Circular Digital Built Environment: An Emerging Framework

Abstract

1. Introduction

- Narrowing the loop: using fewer resources through efficiencies in the production and design process.

- Slowing the loop: using and consuming less, through long product life, product life extension and avoiding unnecessary consumption.

- Closing the loop: reusing materials, or post-consumer recycling.

- Regenerating the loop: focusing on leaving the environment (and society) in a better state than before, e.g., by improving biodiversity.

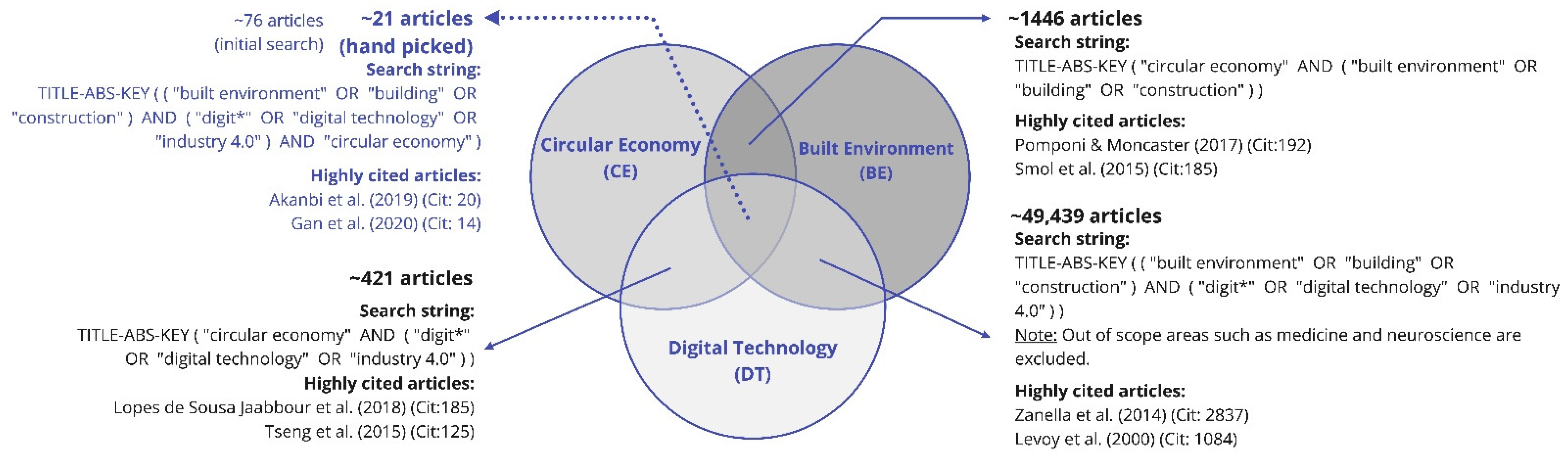

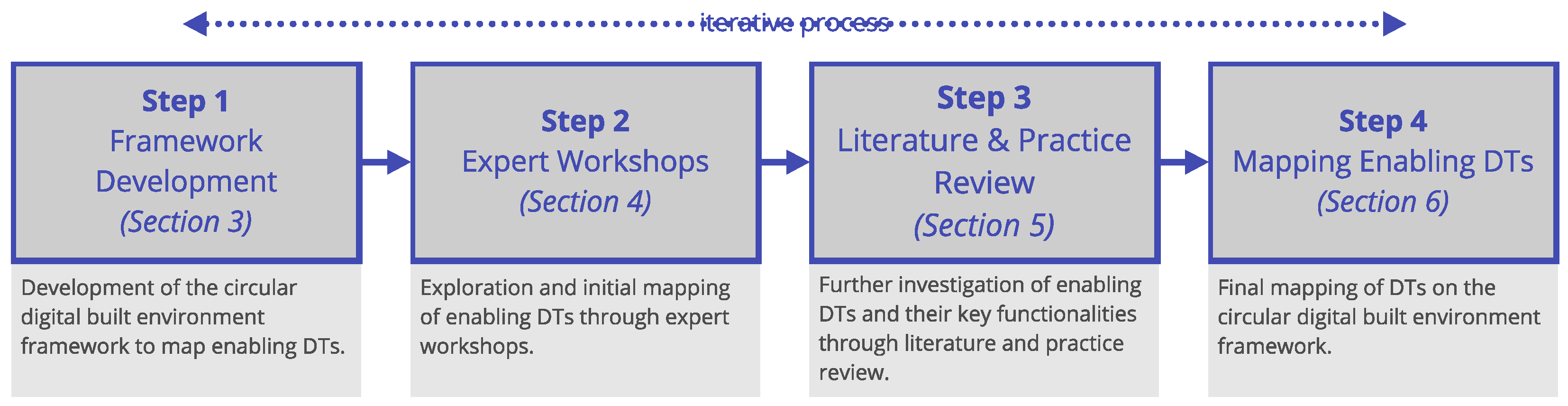

2. Research Design and Methods

2.1. Step 1—Framework Development

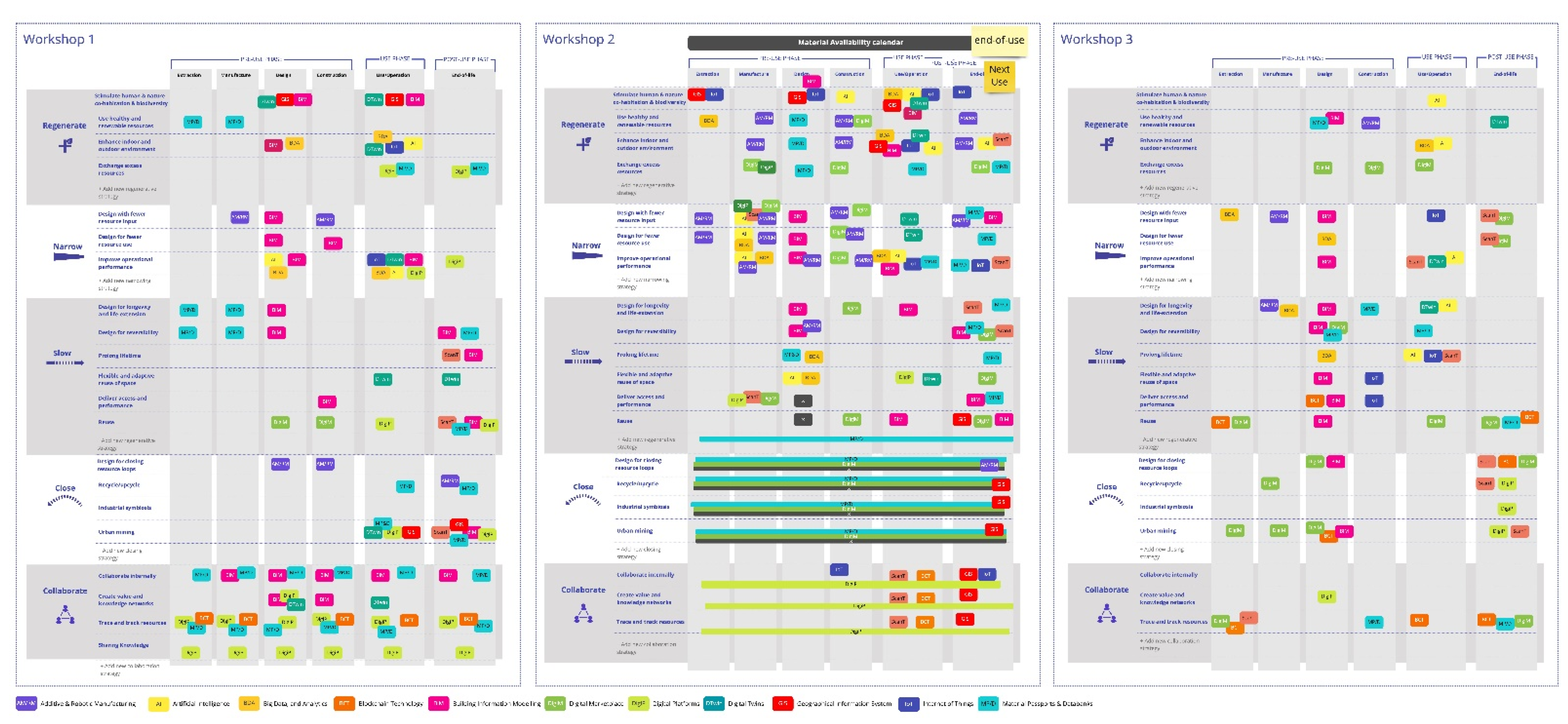

2.2. Step 2—Expert Workshops

- Introduction [10 min]: Upon welcoming the participants, the primary researcher briefly introduces the workshop’s goal and explains the main elements of the CDB framework. The participants are allowed to add notes and suggest new circular building strategies or enabling DTs.

- Questions and Discussion [45 min]: The researcher poses a set of questions: “What DTs can enable CE in the BE? Where would you place them on the framework?” and initiates discussions when needed.

- Closing [5 min]: The researcher receives feedback from the participants and closes the session.

