A Fixed Bed Pervious Concrete Anaerobic Bioreactor for Biological Sulphate Remediation of Acid Mine Drainage Using Simple Organic Matter

Abstract

1. Introduction

2. Experimental Methodology

2.1. AMD Collection and Storage

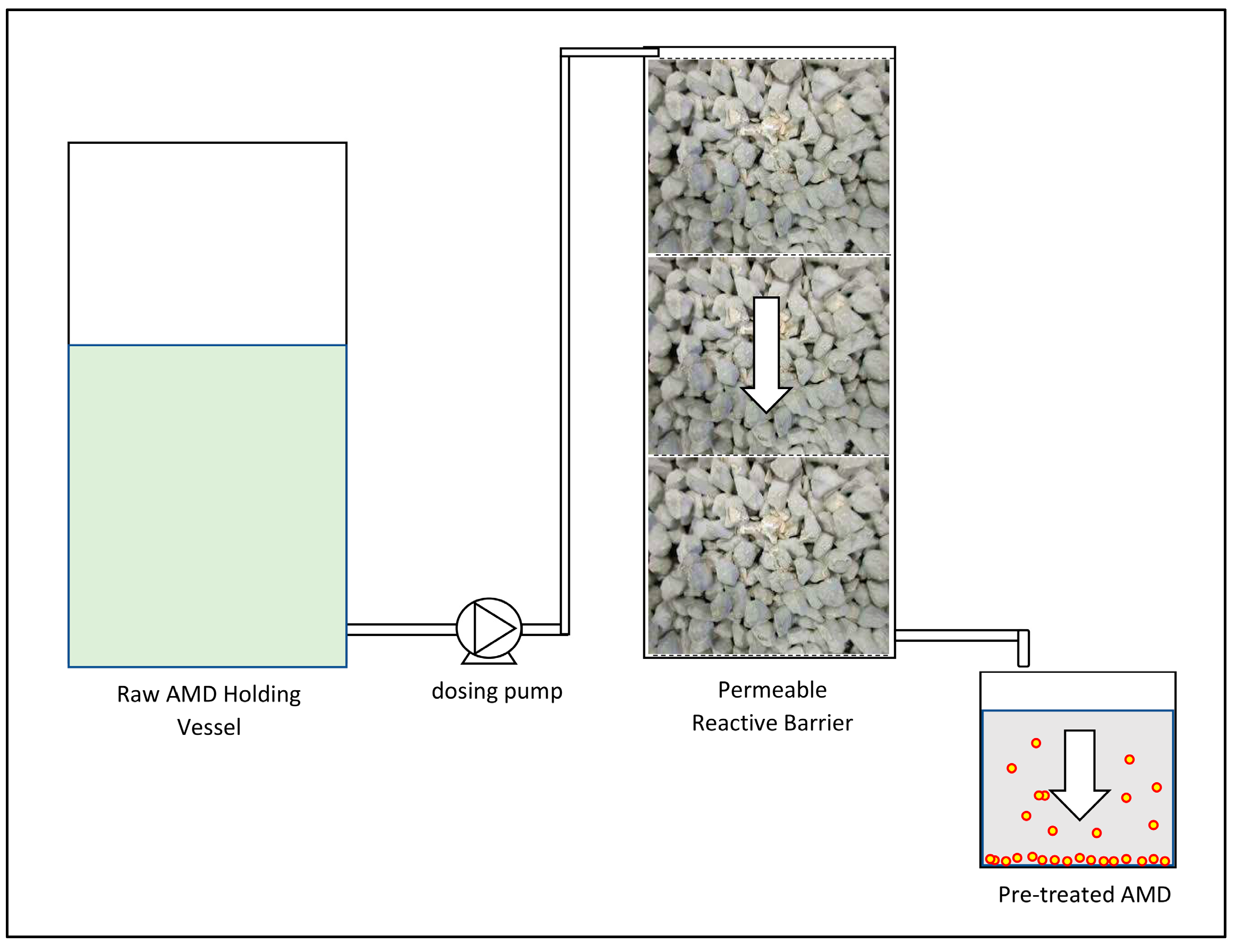

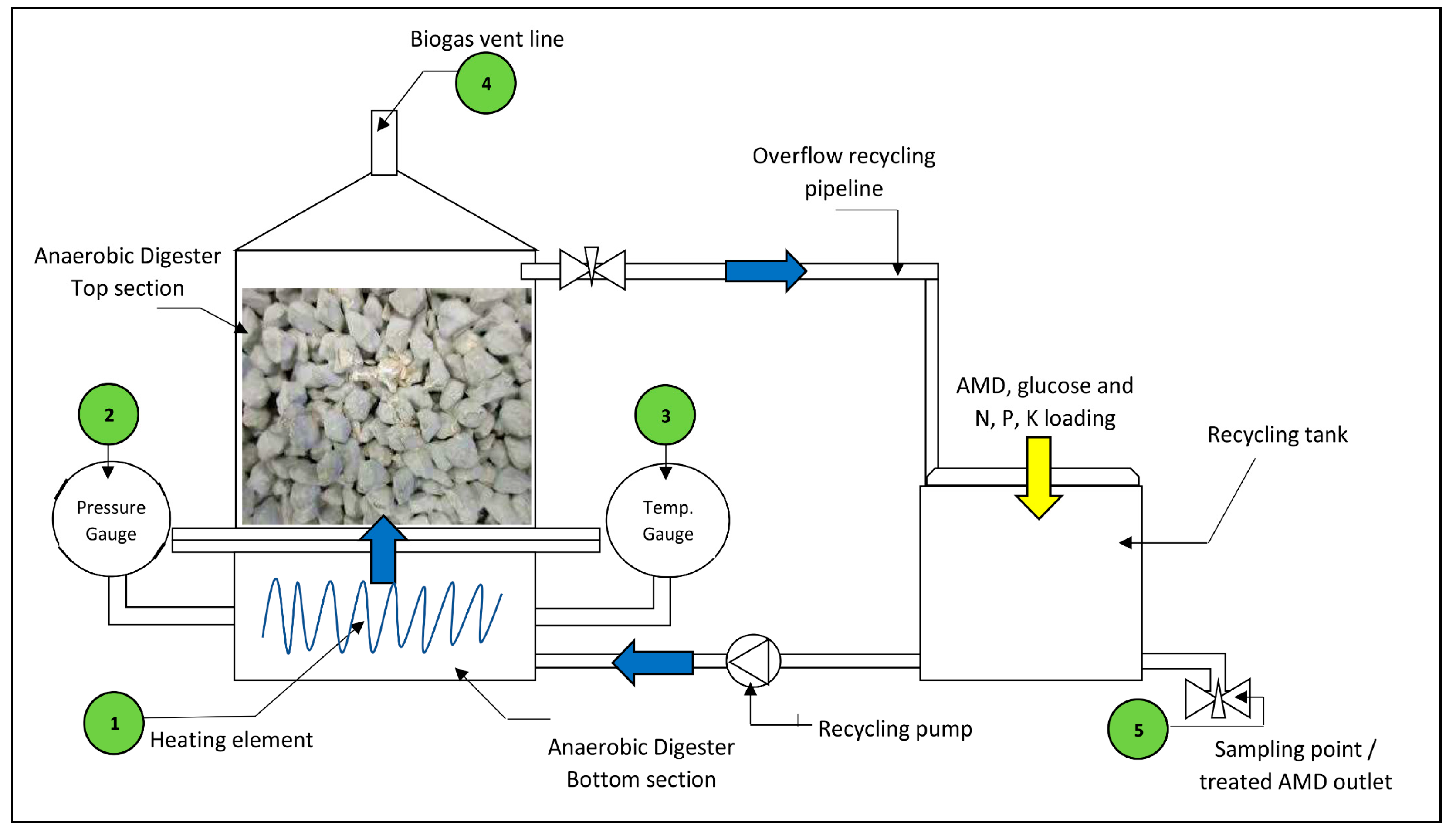

2.2. Process Design and Description

- a 50 W fish tank heating element to maintain the liquid temperature between 36 °C and 38 °C,

