHD was reported as 35.58 ± 24.78 for solar, 40.60 ± 10.52 for biomass, and 33.46 ± 13.45% for combined solar–biomass energy utilization scenario. Additionally, the mean drying rates for banana slices were obtained as approximately 0.28, 0.21, and 0.23 g/gdm/h for solar, biomass, and combined solar–biomass energy utilization circumstances, respectively. A solar–biomass dryer with a bimodal biomass heating system as a backup was developed by Ndirangu et al. [126] for drying six commonly raised crops, including arrowroots, cassava, sweet potatoes, kales, bananas, and spider plant. The experiments were performed under three energy modes of natural ventilation, forced convection, and solar–biomass integration. Different parameters were assessed, including temperature, solar radiation, relative humidity, and weight change. The results revealed that the difference in temperature between the indoor and the ambient is 13.1 °C, 20.8 °C, and 17.9 °C in the case of the natural, forced, and hybrid modes, respectively. It was also found that the drying rate of the hybrid drying mode is 18–19% higher than the other modes.

Rupnar et al. [127] developed a solar-biogas hybrid GHD for drying onion with the capacity of 8 kg/batch, and its performance was evaluated. In this design, solar energy was considered as the primary energy source while biogas was projected to be the secondary heat source to provide a steady operation. The developed dryer was composed of a greenhouse drying chamber (1300 mm × 900 mm), a biogas burner, and a concentric air heating pipe. The hybrid mode of operation was only used when the sunlight was not sufficient to keep the indoor air temperature at 60 °C. From the experiments, the drying time for the onion slices to reach 9.88% (w.b.) from 80.06% (w.b.) was reported as 12 h when the system works under the hybrid drying mode. As can be found from the literature, the most common types of hybrid renewable energy sources that are integrated with GHDs are solar energy and biomass. In several studies, the use of hybrid renewable systems could successfully provide a higher drying rate. In some cases, the use of biomass has been suggested only under the condition of insufficient availability of solar radiation. Table 1 summarizes the results of studies that have investigated the GHDs integrated with various solar technologies.

Table 1.

Summarized results of the most recent studies on SGHDs and their main findings.

4. Economic Analysis

Along with the technical development and analysis for the performance of SGHDs, economic analysis is also equally important. The motive of the economic analysis is to maximize the net benefits and minimize the costs and investments (capital and maintenance). Therefore, an energy conversion device can be technically efficient but its implementation becomes financially infeasible [135]. In some cases, various kinds of engineering modifications have been conceptualized for the performance improvement of SGHDs, but it may incur additional costs with the modified system, making them economically infeasible. Thus, both economic and technical analyses are extremely important for introducing any new or modified model of SGHDs before their practical implementation. The economic analysis reveals the acceptability of a specified technology to the common people in harmony with the technological and environmental inferences [136].

Among various other parameters, the following ones are the major point of concern during an economic analysis for a typical SGHD: primary capital investment, operating and maintenance costs, running costs, interest rate, PP, net present value, cost of the dried product per unit kg, cost of supplementary heating (if required). It has been proposed to assess the economy of the SGHDs according to the following three methods [135,137]: the annualized cost calculation (ACC), lifecycle cost saving calculation (LCSC), and PP calculation. The ACC method determines the cost of the kg/unit of products dried in SGHDs compared with the cost of the products dried in conventional fossil fuel-based electric drying systems, while the LCSC method generally reveals the amount of cost saved by the solar energy-based drying systems compared to the fossil fuel-based conventional drying systems in their whole life cycle. Moreover, the payback period calculation (PPC) method is generally preferred as one of the standard measuring indexes, because in this method, the period of payback is considered and calculated [138,139]. It focuses on how quickly or lately the SGHDs would become profitable and would start producing net benefit. Systems having a long PP are generally not preferred for practical implementation and industrial application as well. Many researchers have carried out economic performance assessments for various kinds of SGHDs. Table 2 indicates a detailed summary.

Table 2.