2.3. Step 3—Literature and Practice Review

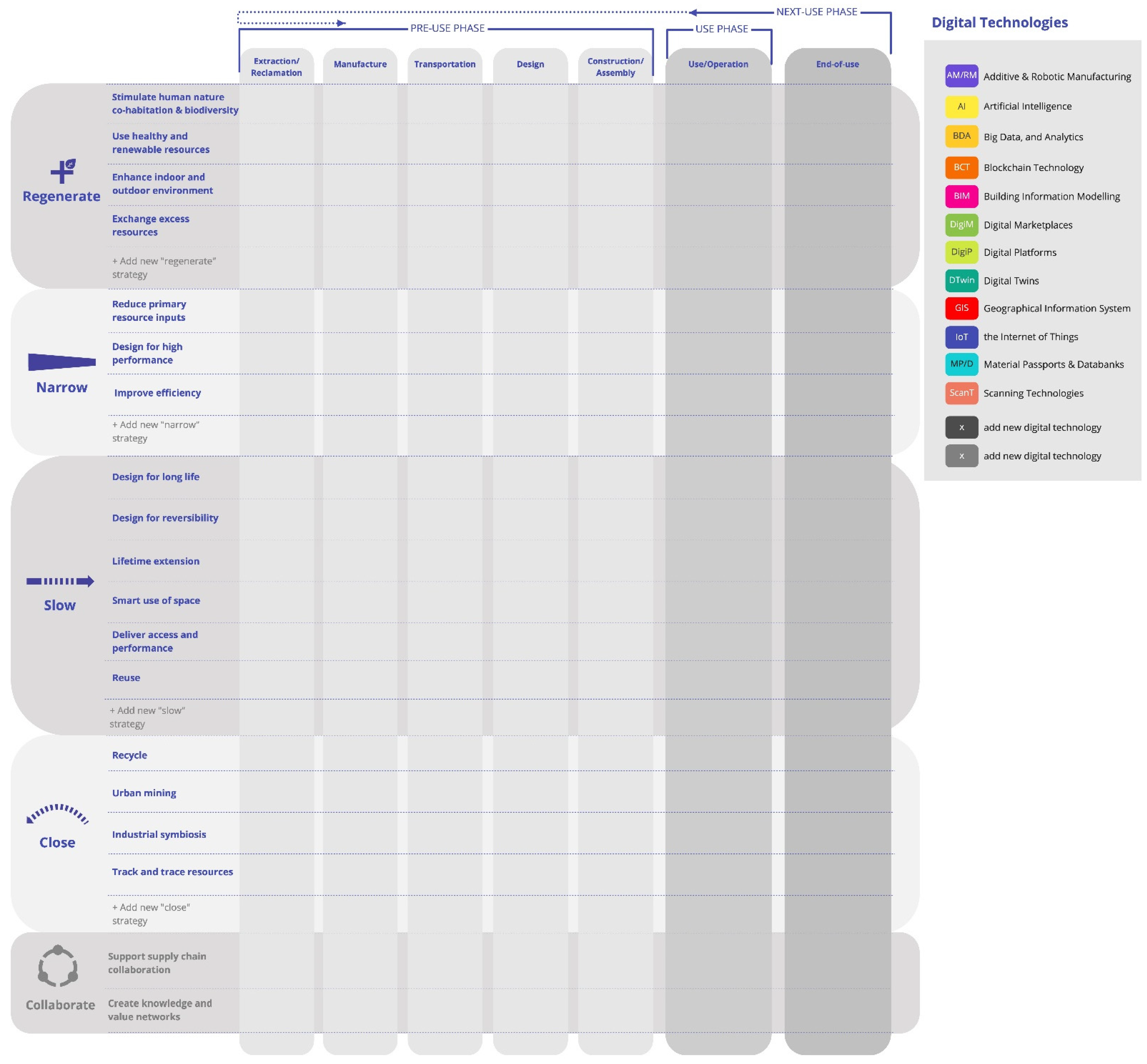

2.4. Step 4—Mapping of Enabling Digital Technologies

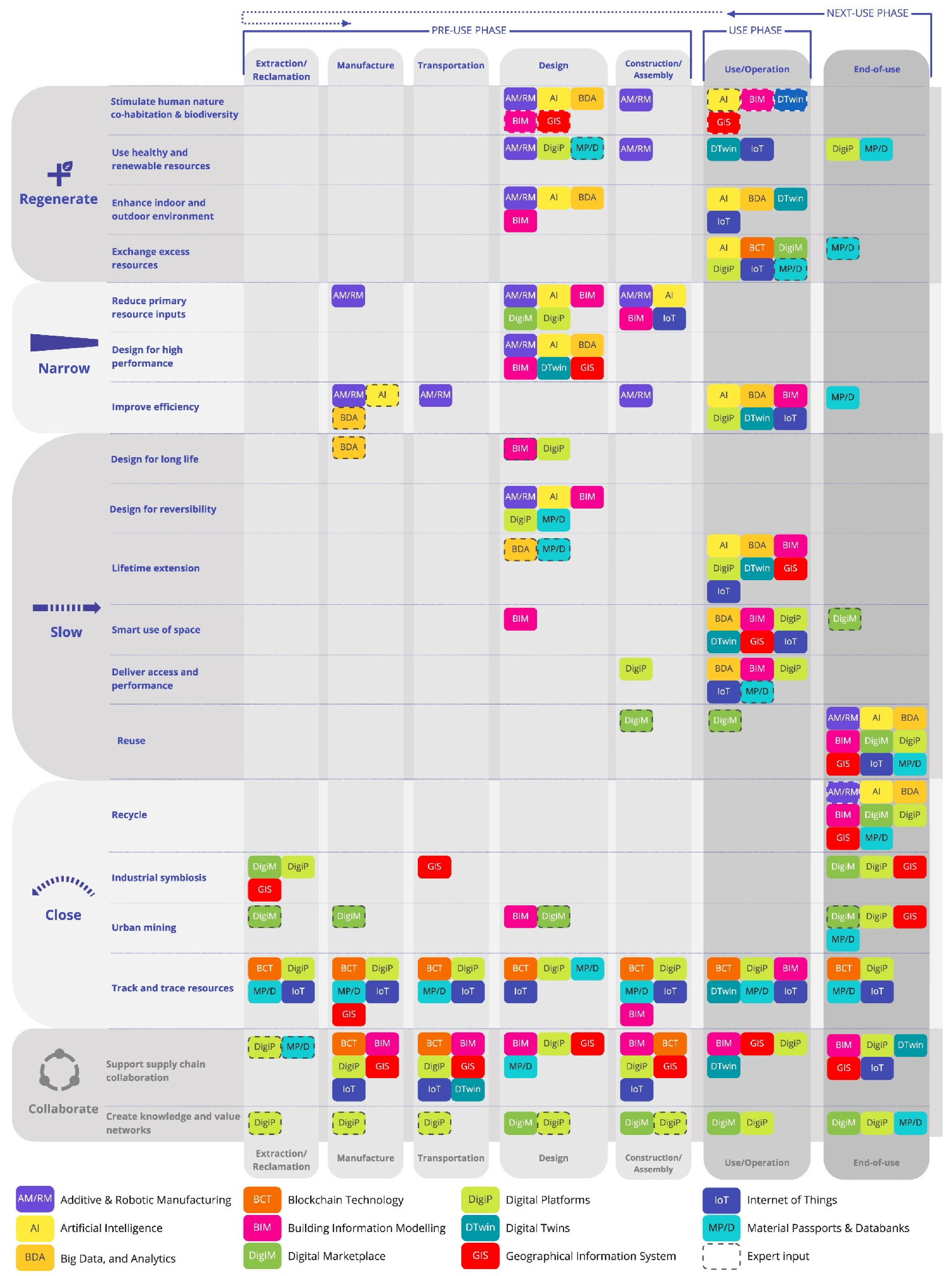

3. Framework Development

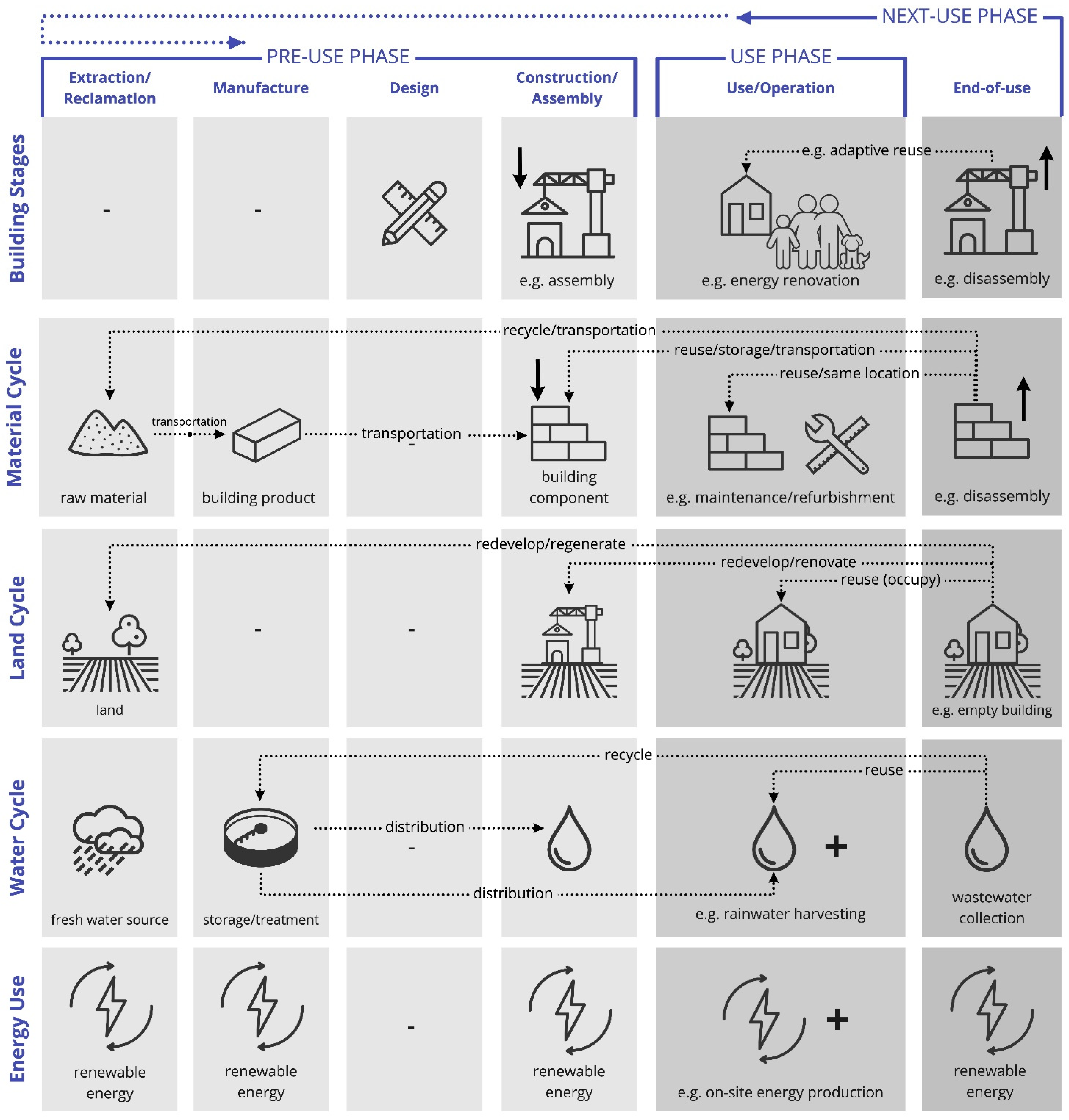

3.1. Life Cycle Stages

3.2. Circular Building Strategies

3.2.1. Regenerate

- “Stimulate human nature co-habitation and local biodiversity”: This is the creation of shared spaces where humans interact with each other and with nature, accommodating green space and promoting biodiversity [78,82,83]. Examples include urban farming [84] and green roof ecosystems [85]. A real-life project is Resilio [86], which implements blue-green roofs in Amsterdam.

- “Use healthy and renewable resources”: This strategy consists in avoiding hazardous contents in building products [78]; using bio-based renewable building materials, for instance, using mycelium (the vegetative structure of fungi) to produce building components [87]; and producing with renewable energy [18]. For example, the British start-up Biohm is producing insulation panels from mycelium [88].

- “Enhance the indoor and outdoor environment”: This strategy includes providing high-quality healthy spaces for people in terms of lighting, air and place organisation [78,83], and enhancing outdoor space, i.e., public and urban areas. An example is the transformation of misused or unused areas (wastescapes) into public spaces for local communities [68].

- “Exchange excess resources”: This strategy includes capturing economic value from regenerative building operation. Positive buildings are equipped with advanced technologies that allow them to share surplus resources with their surroundings (energy, water, food and others) [82]. Particularly for energy, the recent years have seen tremendous advancements in smart grid technology that allow prosumers (consumers who also produce and sell energy) to trade surplus energy within their neighbourhoods [89]. An example is Pando [90], a platform that empowers users to buy and receive local renewable energy within their neighbourhoods through a mobile application.

3.2.2. Narrow

- “Reduce primary resource inputs”: This strategy is based on the dematerialisation approach [74,91]; it aims to minimise the primary resource inputs in buildings and building products. Some examples include optimising lightweight structures [92], using renewable energy in production, designing water circulation systems for sanitary hot water [66], and avoiding extra rooms in the space planning by assessing their added functions [75], i.e., avoiding the second bathroom. Designing from reuse rather than with new materials is also another way to reduce primary resource inputs.

- “Design for high performance”: This design strategy aims to optimise the building performance for fewer resource consumption before, during and after the use phase of buildings. For instance, by considering building characteristics such as geometry, the site, materials, and orientation, design optimisation provides considerable energy savings during the operational phase [69,93]; by optimising the transportation distance, resource consumption could be reduced during the construction and end-of-use stages.

- “Improve efficiency”: This strategy includes enhancing the pre-use, operational, and next-use phase activities for lower resource consumption, such as improving manufacturing systems for high performance, introducing rainwater collection systems in existing buildings or upgrading the building facade for higher energy performance. For example, the Rennovates project implemented a technology-based renovation concept in 249 old single-family houses and upgraded their energy performance to the zero-energy level [94].

3.2.3. Slow

- “Design for long life”: Originally introduced for short-lived consumer products, e.g., mobile phones [17], design for long-life aims to extend the utilisation period of buildings and building products. This can be achieved by creating an emotional connection with users [17], increasing the physical durability of building components [60], and considering the ease and frequency of maintenance work during the design phase [95], i.e., considering easy access to technical building services [60].