- a mechanical pressure gauge for monitoring the static pressure inside the bioreactor,

- a mechanical temperature gauge, range 0–60 °C, for monitoring the AD fluid temperature,

- a vent outlet at the top centre of the AD to release biogas,

- a sampling valve on the recycling tank for daily AMD sample collection.

2.3. Equipment and Materials

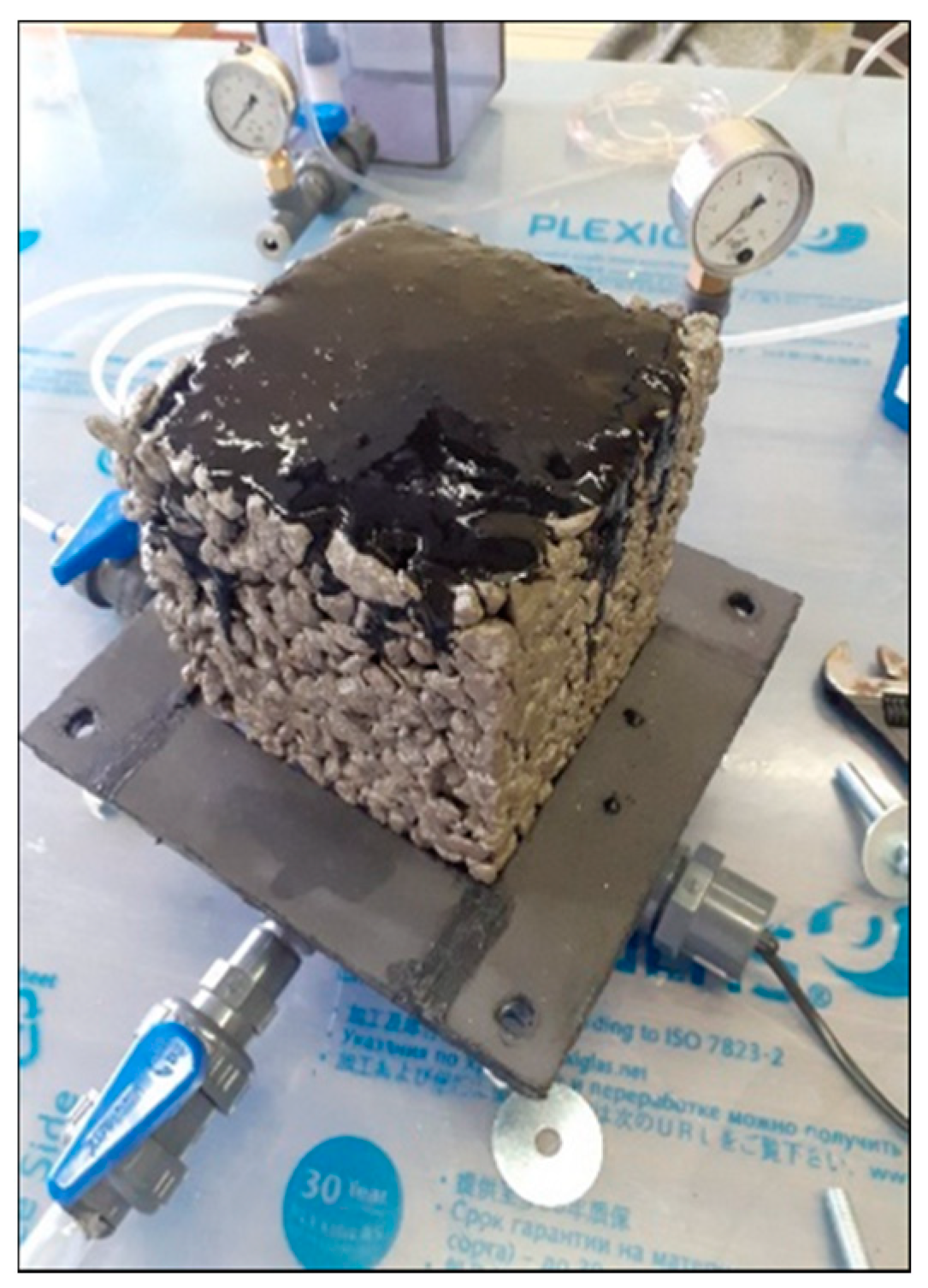

2.3.1. Pervious Concrete Materials and Construction

2.3.2. Seed Sludge Collection, Storage and Loading

2.4. Operational Protocol

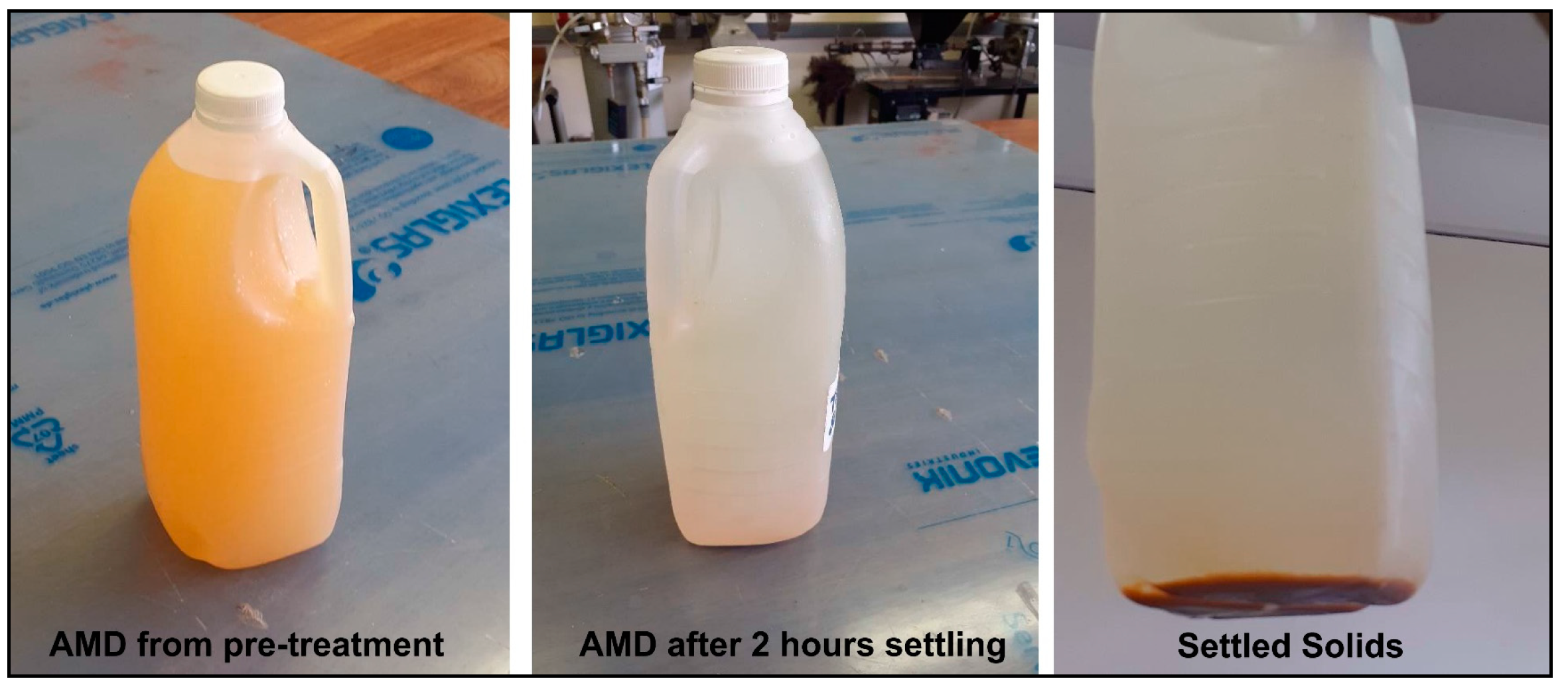

2.4.1. Pre-Treatment Operational Protocol

2.4.2. Bioreactor Operational Protocol

2.5. Chemical Analysis