Summary of some recent studies on the economic analysis of different types of SGHDs.

The above literature depicts that keeping the PP on the lower side is always beneficial and makes the design more feasible. The economic performance of dryers varies with different factors, such as size of the dryer, technical complexity, amount of food dried, type of food crop which is dried, the life span of the solar dryer, local weather conditions, availability of the construction materials for the solar dryers, availability of the local labors and technicians for operation and maintenance, and much more. As the capacity of the solar dryers becomes very large, the initial capital cost is observed to be very high, but at the same time, the PP becomes generally shorter [23]. From the literature, by structure modifications that in most cases cause more complexity in the design, the thermal performance of the dryer improves but not necessarily its economic performance. This is because the economy of a GHD not only depends on the design modifications but also on some other factors as mentioned above. Moreover, with the design modifications, though the energy performance improves, at the same time extra material costs are also added. It can be noticed that the use of a hybrid system, i.e., coupling the GHD with other renewable energy sources and different energy storage methods, can also improve the overall efficiency, reduce the drying time, and improve the overall energy performance of SGHDs. However, as stated earlier, the hybridization of GHDs does not guarantee their economic performance improvement since some additional costs also associate with other RESs and TES units. So, there is a need for trading off between the energy performance and economic performance criteria, such as capital cost, cost of drying, PP, drying time, energy efficiency, total net benefit, net present value, and operation maintenance costs, for decision making to adopt the proper technology for solar greenhouse drying.

5. Conclusions and Prospects

Solar energy has various applications; among them, solar drying is a promising application due to the availability of abundant solar radiation in most of the regions around the globe, especially in tropical regions. In most locations, fossil fuels prominently fulfill the power requirement of conventional dryers, causing environmental problems because of GHG emissions. Therefore, the integration of solar technologies with agricultural dryers is one sustainable solution.

GHDs are known as simple structures used for drying large amounts of materials. However, the main deficiency associated with passive structured SGHDs is that their thermal performance depends on several parameters such as solar radiation, wind speed, ambient temperature, and covering materials. Therefore, in this study, the most recent methods applied to increase the thermal performance of SGHDs are presented and discussed. These methods focus on integrating PV modules, PVT modules, solar thermal collectors, and TES units to GHDs, along with investigating the integration of hybrid power supply units to improve the performance of GHDs. Since the main power requirement in GHDs is thermal energy, the PV modules can be installed to run fans and other electric devices and therefore eliminate the need for grid electricity. However, installing PVT modules, solar thermal collectors, and using TES units inside can supply the heat demand of these structures. These integrations can decrease the reliance of GHDs on fossil fuels by providing the highest number of energy requirements from solar-based power supply units. However, each technology has its pros and cons, and considerations should be taken to find the best solution. Especially for integrating the TES units, the economic aspects should be taken into account. Among all discussed solutions to increase efficiency, hybrid solar dryers are also effective. The most common hybrid GHDs are those integrated with solar energy and biomass. In this case, when sufficient solar energy is not available, the biomass can be used to provide the required power of the greenhouse. Considering the economic aspects, the lower values of the PP are more beneficial and make the SGHDs more profitable. The economic feasibility and performance of SGHDs depend on several factors, including the SGHD’s capacity, technical complexity, amount of the food dried, local weather conditions, and availability of the materials used for the construction of GHDs.

Considering all discussed technologies in this study, choosing the best technology is not an easy task, and several operational and climatic parameters should be considered, while the economy of these structures will also vary from one location to another. The literature indicates that few studies have investigated the quality of the dried product in SGHDS, and for this case, further investigations are suggested. However, the use of SGHDs for drying agricultural produce as well as poultry and marine products can result in a higher quality of the dried product since the drying process can be better controlled. Since most of the agricultural farms are located in remote areas, if SGHDs are also installed in these locations, due to less accessibility to grid electricity and other fossil fuels, the integration with solar systems can be more affordable, especially when TES systems are also embedded and allow the whole structure to stand alone. With more advancements in technology both for the GHDs and for solar-based systems, these sustainable structures will be expected to be more successful and affordable in the future. The ultimate target of utilizing these drying advances is to fundamentally improve agricultural returns for farmers in appreciation for the hard effort they have dedicated to crop development. However, it is a worthy point to evaluate the SGHDs project from an environmental perspective to ensure it does not have a destructive impact on the environment of the location of installation. For further studies, the life cycle assessment (LCA) of these structures is also suggested.