- “Design for reversibility”: Reversible building design incorporates several design strategies that enable multiple resource life cycles until resources become irreversible. The circulation of resources occurs on the spatial, structural and material levels, and it has two main domains [59]: (1) spatial reversibility refers to the ability to functionally transform spaces without causing significant resource consumption, e.g., transforming an office into a classroom, while (2) technical reversibility addresses how structural and material arrangements are made to allow the reuse of building parts in the future, e.g., designing interlocking connections between components so that they can be easily dismantled [59]. The set of strategies that enable reversibility include design for disassembly, design for reuse, modular design, flexible design, adaptable design, design for standardisation, design for upgrades and adjustment, prefabrication, and off-site construction. An example of a reversible building design is the UMAR (Urban Mining and Recycling) project built for disassembly in Switzerland [96].

- “Smart use of space”: The main purpose of flexibility and adaptive reuse strategies is to capture value from the existing buildings or land by introducing new functions; otherwise, they will remain underutilised and lose value. These strategies might exist in different forms, including the transformation of vacant office spaces into housing units [97]; the modification of the building lay-out for a different function [59]; the retrofitting, rehabilitation and redevelopment of cultural heritage buildings [98]; building modular buildings temporarily on a vacant land [99]; and the short-term utilisation of empty spaces through lease agreements [99]. An example is Workfrom, an online platform that lists available cafes, co-working spots and alternative spaces for users, making use of under-occupied spaces in cities [100].

- “Deliver access and performance”, or, more broadly, Product-Service Systems: This business model strategy is focused on providing services instead of the ownership of products [17,30]. This could be achieved in three ways: (1) the customer receives services based on time use (use-oriented), (2) the customer pays for a contractually-set performance or outcome (result-oriented), (3) the customer keeps the ownership of the product but receives high warranty and maintenance services (product-oriented) [30,101]. (NB: the latter is an example of a Product-Service-System where the product is still owned). Examples include co-working spaces which provide workplaces for enterprises as a service, or Signify’s pay-per-lux model for lighting [102].

- “Reuse”: Reuse is concerned with reintroducing buildings and resources back into the system without needing major transformation and resource consumption. Reuse may occur in the same or a different location, and the function of the product may remain or change [27]. Strategies such as ‘reduce primary resource inputs’, ‘design for reversibility’, ‘smart use of space’ and ‘urban mining’ are partially built on reuse. Reuse as a separate strategy can also go beyond these strategies, e.g., reusing greywater in buildings [66] or reusing old window frames to construct an indoor partition in the same place during a façade renovation.

3.2.4. Close

- “Recycle”: Recycling is concerned with remanufacturing resources into equivalent or lower-value resources, and usually requires energy and water for the processes (e.g., glass melting) [27]. This strategy has been dominantly used in BE for treating construction and demolition waste, e.g., recycling concrete aggregates [103]

- “Urban mining”: Heisel and Rau-Oberhuber define urban mining as “the re-activation of materials accumulated in the urban environment, which were not specifically designed for re-use or recycling (thus mining)” ([96], p. 2). The process requires the identification, quantification, and mapping of materials in cities and determining their recycling potential [104]. Urban mining in practice can be seen in the Dutch city of Rotterdam, which has the goal of reducing primary resource use by 50% before 2030 [105]. The municipality of Rotterdam identified and mapped buildings that are scheduled to be demolished in order to harvest materials in the future [105].

- “Industrial symbiosis”: Industrial symbiosis is a concept to benefit from the waste or by-products of different industries by building collaboration and synergetic interactions [106]. For example, researchers demonstrated an industrial symbiosis model between a recycling factory and a concrete production factory based on recycled concrete aggregates [106].

- “Track and trace resources”: Tracking and tracing resources throughout the lifetime of buildings enables us to capture embodied value when they reach their end-of-use phase.

3.2.5. Collaborate (Supporting Strategy)

- Support supply chain collaboration: The first level of collaboration may occur at the level of single materials and technologies and reverse logistics, e.g., to reclaim building materials in a demolition project, or to implement a new technology [107] in a new-built project to increase energy efficiency. This can be done mainly within the existing supply chain network without too much disruption.

- Create knowledge and value networks: The more transformative CE projects start with an ambitious vision of the future [61,107] that may require different types of partners to regenerate, narrow, slow, and close the loops. These partners would share the same vision, bring in new experience, and also support the creation of a new circular ecosystem. A wider sector-engagement is also needed for a broader transition in the sector [107], and there is evidence for such engagement already. For example, a buyer group initiative was established by the contracting authorities in the public and private sector to stimulate circular procurement in the Netherlands [108].

3.3. Circular Digital Built Environment Framework (CDB Framework)

4. Workshop Findings

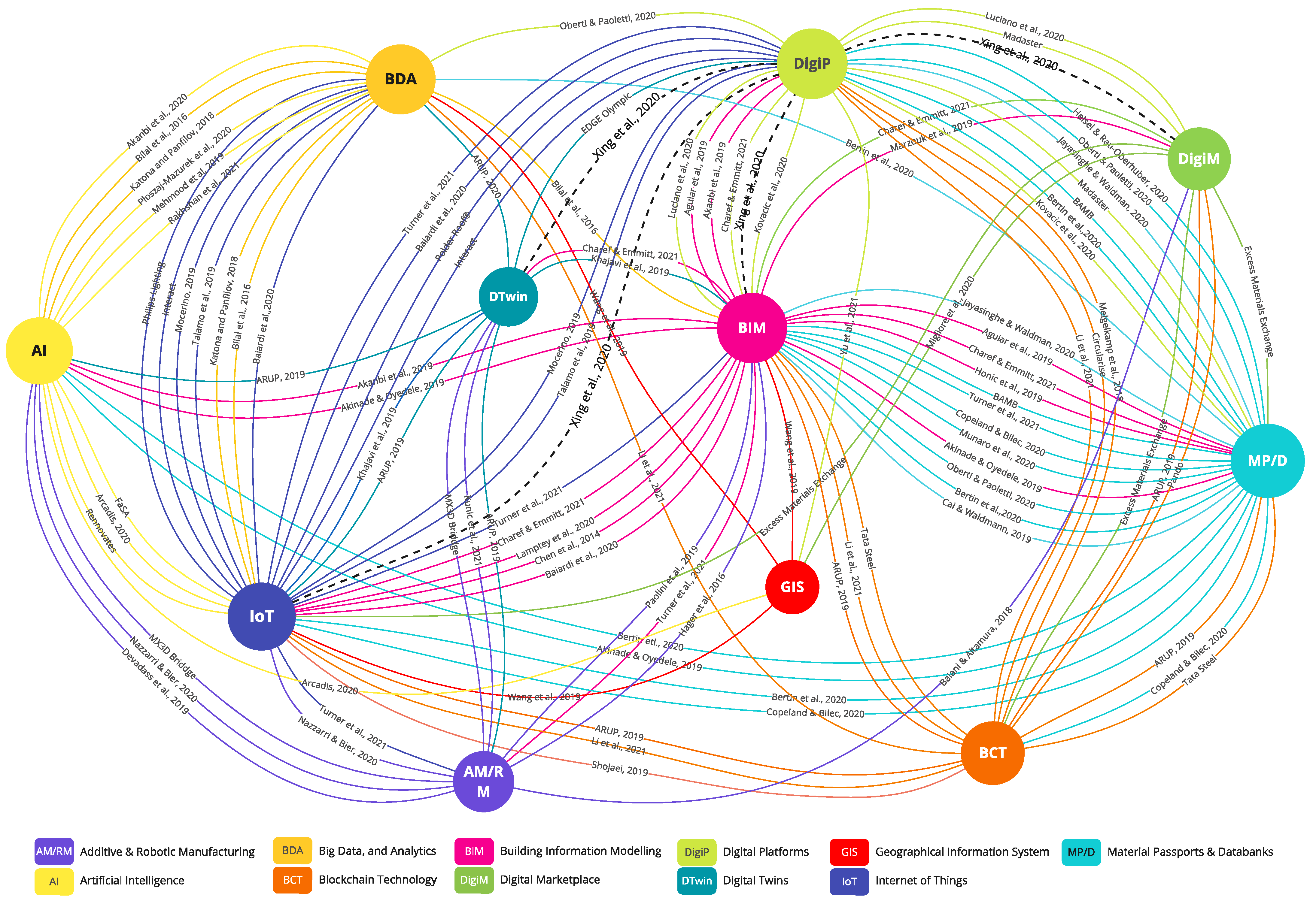

5. Enabling Digital Technologies for a Circular Built Environment

5.1. Additive and Robotic Manufacturing (AM/RM)

- First of all, 3D printing with, e.g., concrete can be used to reduce resource use and waste through design optimization [118,119,120] and can minimise transportation distance [120,121]. AM/RM from, e.g., lightweight PET material fibre enables both lightweight building structures and the use of recycled materials [122]. Researchers demonstrated the potential energy saving of the digital fabrication of a wall or floor component [123,124]. An example from real-life practice is the design of a 3D printed steel bridge that used a software to generate the most material-efficient shape [125].

- AM/RM also allows designers to tailor connection pieces for the reuse of truss and frame elements [128]. The modular design of printed structures enables the reuse of building parts at the end-of-life stage [120]. Digital deconstruction is also being researched, e.g., reversible timber beams can be robotically manufactured and disassembled [129]. Digital reuse is gaining attention in general [130].

5.2. Artificial Intelligence (AI)

- With design optimisation, designers aim to find the perfect solution for predefined performance criteria. Data-driven approaches, such as neural networks (a subset of Machine Learning), provide advanced solutions for the generation of multiple design alternatives and the selection of the most optimal design solution [69,137]. For example, researchers developed and tested a machine learning model to support architects during the early design phase, which can predict the total carbon footprint of regenerative building design alternatives [138].

- Combined with other technologies such as big data and IoT, AI techniques and algorithms provide capabilities to predict defects in systems and determine resource needs in buildings. For the former, for example, computer vision detection models reinforced with deep learning techniques are used to detect the state of an asset, learn from past data and predict future failures [137], and for the latter, researchers highlight the capabilities of machine learning algorithms for the prediction of the energy demand of buildings [139]. An example from practice is the FaSA project (Façade Service Application) [140]. The FaSA application maps the current state of buildings and predicts the maintenance requirements of the façade elements with the help of AI, drone and sensor technologies [140].

- AI techniques are also believed to be useful for end-use phase activities. Akanbi et al. [141] developed deep learning models based on national demolition records to predict the amount of recyclable, reusable and waste materials generated from deconstruction and demolition projects [141]. Rakhshan et al. [142] proposed a predictive model using machine learning techniques to estimate and evaluate the economic reusability of structural elements. Furthermore, Davis et al. [143] designed an on-site waste classification system using a deep learning method that can classify different categories of waste based on digital photographs taken from construction site bins. Similarly, other researchers also used deep learning-based image analysis to obtain the composition details of recycled aggregates in order to improve recycling performance [144].

5.3. Big Data, and Analytics (BDA)

- Big data are used to train machine learning algorithms for designing low carbon regenerative buildings [138], supporting generative design tools [148], and assisting decision making in design processes [30]. Moreover, data mining techniques are employed for the improvement of buildings’ energy performance [149] during the operational phase, leading to the lower use of resources.

- As highlighted by [30], BDA might play a vital role to prolong the lifespan of the products by providing insights into sustainability-oriented decision making during the operational phase. For example, Katona and Panfilov [150] designed and tested a smart maintenance framework on a real-life heating, ventilation and air conditioning unit to detect and prevent failure with the help of sensing technologies and BDA.

- Finally, as we will explain in Section 5.10, together with IoT, BDA are seen as being essential in realizing smart buildings and cities [151].