2.5.1. Dissolved Metals

2.5.2. Sulphate

2.5.3. pH

2.5.4. Total Suspended Solids

2.5.5. Chemical Oxygen Demand

2.5.6. Alkalinity

2.5.7. Volatile Fatty Acids

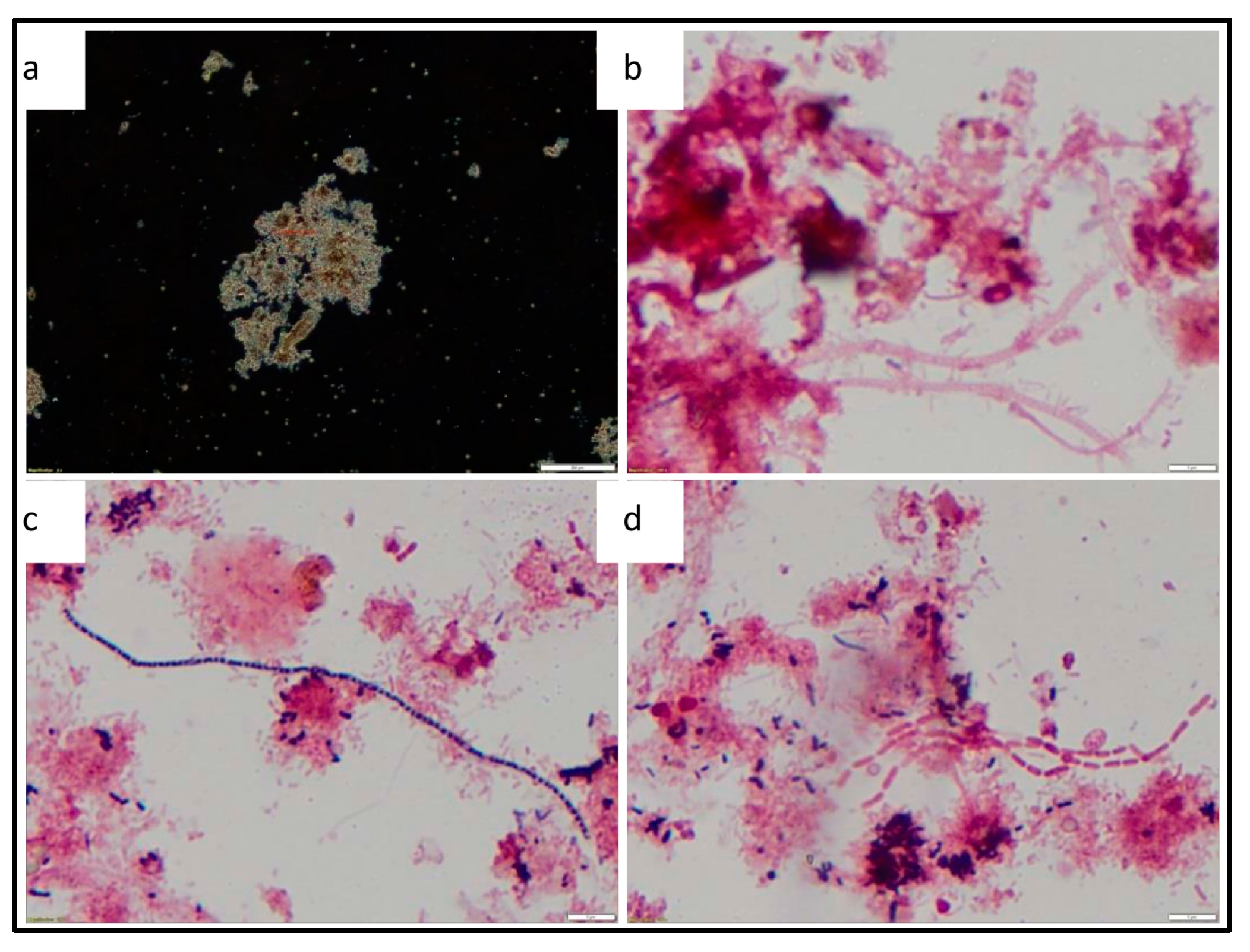

2.6. Microscopic Evaluation

2.7. Statistical Methods

3. Results and Discussions

3.1. Permeable Reactive Barrier Pre-Treatment