Author Contributions

S.G.: Conceptualization Funding acquisition; Methodology; Project administration; Supervision; Visualization; Writing—original draft; Writing—review & editing. B.H.: Methodology; Writing—original draft; Writing—review & editing. L.D.J.: Methodology; Writing—original draft; Writing—review & editing. H.S.: Visualization; Methodology; Writing—original draft; Writing—review & editing. S.S.: Conceptualization; Funding acquisition; Writing—review & editing. A.A.S.: Conceptualization; Funding acquisition; Writing—review & editing. K.K.: Methodology; Writing—original draft; Writing—review & editing. R.S.: Methodology; Writing—original draft; Writing—review & editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Tarbiat Modares University (TMU), grant number IG/39705, and Solar Energy Research Center (SERC), Chile, grant number FONDAP/ANID 15110019.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available in a publicly accessible repository.

Conflicts of Interest

The authors declare no conflict of interest.

References

- United Nations DESA. World Population Prospects 2019; United Nations: San Francisco, CA, USA, 2019. [Google Scholar]

- Gorjian, S.; Ebadi, H. Introduction. In Photovolt. Sol. Energy Convers; Shukla, S.G.A.E., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–26. [Google Scholar] [CrossRef]

- Gorjian, S.; Ebadi, H.; Trommsdorff, M.; Sharon, H.; Demant, M.; Schindele, S. The advent of modern solar-powered electric agricultural machinery: A solution for sustainable farm operations. J. Clean Prod. 2021, 292, 126030. [Google Scholar] [CrossRef]

- Technical Platform on the Measurement and Reduction of Food Loss and Waste|Food and Agriculture Organization of the United Nations. Available online: http://www.fao.org/platform-food-loss-waste/en/ (accessed on 8 January 2021).

- Melikoglu, M. Reutilisation of food wastes for generating fuels and value added products: A global review. Environ. Technol. Innov. 2020, 19, 101040. [Google Scholar] [CrossRef]

- Chegere, M.J. Post-harvest losses reduction by small-scale maize farmers: The role of handling practices. Food Policy 2018, 77, 103–115. [Google Scholar] [CrossRef]

- Awasthi, S.K.; Sarsaiya, S.; Awasthi, M.K.; Liu, T.; Zhao, J.; Kumar, S.; Zhang, Z. Changes in global trends in food waste composting: Research challenges and opportunities. Bioresour. Technol. 2020, 299, 122555. [Google Scholar] [CrossRef] [PubMed]

- Lingayat, A.B.; Chandramohan, V.P.; Raju, V.R.K.; Meda, V. A review on indirect type solar dryers for agricultural crops—Dryer setup, its performance, energy storage and important highlights. Appl. Energy 2020, 258, 114005. [Google Scholar] [CrossRef]

- Babu, A.K.; Kumaresan, G.; Raj, V.A.A.; Velraj, R. Review of leaf drying: Mechanism and influencing parameters, drying methods, nutrient preservation, and mathematical models. Renew. Sustain. Energy Rev. 2018, 90, 536–556. [Google Scholar] [CrossRef]

- Llavata, B.; García-Pérez, J.V.; Simal, S.; Cárcel, J.A. Innovative pre-treatments to enhance food drying: A current review. Curr. Opin. Food Sci. 2020, 35, 20–26. [Google Scholar] [CrossRef]

- Kagande, L. Design and performance evaluation of solar tunnel dryer for tomato fruit drying in Zimbabwe. IOSR J. Eng. 2012, 2, 1–7. [Google Scholar] [CrossRef]