5.4. Blockchain Technology (BCT)

- From a CE perspective, BCT is considered to be an enabling technology, particularly for the management of complex information networks in supply chain management [155,156]. In a sector that is characterized by low productivity and a fragmented supply chain [38], BCT might offer opportunities to leverage efficiency and transparency to maintain the value of resources along their lifecycle. Li et al. [53] proposed a smart product-service system for prefabricated housing production based on IoT and blockchain technologies. A blockchain system was employed to control the cash flow autonomously through smart contracts, and to perform data exchange between relevant stakeholders acting as a shared database [53]. Another example from the practice is Circularise [157], a start-up operating a blockchain information exchange platform to enable circular value chains, which protects the competitive advantage of companies while sharing necessary information with relevant stakeholders [158].

- According to the literature and practice review of Böckel et al. [155], the most frequently mentioned use case of BCT in CE is enabling material passports, because the technology offers the transparency and reliability of data flows across the supply chain network [159], from extraction until end-of-use phase, and further in subsequent use cycles. For example, Tata Steel [160], one of the largest steel-producing companies globally, has piloted a material passport system wherein each of the steel components was given a unique identification and registered on a blockchain, allowing the project stakeholders to follow the life cycle data of the steel products [161].

- BCT enables secure peer-to-peer trading networks [159]. This is especially interesting for local renewable energy exchange, in which intermittency is a big obstacle. Mengelkamp et al. [89] demonstrated the concept of a decentralised local renewable energy market based on a blockchain system to address this issue. Their results suggested that BCT offers secure, transparent and cost-efficient energy trading [89]. An example from practice is a community energy marketplace called Pando [90]. Pando empowers users to buy and receive local renewable energy within their neighbourhoods through a mobile application [90].

5.5. Building Information Modelling (BIM)

- Within the context of sustainable building design, BIM software and extension tools (add-ins) are used for analysing and optimising building performance (e.g., indoor climate, energy, daylighting, site) [164] and for the integration of life-cycle analysis (LCA) into the building design process [165]. Recent studies expand the capabilities of BIM towards early design considerations for slowing and closing resource loops. For example, Akanbi et al. [48] developed a BIM-based tool to predict the reusability and recyclability potential of design alternatives, and [49] proposed a disassembly and deconstruction analytics system to assess the end-of-life performance of building design. Furthermore, Akinade and Oyedele [43] designed an add-in to BIM software using machine learning techniques to estimate the potential construction waste of design alternatives.

- BIM technology can be used from the design until the end-use phase as a model of an asset’s whole life cycle [166], in which resource flows can be traced and monitored. During the use phase, BIM is used to operate and maintain assets [167], and to monitor the operational performance of systems [168]. Emerging sensing technologies integrated into the BIM models provide new capabilities to increase system efficiency. For example, [169] developed a dynamic BIM model by embedding real-time sensor data and monitoring accurate information from the asset. Although rarely seen, BIM can also be used in deconstruction activities where the digital copy of the building does not exist. To this end, van der Berg et al. [170] demonstrated in a case study that BIM could be used for analysing the existing condition of the site, labelling reusable elements and performing deconstruction planning simulations.

- As discussed in Section 3.2.5, collaboration is believed to be essential in creating circular supply chain networks to narrow, slow and close the resource loops in the construction sector [61]. BIM, as a collaboration platform, brings project stakeholders together for effective information sharing and transparent project coordination [43,51,163,171]. Akinade et al. [43], for example, developed a BIM-based construction waste analytics tool by putting supply chain integration at the core. The tool assists material producers and suppliers in estimating waste creation so that they can consider the environmental impact of their products during the manufacturing phase [43].

- Finally, BIM supports material passports and databanks by providing necessary information regarding buildings and its components. Most of the material passports and databanks reviewed in this study use BIM either as a source of material data or as a platform to operate on (See Section 5.9).

5.6. Digital Platforms

- By connecting the supply and demand sides, digital platforms facilitate the creation of circular market ecosystems in the BE in two forms: sharing platforms and digital marketplaces. Sharing platforms operate online, giving temporary access to the idle capacity of resources without transferring the ownership [175], as in the case of Airbnb giving temporary accommodation to travellers. For the BE, there are several examples of sharing platforms; for example, the pilot project called ‘Vacant Space Finding’ [176] allows users to book available spaces in the city of Amsterdam [99]; EquipmentShare [177] allows peer-to-peer construction equipment rental; Workfrom [100] lists cafés and coworking spaces for remote workers. On the other hand, digital or virtual marketplaces allow the exchange of resources between various actors to regain residual value from discarded materials and products. Such platforms might act as business-to-business (B2B), business-to-consumer (B2C) or both, depending on the context in which they operate. An example from the practice of a B2B marketplace is Excess Materials Exchange [178], a cross-industry matching platform for the high-value reuse of materials and waste. Another example of a B2C platform is Enviromate [179], a closed loop marketplace connecting consumers with leftover building materials.

- Furthermore, digital platforms are used to manage information flows in circular building processes. For instance, Xing et al. [55] designed a cloud-based data exchange platform which connects physical building components with their virtual counterparts through RFID tags, allowing designers to explore reusable products from existing building sites. This platform also serves as a marketplace. Oberti-Paoletti [180] proposed a web-based platform to track raw materials from pre-consumer agricultural waste to be used in private civil construction projects. Madaster is a platform that registers the data of buildings, products and materials, and calculates the circularity index of building projects [47]. See [96] for the implementation of Madaster in a case study.

- Digital platforms also facilitate communication and collaboration between supply chain actors. Yu et al. [106] developed a GIS-based collaboration platform to enable industrial symbiosis between recycled concrete supply chain actors. This platform allows stakeholders to monitor material flows and perform negotiations between each other. With the aim of engaging all of the supply chain actors in the decision-making process of public works, the DECORUM project developed a multi-user platform [181]. This platform supports green public procurement by allowing users to assess the circularity and environmental impact of projects, and to develop a marketplace for recycled materials. Finally, other researchers have proposed an interfirm digital platform concept to allow various stakeholders to exchange data throughout the life cycle of a building [45].

5.7. Digital Twins

- Connecting digital twins to material passports has the potential to extend the service life of building elements through predictive maintenance [184] (see also Section 5.9). Moreover, using digital twins and material passports could also enable the reuse at the building’s demolition phase. Chen and Huang [155] and Landahl et al. [185] proposed digital twin platform concepts for the remanufacturing of construction waste or to support design reuse.

- As mentioned in Section 5.10, digital twins could also help manage space to turn buildings into flexible spaces. An example is the EDGE Olympic office building located in Amsterdam [186]. The building has a digital twin that operates on a cloud platform, allowing users to personalise their working environment and use the space flexibly [186].

5.8. Geographical Information System (GIS)

- An essential opportunity that GIS offers for a CE is the identification, mapping and management of resources embedded in building stocks for future reuse or recycling. For example, Wuyts et al. [188] used GIS analysis to identify vacant houses and their material stock in the city of Kitakyushu in Japan in order to make informed decisions on the future use of resources. Depending on the quality of the vacant housing, the authors considered several reuse strategies that include maintenance, the intensive use of space, repurposing and urban mining [188].

- GIS is also used to support urban mining and industrial symbiosis in the BE. For the former, the scholars employed GIS data sets from municipal or governmental authorities to identify, calculate, and map material stocks in cities [104,188,189,190]. For example, Kleeman et al. [189] conducted a GIS-based material stock analysis in Vienna; Oezdemir et al. [104] used GIS as an integral tool to develop a resource cadaster of secondary materials in a district of Germany to facilitate urban mining at a regional level; and Verhagen et al. [190] analysed the building stocks and flows based on GIS datasets to present the potential of urban mining in the Dutch construction sector. For the latter, Yu et al. [106] developed a GIS-based supply chain model for industrial symbiosis based on recycled concrete aggregate. They used GIS to demonstrate material flows in a virtual environment where actors share information and monitor traffic information together with vehicle movements [106].

5.9. Material Passports and Databanks

5.10. The Internet of Things (IoT)

- As discussed in previous sections, the lack of mechanisms to trace the material properties of the existing building stock is a major barrier to reuse. Many scholars proposed the use of RFID and IoT sensors for the digital and physical traceability of building elements in various building lifecycle stages [53,54,55,195,197]. For instance, Turner et al. [54] presented a distributed manufacturing of modular homes in which information flow is achieved throughout every life stage thanks to sensors embedded in the concrete elements. Another application of resource tracking and monitoring through the IoT can be seen in smart building environments, as explained in the next paragraph.

- One of the prominent application areas of IoT in the BE is performance optimisation for preserving resources. Connected devices in buildings can sense, monitor, optimise and control the indoor environment with BDA. For example, Interact [198], an IoT-based lighting system, collects data from the indoor environment through sensors embedded in the lighting system and provides insights into sustainable building operations. Another example from practice is Polder Roof® [199]. Polder Roof® is a green roof system that measures and regulates the rain-water collected on the rooftop with the help of sensing systems and delivers operational insights to the user [199].

- As discussed in Section 5.2, together with BDA, sensor systems help to track, monitor, and control failures [30]; predict the maintenance needs of installations [150]; and enable remote maintenance, repair and upgrades [35].

- IoT technology allows the real-time monitoring of the available space in a given building through smart sensing systems. The Edge, a smart office building, is equipped with around 28,000 sensors, allowing employees to book meeting rooms or workplaces through a user-friendly platform [109,200]. With such a flexible workplace organization, it was possible to dramatically reduce the number of workspaces, i.e., 1080 desks allocated for 2850 employees [200].

- IoT capabilities offer a healthier and comfortable indoor environment by controlling heating, ventilation and space conditioning systems. For example, in The Edge smart office building, the users are provided with a mobile application that enables them to adjust the space lighting and indoor temperature [109,200].

- Several studies addressed the role of the IoT in adopting sustainable business models [30,55,151,201,202]. Nombre and Tavares [151] referred to the partnership between SEAT and Signify Philips Lighting for a “light as a service” business model and argued that IoT empowered both partners to monitor and control installations, leading to cost savings. Other studies highlighted the role of the IoT in service business models [202], buy-and-sell and lease with reuse models [55], and green business models [201].

6. Mapping Enabling Digital Technologies onto the CDB Framework

7. Conclusions

7.1. Discussion of Contributions

7.2. Implications for Practice

7.3. Limitations and Further Research

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Search Focus | Search Strings | Number of Search Results | Number of Relevant Articles | Mapped onto the CDB Framework |

|---|---|---|---|---|

| Additive/Robotic Manufacturing | “circular economy” AND (“3D printing” OR “additive manufacturing” OR robotic* OR “digital fabrication”) AND (construction OR building OR “built environment”) | 24 | 8 | [52,111,122,126,131,204] |

| Artificial Intelligence | “circular economy” AND (ai OR “artificial intelligence” OR “machine learning” OR “deep learning”) AND (construction OR building OR “built environment”) | 16 | 5 | [69,138,141,142,144] |

| Big Data, and Analytics | “circular economy” AND (“big data” OR “big data analytics”) AND (construction OR building OR “built environment”) | 9 | 0 | 0 |

| Blockchain Technology | “circular economy” AND (blockchain OR “block chain”) AND (construction OR building OR “built environment”) | 9 | 2 | [156,197] |

| Building Information Modelling | “circular economy” AND (bim OR “building information model*”) AND (construction OR building OR “built environment”) | 45 | 26 | [43,48,49,54,162,166,168,192,194,195,197,205,206] |

| Digital Marketplaces | “circular economy” AND (marketplace OR “market place” OR “digital market*”) AND (construction OR building OR “built environment”) | 8 | 4 | [181,207] |

| Digital Platforms | “circular economy” AND (platform OR “digital platform” OR “online platform”) AND (construction OR building OR “built environment”) | 52 | 6 | [55,96,106,180,181] |

| Digital Twins | “circular economy” AND “DIGITAL TWIN*” AND (construction OR building OR “built environment”) | 3 | 2 | [208] |

| Geographical Information System | “circular economy” AND (gis OR “Geograph* information system”) AND (construction OR building OR “built environment”) | 14 | 5 | [104,106,188,190] |

| Material Passports and Databanks | “circular economy” AND (passport OR “material passport” OR “resource passport” OR databank OR database) AND (construction OR building OR “built environment”) | 60 | 11 | [50,96,180,191,194,195,209,210] |

| The Internet of Things | “circular economy” AND (iot OR “internet of things” OR “rfid” OR “wireless sensor networks”) AND (construction OR building OR “built environment”) | 25 | 8 | [54,55,197,201,211,212,213] |

| Total | 265 | 77 |

References

- United Nations Department of Economis and Social Affiars. 2018 Revision of World Urbanization Prospects. 2018. Available online: https://www.un.org/development/desa/publications/2018-revision-of-world-urbanization-prospects.html (accessed on 8 April 2021).