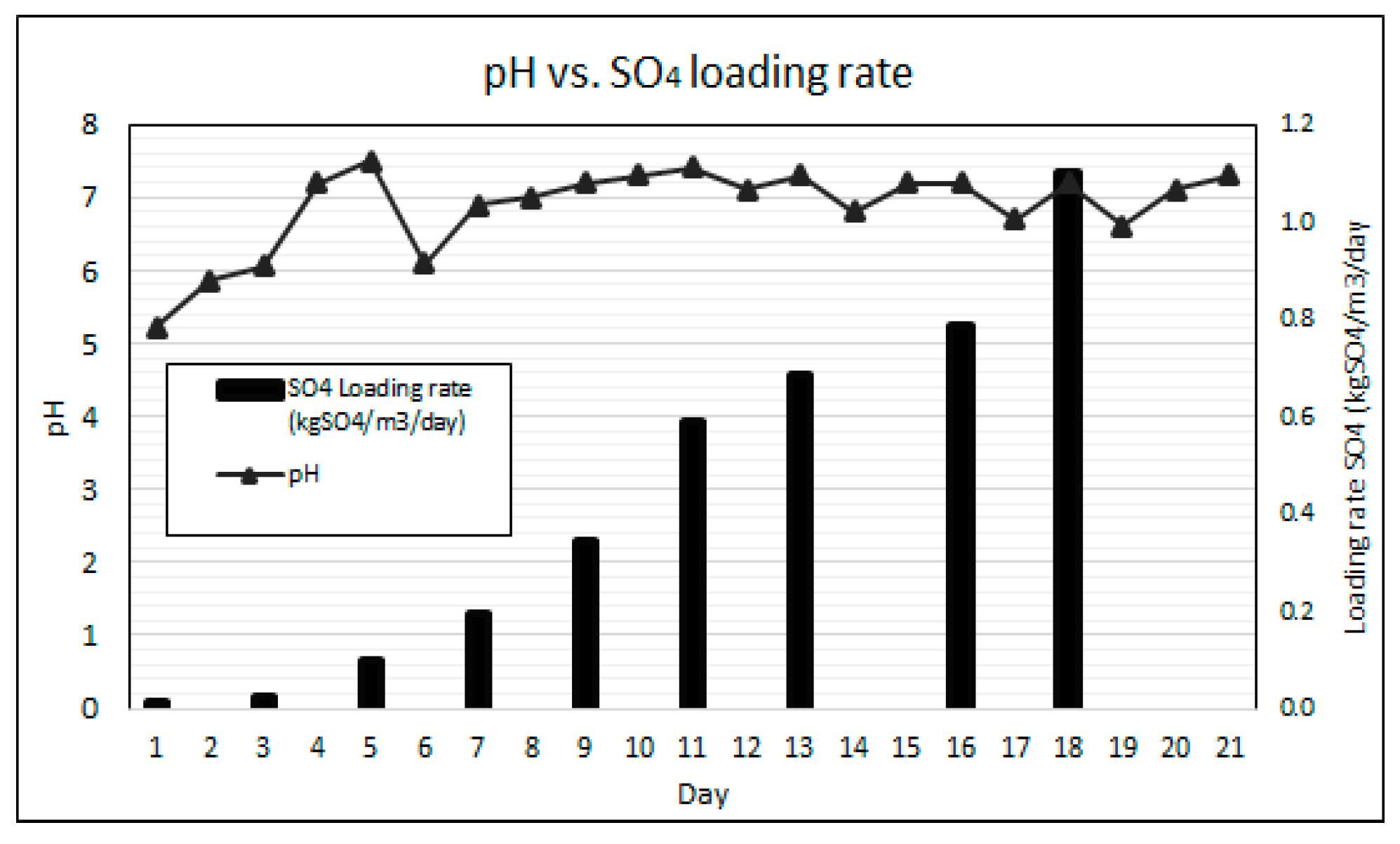

3.2. pH Self-Regulation

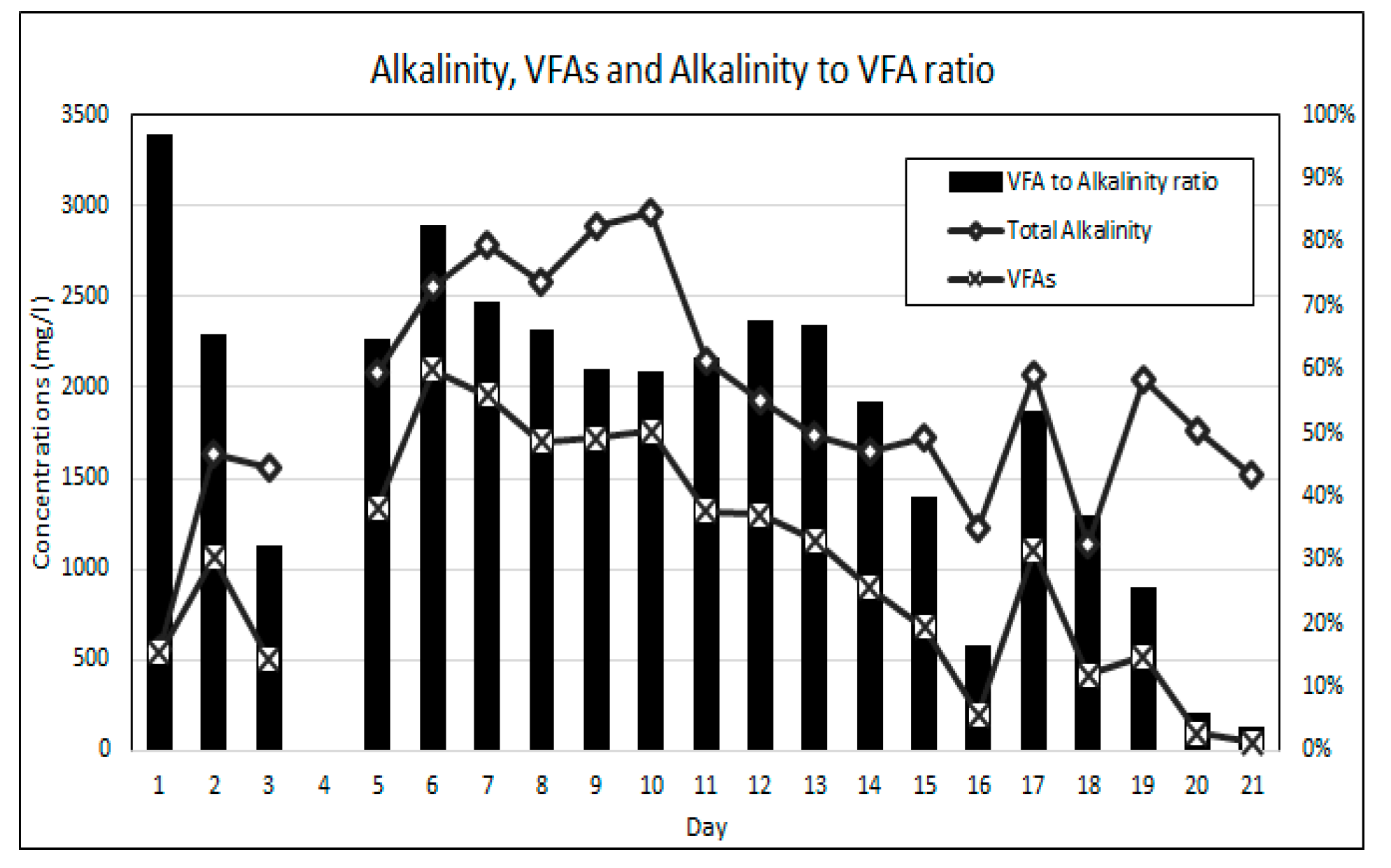

3.3. Alkalinity and Volatile Fatty Acids

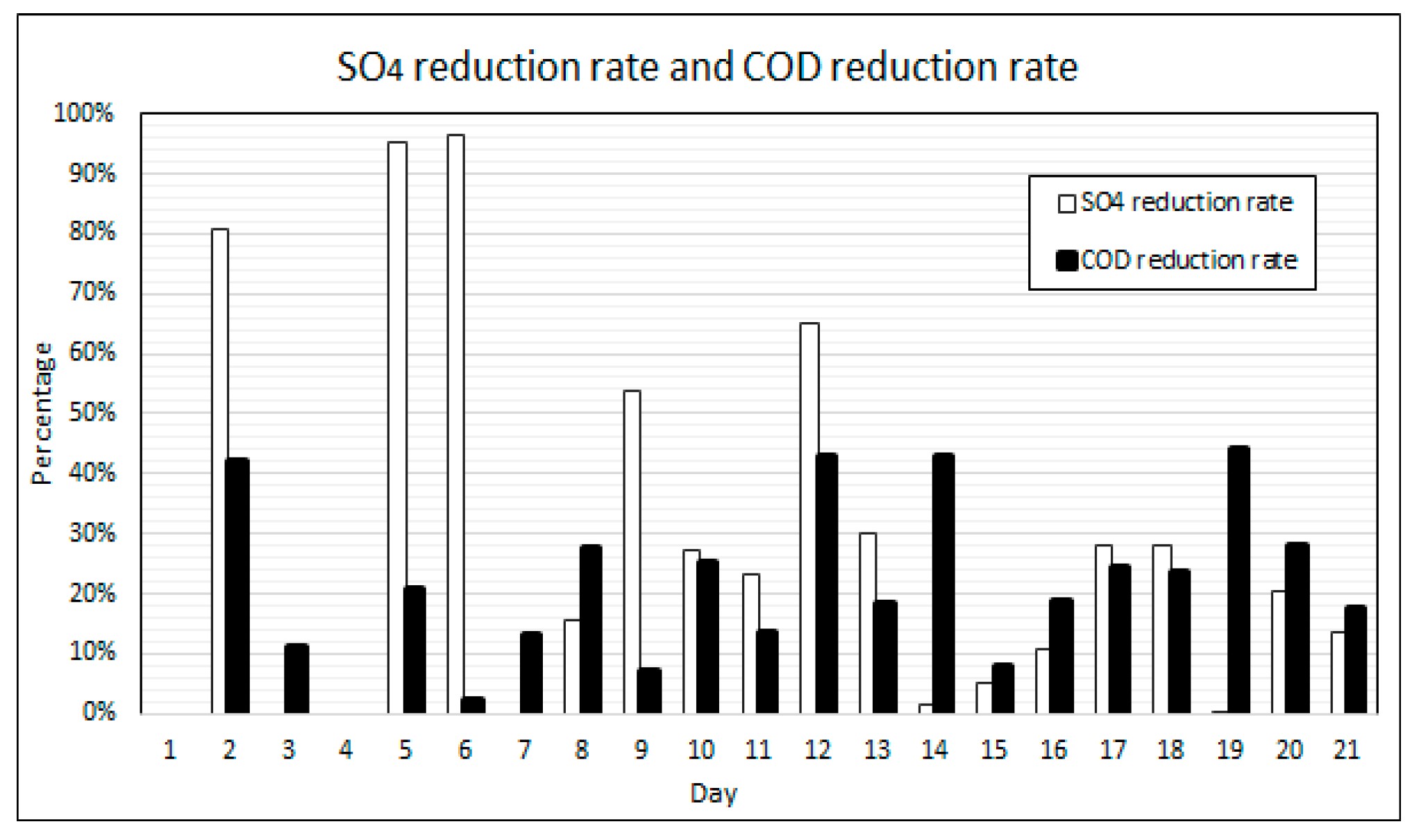

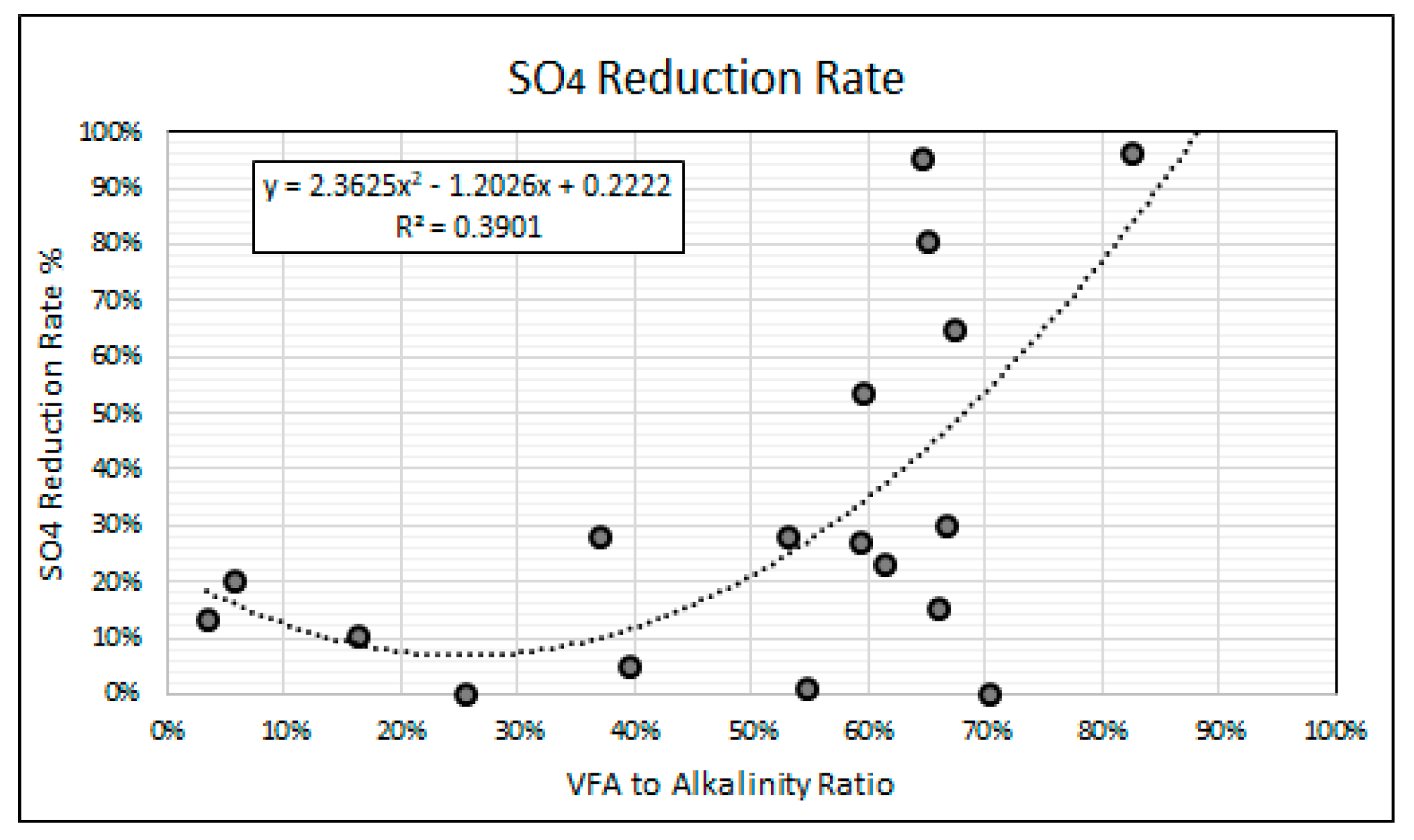

3.4. SO4 Reduction Results

3.5. Hydraulic Retention Time

3.6. Microscopic Results

4. Implications

5. Conclusions

- (I).