- Gorjian, S.; Singh, R.; Shukla, A.; Mazhar, A.R. On-farm applications of solar PV systems. In Photovoltaic Solar Energy Conversion; Gorjian, S., Shukla, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 147–190. [Google Scholar] [CrossRef]

- Walsh, M.J.; Gerber Van Doren, L.; Shete, N.; Prakash, A.; Salim, U. Financial tradeoffs of energy and food uses of algal biomass under stochastic conditions. Appl. Energy 2018, 210, 591–603. [Google Scholar] [CrossRef]

- Fayose, F.; Huan, Z. Heat Pump Drying of Fruits and Vegetables: Principles and Potentials for Sub-Saharan Africa. Int. J. Food Sci. 2016, 2016, 9673029. [Google Scholar] [CrossRef] [PubMed]

- Sims, R.E.H. “Energy-Smart” Food for People and Climate; FAO: Rome, Italy, 2011. [Google Scholar]

- Monforti-Ferrario, F.; Dallemand, J.-F.; Pascua, I.P.; Motola, V.; Banja, M.; Scarlat, N.; Bertoldi, P.; Pennington, D. Energy Use in the EU Food Sector: State of Play and Opportunities for Improvement; Publications Office of the EU: Luxembourg, 2015. [Google Scholar] [CrossRef]

- Singh, P.L. Silk cocoon drying in forced convection type solar dryer. Appl. Energy 2011, 88, 1720–1726. [Google Scholar] [CrossRef]

- Azaizia, Z.; Kooli, S.; Hamdi, I.; Elkhal, W.; Guizani, A.A. Experimental study of a new mixed mode solar greenhouse drying system with and without thermal energy storage for pepper. Renew. Energy 2020, 145, 1972–1984. [Google Scholar] [CrossRef]

- Sharma, A.; Chen, C.R.; Vu Lan, N. Solar-energy drying systems: A review. Renew. Sustain. Energy Rev. 2009, 13, 1185–1210. [Google Scholar] [CrossRef]

- Kemp, I.C. Fundamentals of Energy Analysis of Dryers. Mod. Dry Technol. 2012, 4, 1–45. [Google Scholar] [CrossRef]

- Salehi, F. Recent Applications and Potential of Infrared Dryer Systems for Drying Various Agricultural Products: A Review. Int. J. Fruit Sci. 2020, 20, 586–602. [Google Scholar] [CrossRef]

- Tigampo, S.; Sambou, V.; Dieye, Y.; Toure, P.M.; Bodian, S. Study of air movement and temperature distribution in a greenhouse used as a dryer. MATEC Web Conf. 2020, 307, 01051. [Google Scholar] [CrossRef]

- El Hage, H.; Herez, A.; Ramadan, M.; Bazzi, H.; Khaled, M. An investigation on solar drying: A review with economic and environmental assessment. Energy 2018, 157, 815–829. [Google Scholar] [CrossRef]

- Yildizhan, H.; Taki, M.; Özilgen, M.; Gorjian, S. Renewable energy utilization in apple production process: A thermodynamic approach. Sustain. Energy Technol. Assess. 2021, 43, 100956. [Google Scholar] [CrossRef]

- Gorjian, S.; Minaei, S.; MalehMirchegini, L.; Trommsdorff, M.; Shamshiri, R.R. Applications of solar PV systems in agricultural automation and robotics. In Photovoltaic Solar Energy Conversion; Gorjian, S., Shukla, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 191–235. [Google Scholar] [CrossRef]

- Janjai, S.; Khamvongsa, V.; Bala, B.K. Development, design, and performance of a PV-Ventilated greenhouse dryer. Int. Energy J. 2007, 8, 249–258. [Google Scholar]

- Azaizia, Z.; Kooli, S.; Elkhadraoui, A.; Hamdi, I.; Guizani, A. Investigation of a new solar greenhouse drying system for peppers. Int. J. Hydrogen Energy 2017, 42, 8818–8826. [Google Scholar] [CrossRef]