- UN-Habitat. SDG Indicator 11.1.1 Training Module: Adequate Housing and Slum Upgrading; United Nations Human Settlement Programme (UN-Habitat): Nairobi, Kenya, 2018. [Google Scholar]

- Giljum, S.; Wieland, H.; Lutter, S.; Bruckner, M.; Wood, R.; Tukker, A.; Stadler, K. Identifying priority areas for European resource policies: A MRIO-based material footprint assessment. J. Econ. Struct. 2016, 5, 17. [Google Scholar] [CrossRef]

- Herczeg, M.; McKinnon, D.; Milios, L.; Bakas, I.; Klaassens, E.; Svatikova, K.; Widerberg, O. Resource Efficiency in the Building Sector; DG Environment: Rotterdam, The Netherlands, 2014. [Google Scholar]

- Eurostat. Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Waste_statistics#Total_waste_generation (accessed on 13 April 2021).

- Abergel, T.; Dulac, J.; Hamilton, I.; Jordan, M.; Pradeep, A. 2019 Global Status Report for Buildings and Construction—Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector. Available online: https://www.worldgbc.org/news-media/2019-global-status-report-buildings-and-construction (accessed on 10 March 2021).

- European Commission. Construction Sector—A Global Player; Internal Market, Industry, Entrepreneurship and SMEs Directorate General Energy Directorate General Joint Research Centre (JRC): Brussels, Belgium, 2016. [Google Scholar]

- Potting, J.; Kroeze, C. Cradle to cradle: Old wine or new spirits? Integr. Environ. Assess. Manag. Int. J. 2010, 6, 315–317. [Google Scholar] [CrossRef]

- Boulding, K. The Economics of the Coming Spaceship Earth; Johns Hopkins University Press: New York, NY, USA, 1966. [Google Scholar]

- Sears, P.B. The Closing Circle: Nature, Man & Technology. Nat. Resour. J. 1973, 13, 549. [Google Scholar]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2010. [Google Scholar]

- Benyus, J.M. Biomimicry: Innovation Inspired by Nature; Harper Perennial: New York, NY, USA, 2002. [Google Scholar]

- Stahel, W. The utilization-focused service economy—Resource efficiency and product-life extension. In The Greening of Industrial Ecosystems; Richards, D.J., Allenby, B.E., Eds.; National Academies Press: Washington, DC, USA, 1994. [Google Scholar]

- Bocken, N.M.P.; Olivetti, E.A.; Cullen, J.M.; Potting, J.; Lifset, R. Taking the Circularity to the Next Level: A Special Issue on the Circular Economy. J. Ind. Ecol. 2017, 21, 476–482. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Bocken, N.; Stahel, W.; Dobrauz, G.N.; Koumbarakis, A.; Obst, M.; Matzdorf, P. Circularity as the New Normal-Future Fitting Swiss Businesses; PwC Switzerland: Zurich, Switzerland; WWF Switzerland: Zurich, Switzerland, 2021. [Google Scholar]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Konietzko, J.; Bocken, N.; Hultink, E.J. A Tool to Analyze, Ideate and Develop Circular Innovation Ecosystems. Sustainability 2020, 12, 417. [Google Scholar] [CrossRef]

- World Commission on Environment and Development. Our Common Future; United Nations: Oslo, Norway, 1987. [Google Scholar]

- Ellen MacArthur Foundation. Circularity in the Built Environment: Case Studies. A Compilation of Case Studies from the CE100. 2016. Available online: www.ellenmacarthurfoundation.org/assets/downloads/Built-Env-Co.Project.pdf (accessed on 8 April 2021).

- ARUP. Circular Economy in the Built Environment. Available online: https://www.arup.com/perspectives/publications/research/section/circular-economy-in-the-built-environment (accessed on 10 March 2021).

- Iacovidou, E.; Purnell, P. Mining the physical infrastructure: Opportunities, barriers and interventions in promoting structural components reuse. Sci. Total Environ. 2016, 557–558, 791–807. [Google Scholar] [CrossRef]

- BAMB. Available online: https://www.bamb2020.eu/ (accessed on 11 April 2021).

- Rotor. Available online: http://rotordb.org/en (accessed on 11 April 2021).

- Cycle up. Available online: https://www.cycle-up.fr/ (accessed on 11 April 2021).

- Baubüro In Situ. Available online: https://www.insitu.ch/ (accessed on 11 April 2021).

- De Wolf, C.; Hoxha, E.; Fivet, C. Comparison of environmental assessment methods when reusing building components: A case study. Sustain. Cities Soc. 2020, 61, 102322. [Google Scholar] [CrossRef]

- European Commission. Europe’s Digital Decade: Commission Sets the Course Towards a Digitally Empowered Europe by 2030. 2021. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_21_983 (accessed on 11 April 2021).

- European Commission. EU Circular Economy Action Plan. Available online: https://ec.europa.eu/environment/circular-economy/index_en.htm (accessed on 11 April 2020).

- Bressanelli, G.; Adrodegar, F.; Perona, M.; Saccani, N. Exploring How Usage-Focused Business Models Enable Circular Economy through Digital Technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef]

- Lopes de Sousa Jabbour, A.B.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Okorie, O.; Salonitis, K.; Charnley, F.; Moreno, M.; Turner, C.; Tiwari, A. Digitisation and the Circular Economy: A Review of Current Research and Future Trends. Energies 2018, 11, 3009. [Google Scholar] [CrossRef]

- Pagoropoulos, A.; Pigosso, D.C.A.; McAloone, T.C. The Emergent Role of Digital Technologies in the Circular Economy: A Review. Procedia CIRP 2017, 64, 19–24. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2019, 58, 1662–1687. [Google Scholar] [CrossRef]

- Ingemarsdotter, E.; Jamsin, E.; Kortuem, G.; Balkenende, R. Circular Strategies Enabled by the Internet of Things—A Framework and Analysis of Current Practice. Sustainability 2019, 11, 5689. [Google Scholar] [CrossRef]

- Chan, P.W.; De Wolf, C.; Koutamanis, A. The Digital Potential in Creating a Circular Construction Economy; Technische Universiteit Delft: Delft, The Netherlands, 2020. [Google Scholar]

- ARUP. Digital Twin: Towards a Meaningful Framework. Available online: https://www.arup.com/perspectives/publications/research/section/digital-twin-towards-a-meaningful-framework (accessed on 10 March 2021).

- Hunhevicz, J.J.; Hall, D.M. Do you need a blockchain in construction? Use case categories and decision framework for DLT design options. Adv. Eng. Inform. 2020, 45, 101094. [Google Scholar] [CrossRef]

- Tang, S.; Shelden, D.R.; Eastman, C.M.; Pishdad-Bozorgi, P.; Gao, X. A review of building information modeling (BIM) and the internet of things (IoT) devices integration: Present status and future trends. Autom. Constr. 2019, 101, 127–139. [Google Scholar] [CrossRef]

- Dave, B.; Kubler, S.; Främling, K.; Koskela, L. Opportunities for enhanced lean construction management using Internet of Things standards. Autom. Constr. 2016, 61, 86–97. [Google Scholar] [CrossRef]

- National Centre of Competence in Research. Digital Fabrication. Available online: https://dfab.ch/# (accessed on 8 April 2021).

- Wang, H.; Pan, Y.; Luo, X. Integration of BIM and GIS in sustainable built environment: A review and bibliometric analysis. Autom. Constr. 2019, 103, 41–52. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O. Integrating construction supply chains within a circular economy: An ANFIS-based waste analytics system (A-WAS). J. Clean. Prod. 2019, 229, 863–873. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Kovacic, I.; Honic, M.; Sreckovic, M. Digital Platform for Circular Economy in AEC Industry. Eng. Proj. Organ. J. 2020, 9. Available online: https://publik.tuwien.ac.at/files/publik_290949.pdf (accessed on 6 April 2021). [CrossRef]

- Darko, A.; Chan, A.P.C.; Adabre, M.A.; Edwards, D.J.; Hosseini, M.R.; Ameyaw, E.E. Artificial intelligence in the AEC industry: Scientometric analysis and visualization of research activities. Autom. Constr. 2020, 112, 103081. [Google Scholar] [CrossRef]

- Madaster. Madaster—The Materials Cadastre. Available online: https://madaster.com/ (accessed on 30 March 2021).

- Akanbi, L.A.; Oyedele, L.O.; Akinade, O.O.; Ajayi, A.O.; Davila Delgado, M.; Bilal, M.; Bello, S.A. Salvaging building materials in a circular economy: A BIM-based whole-life performance estimator. Resour. Conserv. Recycl. 2018, 129, 175–186. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Omoteso, K.; Bilal, M.; Akinade, O.O.; Ajayi, A.O.; Davila Delgado, J.M.; Owolabi, H.A. Disassembly and deconstruction analytics system (D-DAS) for construction in a circular economy. J. Clean. Prod. 2019, 223, 386–396. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Rechberger, H. Improving the recycling potential of buildings through Material Passports (MP): An Austrian case study. J. Clean. Prod. 2019, 217, 787–797. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Sibenik, G.; Rechberger, H. Data- and stakeholder management framework for the implementation of BIM-based Material Passports. J. Build. Eng. 2019, 23, 341–350. [Google Scholar] [CrossRef]

- Álvarez-Fernández, M.-I.; Prendes-Gero, M.-B.; González-Nicieza, C.; Guerrero-Miguel, D.-J.; Martínez-Martínez, J.E. Optimum Mix Design for 3D Concrete Printing Using Mining Tailings: A Case Study in Spain. Sustainability 2021, 13, 1568. [Google Scholar] [CrossRef]

- Li, C.Z.; Chen, Z.; Xue, F.; Kong, X.T.R.; Xiao, B.; Lai, X.; Zhao, Y. A blockchain- and IoT-based smart product-service system for the sustainability of prefabricated housing construction. J. Clean. Prod. 2021, 286, 125391. [Google Scholar] [CrossRef]

- Turner, C.; Oyekan, J.; Stergioulas, L.K. Distributed Manufacturing: A New Digital Framework for Sustainable Modular Construction. Sustainability 2021, 13, 1515. [Google Scholar] [CrossRef]

- Xing, K.; Kim, K.P.; Ness, D. Cloud-BIM Enabled Cyber-Physical Data and Service Platforms for Building Component Reuse. Sustainability 2020, 12, 329. [Google Scholar] [CrossRef]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Google. Available online: https://www.google.com/ (accessed on 6 April 2021).

- Ecosia. Available online: https://www.ecosia.org/ (accessed on 6 April 2021).