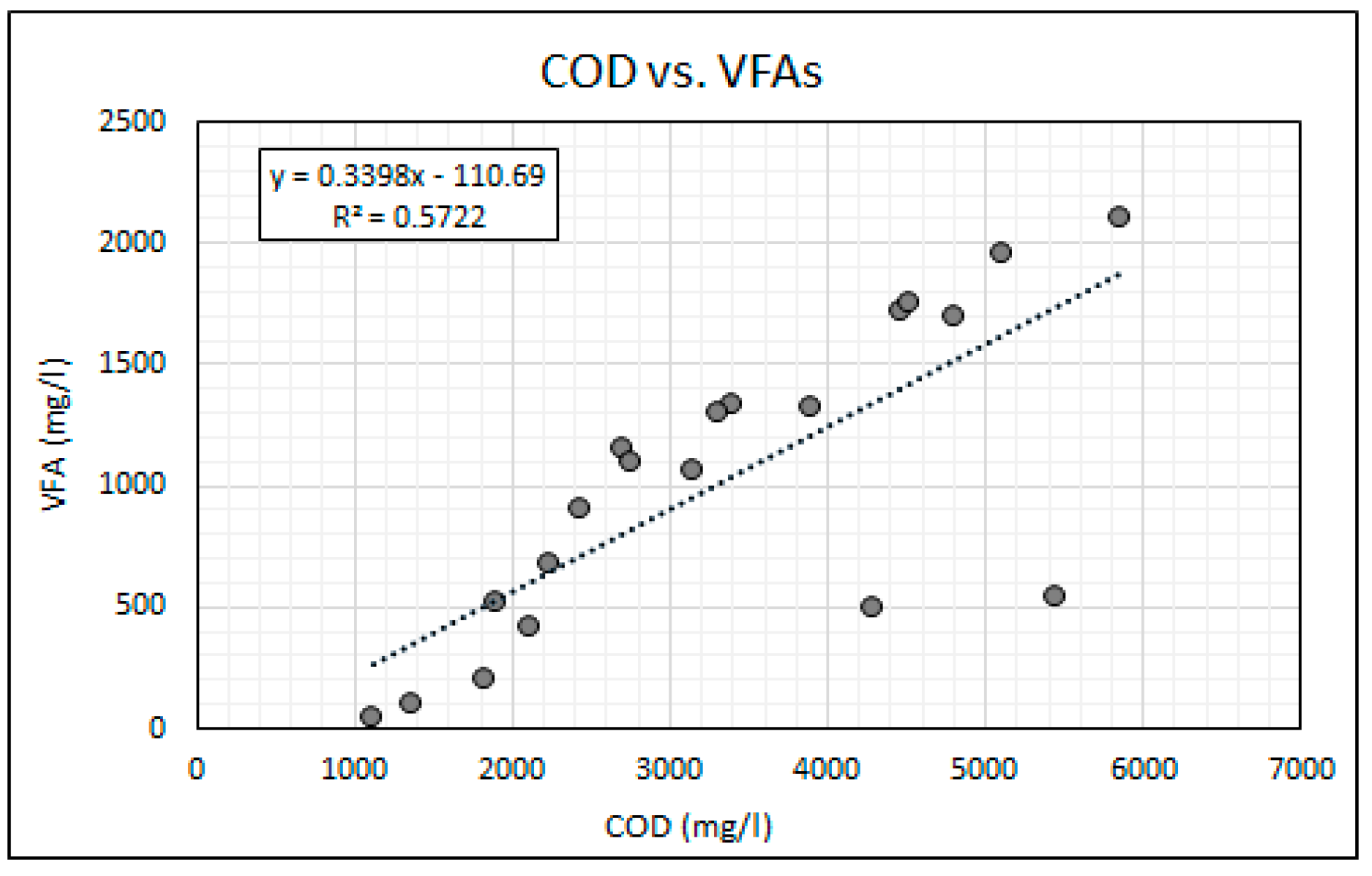

- The study found a statistically significant relationship between the availability of COD from simple organic matter and the generation of VFAs with a two-tail significance value (p value) of less than 0.01 and r value of 0.756. The research findings indicate that when using simple organic matter for biological SO4 reduction, the methanogenesis and sulphidogenic processes are rate limiting.

- (II).

- High SO4 reduction rates were achieved during the initial half of the experiment and it was found that the reduction rates were highly dependent on the availability of COD and the biological generation of VFAs. SO4 reduction rates ranging from 96% and 55% were achieved with VFA to alkalinity ratios above 0.6 and VFA concentrations exceeding 800 mg/L.

- (III).

- Pervious concrete as a fixed reactive medium was able to maintain the bioreactor pH between 6.5 and 7.5 upon process stability. The study findings indicate that the pH regulation performance of the pervious concrete medium is dependent on acidity loading rates and the volumetric design for buffering capacity. The self-regulation capabilities of pervious concrete can be a viable solution to reduce operational cost and operational complexity of AMD remediation bioreactors to promote viability of the process. Further investigation is required to assess the longevity of the pH regulation capabilities.

Author Contributions

Funding

Open Access Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Akcil, A.; Koldas, S. Acid Mine Drainage (AMD): Causes, treatment and case studies. J. Clean. Prod. 2006, 14, 1139–1145. [Google Scholar] [CrossRef]

- Johnson, B.D.; Hallberg, K.B. Acid Mine Drainage Remediation Options: A Review. Sci. Total Environ. 2005, 338, 3–14. [Google Scholar] [CrossRef]

- McCarthy, S. The Impact of Acid Mine Drainage in South Africa. S. Afr. J. Sci. 2011, 107, 1–7. [Google Scholar] [CrossRef]

- de Klerk, A.R.; Oberholster, P.J.; van Wyk, J.H.; Truter, J.C.; Schaefer, L.M.; Botha, A.M. The Effect of Rehabilitation Measures on Ecological Infrustructure in Response to Acid Mine Drainage from Coal Mining. Ecol. Eng. 2016, 95, 463–474. [Google Scholar] [CrossRef]

- Udayabhanu, G.; Prasad, B. Studies on environmental impact of acid mine drainage generation and its treatment: An appraisal. Indian J. Environ. Prot. 2010, 30, 953–967. [Google Scholar]

- Rose, P. Long-term sustainability in the management of acid mine drainage wastewaters–development of the Rhodes BioSURE Process. Water S. Afr. 2013, 39, 583–592. [Google Scholar] [CrossRef][Green Version]

- Thisani, S.K.; Kallon, D.V.V.; Byrne, P. Geochemical Classification of Global Mine Water Drainage. Sustainability 2020, 12, 10244. [Google Scholar] [CrossRef]

- Akinpelu, E.A.; Ntwampe, S.K.; Fosso-Kankeu, E.; Waanders, F. Comparative analysis of brewing wastewater and lactate as carbon sources for microbial community treating acid mine drainage in anaerobic MBBR systems. Environ. Technol. 2020, 1–8. Available online: https://www.tandfonline.com/doi/abs/10.1080/09593330.2020.1771431 (accessed on 3 June 2021). [CrossRef] [PubMed]