- Hamdi, I.; Kooli, S.; Elkhadraoui, A.; Azaizia, Z.; Abdelhamid, F.; Guizani, A. Experimental study and numerical modeling for drying grapes under solar greenhouse. Renew. Energy 2018, 127, 936–946. [Google Scholar] [CrossRef]

- Iskandar, A.N.; Ya’acob, M.E.; Anuar, M.S. Tropical field performance of dual-pass PV tray dryer. AIP Conf. Proc. 2017, 020016. [Google Scholar] [CrossRef]

- Eltawil, M.A.; Azam, M.M.; Alghannam, A.O. Energy analysis of hybrid solar tunnel dryer with PV system and solar collector for drying mint (MenthaViridis). J. Clean Prod. 2018, 181, 352–364. [Google Scholar] [CrossRef]

- Amer, B.M.A.; Gottschalk, K.; Hossain, M.A. Integrated hybrid solar drying system and its drying kinetics of chamomile. Renew. Energy 2018, 121, 539–547. [Google Scholar] [CrossRef]

- Prakash, O.; Laguri, V.; Pandey, A.; Kumar, A.; Kumar, A. Review on various modelling techniques for the solar dryers. Renew. Sustain. Energy Rev. 2016, 62, 396–417. [Google Scholar] [CrossRef]

- Djebli, A.; Hanini, S.; Badaoui, O.; Haddad, B.; Benhamou, A. Modeling and comparative analysis of solar drying behavior of potatoes. Renew. Energy 2020, 145, 1494–1506. [Google Scholar] [CrossRef]

- Pinna-Hernández, M.G.; Fernández, F.G.A.; Segura, J.G.L.; López, J.L.C. Solar Drying of Greenhouse Crop Residues for Energy Valorization: Modeling and Determination of Optimal Conditions. Agronomy 2020, 10, 2001. [Google Scholar] [CrossRef]

- VijayaVenkataRaman, S.; Iniyan, S.; Goic, R. A review of solar drying technologies. Renew. Sustain. Energy Rev. 2012, 16, 2652–2670. [Google Scholar] [CrossRef]

- Assoa, Y.B.; Sauzedde, F.; Boillot, B.; Boddaert, S. Development of a building integrated solar photovoltaic/thermal hybrid drying system. Energy 2017, 128, 755–767. [Google Scholar] [CrossRef]

- Patil, R.; Gawande, R. A review on solar tunnel greenhouse drying system. Renew. Sustain. Energy Rev. 2016, 56, 196–214. [Google Scholar] [CrossRef]

- Saini, V.; Tiwari, S.; Tiwari, G.N. Environ economic analysis of various types of photovoltaic technologies integrated with greenhouse solar drying system. J. Clean Prod. 2017, 156, 30–40. [Google Scholar] [CrossRef]

- Fudholi, A.; Sopian, K.; Ruslan, M.H.; Alghoul, M.A.; Sulaiman, M.Y. Review of solar dryers for agricultural and marine products. Renew. Sustain. Energy Rev. 2010, 14, 1–30. [Google Scholar] [CrossRef]

- Udomkun, P.; Romuli, S.; Schock, S.; Mahayothee, B.; Sartas, M.; Wossen, T.; Njukwe, E.; Vanlauwe, B.; Müller, J. Review of solar dryers for agricultural products in Asia and Africa: An innovation landscape approach. J. Environ. Manag. 2020, 268, 110730. [Google Scholar] [CrossRef] [PubMed]

- Banout, J. Solar Drying Systems. Solar Drying Technology, Green Energy and Technology; Springer: Singapore, 2017; pp. 39–67. [Google Scholar] [CrossRef]

- Tiwari, S.; Tiwari, G.N.; Al-Helal, I.M. Development and recent trends in greenhouse dryer: A review. Renew. Sustain. Energy Rev. 2016, 65, 1048–1064. [Google Scholar] [CrossRef]