- Durmisevic, E. Circular Economy in Construction, Design Strategies for Reversible Buildings; BAMB Consortium, Ed.; BAMB (Buildings as Material Banks): Brussels, Belgium, 2019. [Google Scholar]

- Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2020, 1–21. [Google Scholar] [CrossRef]

- Leising, E.; Quist, J.; Bocken, N. Circular Economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989. [Google Scholar] [CrossRef]

- NEN. NEN-EN 15978:2011-Sustainability of Construction Works. Assessment of Environmental Performance of Buildings. Calculation Method; British Standards Institution: London, UK, 2011. [Google Scholar]

- Benachio, G.L.F.; do Carmo Duarte Freitas, M.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Mannan, M.; Al-Ghamdi, S.G. Environmental impact of water-use in buildings: Latest developments from a life-cycle assessment perspective. J. Environ. Manag. 2020, 261, 110198. [Google Scholar] [CrossRef]

- Tahir, S.; Steele, K.; Shouler, M.; Steichen, T.; Penning, P.; Martin, N.; Ellen MacArthur Foundation. Water and Circular Economy: A White Paper; ARUP: London, UK; Antea Group: St. Paul, MN, USA; Ellen MacArthur Foundation: Cowes, UK, 2018. [Google Scholar]

- Pimentel-Rodrigues, C.; Siva-Afonso, A. Reuse of resources in the use phase of buildings. Solutions for water. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012050. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Amenta, L.; van Timmeren, A. Beyond Wastescapes: Towards Circular Landscapes. Addressing the Spatial Dimension of Circularity through the Regeneration of Wastescapes. Sustainability 2018, 10, 4740. [Google Scholar] [CrossRef]

- Gan, V.J.L.; Lo, I.M.C.; Ma, J.; Tse, K.T.; Cheng, J.C.P.; Chan, C.M. Simulation optimisation towards energy efficient green buildings: Current status and future trends. J. Clean. Prod. 2020, 254, 120012. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. Towards circular and more sustainable buildings: A systematic literature review on the circular economy in the built environment. J. Clean. Prod. 2020, 260, 121134. [Google Scholar] [CrossRef]

- Van Stijn, A.; Gruis, V. Towards a circular built environment—An integral design tool for circular building components. Smart Sustain. Built Environ. 2019, 9, 2046–6099. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.; Gruner, R.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Kedir, F.; Hall, D.M. Resource efficiency in industrialized housing construction—A systematic review of current performance and future opportunities. J. Clean. Prod. 2021, 286, 125443. [Google Scholar] [CrossRef]

- Geldermans, R.J. Design for Change and Circularity–Accommodating Circular Material & Product Flows in Construction. Energy Procedia 2016, 96, 301–311. [Google Scholar] [CrossRef]

- Kyrö, R. Share, Preserve, Adapt, Rethink—A focused framework for circular economy. In Proceedings of the BEYOND 2020—World Sustainable Built Environment Online Conference, Göteborg, Sweden, 2–4 November 2020. [Google Scholar]

- Morseletto, P. Restorative and regenerative: Exploring the concepts in the circular economy. J. Ind. Ecol. 2020, 24, 763–773. [Google Scholar] [CrossRef]

- Attia, S. Regenerative and Positive Impact Architecture—Learning from Case Studies; Springer: Liège, Belgium, 2018. [Google Scholar]

- Lyle, J.T. Regenerative Design for Sustainable Development; John Wiley & Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Mang, P.; Reed, B. Designing from place: A regenerative framework and methodology. Build. Res. Inf. 2012, 40, 23–38. [Google Scholar] [CrossRef]

- Reed, B. Shifting from ‘sustainability’ to regeneration. Build. Res. Inf. 2007, 35, 674–680. [Google Scholar] [CrossRef]

- Craft, W.; Ding, L.; Prasad, D.; Partridge, L.; Else, D. Development of a Regenerative Design Model for Building Retrofits. Procedia Eng. 2017, 180, 658–668. [Google Scholar] [CrossRef]

- Kubbinga, B.; Bamberger, M.; van Noort, E.; van den Reek, D.; Blok, M.; Roemers, G.; Hoek, J.; Faes, K. A Framework for Circular Buildings—Indicators for Possible Inclusion in BREEAM; Circle Economy: Amsterdam, The Netherlands; Metabolic: Amsterdam, The Netherlands; Dutch Green Building Council: Den Haag, The Netherlands; SGS: Geneva, Switzerland; REDEVCO Foundation: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Thomaier, S.; Specht, K.; Henckel, D.; Dierich, A.; Siebert, R.; Freisinger, U.B.; Sawicka, M. Farming in and on urban buildings: Present practice and specific novelties of Zero-Acreage Farming (ZFarming). Renew. Agric. Food Syst. 2014, 30, 43–54. [Google Scholar] [CrossRef]

- Calheiros, C.S.C.; Stefanakis, A.I. Green Roofs Towards Circular and Resilient Cities. Circ. Econ. Sustain. 2021. [Google Scholar] [CrossRef]

- RESILIO. Blauw-Groene Daken. Available online: https://resilio.amsterdam/en/ (accessed on 24 March 2021).

- Strunge, J.W. Enabling regenerative building design through biohacking. In Proceedings of the BEYOND 2020—World Sustainable Built Environment Online Conference, Göteborg, Sweden, 2–4 November 2020. [Google Scholar]

- Biohm. Mycelium Insulation. Available online: https://www.biohm.co.uk/mycelium (accessed on 24 March 2021).

- Mengelkamp, E.; Notheisen, B.; Beer, C.; Dauer, D.; Weinhardt, C. A blockchain-based smart grid: Towards sustainable local energy markets. Comput. Sci. Res. Dev. 2017, 33, 207–214. [Google Scholar] [CrossRef]

- Lo 3 Energy. Pando. Available online: https://lo3energy.com/pando/ (accessed on 15 March 2021).

- Skillington, K.; Crawford, R.H. Design for Dematerialisation—Examining an approach for reducing the life cycle energy requiremen. In Proceedings of the BEYOND 2020—World Sustainable Built Environment Online Conference, Göteborg, Sweden, 2–4 November 2020. [Google Scholar]

- Block, P.; Schlueter, A.; Veenendaal, D.; Bakker, J.; Begle, M.; Hischier, I.; Hofer, J.; Jayathissa, P.; Maxwell, I.; Echenagucia, T.M.; et al. NEST HiLo: Investigating lightweight construction and adaptive energy systems. J. Build. Eng. 2017, 12, 332–341. [Google Scholar] [CrossRef]

- Konis, K.; Gamas, A.; Kensek, K. Passive performance and building form: An optimization framework for early-stage design support. Sol. Energy 2016, 125, 161–179. [Google Scholar] [CrossRef]

- Enervalis. Rennovates Project. Available online: https://www.enervalis.com/rennovates-project/ (accessed on 24 March 2021).

- Wood, B. Maintenance Integrated Design and Manufacture of Buildings: Toward a Sustainable Model. J. Archit. Eng. 2012, 18, 192–197. [Google Scholar] [CrossRef]

- Heisel, F.; Rau-Oberhuber, S. Calculation and evaluation of circularity indicators for the built environment using the case studies of UMAR and Madaster. J. Clean. Prod. 2020, 243, 118482. [Google Scholar] [CrossRef]

- Olivadese, R.; Remøy, H.; Berizzi, C.; Hobma, F. Reuse into housing: Italian and Dutch regulatory effects. Prop. Manag. 2017, 35, 165–180. [Google Scholar] [CrossRef]

- Foster, G. Circular economy strategies for adaptive reuse of cultural heritage buildings to reduce environmental impacts. Resour. Conserv. Recycl. 2020, 152, 104507. [Google Scholar] [CrossRef]

- ARUP. From Principles to Practices: Realising the Value of the Circular Economy in Real Estate. Available online: https://www.arup.com/perspectives/publications/research/section/realising-the-value-of-circular-economy-in-real-estate (accessed on 10 January 2021).

- Workfrom. Available online: https://workfrom.co/ (accessed on 24 March 2021).

- Fargnoli, M.; Lleshaj, A.; Lombardi, M.; Sciarretta, N.; Di Gravio, G. A BIM-based PSS Approach for the Management of Maintenance Operations of Building Equipment. Buildings 2019, 9, 139. [Google Scholar] [CrossRef]

- Philips Lighting. RAU Amsterdam. Available online: https://www.lighting.philips.nl/inspiratie/projecten/kantoor/architectenbureau-rau (accessed on 25 March 2021).

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Oezdemir, O.; Krause, K.; Hafner, A. Creating a Resource Cadaster—A Case Study of a District in the Rhine-Ruhr Metropolitan Area. Buildings 2017, 7, 45. [Google Scholar] [CrossRef]

- Metabolic. Urban Mining and Circular Construction—What, Why and How it Works. Available online: https://www.metabolic.nl/news/urban-mining-and-circular-construction/ (accessed on 26 April 2021).

- Yu, Y.; Yazan, D.M.; Bhochhibhoya, S.; Volker, L. Towards Circular Economy through Industrial Symbiosis in the Dutch construction industry: A case of recycled concrete aggregates. J. Clean. Prod. 2021, 293, 126083. [Google Scholar] [CrossRef]

- Brown, P.; Bocken, N.; Balkenende, R. Why Do Companies Pursue Collaborative Circular Oriented Innovation? Sustainability 2019, 11, 635. [Google Scholar] [CrossRef]

- Pianoo. Buyer Groups for Sustainability. Available online: https://www.pianoo.nl/en/sustainable-public-procurement/buyer-groups-sustainability (accessed on 13 April 2021).

- Deloitte. The Edge of Tomorrow. Available online: https://www2.deloitte.com/ru/en/pages/about-deloitte/articles/gx-the-edge-of-tomorrow.html (accessed on 16 March 2021).

- Gibson, I.; Rosen, D.; Stucker, B. Introduction and Basic Principles. In Additive Manufacturing Technologies. 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Gibson, I., Rosen, D., Stucker, B., Eds.; Springer: New York, NY, USA, 2015; pp. 1–18. [Google Scholar] [CrossRef]

- Albar, A.; Swash, M.R.; Ghaffar, S. The Design and Development of an Extrusion System for 3D Printing Cementitious Materials. In Proceedings of the 2019 3rd International Symposium on Multidisciplinary Studies and Innovative Technologies (ISMSIT), Ankara, Turkey, 11–13 October 2019. [Google Scholar]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Devadass, P.; Heimig, T.; Stumm, S.; Kerber, E.; Cokcan, S.B. Robotic Constraints Informed Design Process. In Proceedings of the 39th Annual Conference of the Association for Computer Aided Design in Architecture (ACADIA), Austin, TX, USA, 24–26 October 2019; pp. 130–139. [Google Scholar]

- Huang, Y.; Garrett, C.R.; Mueller, C.T. Automated sequence and motion planning for robotic spatial extrusion of 3D trusses. Constr. Robot. 2018, 2, 15–39. [Google Scholar] [CrossRef]

- Ercan Jenny, S.; Lloret-Fritschi, E.; Gramazio, F.; Kohler, M. Crafting plaster through continuous mobile robotic fabrication on-site. Constr. Robot. 2020, 4, 261–271. [Google Scholar] [CrossRef]

- De Soto, B.; Agustí-Juan, I.; Hunhevicz, J.; Joss, S.; Graser, K.; Habert, G.; Adey, B.T. Productivity of digital fabrication in construction: Cost and time analysis of a robotically built wall. Autom. Constr. 2018, 92, 297–311. [Google Scholar] [CrossRef]

- Robeller, C.; Mayencourt, P.; Weinand, Y. Snap-fit Joints—CNC fabricated, Integrated Mechanical Attachment for Structural Wood Panels. In Proceedings of the ACADIA 2014 Design Agency: Proceedings of the 34th Annual Conference of the Association for Computer Aided Design in Architecture, Los Angeles, CA, USA, 23–25 October 2014; pp. 189–198. [Google Scholar]

- Rippmann, M.; Liew, A.; Van Mele, T.; Block, P. Design, fabrication and testing of discrete 3D sand-printed floor prototypes. Mater. Today Commun. 2018, 15, 254–259. [Google Scholar] [CrossRef]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—Technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Oberti, I.; Plantamura, F. Is 3D printed house sustainable? In Proceedings of the International Conference CISBAT 2015 Future Buildings and Districts Sustainability from Nano to Urban Scale, Lausanne, Switzerland, 9–11 September 2011; pp. 173–178. [Google Scholar]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D Printing of Buildings and Building Components as the Future of Sustainable Construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef]

- Wang, J. Digital Architextiles—Nonwoven textile thermoforming in robotic fabrication. In Proceedings of the Anthropocene, Design in the Age of Humans—25th CAADRIA Conference Bangkok, Thailand, 7–10 April 2019; pp. 45–54. [Google Scholar]

- Agustí-Juan, I.; Habert, G. Environmental design guidelines for digital fabrication. J. Clean. Prod. 2017, 142, 2780–2791. [Google Scholar] [CrossRef]

- He, Y.; Zhang, Y.; Zhang, C.; Zhou, H. Energy-saving potential of 3D printed concrete building with integrated living wall. Energy Build. 2020, 222, 110110. [Google Scholar] [CrossRef]

- MX3D. MX3D Bridge. Available online: https://mx3d.com/projects/mx3d-bridge/ (accessed on 14 April 2021).