- Msagati, T.A.; Nkambule, T.I.; Kefeni, K.; Mamba, B. Synthesis and application of hematite nanoparticles for acid mine drainage treatment. J. Environ. Chem. Eng. 2018, 6, 1865–1874. [Google Scholar]

- Novhe, O.; Yibas, B.; Coetzee, H.; Atanasova, M.; Netshitungulwana, R.; Modiba, M.; Mashalane, T. Long-Term Remediation of Acid Mine Drainage from Abandoned Coal Mine Using Integrated (Anaerobic and Aerobic) Passive Treatment System, in South Africa: A Pilot Study. In Proceedings of the International Mine Water Association, Leipzig, Germany, 11–15 July 2016; pp. 668–674. [Google Scholar]

- Sun, R.; Li, Y.; Lin, N.; Ou, C.; Wang, X.; Zhang, L.; Jiang, F. Removal of heavy metals using a novel sulfidogenic AMD treatment system with sulfur reduction: Configuration, performance, critical parameters and economic analysis. Environ. Int. 2020, 136, 105457. [Google Scholar] [CrossRef]

- Janssen, A.J.; Ruitenberg, R.; Buisman, C.J. Industrial applications of new sulphur biotechnology. Water Sci. Technol. 2001, 44, 85–90. [Google Scholar] [CrossRef]

- Sanchez-Andrea, I.; Sanz, J.L.; Bijimans, M.F.; Stams, A.J. Sulfate reduction at low pH to remediate acid mine drainage. J. Hazard. Mater. 2014, 269, 98–109. [Google Scholar] [CrossRef]

- Neda, A.; Whittington-Jones, K.; Rose, P.D. Salinity, Sanitation and Sustainability Vol. 4: The Rhodes BioSURE Process; Water Research Commission: Pretoria, South Africa, 2007. [Google Scholar]

- Pionapen, J.; Wentzel, M.C.; Ekama, G.A. Biological sulphate reduction with primary sewage sludge in an upflow anaerobic sludge bed (UASB) reactor-Part 1: Feasibility study. Water SA 2009, 35, 525–534. [Google Scholar] [CrossRef]

- Foucher, S.; Battaglia-Brunet, F.; Ignatiadis, I.; Morin, D. Treatment by sulfate reducing bacteria of Chessy acid mine drainage and metal recovery. Chem. Eng. Sci. 2001, 56, 1639–1645. [Google Scholar] [CrossRef]

- Isa, Z.; Grusenmeyer, S.; Verstraete, W. Sulphate reduction relative to methane production in high rate anaerobic digestion: Microbiological aspects. Appl. Environ. Microbiol. 1986, 51, 580–587. [Google Scholar] [CrossRef]

- Papirio, S.; Villa-Gomez, D.K.; Esposito, G.; Pirozzi, F.; Lens, P.N. Acid Mine Drainage Treatment in Fluidized Bed Bioreactors by Sulfate Reducing Bacteria: A Critical Review. Crit. Rev. Environ. Sci. Technol. 2013, 43, 2545–2580. [Google Scholar] [CrossRef]

- Visser, A. The Anaerobic Treatment of Sulphate Containing Wastewater. Ph.D. Thesis, Wageningen Agricultural University, Wageningen, The Netherlands, 1995. [Google Scholar]

- Opollo, S.O. Integrated Anaerobic Digestion and UV Photocatalytic Treatment of Industrial Wastewater in Fluidized Bed Reactors. Ph.D. Thesis, Vaal University of Technology, Vanderbjilpark, South Africa, 2016. [Google Scholar]

- Gerardi, M.H. Wastewater Bacteria; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Yang, P.Y.; Wang, M.L.; Viraraghaven, T. Biotechnology applications in wastewater treatment. Environ. Sanit. Rev. 1990, 29, 88. [Google Scholar]

- Archarya, B.K.; Mohana, S.; Madamwar, D. Anaerobic treatment of distillery spent wash-a study on upflow anaerobic fixed film bioreactor. Bioresour. Technol. 2008, 99, 621–4626. [Google Scholar]

- Kaksonen, A.H.; Sahinhaya, E. Review of sulfate reduction based bioprocesses for acid mine drainage treatment and metals recovery. Eng. Life Sci. 2007, 7, 541–564. [Google Scholar] [CrossRef]

- Shabalala, A.N.; Ekolu, S.O.; Diop, S.; Solomon, F. Pervious concrete reactive barrier for removal of heavy metals from acid mine drainage-column study. J. Hazard. Mater. 2017, 353, 641–653. [Google Scholar]

- Waybrant, K.R.; Blowes, D.W.; Ptacek, C.J. Selection of Reactive Mixtures for use in Permeable Reactive Walls for Treatment of Mine Drainage. Environ. Sci. Technol. 1998, 32, 1972–1979. [Google Scholar] [CrossRef]

- Klemps, R.; Cypionka, H.; Widdel, F.; Pfennig, N. Growth with hydrogen, and further physiological characteristics of Desulfotomaculum species. Arch. Microbiol. 1985, 142, 203–208. [Google Scholar] [CrossRef]

- McCauley, C.A.; O’Sullivan, A.D.; Milke, M.W.; Weber, P.A.; Trumm, D.A. Sulfate and metal removal in bioreactors treating acid mine drainage dominated with iron and aluminum. Water Res. 2009, 43, 961–970. [Google Scholar] [CrossRef]

- Cement & Concrete Institute. Cementitious Material for Concrete Standards, Selection and Properties; Cement & Concrete Institute: Midrand, South Africa, 2009. [Google Scholar]

- Ekolu, S.O.; Azane, F.Z.; Diop, S. A concrete reactive barrier for acid mine drainage treatment. Proc. Inst. Civ. Eng. Water Manag. 2014, 167, 373–380. [Google Scholar] [CrossRef]

- Mafanya, L.; Kallon, D.V.V. A Contribution to the Debate on the Problem of Acid Mine Drainage in South Africa. SAIIE31 2020, 718–729. [Google Scholar]

- Mafanya, L.; Kallon, D.V.V.; Simelane, S.P. Flow Properties Upon Treatment of Acid Mine Drainage Using Pervious Concrete Slabs SAIIE NeXXXt 2019, 399–403. Available online: https://conferences.sun.ac.za/index.php/SAIIENeXXXt/SAIIENeXXXt/paper/viewFile/4299/611 (accessed on 3 June 2021).

- Alam, T. Estimatation of Chemical Oxygen Demand in Wastewater Using UV-VIS Spectroscopy; Simon Fraser University: Burnaby, BC, Canada, 2015. [Google Scholar]

- Mafanya, L.; Kallon, D.V.V.; Simelane, S.P. Chemical Analysisi of AMD Properties Based on Factorial Method. Open Innov. 2019, 399–403. [Google Scholar]

- Rambabu, K.; Banat, F.; Pham, Q.M.; Ho, S.H.; Ren, N.Q.; Show, P.L. Biological Remediation of Acid Mine Drainage: Review of Past Trends and Current Outlook. Environ. Sci. Ecotechnol. 2020, 2, 100024. Available online: https://www.researchgate.net/publication/340030074_Biological_Remediation_of_Acid_Mine_Drainage_Review_of_Past_Trends_and_Current_Outlook (accessed on 3 June 2021).