- Mustayen, A.G.M.B.; Mekhilef, S.; Saidur, R. Performance study of different solar dryers: A review. Renew. Sustain. Energy Rev. 2014, 34, 463–470. [Google Scholar] [CrossRef]

- Kumar, M.; Sansaniwal, S.K.; Khatak, P. Progress in solar dryers for drying various commodities. Renew. Sustain. Energy Rev. 2016. [Google Scholar] [CrossRef]

- Seveda, M.S.; Jhajharia, D. Design and performance evaluation of solar dryer for drying of large cardamom (Amomum subulatum). J. Renew. Sustain. Energy 2012. [Google Scholar] [CrossRef]

- Jain, D.; Tiwari, G.N. Effect of greenhouse on crop drying under natural and forced convection II. Thermal modeling and experimental validation. Energy Convers. Manag. 2004. [Google Scholar] [CrossRef]

- Tomar, V.; Tiwari, G.N.; Norton, B. Solar dryers for tropical food preservation: Thermophysics of crops, systems and components. Sol. Energy 2017. [Google Scholar] [CrossRef]

- Tsotsas, E.; Mujumdar, A.S. Modern Drying Technology; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar] [CrossRef]

- Tsotsas, E.; Mujumdar, A.S. Modern Drying Technology Vol. 1 Computational Tools at Different Scales. Dry Technol. 2008. [Google Scholar] [CrossRef]

- Tiwari, S.; Tiwari, G.N.; Al-Helal, I.M. Performance analysis of photovoltaic–thermal (PVT) mixed mode greenhouse solar dryer. Sol. Energy 2016, 133, 421–428. [Google Scholar] [CrossRef]

- Tiwari, S.; Tiwari, G.N. Exergoeconomic analysis of photovoltaic-thermal (PVT) mixed mode greenhouse solar dryer. Energy 2016, 114, 155–164. [Google Scholar] [CrossRef]

- Tiwari, S.; Tiwari, G.N. Energy and exergy analysis of a mixed-mode greenhouse-type solar dryer, integrated with partially covered N-PVT air collector. Energy 2017, 128, 183–195. [Google Scholar] [CrossRef]

- Tiwari, A. A Review on Solar Drying of Agricultural Produce. J. Food Process. Technol. 2016. [Google Scholar] [CrossRef]

- El-Sebaii, A.A.; Shalaby, S.M. Solar drying of agricultural products: A review. Renew. Sustain. Energy Rev. 2012, 16, 37–43. [Google Scholar] [CrossRef]

- Mujumdar, A. Principles, Classification, and Selection of Dryers. In Handbook of Industrial Drying, 3th ed.; CRC: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A. Historical Review and Recent Trends in Solar Drying Systems. Int. J. Green Energy 2013, 10, 690–738. [Google Scholar] [CrossRef]

- Ghatrehsamani, S.H.; Dadashzadeh, M.; Zomorodian, A. Kinetics of apricot thin layer drying in a mixed and indirect mode solar dryer. Int. J. Agric. Sci. 2012, 4, 262–267. [Google Scholar] [CrossRef]

- Bala, B.K.; Woods, J.L. Simulation of the indirect natural convection solar drying of rough rice. Sol. Energy 1994. [Google Scholar] [CrossRef]

- Simate, I.N. Optimization of mixed-mode and indirect-mode natural convection solar dryers. Renew. Energy 2003. [Google Scholar] [CrossRef]

- Simate, I.N. Simulation of the mixed-mode natural-convection solar drying of maize. Dry Technol. 2001. [Google Scholar] [CrossRef]

- Lamrani, B.; Draoui, A. Modelling and simulation of a hybrid solar-electrical dryer of wood integrated with latent heat thermal energy storage system. Therm. Sci. Eng. Prog. 2020. [Google Scholar] [CrossRef]

- Mohammed, S.; Fatumah, N.; Shadia, N. Drying performance and economic analysis of novel hybrid passive-mode and active-mode solar dryers for drying fruits in East Africa. J. Stored Prod. Res. 2020. [Google Scholar] [CrossRef]