- Baiani, S.; Altamura, P. Waste materials superuse and upcycling in architecture: Design and experimentation. Techne 2018, 16, 142–151. [Google Scholar] [CrossRef]

- Bier, H.H.; Nazzarri, G. Towards Circular Economy in Architecture by Means of Data-driven Design-to-Robotic-Production. In Proceedings of the 37th International Symposium on Automation and Robotics in Construction, Kitakyushu, Japan, 26–30 October 2020. [Google Scholar]

- Brütting, J.; Senatore, G.; Fivet, C. Design and fabrication of a reusable kit of parts for diverse structures. Autom. Constr. 2021, 125, 103614. [Google Scholar] [CrossRef]

- Kunic, A.; Naboni, R.; Kramberger, A.; Schlette, C. Design and assembly automation of the Robotic Reversible Timber Beam. Autom. Constr. 2021, 123, 103531. [Google Scholar] [CrossRef]

- Kuzmenko, K.; Roux, C.; Feraille, A.; Baverel, O. Assessing environmental impact of digital fabrication and reuse of constructive systems. Structures 2020, 31, 1300–1310. [Google Scholar] [CrossRef]

- Robertson, O.; Høgdal, F.; Mckay, L.; Lenau, T. Fungal Future: A review of mycelium biocomposites as an ecological alternative insulation material. In Proceedings of the NordDesign 2020, Copenhagen, Denmark, 12–14 August 2020. [Google Scholar]

- Smith, R.S.H.; Bader, C.; Sharma, S.; Kolb, D.; Tang, T.C.; Hosny, A.; Moser, F.; Weaver, J.C.; Voigt, C.A.; Oxman, N. Hybrid Living Materials: Digital Design and Fabrication of 3D Multimaterial Structures with Programmable Biohybrid Surfaces. Adv. Funct. Mater. 2019, 30, 1907401. [Google Scholar] [CrossRef]

- Stuart, R.; Norvig, P. Artificial Intelligence: A Modern Approach, 2nd ed.; Pearson Education Inc.: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- IBM. Artificial Intelligence (AI). 2020. Available online: https://www.ibm.com/cloud/learn/what-is-artificial-intelligence (accessed on 19 March 2021).

- IBM. AI vs. Machine Learning vs. Deep Learning vs. Neural Networks: What’s the Difference? 2020. Available online: https://www.ibm.com/cloud/blog/ai-vs-machine-learning-vs-deep-learning-vs-neural-networks (accessed on 19 March 2021).

- Ellen MacArthur Foundation; Google. Artificial Intelligence and the Circular Economy—AI as a Tool to Accelerate the Transition. Available online: https://www.ellenmacarthurfoundation.org/publications/artificial-intelligence-and-the-circular-economy (accessed on 19 March 2019).

- Arcadis. Artificial Intelligence in the AAEC Indsutry—A Code of Practice. Available online: https://www.arcadis.com/en/knowledge-hub/blog/global/susanne-knorr/2020/the-future-of-architecture,-engineering,-and-construction-is-digital-and-intelligent (accessed on 2 June 2021).

- Płoszaj-Mazurek, M.; Ryńska, E.; Grochulska-Salak, M. Methods to Optimize Carbon Footprint of Buildings in Regenerative Architectural Design with the Use of Machine Learning, Convolutional Neural Network, and Parametric Design. Energies 2020, 13, 5289. [Google Scholar] [CrossRef]

- Mehmood, M.U.; Chun, D.; Zeeshan; Han, H.; Jeon, G.; Chen, K. A review of the applications of artificial intelligence and big data to buildings for energy-efficiency and a comfortable indoor living environment. Energy Build. 2019, 202. [Google Scholar] [CrossRef]

- Facade Service Applicatie. Platform voor Digitale Innovatie in de Vasgoedmarkt. Available online: https://facadeserviceapplicatie.nl/ (accessed on 29 March 2021).

- Akanbi, L.A.; Oyedele, A.O.; Oyedele, L.O.; Salami, R.O. Deep learning model for Demolition Waste Prediction in a circular economy. J. Clean. Prod. 2020, 274, 122843. [Google Scholar] [CrossRef]

- Rakhshan, K.; Morel, J.-C.; Daneshkhah, A. A probabilistic predictive model for assessing the economic reusability of load-bearing building components: Developing a Circular Economy framework. Sustain. Prod. Consum. 2021, 27, 630–642. [Google Scholar] [CrossRef]

- Davis, P.; Aziz, F.; Newaz, M.T.; Sher, W.; Simon, L. The classification of construction waste material using a deep convolutional neural network. Autom. Constr. 2021, 122, 103481. [Google Scholar] [CrossRef]

- Lau Hiu Hoong, J.D.; Lux, J.; Mahieux, P.-Y.; Turcry, P.; Aït-Mokhtar, A. Determination of the composition of recycled aggregates using a deep learning-based image analysis. Autom. Constr. 2020, 116, 103204. [Google Scholar] [CrossRef]

- McKinsey Global Institute. Big Data: The Next Frontier for Innovation, Competition, and Productivity. Available online: https://www.mckinsey.com/business-functions/mckinsey-digital/our-insights/big-data-the-next-frontier-for-innovation (accessed on 2 June 2021).

- Gandomi, A.; Haider, M. Beyond the hype: Big data concepts, methods, and analytics. Int. J. Inf. Manag. 2015, 35, 137–144. [Google Scholar] [CrossRef]

- Yin, S.; Kaynak, O. Big Data for Modern Industry: Challenges and Trends (Point of View). Proc. IEEE 2015, 103, 143–146. [Google Scholar] [CrossRef]

- Bilal, M.; Oyedele, L.O.; Qadir, J.; Munir, K.; Ajayi, S.O.; Akinade, O.O.; Owolabi, H.A.; Alaka, H.A.; Pasha, M. Big Data in the construction industry: A review of present status, opportunities, and future trends. Adv. Eng. Inform. 2016, 30, 500–521. [Google Scholar] [CrossRef]

- Fan, C.; Xiao, F. Mining big building operational data for improving building energy efficiency: A case study. Build. Serv. Eng. Res. Technol. 2017, 39, 117–128. [Google Scholar] [CrossRef]

- Panfilov, P.; Katona, A. Building Predictive Maintenance Framework for Smart Environment Application Systems. In Proceedings of the 29th International DAAAM Symposium “Intelligent Manufacturing & Automation”, Zadar, Croatia, 24–27 October 2018; pp. 460–470. [Google Scholar] [CrossRef]

- Nobre, G.C.; Tavares, E. Scientific literature analysis on big data and internet of things applications on circular economy: A bibliometric study. Scientometrics 2017, 111, 463–492. [Google Scholar] [CrossRef]

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System. Available online: https://bitcoin.org/en/bitcoin-paper (accessed on 14 March 2021).

- Arun, J.S.; Cuomo, J.; Gaur, N. Blockchain for Business; Addison-Wesley Professional: Boston, MA, USA, 2019. [Google Scholar]

- Swan, M. Blockchain: Blueprint for a New Economy; McGovern, T., Ed.; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2015. [Google Scholar]

- Böckel, A.; Nuzum, A.-K.; Weissbrod, I. Blockchain for the Circular Economy: Analysis of the Research-Practice Gap. Sustain. Prod. Consum. 2021, 25, 525–539. [Google Scholar] [CrossRef]

- Shojaei, A. Exploring Applications of Blockchain Technology in the Construction Industry. In Proceedings of the 10th International Structural Engineering and Construction Conference, Chicago, IL, USA, 20–25 May 2019. [Google Scholar]

- Circularise. Available online: https://www.circularise.com/ (accessed on 15 March 2021).

- Licht, J.; de Jong, T.; Oudshoorn, K.; Pasotti, P. Circularise-White Paper. Available online: https://www.circularise.com/whitepaper (accessed on 15 March 2021).

- ARUP. Blockchain and the Built Environment. Available online: https://www.arup.com/perspectives/publications/research/section/blockchain-and-the-built-environment (accessed on 1 March 2021).

- Tata Steel. Available online: https://www.tatasteel.com/ (accessed on 15 March 2021).

- Penzes, B. Blockchain Technology in the Construction Industry—Digital Transformation for High Productivity; Institution of Civil Engineers: London, UK, 2018. [Google Scholar]

- Charef, R.; Emmitt, S. Uses of building information modelling for overcoming barriers to a circular economy. J. Clean. Prod. 2021, 285, 124854. [Google Scholar] [CrossRef]

- Wong, K.D.; Fan, Q. Building information modelling (BIM) for sustainable building design. Facilities 2013, 31, 138–157. [Google Scholar] [CrossRef]

- Habibi, S. The promise of BIM for improving building performance. Energy Build. 2017, 153, 525–548. [Google Scholar] [CrossRef]

- Xue, K.; Hossain, M.U.; Liu, M.; Ma, M.; Zhang, Y.; Hu, M.; Chen, X.; Cao, G. BIM Integrated LCA for Promoting Circular Economy towards Sustainable Construction: An Analytical Review. Sustainability 2021, 13, 1310. [Google Scholar] [CrossRef]

- Aguiar, A.; Vonk, R.; Kamp, F. BIM and Circular Design. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012068. [Google Scholar] [CrossRef]

- Gao, X.; Pishdad-Bozorgi, P. BIM-enabled facilities operation and maintenance: A review. Adv. Eng. Inform. 2019, 39, 227–247. [Google Scholar] [CrossRef]

- Davila Delgado, J.M.; Oyedele, L.O. BIM data model requirements for asset monitoring and the circular economy. J. Eng. Des. Technol. 2020, 18, 1269–1285. [Google Scholar] [CrossRef]

- Chen, J.; Bulbul, T.; Taylor, J.E.; Olgun, G. A Case Study of Embedding Real-time Infrastructure Sensor Data to BIM. In Proceedings of the Construction Research Congress 2014, Atlanta, GA, USA, 19–21 May 2014. [Google Scholar]

- Van den Berg, M.; Voordijk, H.; Adriaanse, A. BIM uses for deconstruction: An activity-theoretical perspective on reorganising end-of-life practices. Constr. Manag. Econ. 2021, 39, 323–339. [Google Scholar] [CrossRef]

- Chan, P.W. Construction in the platform society—New directions for construction management research. In Proceedings of the 36th Annual Conference 2020 (ARCOM 2020), Leeds, UK, 7–8 September 2020; pp. 396–405. [Google Scholar]

- De Reuver, M.; Sørensen, C.; Basole, R.C. The Digital Platform: A Research Agenda. J. Inf. Technol. 2018, 33, 124–135. [Google Scholar] [CrossRef]

- Asadullah, A.; Faik, I.; Kankanhalli, A. Digital Platforms: A Review and Future Directions. In Proceedings of the Pacific Asia Conference on Information Systems (PACIS), Yokohama, Japan, 26–30 June 2018. [Google Scholar]

- Konietzko, J.; Bocken, N.; Hultink, E.J. Online Platforms and the Circular Economy. In Innovation for Sustainability; Bocken, N., Ritala, P., Albareda, L., Verburg, R., Eds.; Palgrave Macmillan: Cham, Switzerland, 2019; pp. 435–450. [Google Scholar] [CrossRef]

- Ranjbari, M.; Morales-Alonso, G.; Carrasco-Gallego, R. Conceptualizing the Sharing Economy through Presenting a Comprehensive Framework. Sustainability 2018, 10, 2336. [Google Scholar] [CrossRef]

- City of Amsterdam. Vacant Space Finding. Available online: https://maps.amsterdam.nl/stadsloods/?LANG=en (accessed on 1 April 2021).