- Widdel, F. Microbiology and Ecology of Sulphate- and Sulphur-Reducing Bacteria; Wiley: New York, NY, USA, 1988; pp. 456–486. [Google Scholar]

- Widdel, F.; Bak, F. Gram-Negative Mesophilic Sulfate-Reducing Bacteria. In The Prokaryotes, 2nd ed.; Springer: New Year, NY, USA, 1992; pp. 3352–3378. [Google Scholar]

- Sánchez, E.; Borja, R.; Travieso, L.; Martın, A.; Colmenarejo, M.F. Effect of organic loading rate on the stability, operational parameters and performance of a secondary upflow anaerobic sludge bed reactor treating piggery waste. Bioresour. Technol. 2005, 3, 335–344. [Google Scholar] [CrossRef]

- Wang, L.H.; Wang, Q.; Cai, W.; Sun, X. Influence of mixing proportion on the solid-state anaerobic co-digestion of distiller’s grains and food waste. Biosyst. Eng. 2012, 112, 130–137. [Google Scholar] [CrossRef]

- Gilbert, O.; de Pablo, J.; Cortina, J.L.; Ayora, C. Chemical characterization of natural organic substrates for biological mitigation of acid mine drainage. Water Res. 2004, 38, 4186–4196. [Google Scholar] [CrossRef] [PubMed]

- Ganidi, N.; Tyrrel, S.; Cartmell, E. Anaerobic digestion foaming causes-a review. Bioresour. Technol. 2009, 100, 5546–5554. [Google Scholar] [CrossRef]

- Pilarska, A.A. Anaerobic Co-Digestion of Waste Wafers from Confectionery Production with Sewage Sludge. Pol. J. Environ. Stud. 2018, 27, 237–245. [Google Scholar] [CrossRef]

| Determinand | Concentration | Units |

|---|---|---|

| Sulphate (SO4) | 2232 | mg/L |

| Total Suspended Solids (TSS) | <3 | mg/L |

| Calcium (Ca) | 568 | mg/L |

| Sodium (Na) | 228 | mg/L |

| Ferrous Iron (Fe2+) | 40,783 | µg/L |

| Manganese (Mn) | 11,124 | µg/L |

| Magnesium (Mg) | 402 | mg/L |

| Aluminium (Al) | 76,587 | µg/L |

| Potassium (K) | 7.59 | mg/L |

| Copper (Cu) | 1.02 | µg/L |

| Zinc (Zn) | 84 | µg/L |

| Boron (B) | 51 | µg/L |

| Nickel (Ni) | 54 | µg/L |

| Lead (Pb) | 3.05 | µg/L |

| pH | 2.7 | - |

| Turbidity | 0.9 | NTU |

| Cube Description | Mix Proportion (dry)—Kg per m3 | % Extender | Porosity | ||||||

|---|---|---|---|---|---|---|---|---|---|

| CEM 1 | Fly Ash | Silica Fume | 9.5 mm Granite | 13.2 mm Granite | Optima 175 | Water | |||

| Fixed Bed AD | 152 | 14 | 7 | - | 1468 | 1.35 | 60 | 12.1% | 33.2% |

| Pre-treatment | 197 | 18 | 9 | 1462 | - | 1.75 | 75 | 12.1% | 21.5% |

| Ramp-Up Cycle Number | Experiment Duration (Hours) | AMD Ramp-Up Volume (ml) | SO4 Loading Rate (kgSO4/m3/day) | Glucose Addition (mg) | Glucose Loading Rate (kg/m3/day) | Glucose to SO4 Loading Ratio |

|---|---|---|---|---|---|---|

| 1 | 0 | 30 | 0.015 | 5000 | 1.22 | 82.63 |

| 24 | - | - | - | - | - | |

| 2 | 48 | 45 | 0.022 | 2000 | 0.49 | 22.14 |

| 72 | - | - | - | - | - | |

| 3 | 96 | 200 | 0.098 | 10,000 | 2.44 | 24.91 |

| 120 | - | - | - | - | - | |

| 4 | 144 | 400 | 0.196 | 6000 | 1.47 | 7.474 |

| 168 | - | - | - | - | - | |

| 5 | 192 | 700 | 0.343 | 6000 | 1.47 | 4.271 |

| 216 | - | - | - | - | - | |

| 6 | 240 | 1200 | 0.589 | 8000 | 1.75 | 2.549 |

| 264 | - | - | - | - | - | |

| 7 | 288 | 1400 | 0.687 | 6000 | 1.47 | 2.491 |

| 312 | - | - | - | - | - | |

| 336 | - | - | - | - | - | |

| 8 | 360 | 2007 | 0.785 | 7000 | 1.71 | 2.18 |

| 384 | - | - | - | - | - | |

| 9 | 408 | 2400 | 1.104 | 6000 | 1.19 | 1.076 |

| 432 | - | - | - | - | - | |

| 456 | - | - | - | - | - | |

| 480 | - | - | - | - | - |

| AMD Source | SO4 (mg/L) | Ca (mg/L) | Na (mg/L) | Fe (mg/L) | Mn (mg/L) | Mg (mg/L) | Al (mg/L) | K (mg/L) | pH | Turbidity (NTU) |

|---|---|---|---|---|---|---|---|---|---|---|

| Raw AMD | 2232 | 568 | 228 | 40.783 | 11.124 | 402 | 76.587 | 7.59 | 2.7 | 0.9 |

| Pre-treated AMD | 2007 | 621 | 188 | <0.1 | 12.2 | 310 | 13.2 | 32.9 | 4.3 | <1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thisani, S.K.; Kallon, D.V.V.; Byrne, P. A Fixed Bed Pervious Concrete Anaerobic Bioreactor for Biological Sulphate Remediation of Acid Mine Drainage Using Simple Organic Matter. Sustainability 2021, 13, 6529. https://doi.org/10.3390/su13126529

Thisani SK, Kallon DVV, Byrne P. A Fixed Bed Pervious Concrete Anaerobic Bioreactor for Biological Sulphate Remediation of Acid Mine Drainage Using Simple Organic Matter. Sustainability. 2021; 13(12):6529. https://doi.org/10.3390/su13126529

Chicago/Turabian StyleThisani, Sandisiwe Khanyisa, Daramy Vandi Von Kallon, and Patrick Byrne. 2021. "A Fixed Bed Pervious Concrete Anaerobic Bioreactor for Biological Sulphate Remediation of Acid Mine Drainage Using Simple Organic Matter" Sustainability 13, no. 12: 6529. https://doi.org/10.3390/su13126529

APA StyleThisani, S. K., Kallon, D. V. V., & Byrne, P. (2021). A Fixed Bed Pervious Concrete Anaerobic Bioreactor for Biological Sulphate Remediation of Acid Mine Drainage Using Simple Organic Matter. Sustainability, 13(12), 6529. https://doi.org/10.3390/su13126529