- Reyes, A.; Mahn, A.; Cubillos, F.; Huenulaf, P. Mushroom dehydration in a hybrid-solar dryer. Energy Convers. Manag. 2013. [Google Scholar] [CrossRef]

- Gudiño-Ayala, D.; Calderón-Topete, Á. Pineapple drying using a new solar hybrid dryer. Energy Procedia 2014. [Google Scholar] [CrossRef]

- Dhanushkodi, S.; Wilson, V.H.; Sudhakar, K. Mathematical modeling of drying behavior of cashew in a solar biomass hybrid dryer. Resour. Technol. 2017. [Google Scholar] [CrossRef]

- Gorjian, S.; Calise, F.; Kant, K.; Ahamed, M.S.; Copertaro, B.; Najafi, X.; Zhang, G.; Aghaei, M.; Shamshiri, R.R. A review on opportunities for implementation of solar energy technologies in agricultural greenhouses. J. Clean Prod. 2021, 124807. [Google Scholar] [CrossRef]

- Gorjian, S.; Ebadi, H.; Najafi, G.; Singh Chandel, S.; Yildizhan, H. Recent advances in net-zero energy greenhouses and adapted thermal energy storage systems. Sustain. Energy Technol. Assess. 2021, 43, 100940. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A. Solar greenhouse drying: A review. Renew. Sustain. Energy Rev. 2014, 29, 905–910. [Google Scholar] [CrossRef]

- Ekechukwu, O.; Norton, B. Review of solar-energy drying systems II: An overview of solar drying technology. Energy Convers. Manag. 1999, 40, 615–655. [Google Scholar] [CrossRef]

- Janjai, S.; Lamlert, N.; Intawee, P.; Mahayothee, B.; Bala, B.K.; Nagle, M.; Müller, J. Experimental and simulated performance of a PV-ventilated solar greenhouse dryer for drying of peeled longan and banana. Sol. Energy 2009, 83, 1550–1565. [Google Scholar] [CrossRef]

- Nayak, S.; Tiwari, G.N. Energy and exergy analysis of photovoltaic/thermal integrated with a solar greenhouse. Energy Build. 2008, 40, 2015–2021. [Google Scholar] [CrossRef]

- Ganguly, A.; Misra, D.; Ghosh, S. Modeling and analysis of solar photovoltaic-electrolyzer-fuel cell hybrid power system integrated with a floriculture greenhouse. Energy Build. 2010, 42, 2036–2043. [Google Scholar] [CrossRef]

- Kaewkiew, J.; Nabnean, S.; Janjai, S. Experimental investigation of the performance of a large-scale greenhouse type solar dryer for drying chilli in Thailand. Procedia Eng. 2012. [Google Scholar] [CrossRef]

- Barnwal, P.; Tiwari, A. Design, construction and testing of hybrid photovoltaic integrated greenhouse dryer. Int. J. Agric. Res. 2008, 3, 110–120. [Google Scholar] [CrossRef]

- Sevda, M.S.; Rathore, N.S. Performance evaluation of the semicylindrical solar tunnel dryer for drying handmade paper. J. Renew. Sustain. Energy 2010. [Google Scholar] [CrossRef]

- Rathore, N.S.; Panwar, N.L. Experimental studies on hemi cylindrical walk-in type solar tunnel dryer for grape drying. Appl. Energy 2010. [Google Scholar] [CrossRef]

- Hegde, V.N.; Hosur, V.S.; Rathod, S.K.; Harsoor, P.A.; Narayana, K.B. Design, fabrication and performance evaluation of solar dryer for banana. Energy Sustain. Soc. 2015. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A. Performance evaluation of greenhouse dryer with opaque north wall. Heat Mass Transf. Stoffuebertragung 2014. [Google Scholar] [CrossRef]

- Chauhan, P.S.; Kumar, A. Performance analysis of greenhouse dryer by using insulated north-wall under natural convection mode. Energy Rep. 2016, 2, 107–116. [Google Scholar] [CrossRef]