- EquipmentShare. Available online: https://www.equipmentshare.com/ (accessed on 1 April 2021).

- Excess Materials Exchange. The Most Valuable Match. Available online: https://excessmaterialsexchange.com/en_us/ (accessed on 1 April 2021).

- Enviromate. Enviromate. Available online: https://www.enviromate.co.uk/ (accessed on 1 April 2021).

- Oberti, I.; Paoletti, I. Da.Ma.Tra: Material Traceability Database. In Digital Transformation of the Design, Construction and Management Processes of the Built Environment; Dianotti, B., Gianinetto, M., Della Torre, S., Eds.; Springer: Cham, Switzerland, 2020; pp. 85–93. [Google Scholar] [CrossRef]

- Luciano, A.; Cutaia, L.; Cioffi, F.; Sinibaldi, C. Demolition and construction recycling unified management: The DECORUM platform for improvement of resource efficiency in the construction sector. Environ. Sci. Pollut. Res. Int. 2020, 28, 24558–25469. [Google Scholar] [CrossRef] [PubMed]

- Khajavi, S.H.; Motlagh, N.H.; Jaribion, A.; Werner, L.C.; Holmstrom, J. Digital Twin: Vision, Benefits, Boundaries, and Creation for Buildings. IEEE Access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2017, 94, 3563–3576. [Google Scholar] [CrossRef]

- Kedir, F.; Bucher, D.F.; Hall, D.M. A Proposed Material Passport Ontology to Enable Circularity for Industrialized Construction. In Proceedings of the 2021 European Conference on Computing in Construction, Rhodes, Greece, 25–27 July 2021. [Google Scholar]

- Landahl, J.; Panarotto, M.; Johannesson, H.; Isaksson, O.; Lööf, J. Towards Adopting Digital Twins to Support Design Reuse during Platform Concept Development. In Proceedings of the NordDesign 2018, Linköping, Sweden, 14–17 August 2018. [Google Scholar]

- Edge Olympic. Available online: https://edge-olympic.com/ (accessed on 9 April 2021).

- Longley, P.A.; Goodchild, M.F.; Maguire, D.J.; Rhind, D.W. Geographical information systems. In The Routledge Handbook of Mapping and Cartography; Alexander, K., Peter, V., Eds.; Routledge: New York, NY, USA, 2018. [Google Scholar]

- Wuyts, W.; Sedlitzky, R.; Morita, M.; Tanikawa, H. Understanding and Managing Vacant Houses in Support of a Material Stock-Type Society—The Case of Kitakyushu, Japan. Sustainability 2020, 12, 5363. [Google Scholar] [CrossRef]

- Kleemann, F.; Lederer, J.; Rechberger, H.; Fellner, J. GIS-based Analysis of Vienna’s Material Stock in Buildings. J. Ind. Ecol. 2016, 21, 368–380. [Google Scholar] [CrossRef]

- Verhagen, T.J.; Sauer, M.L.; van der Voet, E.; Sprecher, B. Matching Demolition and Construction Material Flows, an Urban Mining Case Study. Sustainability 2021, 13, 653. [Google Scholar] [CrossRef]

- Munaro, M.R.; Fischer, A.C.; Azevedo, N.C.; Tavares, S.F. Proposal of a building material passport and its application feasibility tothe wood frame constructive system in Brazil. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012018. [Google Scholar] [CrossRef]

- Cai, G.; Waldmann, D. A material and component bank to facilitate material recycling and component reuse for a sustainable construction: Concept and preliminary study. Clean Technol. Environ. Policy 2019, 21, 2015–2032. [Google Scholar] [CrossRef]

- Luscuere, L.M.; Zanatta, R.; Mulhall, D. Deliverable 7—Operational Materials Passports; BAMB: Brussels, Belgium, 2019. [Google Scholar]

- Jayasinghe, L.B.; Waldmann, D. Development of a BIM-Based Web Tool as a Material and Component Bank for a Sustainable Construction Industry. Sustainability 2020, 12, 1766. [Google Scholar] [CrossRef]

- Bertin, I.; Mesnil, R.; Jaeger, J.-M.; Feraille, A.; Le Roy, R. A BIM-Based Framework and Databank for Reusing Load-Bearing Structural Elements. Sustainability 2020, 12, 3147. [Google Scholar] [CrossRef]

- Li, S.; Xu, L.D.; Zhao, S. The internet of things: A survey. Inf. Syst. Front. 2014, 17, 243–259. [Google Scholar] [CrossRef]

- Copeland, S.; Bilec, M. Buildings as material banks using RFID and building information modeling in a circular economy. Procedia CIRP 2020, 90, 143–147. [Google Scholar] [CrossRef]

- Interact. Available online: https://www.interact-lighting.com/global (accessed on 16 March 2021).

- Company, M. Polder Roof. Available online: https://metropolder.com/en/#polderroof (accessed on 16 March 2021).

- MAPIQ. Deloitte, Amsterdam. Available online: https://www.mapiq.com/customer-story/deloitte (accessed on 16 March 2021).

- Lamptey, T.; Owusu-Manu, D.-G.; Acheampong, A.; Adesi, M.; Ghansah, F.A. A framework for the adoption of green business models in the Ghanaian construction industry. Smart Sustain. Built Environ. 2020. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Intelligent Assets: Unlocking the Circular Economy Potential. 2016. Available online: https://www.ellenmacarthurfoundation.org/publications/intelligent-assets (accessed on 16 March 2021).

- Ellen MacArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition. 2015. Available online: https://www.ellenmacarthurfoundation.org/publications/towards-a-circular-economy-business-rationale-for-an-accelerated-transition (accessed on 5 March 2021).

- Bruce, C.; Sweet, K.; Ok, J. Closing the Loop—Recycling Waste Plastic. In Proceedings of the Anthropocene. Design in the Age of Humans—25th International Conference of the Association for Computer-Aided Architectural Design Research in Asia (CAADRIA), Bangkok, Thailand, 5–6 August 2020; pp. 135–144. [Google Scholar]

- Marzouk, M.; Elmaraghy, A.; Voordijk, H. Lean Deconstruction Approach for Buildings Demolition Processes Using BIM. Lean Constr. J. 2019. Available online: https://research.utwente.nl/en/publications/lean-deconstruction-approach-for-buildings-demolition-processes-u (accessed on 16 March 2021).

- Nazareth, A.P. How close is the built environment to achieving circularity? In Proceedings of the SBE19 Brussels BAMB-CIRCPATH “Buildings as Material Banks—A Pathway For A Circular Future”, Brussels, Belgium, 5–7 February 2019. [Google Scholar]

- Migliore, M.; Talamo, C.; Paganin, G. A Virtual Marketplace for Waste Valorization. In Strategies for Circular Economy and Cross-sectoral Exchanges for Sustainable Building Products; Migliore, M., Talamo, C., Paganin, G., Eds.; Springer: Cham, Switzerland, 2020; pp. 135–158. [Google Scholar] [CrossRef]

- Chen, Z.; Huan, L. Digital Twin in Circular Economy—Remanufacturing in Construction. In Proceedings of the BEYOND 2020—World Sustainable Built Environment Online Conference, Göteborg, Sweden, 2–4 November 2020. [Google Scholar]

- Gepts, B.; Meex, E.; Nuyts, E.; Knapen, E.; Verbeeck, G. Existing databases as means to explore the potential of the building stock as material bank. In Proceedings of the SBE19 Brussels BAMB-CIRCPATH “Buildings as Material Banks—A Pathway For A Circular Future”, Brussels, Belgium, 5–7 February 2019. [Google Scholar]

- Luscuere, L.M. Materials Passports: Optimising value recovery from materials. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2017, 170, 25–28. [Google Scholar] [CrossRef]

- Baiardi, L.; Ciaramella, A.; Bellintani, S. A Development and Management Model for “Smart” Temporary Residences. In Regeneration of the Built Environment from a Circular Economy Perspective; Della Torre, S., Cattaneo, S., Lenzi, C., Zanelli, A., Eds.; Springer: Cham, Switzerland, 2020; pp. 337–346. [Google Scholar] [CrossRef]

- Mocerino, C. Intelligence of LED towards innovative nanotechnologies in the efficiency of building envelopes. In Proceedings of the International Conference in Engineering Applications (ICEA), Sao Miguel, Portugal, 8–11 July 2019; pp. 1–6. [Google Scholar]

- Talamo, C.; Pinto, M.R.; Viola, S.; Atta, N. Smart cities and enabling technologies: Influences on urban Facility Management services. In Proceedings of the SBE19 Milan—Resilient Built Environment for Sustainable Mediterranean Countries, Milan, Italy, 4–5 September 2019. [Google Scholar]

| Groups | Occupational Background | Years of Experience | Field of Expertise |

|---|---|---|---|

| Workshop 1 | Academic | 20 | Design and construction management |

| Practitioner | 25 | CE; CBE | |

| Practitioner | 10 | DCT | |

| Academic | 20 | DCT | |

| Practitioner | 40 | DCT | |

| Workshop 2 | Academic | 10 | DCT; Biomaterials |

| Practitioner | 20 | CE; CBE; Waste management | |

| Architect/Practitioner | 25 | CE; CBE; Reversible building design | |

| Academic | 15 | DCT; Sustainable design strategies | |

| Architect/Practitioner | 32 | CBE; Design philosophy | |

| Practitioner | 15 | CE; CBE | |

| Workshop 3 | Consultant | 15 | CE; CBE; DCT |

| Practitioner/Consultant | 17 | CE; CBE; DCT | |

| Engineer | 14 | DCT; Prefab timber system design | |

| Academic | 16 | CBE | |

| Consultant | 15 | CE; CBE; DCT |

| Core Principle | Circular Building Strategy | Description and Example |

|---|---|---|

| Regenerate | Stimulate human nature co-habitation and local biodiversity | Create spaces for human nature interaction and biodiversity, e.g., green roof project in Amsterdam [86]. |

| Use healthy and renewable resources | Eliminate toxic contents, use bio-based materials, and produce with renewable energy, e.g., producing insulation panels from mycelium [88]. | |

| Enhance indoor and outdoor environment | Improve the indoor environment and regenerate degraded outdoor spaces, e.g., transformation of misused urban areas into public spaces [68]. | |

| Exchange excess resources | Exchange surplus resources produced by regenerative buildings, e.g., exchanging renewable energy within the neighbourhood [90]. | |

| Narrow | Reduce primary resource inputs | Minimise primary resource use and waste, e.g., optimisation of lightweight structures [92]. |

| Design for high performance | Optimise buildings and systems for fewer resource use, e.g., early design optimisation for passive performance [93]. | |

| Improve efficiency | Enhance performance of building systems and operations to minimise resource consumption, e.g., deep energy renovation of old houses [94]. | |

| Slow | Design for long life | Design buildings with durable materials, consider ease of maintenance and repair, and design for emotional attachment. |

| Design for reversibility | Design buildings and products for multiple life cycles with deconstruction and transformation strategies, e.g., the UMAR Project [96]. | |

| Lifetime extension | Extend the service time of buildings and components by restorative activities such as repair, maintenance and refurbishment. | |

| Smart use of space | Deliver new functionalities to underutilised buildings, and land through adaptive reuse and flexibility, e.g., flexible office spaces [109]. | |

| Deliver access and performance | Provide access, functionality or services without offering ownership of buildings and building products, e.g., pay-per-lux model for lighting [102]. | |